Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

41results about How to "Excellent etching properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Etching Agent Composite Used For Etching Conductive Multi-layer Film And Etching Method Using The Same

InactiveCN102409342AReduce manufacturing costShorten production timeSemiconductor/solid-state device manufacturingSurface treatment compositionsAcetic acidPhosphoric acid

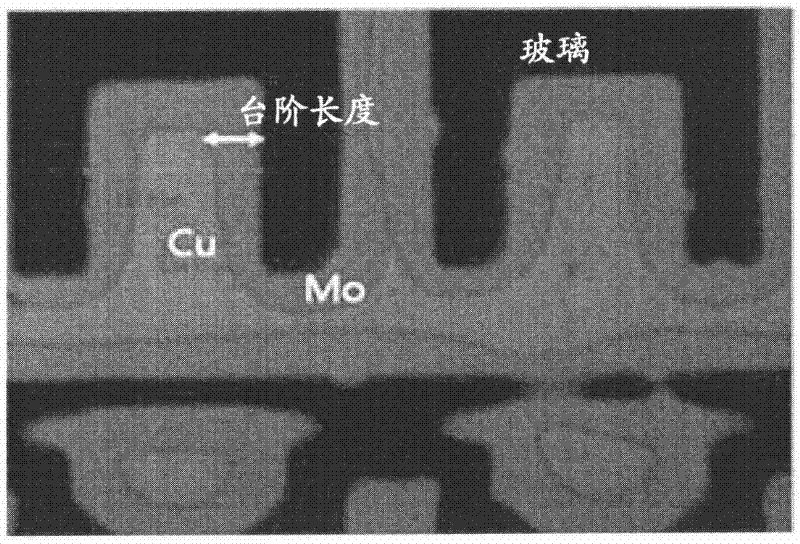

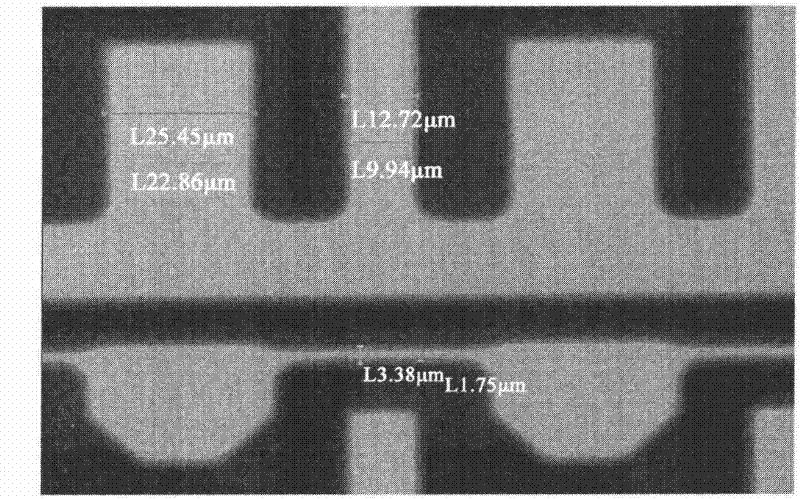

The invention discloses an etching agent composite used for etching conductive multi-layer film and an etching method using the same. The etching agent composite includes, by weight, 50 to 80 percents phosphoric acid of a total weight of the composite, 0.5 to 10 percents nitric acid, 5 to 30 percents acetic acid, 0.01 to 5 percents imidazole, and the rest is water. The multi-layer film includes at least one copper or copper alloy layer, and at least one molybdenum or molybdenum alloy layer. The multi-layer film can be a Cu / Mo lamination film, a Cu / Mo alloy lamination film or a Cu alloy / Mo alloy lamination film. The multi-layer film can be etched by the etching agent composite efficiently and well. Besides, a constitutional layer of the multi-layer film can be etched in batch. The imidazole is an annexing agent working as a reaction control agent of a Cu / Mo primary battery.

Owner:PLANSEE SE

Transparent electrode made from indium-zinc-oxide and etchant for etching the same

InactiveUS7279765B2Excellent etching propertiesShort timeAfter-treatment detailsElectrolytic capacitorsLiquid-crystal displayIndium zinc oxide

A pixel electrode employs a transparent electrode made from indium-zinc-oxide (IZO) that is capable of preventing damage and bending thereof. In a liquid crystal display device containing pixel electrodes, the transparent electrode is made from indium-zinc-oxide (IZO) having an amorphous structure so that it can be etched within a short period of time with a low concentration of etchant. Accordingly, it is possible to prevent damage and bending of the transparent electrode upon the patterning thereof.

Owner:LG DISPLAY CO LTD

Etchant composition, method for forming metal wire patterns and method for manufacturing array substrate

InactiveCN106148961AExtend the lifespanSimplify the etch processNon-linear opticsOrganic acidLiquid-crystal display

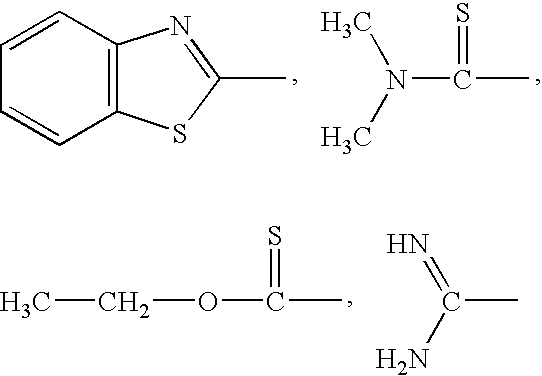

The invention discloses an etchant composition used for copper layers and titanium layers and a method for manufacturing an array substrate of a liquid crystal display using the etchant composition. The etchant composition comprises 0.5 wt.% to 20 wt.% of persulfate, 0.01 wt.% to 2 wt.% of a fluorine compound, 1 wt.% to 10 wt.% of inorganic acid (salt), 5 wt.% to 20 wt.% of organic acid (salt), 0.1 wt.% to 5 wt.% of a cyclamine compound containing alkyl (containing 1 to 5 carbon atoms) tetrazole, 0.1 wt.% to 10 wt.% of a sulfonic acid compound and the balance of water. Thus, the copper layers and the titanium layers can be evenly etched in batches at a high etching speed, and even when the number of treated sheets is increased, the inclination angles of etched patterns are reduced.

