Manufacturing method for array substrate of thin film transistor LCD

A technology of thin film transistors and array substrates, which is applied in the production field of array substrates of thin film transistor liquid crystal displays, can solve the problems of high cost and low yield rate, and achieve the effects of simplifying the manufacturing process, improving production efficiency, improving efficiency and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

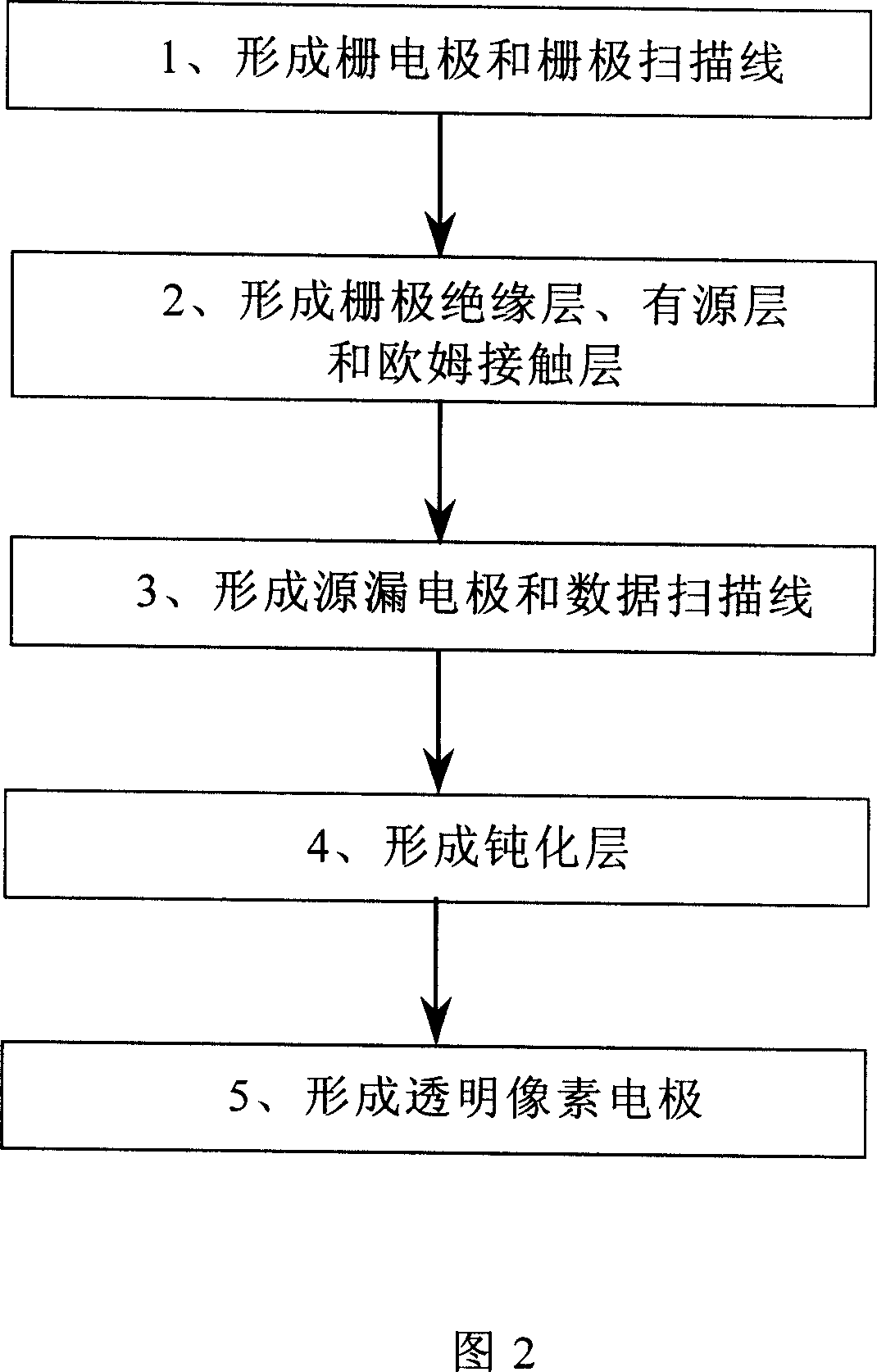

[0037] Below in conjunction with accompanying drawing and specific embodiment, the present invention is described in further detail:

