Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

98results about How to "Increase coating thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

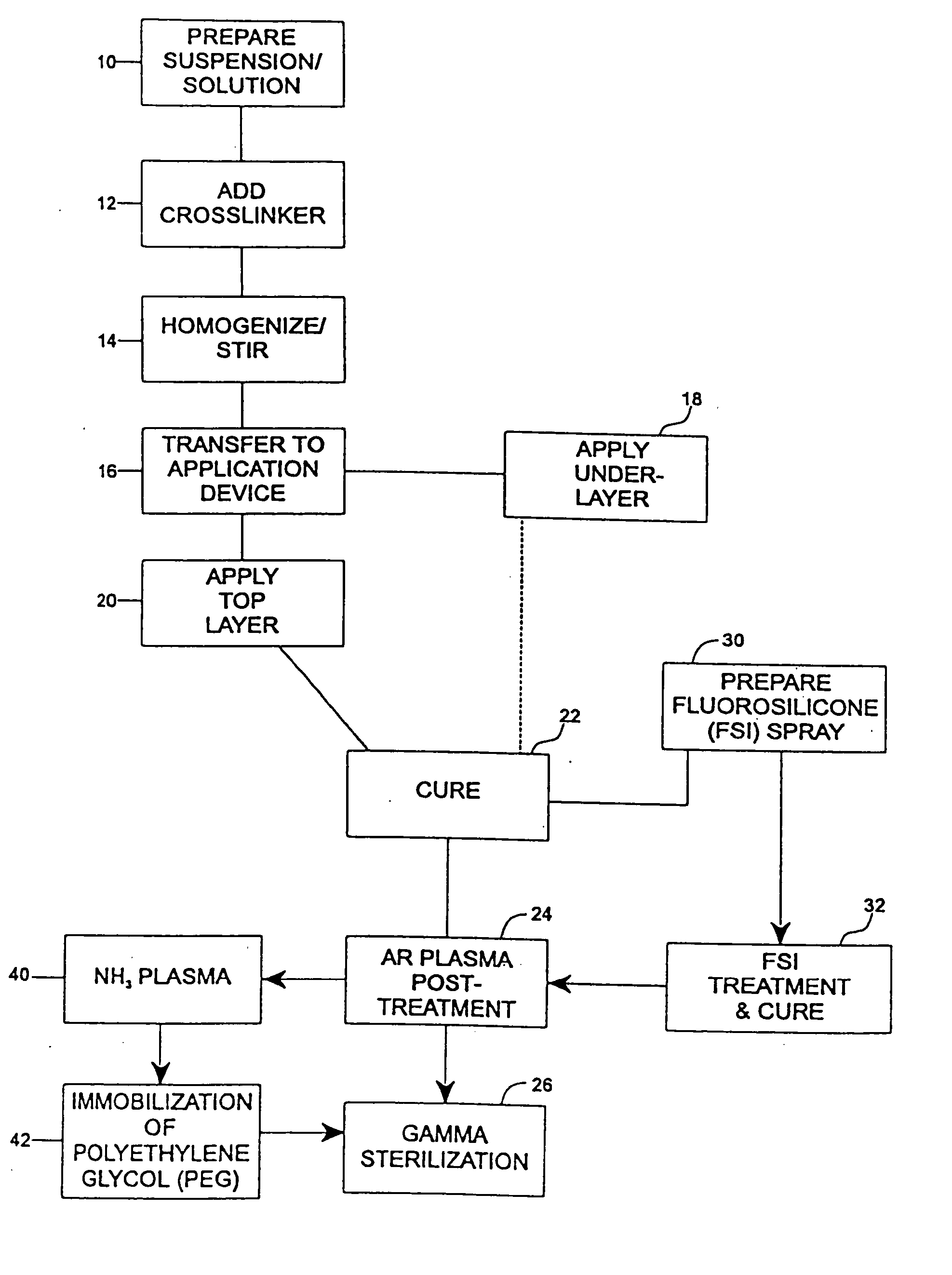

Methods of forming a coating for a prosthesis

InactiveUS6503556B2Increase the amount addedIncrease the number ofRadiation applicationsGlovesProsthesisImplanted device