Owner:DONGWOO FINE CHEM CO LTD

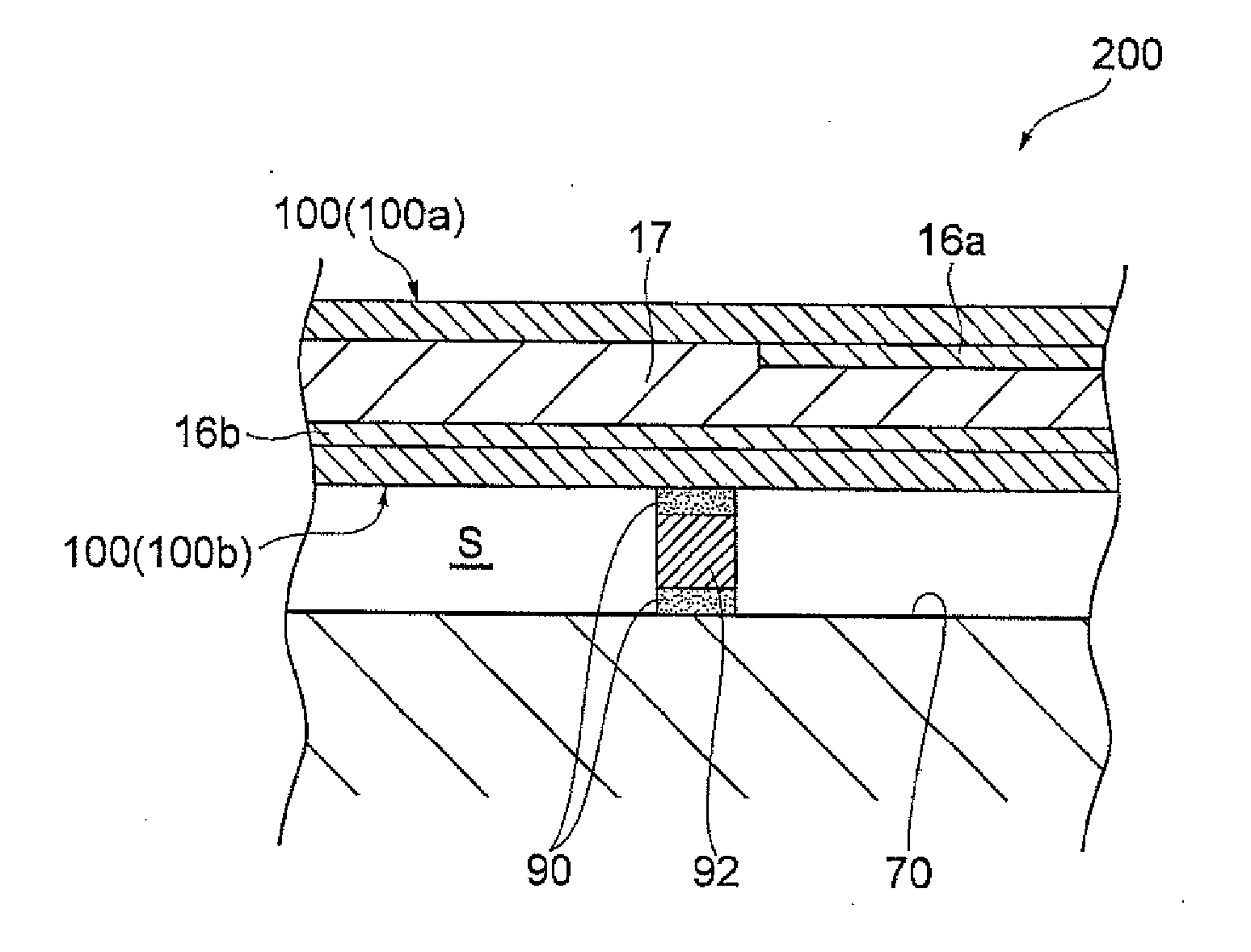

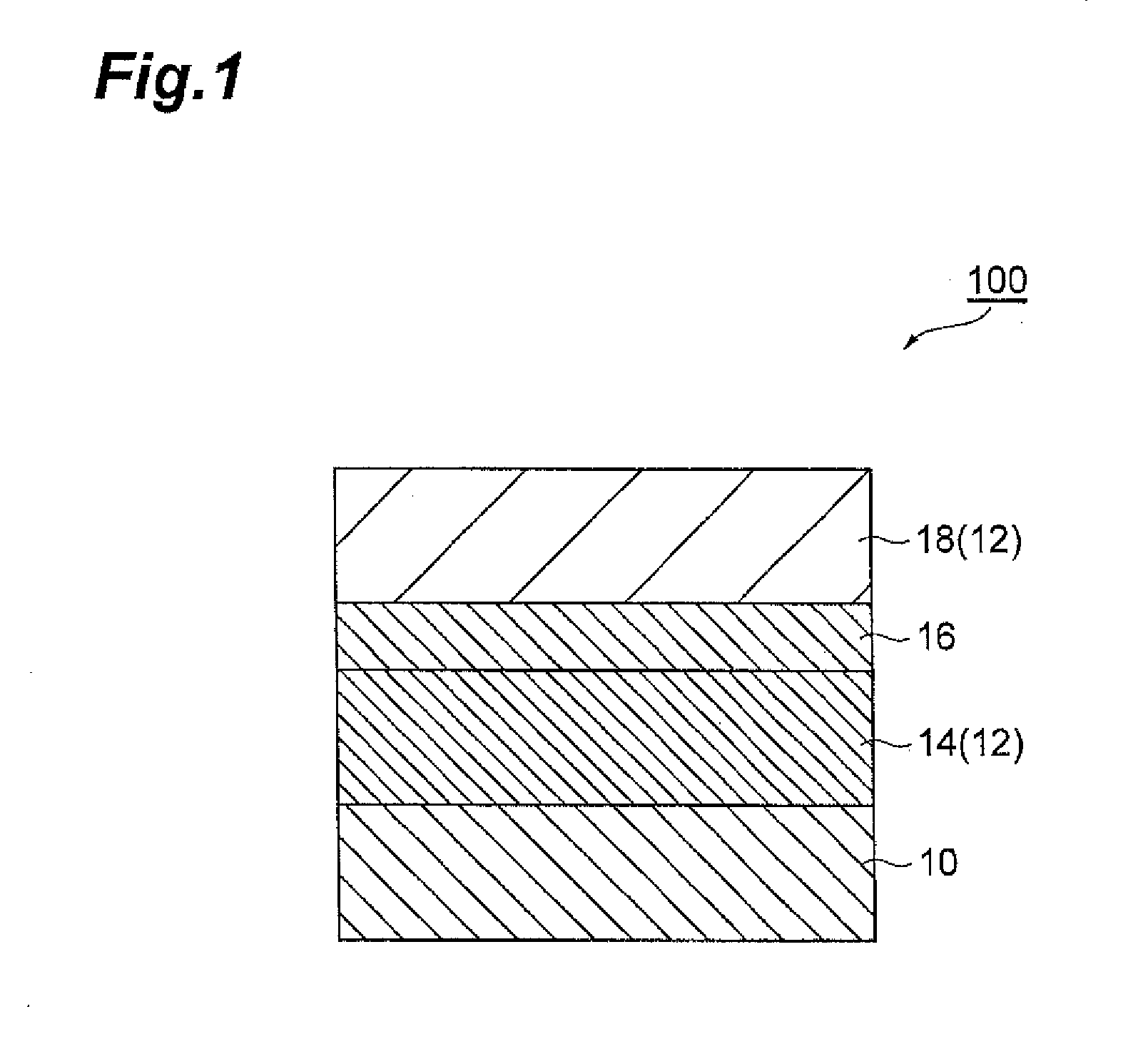

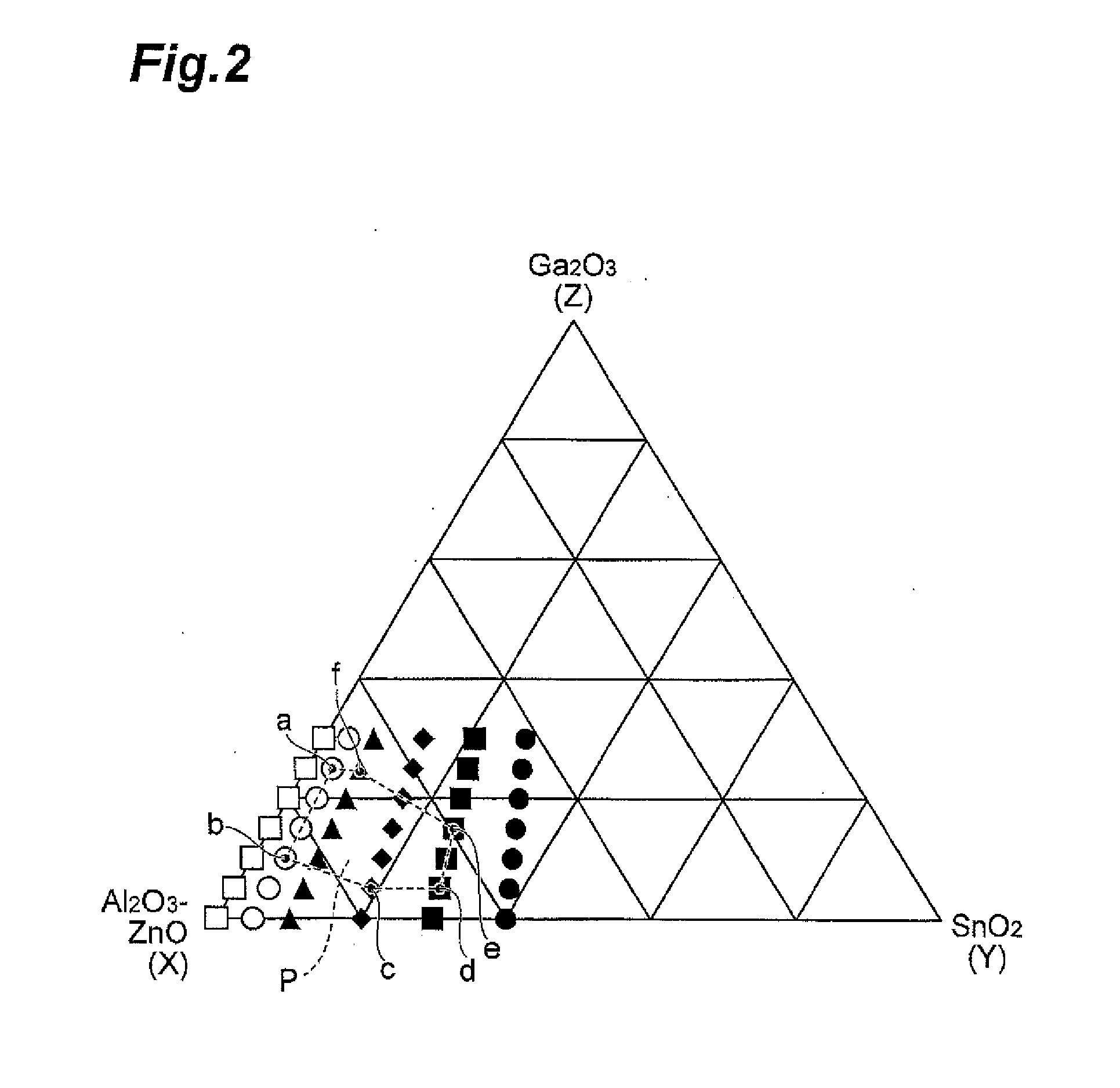

Transparent conductor and touch panel

ActiveUS20150205409A1Display clearExcellent storage reliabilityDigital data processing detailsVacuum evaporation coatingElectrical conductorFour component

The transparent conductor includes a transparent substrate, a first metal oxide layer, a metal layer, and a second metal oxide layer laminated. At least one of the first and the second metal oxide layers contains four components of Al2O3, ZnO, SnO2, and Ga2O3. X, Y, and Z are within a region surrounded by line segments between point a, point b, point c, point d, point e, and point f, in terms of (X, Y, Z) coordinates shown in a ternary diagram in FIG. 2, or on the line segments where X is a total molar ratio of the Al2O3 and the ZnO, Y is a molar ratio of the SnO2, and Z is a molar ratio of the Ga2O3, relative to the total amount of the four components. A molar ratio of the Al2O3 relative to the total amount of the four components is 1.5 to 3.5% by mole.

