Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

48results about How to "Reduce powder loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

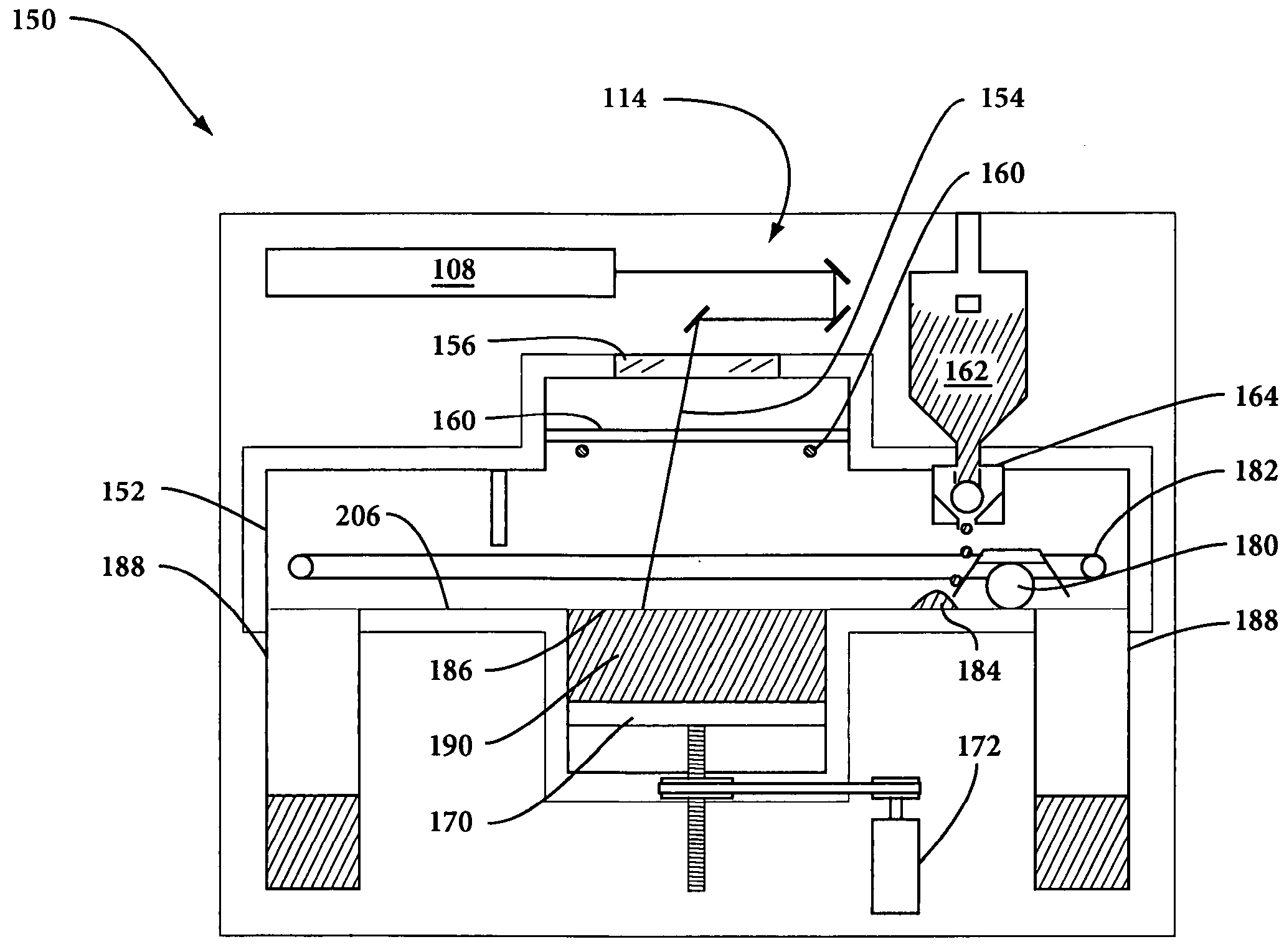

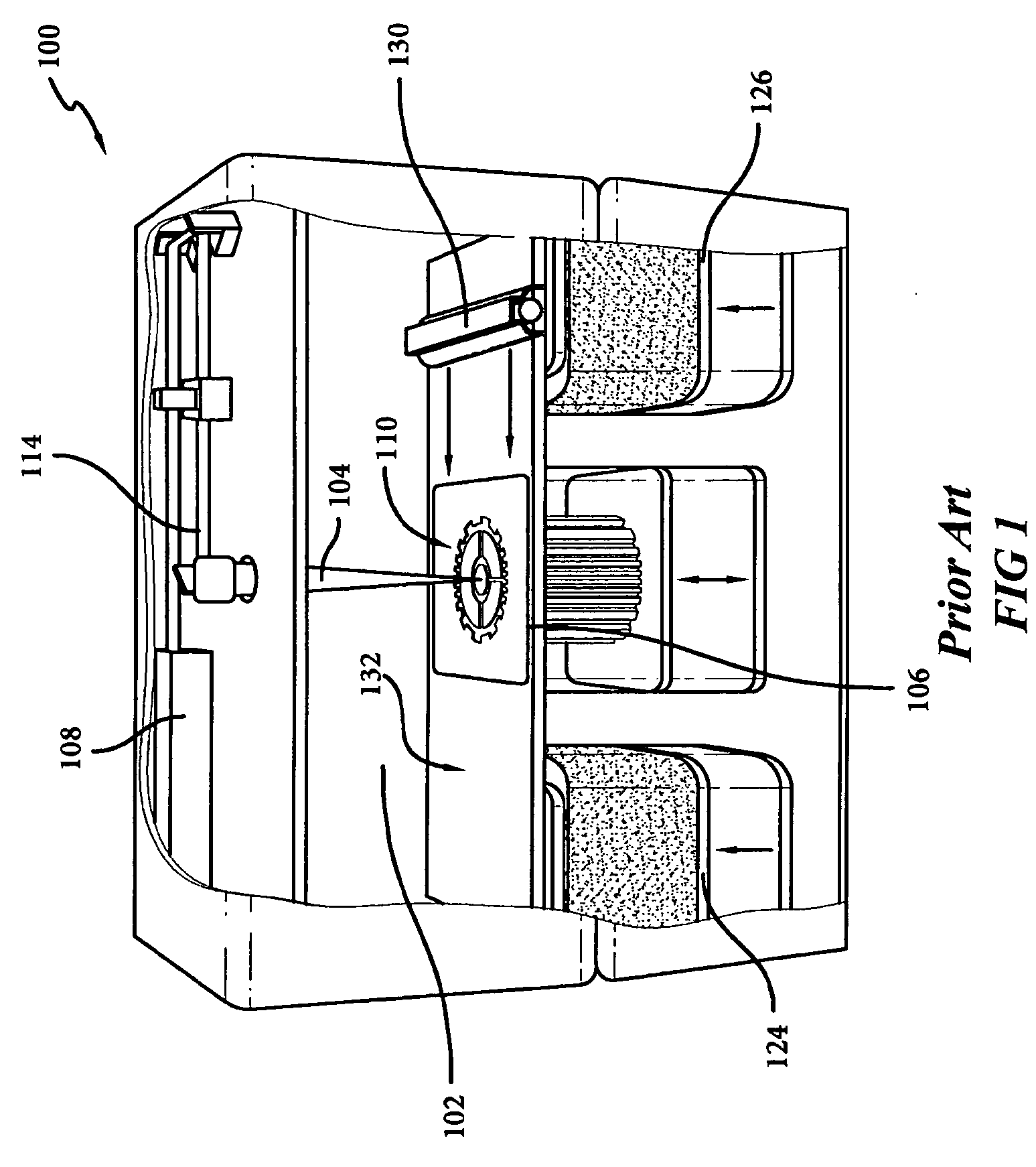

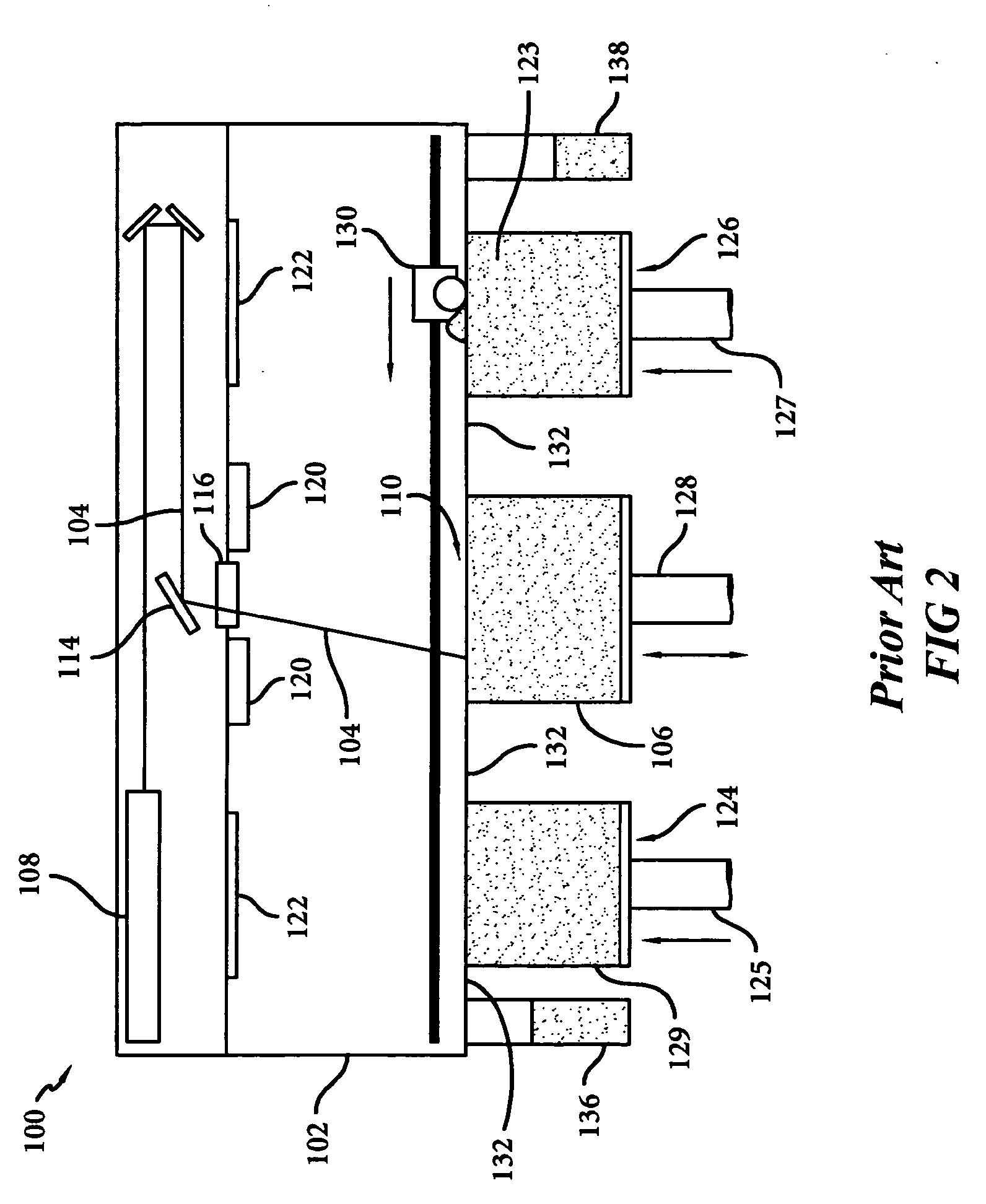

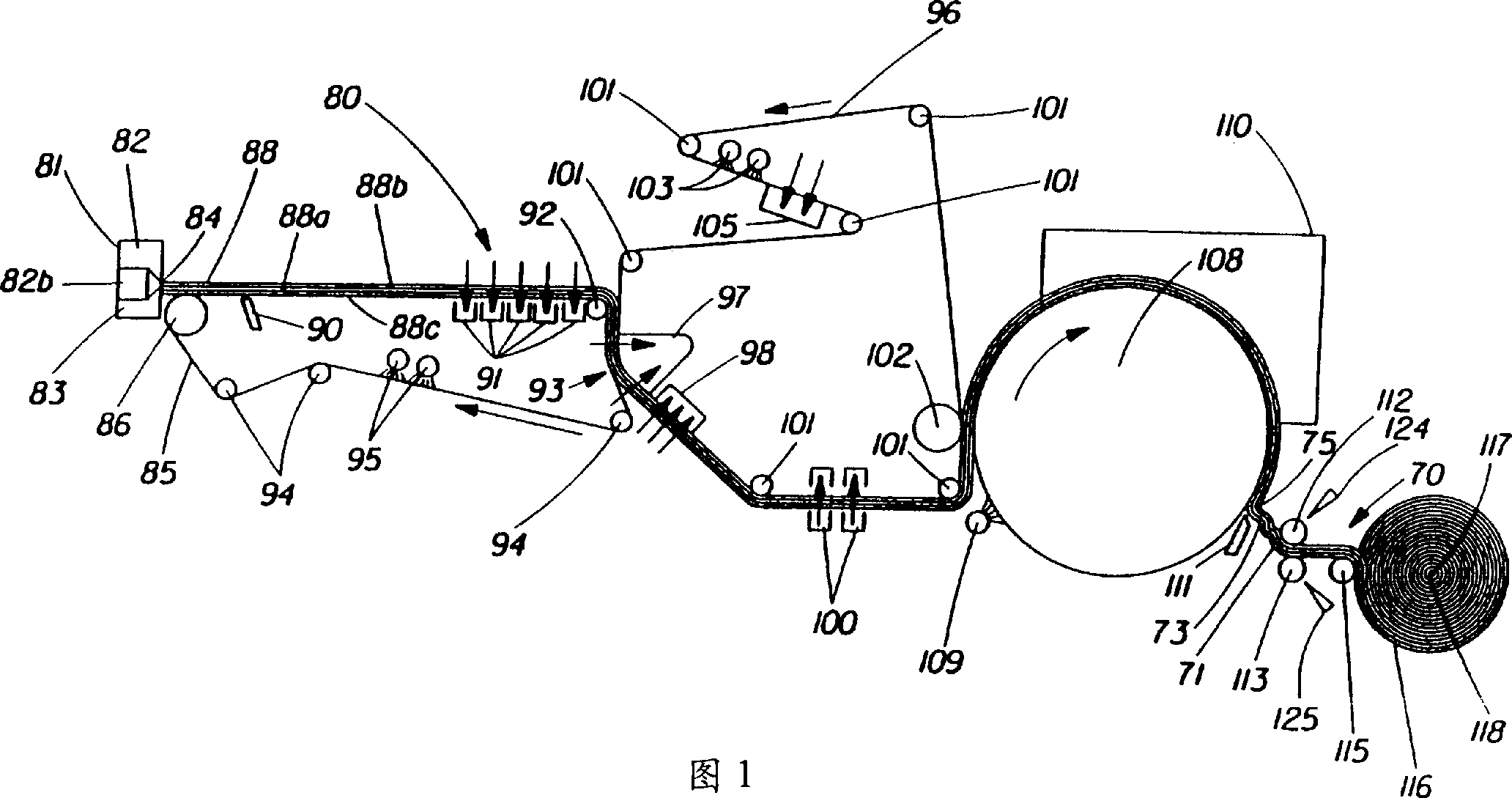

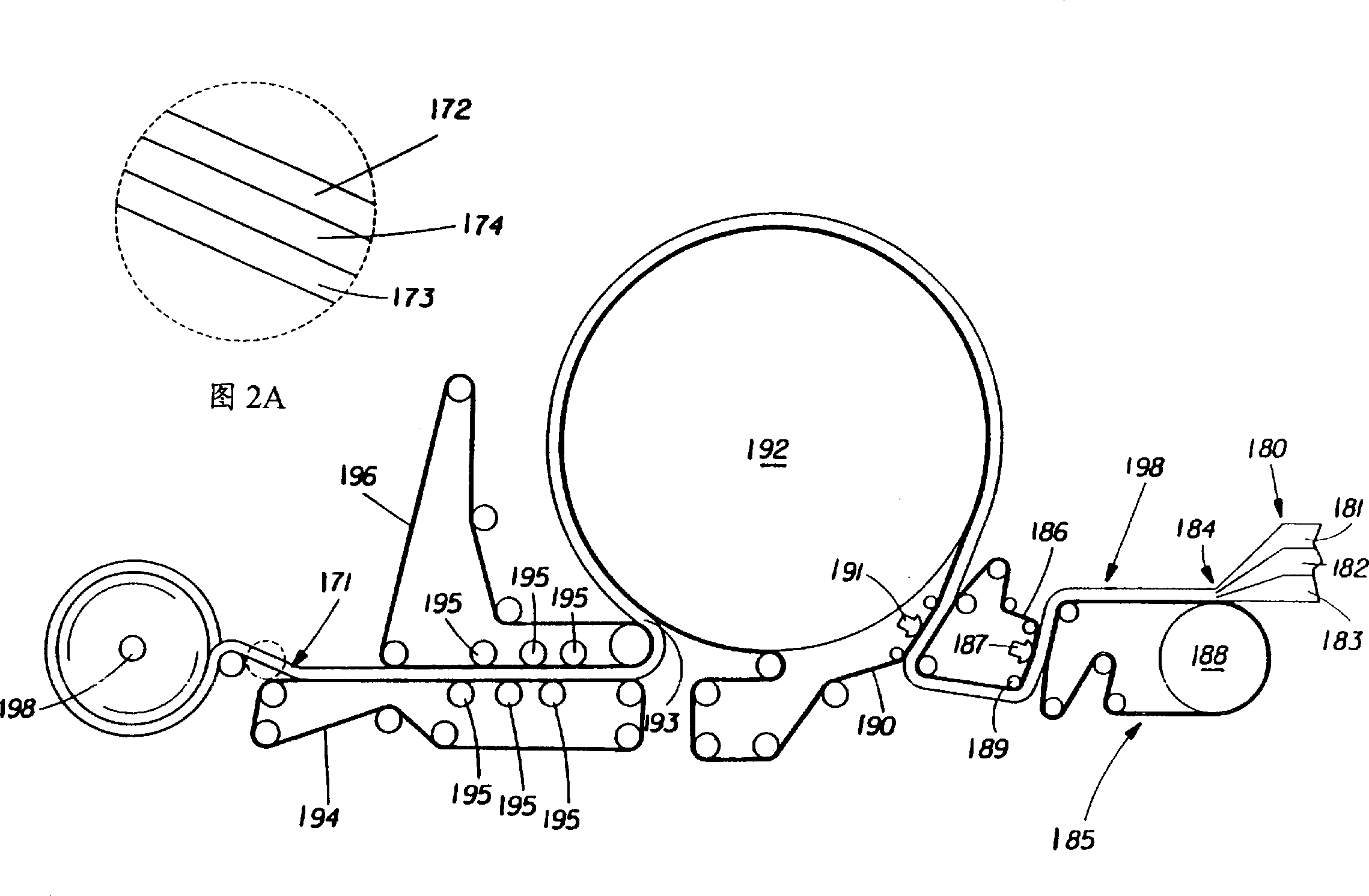

Selective Laser Sintering Powder Recycle System

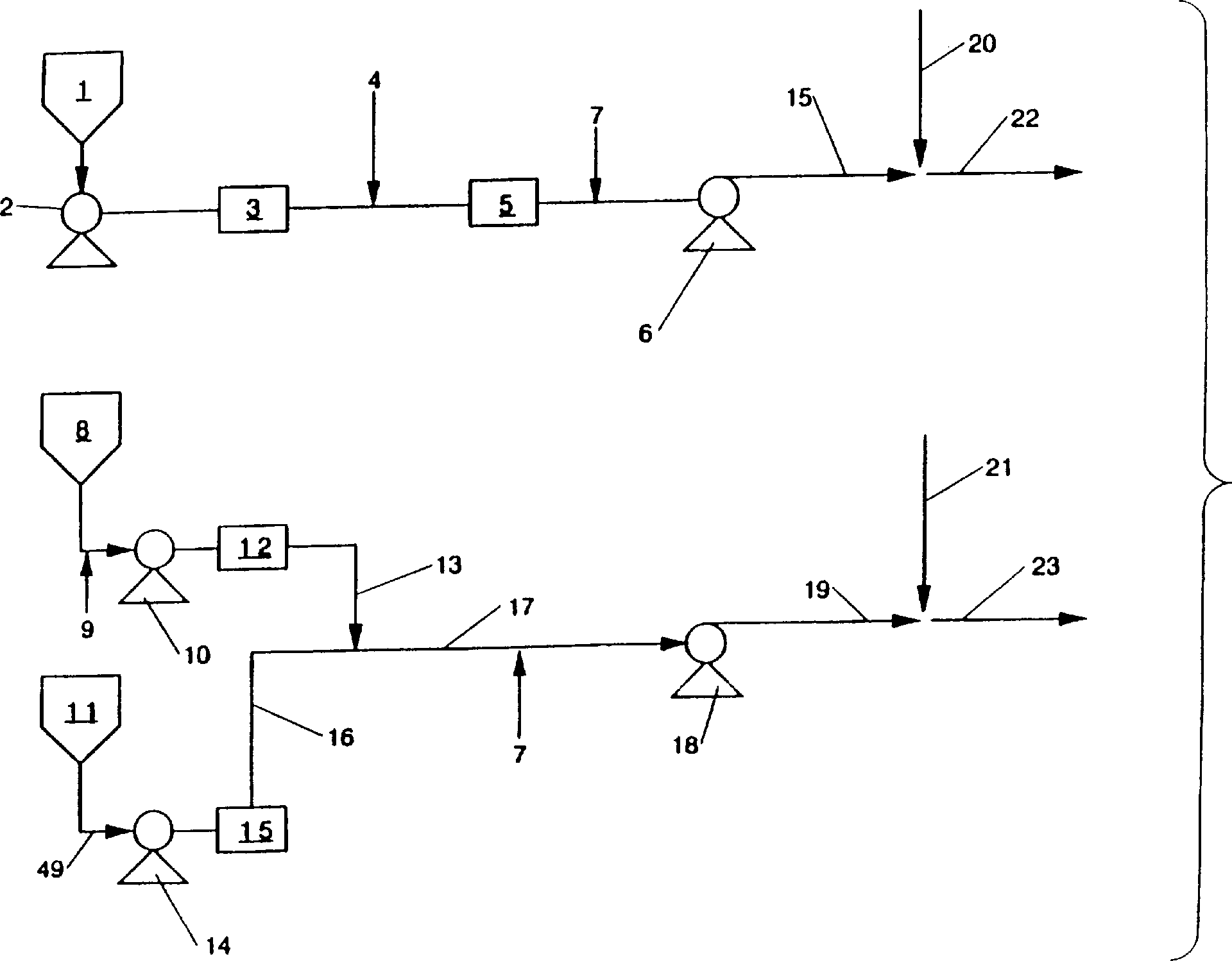

ActiveUS20090169664A1Good blendingReduce powder lossFlow mixersTransportation and packagingSelective laser sinteringMetallurgy

A method and apparatus for forming three-dimensional objects by laser sintering that includes the use of dense phase pneumatic conveying to internally recycle overflow powder, and to thoroughly blend overflow, recovered and virgin powder to provide a consistent powder feed mix to a laser sintering machine. Overflow powder from the laser sintering machine is recovered and recycled back into the laser sintering machine for reuse. The approach results in a compact and reliable powder recycle system with complete blending and minimum attrition to the handled powder.