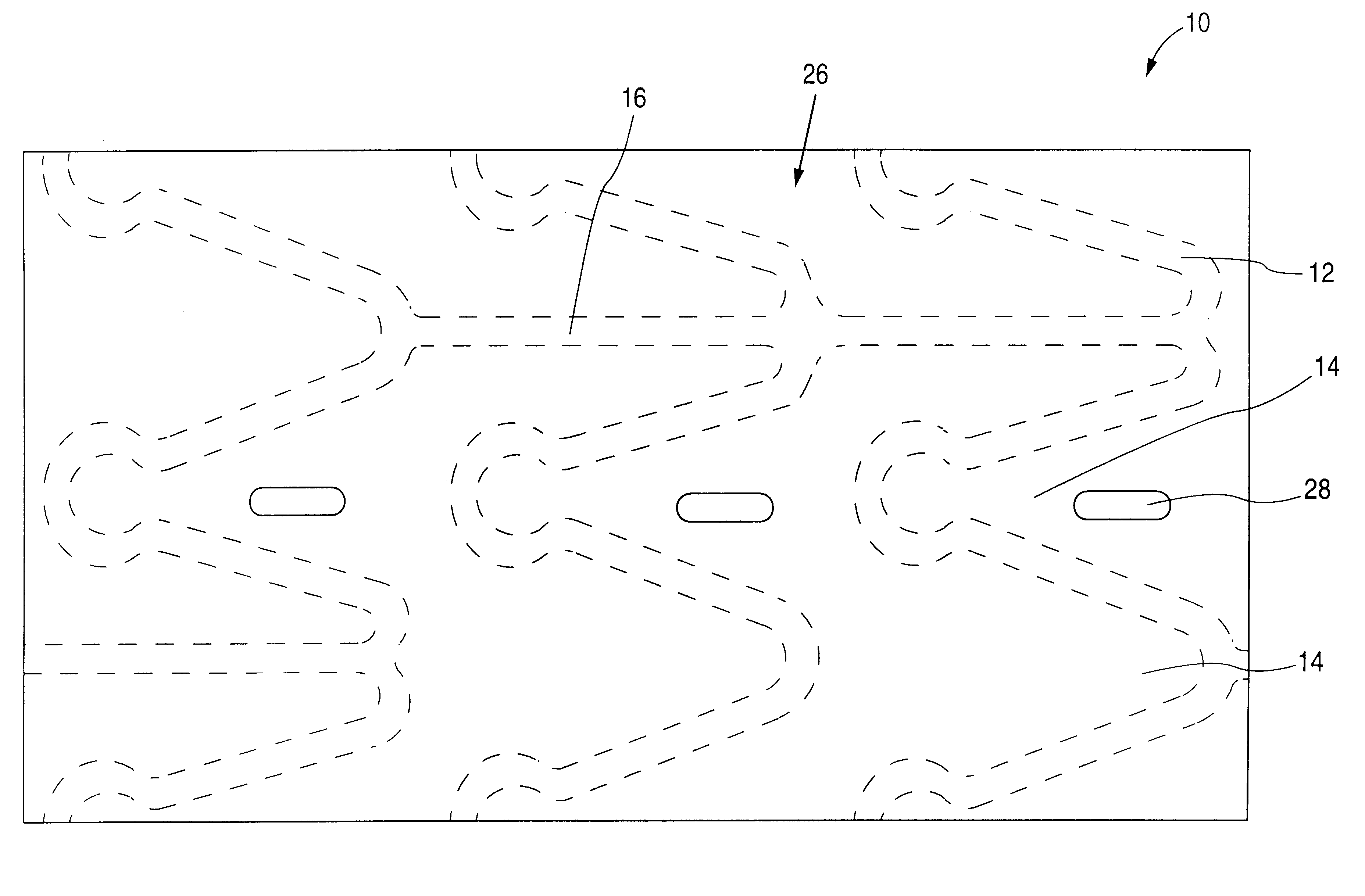

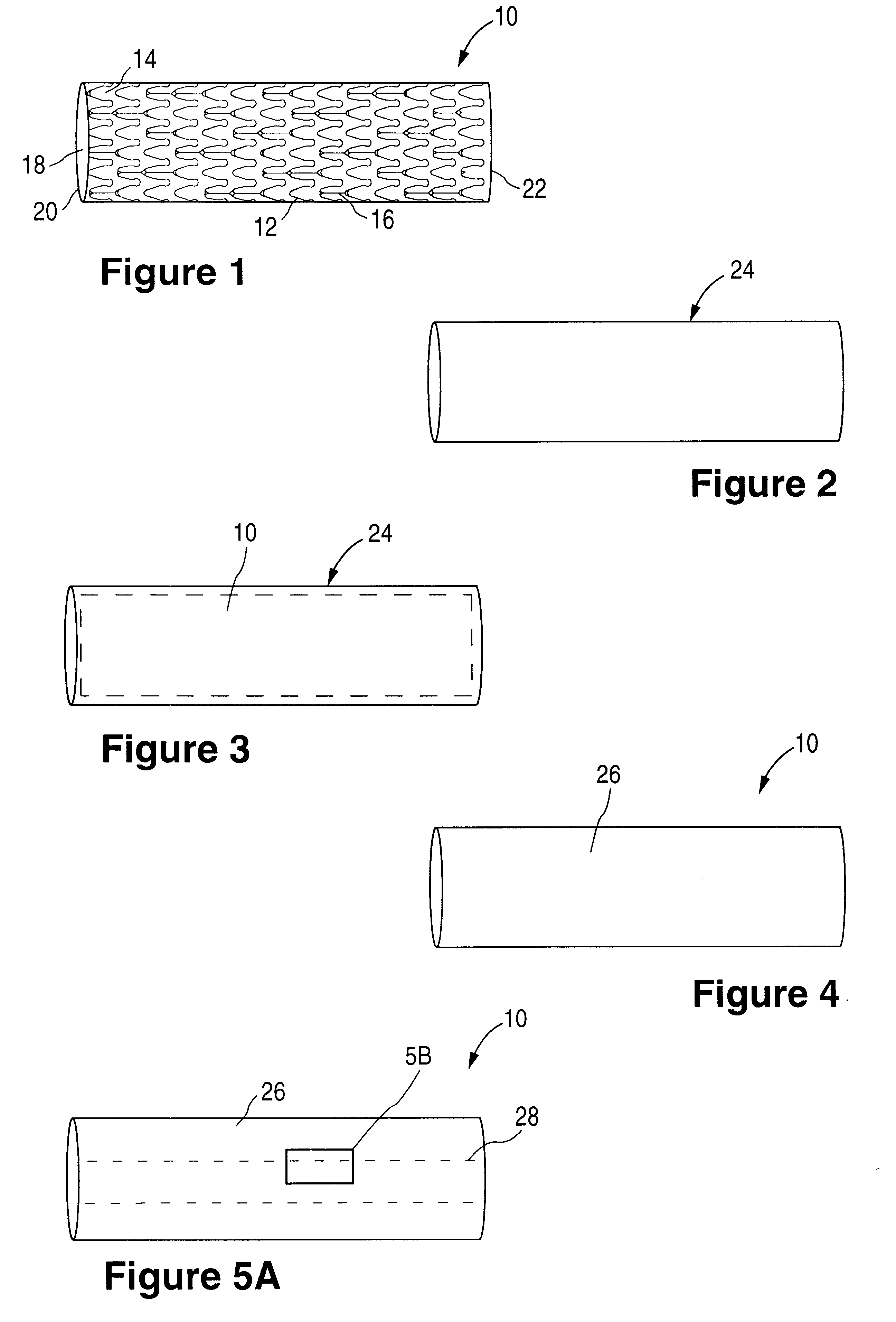

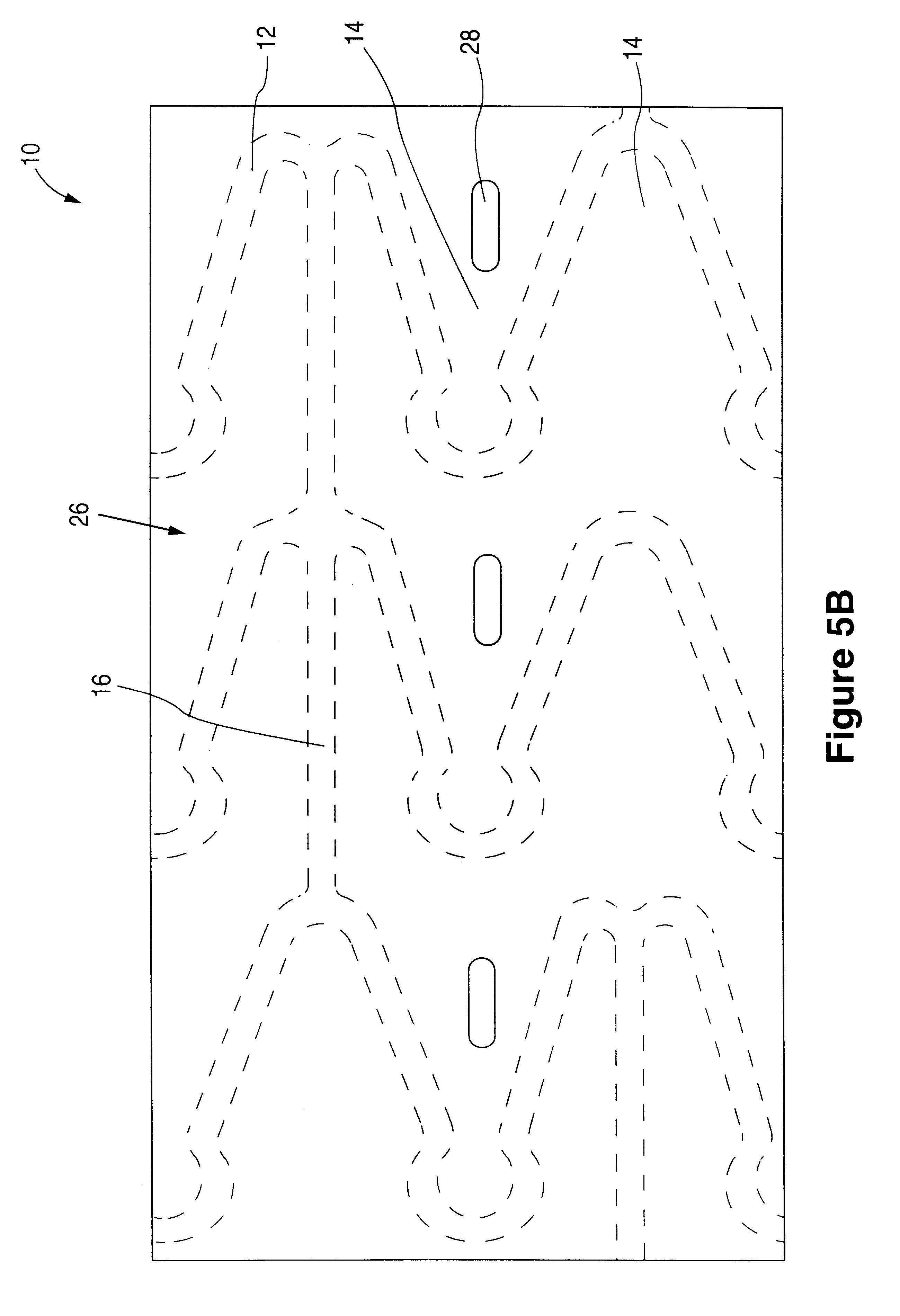

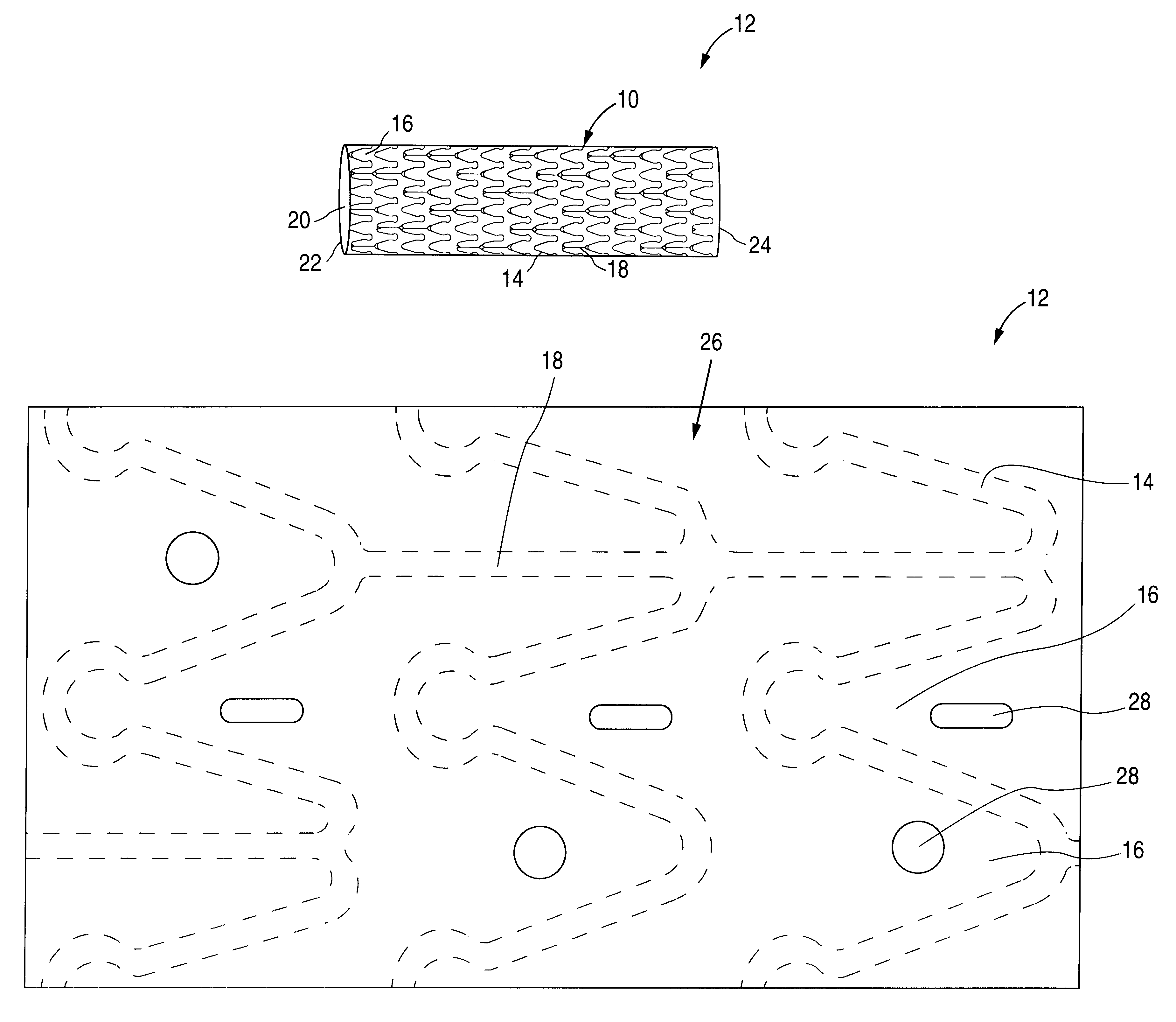

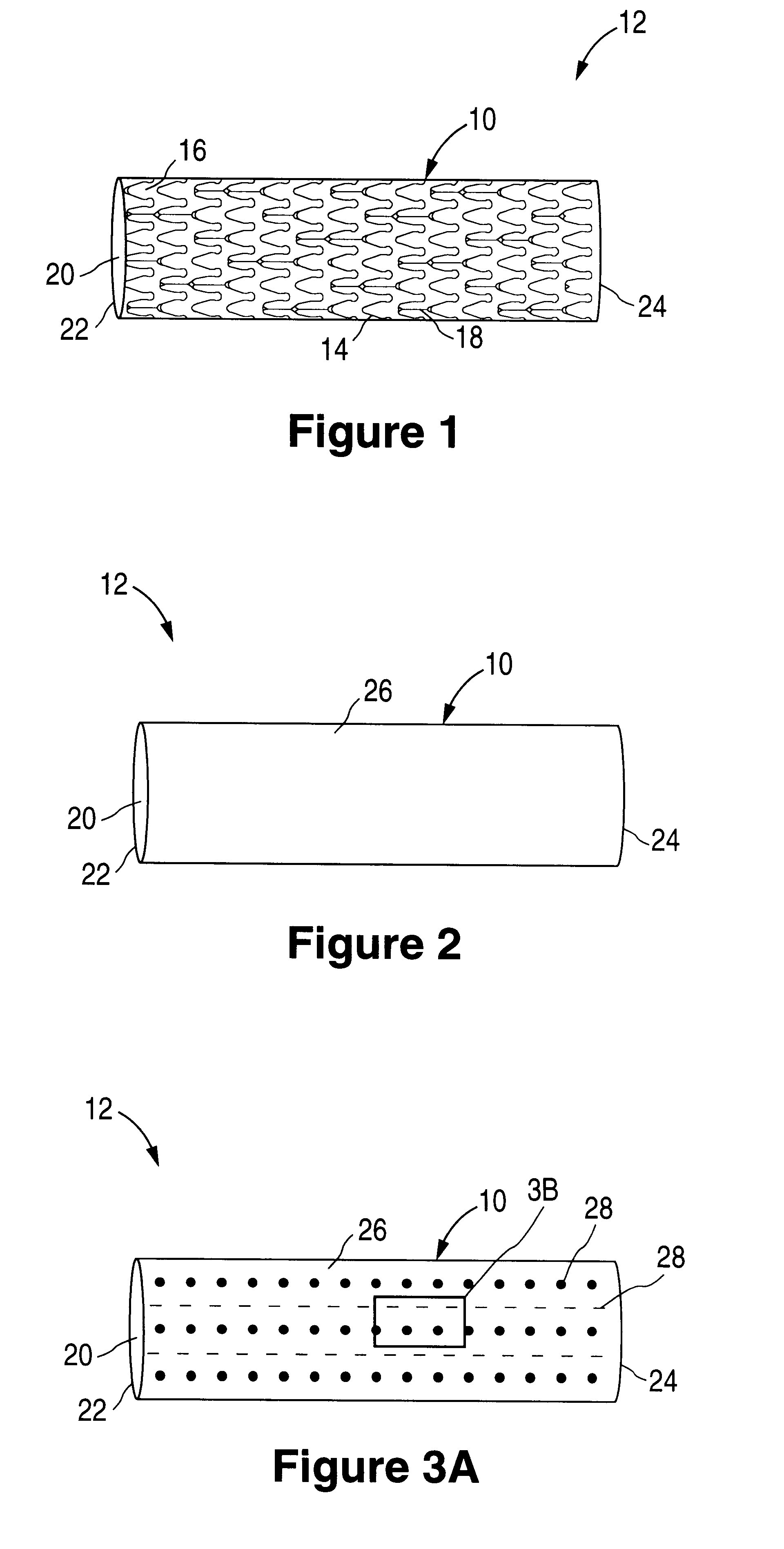

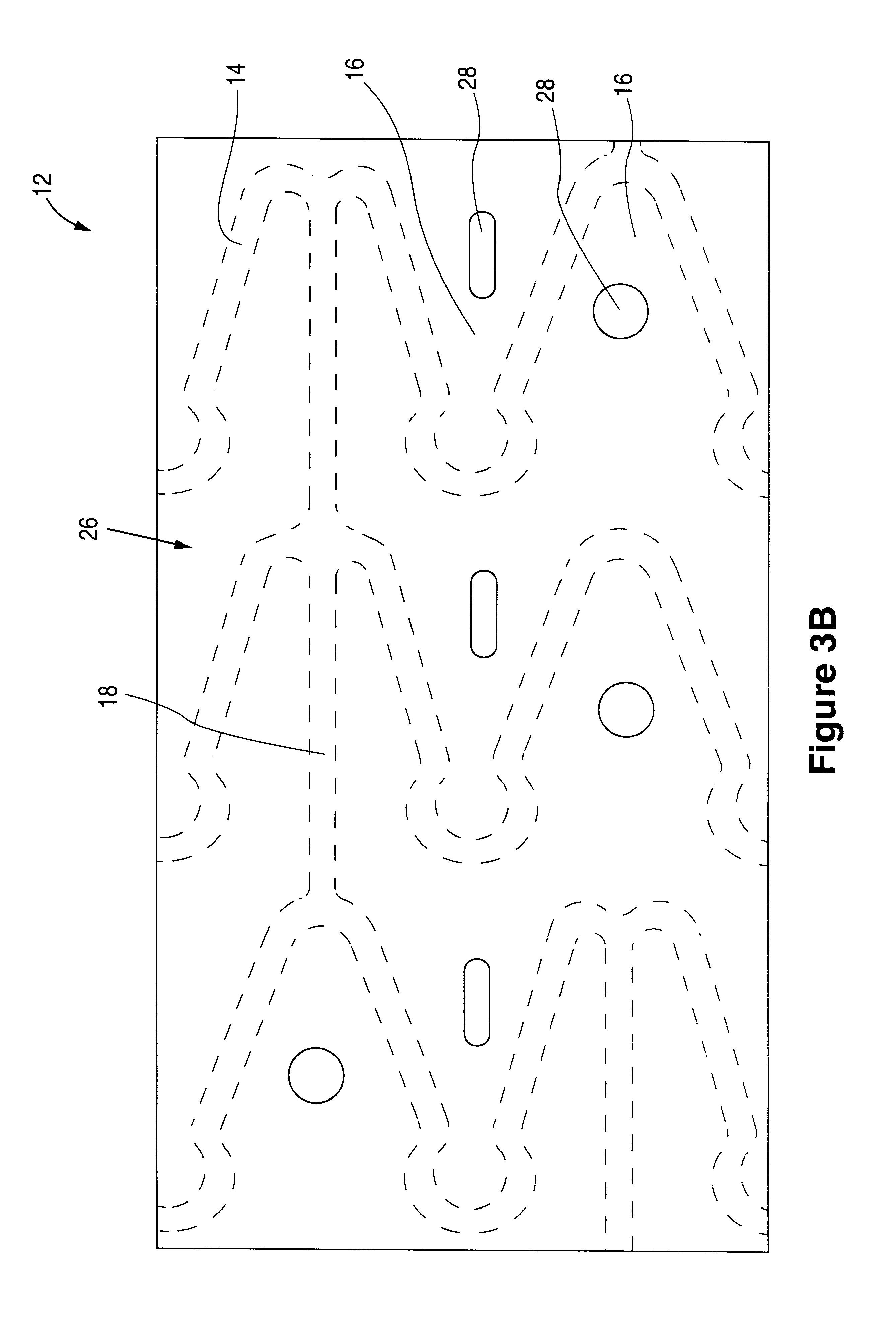

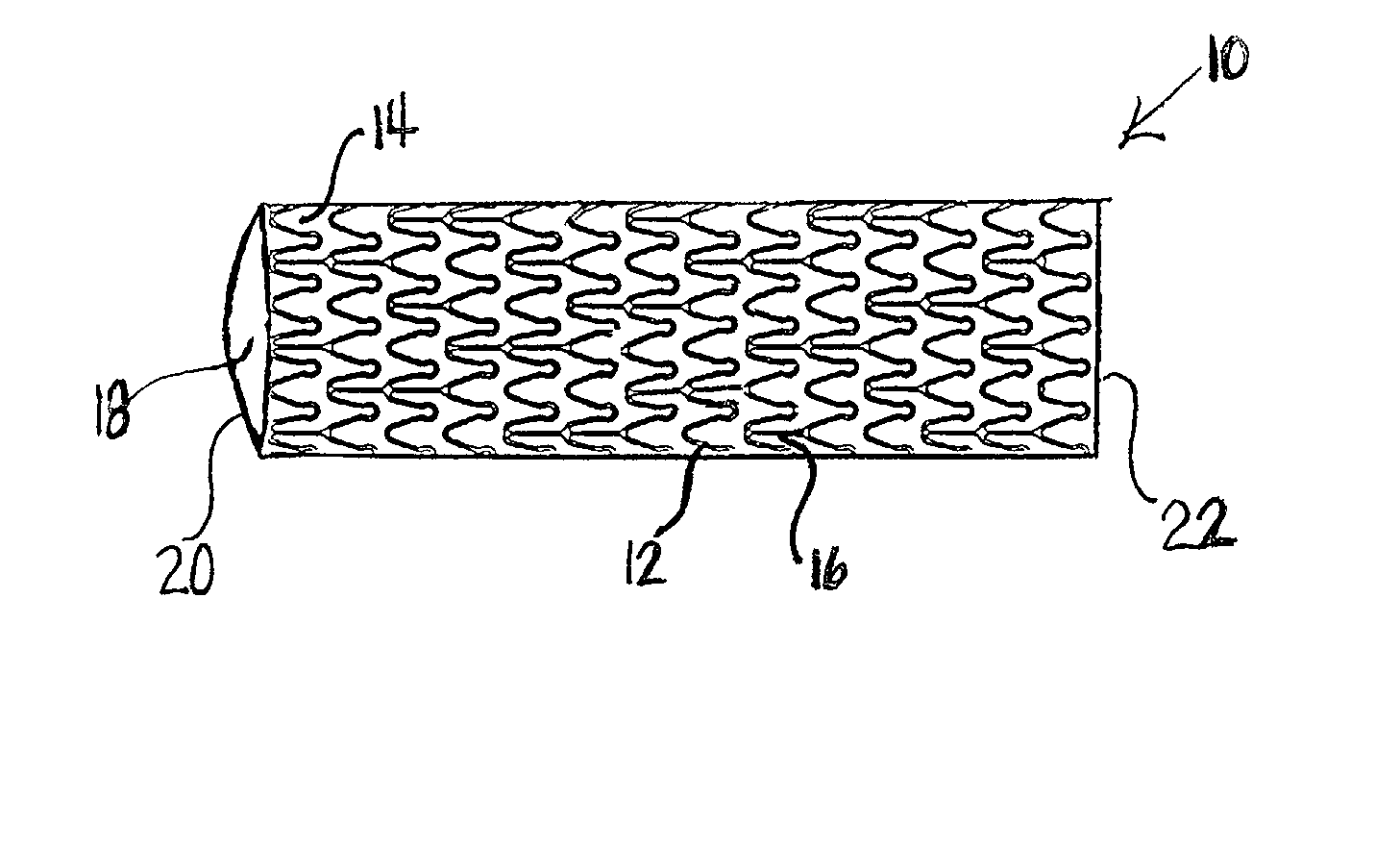

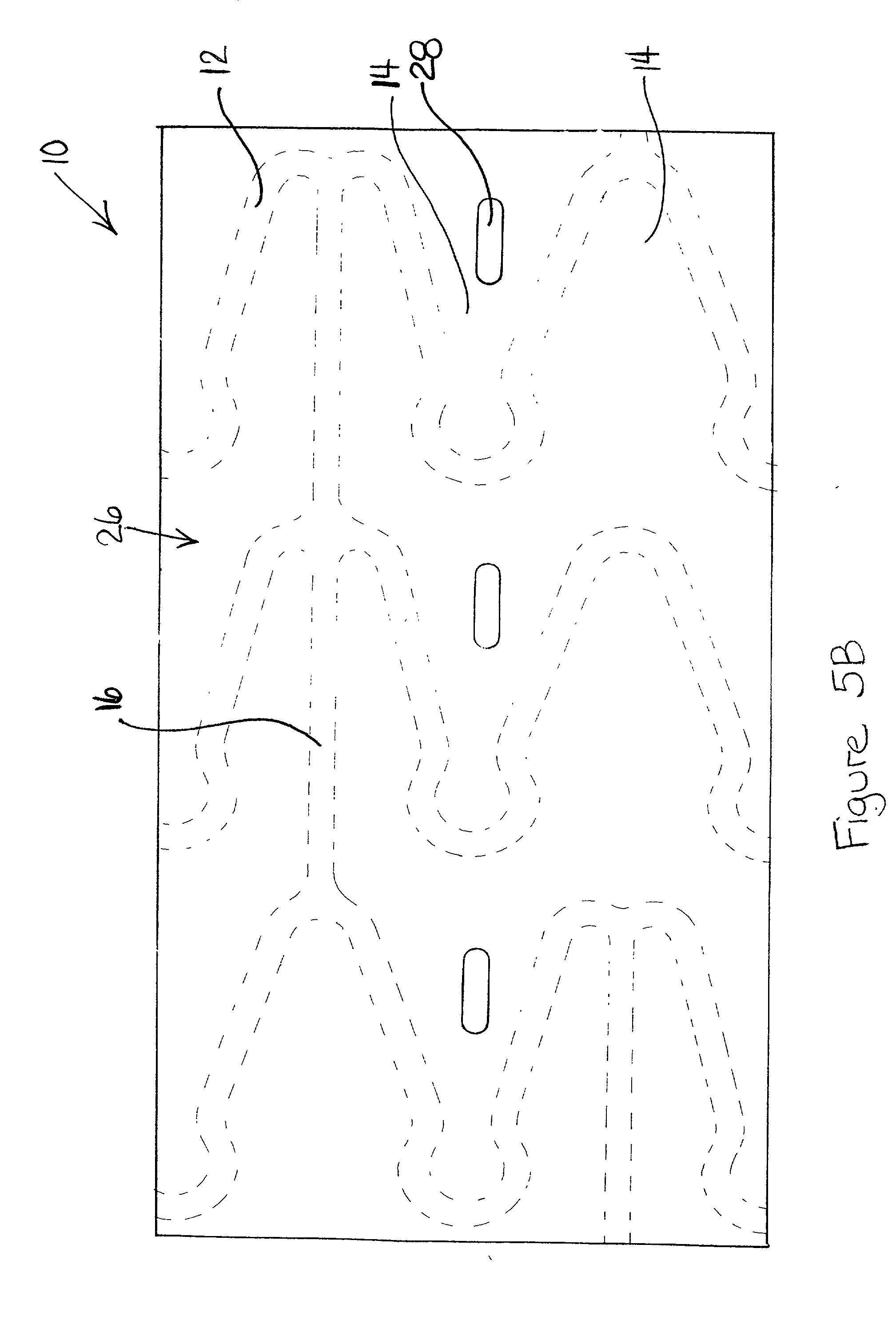

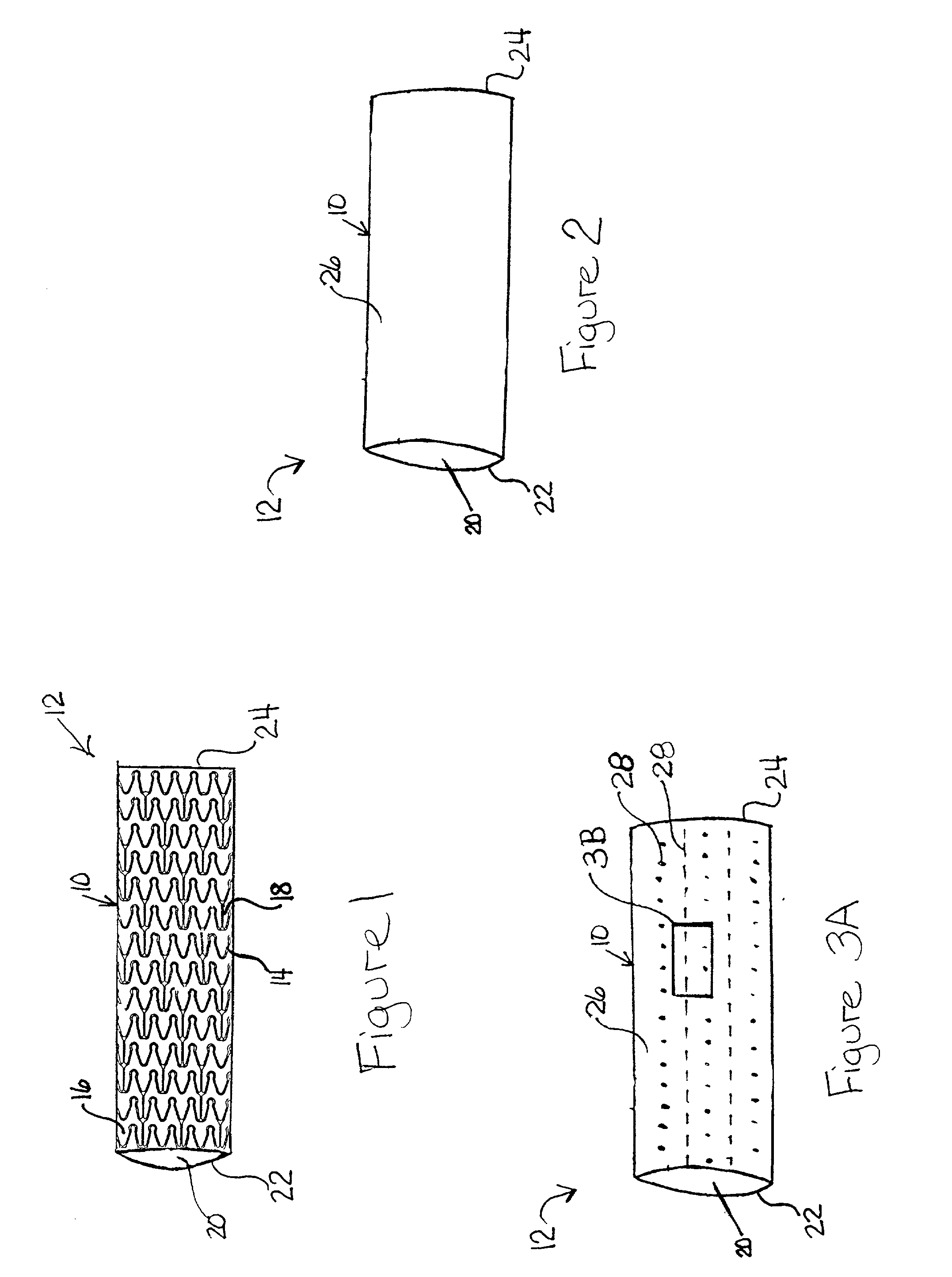

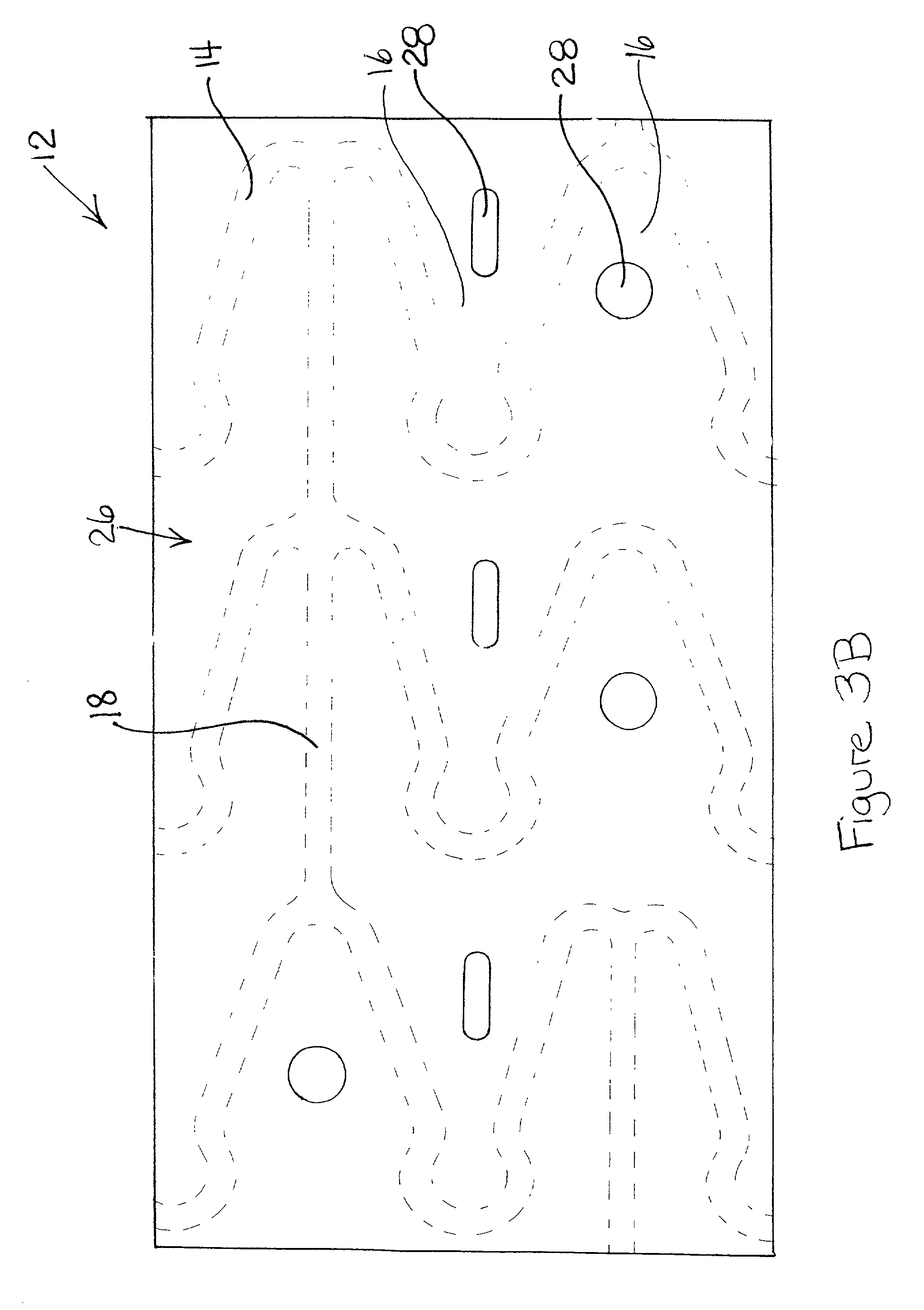

Methods of forming a coating onto an implantable device or endoluminal prosthesis, such as a stent, are provided. The coating may be used for the delivery of an active ingredient. The coating may have a selected pattern of interstices for allowing a fluid to seep through the coating in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

Sheath for a prosthesis and methods of forming the same

InactiveUS6540776B2Increase the amount addedIncrease the number ofStentsPharmaceutical containersProsthesisImplanted device

Owner:ABBOTT CARDIOVASCULAR

Methods of forming a coating for a prosthesis

InactiveUS20020122877A1Increase the amount addedIncrease the number ofRadiation applicationsGlovesProsthesisImplanted device

Methods of forming a coating onto an implantable device or endoluminal prosthesis, such as a stent, are provided. The coating may be used for the delivery of an active ingredient. The coating may have a selected pattern of interstices for allowing a fluid to seep through the coating in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

Packaging biological materials

InactiveUS6548132B1Reduction in tackUniform propertyWrappersPreformed elementsPolymer scienceBiological materials

Novel gas-permeable membranes which are particularly useful in the packaging of fresh cut fruit and vegetables, and other respiring biological materials. The membranes comprise a microporous film or other gas-permeable substrate and, coated on the substrate, a layer of a block copolymer having a heat of fusion of at least 5 J / g and containing polysiloxane polymeric blocks and crystalline polymeric blocks having a melting point of -5 to 40° C.

