Ultrathin glass corner machining method and special computerized numerical control (CNC) cutter

A technology of ultra-thin glass and processing method, which is applied in the direction of manufacturing tools, metal processing equipment, machine tools suitable for grinding the edge of workpieces, etc. The effect of improving efficiency, improving the pass rate, and not easy to scratch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] For the simultaneous chamfering of the upper and lower sides of each glass 5, a special CNC tool 6 is configured, and the two chamfering slopes of the convex ring chamfering portion 5a form an acute angle; the special CNC tool 6 is as follows: Figure 5 shown.

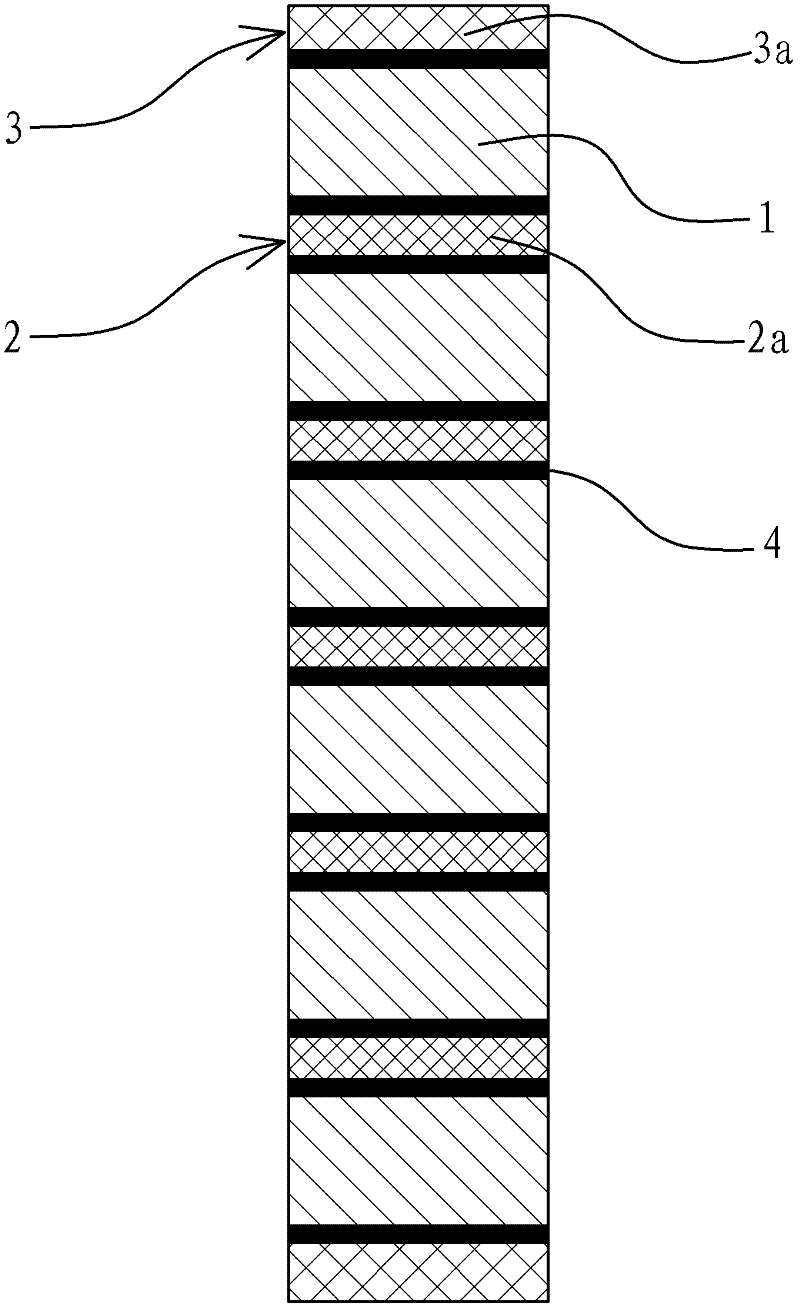

[0032] Such as figure 1As shown, the original glass sheet with a thickness of 0.85mm is selected, and the glass sheet can be flat glass or curved glass. Use a cutting machine to cut into several single-piece rectangular sheets according to the size and shape of the product design. The several single-piece rectangular sheets can be directly purchased or customized in the market. Take six pieces of single-piece glass 1 and stack them into a rectangular block For glass, a spacer layer 2 with a thickness of 1mm is arranged between every adjacent two pieces of single glass 1. The specific structure of the spacer layer 2 is: take a spacer 2a with a thickness of 0.6mm, and place it on top of the spacer 2a. Both the s...

