Aluminum alloy wheel finishing varnish capable of thick-film spraying and re-coating and preparation method thereof

A technology of overcoating varnish and aluminum alloy, applied in coatings, anti-corrosion coatings, etc., can solve the problems of one-time adhesion rework adhesion deviation, easy to appear silk rust, high painting cost, achieve ideal paint film hardness, paint film The effect of increased thickness and improved anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

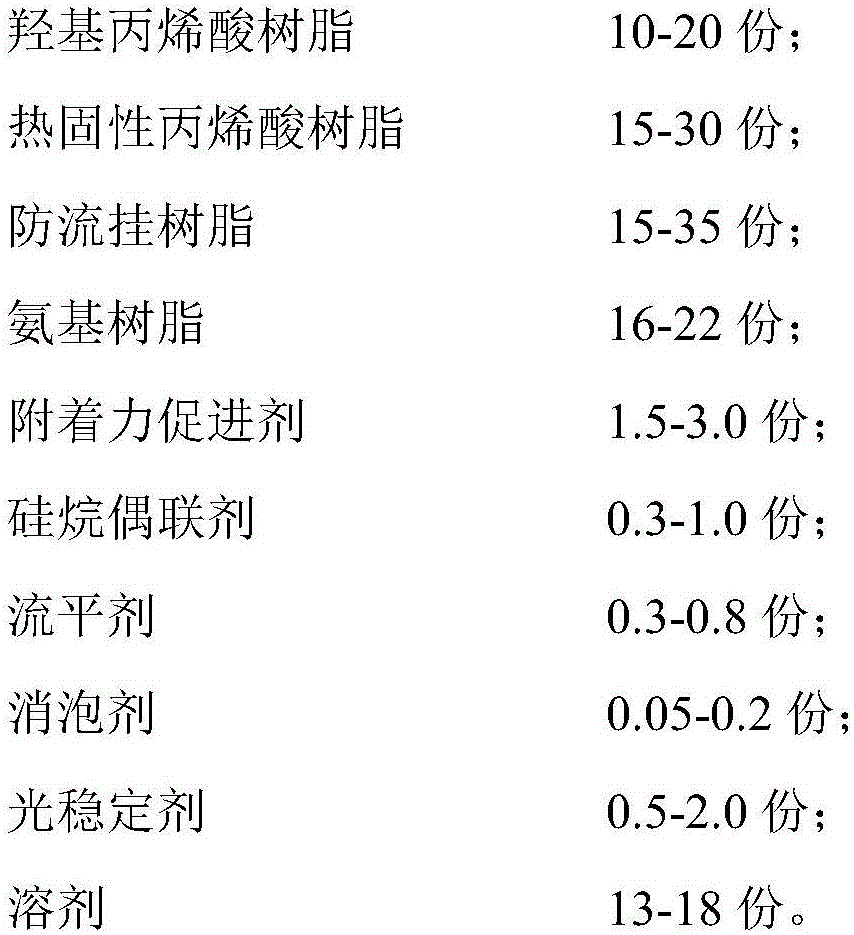

[0026] The thick-film spraying recoatable aluminum alloy wheel finish varnish of the present embodiment is made up of following composition:

[0027] Table 1: Thick-film spraying recoatable aluminum alloy wheel finish varnish (embodiment 1)

[0028]

[0029] The preparation method of the thick film spraying recoatable aluminum alloy wheel finish varnish of the present embodiment may further comprise the steps:

[0030] S1: Add hydroxyl acrylic resin, thermosetting acrylic resin, anti-sagging resin, amino resin, and solvent into the reaction kettle in sequence, and disperse for 20 minutes at a speed of 500 RPM;

[0031] S2: Add the adhesion promoter, silane coupling agent, leveling agent, defoamer, and light stabilizer into the reaction kettle with a rotation speed of 600 RPM while dispersing, and disperse for 20 minutes at a rotation speed of 1500 RPM;

[0032] S3: Use a 5 μm filter bag filter to filter the package.