Owner:LANDEC

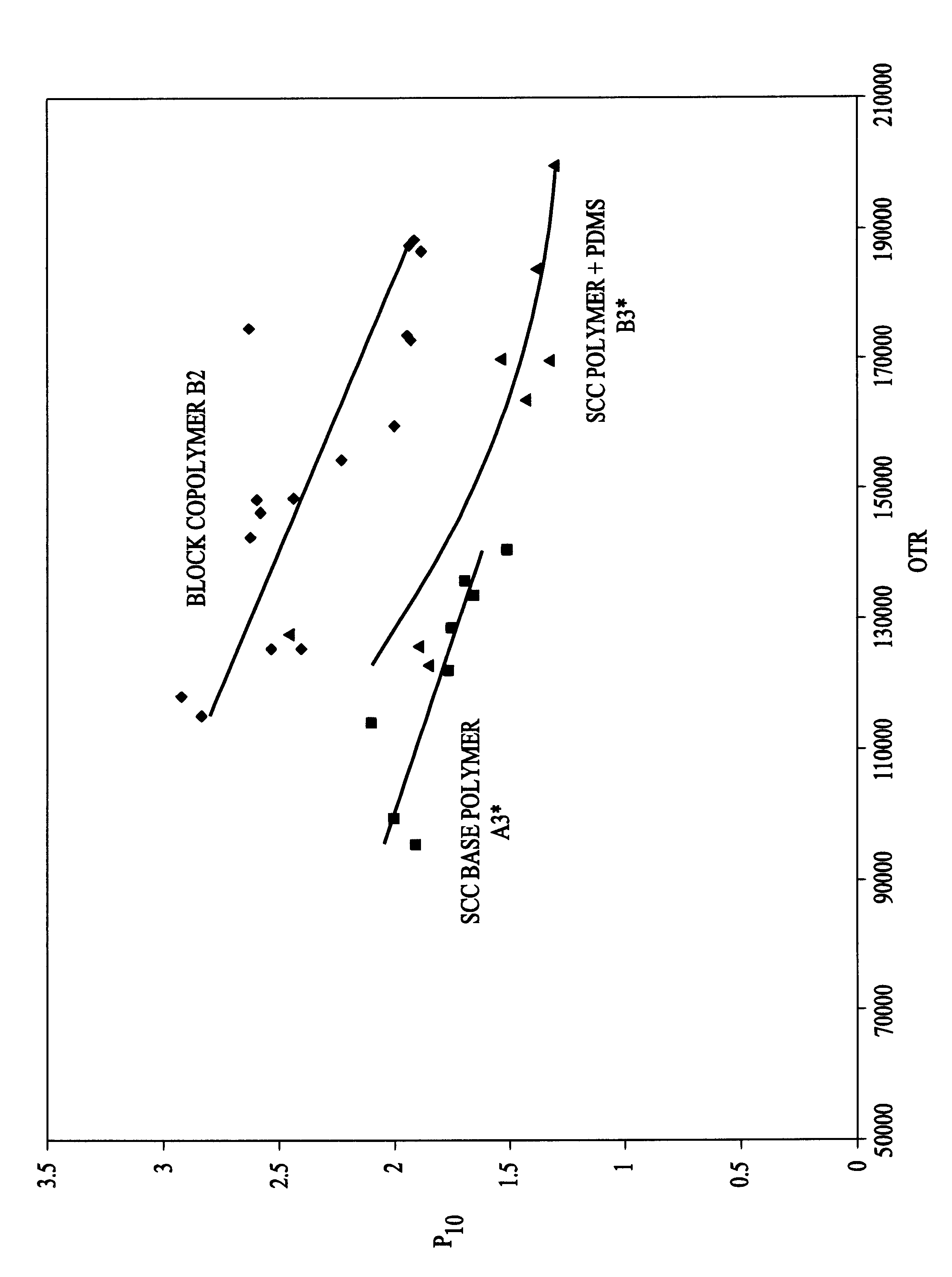

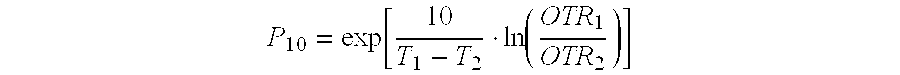

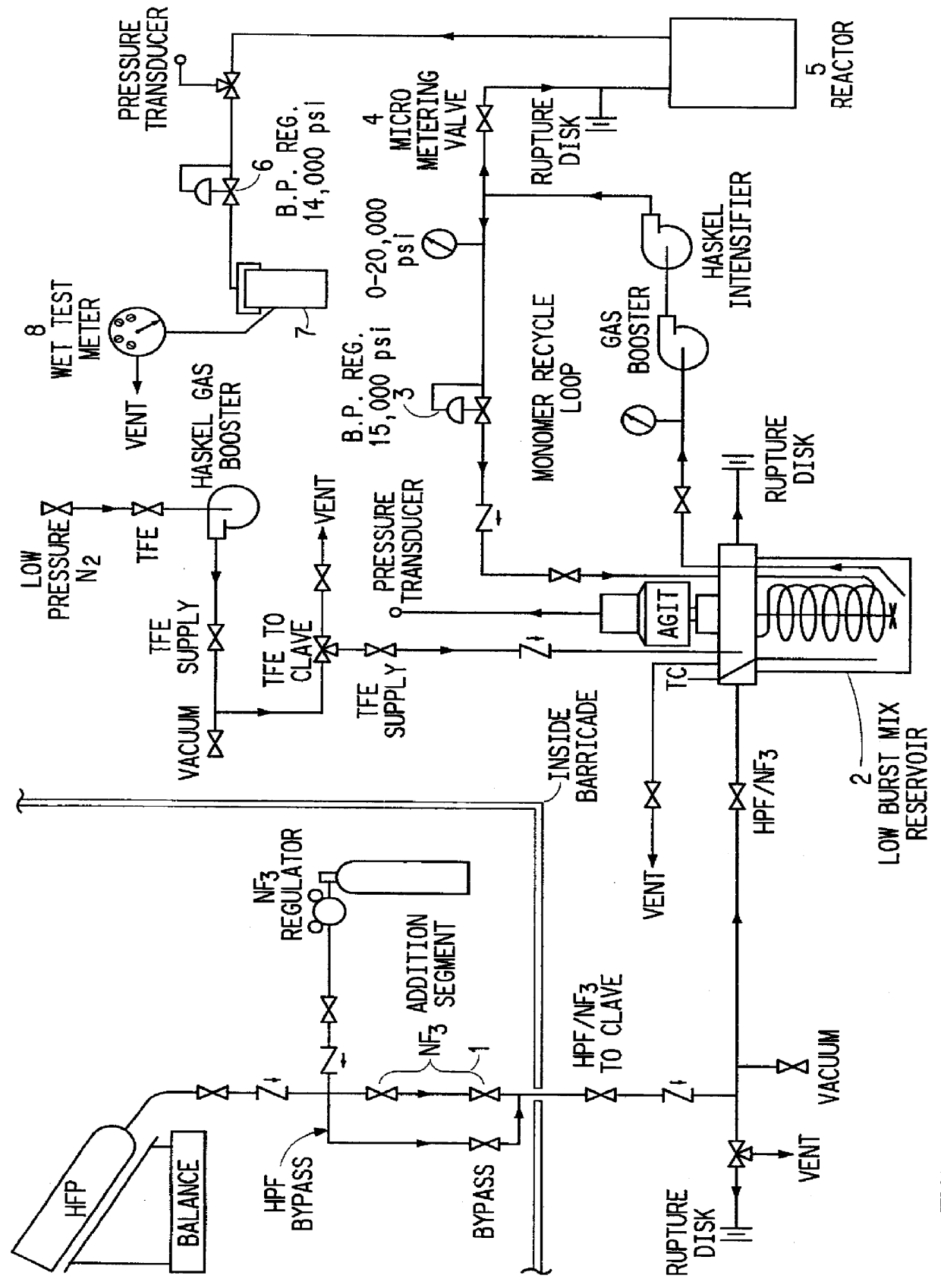

Amorphous tetrafluoroethylene-hexafluoropropylene copolymers

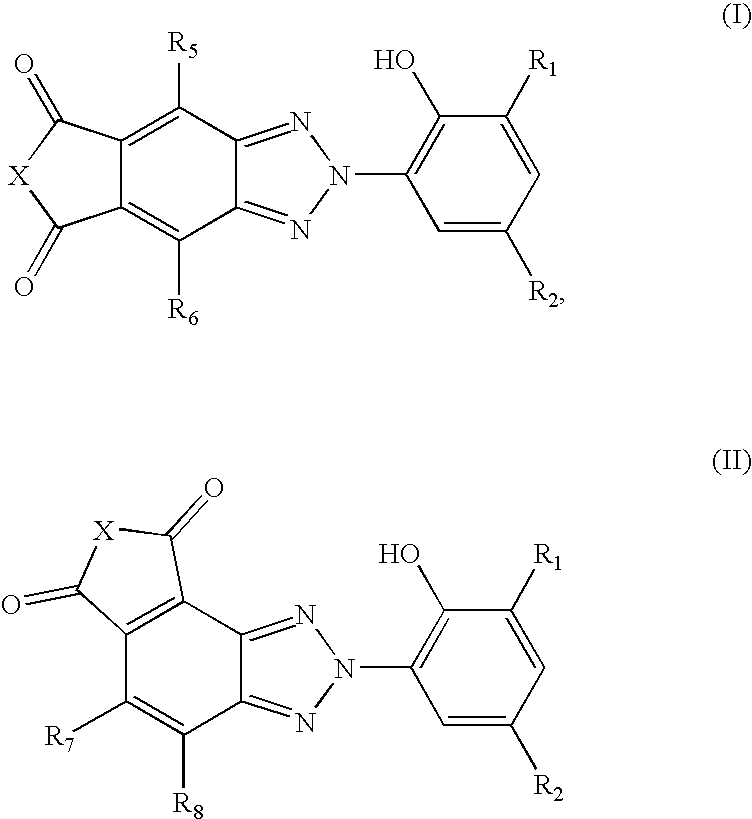

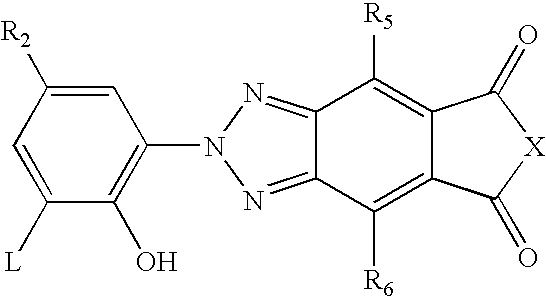

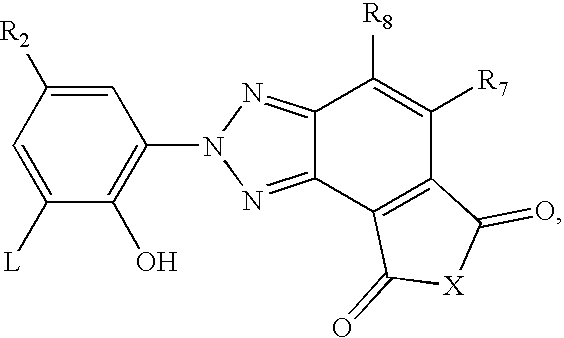

InactiveUS6133389AThin coatingIncrease coating thicknessOrganic chemistryCoatingsPolymer scienceHexafluoropropylene

Disclosed herein are novel amorphous tetrafluoroethylene-hexafluoropropylene (TFE-HFP) dipolymers, and other copolymers containing TFE, HFP and a third monomer, many of which are more random than previous amorphous TFE-HFP copolymers, as well as a novel high productivity continuous process for making these polymers. The polymers are particularly useful in the form of coatings, films and encapsulants.