Owner:TDK CORPARATION

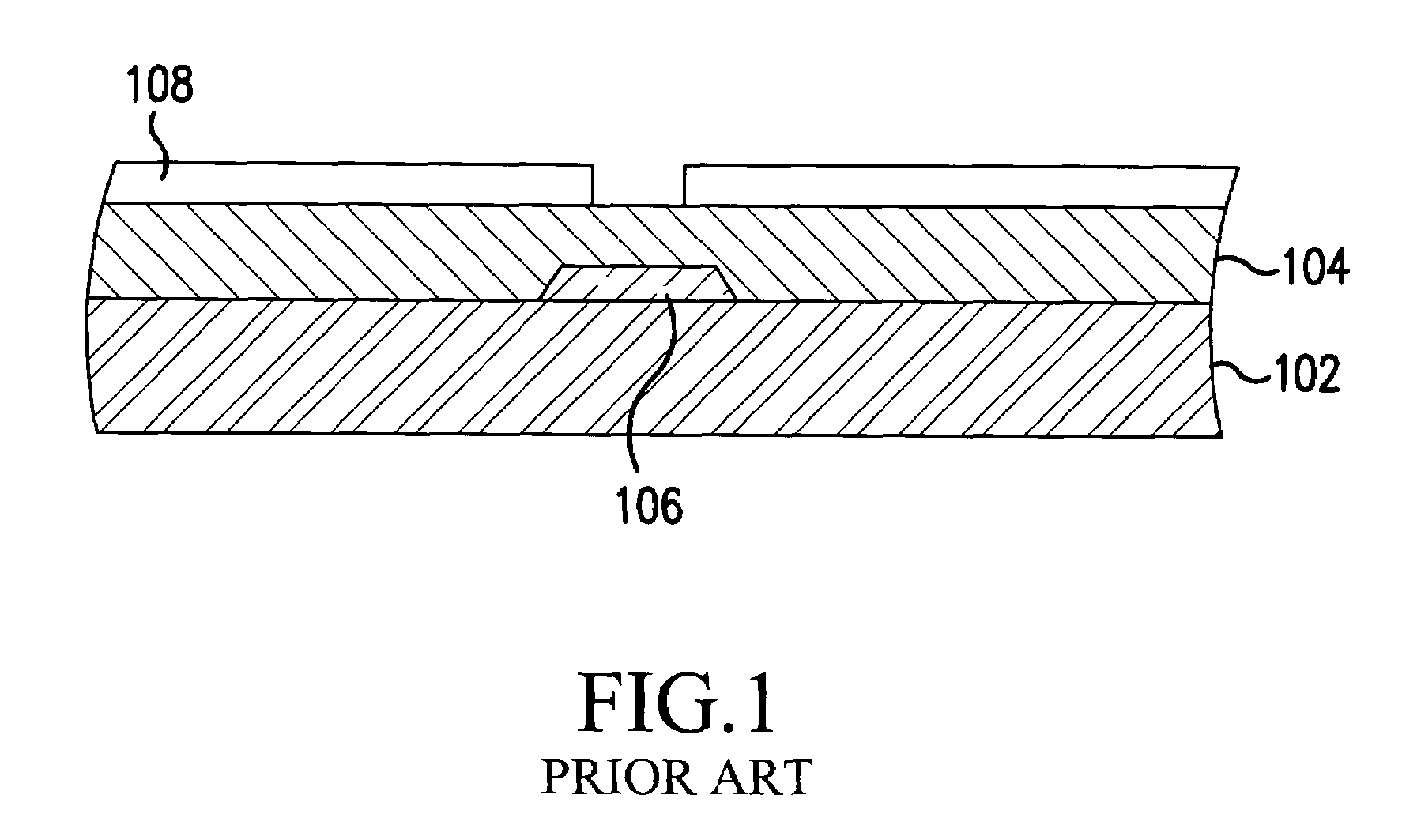

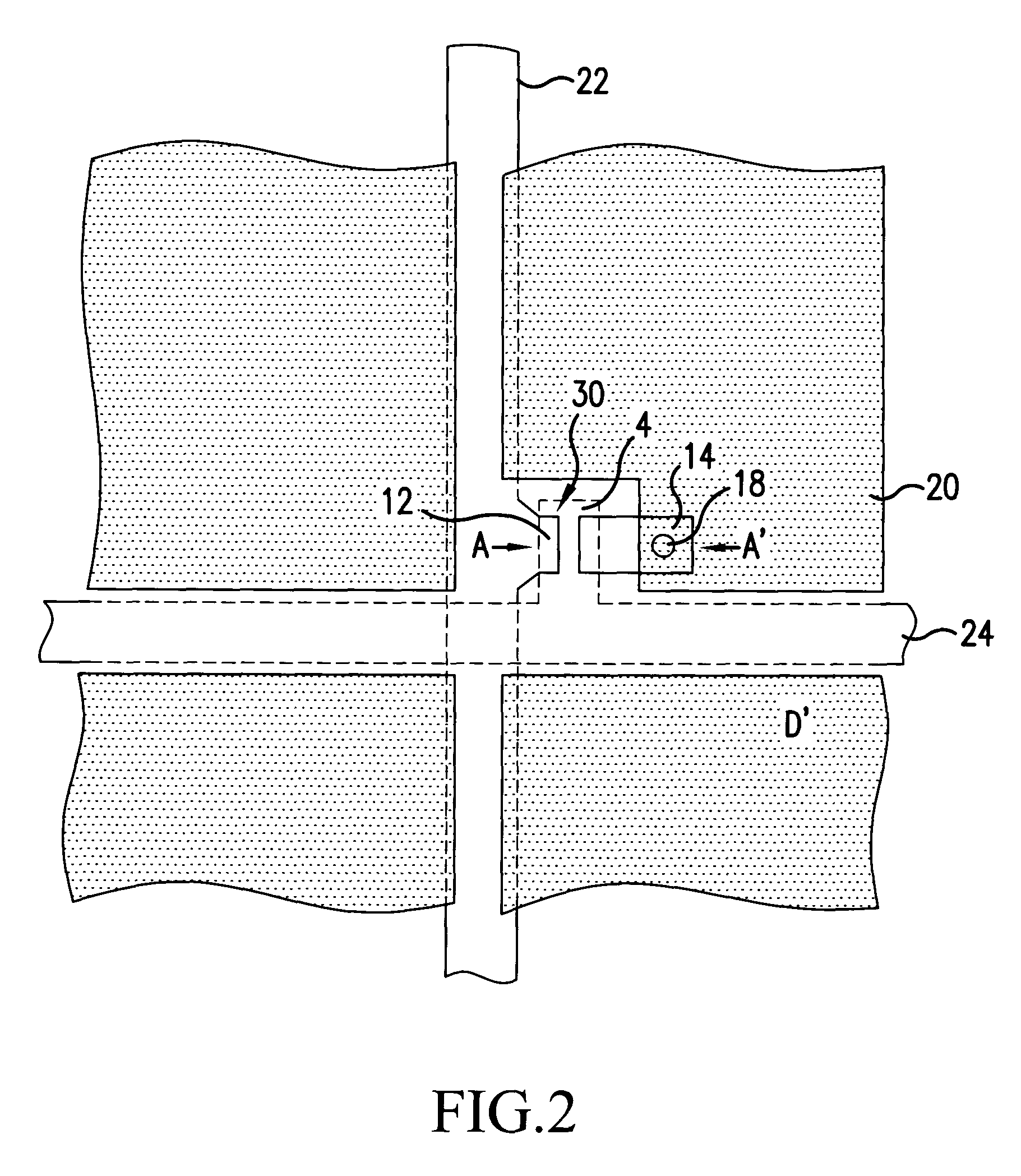

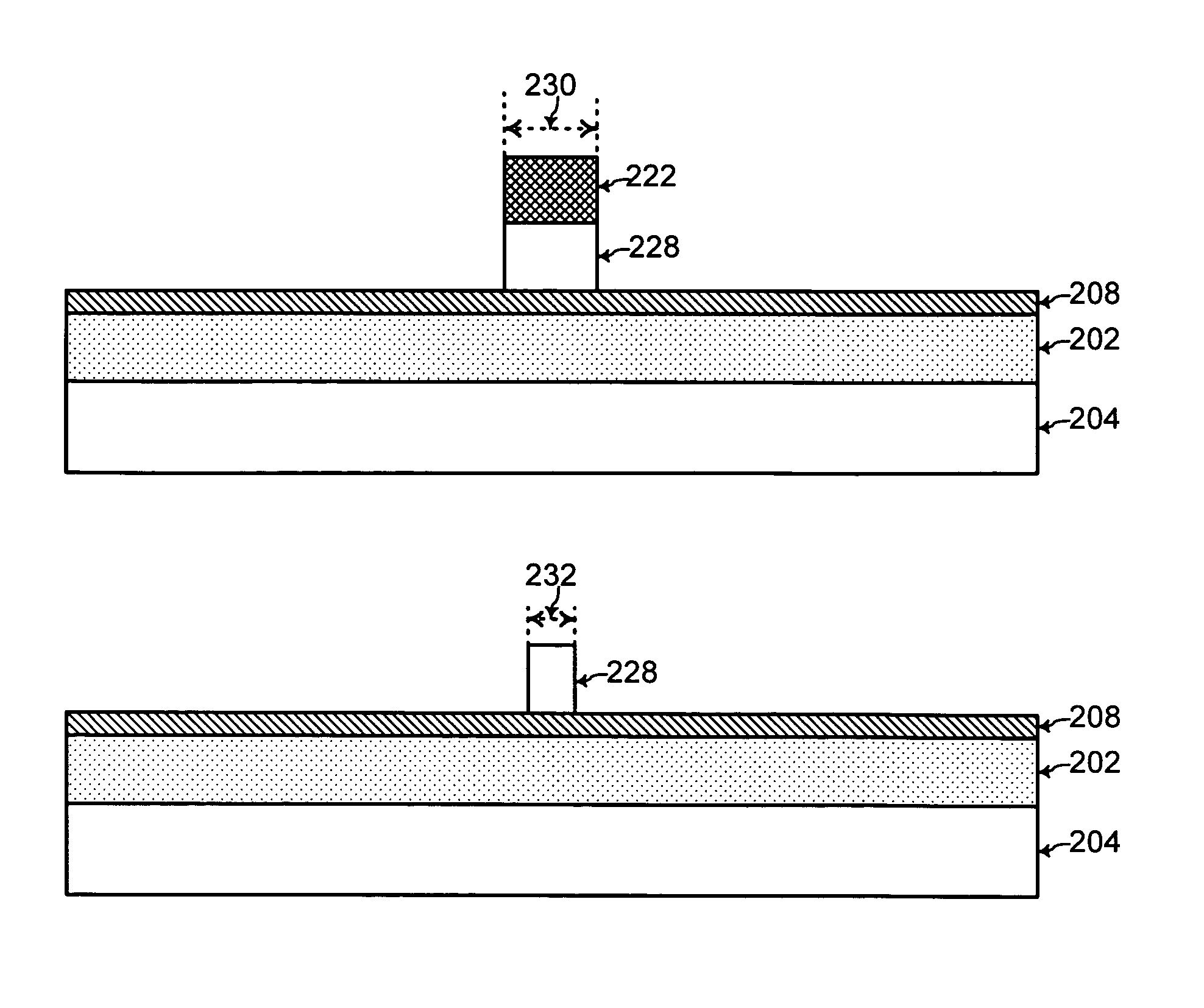

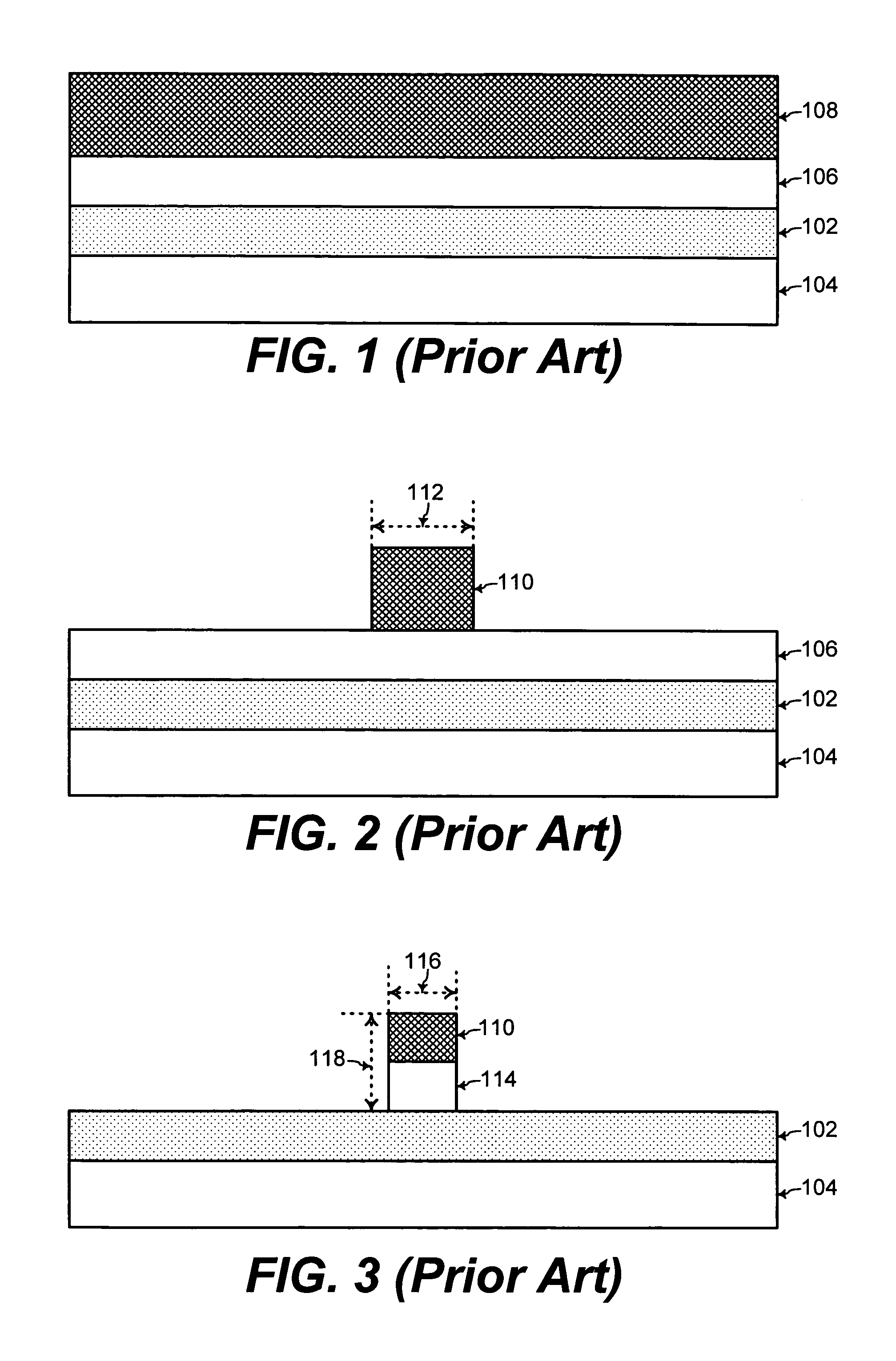

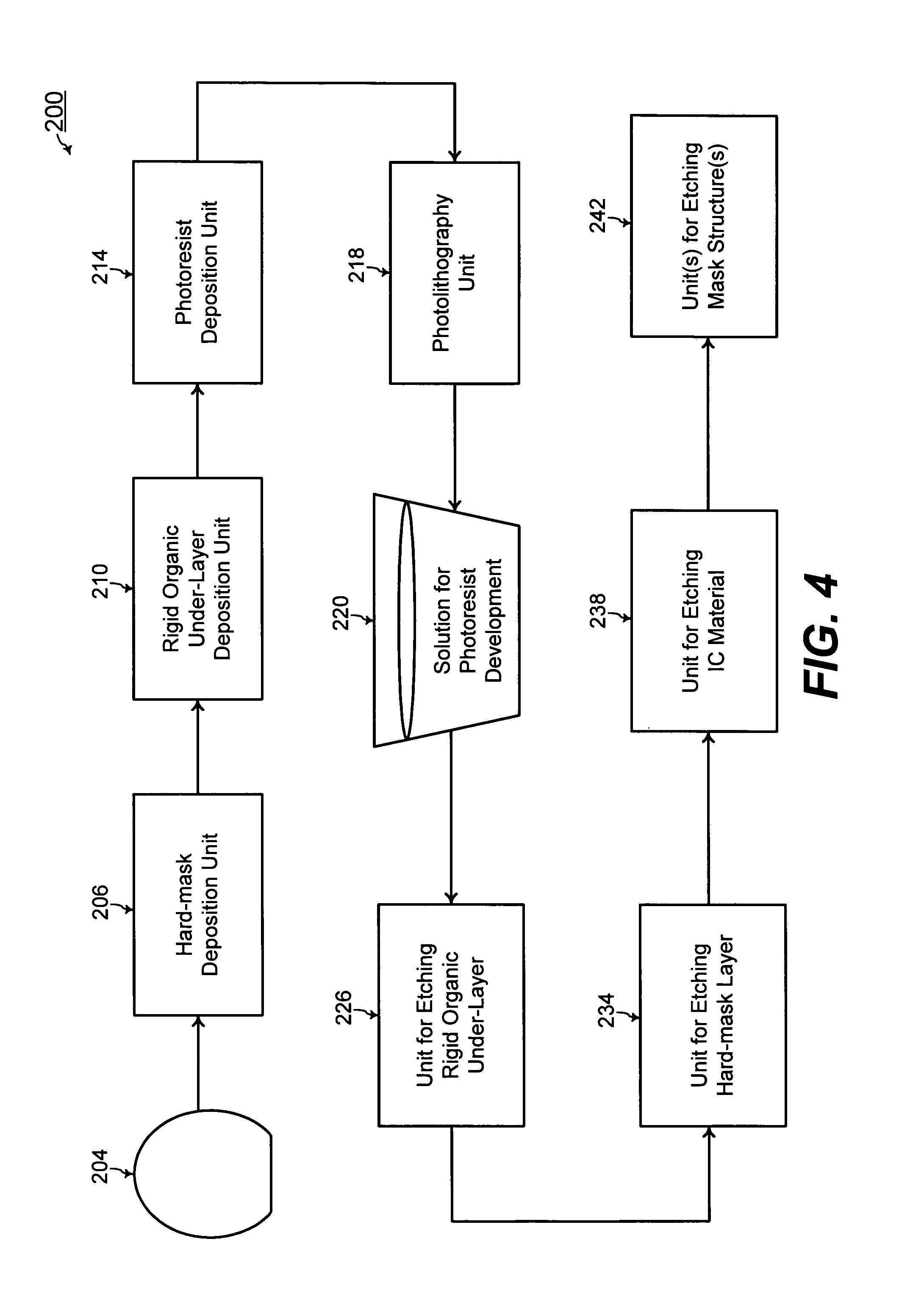

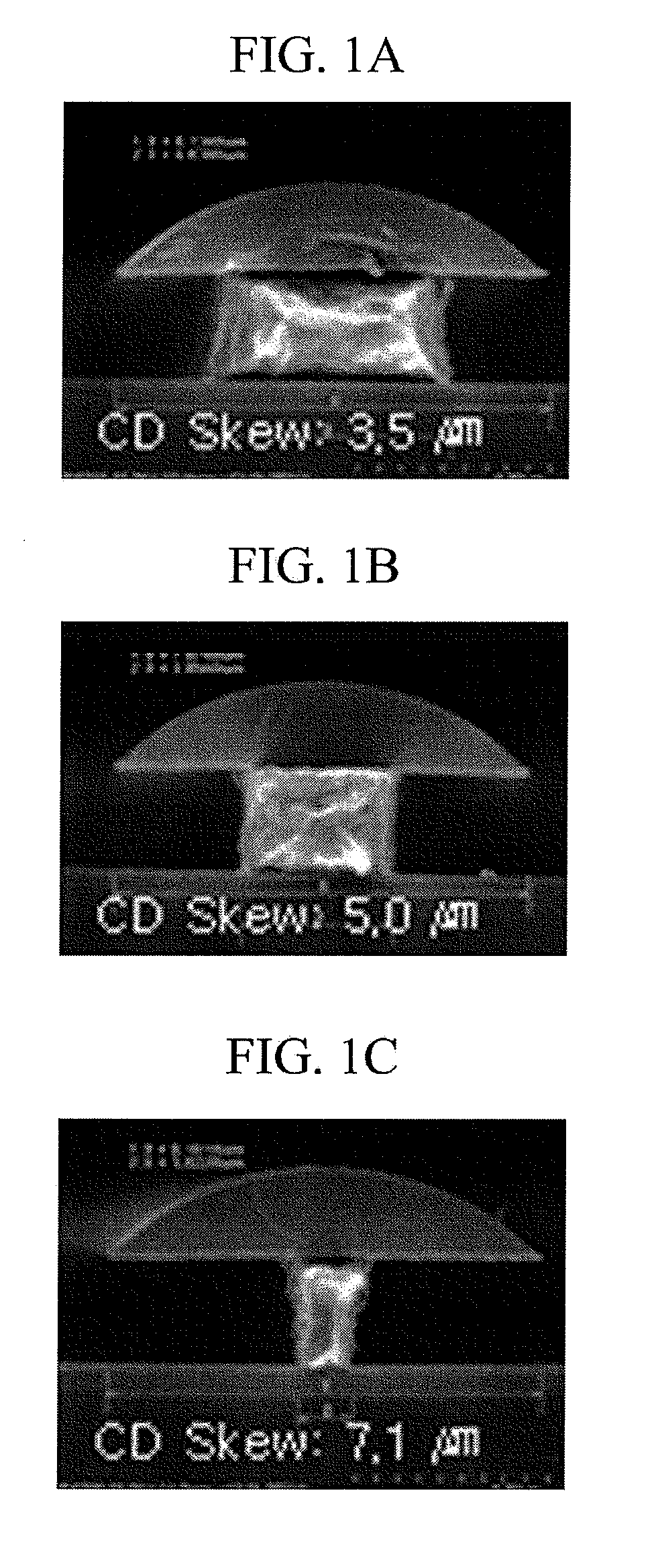

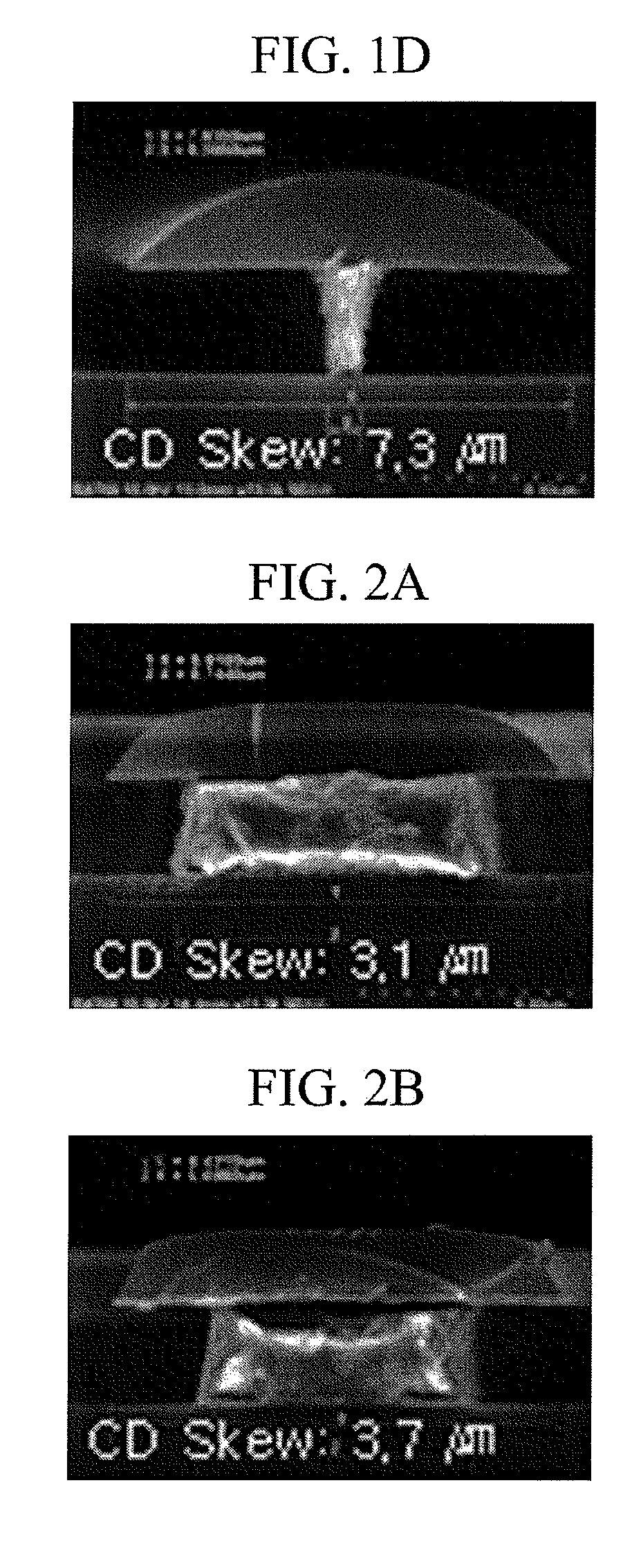

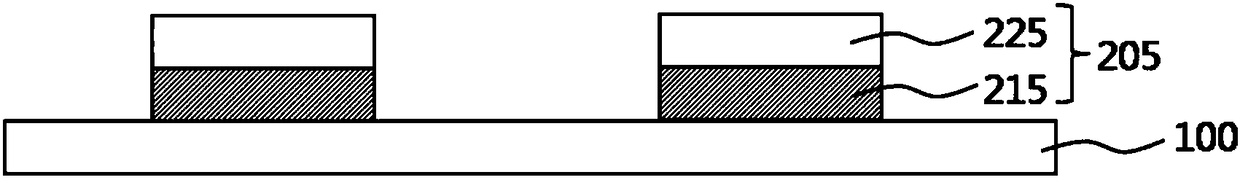

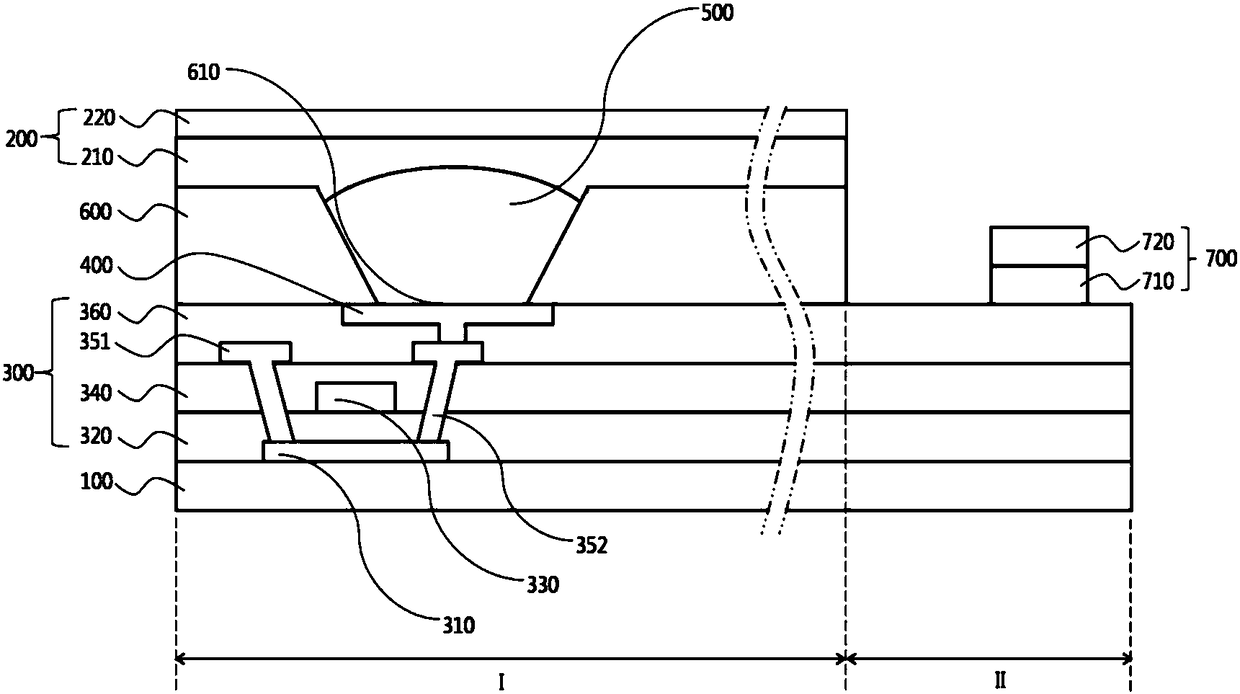

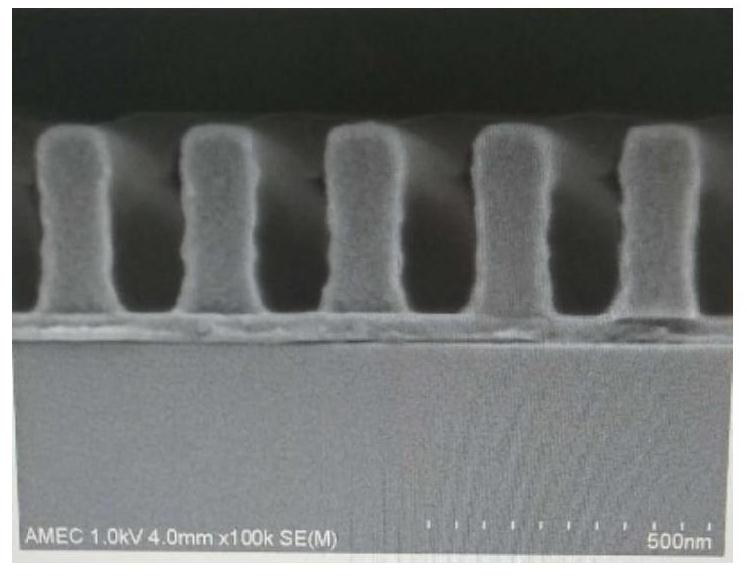

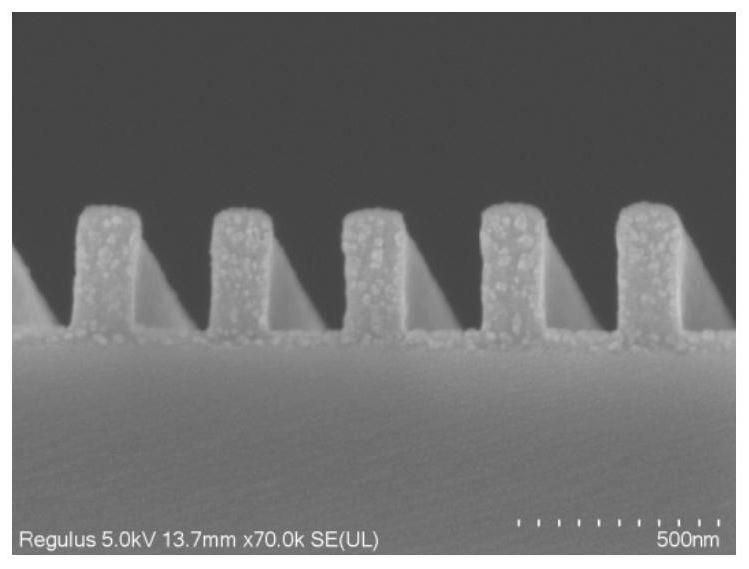

