The roof caving and tunnel protecting method

A technology for roadway and coal seam roof, applied in the field of surrounding rock stability of coal mine roadway, can solve the problems of increasing roadway deformation, limited control effect, restricting roadway passage and transportation function, etc., so as to improve coal mining rate and reduce coal pillar width. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further explained below in conjunction with the accompanying drawings.

[0036] A method for controlling roof caving and roadway protection of the present invention includes the following:

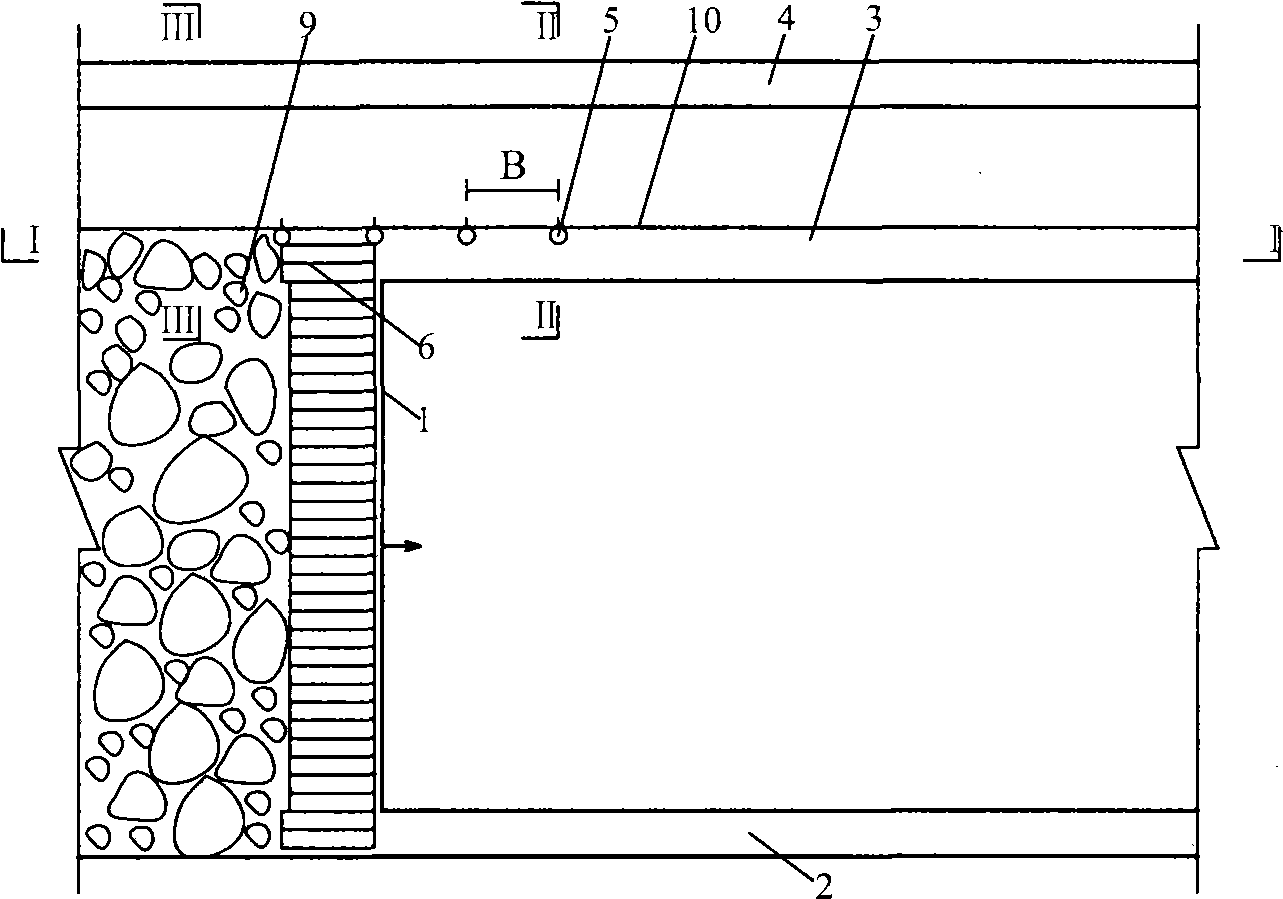

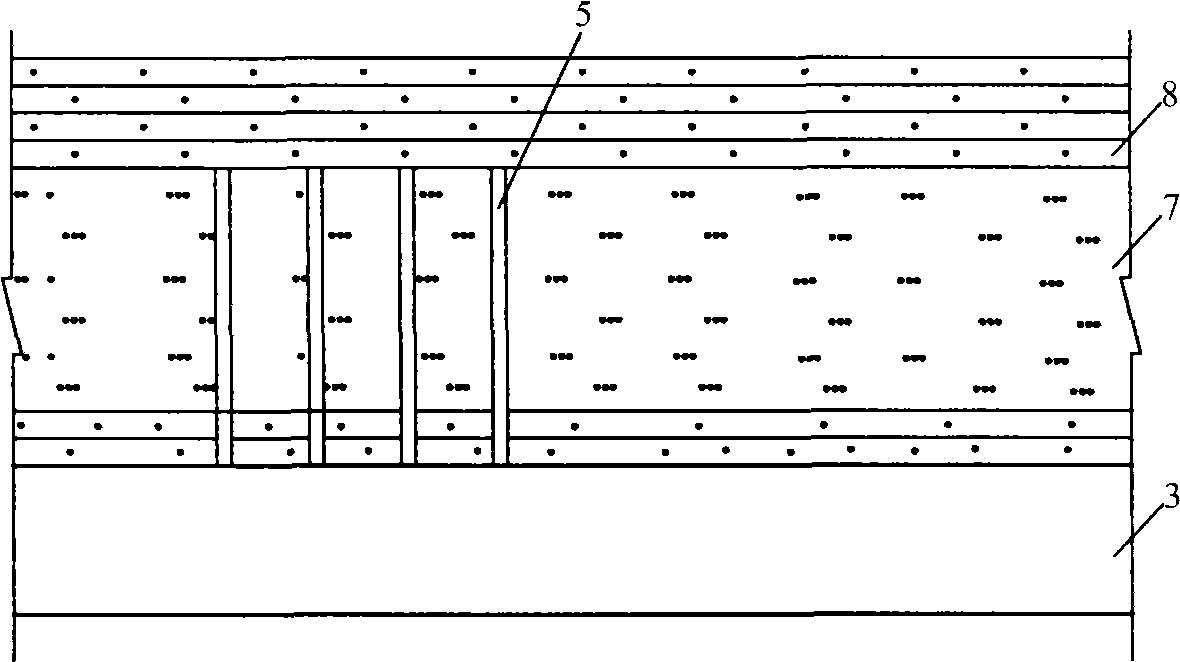