Owner:THE CHEMOURS CO FC LLC

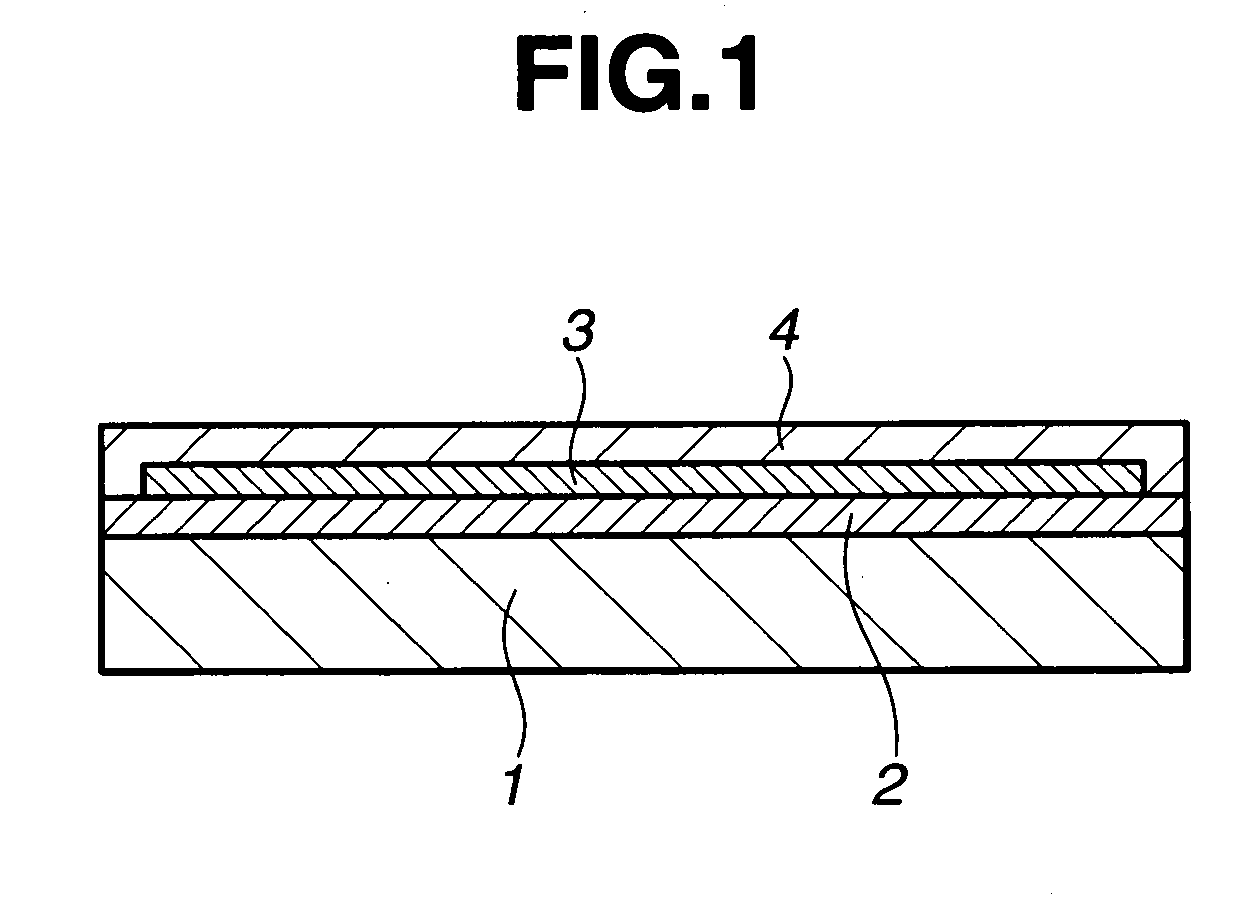

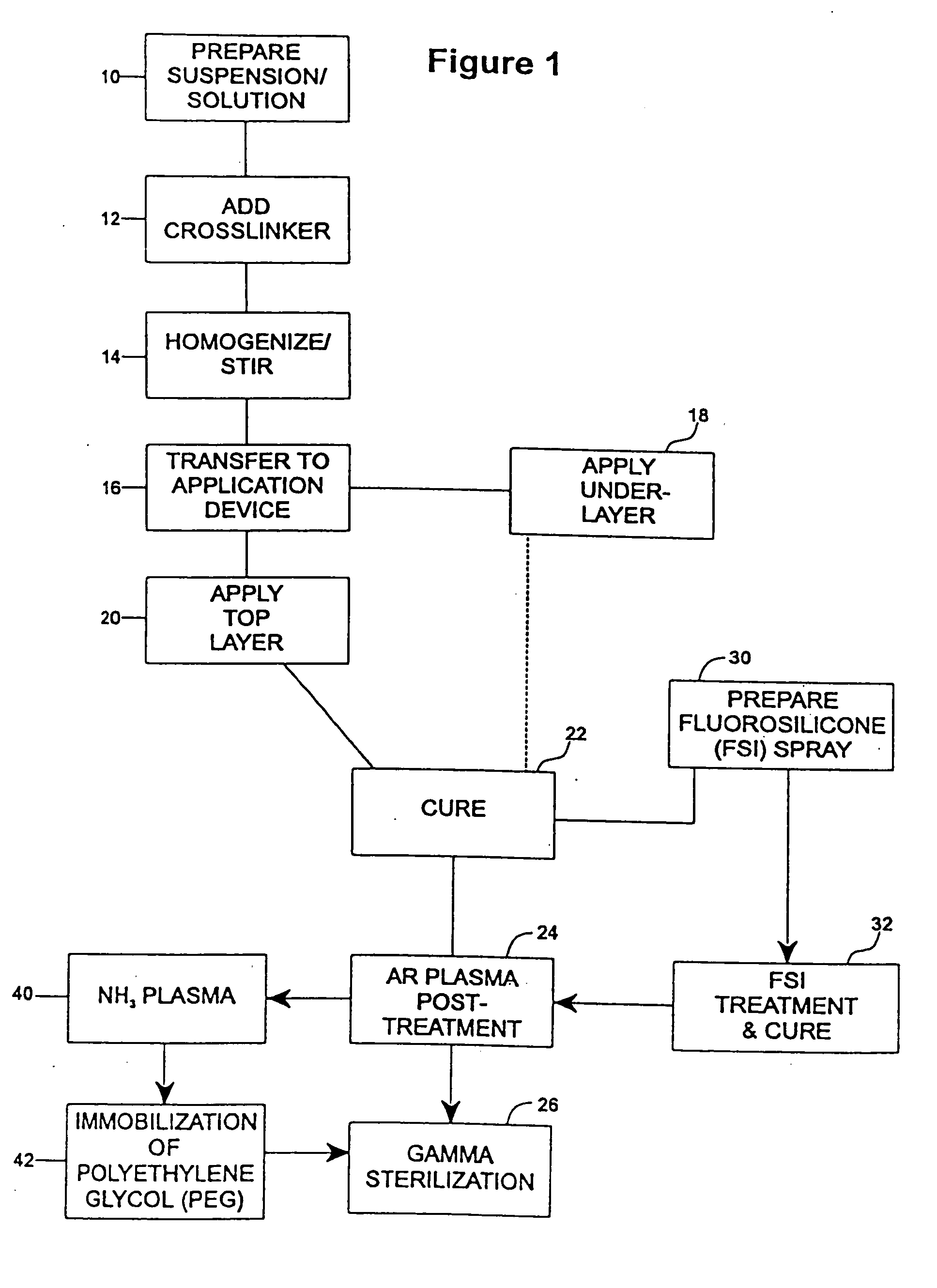

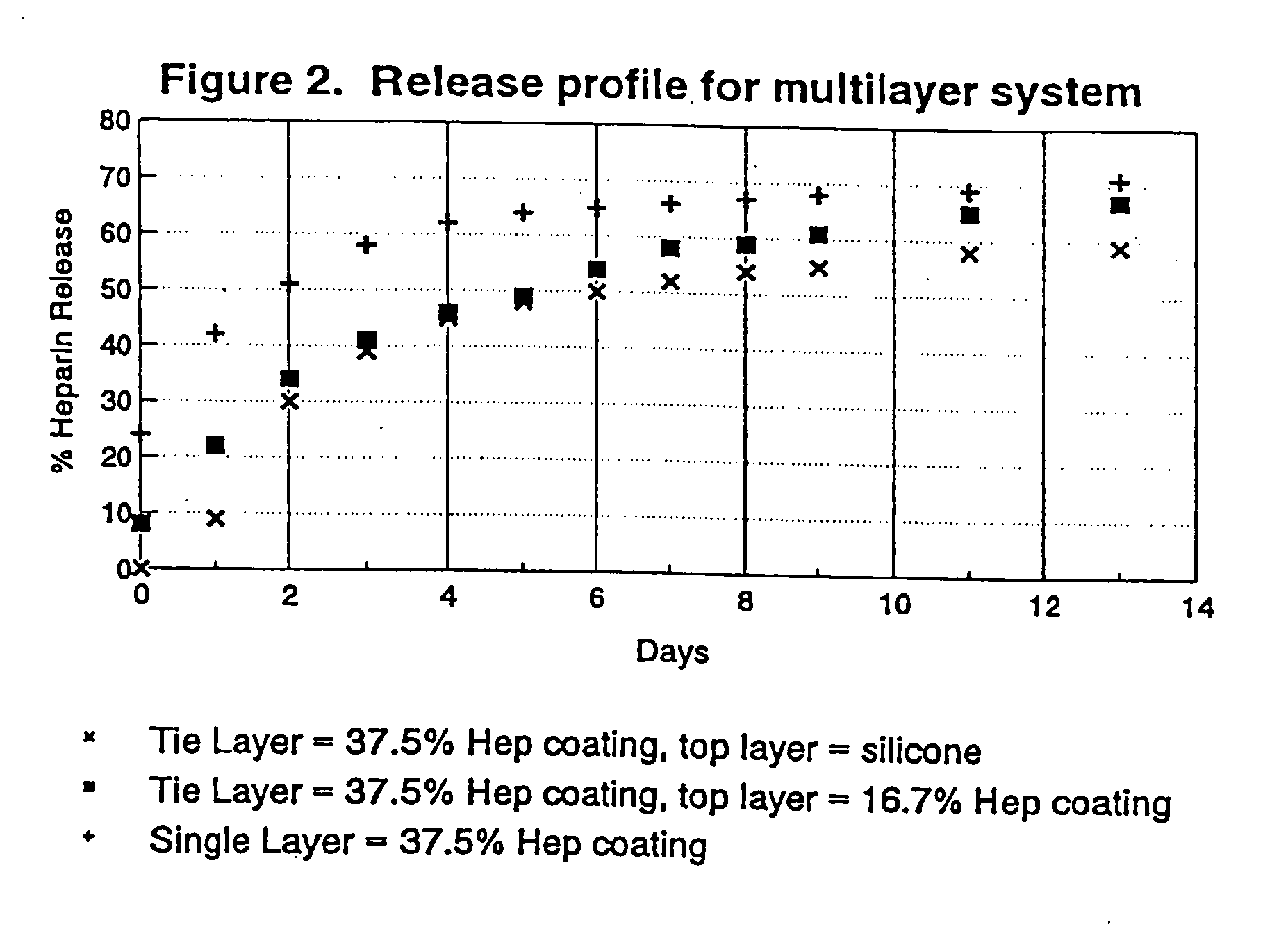

Drug coating with topcoat

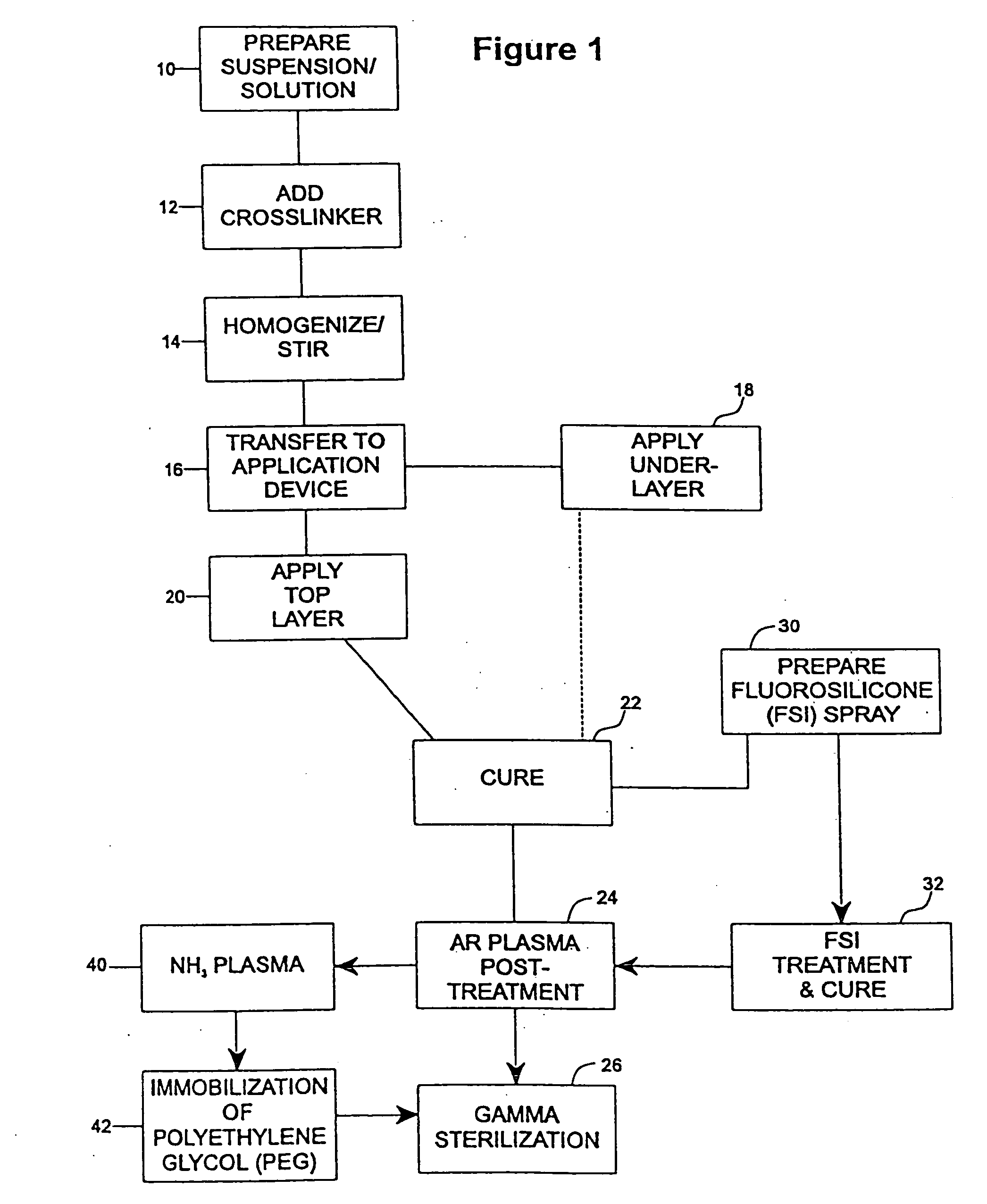

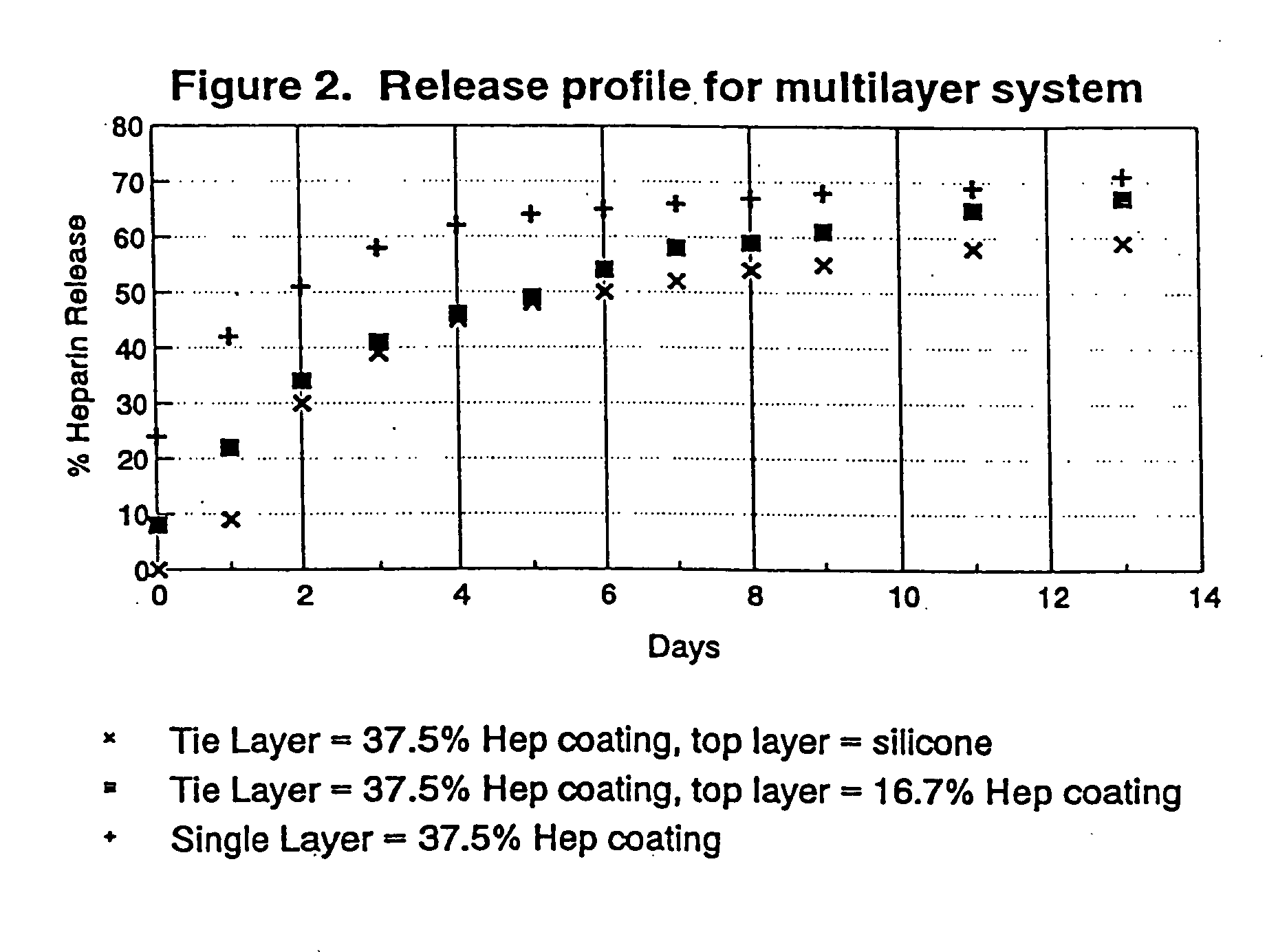

InactiveUS20050187611A1Long release timeReduced burst effectStentsSurgeryThrombogenicityDrug coating

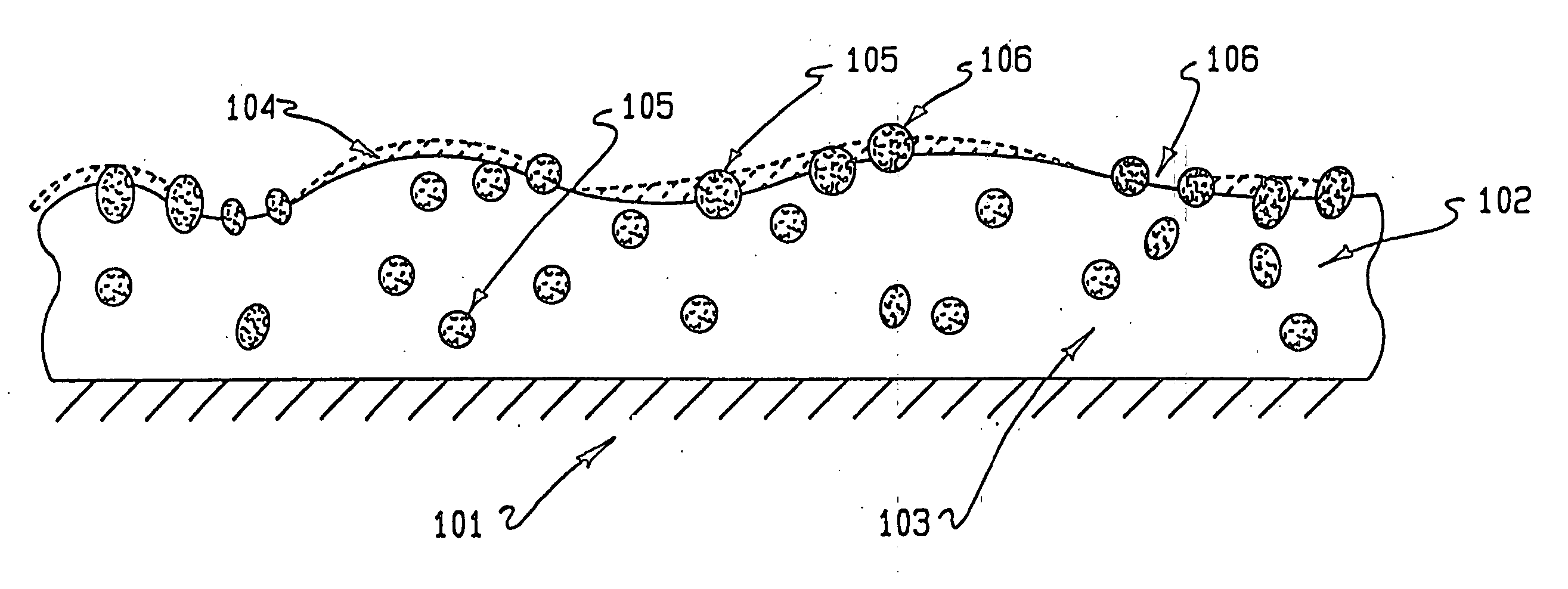

A coating and method for a coating an implantable device or prostheses are disclosed. The coating includes an undercoat of polymeric material containing an amount of biologically active material, particularly heparin, dispersed herein. The coating further includes a topcoat which covers less than the entire surface of the undercoat and wherein the topcoat comprises a polymeric material substantially free of pores and porosigens. The polymeric material of the topcoat can be a biostable, biocompatible material which provides long term non-thrombogenicity to the device portion during and after release of the biologically active material.