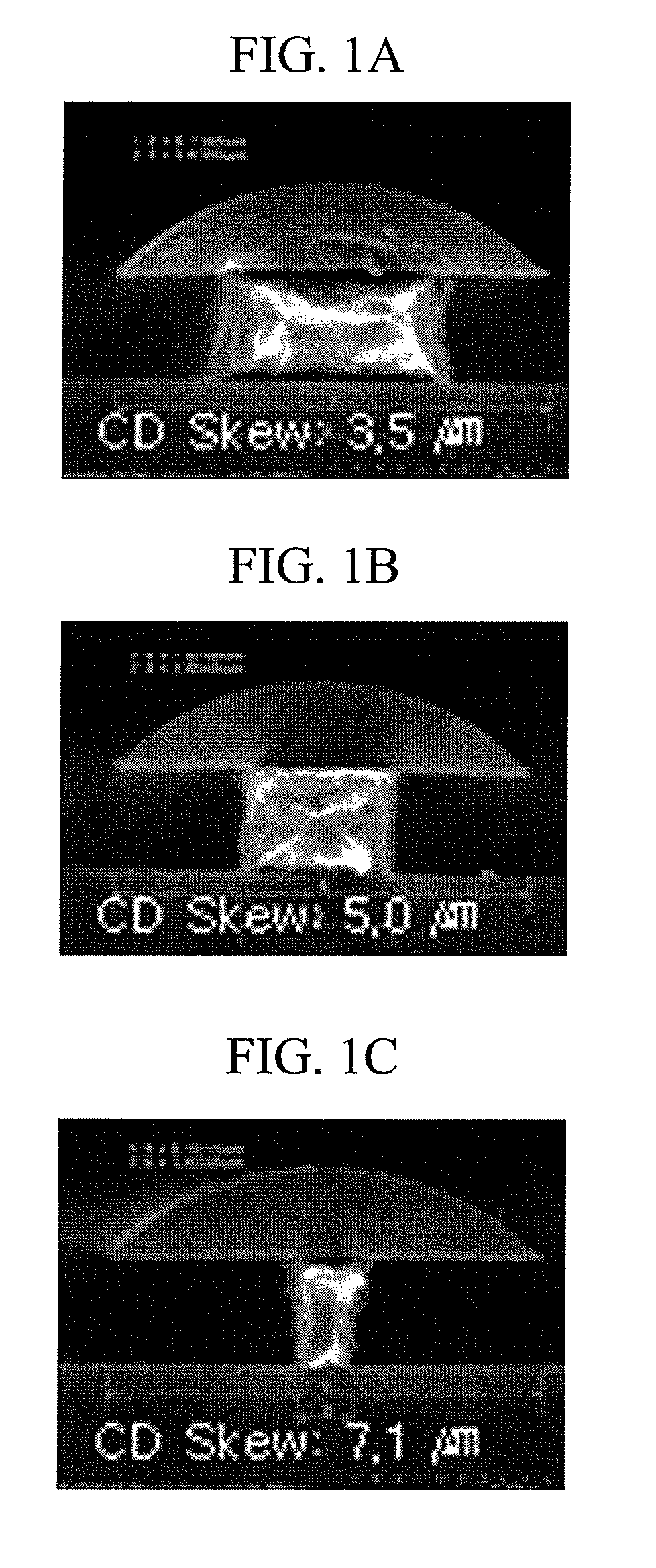

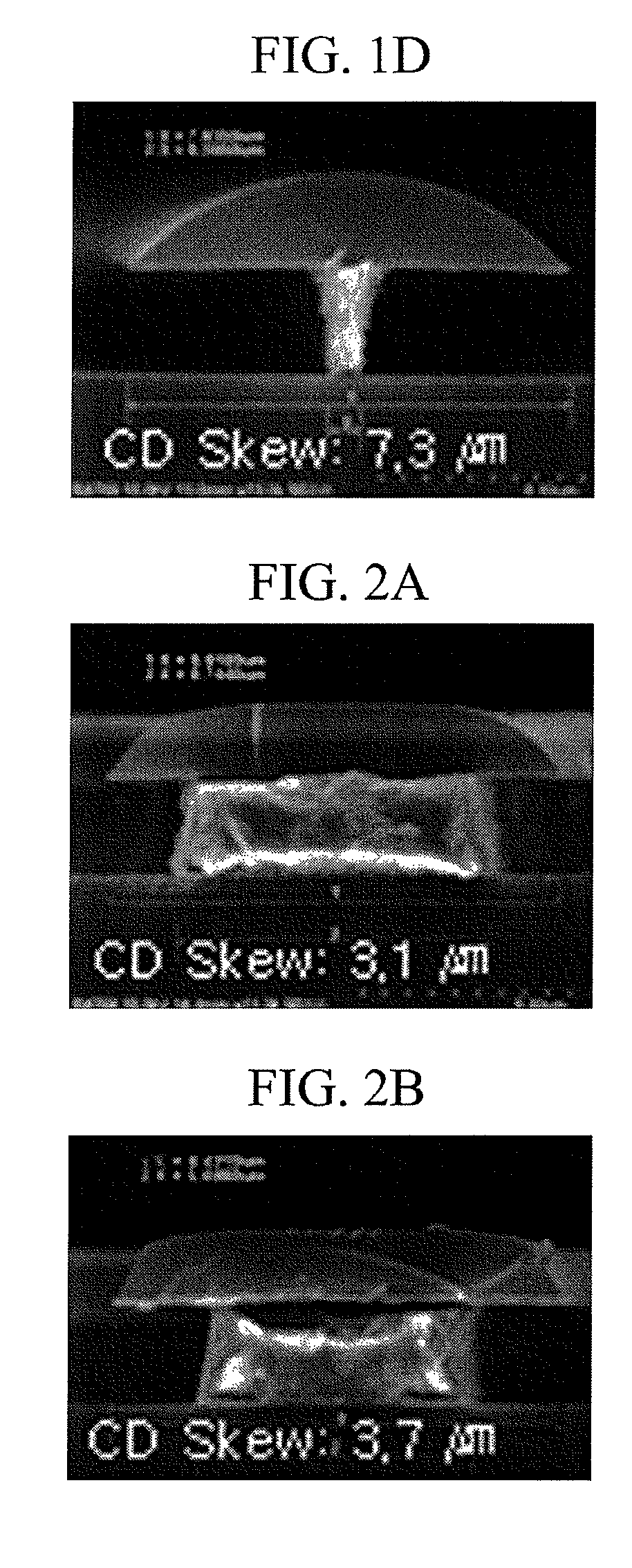

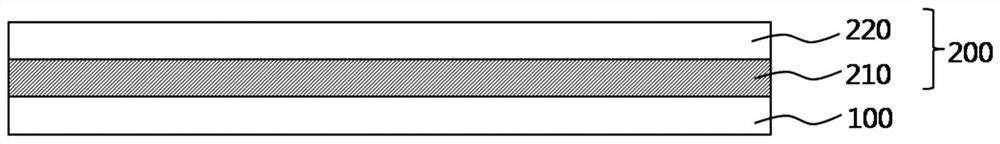

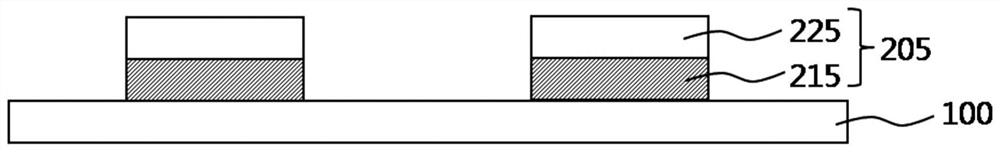

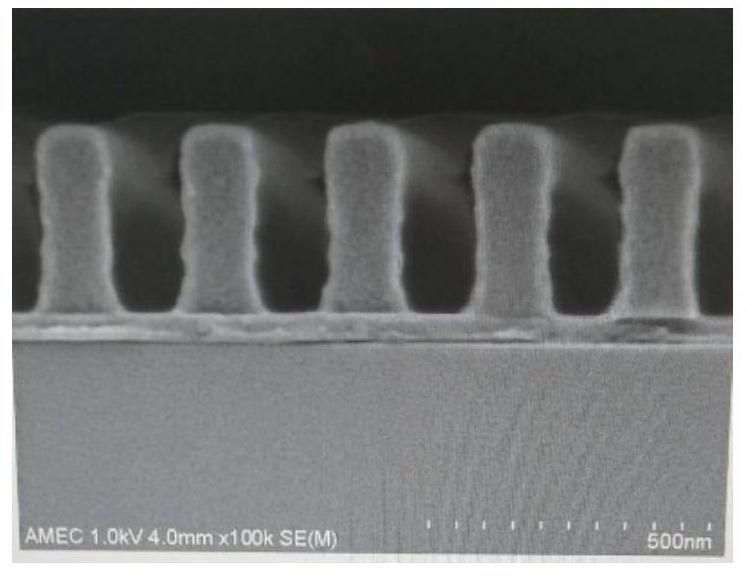

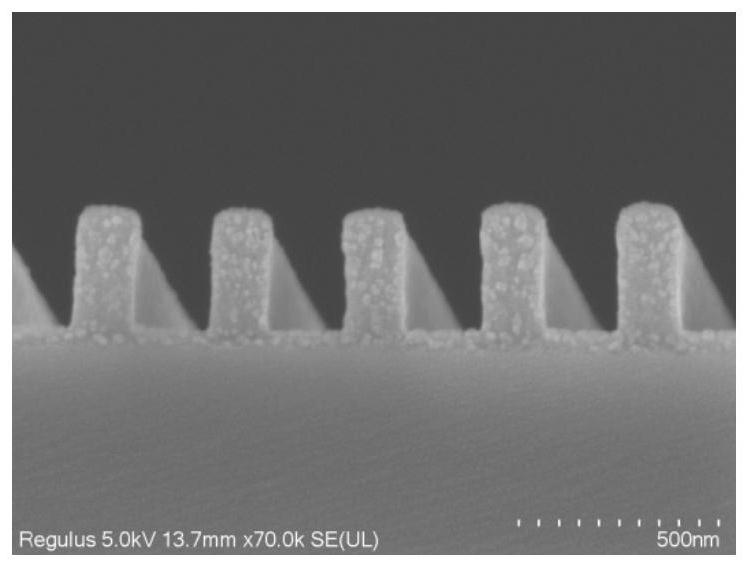

Patterning with rigid organic under-layer

InactiveUS7122455B1Improve mechanical propertiesExcellent etching propertiesSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringCritical dimension

For patterning an IC (integrated circuit) material, a rigid organic under-layer is formed over the IC material, and the rigid organic under-layer is patterned to form a rigid organic mask structure. In addition, the rigid organic mask structure is trimmed to lower a critical dimension of the rigid organic mask structure beyond the limitations of traditional BARC mask structures. Any portion of the IC material not under the rigid organic mask structure is etched away to form an IC structure.

