Strip filling integral backstopping coal mining method

A coal mining method and strip filling technology, which are applied in the fields of filling, ground mining, mining equipment, etc., can solve the problems of small surface subsidence, low recovery rate of coal resources, surface subsidence deformation, etc., and achieve the safety of mining operations. , The effect of protecting surface buildings and attachments, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

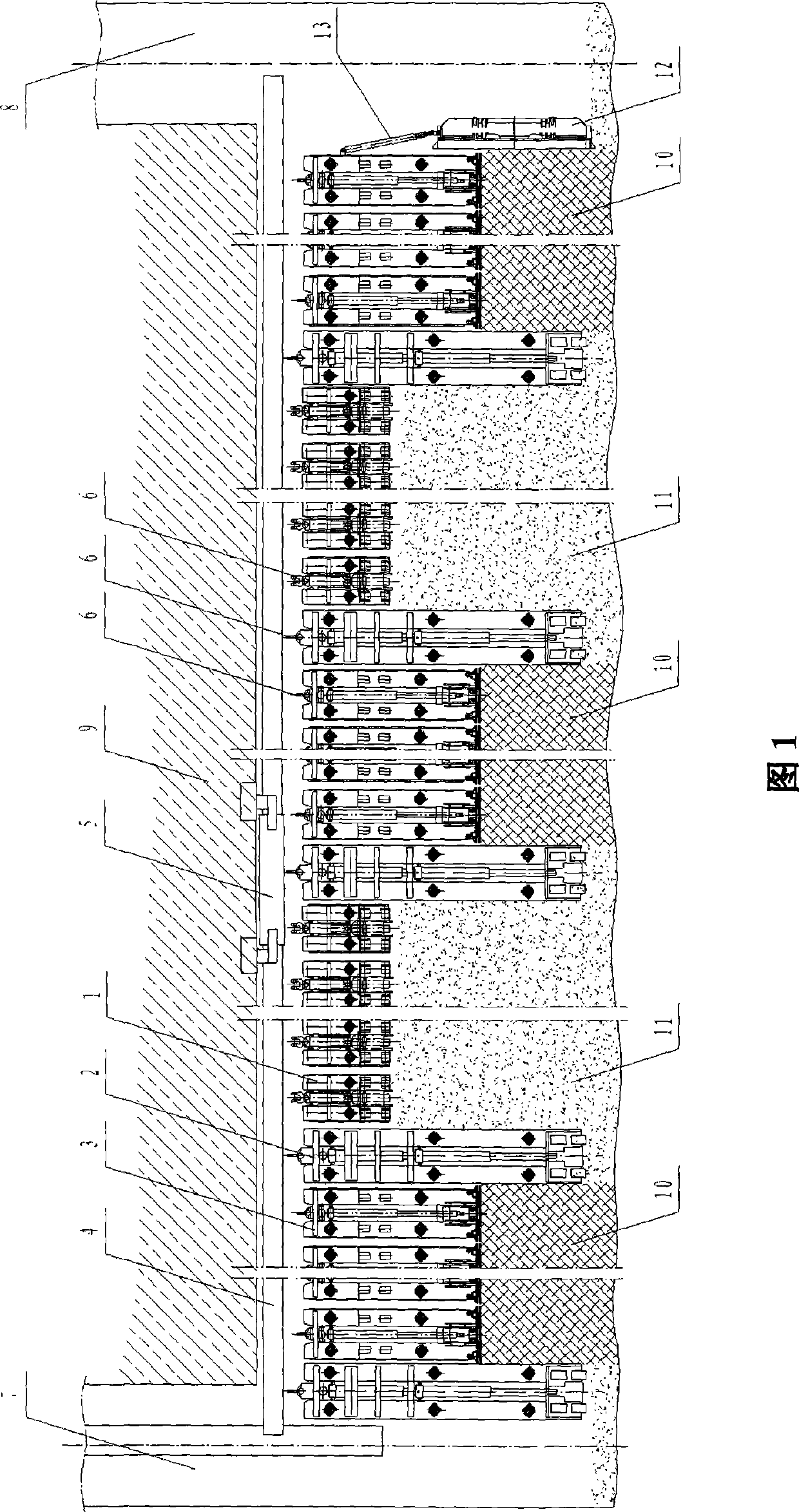

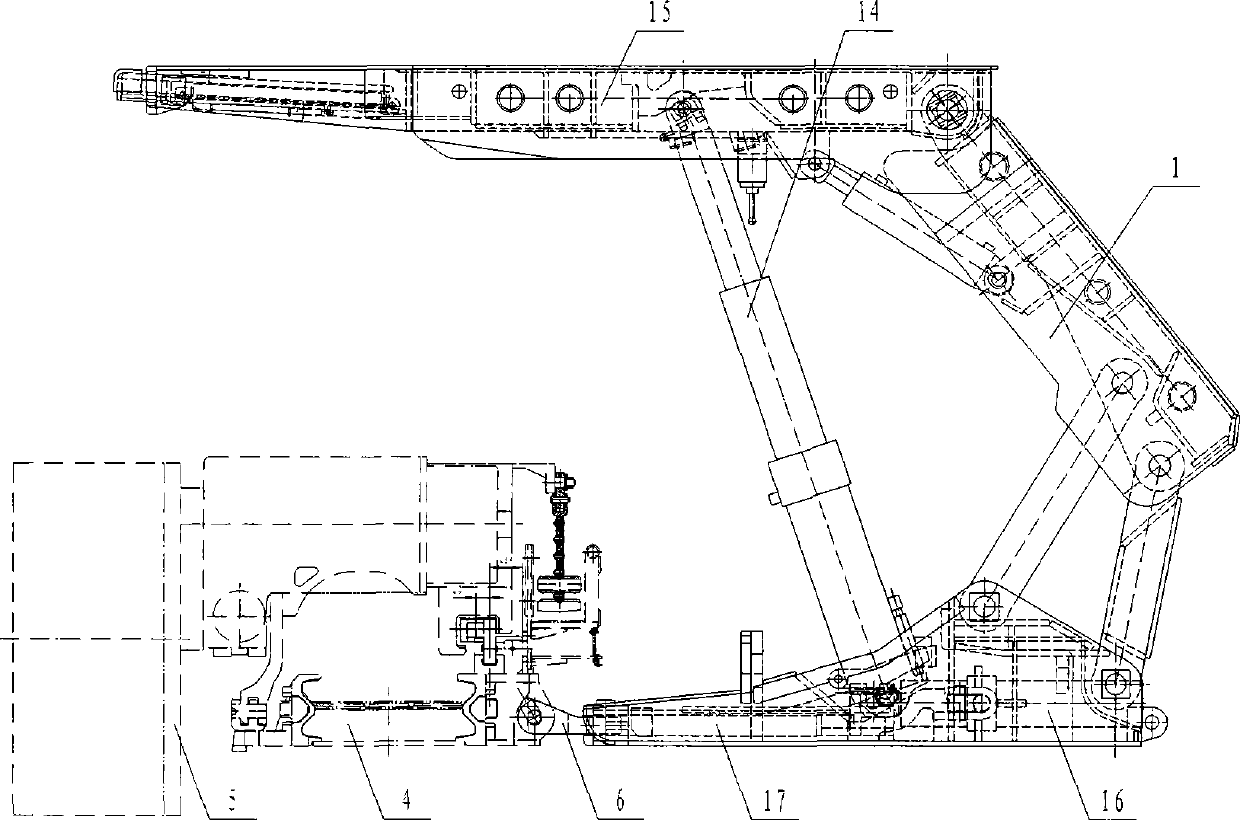

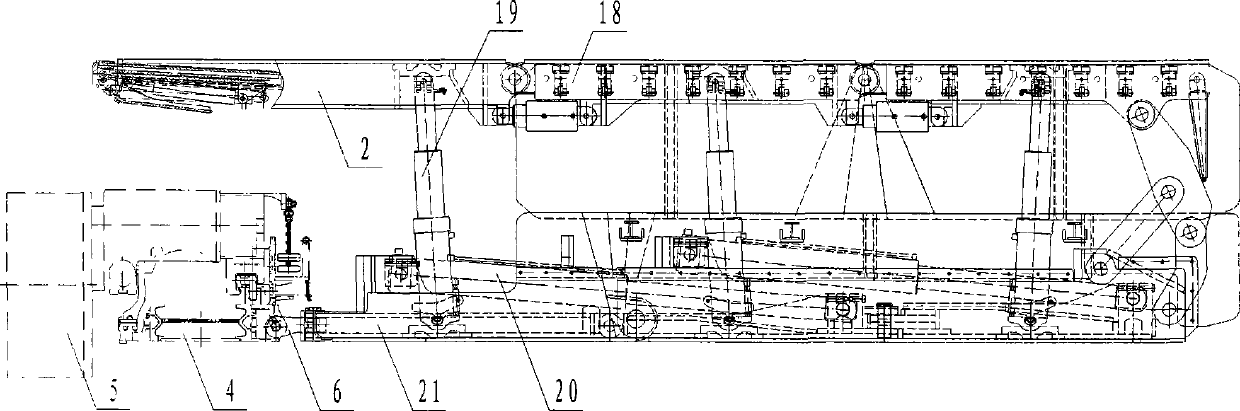

[0024] The specific operation steps of the present invention will be described in detail according to FIGS. 1 to 6 . This strip filling integral recovery coal mining method comprehensively utilizes mature recovery technology and commonly used equipment such as conveyor 4, coal shearer 5, working face hydraulic support 1, and configures the mature support that the inventor has used on the working face at the same time Equipment, such as roadside filling side formwork support 2 (notification number CN200999614Y) and roadside filling back formwork support 3 (notification number CN200999613Y), and devices such as newly designed adjustable hydraulic formwork 12. A kind of specific implementation method of the present invention adopts the following steps: as shown in Figure 1, at first arrange the transport roadway 7 and the return air roadway 8 of the working face in the mining area and after cutting out the eye, lay the conveyer 4 and along the working face The transporter 4 recip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com