Owner:BOSTON SCI SCIMED INC

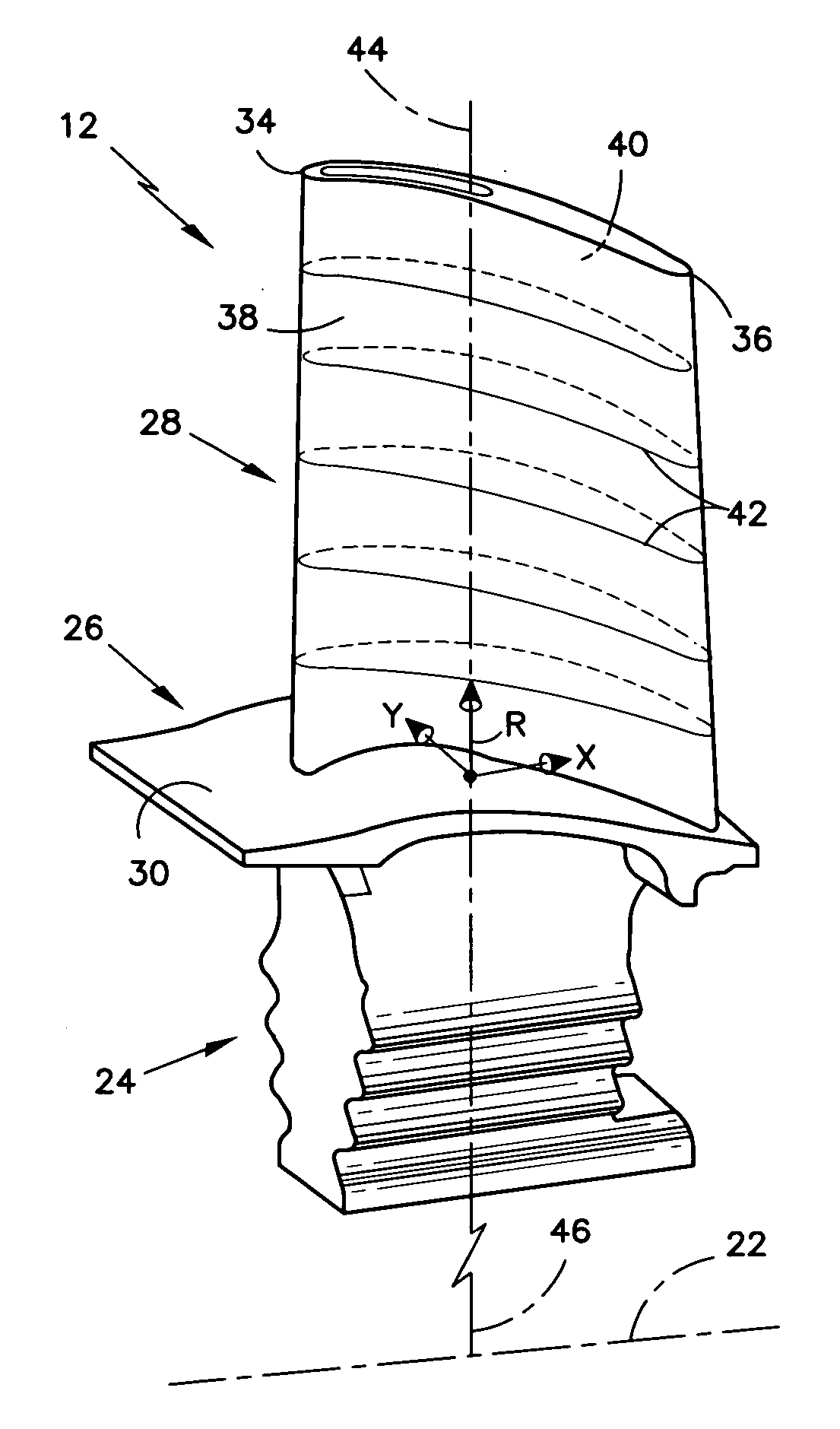

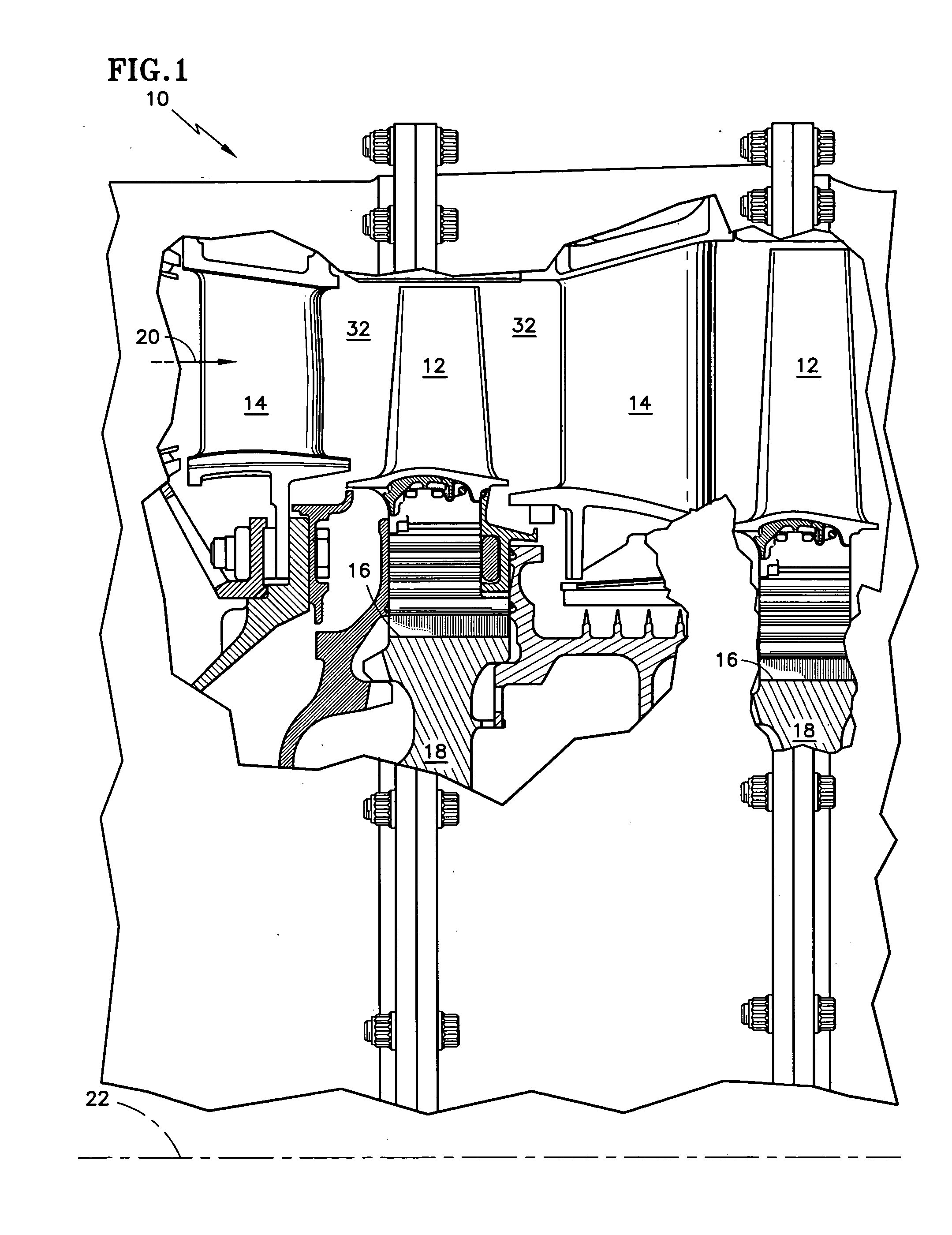

Airfoil profile with optimized aerodynamic shape

ActiveUS7094034B2Improve turbine efficiencyImprove aerodynamic performanceEngine manufactureOther chemical processesTurbine bladeEngineering

Owner:RTX CORP

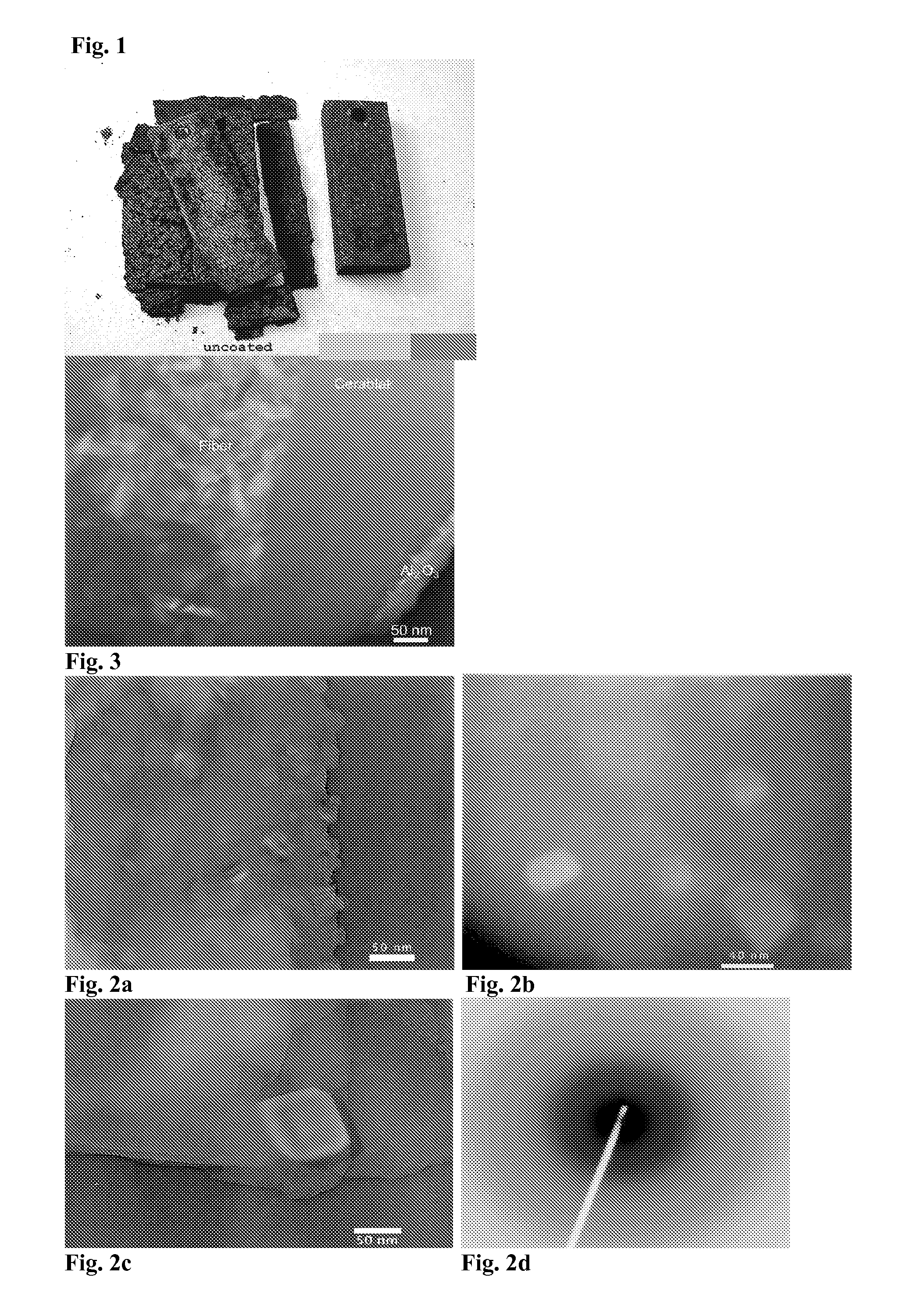

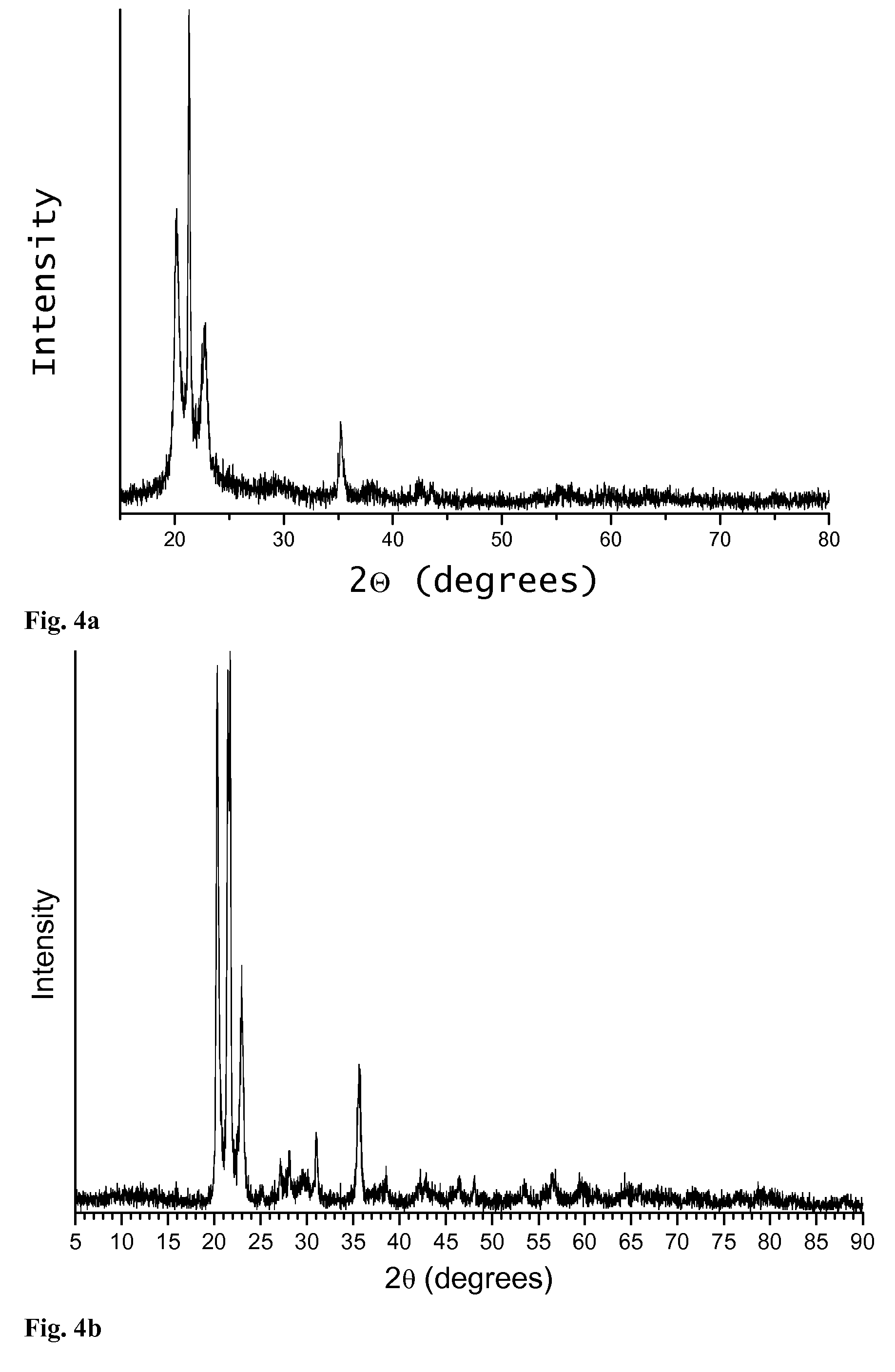

Monolithic zeolite coated structures and a method of manufacture

InactiveUS6936561B2Tight controlHigh degreeMolecular sieve catalystsDispersed particle separationHoneycombHoneycomb like

Structured zeolite coated structures comprising thick porous inorganic zeolite coatings disposed on monolithic support structures, which can be honeycomb shaped, are disclosed. The zeolite coatings have open interconnected pores of controlled pore size and are characterized by improved durability, physical integrity, and adherence sufficient to enable use as supports for catalysts in liquid phase applications under harsh reaction conditions. Methods for making zeolite coated structures are also disclosed.

Owner:CORNING INC

Investment casting

InactiveUS6450243B1Shorten the timeCoating thicknessFoundry mouldsMoulding machinesFiberWater insoluble

The present invention relates to improvements in and relating to investment casting. In particular, the invention provides a method of investment casting, comprising the steps of mixing a binder, a refractory material, and a quantity of water-insoluble organic fibers to form a slurry; coating an expendable pattern with a coat of said slurry; and drying said coat or allowing said coat to dry to form a shell. The present invention further provides a refractory slurry for use in the method of the invention, and a kit of ingredients for putting the method of the invention into effect.

Owner:BUNTROCK IND INC

Sheath for a prosthesis and methods of forming the same

InactiveUS20020123788A1Increase the amount addedIncrease the number ofStentsPharmaceutical containersMedicineProsthesis

An implantable device or endoluminal prosthesis, such as a stent, having a sheath and a method of forming the sheath are provided. The sheath may be used for the delivery of an active ingredient. The sheath may have a selected pattern of interstices for allowing a fluid to seep through the sheath in the direction of the pattern created.

Owner:ABBOTT CARDIOVASCULAR

High film build coating composition containing polytrimethylene ether diol

The present disclosure is directed to a coating composition that is capable of producing coatings being sag-free at high coating thicknesses, having excellent adhesion to substrates, and good appearance. This disclosure is further directed to a coating composition comprising components derived from renewable resources.

Owner:AXALTA COATING SYST IP CO LLC

Multicoat paint systems, process for producing them, and their use in automaking

InactiveUS20090317629A1Improves UV stabilityLess influenceSynthetic resin layered productsPretreated surfacesUv absorbanceMoisture exposure

The present disclosure provides multicoat systems exhibiting ultraviolet (UV) stability after ultraviolet exposure and moisture exposure. The systems comprise at least one primer (G), at least one pigmented coating (P) disposed on a surface of the primer, and at least one ultraviolet (UV) absorber which has an absorption maximum of at least 370 nm. The pigmented coating (P) may be comprised of two or more coatings (P1), (P2) to (Pn). The multicoat systems may also comprise a transparent coating material (T) to form a transparent coating (K). The present multicoat systems demonstrate ultraviolet stability, reduced delamination of the pigmented coat from the primer and are available in a variety of shades for use in the finishing, refinishing and coating of component parts.The present disclosure also provides for a process for producing the multicoat system, and provides for the use of the system.

Owner:BASF COATINGS GMBH

Self-assembly of coatings utilizing surface charge

ActiveUS20120073971A1Increase coating thicknessPromote formationCell electrodesVolume/mass flow measurementSurface chargesSolid-state battery