Owner:GLOBALFOUNDRIES INC

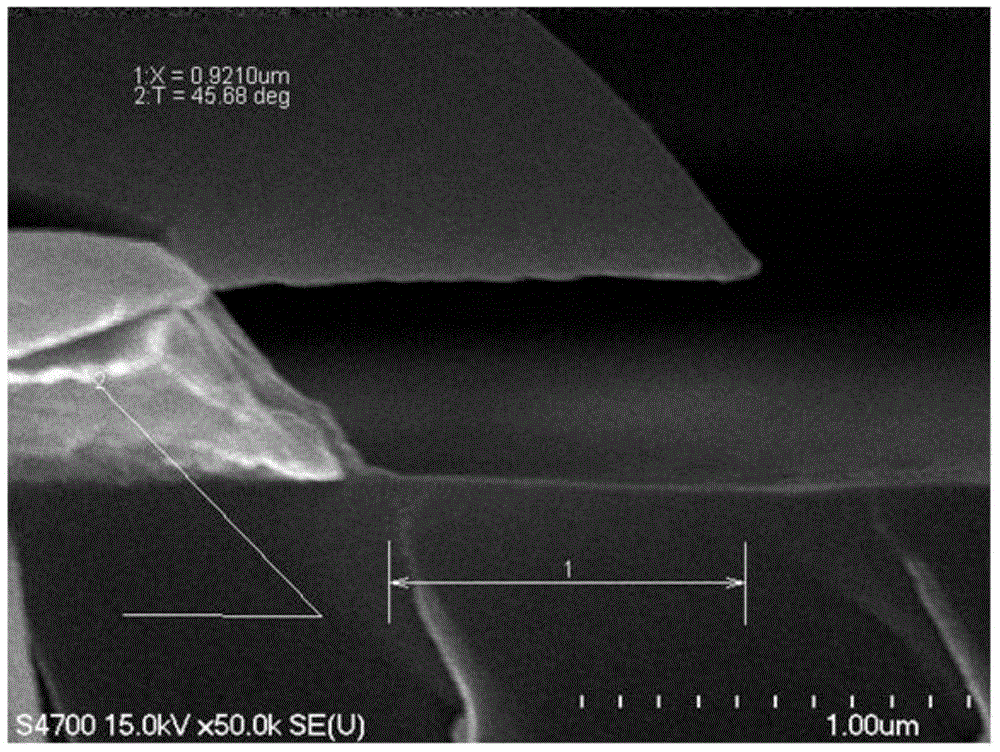

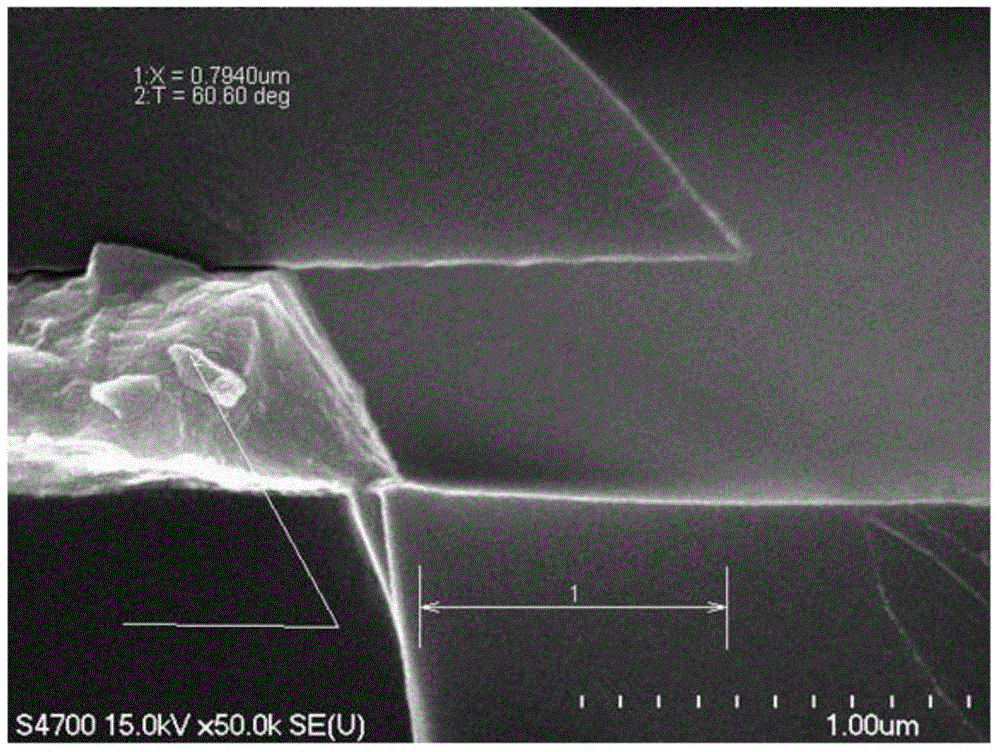

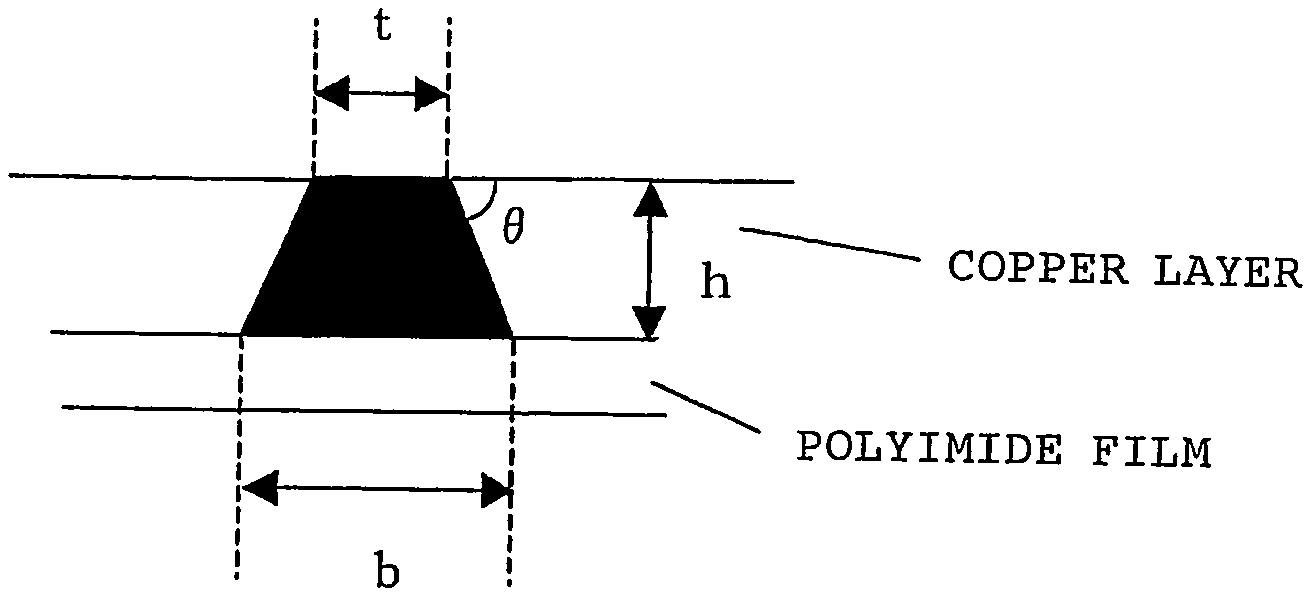

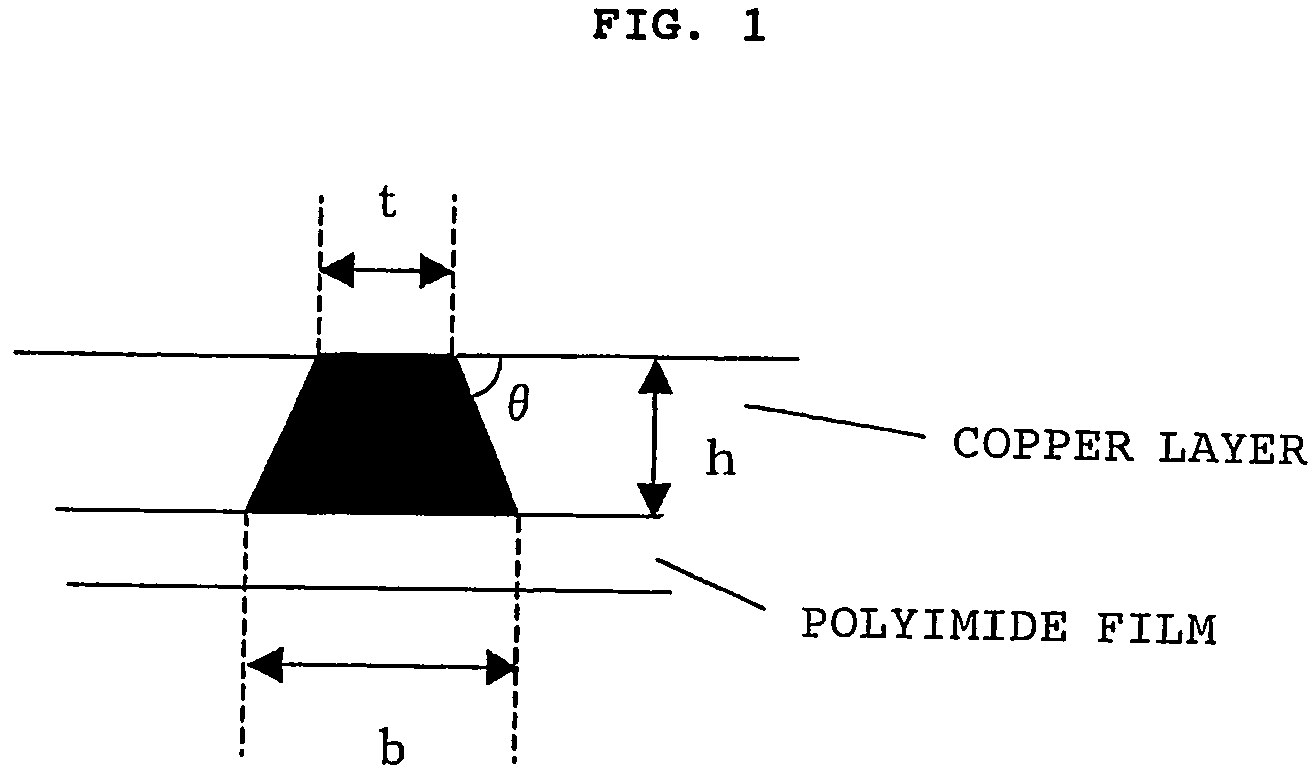

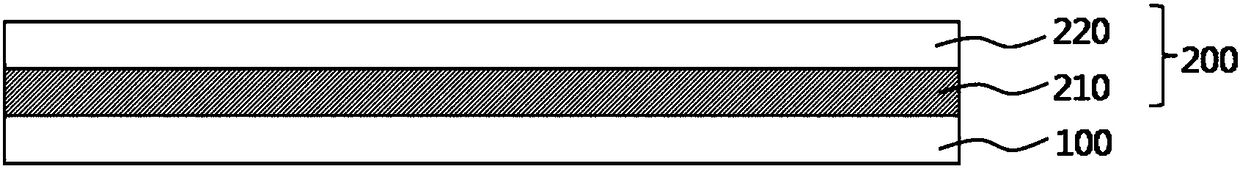

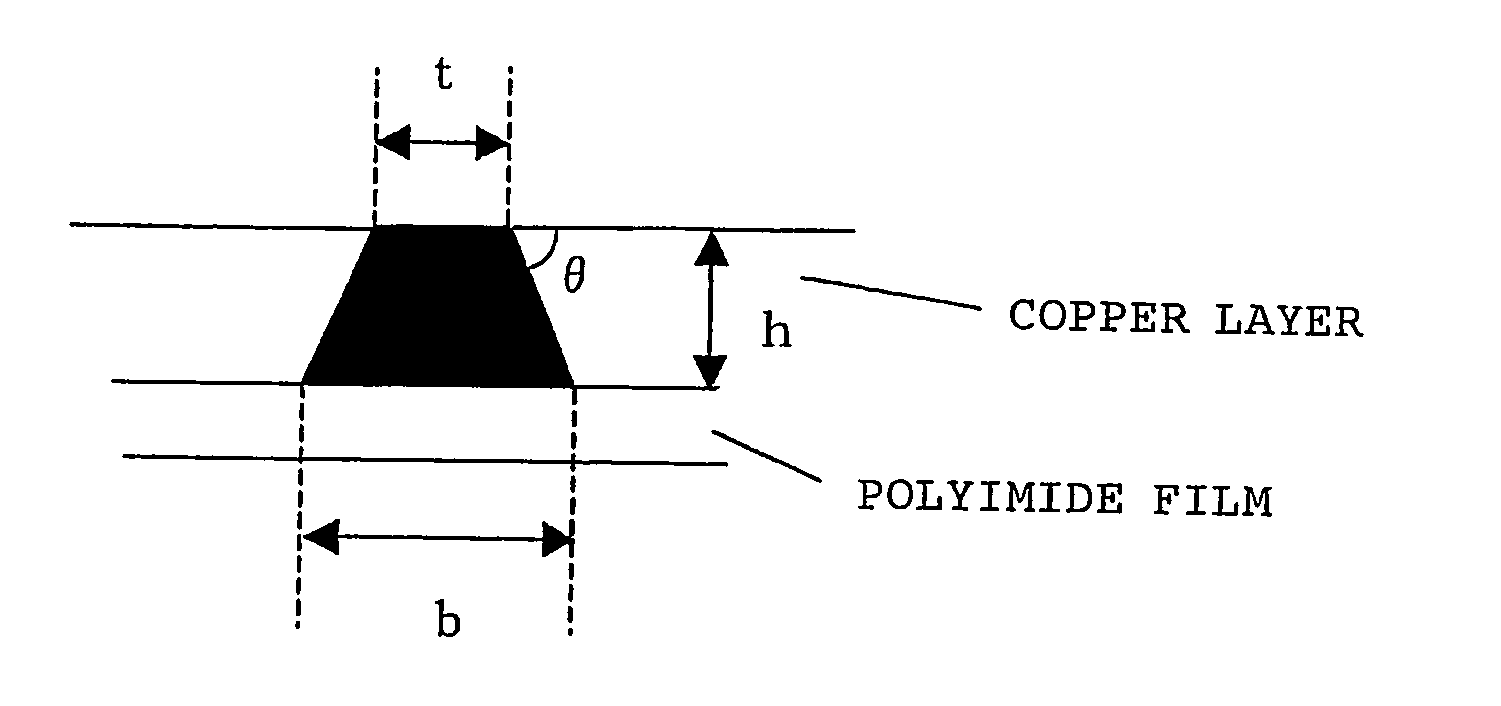

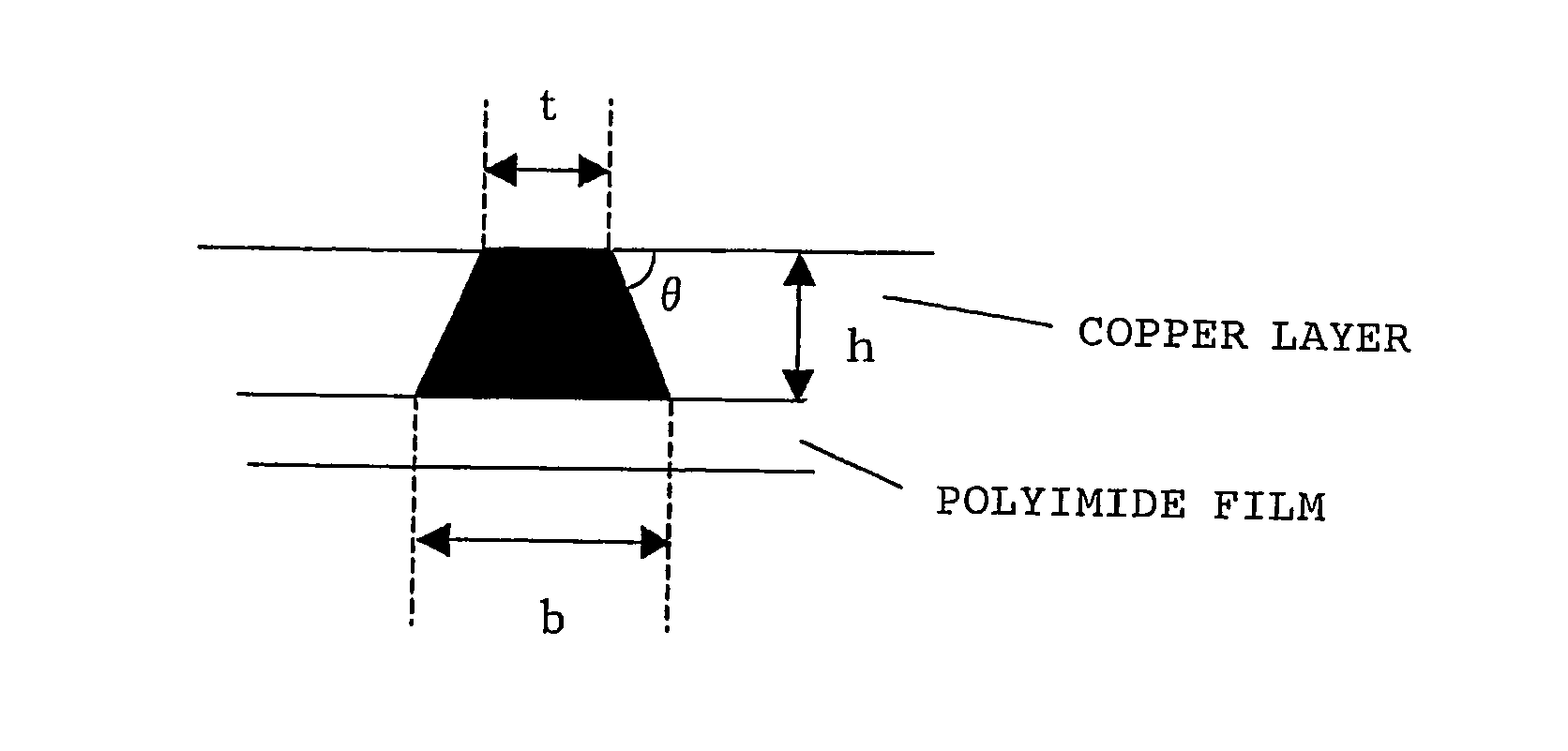

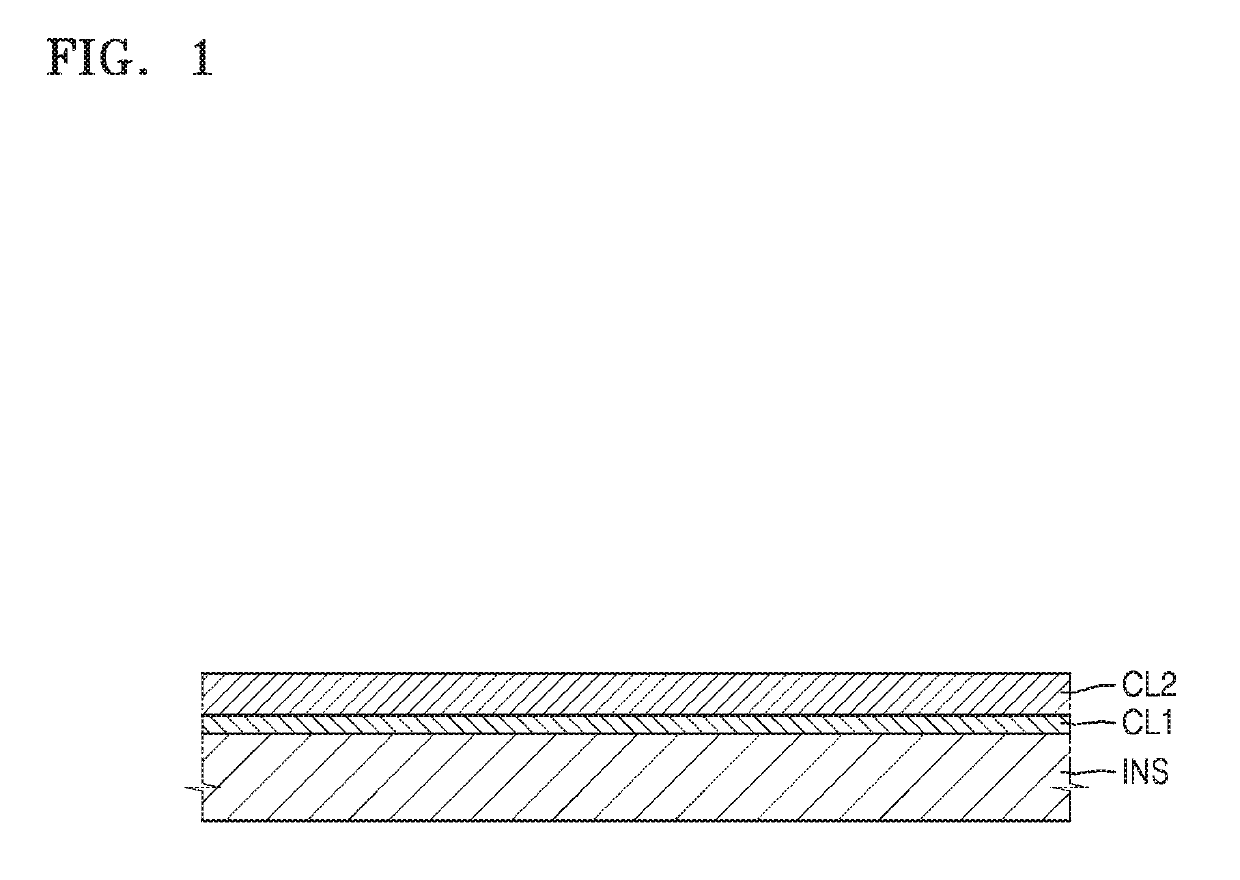

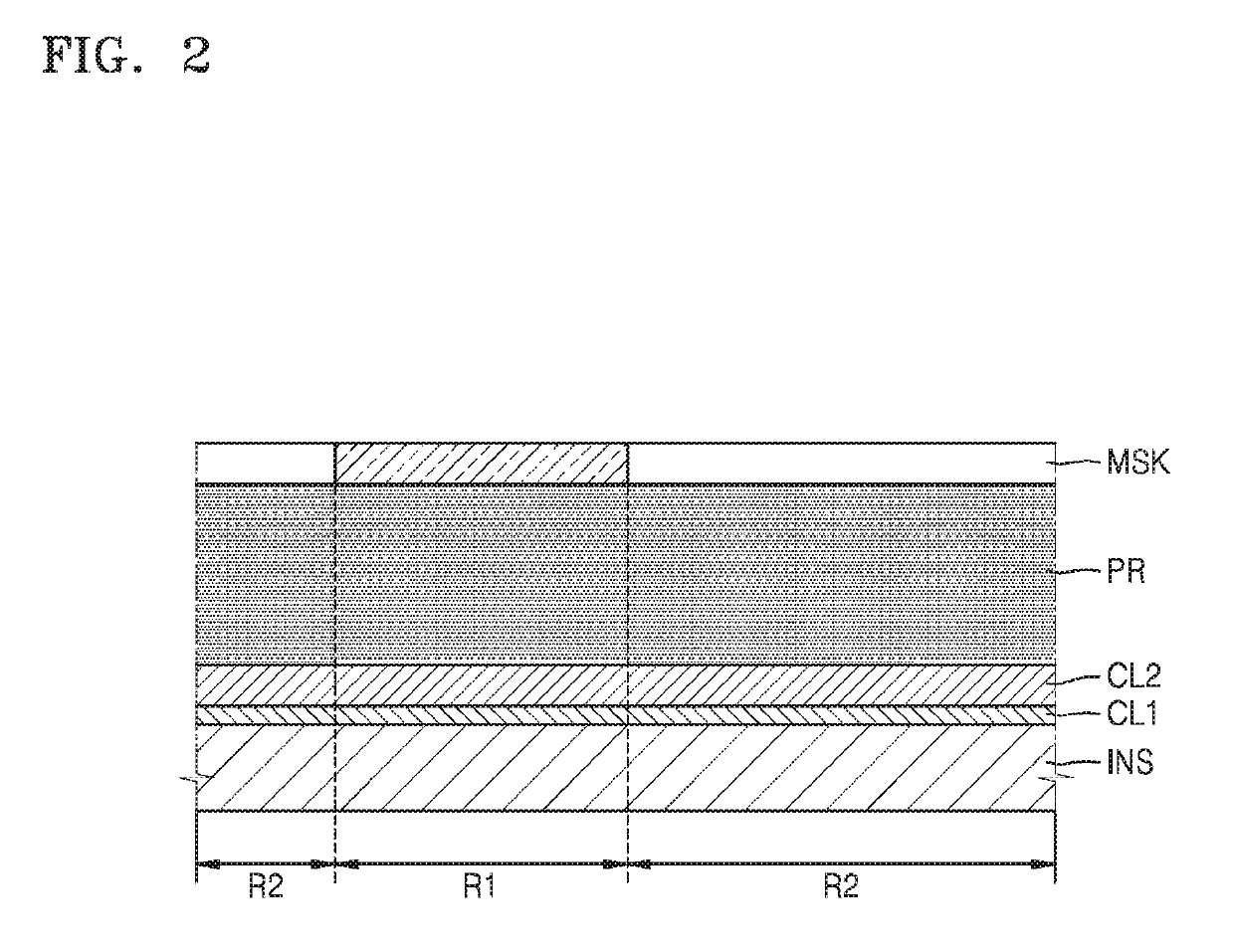

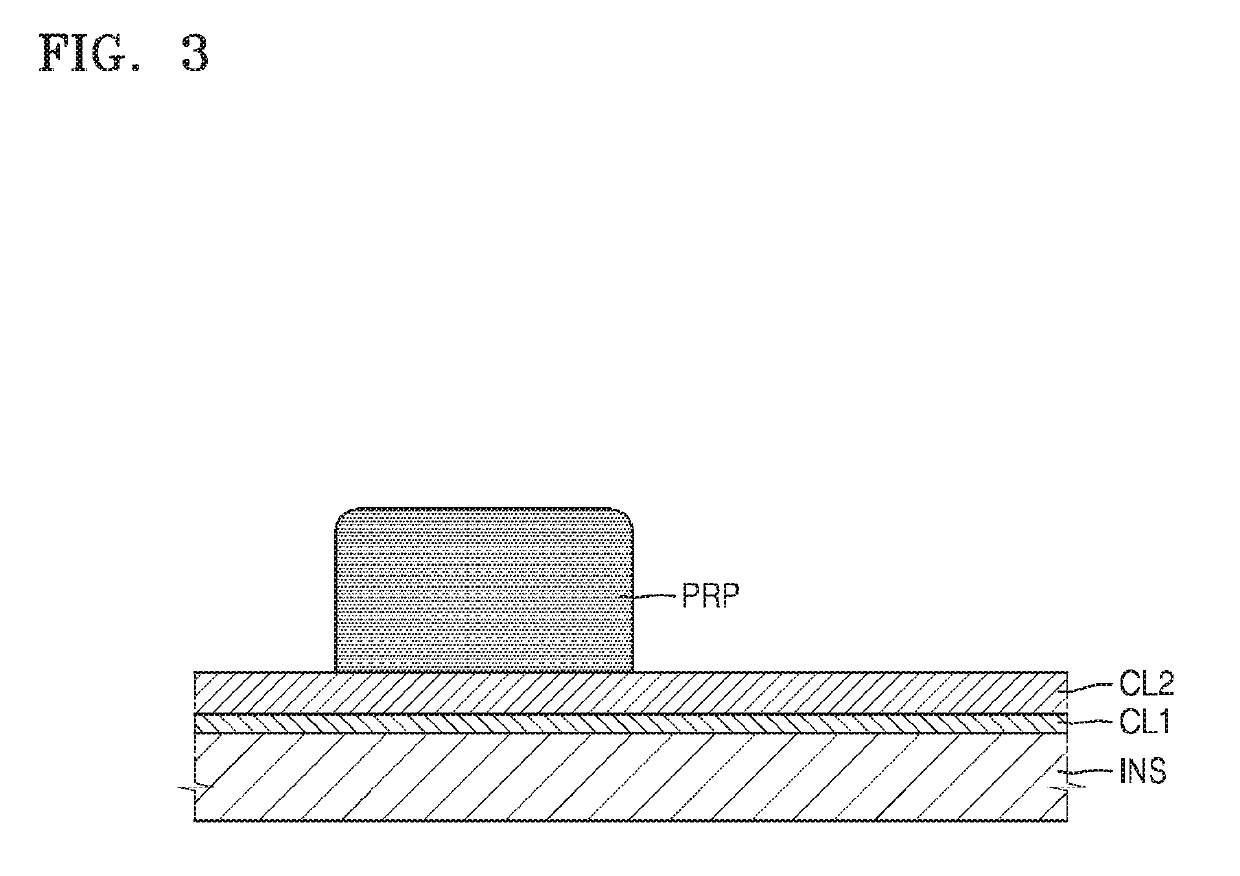

Two-Layer Flexible Substrate

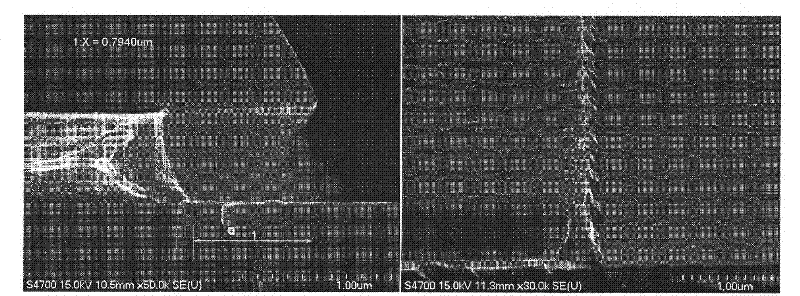

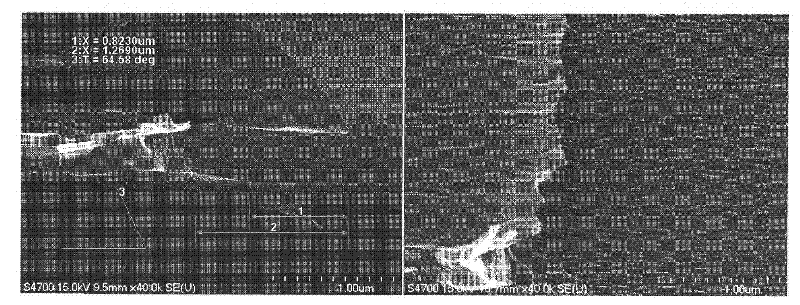

ActiveUS20090092789A1Increase productionExcellent etching characteristic and adherence to resistInsulating substrate metal adhesion improvementPrinted circuit aspectsAdhesiveSurface roughness

The invention provides a two-layer flexible substrate free of surface defects and having excellent etching characteristics and adherence to resist.The two-layer flexible substrate has a copper layer provided on one or both faces of an insulator film without using an adhesive, wherein the surface roughness (Ra) of the copper layer is 0.10 to 0.25 μm, and wherein the average crystal grain size [of copper] is no greater than 0.8 μm at 1 μm from the insulator film in the cross section of the copper layer. Preferably, the insulator film is a polyimide film.

