Room temperature fast-drying highly-anticorrosive two-component waterborne epoxy coating and preparation method thereof

A water-based epoxy and anti-corrosion coating technology, applied in the field of coatings, can solve the problems of decreased interlayer adhesion and anti-corrosion performance of composite coatings, inconvenient coating construction, slow drying time, etc., to achieve excellent anti-corrosion performance, fast curing speed, Good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

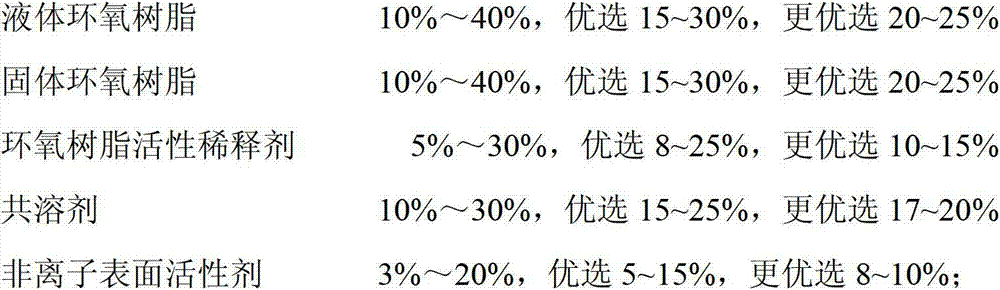

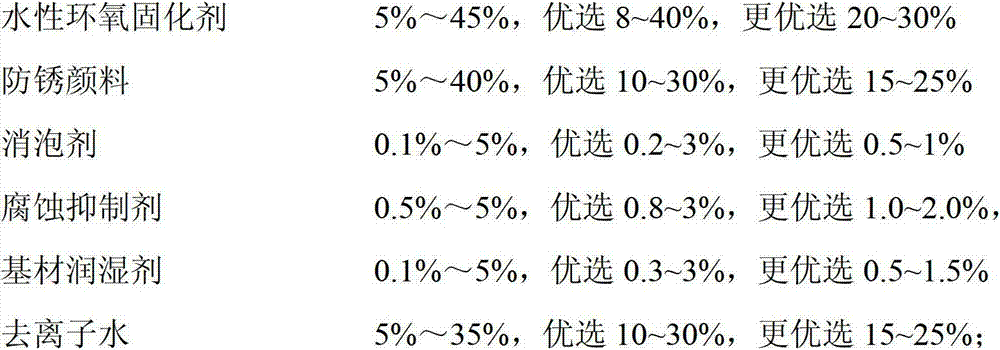

Method used

Image

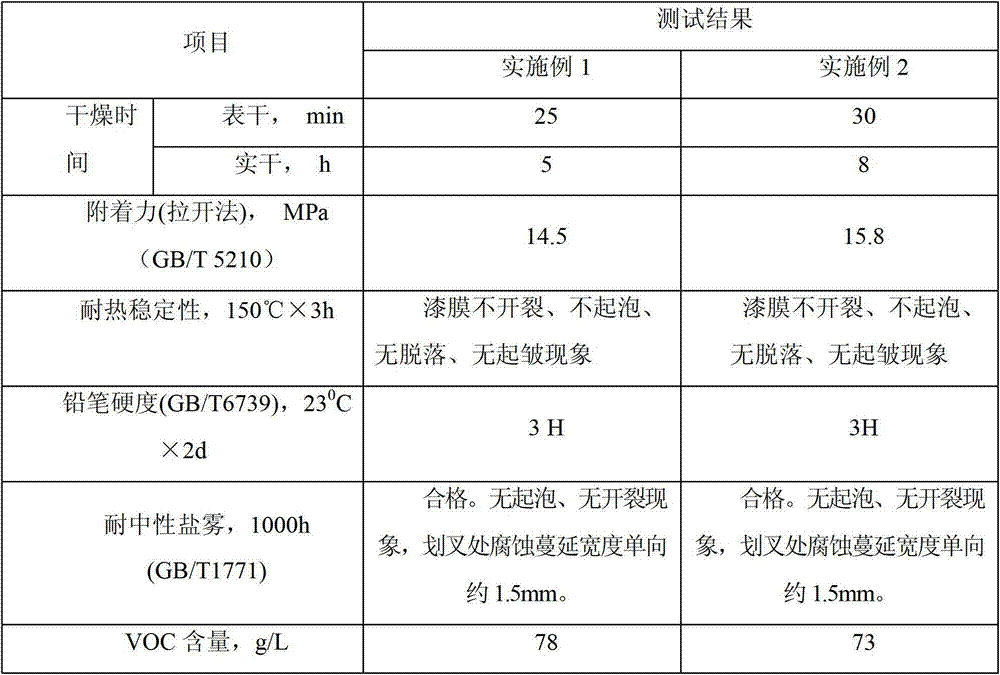

Examples

preparation example Construction

[0085] The present invention also provides the preparation method of above-mentioned room temperature quick-drying waterborne epoxy anticorrosion coating, comprises the following steps:

[0086] (1) Preparation method of component A:

[0087] a) Put the formula amount of liquid epoxy resin, epoxy resin reactive diluent, and co-solvent into the dispersion tank, disperse evenly at a low speed (for example, 10~20min, preferably 15min), and raise the temperature of the material liquid to 70~90°C, preferably 72 ~88°C, or 73~87°C, more preferably 75~85°C, or 76~84°C, 77~83°C, most preferably 78~82°C, or 79~81°C, for example 80°C;

[0088] b) Add the formula amount of solid epoxy resin, stir evenly after melting, and lower the temperature of the material liquid to 40~60°C, preferably 42~58°C, or 43~57°C, more preferably 45~55°C, or 46~ 54°C, 47~53°C, most preferably 48~52°C, or 49~51°C, such as 50°C;

[0089] c) High-speed stirring step b) the obtained material liquid, add the form...

Embodiment 1

[0104] A component preparation method:

[0105] Weigh 120Kg of Nanya 128 epoxy resin, 30Kg of AGE active diluent from Shanghai Resin Factory, 50Kg of propylene glycol methyl ether acetate, disperse at low speed for 15min, heat up to 80°C, then add 150Kg of Yueyang Petrochemical E20 solid epoxy resin, and stir after E20 melts Evenly, cool down to 50°C, add 50Kg of 20% LS500 surfactant under high-speed stirring, then disperse at high speed for 20 minutes, filter and pack to obtain component A.

[0106] Component B: Weigh 32Kg of EH613W water-based epoxy curing agent from Cytec, 110Kg of deionized water, 5Kg of TeKgo760W dispersant from Degussa, 2.5Kg of BYK420 anti-sedimentation thixotropic agent, iron oxide red 25Kg, mica iron oxide 45Kg, zinc phosphate 30Kg, organically modified aluminum molybdenum orthophosphate zinc ( ZAM-PLUS, organically modified zinc aluminum molybdenum phosphate hydrate, Heubach GmbH (Germany) 25Kg, 800 mesh mica powder 50Kg, precipitated barium sulfat...

Embodiment 2

[0109] Preparation method of component A: Weigh 150Kg of CYD-128 epoxy resin from Yueyang Baling Petrochemical, 35Kg of AGE active diluent from Shanghai Resin Factory, 58Kg of propylene glycol methyl ether acetate, disperse at low speed for 15min, heat up to 80°C, and then add Yueyang Baling Petrochemical E20 solid epoxy resin 150Kg, after the E20 is melted, stir evenly, cool down to 50°C, add 20% LS500 surfactant 57Kg under high-speed stirring, then disperse at high speed for 20 minutes, filter and pack to obtain component A.

[0110] Preparation method of component B: Weigh 64Kg of VEH2188W water-based epoxy curing agent from Cytec, 80Kg of deionized water, 4Kg of 6208 dispersant from Cytec, 2.4Kg of BYK420 anti-sedimentation thixotropic agent, Iron oxide red 24Kg, mica iron oxide 44Kg, zinc phosphate 30Kg, organically modified aluminum molybdenum zinc orthophosphate ( ZAM-PLUS, organically modified zinc aluminum molybdenum phosphate hydrate, Heubach GmbH (Germany) 25Kg, 80...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com