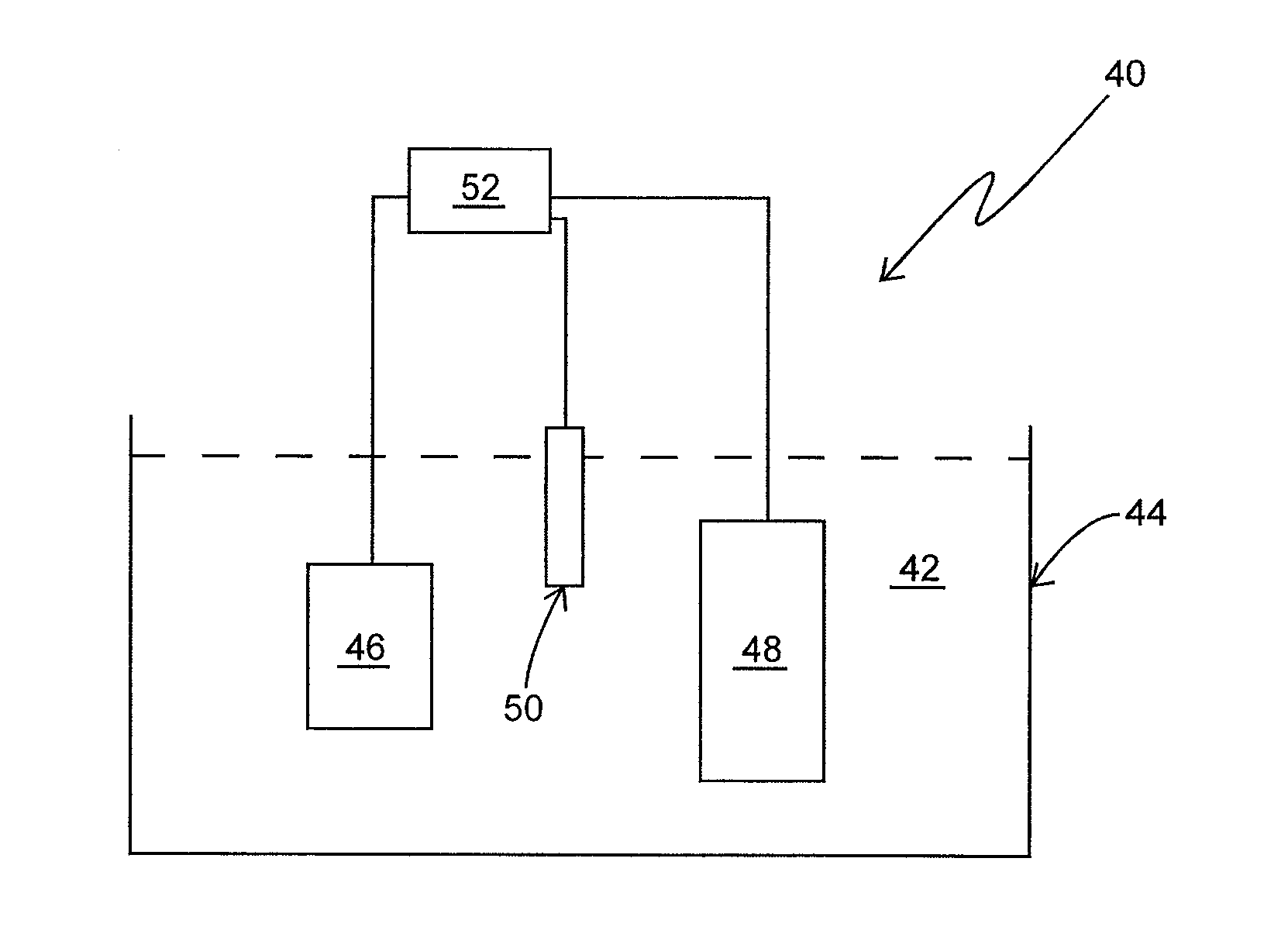

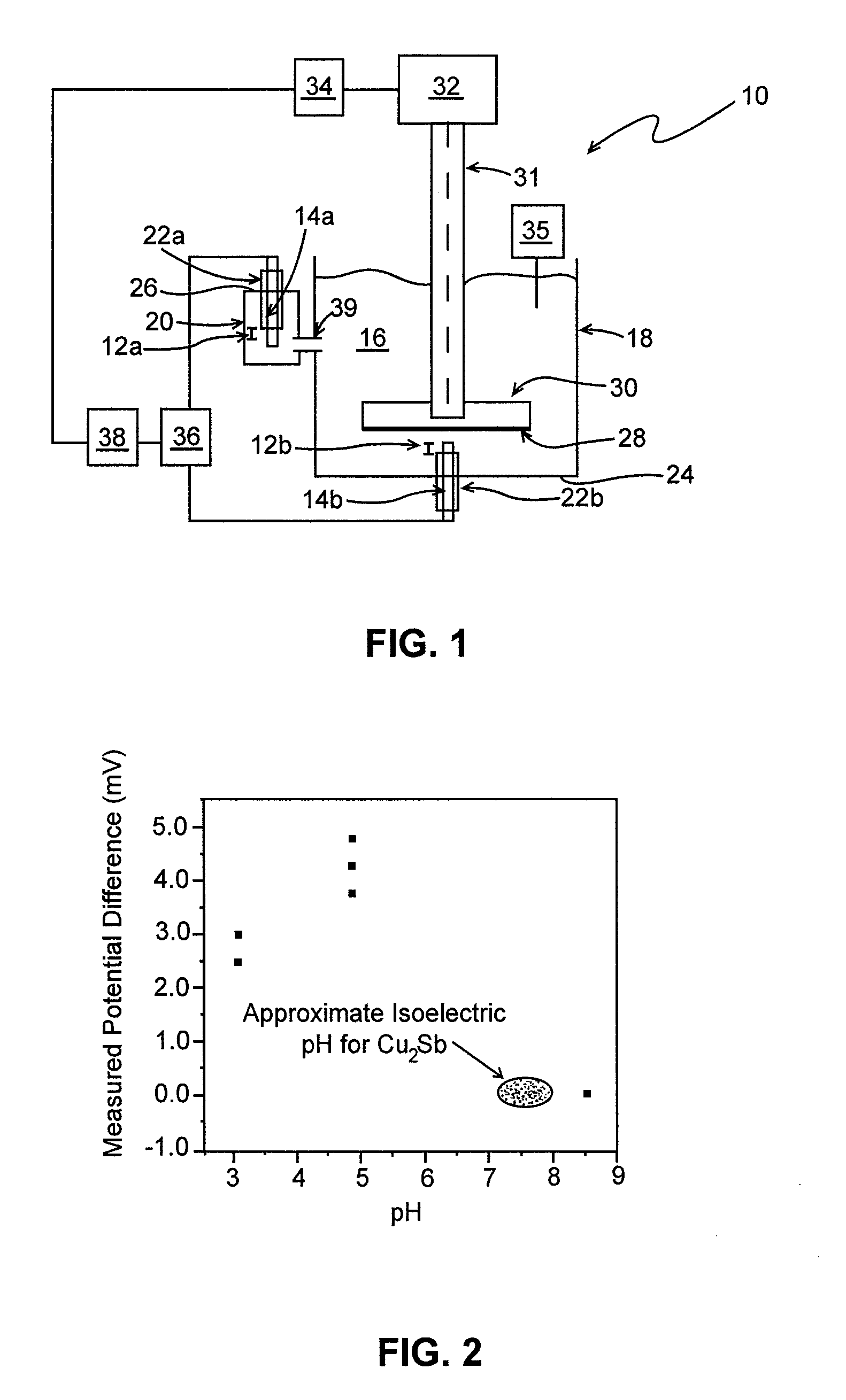

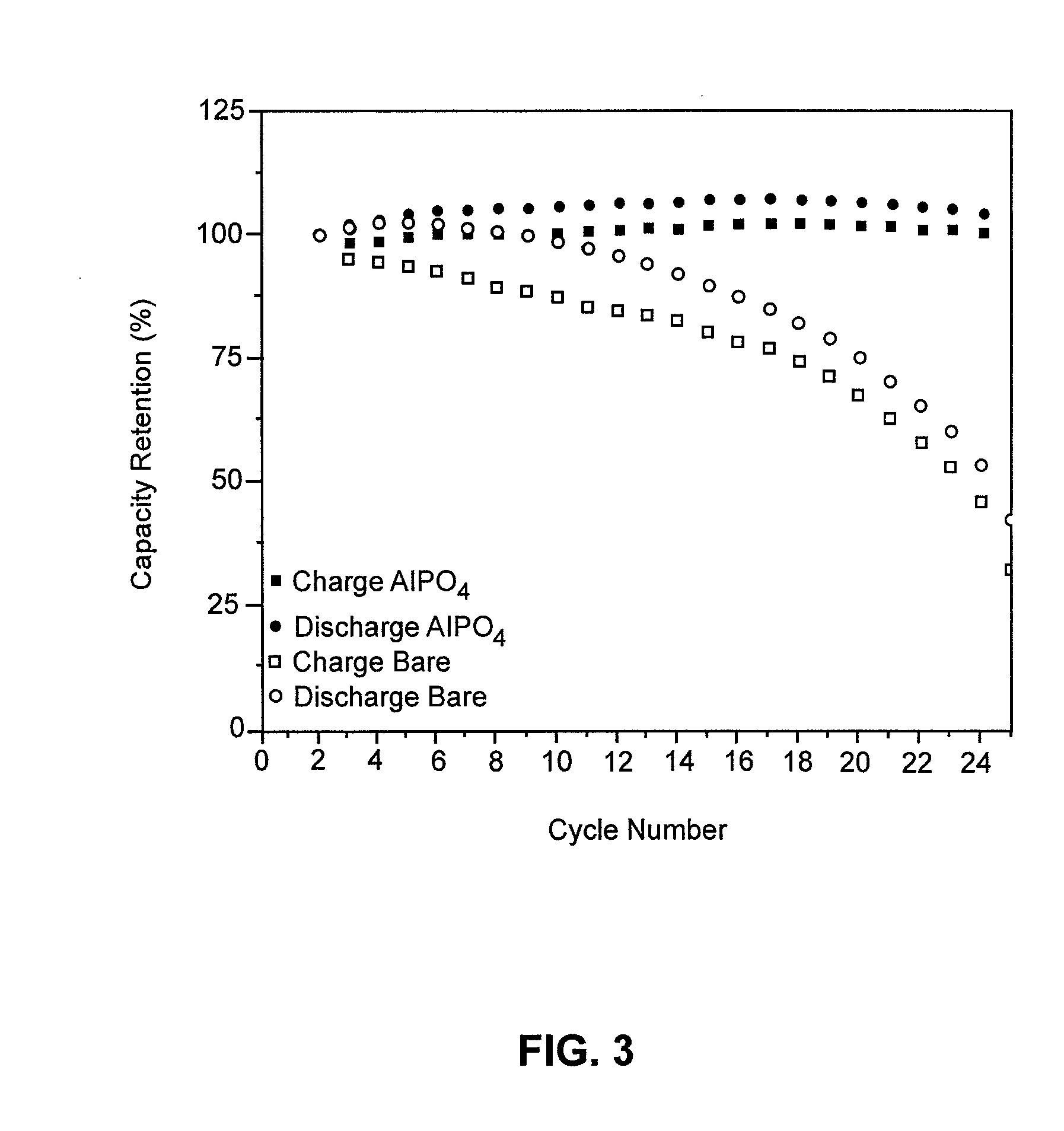

An apparatus and method for measuring the isoelectric pH for materials deposited on or otherwise affixed onto and in contact with an electrode surface, and a method for utilizing the isoelectric pH to form nanometer thickness, self-assembled layers on the material, are described. Forming such layers utilizing information obtained about the isoelectric pH values of the substrate and the coating is advantageous since the growth of the coating is self-limiting because once the surface charge has been neutralized there is no longer a driving force for the solid electrolyte coating thickness to increase, and uniform coatings without pinhole defects will be produced because a local driving force for assembly will exist if any bare electrode material is exposed to the solution. The present self-assembly procedure, when combined with electrodeposition, may be used to increase the coating thickness. Self-assembly, with or without additional electrodeposition, allows intimate contact between the anode, electrolyte and cathode which is required for successful application to solid-state batteries, as an example.

Owner:COLORADO STATE UNIVERSITY

High Temperature Amorphous Composition Based on Aluminum Phosphate

InactiveUS20090064893A1Enhanced amorphous characterEnhanced associated stabilityHot-dipping/immersion processesPhosphatesPhosphoric acidALUMINUM PHOSPHATE