Owner:3D SYST INC

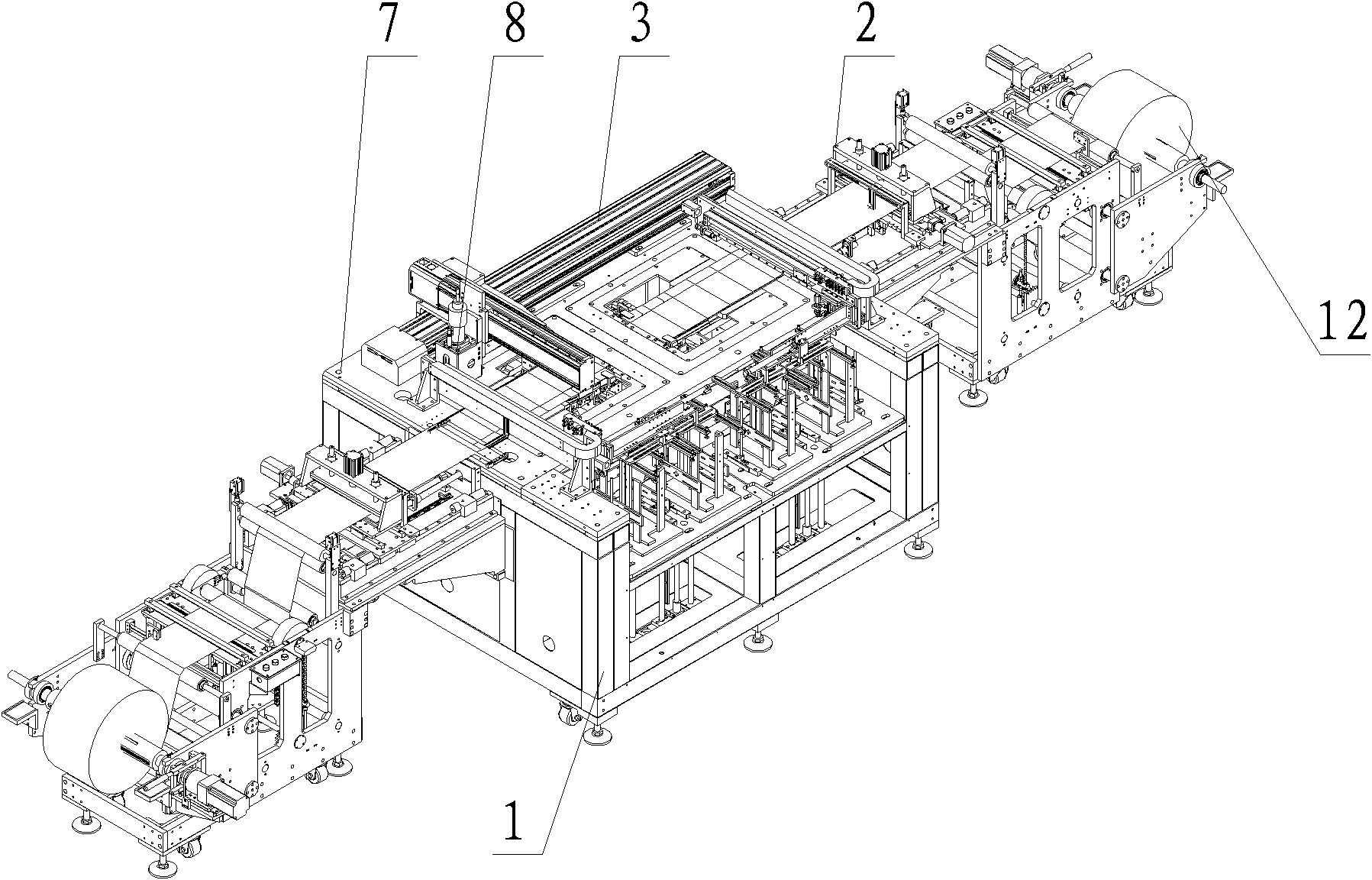

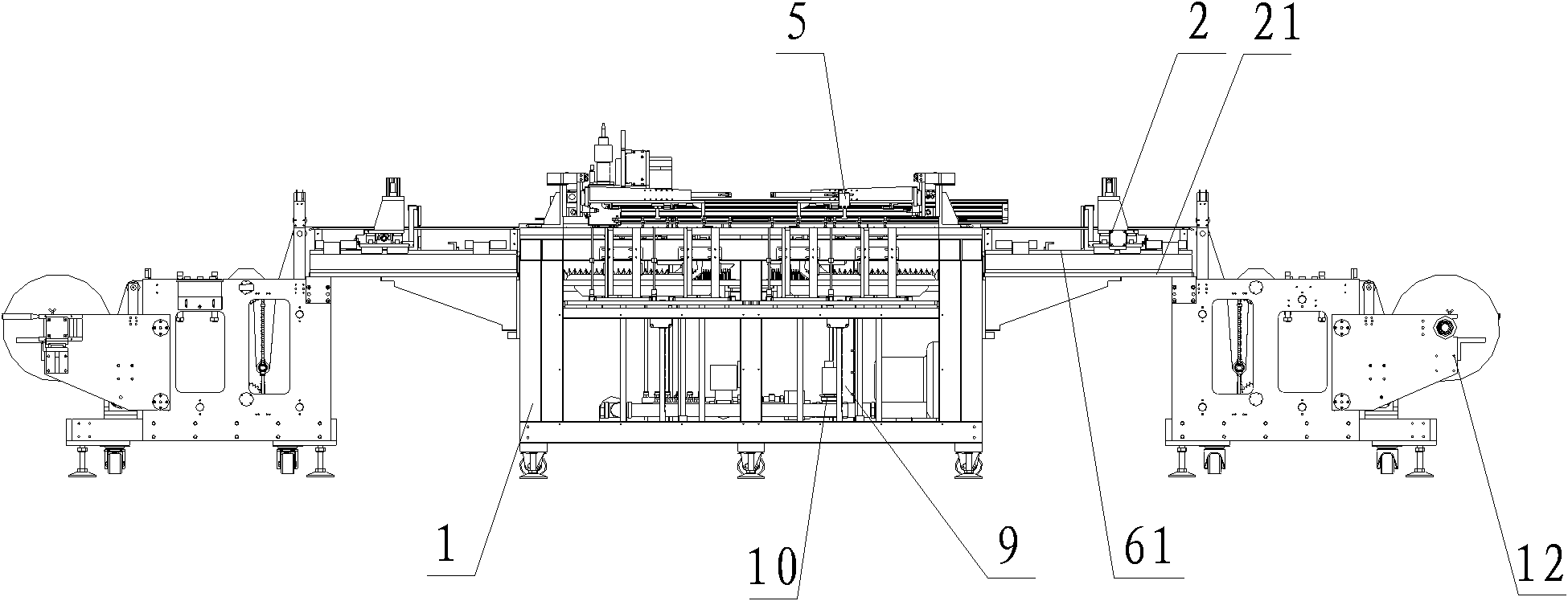

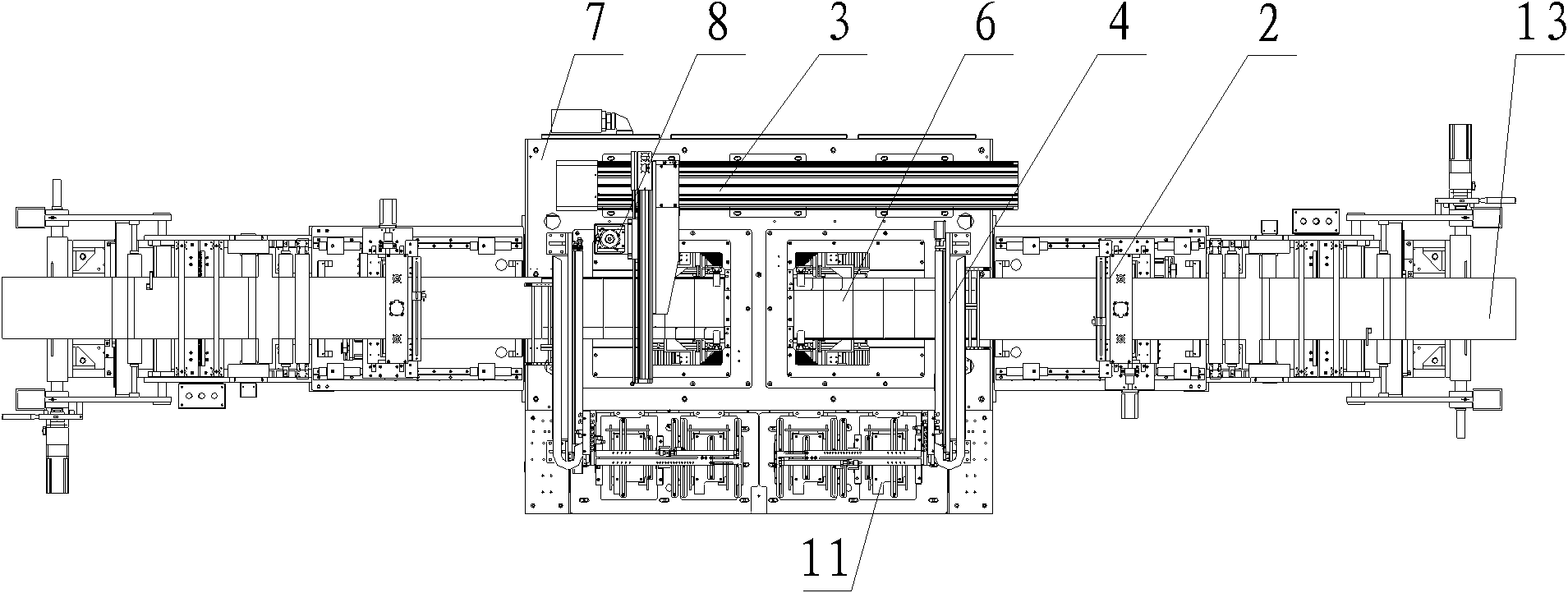

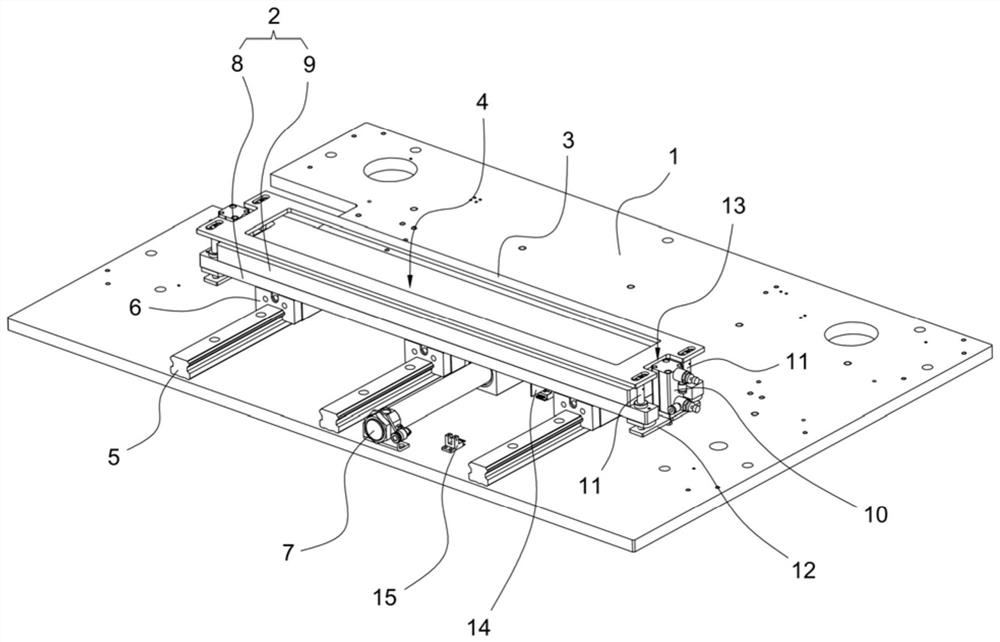

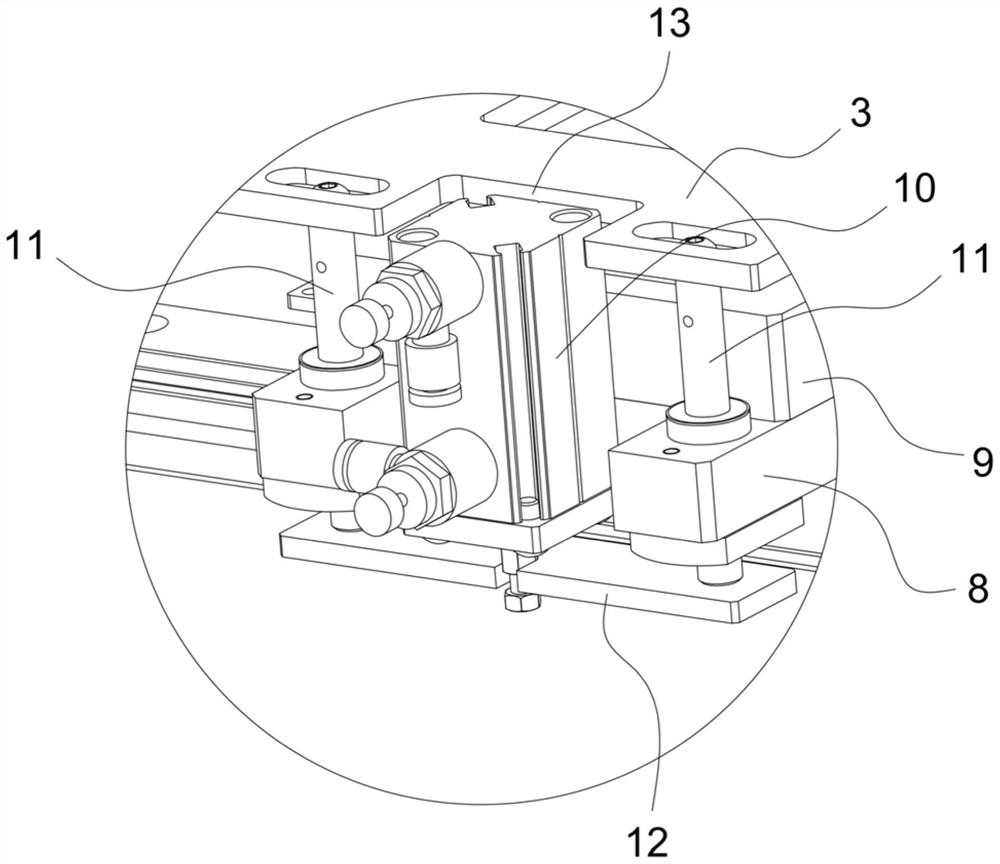

Pole piece laser cutting machine

ActiveCN102642089AOvercome deformationSmall size errorProgramme-controlled manipulatorElectrode manufacturing processesCapacitanceLaser technology

The invention discloses a pole piece laser cutting machine. The machine comprises a base frame part, a laser cutter, a cutting manipulator part, a control system and at least a piece feeding component, wherein the cutting manipulator part is used for driving the laser cutter; each piece feeding component comprises a material clamping manipulator part, a feeding fixed-length part and an emptying part; the cutting manipulator part and the material clamping manipulator part are installed on the base frame part; the feeding fixed-length part is arranged between the material clamping manipulator part and the emptying part; and the control system is connected with the cutting manipulator part, the material clamping manipulator part and the feeding fixed-length part. The machine has the following beneficial effects: the machine realizes the piece preparation processes of the lithium ion batteries or super capacitors by adopting the laser technology, can solve the problem that the pole pieces are easy to deform and have bigger burrs as the traditional cutting processes are adopted in the prior art, simultaneously improves the piece preparation process quality under the control of the control system and increases the yield.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

Soft tissue paper containing fine particulate fillers

InactiveCN1244899ALess quantityExcellent optical propertiesSpecial paperPaper/cardboardFiberWater insoluble

Soft, strong, and low dusting tissue paper webs useful in the manufacture of soft, absorbent sanitary products such as bath tissue, facial tissue, and absorbent towels are disclosed. The tissue papers copmrise fibers such as wood pulp and a non-cellulosic, water insoluble particulate filler such as kaolin clay and possess biased surface properties.

Owner:INSTITUTE OF PAPER SCIENCE AND TECHNOLOGY

Cation surface sizing agent and preparation method thereof

InactiveCN101649583AReduce manufacturing costPrevent penetrationWater-repelling agents additionPaper/cardboardAmylaseSizing

The invention provides a cation surface sizing agent and preparation method thereof. Raw materials are as follows by weight percent: 8-17% of styrene, 5-15% of butyl acrylate, 0.5-5% of acrylamide, 0.5-5% of N-hydroxymethyl acrylamide, 1-5% of methyl acryloyl ethyl trimethylammonium chloride, 2-8% of starch, 0.001-0.003% of amylase, 0.2-0.7% of organic acid, 0.2-0.8% of emulsifier, 1-5% of 27% hydrogen peroxide, 0.01-0.05% of iron dichloride, the balance water. The cation surface sizing agent is prepared by starch pasting, monomer pre-emulsion and emulsion polymerization. The invention is usedfor surface sizing of paper and achieves the aim of improving physical performances of paper such as water-resistance, ring crush compression resistance, surface strength and the like.

Owner:东莞市清正合成高新材料有限公司 +1

Surface sizing agent for paper making

InactiveCN101225623AImprove qualityMeet quality requirementsWater-repelling agents additionNon-macromolecular organic additionIsooctyl acrylateEmulsion

The invention relates to a surface sizing agent for paper making, which has the material formula with a plurality of components and weight percentages as follows: starch 6.5-8%, styrene 4.5-6%, acrylonitrile 4-5%, n-butyl methacrylate 5.5-6.5, methacrylic acid iso-octyl 2-3.5, iso-octyl acrylate 0.4-1%, hydrogen peroxide 0.2-0.5%, formic acid0.5-1%, ferrous sulfate 0.5-4%, n-dodecyl mercaptan 0.5-3%, amylase 0-0.2% and water the rest, wherein at least one is chosen from n-butyl methacrylate, methacrylic acid iso-octyl and iso-octyl acrylate. The appearance of the surface sizing agent is slight yellow emulsion, and the main component is styrene-acrylic copolymer which is easily soluble at normal temperature. The surface sizing agent for paper making has the advantages of greatly increasing paper surface intensity, decreasing hair and powder shedding, and improving the sizing degree, smoothness and printability of paper.

Owner:杨春先

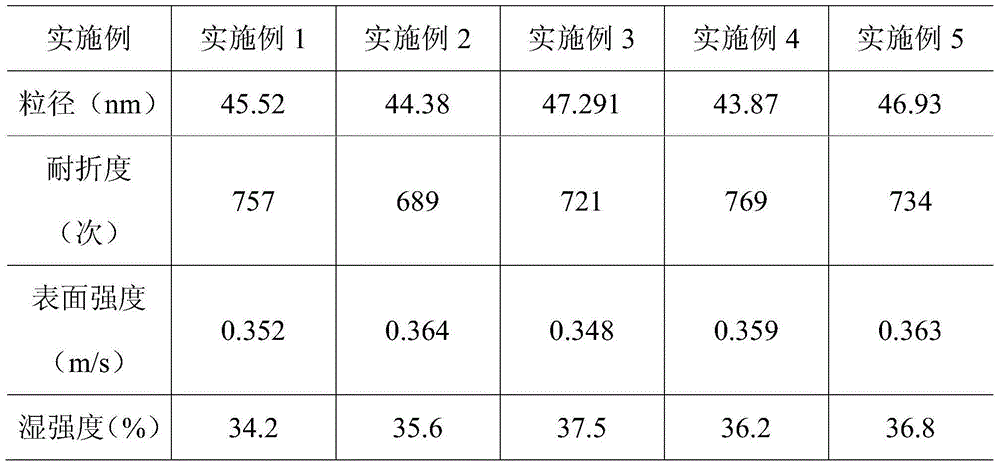

Organic silicon modified styrene-acrylate microemulsion reinforcing agent as well as preparation method and application thereof

ActiveCN104311716AStrong affinityImprove bindingReinforcing agents additionFunctional monomerChemistry

The invention discloses an organic silicon modified styrene-acrylate microemulsion reinforcing agent as well as a preparation method and application thereof. The preparation method comprises the following steps: firstly adding acrylic acid, hydroxyl-containing vinyl monomer, acrylate, styrene and organic silicon functional monomer into a reactor; adding a water-soluble initiator into the reactor for polymerisation; then cooling to room temperature and adding alkali for neutralizing; finally, slowly adding water into the reactor while stirring at a high speed to disperse so as to obtain the organic silicon modified styrene-acrylate microemulsion reinforcing agent. The organic silicon modified styrene-acrylate microemulsion reinforcing agent disclosed by the invention has the advantages of high binding force with paper fibers, good film forming performance and good water resistance and is applied to paper coating. Compared with the common styrene-acrylate emulsion, the organic silicon modified styrene-acrylate microemulsion reinforcing agent disclosed by the invention has the following advantages: the surface strength, folding endurance and wet-and-dry strength of the paper can be obviously improved, no organic solvent or surfactant is added in the preparation process, and the organic silicon modified styrene-acrylate microemulsion reinforcing agent is a high-performance environment-friendly paper-making and printing surface coating reinforcement product.