Embodiment 2

[0034] For simultaneous chamfering of the upper and lower sides of multiple pieces of glass, a special CNC tool 27 is configured, and the two chamfering slopes of the convex ring chamfering part 5a form an obtuse angle; Figure 6 shown.

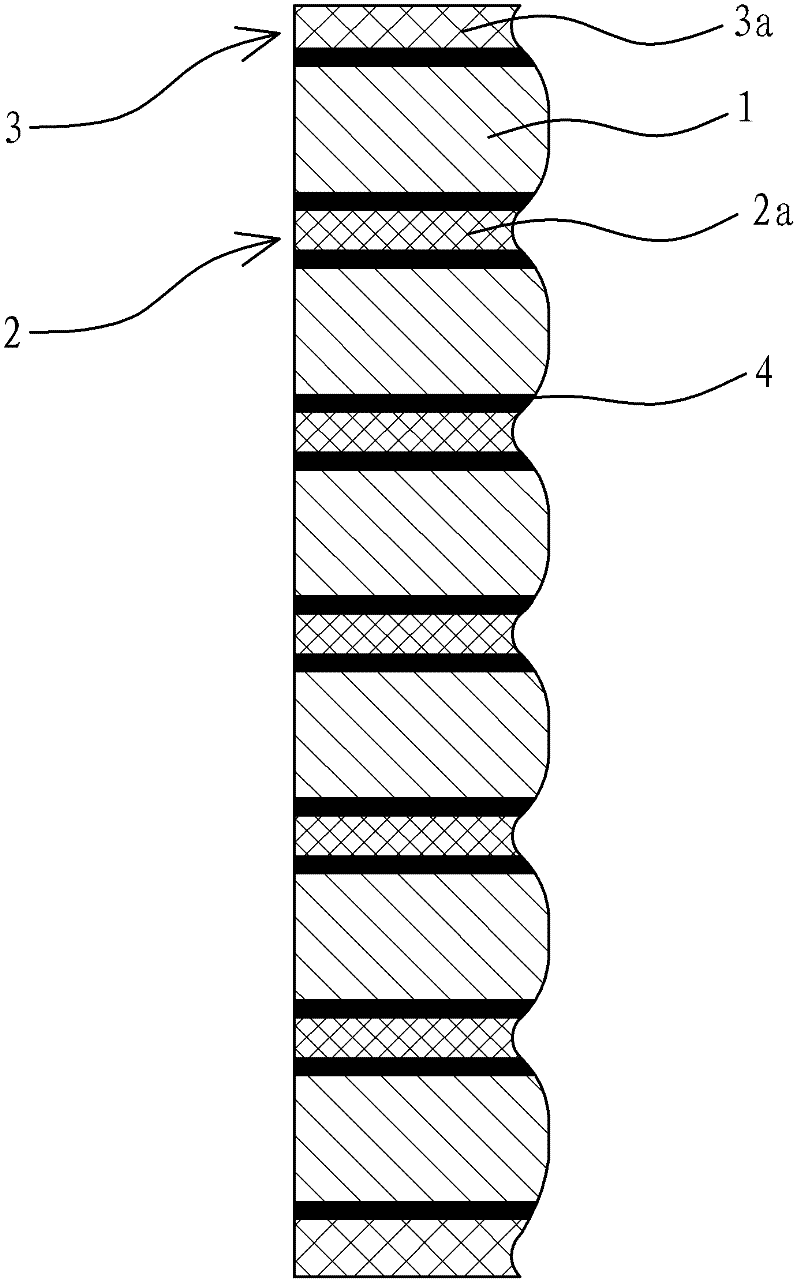

[0035] Such as image 3 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that: take six pieces of monolithic glass 1 to be superimposed on each other to form a rectangular block glass, and arrange A spacer layer 2 with a thickness of 1mm, 1mm, 0.5mm, 2mm, and 1mm, the spacer layer 2 is directly formed by an adhesive 4, and each adjacent two pieces of single glass 1 are connected by an adhesive 4, such as Figure 4 As shown, according to the thickness of the monolithic glass 1 and the thickness of the adhesive 4 bonded between the monolithic glass 1, a pair of each monolithic glass 1 is processed at the same time. The two chamfering slopes of the first convex annular chamfering porti...