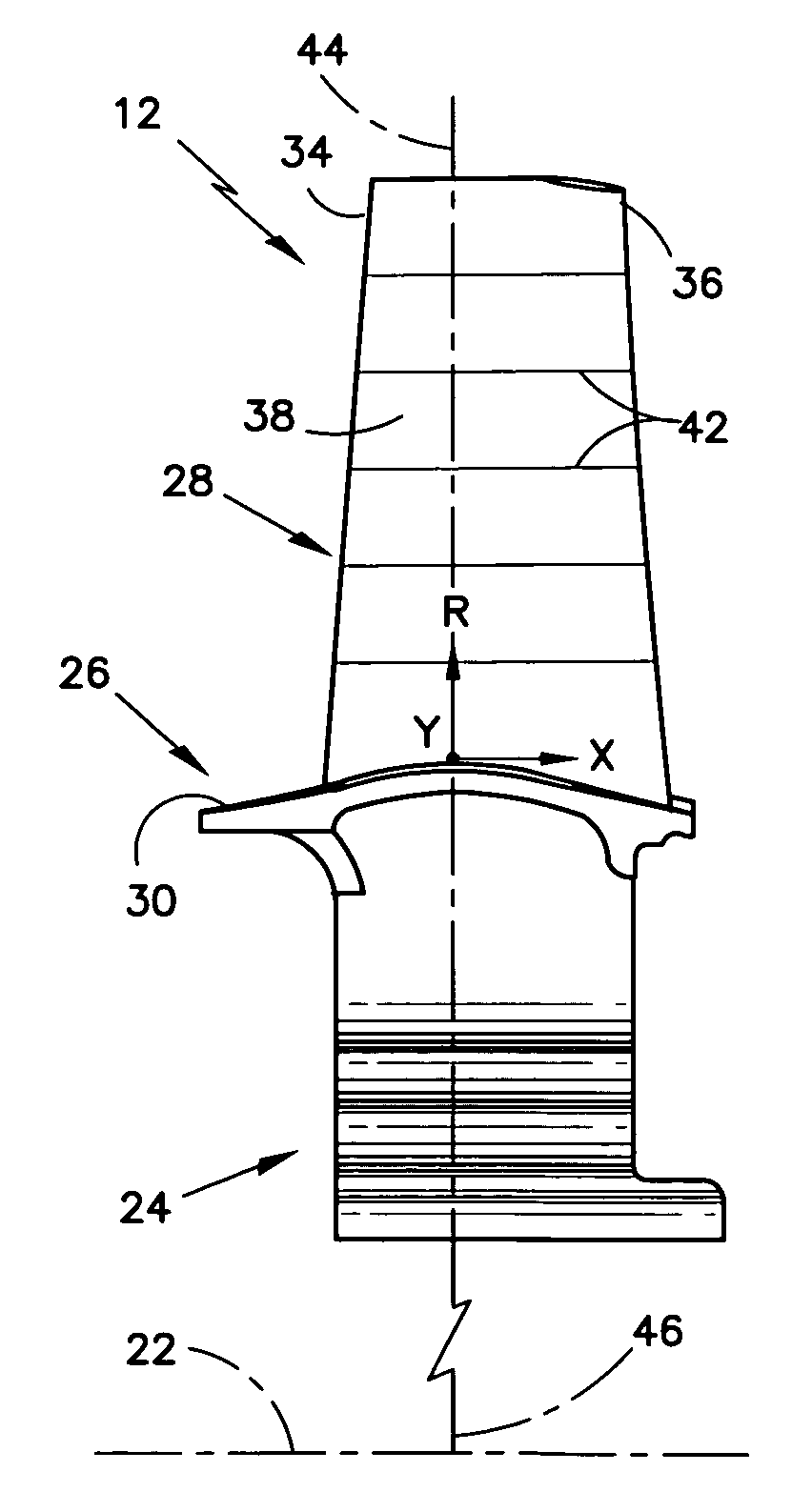

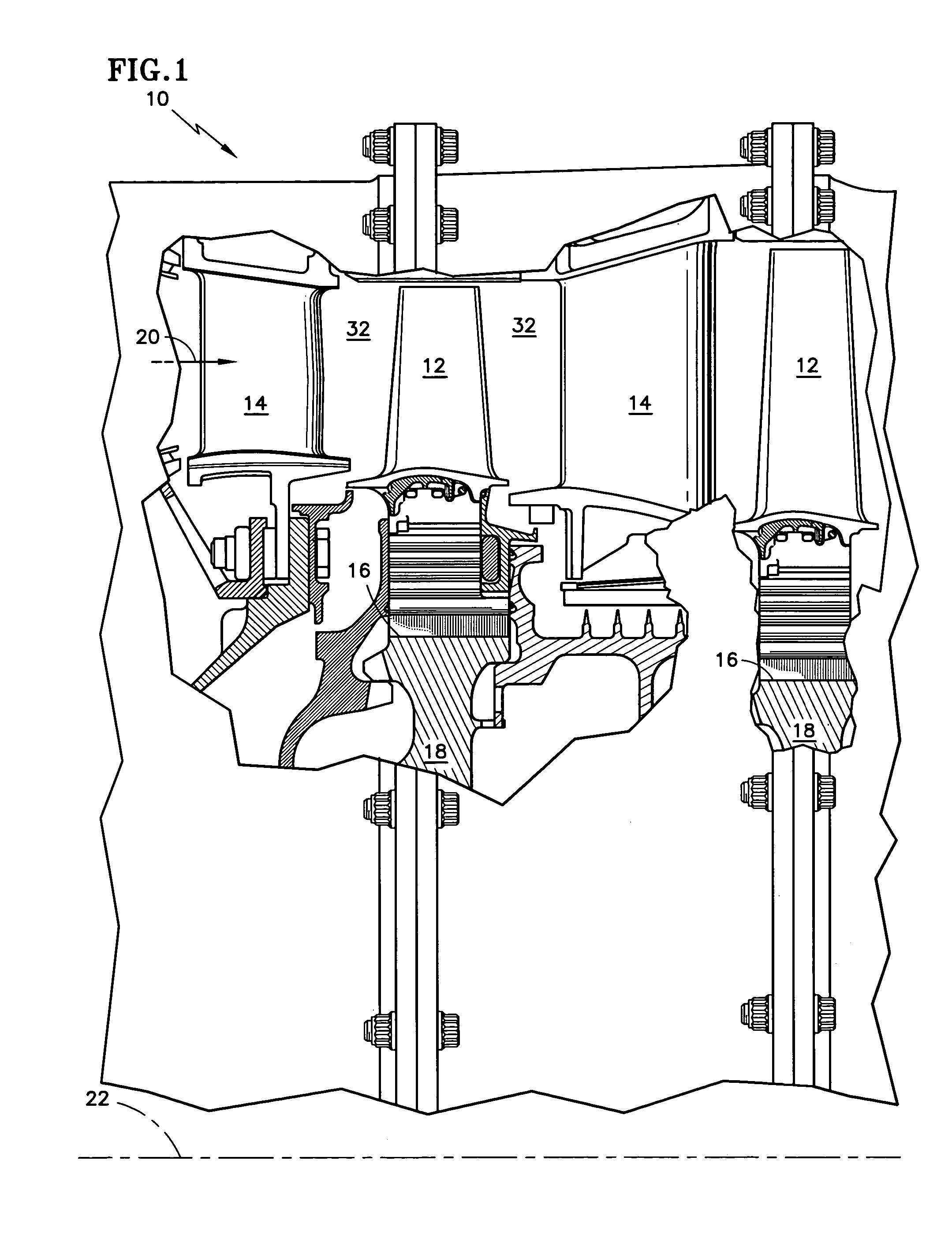

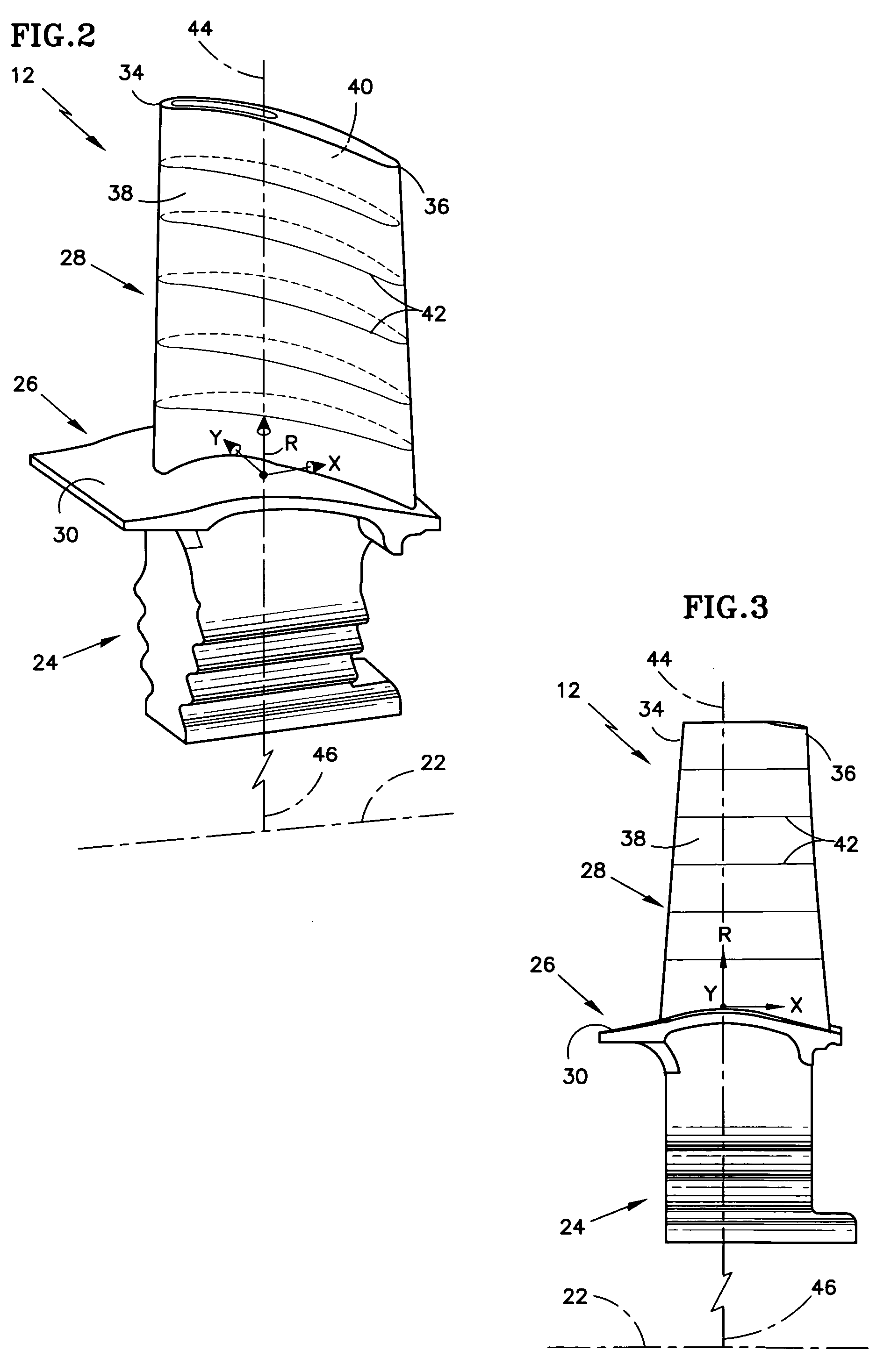

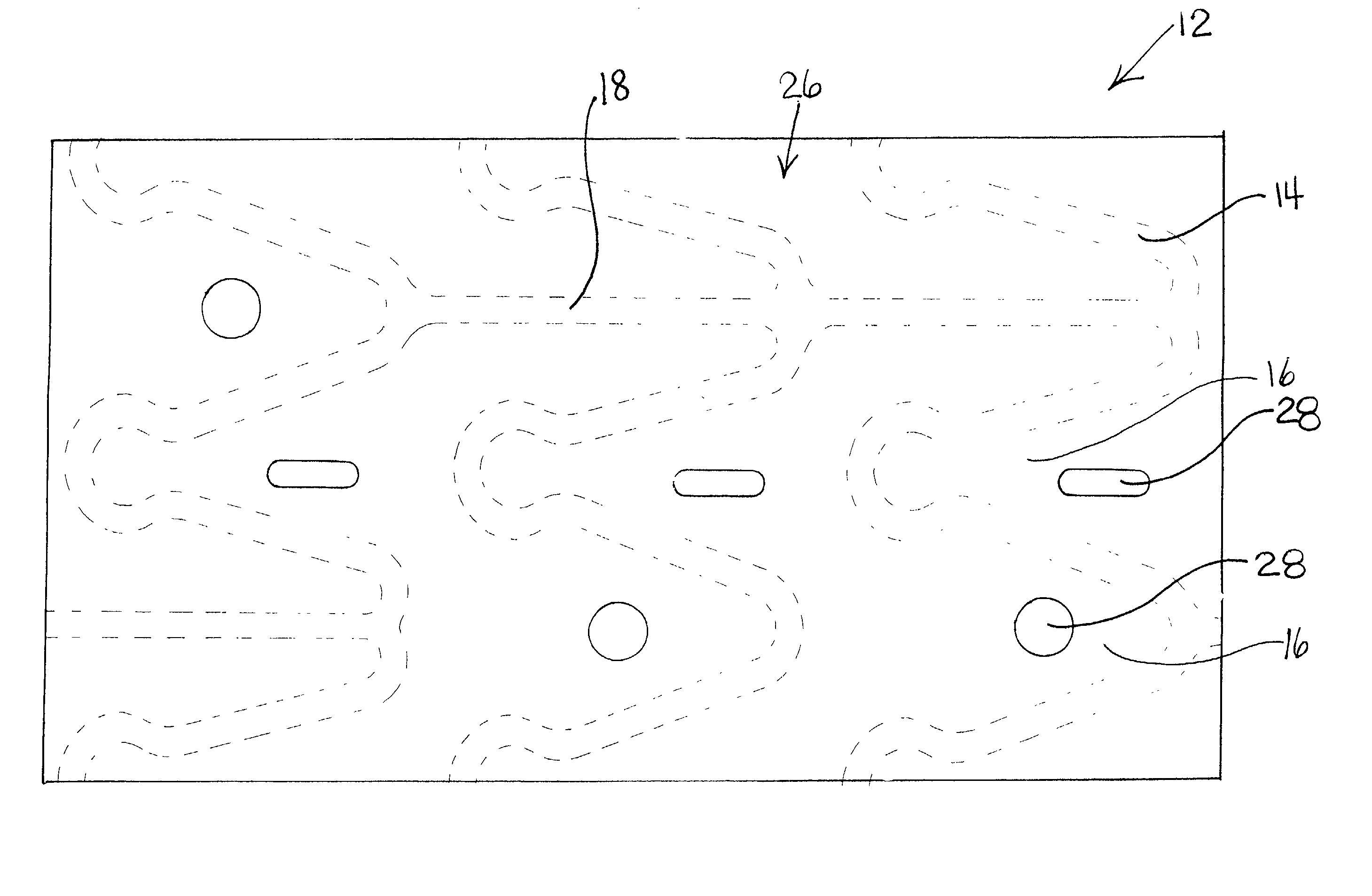

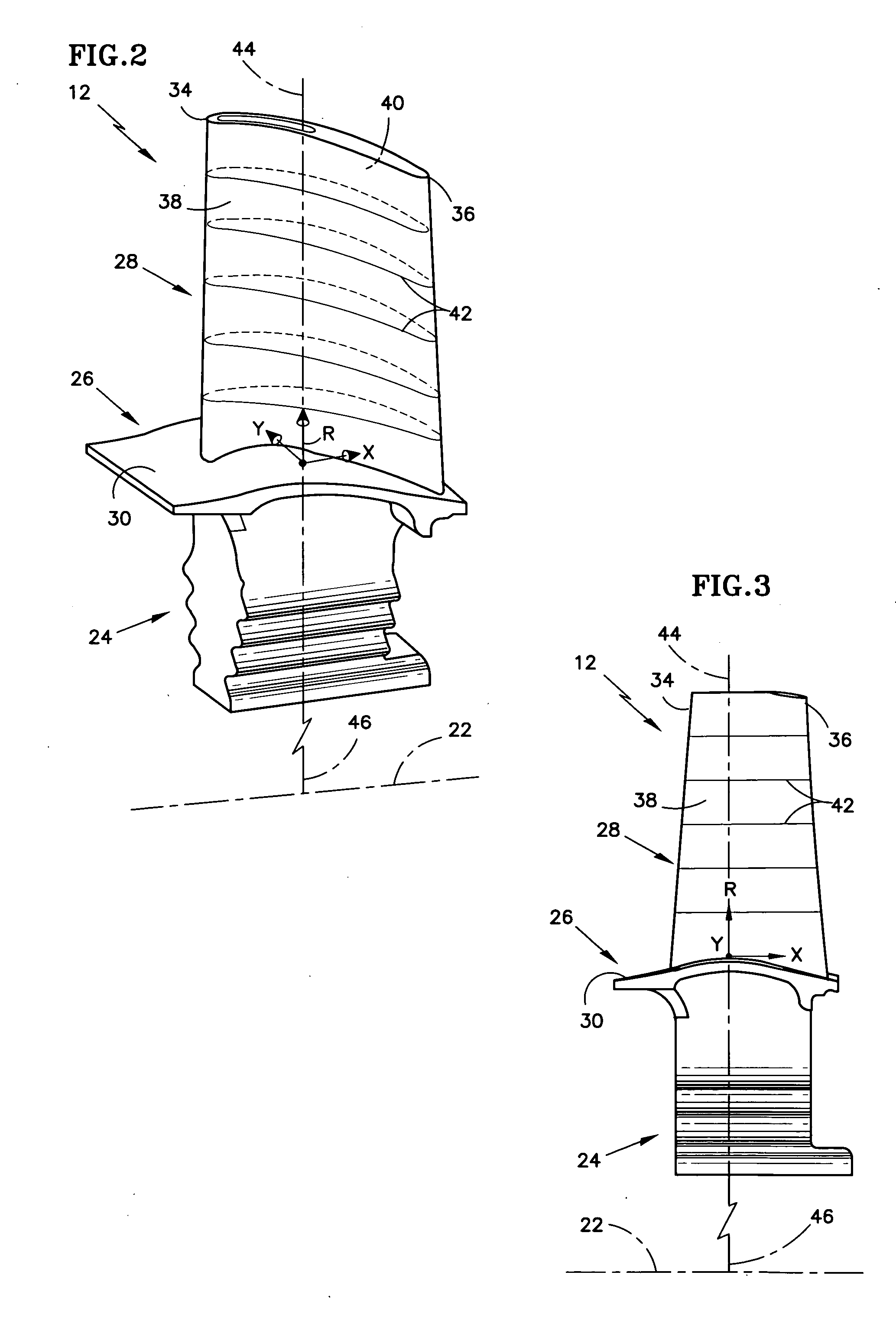

Airfoil profile with optimized aerodynamic shape

ActiveUS20060024168A1Improve turbine efficiencyImprove aerodynamic performanceEngine manufactureOther chemical processesTurbine bladeEngineering

Provided is an aerodynamic profile for use in gas turbine airfoil and a turbine blade comprising such profiles. The profiles counteract a reduction in area between adjacent airfoils due to an increase in coating thickness. A plurality of radial sections forms both coated and uncoated nominal profiles of the airfoils. The sections are located within a tolerance measured in any direction perpendicular to an airfoil stacking line extending radially from a central axis and defined by X, Y, and R Cartesian coordinate values in inches. The R values are measured perpendicular to a plane normal to the airfoil stacking line with R values of zero at a lowermost radial section and increasing in the radial direction. The X and Y values are measured perpendicular to the airfoil stacking line.

Owner:RTX CORP

Electrostatic chuck

InactiveUS20050168908A1High dielectric strengthImprove propertiesMolten spray coatingLayered productsOxide coatingDielectric strength

Owner:SHIN ETSU CHEM IND CO LTD

Investment casting

InactiveUS6769475B2Shorten the timeCoating thicknessFoundry mouldsFoundry coresInvestment castingWater insoluble

The present invention relates to improvements in and relating to investment casting. In particular, the invention provides a method of investment casting, comprising the steps of mixing a binder, a refractory material, and a quantity of water-insoluble organic fibres to form a slurry; coating an expendable pattern with a coat of said slurry; and drying said coat or allowing said coat to dry to form a shell. The present invention further provides a refractory slurry for use in the method of the invention, and a kit of ingredients for putting the method of the invention into effect.

Owner:BUNTROCK IND INC

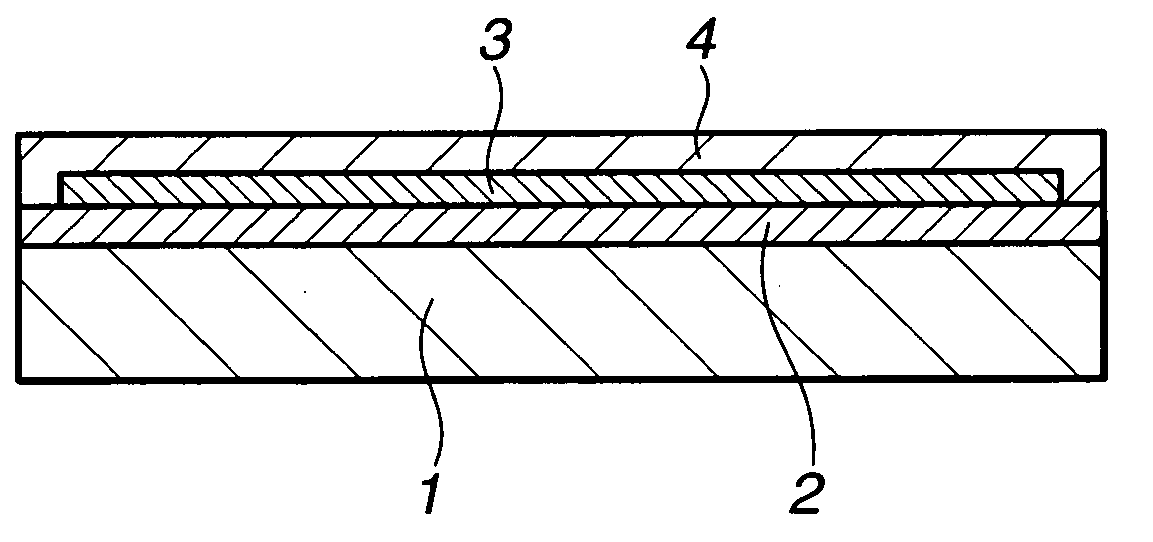

Drug coating with topcoat

InactiveUS20050208200A1Increase coating thicknessLow drug loadStentsSurgeryThrombogenicityDrug coating

A coating and method for a coating an implantable device or prostheses are disclosed. The coating includes an undercoat of polymeric material containing an amount of biologically active material, particularly heparin, dispersed therein. The coating further includes a topcoat which covers less than the entire surface of the undercoat and wherein the topcoat comprises a polymeric material substantially free of pores and porosigens. The polymeric material of the topcoat can be a biostable, biocompatible material which provides long term non-thrombogenicity to the device portion during and after release of the biologically active material.

Owner:BOSTON SCI SCIMED INC

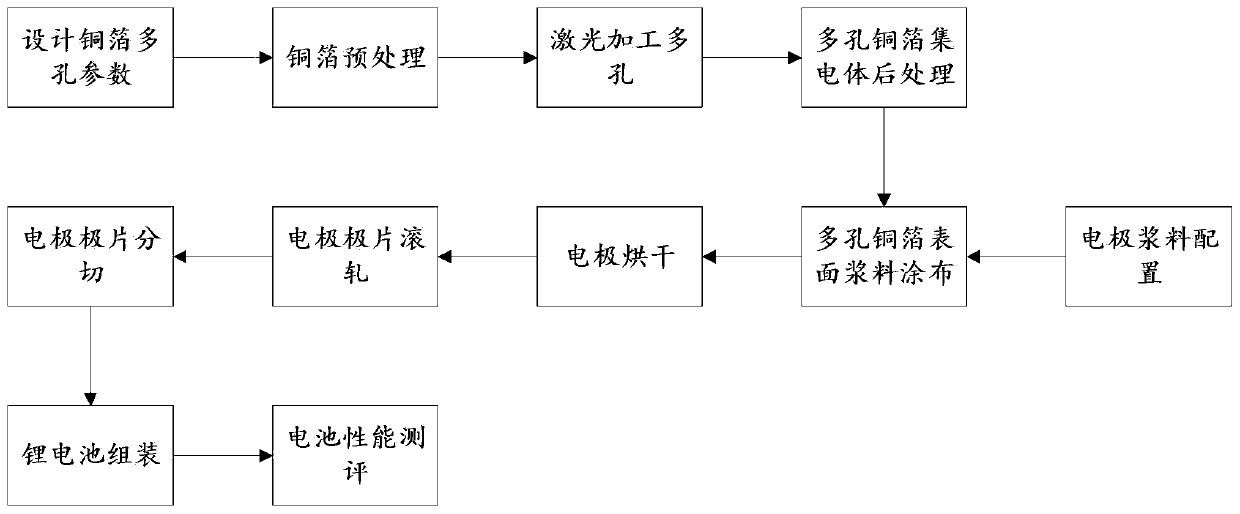

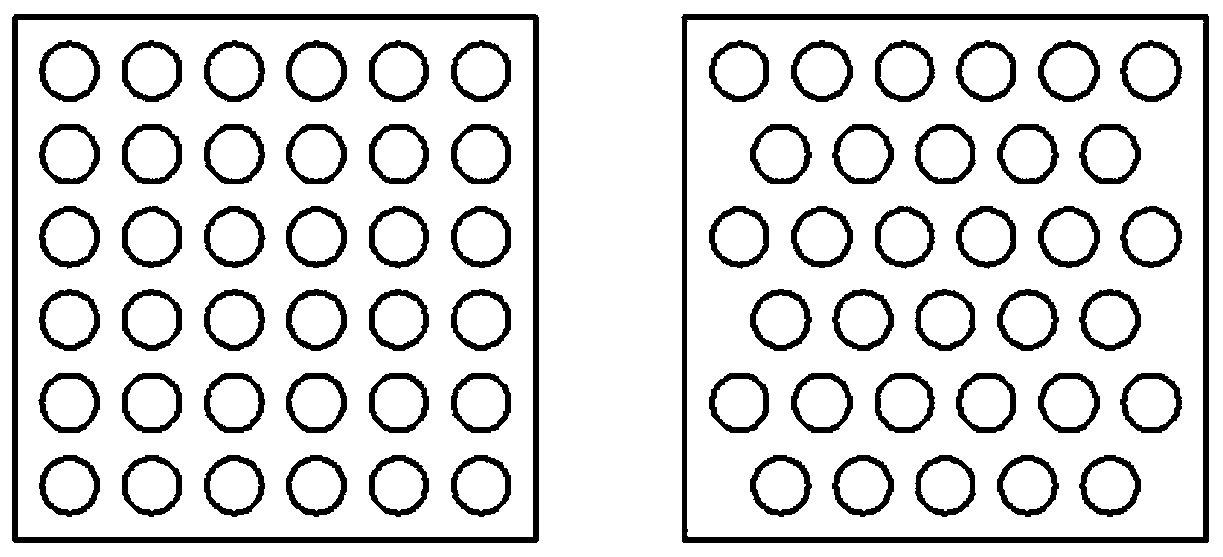

Method for preparing porous copper foil current collector of lithium battery

InactiveCN110492107ARealize multi-hole processingQuality improvementElectrode carriers/collectorsLaser beam welding apparatusComposite filmCopper foil

The embodiment of the invention discloses a method for preparing a porous copper foil current collector of a lithium battery, and relates to the technical field of lithium battery preparation. The method comprises the following steps: S1, pretreating a copper foil; S2, machining multiple holes in the copper foil in a laser machining mode; S3, carrying out post-treatment on the copper foil; S4, coating two sides of the copper foil with the electrode slurry; S5, drying the copper foil coated with the electrode slurry in a drying oven; and S6, performing rolling and slitting treatment on the dried copper foil to obtain a lithium battery electrode plate. According to the method, on the premise that the mechanical strength of the foil is guaranteed, the invalid quality of the copper foil current collector is reduced, the conductivity is improved, the adhesive force between the copper foil current collector and a negative active material composite film is enhanced, and the technical effectsof effectively improving the mechanical stability, the overall specific capacity, the rapid charging and discharging capacity and the long-term cycle life of the lithium battery electrode are achieved.

Owner:INNO LASER TECH CORP LTD +1

Rivet and coating technique

InactiveUS20050129932A1Avoiding any impairment of strengthSoft and more resilientRivetsSynthetic resin layered productsSolventHeat treated

A previously heat treated aluminum alloy rivet is sand blasted with aluminum oxide, washed with a corrosion resistant solution, dried, and then a coating is applied to the rivet. The coating includes solvent, resin, plasticizer and a corrosion inhibitor. The coating is cured at an elevated temperature below 300° F., preferably in the order of 250° F. for about an hour, or between one-half and one and one-half hours. The resultant rivet has a relatively thick gasket-like coating about 0.0007 to about 0.001 or 0.002 inch thick, and retains its high shear strength resulting from the initial pre-coating heat treatment. As an alternative pre-treatment, the rivets may be chromic acid anodized.

Owner:INNOVATIVE COATING TECH CORP

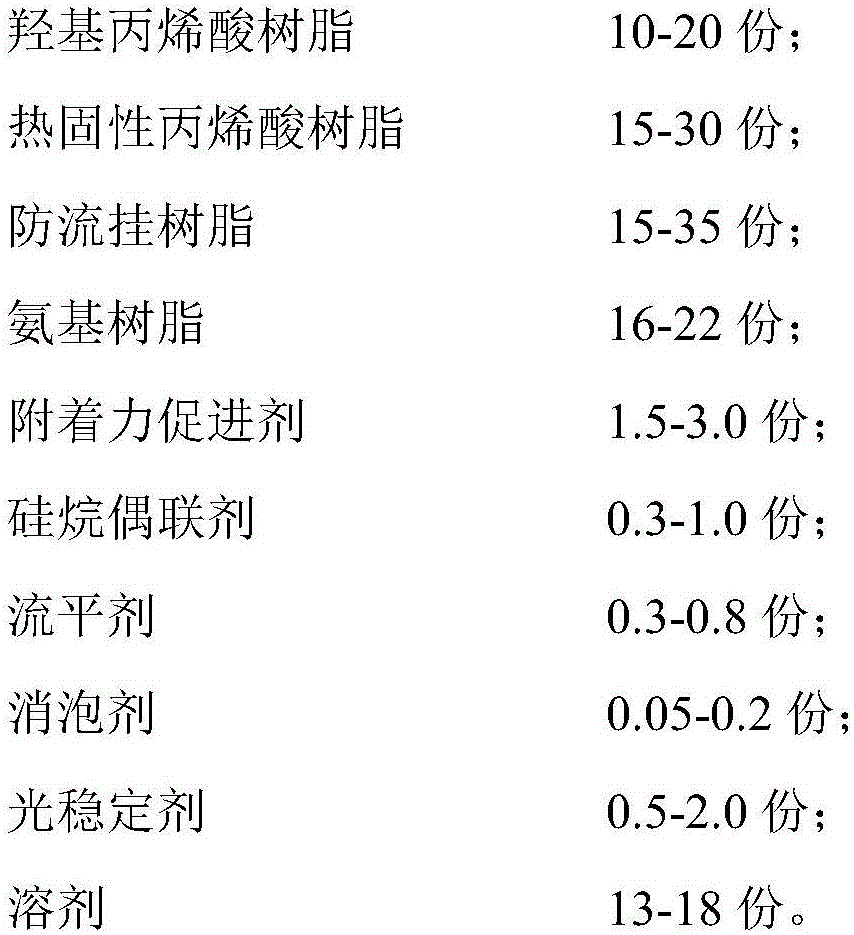

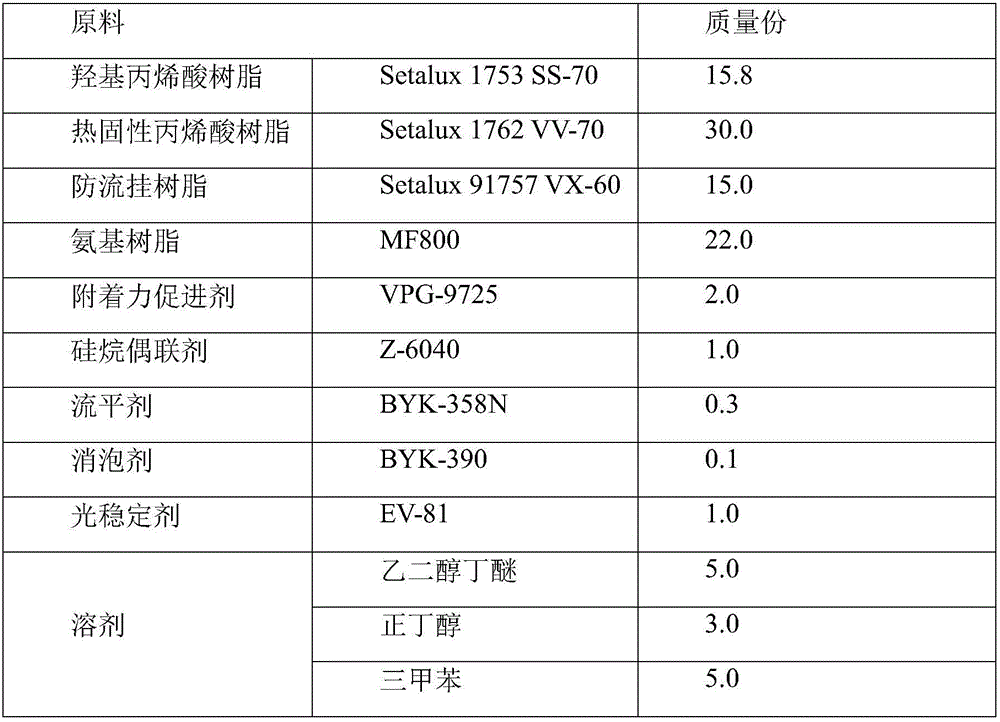

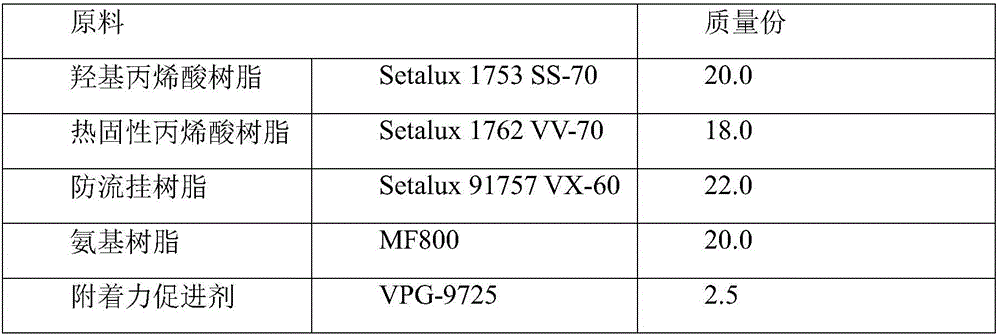

Aluminum alloy wheel finishing varnish capable of thick-film spraying and re-coating and preparation method thereof

The invention relates to an aluminum alloy wheel finishing varnish capable of thick-film spraying and re-coating, wherein the aluminum alloy wheel finishing varnish is prepared from the following components in parts by weight: 10-20 parts of hydroxyl acrylic resin, 15-30 parts of thermosetting acrylic resin, 15-35 parts of anti-sagging resin, 16-22 parts of amino resin, 1.5-3.0 parts of an adhesion promoter, 0.3-1.0 part of a silane coupling agent, 0.3-0.8 part of a leveling agent, 0.05-0.2 part of a defoaming agent, 0.5-2.0 parts of a light stabilizer, and 13-18 parts of a solvent. The invention also provides a preparation method for the aluminum alloy wheel finishing varnish capable of thick-film spraying and re-coating. The aluminum alloy wheel finishing varnish capable of thick-film spraying and re-coating has the relatively large advantages in salt fog resistance, water resistance, recoatability and the like, and has excellent re-coating adhesive force and good weather resistance.