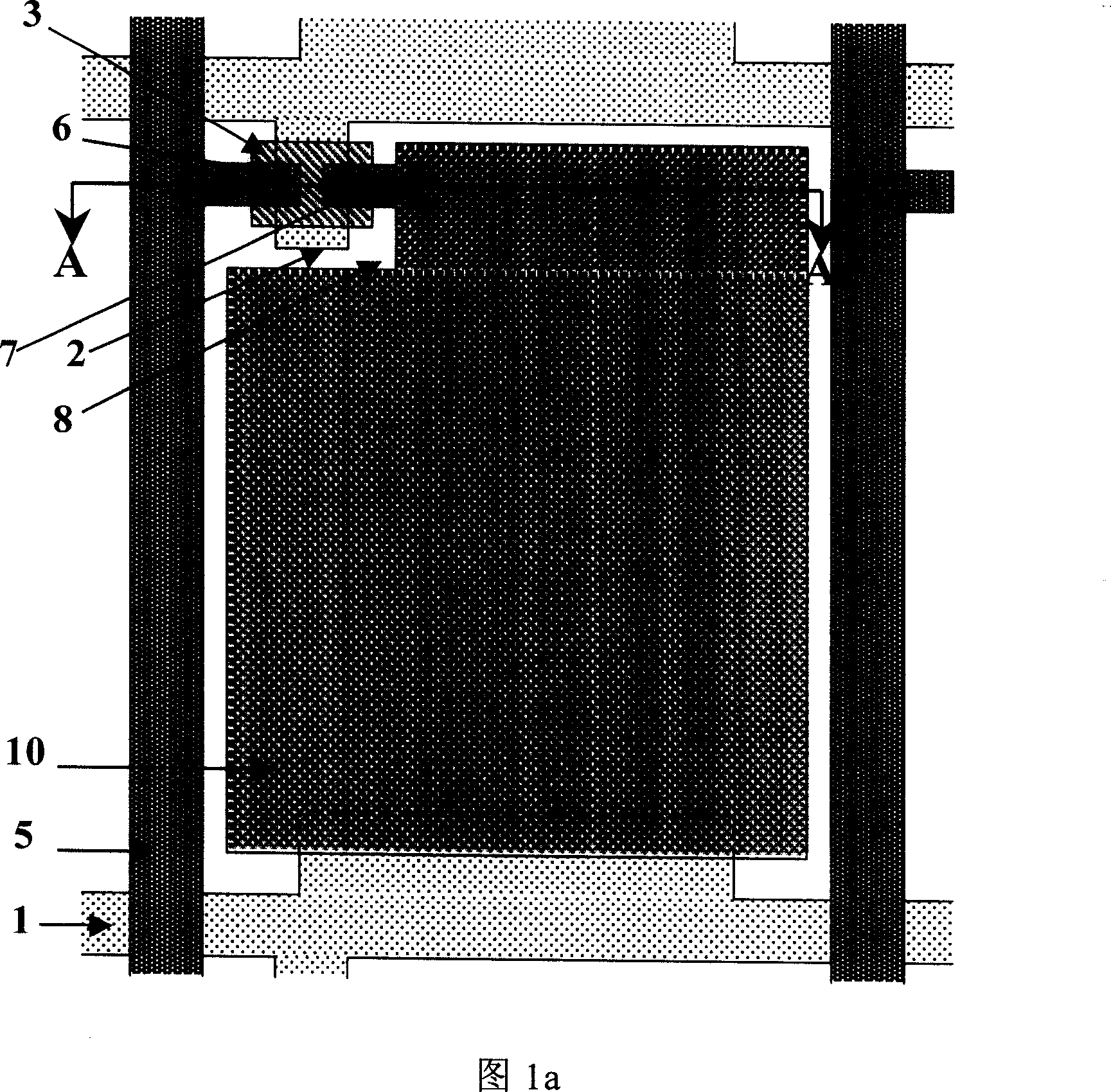

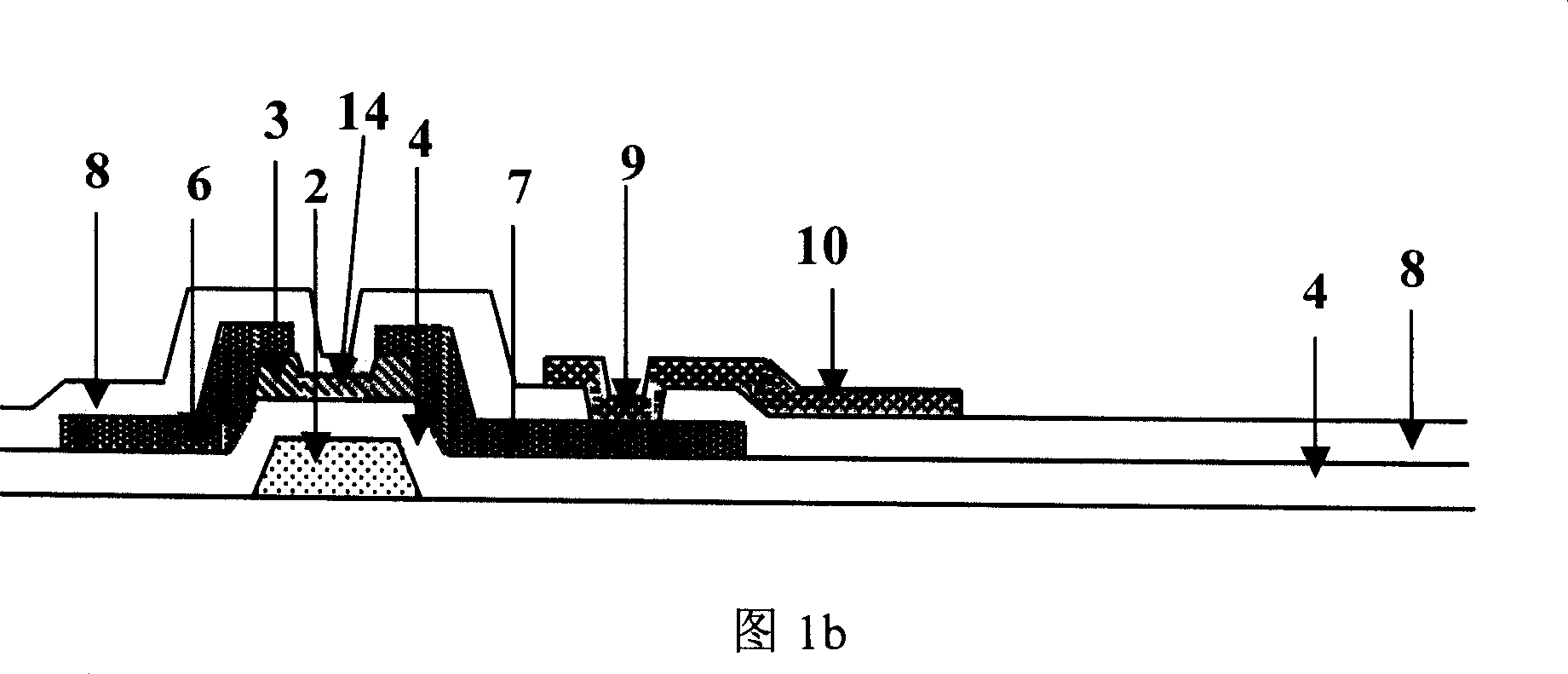

[0038] First, a gate metal thin film with a thickness of 1000 Ȧ to 7000 Ȧ is prepared on the substrate by magnetron sputtering. The gate metal thin film is usually made of metals such as molybdenum, aluminum, aluminum-nickel alloy, molybdenum-tungsten alloy, chromium, or copper, or a combination of the above-mentioned materials. As shown in FIG. 3 a and FIG. 3 b , the first mask plate is used for exposure and development, and then chemical etching is performed to form patterns of gate scanning lines 1 and gate electrodes 2 on a certain area of the glass substrate.

[0039] Then, a gate insulating layer 4 film with a thickness of 1000 Ȧ to 6000 Ȧ and a semiconductor layer 3 film (including an active layer and an ohmic contact layer) with a thickness of 1000 Ȧ to 6000 Ȧ are successively deposited on the array substrate by chemical vapor deposit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com