Chocolate thermal-insulation cylinder

A chocolate and heat preservation technology, applied in cocoa, food science, application, etc., can solve the problems of rough and soft texture, single function of heat preservation cylinder, dull appearance, etc., and achieve the effect of preventing separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] In order to further understand the content, characteristics and effects of the present invention, the following embodiments are given as examples and detailed descriptions are as follows in conjunction with the accompanying drawings:

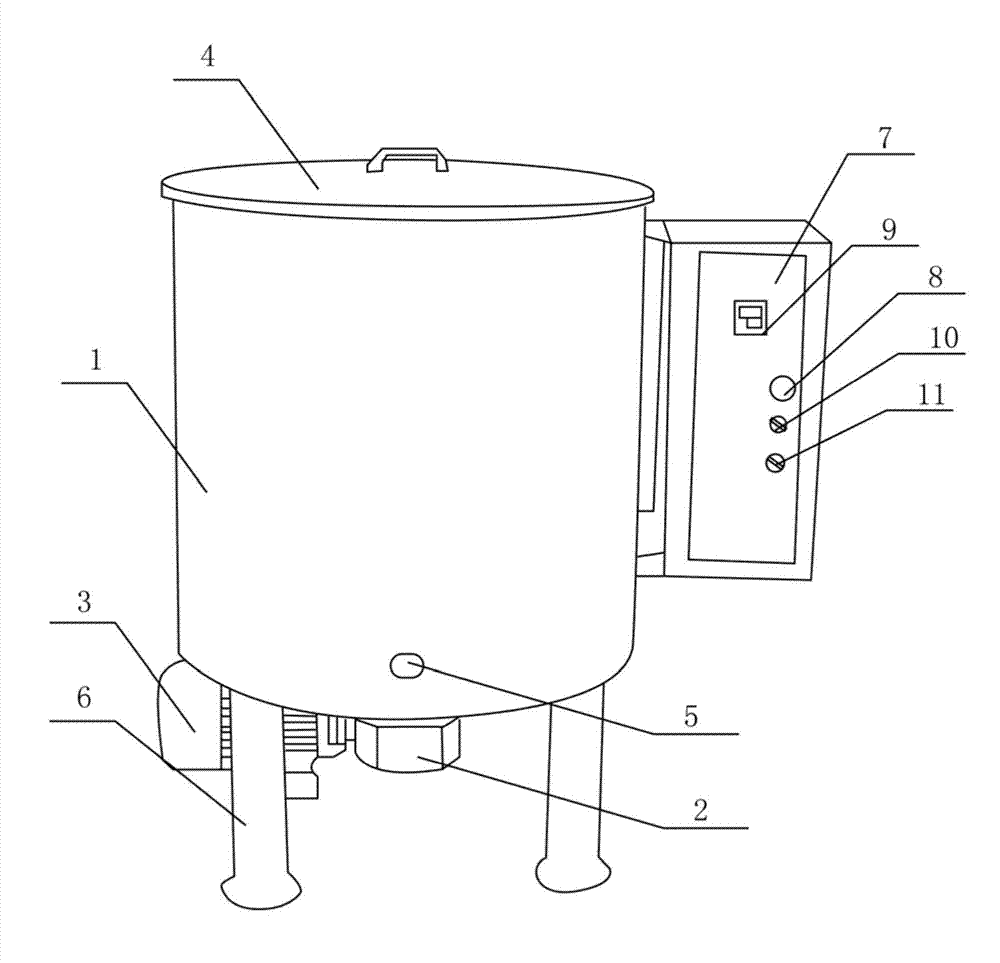

[0012] A chocolate insulation tank, comprising a barrel body 1, a stirring device 2 and a motor 3, the upper end of the barrel body 1 is provided with a barrel cover 4, and the lower end is provided with a discharge port 5, the barrel body 1 is connected to a bracket 6, the stirring device 2 and the motor 3 is located at the bottom of the barrel body 1, and one side of the barrel body 1 is provided with a controller 7, and the controller 7 is provided with a switch 8, a display screen 9, a temperature adjustment knob 10 and a speed adjustment knob 11. The display screen 9 can display temperature and speed indications simultaneously, and for the convenience of operation, the display screen 9 is located at the middle and upper part of the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com