Owner:SHAANXI UNIV OF SCI & TECH

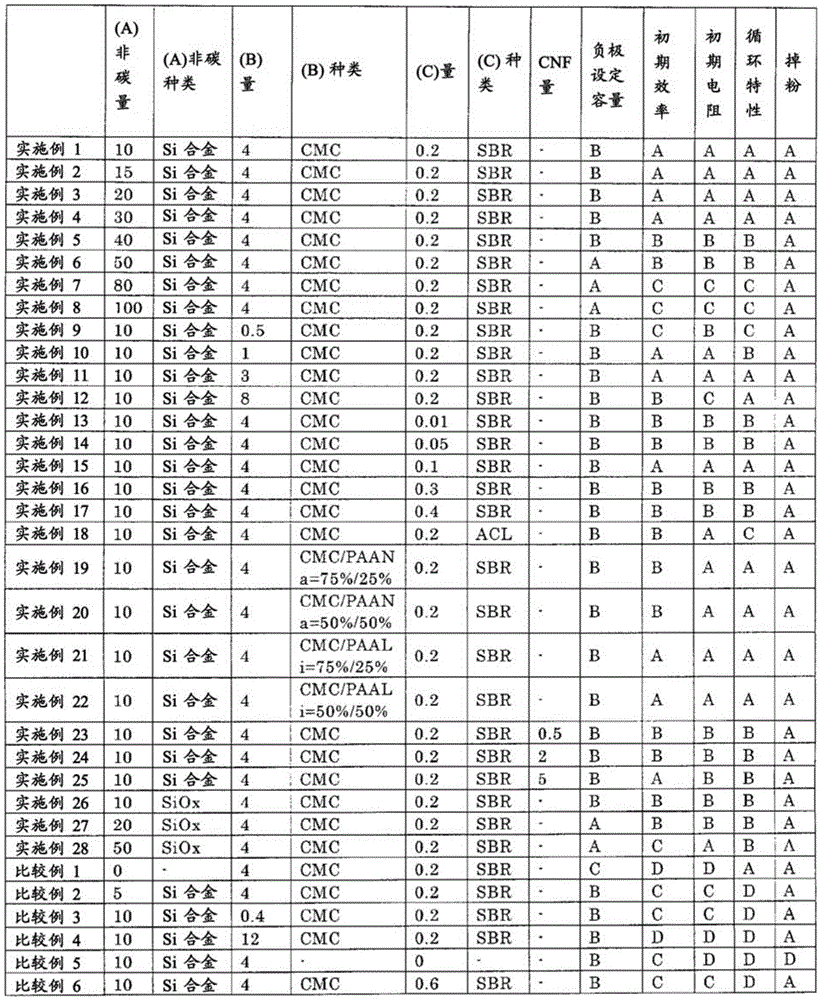

Slurry composition for negative electrodes of lithium ion secondary batteries, negative electrode for lithium ion secondary batteries, and lithium ion secondary battery

InactiveCN105637683AReduce powder lossEasy to manufacture capacitanceElectrode rolling/calenderingElectrode thermal treatmentParticulatesLithium

A slurry composition for negative electrodes of lithium ion secondary batteries, which contains 100 parts by mass of (A) an active material containing 8% by mass or more of a non-carbon negative electrode active material, 0.5-10 parts by mass of (B) a water-soluble polymer having a carboxyl group, 0.01-0.5 part by mass of (C) a particulate polymer, and water; a negative electrode for lithium ion secondary batteries, which comprises a negative electrode mixture layer obtained from this slurry composition for negative electrodes of lithium ion secondary batteries; and a lithium ion secondary battery which comprises this negative electrode for lithium ion secondary batteries.

Owner:ZEON CORP

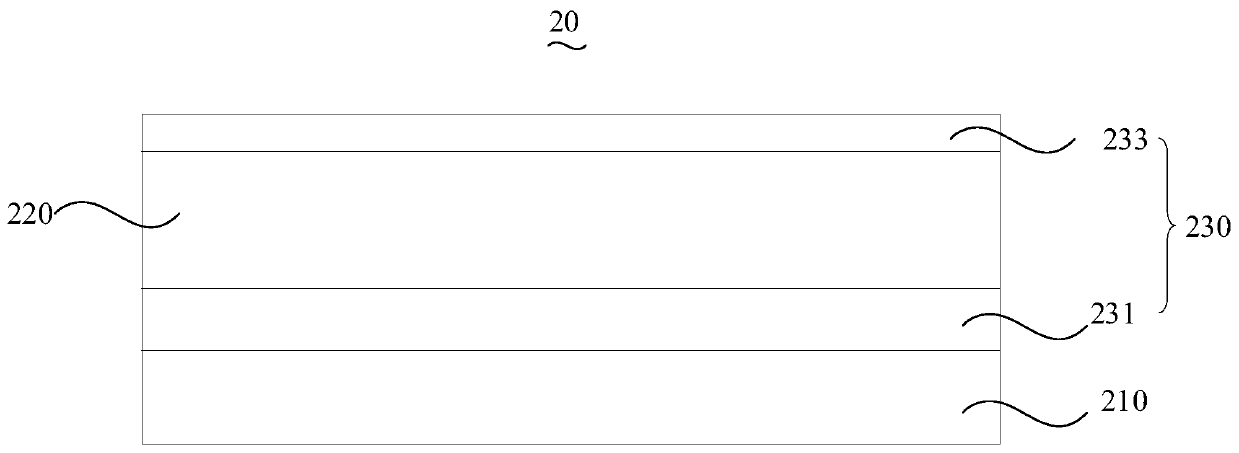

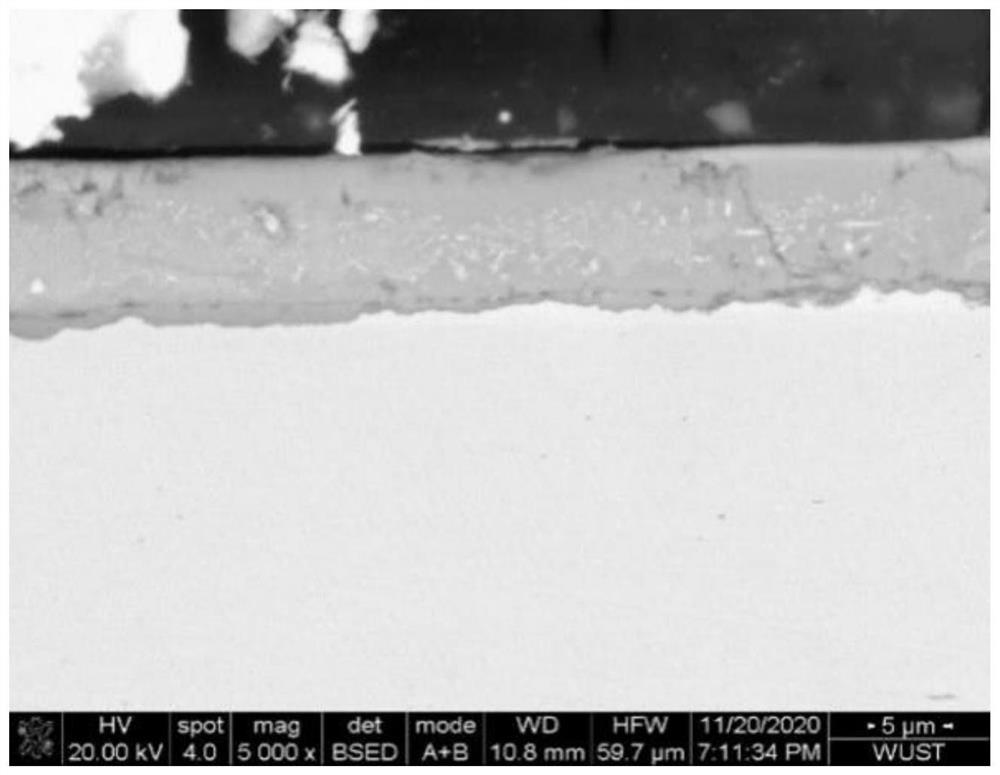

Separator for lithium ion cell

ActiveCN104521029ALower internal resistanceReduce leakage currentCell component detailsElectrolyte accumulators manufactureLithiumInorganic particle

A separator for a lithium ion cell, the separator comprising at least a porous body principally made of inorganic particles, wherein the separator is characterized in that the organic particles are of amorphous configuration. The performance of the separator for a lithium ion cell is such that internal resistance is low, pinholing and flaking is minimal, and current leakage is small.

Owner:MITSUBISHI PAPER MILLS LTD

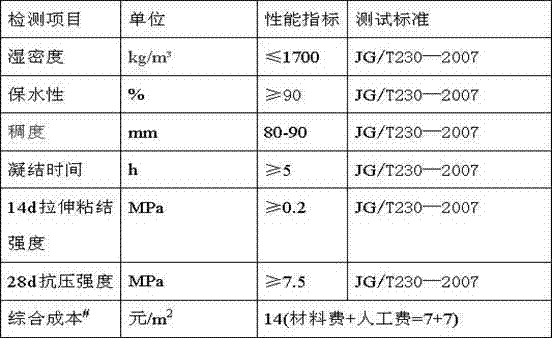

Mechanized construction plastering mortar and preparation method thereof

The invention discloses mechanized construction plastering mortar and a preparation method thereof. The plastering mortar is formed by mixing powder, aggregate and water, and a mass ratio of the powder, the aggregate and the water is (200-300):(700-800):(160-250); the powder is formed by mixing portland cement clinker, plaster, granulated blast-furnace slag, coal ash, limestone powder and a chemical addition agent, and a mass ratio of the portland cement clinker, the plaster, the granulated blast-furnace slag, the coal ash, the limestone powder and the chemical addition agent is (100-300): (50-100): (50-200): (100-400): (100-400): (2-5). According to the invention, after the detection in a factory according to a quality requirement and the measuring packing, the powder and the aggregate are respectively sent to a construction site or a dedicated distributing bin for burdening, and the mechanized construction is performed; compared with dry-mixed mortar, the aggregate is not required to be dried, so that the drying cost and a part of transportation cost of the aggregate are reduced, and the material cost is substantially lowered; and simultaneously the advantages that the dry-mixed mortar quality can be controlled and the construction site environment is good are maintained.

Owner:郑州工大高新材料科技有限公司

Quick-charging and safe low-temperature lithium ion battery and manufacturing method thereof

InactiveCN111370752AIncrease contact areaEliminate the "partition wall effect"Final product manufactureSecondary cellsInternal resistanceFast charging

The invention discloses a quick-charging and safe low-temperature lithium ion battery and a manufacturing method thereof. The battery is prepared by putting a dry battery cell into a shell, injectingelectrolyte, forming, sealing and grading capacity, and the dry battery cell is formed by winding a positive plate, a ceramic diaphragm, a negative plate and a ceramic diaphragm. The positive / negativeelectrode active substance is secondary micron particles formed by primary nanoparticles, and the nanoscale particles can effectively shorten the migration distance of lithium ions and improve the migration speed of the lithium ions in the charging and discharging process of the battery. Meanwhile, the multiple tabs led out from the positive and negative plates of the dry battery cell are gathered and then are welded with the planar metal sheet current collector to form a full tab. The internal resistance and the temperature rise of the battery in the charging process are effectively reduced,the problem of high-rate quick charging of the battery is solved, the high-current charging and discharging performance of the battery is improved, and the safety stability and the low-temperature electrochemical performance of the battery are also improved.

Owner:LONG POWER SYST NANTONG CO LTD

On-line welding flux circulation recycle device for submerged arc welding

InactiveCN105499766AAchieve recyclingAchieve separationMetal working apparatusTubular articlesEngineeringImpurity

The invention discloses an on-line welding flux circulation recycle device for submerged arc welding. The on-line welding flux circulation recycle device comprises an upper hopper, wherein a negative-pressure device is arranged on the upper part of the upper hopper; a material suction opening is arranged on the upper hopper; the lower part of the upper hopper is connected with a lower hopper; and the lower hopper is used for providing airtightness for the equipment when the upper hopper discharges recycled welding flux. According to the on-line welding flux circulation recycle device, the recycle process is fully sealed; the recycle rate of the welding flux is high; and the impurity separation effect is good.