Embodiment 2

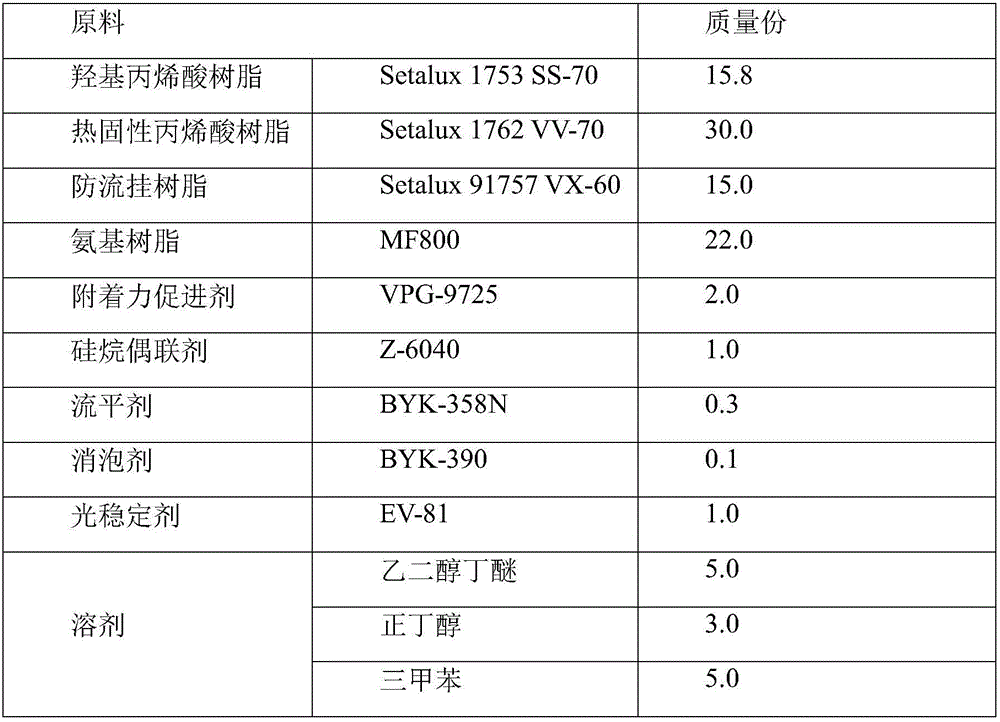

[0034] The thick-film spraying recoatable aluminum alloy wheel finish varnish of the present embodiment is made up of following composition:

[0035] Table 2: Thick-film spraying recoatable aluminum alloy wheel finish varnish (embodiment 2)

[0036]

[0037]

[0038] The preparation method of the thick film spraying recoatable aluminum alloy wheel finish varnish of the present embodiment may further comprise the steps:

[0039] S1: Add hydroxyl acrylic resin, thermosetting acrylic resin, anti-sag resin, amino resin, and solvent into the reaction kettle in sequence, and disperse for 10 minutes at a speed of 1500 RPM;

[0040] S2: Add the adhesion promoter, silane coupling agent, leveling agent, defoamer, and light stabilizer into the reaction kettle with a rotation speed of 400 RPM while dispersing, and disperse for 30 minutes at a rotation speed of 600 RPM;

[0041] S3: Use a 10 μm filter bag filter to filter the package.

Embodiment 3

[0043] The thick-film spraying recoatable aluminum alloy wheel finish varnish of the present embodiment is made up of following composition:

[0044] Table 3: Thick-film spraying recoatable aluminum alloy wheel finish varnish (embodiment 3)

[0045]

[0046] The preparation method of the thick film spraying recoatable aluminum alloy wheel finish varnish of the present embodiment may further comprise the steps:

[0047]S1: Add hydroxyl acrylic resin, thermosetting acrylic resin, anti-sagging resin, amino resin, and solvent into the reaction kettle in sequence, and disperse for 15 minutes at a speed of 1000 RPM;

[0048] S2: Add the adhesion promoter, silane coupling agent, leveling agent, defoamer, and light stabilizer into the reaction kettle with a rotation speed of 500RPM while dispersing, and disperse for 25min at a rotation speed of 1000RPM;

[0049] S3: Use a 15 μm filter bag filter to filter the package.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com