Bulk light-emitting diode (LED) feeder

A feeder and bulk technology is applied in the field of bulk LED feeders to achieve the effects of reducing production costs, simplifying production processes and eliminating purchases

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In order to facilitate the understanding of those skilled in the art, the present invention will be further described below in conjunction with the embodiments and accompanying drawings, and the contents mentioned in the embodiments are not intended to limit the present invention.

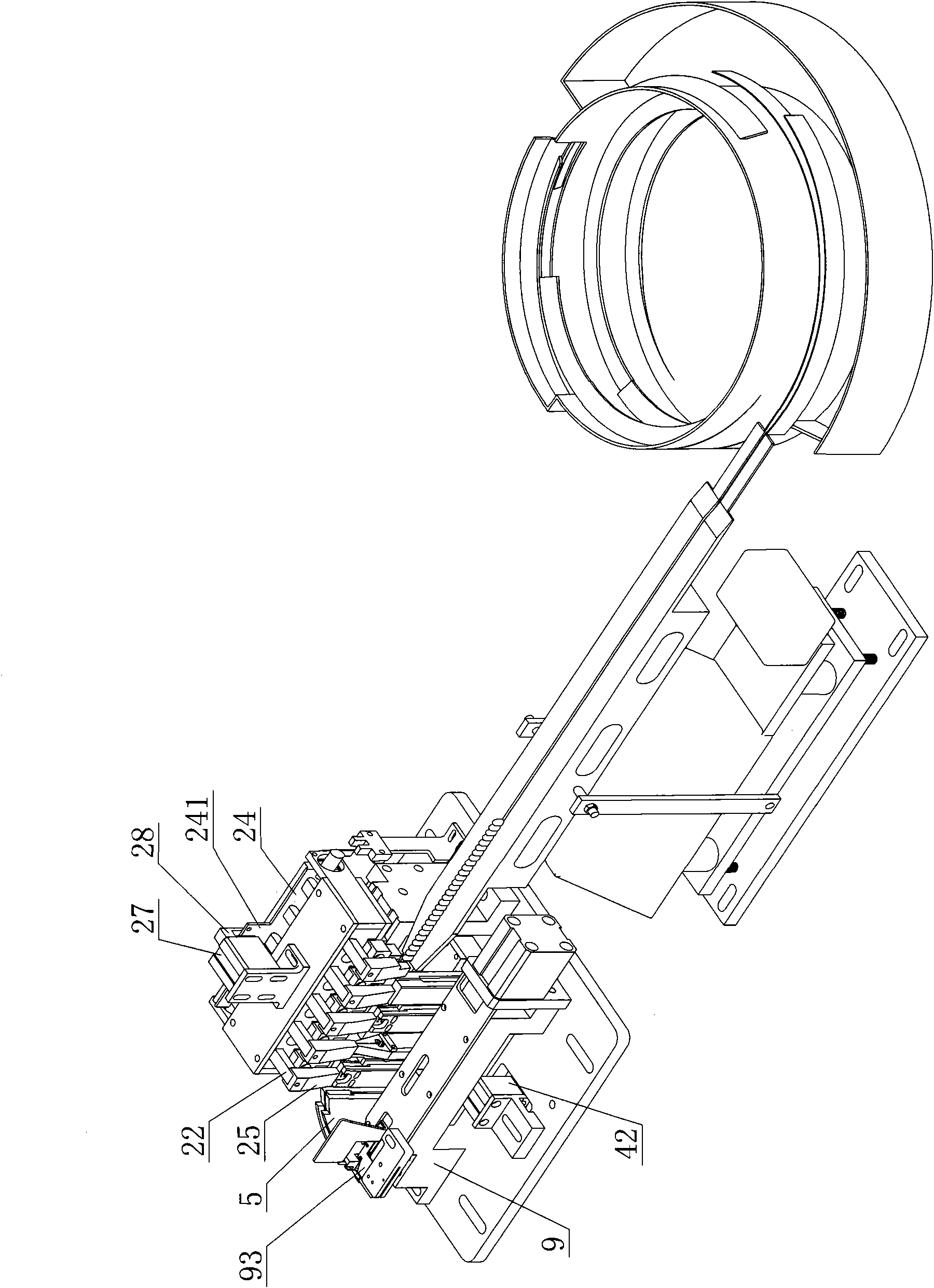

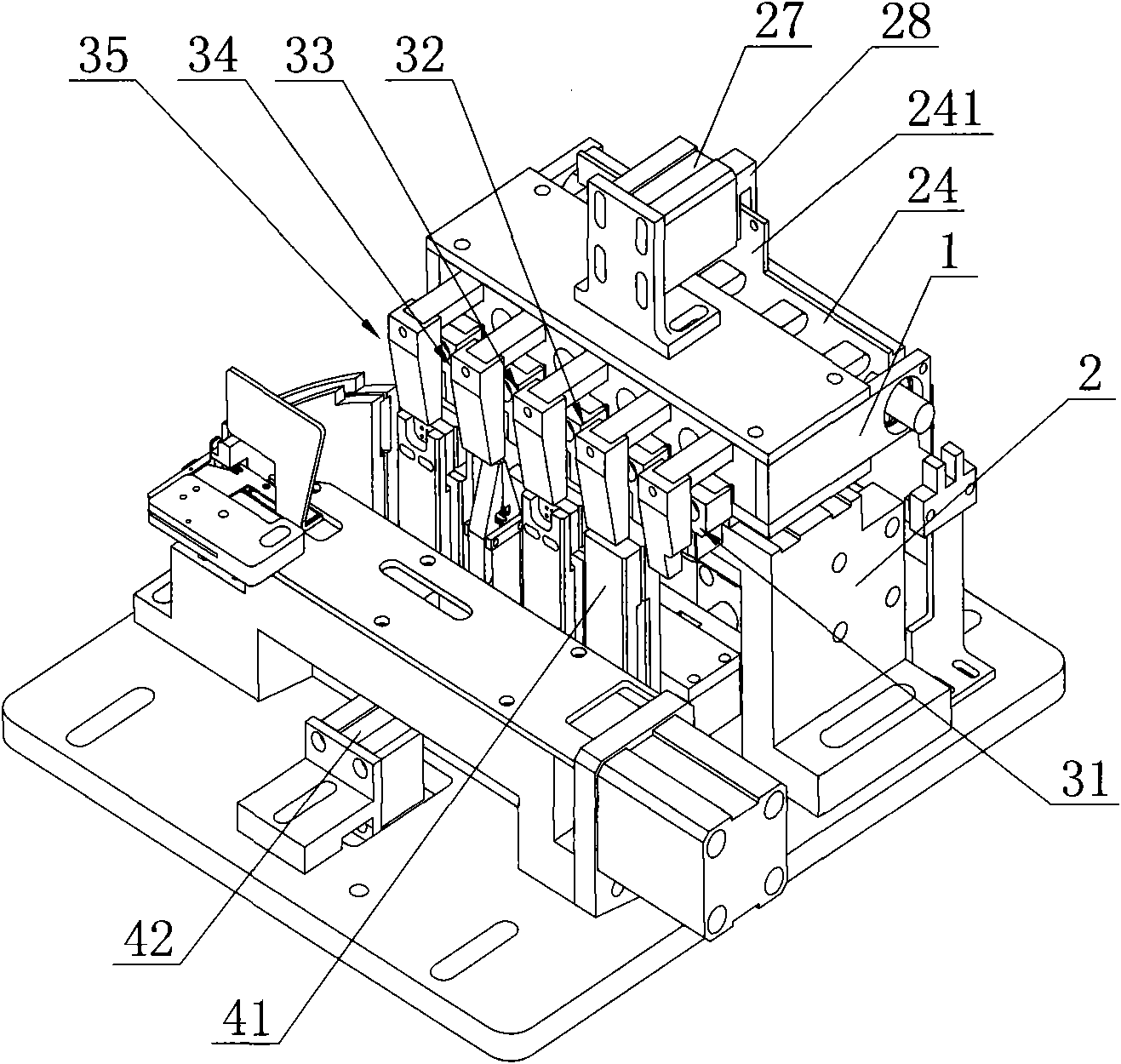

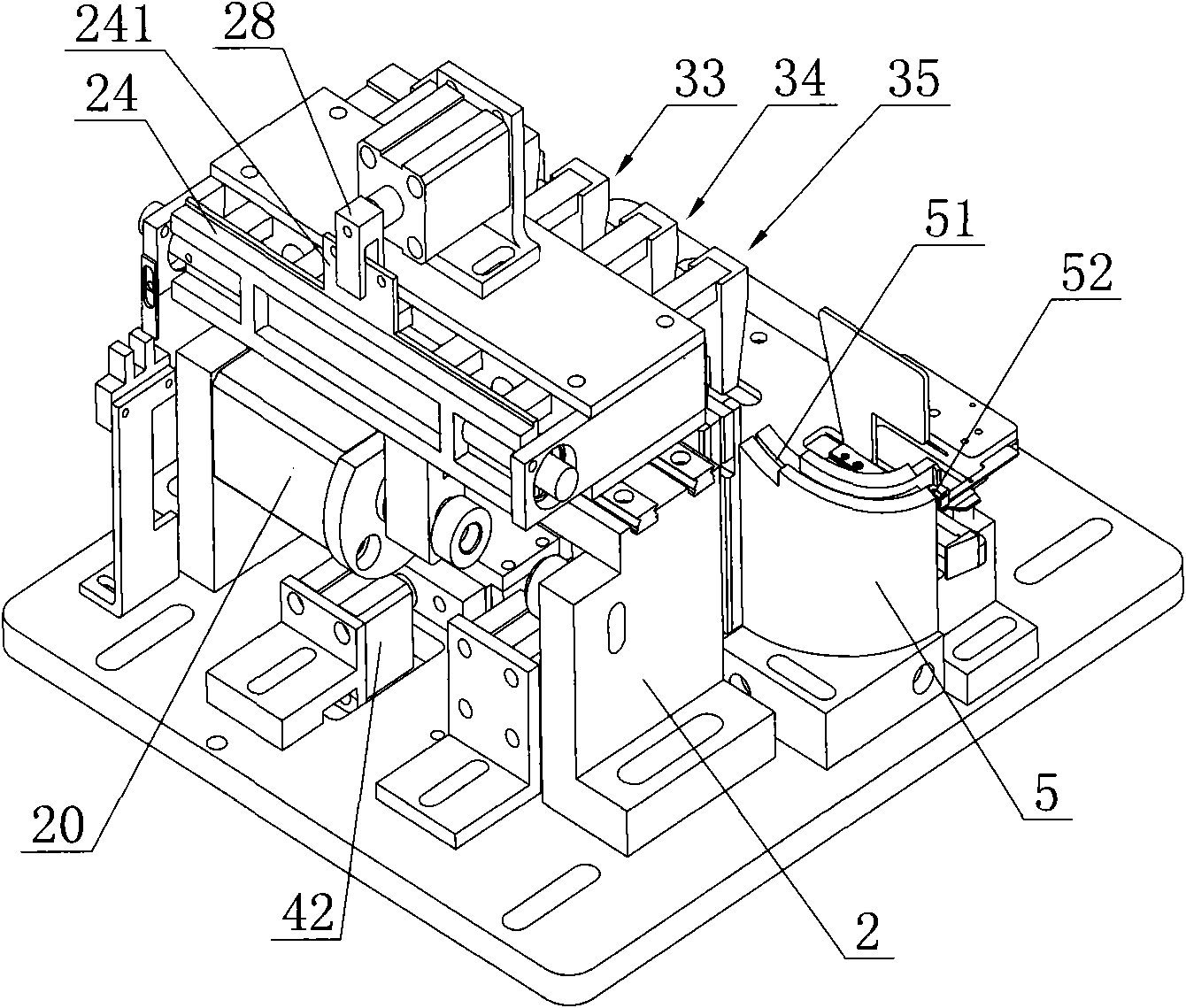

[0045] Such as Figures 1 to 12The bulk LED feeder shown includes a working table, a vibrating plate, a linear vibrator, and an LED feeding body. The vibrating plate, a linear vibrator, and the LED feeding body are arranged on the working table in accordance with the working sequence. The LED feeding body It includes a clamping and pushing mechanism, a shaping mechanism arranged under the clamping and pushing mechanism according to the working order, a polarity detection and adjusting mechanism, a sliding guide rail mechanism and a feeding station mechanism; the clamping and pushing mechanism includes a clamping body 1, The slide rail seat 2 arranged on the workbench and the push cylinder 20...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com