Owner:ZHEJIANG KINGLAND & PIPELINE TECH

Preparation method of magnetic fat hydrogenation catalyst

ActiveCN103506124AReduce powder lossImprove recycling ratesFatty acid hydrogenationMetal/metal-oxides/metal-hydroxide catalystsStearic acidSilicon dioxide

The invention provides a preparation method of a magnetic fat hydrogenation catalyst. The preparation method is characterized in that the catalyst adopts magnetic compound oxide SiO2 / Fe3O4 as a carrier and nickel as an active constituent and comprises 5 to 40 weight percent of nickel, 20 to 60 weight percent of SiO2, 10 to 40 weight percent of Fe3O4 and the balance of stearic acid; during the preparation process of the catalyst, magnetic powdered ferroferric oxide is injected and is coated with silicon dioxide, and the magnetic fat hydrogenation catalyst is prepared through a method of precipitation. The nickel serving as the active constituent is magnetic and is bonded with the carrier relatively firmly, so that the possibility of the phenomena of chalking and disappearance of the catalyst during a reaction process can be lowered, and the quality of a hydrogenization product can be improved. Besides, the catalyst has the advantage that the reclaiming and utilization ratio of the catalyst can be improved through reclaiming of an additional magnetic field, so that the manufacturing cost of a fat processing enterprise can be reduced.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

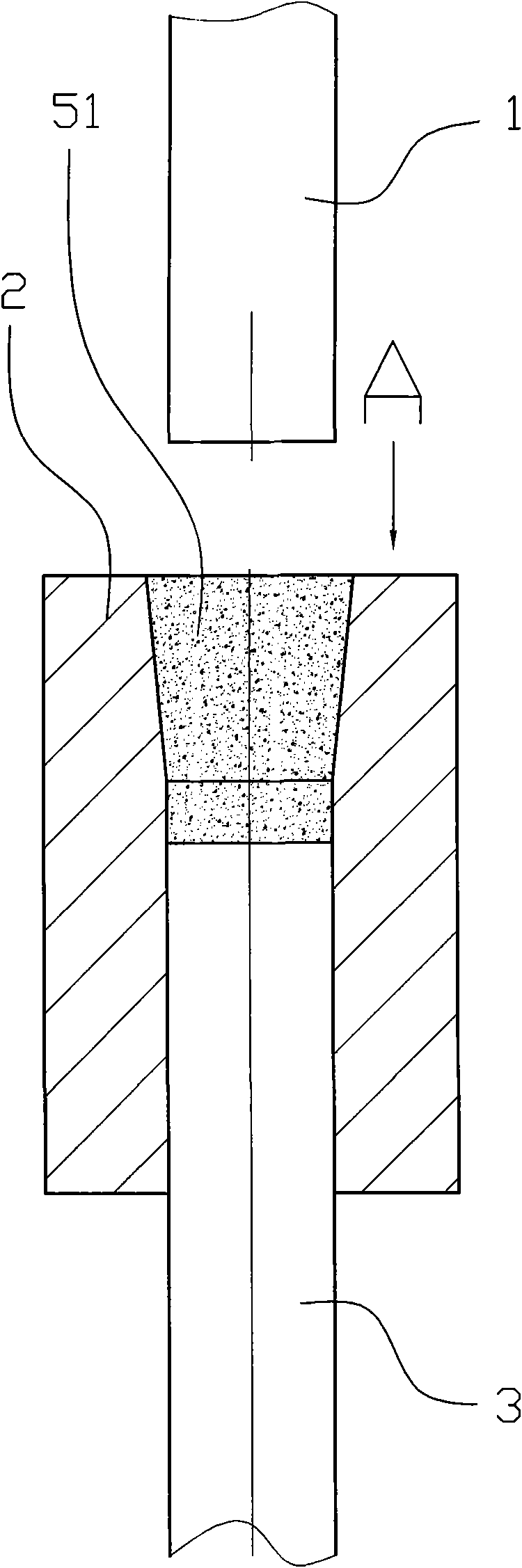

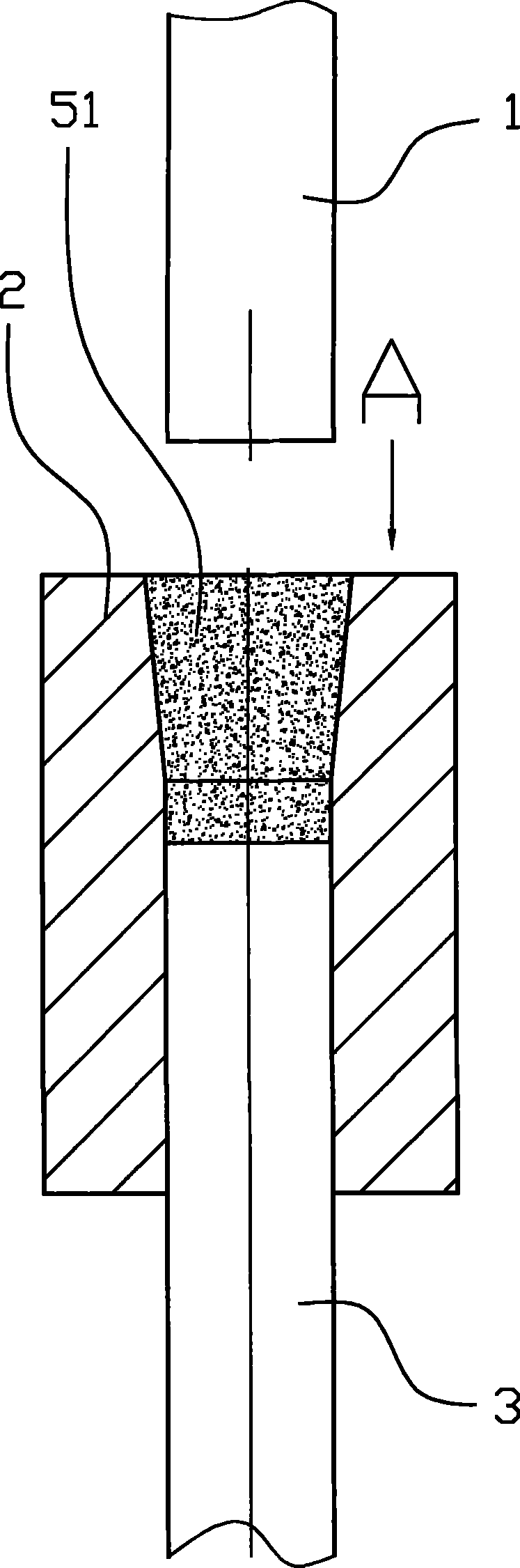

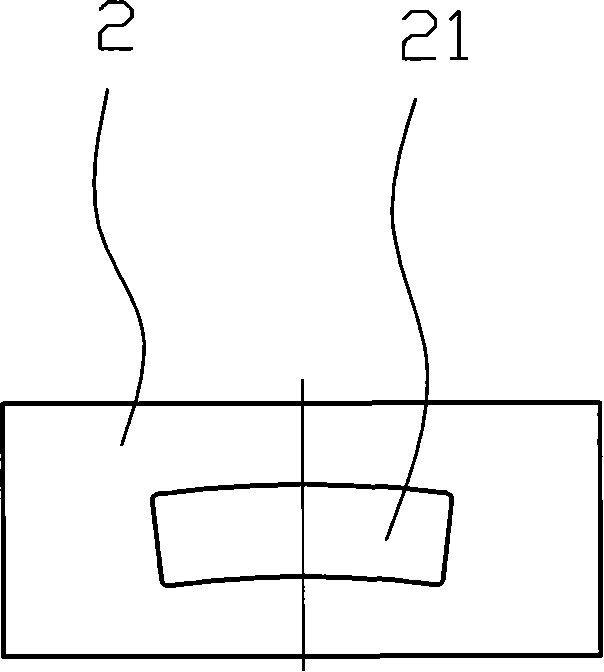

One-step forming process for sintered NdFeB permanent magnet of motor and mould thereof

InactiveCN101582611ASimple processUniform densityInductances/transformers/magnets manufactureManufacturing stator/rotor bodiesSurface finishingMagnetic orientation

The invention discloses a one-step forming process for a sintered NdFeB permanent magnet of a motor and a mould thereof. The one-step forming process comprises the following steps of preparing raw materials, smelting, casting, pulverizing, performing magnetic orientation press molding to the raw materials into a tile magnet, sintering, performing backfire and performing surface processing to the material into a finished product. The mould comprises an upper pressing head, a lower pressing head and a cavity die body, wherein the lower pressing head is connected with a hydraulic arm, a cavity of the cavity die body is a tile cavity, the upper pressing head is connected with a demolding micro-pressure protecting device, and the demolding micro-pressure protecting device is linked with a hydraulic machine. The invention has the advantages of saving the procedures of processing a square magnet into the tile magnet to achieve the aims of time-saving, money-saving and labor-saving; and changing the prior process of making the tilt material by using the square material to achieve the efficacy of processing corner-free materials and reducing the loss of powder quantity. The mould improves the designs and the process manufacture of a cavity die inner cavity and the upper and lower pressing heads. A forming bidirectional pressing special device and the demolding micro-pressure protecting special device are adopted to ensure the even density of a forming blank and reduce the phenomena of hidden cracking, edge breaking, corner defect, and the like caused by the density difference.

Owner:宁波永久磁业有限公司

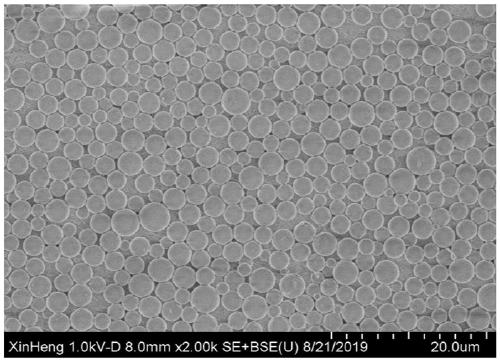

PMMA polymer coating diaphragm and preparation method thereof

PendingCN111354907AAvoid uneven coatingImprove adhesionSecondary cellsCell component detailsPolymer sciencePolymer chemistry

The invention discloses a PMMA polymer coating diaphragm and a preparation method thereof, and belongs to the field of battery diaphragms. The PMMA polymer coating diaphragm comprises a base membraneand a PMMA polymer coating coated on at least one surface of the base membrane; the PMMA polymer coating contains PMMA powder, a dispersing aid, a first binder and a second binder. The preparation method comprises the following steps: preparing PMMA coating slurry, and enabling the surface of a base film to coated with the PMMA coating slurry; the solubility of the PMMA in a water system can be improved, the PMMA powder can be effectively dispersed in a water system, the bonding strength of the diaphragm and the pole piece is enhanced, the problem of non-uniform coating of a PMMA polymer partis better solved, meanwhile, the phenomena of swelling and deformation of the battery are effectively inhibited, the hardness and consistency of the battery are improved, and the oxidation resistanceand long-term cycle performance of the battery are improved.