Embodiment 3

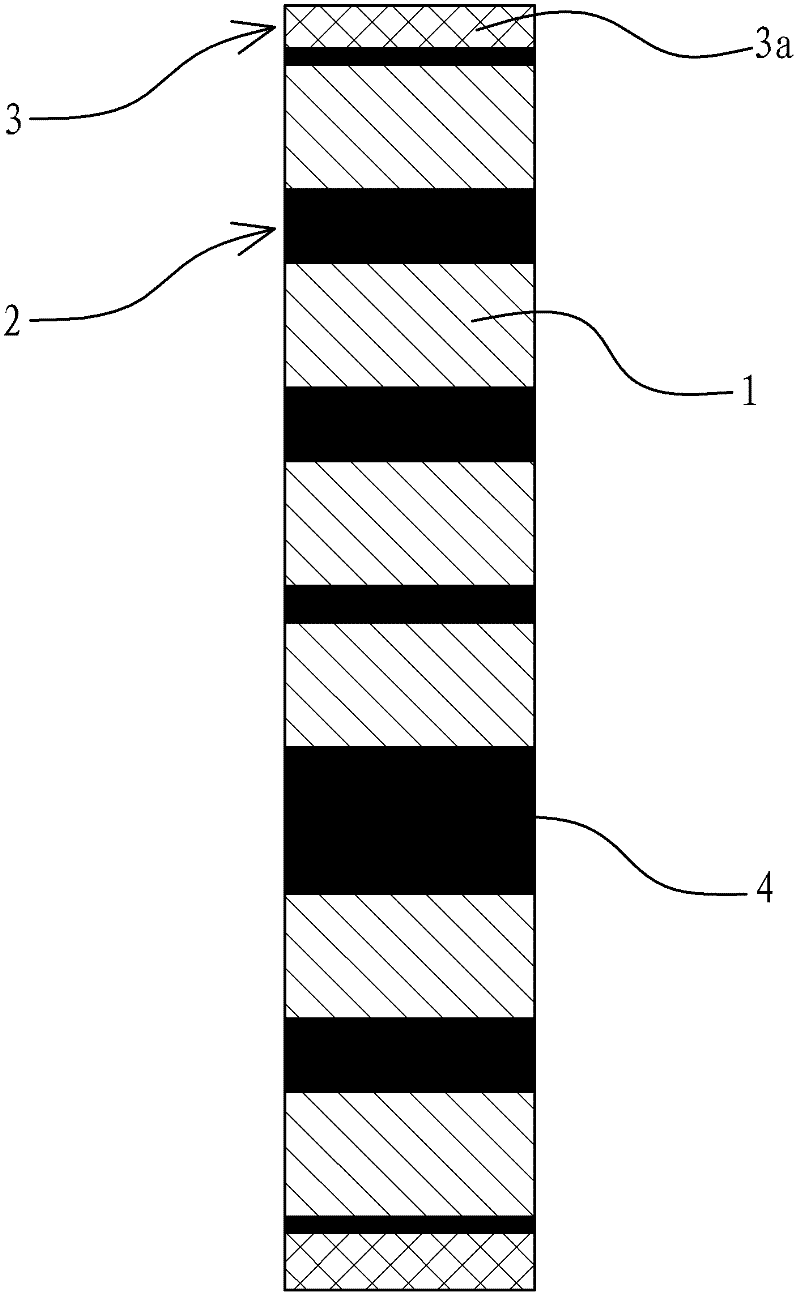

[0037] For the simultaneous chamfering of the upper sides of multiple pieces of glass, a special CNC tool 3 8 is configured, and the convex ring chamfering portion 5a has only one chamfering slope; the special CNC tool 3 8 is as Figure 7 shown.

[0038] The structure of this embodiment is basically the same as that of Embodiment 2, the difference is that a pair of each single glass is set according to the thickness of the single glass 1 and the thickness of the adhesive 4 bonded between the single glass 1 1 Simultaneously process the special CNC tool 3 8 for corner processing, the convex annular chamfering portion 5a of the special CNC tool 3 8 is composed of a single chamfering slope, and the chamfering slope faces the upper side of the laminated upper and lower single glass 1 The corners are chamfered at the same time, and the lower side corners of the upper and lower single glass are not chamfered. After the special CNC tool 38 is designed, each single glass 1 in the recta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com