Shorting switch and system to eliminate arcing faults in power distribution equipment

A short-circuit switch, flashover fault technology, applied in electrical switches, circuit devices, emergency protection circuit devices, etc., can solve problems such as expensive purchase and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

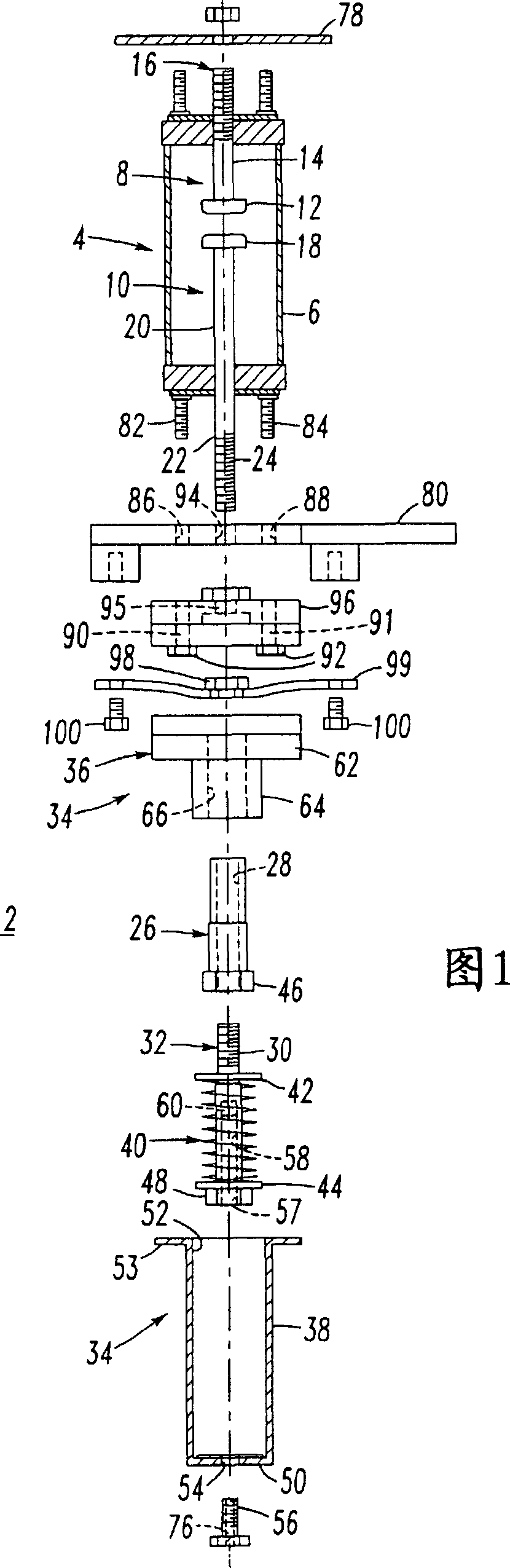

[0052] Referring to Figure 1, a single phase, spring loaded, high speed vacuum short circuit switch 2 eliminates flashover faults within a power distribution device (not shown). The shorting switch 2 comprises a single vacuum switch, such as a conventional vacuum interrupter (VI) 4 (e.g., a 3" VI bottle manufactured by Eaton / Catella-Hammer). As is known, the vacuum interrupter 4 comprises a vacuum-tight enclosure or A sealed vacuum chamber (e.g., a vacuum bottle 6) that contains a fixed contact assembly 8 and a movable contact assembly 10 that can be in electrical contact with the fixed contact assembly 8. Movement along the longitudinal axis is between a closed circuit position (not shown) and an open circuit position (shown in FIG. 1 ) spaced apart from the fixed contact assembly 8 .

[0053] The fixed contact assembly 8 includes a fixed contact 12 sealed in the airtight vacuum bottle 6 and a conductor 14 connected to one end of the fixed contact. The electrical conductor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com