Owner:安徽金力新能源有限公司

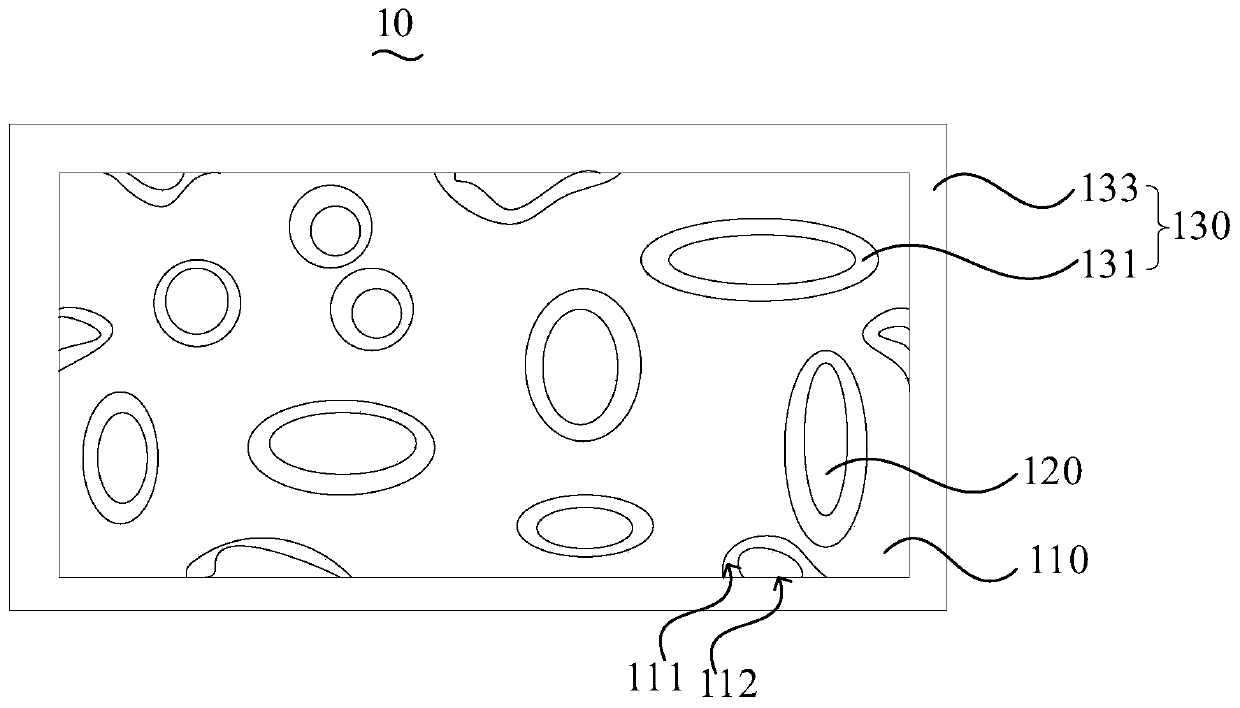

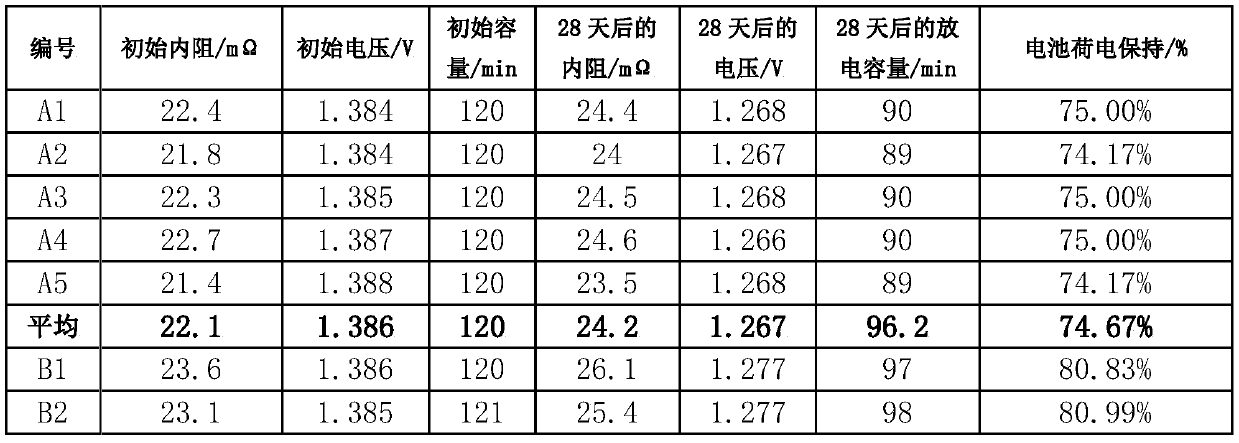

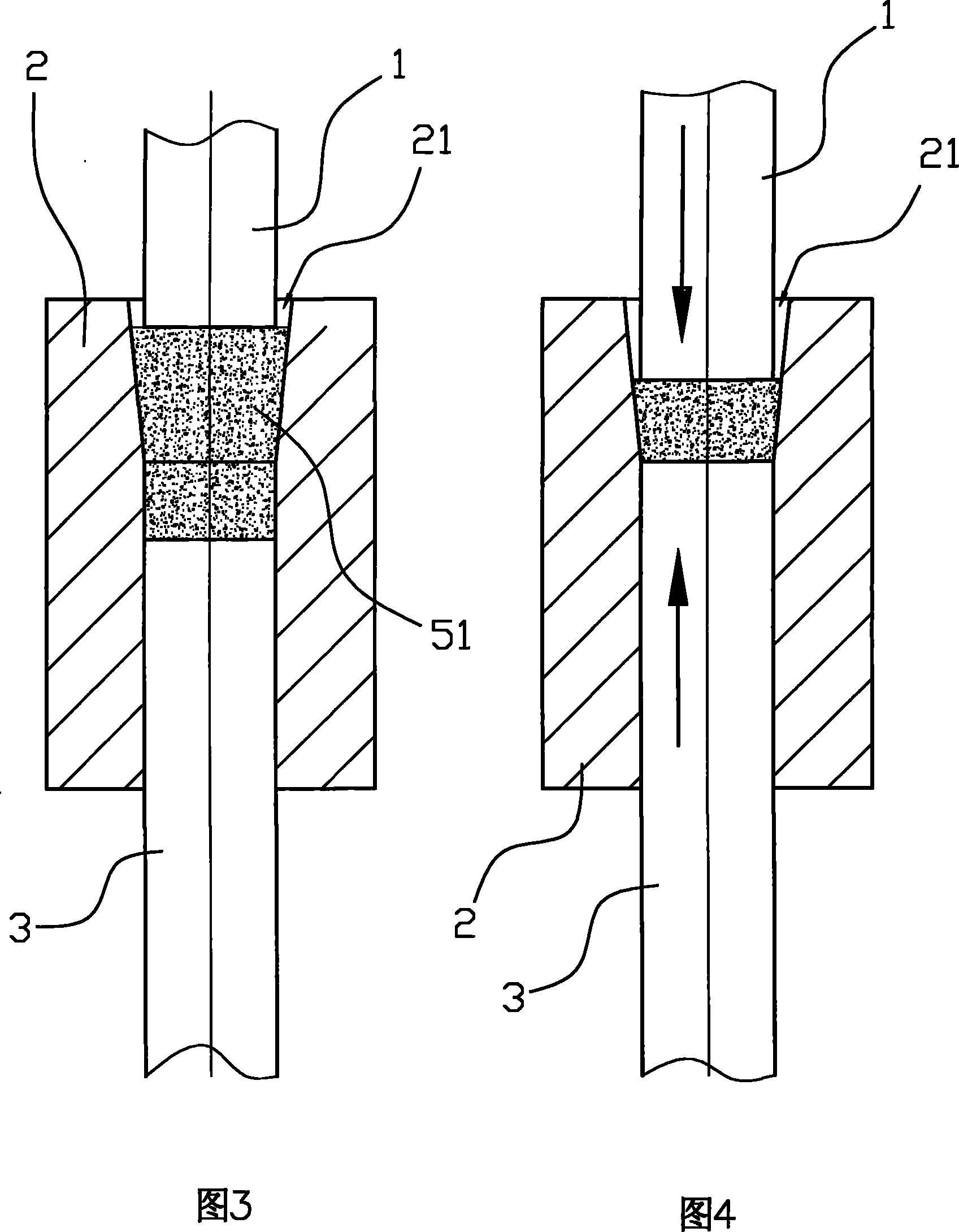

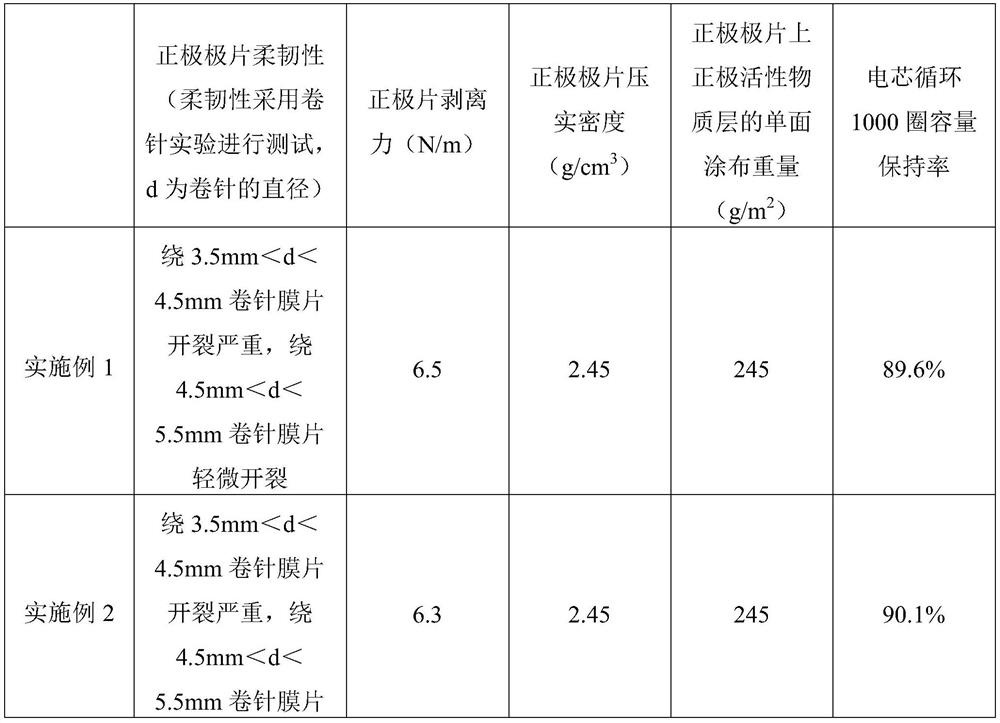

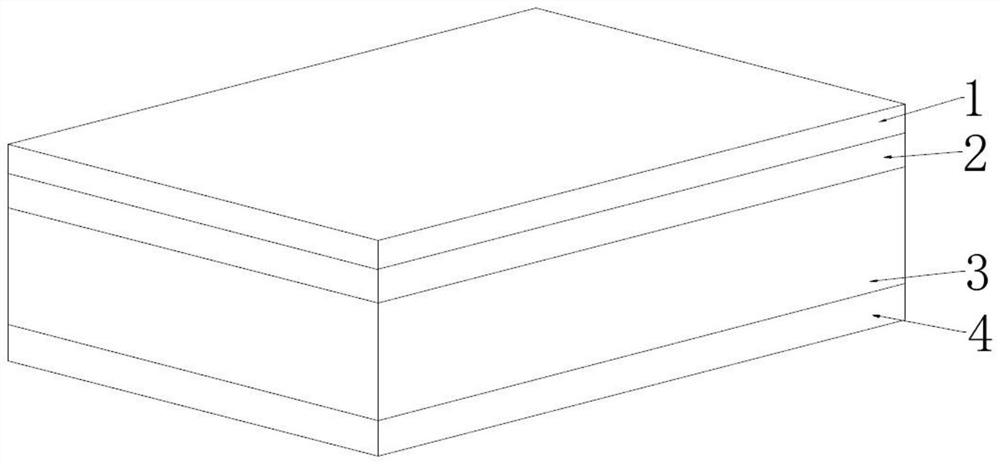

Electrode plate and preparation method thereof and battery

InactiveCN111063860AReduce glitchesReduce powder lossCell electrodesLi-accumulatorsCharge retentionElectrical battery

The invention relates to an electrode plate and a preparation method thereof and a battery. The electrode plate comprises a current collector with seepage holes, an electrode material and a protectivefilm, wherein the seepage holes are filled with the electrode material. The protective film comprises at least one of a top film and an interlayer film, the interlayer film is arranged on the hole walls of the seepage holes and bonded with the electrode material and the hole walls, and the top film is bonded with the surface of the current collector. According to the electrode plate, the protective film containing an adhesive is arranged, so that burrs and powder falling caused by bending of the electrode plate during winding are reduced, and the charge retention rate is higher and the safetyis better when the electrode plate is applied to a battery.

Owner:SHENZHEN BETTERPOWER BATTERY +1

Preparation method for negative ion organosilicon modified polyacrylate paper reinforcing agent

ActiveCN103554345AImprove bindingImprove folding resistanceReinforcing agents additionFiberFolding endurance

The invention relates to a preparation method for a negative ion organosilicon modified polyacrylate paper reinforcing agent. A transparent negative ion organosilicon modified polyacrylate emulsion is obtained by solution polymerization, by using methylacrylic acid, functional vinyl monomers, lipophilic monomers and gamma-methacryloxy propyl trimethoxyl silane as comonomers and isopropanol as a solvent and a chain transfer agent to carry out free radical polymerization of acrylic monomers, and through the steps of cooling, triethylamine neutralization and water dispersion. The obtained negative ion organosilicon modified polyacrylate paper reinforcing agent can not only effectively increase paper surface strength and folding endurance but also increase waterproof property of the paper surface. Besides, due to the addition of gamma-methacryloxy propyl trimethoxyl silane, adhesion properties between fibers and inorganic fillers are increased; and defects of ash and fiber falling during a printing process of the paper. Meanwhile, the product is simple in preparation process, low in raw material cost and simple in glue-applying process and can be easily applied and popularized in real industries.

Owner:SHAANXI UNIV OF SCI & TECH

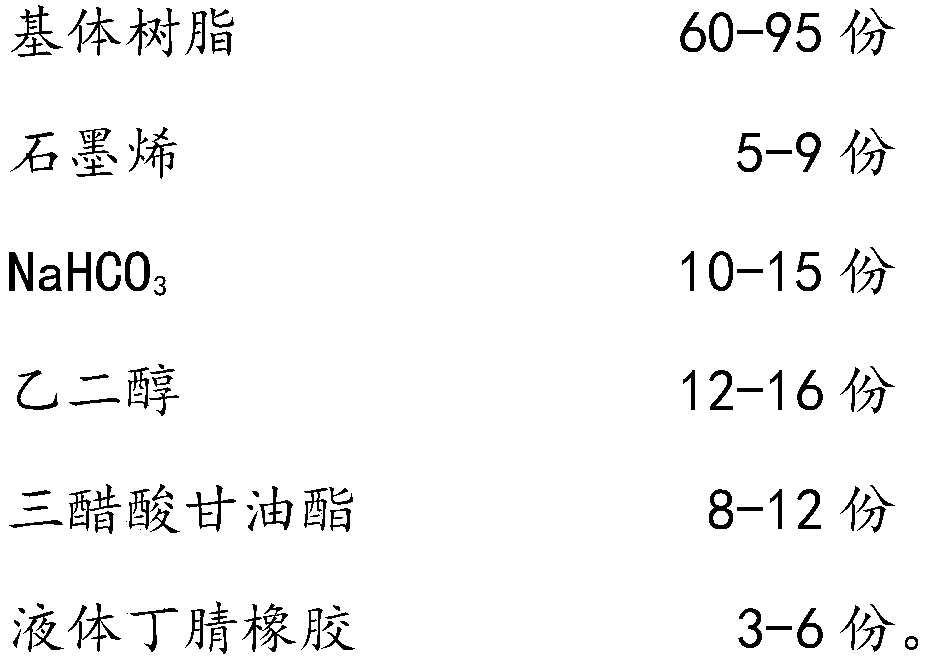

Novel environment-friendly foamed material as well as preparation method and foaming process thereof

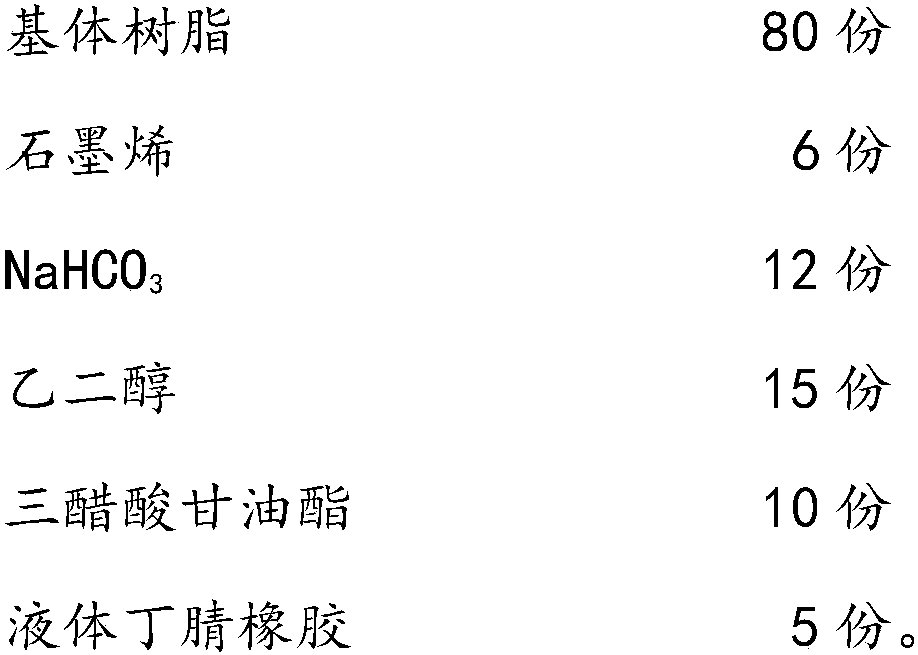

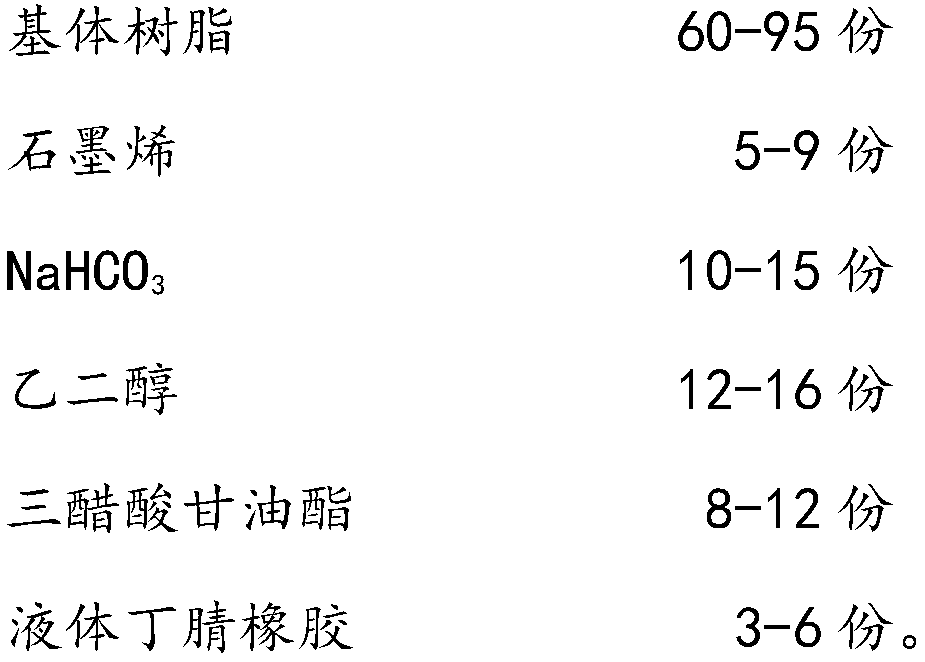

The invention provides a novel environment-friendly foamed material as well as a preparation method and a foaming process thereof. The novel environment-friendly foamed material comprises the following raw materials in parts by weight: 60-95 parts of a substrate resin, 5-9 parts of graphene, 10-15 parts of NaHCO3, 12-16 parts of ethylene glycol, 8-12 parts of glycerol triacetate and 3-6 parts of liquid nitrile rubber. A foamed material made of the novel environment-friendly foamed material provided by the invention has the advantages of being high in strength, sufficient in toughness, good inelasticity, good in anti-electrostatic resistance, uniform in foaming aperture and small in powder peeling; the raw materials are relatively small in environment influence, so that the material has certain environment protection properties, can be applied to different situations, is capable of meeting requirements of different scenes and has wide market prospects.

