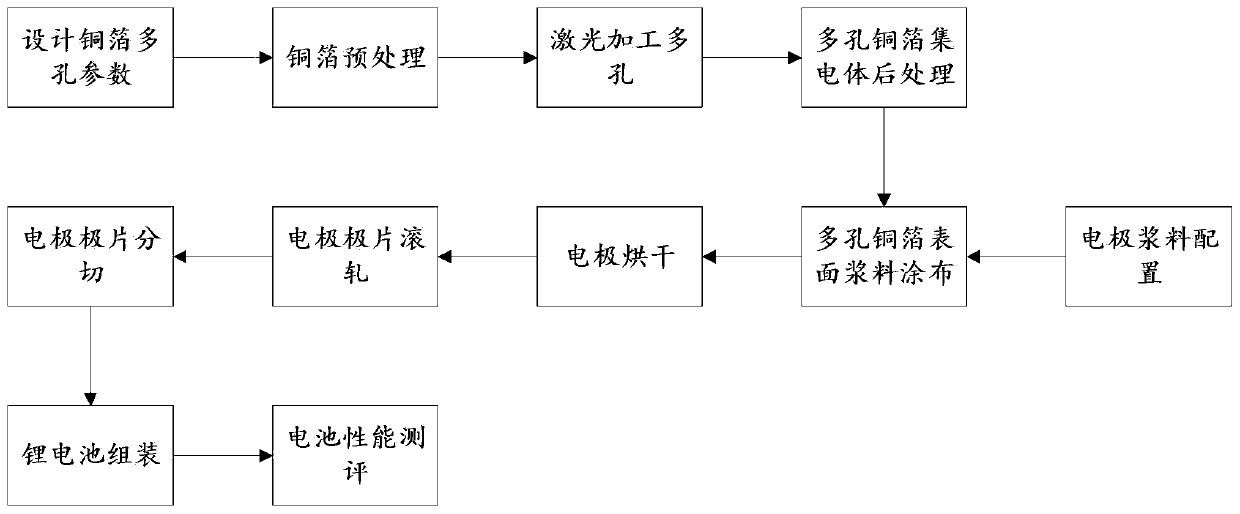

Method for preparing porous copper foil current collector of lithium battery

A lithium battery, porous copper technology, applied in battery electrodes, electrode carriers/current collectors, circuits, etc., can solve the problems of safety performance, rate performance and cycle stability deterioration, electrical contact reduction, conductive agent and binder. Problems such as poor adhesion effect, to achieve the effect of improving mechanical stability, reducing weight ratio, and improving three-dimensional transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

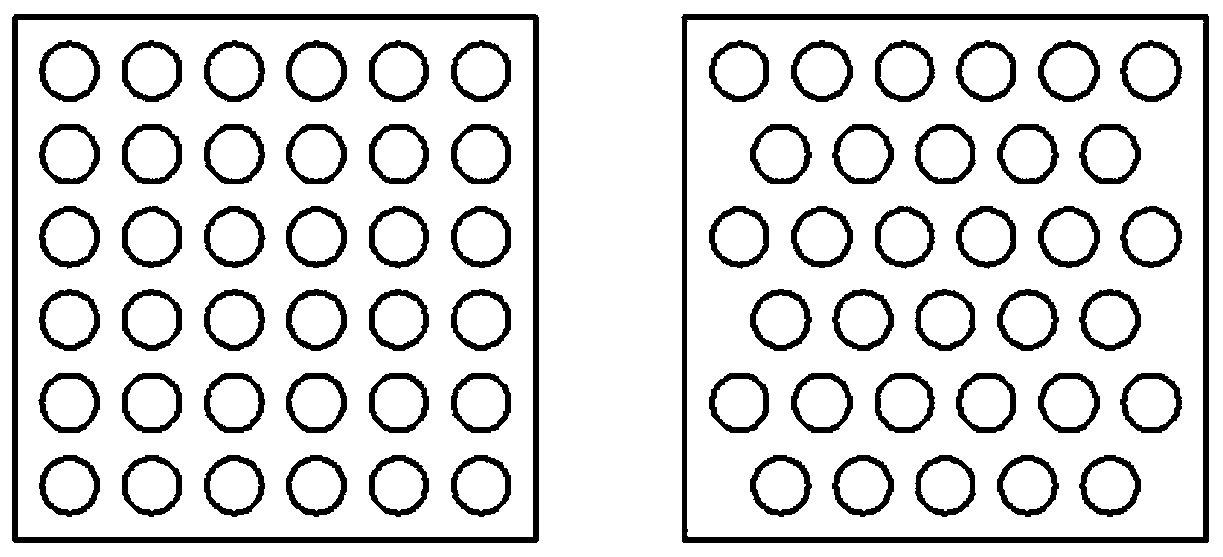

specific Embodiment 1

[0085] The porous copper foil current collector prepared according to the method for preparing a lithium battery porous copper foil current collector provided in the embodiment of the present invention, wherein the thickness of the copper foil is 12um, and the parameters of the laser used are: the wavelength of the laser is 355nm, the pulse width It is 45ns and the power is 20W. The scanning speed of the galvanometer scanning system is 5000mm / s; the porous shape of the copper foil current collector is circular, the aperture is 10um, and the hole spacing n is d≤n≤10d; the electrode of the copper foil current collector The slurry is prepared from negative electrode active material, conductive agent, binder and organic solvent at a mass ratio of 95:3:2, wherein the negative electrode active material is graphite, and the coating thickness of the electrode slurry is 30 μm.

specific Embodiment 2

[0087] The porous copper foil current collector prepared according to the method for preparing a lithium battery porous copper foil current collector provided in the embodiment of the present invention, wherein the thickness of the copper foil is 6um, and the laser parameters used are: the laser wavelength is 355nm, the pulse width It is 45ns and the power is 3W. The scanning speed of the galvanometer scanning system is 3000mm / s; the porous shape of the copper foil current collector is square, the aperture is 80um, and the hole spacing n is d≤n≤10d; the electrode slurry of the copper foil current collector The material is made of negative electrode active material, conductive agent, binder and organic solvent at a mass ratio of 80:10:10, wherein the negative electrode active material is silicon and silicon oxide, and the thickness of the electrode slurry coating is 60 μm.

specific Embodiment 3

[0089] The porous copper foil current collector prepared according to the method for preparing a lithium battery porous copper foil current collector provided in the embodiment of the present invention, wherein the thickness of the copper foil is 9um, and the laser parameters used are: the laser wavelength is 355nm, the pulse width It is 25ns and the power is 10W. The scanning speed of the galvanometer scanning system is 4000mm / s; the porous shape of the copper foil current collector is pentagonal and hexagonal, the aperture is 40um, and the hole spacing n is d≤n≤10d; the copper foil current collector The electrode slurry of the body is made of negative electrode active material, conductive agent, binder and organic solvent according to the mass ratio of 85:8:7, wherein the negative electrode active material is tin, tin oxide and transition metal oxide, and the electrode slurry The coating thickness was 130 μm.

[0090] see image 3 , which is a photo of a porous copper foil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com