[0037] The coal mining face coal wall 1, the working face transportation lane 2 and the working face return air lane 3 form the production system of the working face as shown in the figure. The control caving is implemented in the working face return air lane to protect adjacent work Surface transportation lane 4. Under this condition, the process of implementing controlled placement is as follows:

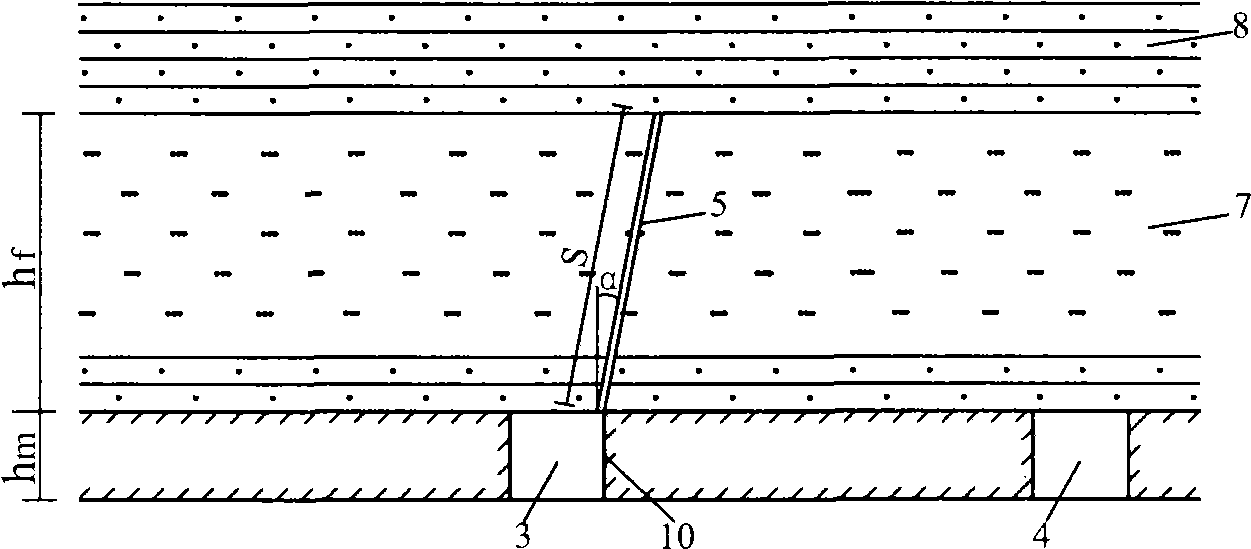

[0038] 1) In the return air tunnel 3, the coal wall of the advanced coal mining face is 3~5m, close to the coal pillar side coal wall 10 of the return airway, and inclined α=15~45° to the coal pillar side. Drilling spacing B=3~5m, and the drilling depth S is based on the minimum control height h f To determine, the minimum control height h f Is based on the bre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com