Owner:厦门派探特环保科技有限公司

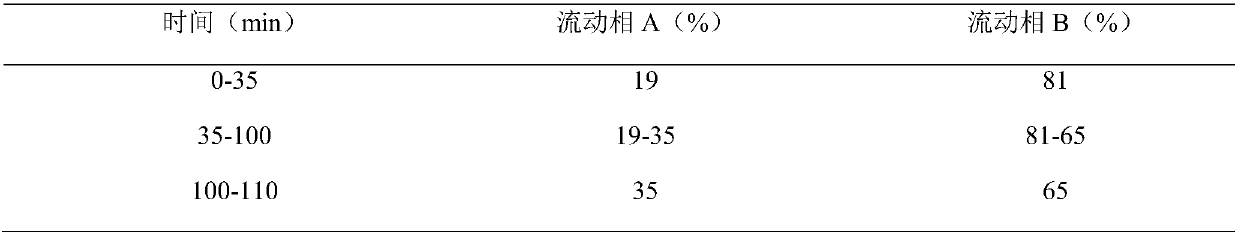

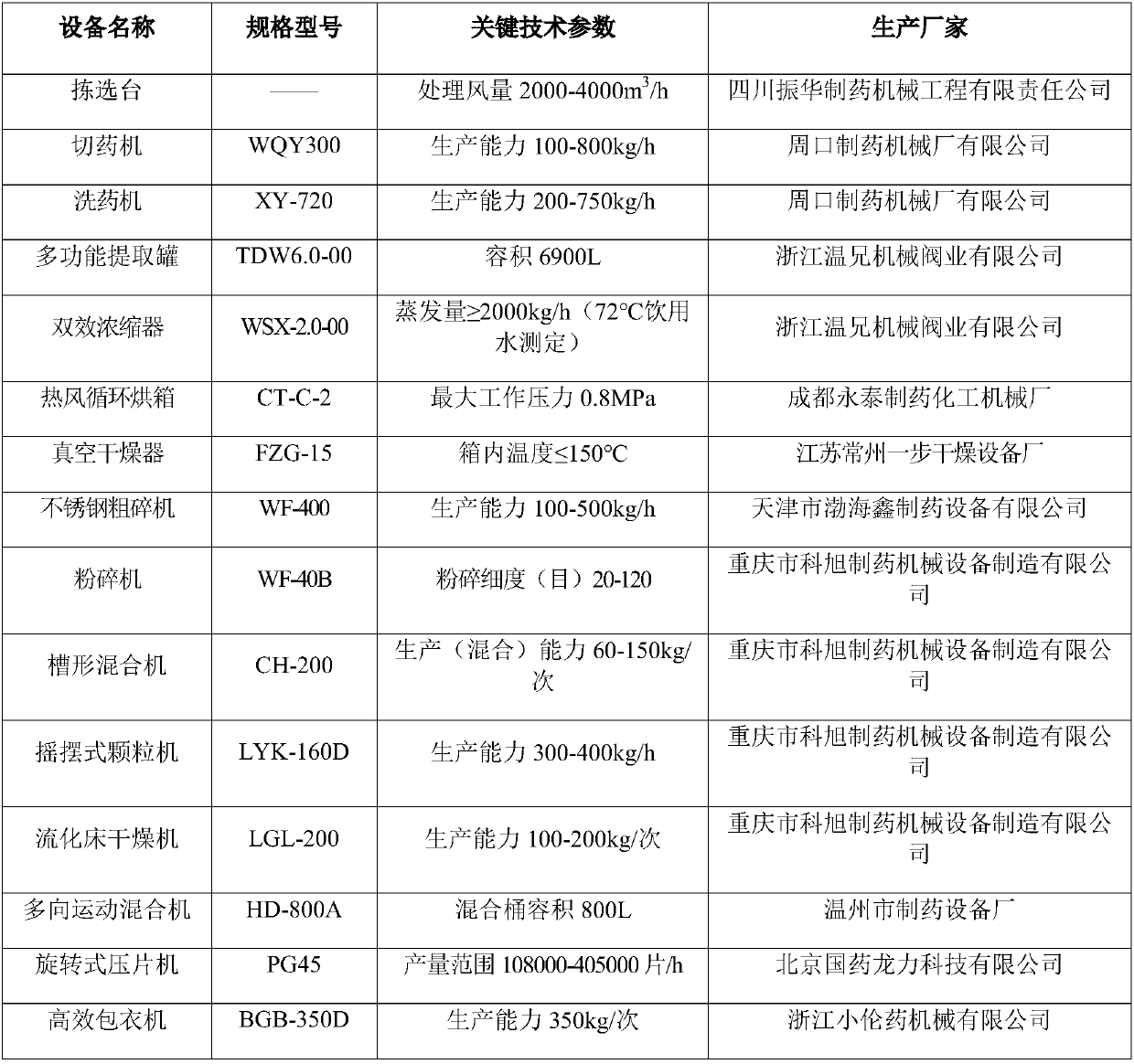

Process for preparing Hongjin stasis elimination tablet

ActiveCN109528901AReduce the risk of growthShorten the production cycleAnthropod material medical ingredientsComponent separationLow-substituted hydroxypropylcelluloseMagnesium stearate

The invention provides a process for preparing Hongjin stasis elimination tablets and belongs to the technical field of pharmacy. To solve various problems in concentration modes in the prior art, drying modes of concentrated ointments, auxiliary materials and identification, a preparation process of the Hongjin stasis elimination tablets is further improved, including steps of directly concentrating extracts, independently drying ointments, increasing amounts of auxiliary materials such as low-substituted hydroxypropylcellulose, povidone K30 and magnesium stearate, and changing medicine identification items and content testing items, and furthermore the purposes of shortening production cycle, reducing energy consumption, reducing pollution risks and improving product quality are achieved.

Owner:四川维奥制药有限公司

Battery pole piece automatic punching machine and punching method thereof

PendingCN107649568AReduce powder lossImprove consistencyMetal-working feeding devicesPositioning devicesPunchingEngineering

The invention provides a battery pole piece automatic punching machine. The battery pole piece automatic punching machine comprises a rack, a pole piece deviation correction unwinding device, a pole piece tension device, a punching transmission device, a pull device, a material collection device, a rolling device and a deviation correction fixed-length adjusting device, wherein the pole piece deviation correction unwinding device, the pole piece tension device, the punching transmission device, the pull device, the material collection device, the rolling device and the deviation correction fixed-length adjusting device are arranged on the rack. The pole piece deviation correction unwinding device is used for mounting of pole pieces. After being unwound, the pole pieces sequentially pass through the pole piece tension device, the rolling device, the deviation correction fixed-length adjusting device, the punching transmission device and the pull device. The pole piece tension device isused for adjusting the tension of the pole pieces. The rolling device is used for keeping the positions of the pole pieces. The pull device is used for pulling out a pole piece coil outwards. The deviation correction fixed-length adjusting device is used for correcting the positions of the pole pieces. The punching transmission device is used for punching the pole pieces by adopting a punching mold. The material collection device is arranged below the punching transmission device and used for collecting the punch-formed pole pieces. The battery pole piece automatic punching machine has the beneficial effects of being high in product consistency and production efficiency. The invention provides a punching method of the battery pole piece automatic punching machine.

Owner:深圳市佰瑞自动化设备有限公司

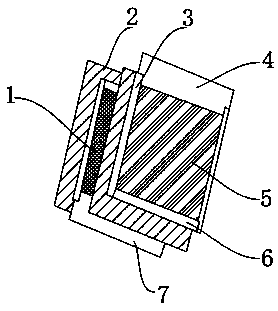

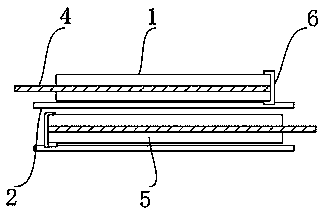

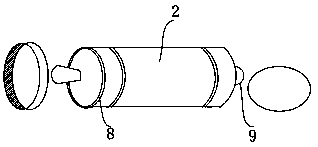

Shadow mask carrying device and method therefor

InactiveCN101434370ABalance transfer movementStable transport and movementLifting devicesEngineeringShadow mask

The invention discloses an aperture mask carrying device, which is characterized by comprising an aperture mask carrying car body (1), a lifting handle (2), a cylinder (3), a yoke frame (4), a yoke (5), an elevating screw (6) and a wheel (7), wherein, the wheel (7) is arranged on the bottom of the aperture mask carrying car body (1); a handle (8) is arranged outside of the aperture mask carrying car body (1); the elevating screw (6) is arranged on the aperture mask carrying car body (1); the yoke frame (4) is arranged on the elevating screw (6); the cylinder (3) is arranged on the yoke frame (4); the yoke (5) is arranged on the yoke frame (4); and the lifting handle (2) is arranged on the aperture mask carrying car body (1) corresponding to the yoke frame (4). The carrying device has the advantages of smooth aperture mask carrying, uniform powder and no pollution.

Owner:NANJING HUAXIAN HIGH TECH CO LTD

Solid battery pack binder composition

InactiveCN109004221AExcellent softness and adhesionExcellent output characteristics and charge-discharge cycle characteristicsCell electrodesLi-accumulatorsSolid-state batteryStructural unit

A solid-state battery pack binder composition disclosed in the invention comprises a copolymer comprising an alkylene structural unit and a nitrile-containing monomer unit, a fluoropolymer, a conductive polymer, a sulfonated polymer, an inorganic substance and an organic solvent. A binder composition for all-solid-state batteries capable of producing all-solid-state batteries having good battery characteristics can be provided.

Owner:ZHEJIANG GODSEND POWER TECH

Low-dust aerogel product and preparation method thereof

PendingCN114801395ANot easy to misplaceReduce sheddingLamination ancillary operationsSynthetic resin layered productsFiberMolten state

The invention belongs to the technical field of thermal insulation materials, and relates to a low-dust aerogel product and a preparation method thereof.The preparation method of the low-dust aerogel product comprises the steps that 1, a hot melt adhesive net film, a fiber felt and a hot melt adhesive net film are sequentially stacked and laid, and a stacked material is obtained; step 2, dipping the stacked material in the sol to form a wet fiber felt; 3, the wet fiber felt obtained after dipping treatment in the step 2 is subjected to gelation and drying treatment, and a composite aerogel felt is obtained; and step 4, carrying out heating treatment on the composite aerogel felt to obtain the low-dust aerogel product. According to the invention, the hot melt adhesive net film in a heated and molten state is infiltrated on the surface of the fiber felt to form packaging protection, so that aerogel powder falling off from the surface of the aerogel product is reduced, the aerogel product without powder falling can be prepared, the health of production and use personnel is ensured, and the market demand is met.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

Coating surface density sampler

PendingCN113358394AHigh dimensional accuracyReduce glitchesWithdrawing sample devicesSample qualityEngineering

The invention relates to the technical field of sampling equipment, in particular to a coating surface density sampler which comprises a workbench, a flattening mechanism and a sampling cutter, wherein the flattening mechanism comprises a bearing base and a pressing plate, the pressing plate has a sampling opening, the pressing plate presses downwards to flatten materials, and the flattened materials are exposed out of the sampling opening; the sampling cutter comprises a rack, a cutter handle and a cutter, the rack is provided with a supporting frame and a cutter handle driving part, and the output end of the cutter handle driving part is connected with the cutter handle; and the cutter handle has a cutter groove, and the cutter is arranged in the cutter groove in a sliding mode. Under the action of pressure, the materials are flattened, wrinkles are smoothed, samples are punched out from a sampling opening during sampling, the punched samples are high in size precision, small in burr, little in powder falling, good in quality and high in follow-up detection precision, the device can be further suitable for flattening the materials of different sizes, full-automatic punching is achieved, and the sizes and shapes of a plurality of samples are kept consistent, and the sample quality is good.

Owner:东莞市红木棉电子科技有限公司

One-step forming process for sintered NdFeB permanent magnet of motor and mould thereof

InactiveCN101582611BSimple processUniform densityInductances/transformers/magnets manufactureManufacturing stator/rotor bodiesDensity differenceMaterials science

The invention discloses a one-step forming process for a sintered NdFeB permanent magnet of a motor and a mould thereof. The one-step forming process comprises the following steps of preparing raw materials, smelting, casting, pulverizing, performing magnetic orientation press molding to the raw materials into a tile magnet, sintering, performing backfire and performing surface processing to the material into a finished product. The mould comprises an upper pressing head, a lower pressing head and a cavity die body, wherein the lower pressing head is connected with a hydraulic arm, a cavity ofthe cavity die body is a tile cavity, the upper pressing head is connected with a demolding micro-pressure protecting device, and the demolding micro-pressure protecting device is linked with a hydraulic machine. The invention has the advantages of saving the procedures of processing a square magnet into the tile magnet to achieve the aims of time-saving, money-saving and labor-saving; and changing the prior process of making the tilt material by using the square material to achieve the efficacy of processing corner-free materials and reducing the loss of powder quantity. The mould improves the designs and the process manufacture of a cavity die inner cavity and the upper and lower pressing heads. A forming bidirectional pressing special device and the demolding micro-pressure protectingspecial device are adopted to ensure the even density of a forming blank and reduce the phenomena of hidden cracking, edge breaking, corner defect, and the like caused by the density difference.

