Solid-filling coal mining method with two pre-excavating tunnels for advancing

A coal mining method and solid filling technology, which is applied in the direction of filling, ground mining, mining equipment, etc., can solve problems such as the inability to guarantee the application effect of filling technology, achieve control of mine pressure appearance and surface subsidence, ensure safe use, and improve coal mining efficiency. The effect of resource recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

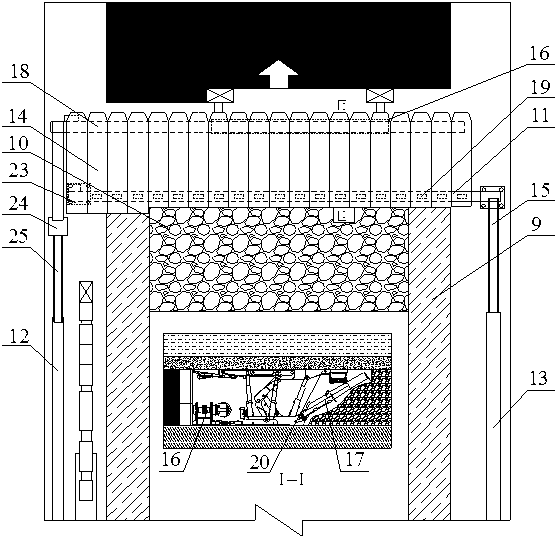

[0019] Implementation of the present invention will be further described below in conjunction with accompanying drawing:

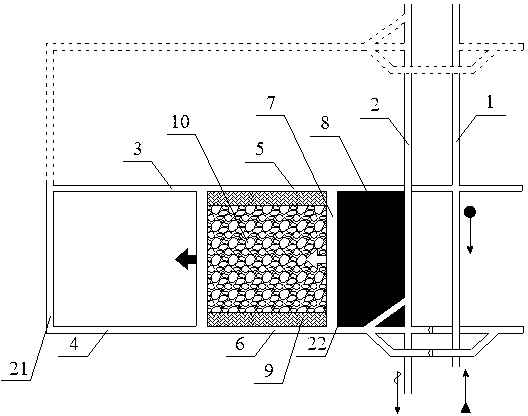

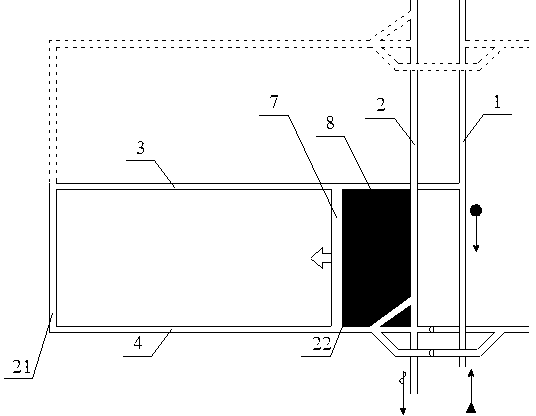

[0020] The pre-excavation two-lane forward solid filling coal mining method of the present invention: first, an incision is made from the coal transport uphill 1, and the coal body is excavated from the uphill to the section boundary direction to form a pre-excavation transportation lane 3; an incision is made from the rail uphill 2 , and form the pre-excavation track roadway 4 by excavating from the uphill to the section boundary in the coal body; when the two pre-excavation roadways are excavated to the section boundary, stop the excavation; , forming a connecting lane 21 to connect the pre-excavation transport lane 3 and the pre-excavation track lane 4; the pre-excavation transport lane 3 enters the air, and the pre-excavation track lane 4 returns air to form an initial ventilation system;

[0021] The protective coal pillar 8 is reserved, and the cutou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com