Owner:广东四方威凯新材料有限公司

Cutting tool

ActiveUS20080286608A1High porosityMinimize formationPigmenting treatmentRecord information storageCemented carbideWear resistance

The invention provides a single or a multilayer PVD coated sharp edged cutting tool, which can at the same time exhibit satisfactory wear and thermochemical resistance as well as resistance to edge chipping. The cutting tool comprises a sintered body made of a cemented carbide, a CBN, a cermet or a ceramic material having a cutting edge with an edge radius Re, a flank and a rake face and a multilayer coating consisting of a PVD coating comprising at least one oxidic PVD layer covering at least parts of the surface of the sintered body. In one embodiment the edge radius Re is smaller than 40 μm, preferably smaller than or equal to 30 μm. The covered parts of the surface preferably comprise at least some parts of the sharp edge of the sintered body.

Owner:OERLIKON SURFACE SOLUTIONS AG PFAFFIKON

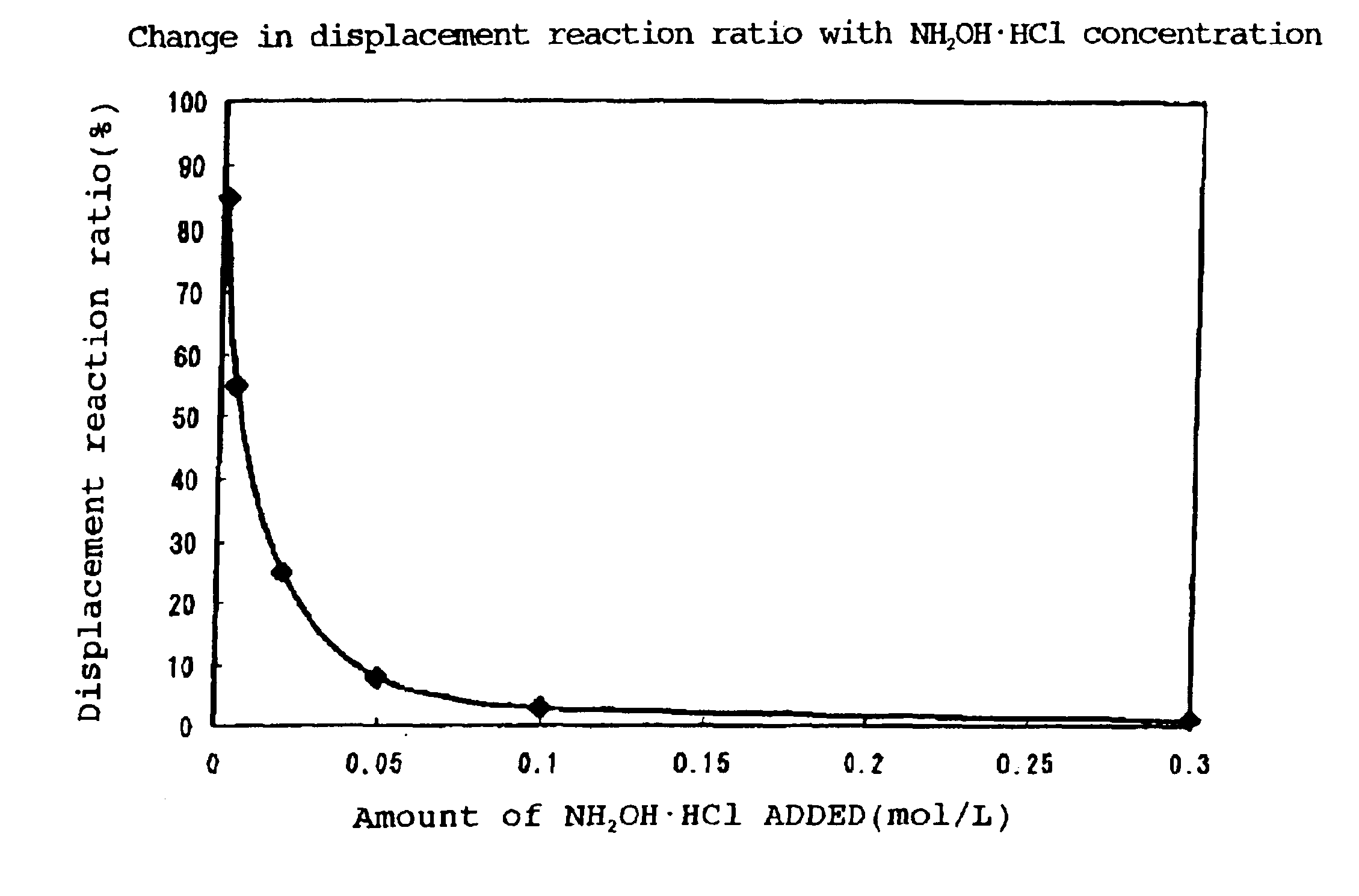

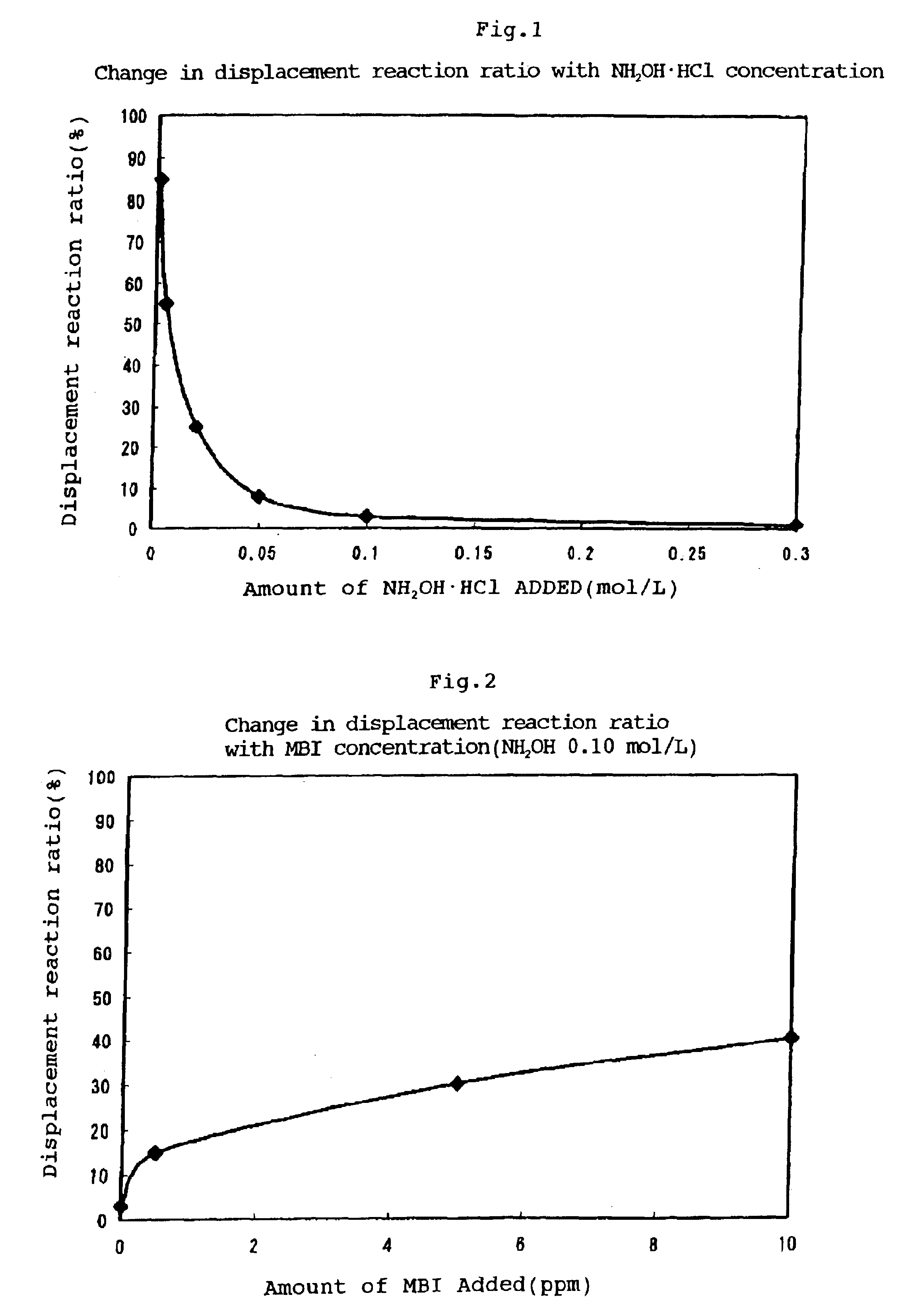

Electroless gold plating solution

InactiveUS6855191B2Good adhesionIncrease coating thicknessLiquid surface applicatorsAnti-corrosive paintsDisplacement reactionsPorosity

An electroless gold plating solution is provided in which an amount of gold deposited by a displacement reaction is at least 15 μg / cm2, and the electroless gold plating solution includes a reducing agent that is oxidized by gold, and a reducing agent that is of the same type as or is a different type from the above reducing agent and is oxidized by a substrate metal. The solution can form a uniform gold coating having good adhesion and low porosity in one step.

Owner:KANTO CHEM CO INC

Investment casting

InactiveUS20020195225A1Thick coatingIncrease coating thicknessFoundry mouldsFoundry coresInvestment castingFiber

The present invention relates to improvements in and relating to investment casting. In particular, the invention provides a method of investment casting, comprising the steps of mixing a binder, a refractory material, and a quantity of water-insoluble organic fibers to form a slurry; coating an expendable pattern with a coat of said slurry; and drying said coat or allowing said coat to dry to form a shell. The present invention further provides a refractory slurry for use in the method of the invention, and a kit of ingredients for putting the method of the invention into effect.

Owner:BUNTROCK IND INC

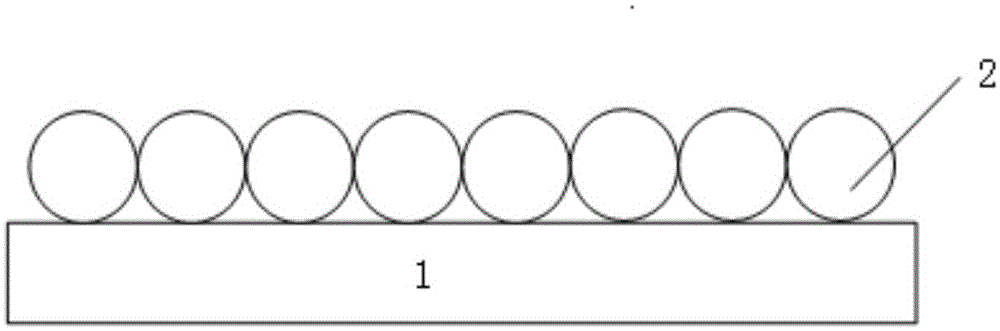

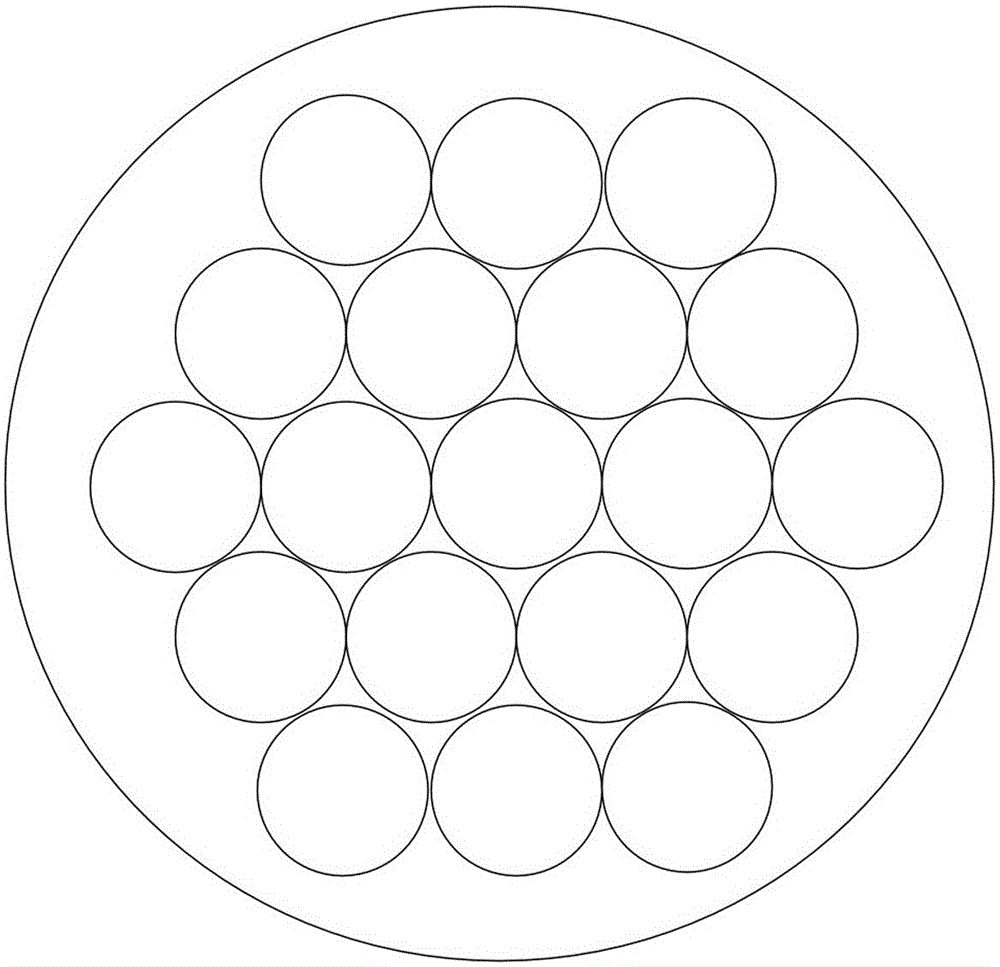

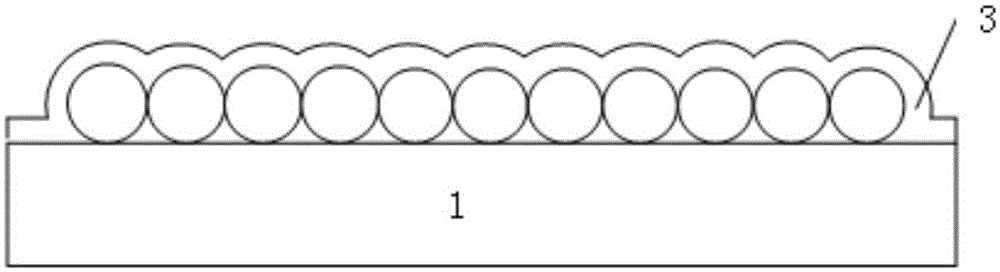

Metal nanoparticle structure array and preparation method thereof

ActiveCN106365117AIncrease the areaHigh densityMaterial nanotechnologyIndividual molecule manipulationPolystyreneVolumetric Mass Density

The invention discloses a metal nanoparticle structure array and a preparation method thereof. The preparation method comprises the following steps: (1) preparing an ordered polystyrene nano spherical dense arrangement; (2) depositing a metal film; and (3) preparing a single-layer ordered metal nanoparticle structure array. The invention further discloses a method for preparing a double-layer or a multi-layer ordered metal nanoparticle structure array. An alumina film is arranged between every two adjacent layers of the ordered metal nanoparticle structure array of the metal nanoparticle structure array disclosed by the invention. The preparation method disclosed by the invention is simple in process, economical and efficient, controllable in nano size gaps and good in repeatability, and the metal nanoparticle structure array has the advantages of being large in area, high in density, controllable in nano size gaps, and the like.

Owner:NAT UNIV OF DEFENSE TECH

Method of preparing high-temperature oxidation-resistant coating on surface of refractory metal material

ActiveCN106048488AHigh bonding strengthIncrease coating thicknessMolten spray coatingThermal sprayingNiobium

The invention discloses a method of preparing a high-temperature oxidation-resistant coating on the surface of a refractory metal material. The method is characterized in that by adopting a plasma arc spray welding technology, a Mo-Si-B alloy high-temperature oxidation-resistant coating is prepared on the surface of refractory metal. With the adoption of Mo-Si-B alloy powder containing required components, and by controlling a dilution rate, coating components can be controlled, and a foundation is established for the flexible design of the coating components; compared with the traditional pack cementation method, thermal spraying method and magnetron sputtering method, with the adoption of the plasma arc spray welding technology, the coating bonding strength, the coating thickness and the coating compactness are improved obviously, and a guarantee is provided for the Mo-Si-B alloy high-temperature oxidation-resistant coating which is long in service life. According to the Mo-Si-B alloy high-temperature oxidation-resistant coating, the oxidation resistance at high temperature of refractory metal like molybdenum, niobium, tantalum and alloys of molybdenum, niobium and tantalum is improved effectively, and the service lives of refractory metal spare parts are prolonged obviously.

Owner:XIAN UNIV OF TECH

Coated Pet Chew and Method of Making

InactiveUS20100047397A1Extended shelf lifeLength of timeMeat/fish preservationConfectioneryNuclear medicine

Owner:SERGEANTS PET CARE PRODS

Method for producing thick crack-free coatings from hydrogen silsesquioxane resin

InactiveUS6022625AIncrease coating thicknessShorter and low temperaturePretreated surfacesSemiconductor/solid-state device manufacturingCrack freePhysical chemistry

This invention pertains to a method for producing crack-free, insoluble, greater than 1.25 mu m thick coatings from hydrogen silsesquioxane resin compositions. The method for producing the coating comprises applying a fillerless hydrogen silsesquioxane resin composition onto a substrate and thereafter heating the hydrogen silsesquioxane resin at a temperature of less than 500 DEG C. for a controlled period of time to produce the crack-free coating having a thickness of greater than 1.25 mu m. The resins may be cured in an inert or oxygen containing environment.

Owner:DOW CORNING CORP

Conductive Paste and Wiring Board Using Same

InactiveUS20090042001A1Forming accuratelyIncrease conductive resistanceConductive materialSynthetic resin layered productsConductive pasteBoiling point

Owner:SUMITOMO ELECTRIC IND LTD

Low temperature curing coating composition containing sag control agent and use thereof

ActiveUS20150337166A1Extended shelf lifeHigh glossPretreated surfacesPolyurea/polyurethane coatingsLow temperature curingMelamine

The present disclosure is directed to a coating composition for producing coatings sag-free at high coating thicknesses, being quick dry and having good appearance. This disclosure is further directed to a coating composition comprising a crosslinking activator comprising: a) one or more alkylated melamines that are essentially unreactive to a polyisocyanate, and b) a polyurea sag control agent formed by reacting an amine and an isocyanate in the presence of the alkylated melamines. The coating composition can be used to form coating layers having a sag-free wet coating thickness in a range of from 10 to 36 mil (about 0.25 to 0.91 mm) The coating composition can be particularly suitable for vehicle coatings.

Owner:AXALTA COATING SYST IP CO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com