Owner:宁波永久磁业有限公司

Preparation method of alumina particles

InactiveCN104477954AAvoid pollutionReduce powder lossAluminium oxides/hydroxidesUltimate tensile strengthVolume density

The invention relates to a preparation method of alumina particles. The method comprises the following steps: by taking high-purity alumina powder as a raw material, firstly, performing air-flow grinding to the high-purity alumina powder through an air-flow mill, wherein the size fraction of the powder is in normal distribution after air-flow grinding, and D50 is controlled at 5-25mm; then pelletizing through a disk pelletizer, then performing high-temperature roasting at 1700-1800DEG C, to obtain high-purity alumina particles with the volume density of 3.2-3.6g / cm<3>. According to the method, the pollution of equipment on the high-purity alumina powder during the grinding of powder can be avoided by adopting the air-flow mill; the full-automatic disk pelletizer is adopted during pelletizing, so that not only can the bulk density and strength of products be enhanced, and the powder falling of particles can be reduced, but also the labor intensity of workers can be greatly lightened. The product meets the demand of downstream sapphire production factories.

Owner:连云港乐园新材料科技有限公司

Cation surface sizing agent and preparation method thereof

InactiveCN101649583BReduce manufacturing costPrevent penetrationWater-repelling agents additionPaper/cardboardAmylaseBalance water

Owner:东莞市清正合成高新材料有限公司 +1

Modified phenol formaldehyde resin thermal insulation board and preparation method thereof

The invention relates to the technical field of building thermal insulation materials, particularly to a modified phenol formaldehyde resin thermal insulation board, which comprises the following rawmaterials by weight: 80-130 parts of a phenol formaldehyde resin, 30-50 parts of an inorganic filler, 15-25 parts of modified plant fiber, 5-10 parts of a foaming agent, 3-5 parts of a curing agent and 3-5 parts of a surfactant, wherein the modified plant fibers comprise one or a plurality of materials selected from modified willow branch fibers, modified wisteria fibers and modified vinca major lfibers. According to the invention, the defects of high brittleness and high acidity of the traditional modified phenol formaldehyde resin thermal insulation board are overcome; by modifying the specific plant fibers, the specific toughness of the plant fibers is further improved, and the toughening effect is remarkable; and the modified plant fibers are weakly alkaline and are matched with otherraw materials, so that the acidity of the modified phenol formaldehyde resin thermal insulation board is reduced. The invention further provides a preparation method of the modified phenol formaldehyde resin thermal insulation board, wherein the preparation method has advantages of simpleness and easy operation.

Owner:天津市天地阳光保温材料有限公司

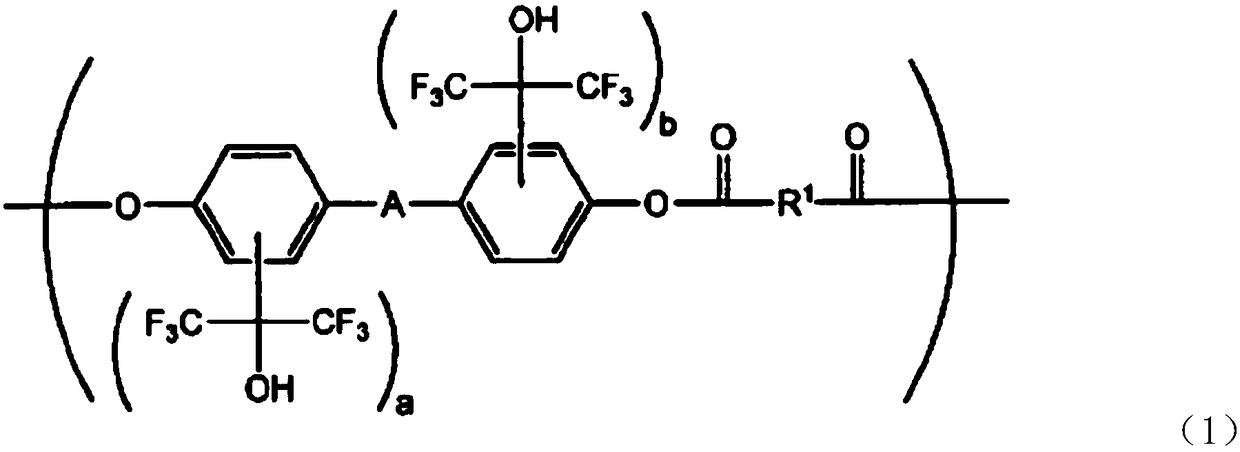

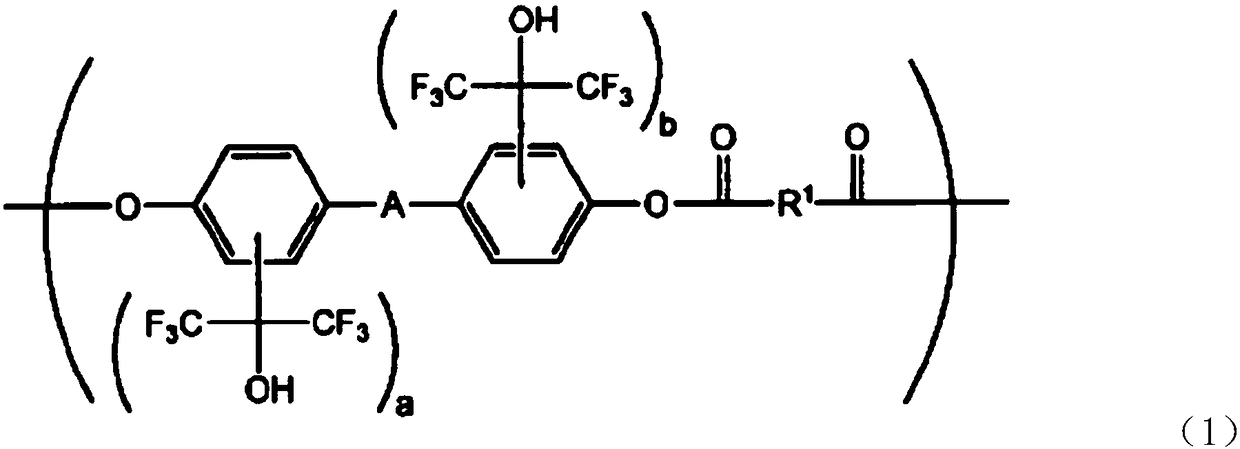

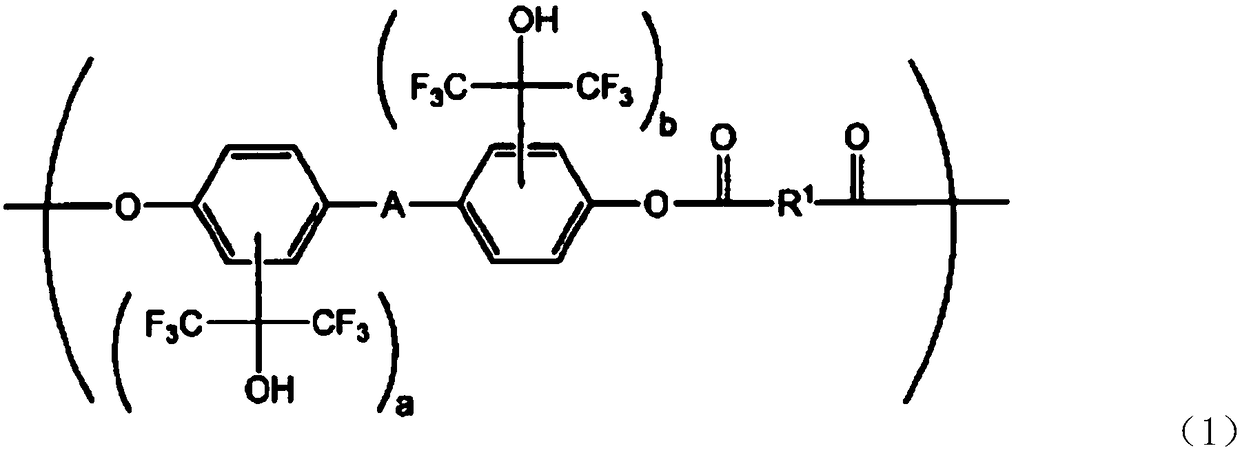

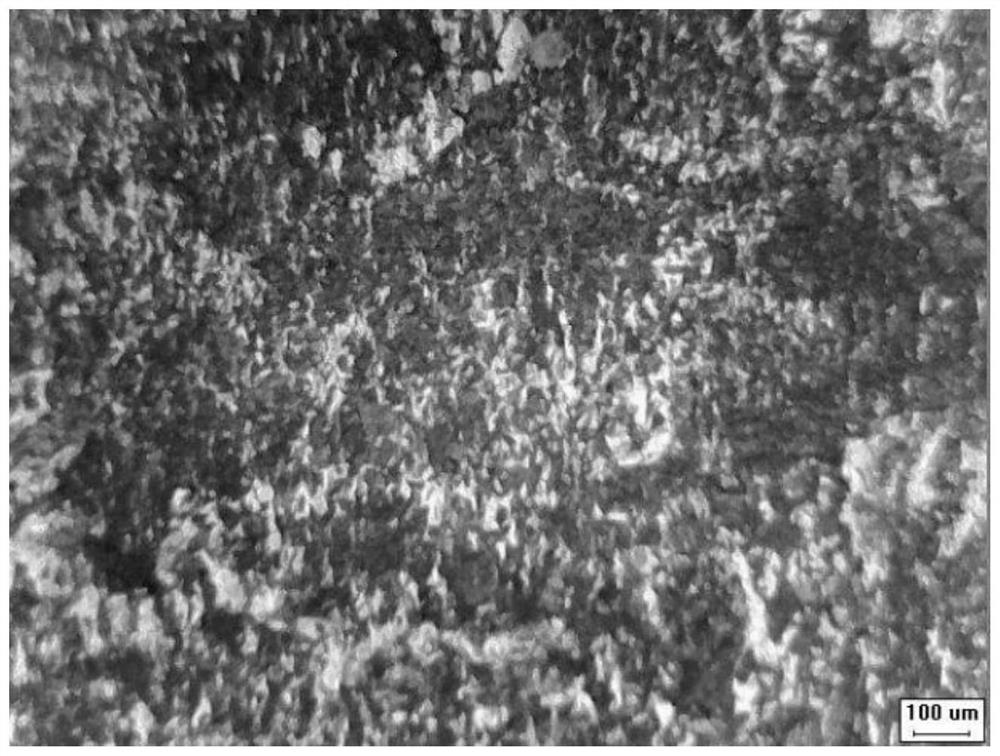

Positive electrode slurry, positive electrode plate and lithium battery

ActiveCN114678530AGood flexibilityIncrease coating thicknessNon-aqueous electrolyte accumulator electrodesLi-accumulatorsElectrical batteryPolyvinylidene difluoride

The invention discloses a positive electrode slurry, a positive electrode plate and a lithium battery, the positive electrode slurry comprises a binder, the binder comprises polyvinylidene fluoride and an additive, the chemical formula of the additive is shown in the specification, R1 comprises-H, CH3 or-OH, and R2 comprises-NHCH2CH3, N (CH2CH3) 2,-NH2 or-OH. By adopting the positive electrode slurry, the problems that a positive electrode plate is hard and brittle and the positive electrode slurry is too thick and cracked due to the positive electrode slurry only using PVDF as the binder in the prior art can be effectively solved, and by adopting the binder for the positive electrode slurry, the coating thickness of the positive electrode slurry can be improved while the flexibility of the positive electrode plate is improved; and meanwhile, hydrogen bond acting force can be formed between the positive electrode slurry and the positive electrode current collector, and the PVDF is subjected to cross-linking reaction in the coating and baking stages, so that the cohesion and stripping force of the positive electrode plate are improved, powder falling is reduced, and the cycle performance and safety performance of the battery are further improved.

Owner:XIAMEN HAICHEN NEW ENERGY TECH CO LTD

Insulating coating of electromagnetic shielding film with high insulating property and preparation method of insulating coating

PendingCN114539584AReduce insulation damageHigh strengthConjugated diene hydrocarbon coatingsEpoxy resin coatingsInsulation layerElectromagnetic shielding

The invention discloses an insulating coating of a high-insulating-performance electromagnetic shielding film and a preparation method of the insulating coating, and relates to the technical field of multilayer epoxy resin surface coating treatment and preparation. The film comprises a PET film, the lower side of the PET film is coated with a film layer, and the lower side of the film layer is coated with five epoxy resin layers. Compared with other electromagnetic shielding film insulation layers used at home and abroad in insulation performance, the electromagnetic shielding film insulation layer does not use silicon dioxide at all, reduces the damage of silicon dioxide to the insulation performance, increases rubber and epoxy resin coatings, achieves complete insulation, and is safe and environment-friendly, and five layers of epoxy resin are added on the surface of the insulation layer. And the surface epoxy resin forms a continuous and complete film layer which is firmly combined with the PET original film during drying, so that the strength of the film surface is effectively improved.

Owner:广东派尔新材料科技有限公司

High-strength steel and preparation method thereof

The invention provides high-strength steel and a preparation method thereof, and relates to the technical field of steel preparation. The high-strength steel comprises a steel body and mill scale on the surface of the steel body, wherein the steel body comprises, by weight, 0.065%-0.105% of C, 1.45%-1.65% of Mn, 0.07%-0.15% of Si, 0.02%-0.06% of Nb, 0.04%-0.06% of V, 0.09%-0.14% of Ti, 0.07%-0.025% of Cr, less than or equal to 0.005% of S, less than or equal to 0.020% of P and 97.0%-99.0% of Fe; the weight percentage content of Nb, V and Ti meets the condition that the sum of Nb%, V% and Ti% is less than 0.24%; and the mill scale comprises a Fe3O4 + alpha-Fe eutectoid structure, FeO and Fe3O4. The high-strength steel has high strength and excellent plasticity, and surface mill scale powder falling is little.

Owner:湖南华菱涟源钢铁有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com