Slurry composition for negative electrodes of lithium ion secondary batteries, negative electrode for lithium ion secondary batteries, and lithium ion secondary battery

A secondary battery, lithium ion technology, used in secondary batteries, small-sized batteries/batteries, large-sized batteries/batteries, etc. High, powder drop reduction, high capacitance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

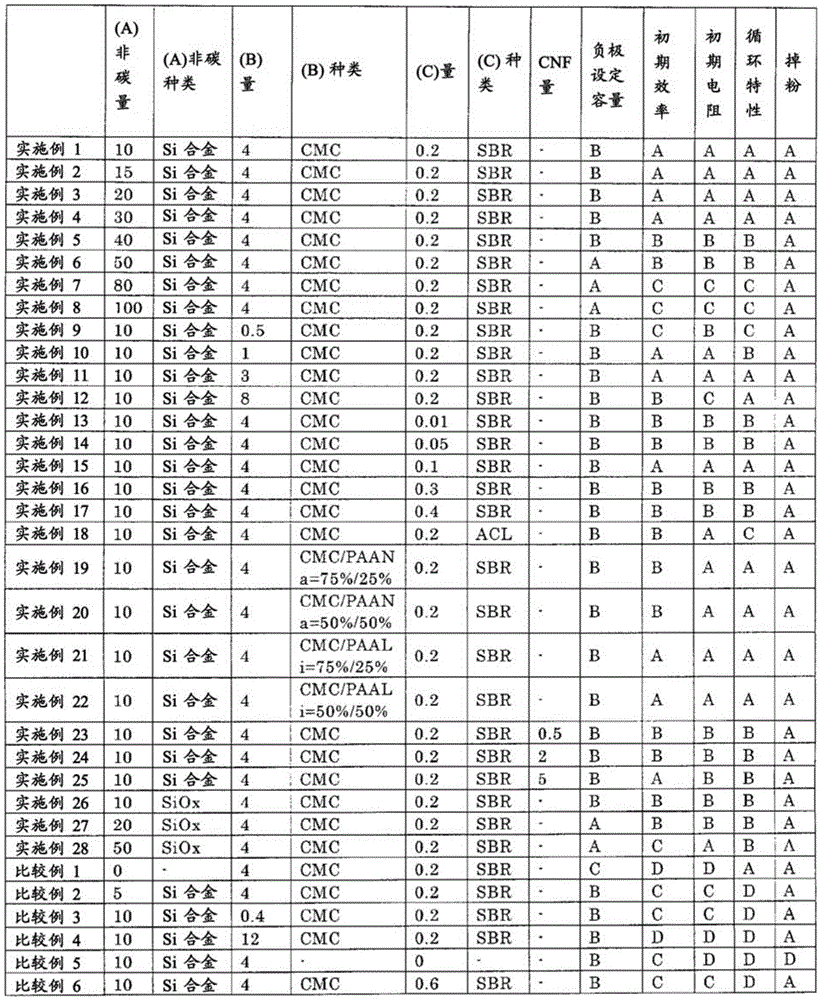

Examples

preparation example Construction

[0129] [1.7. Preparation of slurry composition]

[0130] The slurry composition of the present invention can be prepared by dispersing the above-mentioned components in an aqueous medium as a dispersion medium after optionally premixing them partially; The adhesive composition of the object (C) is prepared by dispersing the adhesive composition and the active material (A) in an aqueous medium as a dispersion medium. From the viewpoint of the dispersibility of each component in the slurry composition, it is preferable to prepare the slurry composition by dispersing each of the above-mentioned components in an aqueous medium as a dispersion medium. Specifically, it is preferable to mix the above-mentioned components with an aqueous medium by using a mixer such as a ball mill, a sand mill, a bead mill, a pigment disperser, an attritor, an ultrasonic disperser, a homogenizer, a planetary mixer, FILMIX, etc. to prepare the slurry composition. The mixing of each of the above-menti...

Embodiment

[0155] Hereinafter, although this invention is demonstrated concretely based on an Example, this invention is not limited to these Examples. In the following description, unless otherwise specified, "%" and "part" which show an amount are based on mass. In addition, the operations described below were performed under conditions of normal temperature and normal pressure unless otherwise specified.

[0156] In Examples and Comparative Examples, the glass transition temperature and gel content of the particulate polymer (C), negative electrode set capacity, initial efficiency, initial resistance, cycle characteristics, and powder shedding were evaluated using the following methods, respectively .

[0157]

[0158] The aqueous dispersion containing the particulate polymer (C) was dried in an environment of 50% humidity and 23 to 26° C. for 3 days to obtain a film with a thickness of 1±0.3 mm.

[0159] The film was dried in a vacuum dryer at 60° C. for 10 hours.

[0160] Then,...

manufacture example 1

[0199] [Production Example 1: Preparation of Particulate Polymer (C1)]

[0200] Add 65 parts of styrene as an aromatic vinyl monomer, 35 parts of 1,3-butadiene as an aliphatic conjugated diene monomer, and 35 parts of 1,3-butadiene as an ethylenically unsaturated carboxylic acid 2 parts of itaconic acid as a monomer, 1 part of 2-hydroxyethyl acrylate as a hydroxyl-containing monomer, 0.3 parts of tert-dodecyl mercaptan as a molecular weight regulator, and dodecylbenzenesulfonic acid as an emulsifier 5 parts of sodium, 150 parts of ion-exchanged water as a solvent, and 1 part of potassium persulfate as a polymerization initiator were sufficiently stirred, then heated to 55° C. to initiate polymerization.

[0201] When the monomer consumption reached 95.0%, cooling was performed to terminate the reaction. To the aqueous dispersion containing the thus obtained polymer, 5% aqueous sodium hydroxide solution was added to adjust the pH to 8. Then, unreacted monomers were removed by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com