Owner:JX NIPPON MINING& METALS CORP

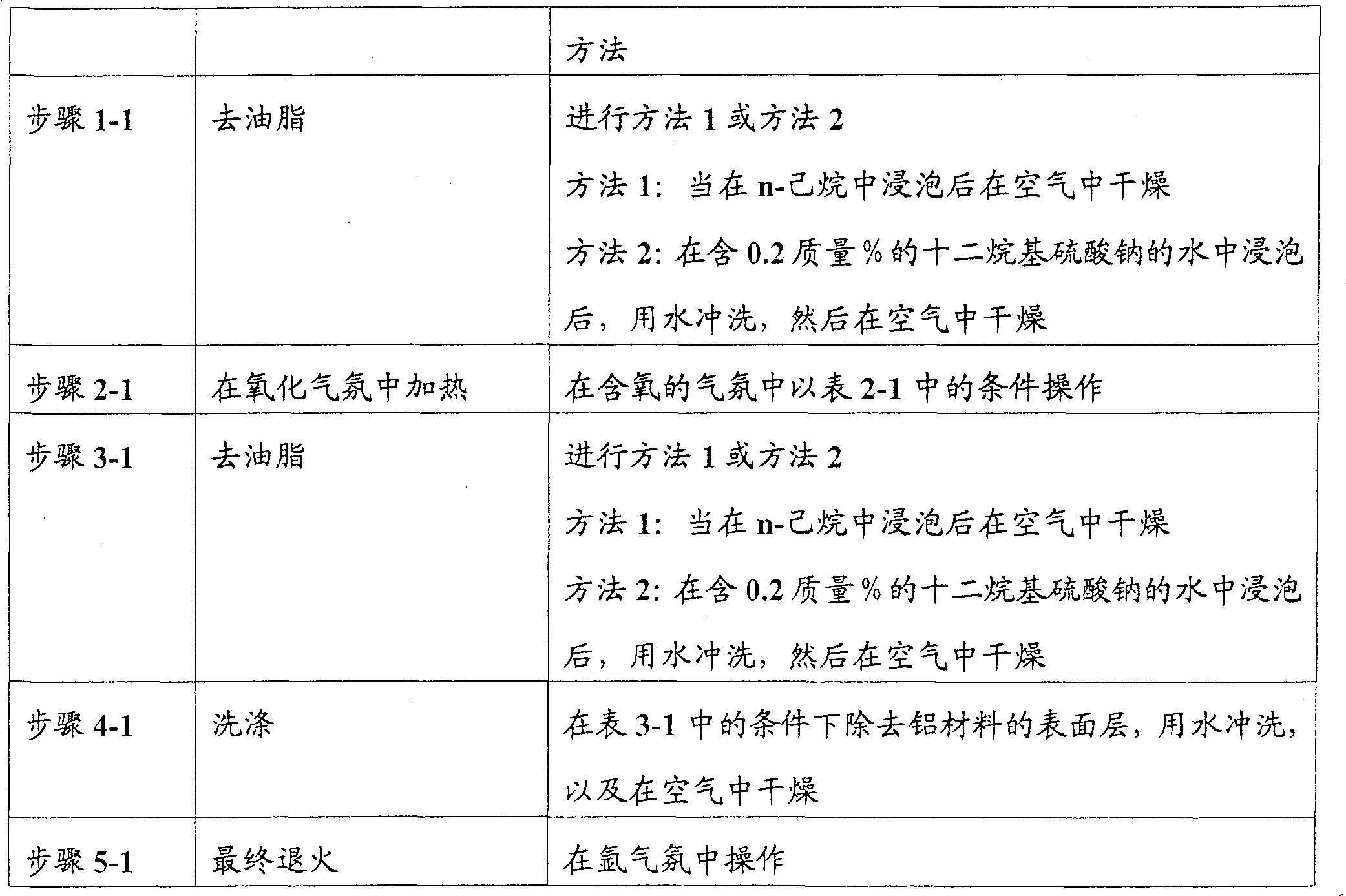

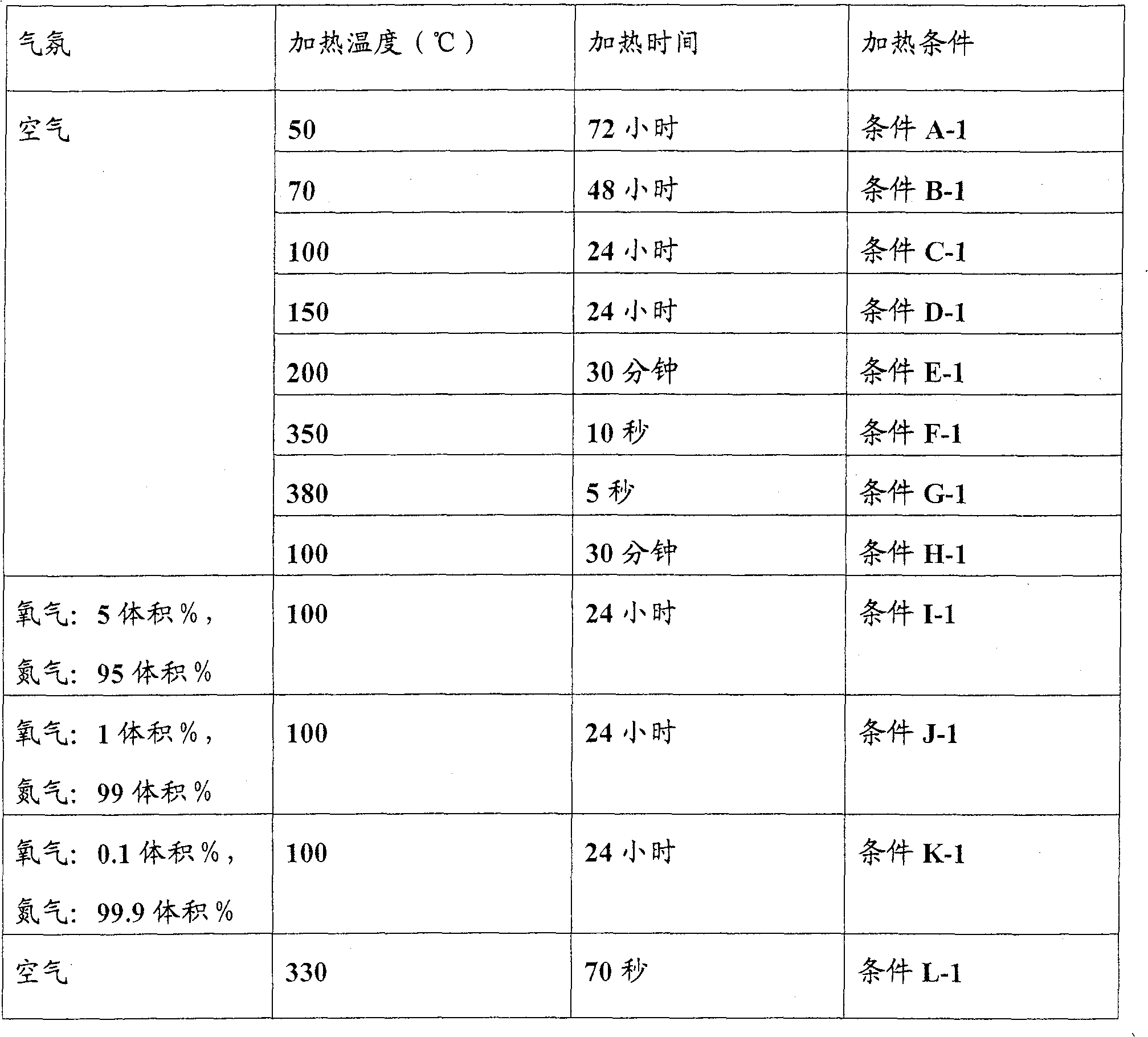

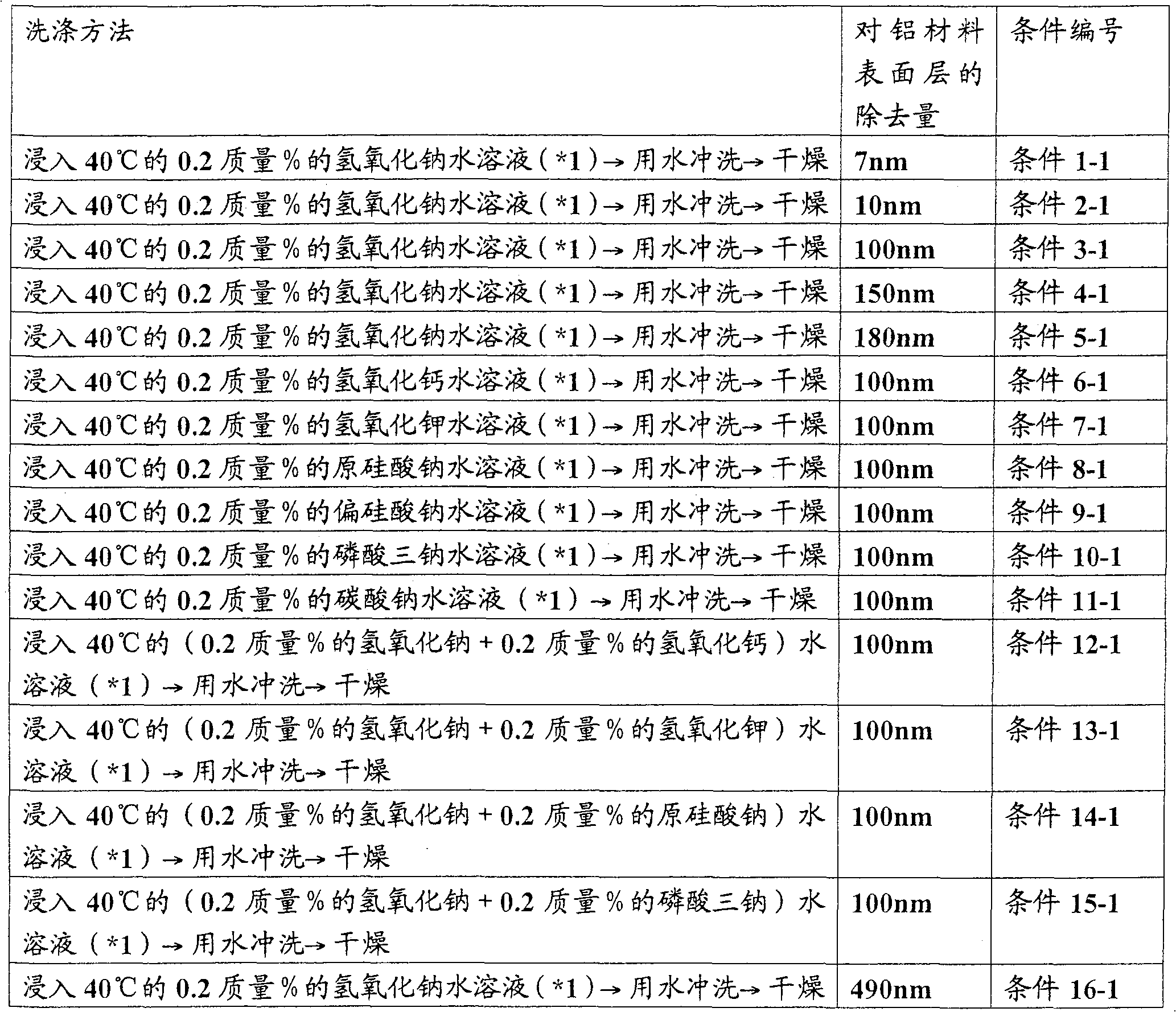

Method of manufacturing aluminum material for electrolytic capacitor electrodes, aluminum material for electrolytic capacitor electrodes, anode material for aluminum electrolytic capacitors, and alumi

InactiveCN1942984AExcellent etching propertiesLarge capacityAnodisationElectrolytic capacitorsElectrolysisSurface layer

A method for manufacturing an aluminum material used for an electrode of an electrolytic capacitor of the present invention, comprising the steps of heating the aluminum material in an oxidizing atmosphere, removing a surface layer of the aluminum material by washing the heated aluminum material, and treating the aluminum material obtained by washing Perform final annealing.

Owner:SHOWA DENKO KK

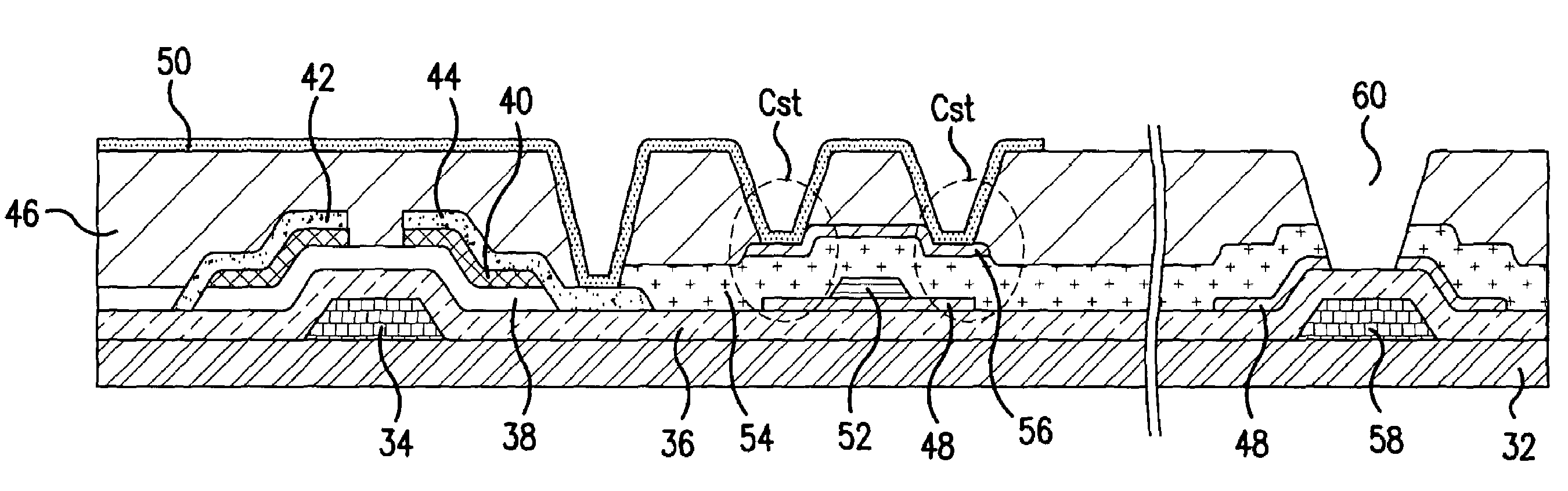

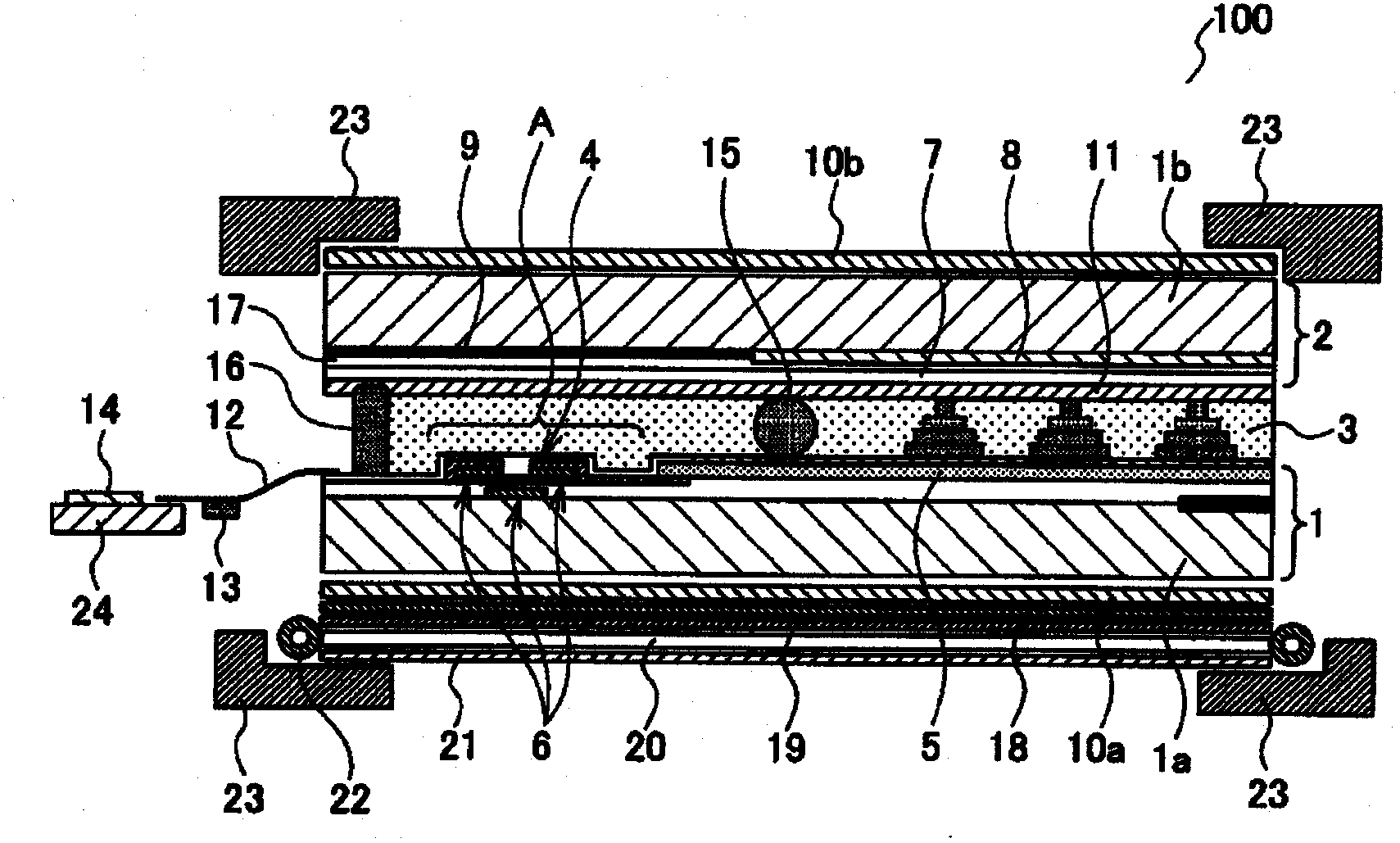

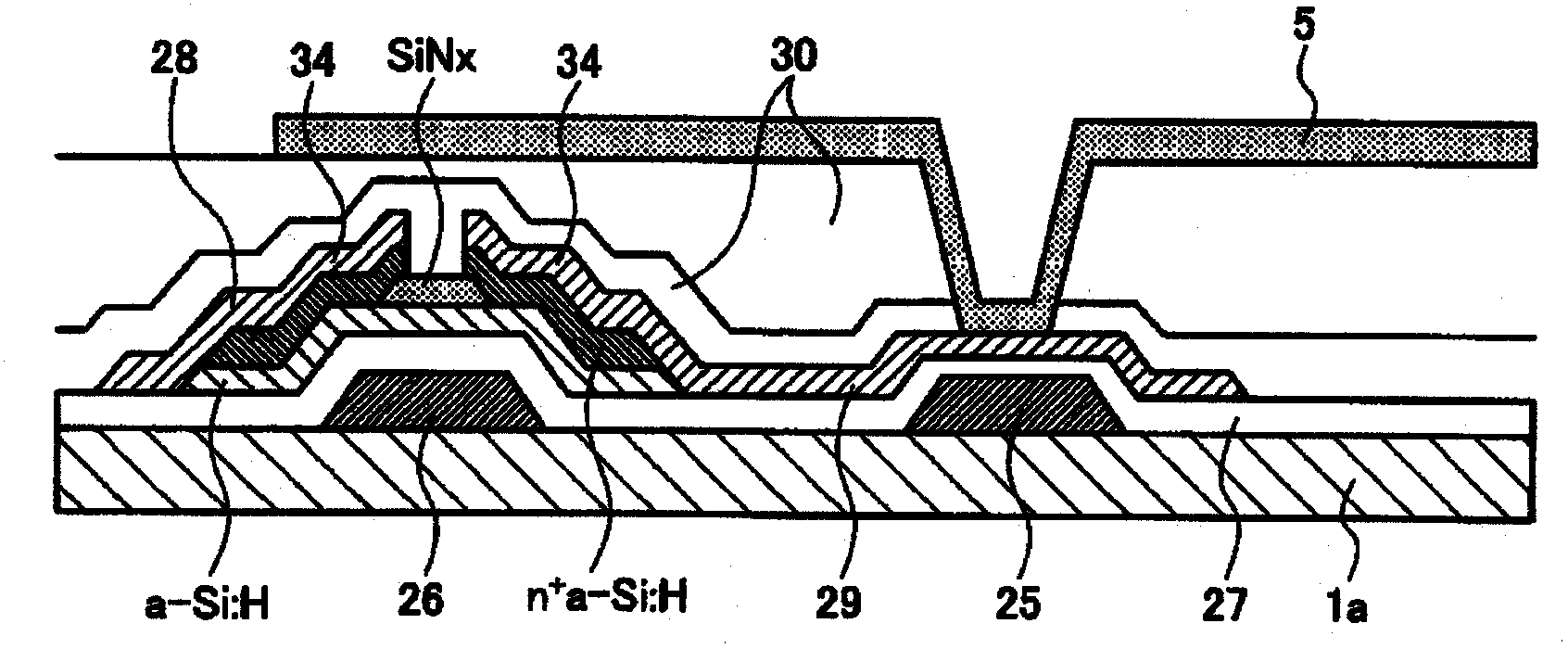

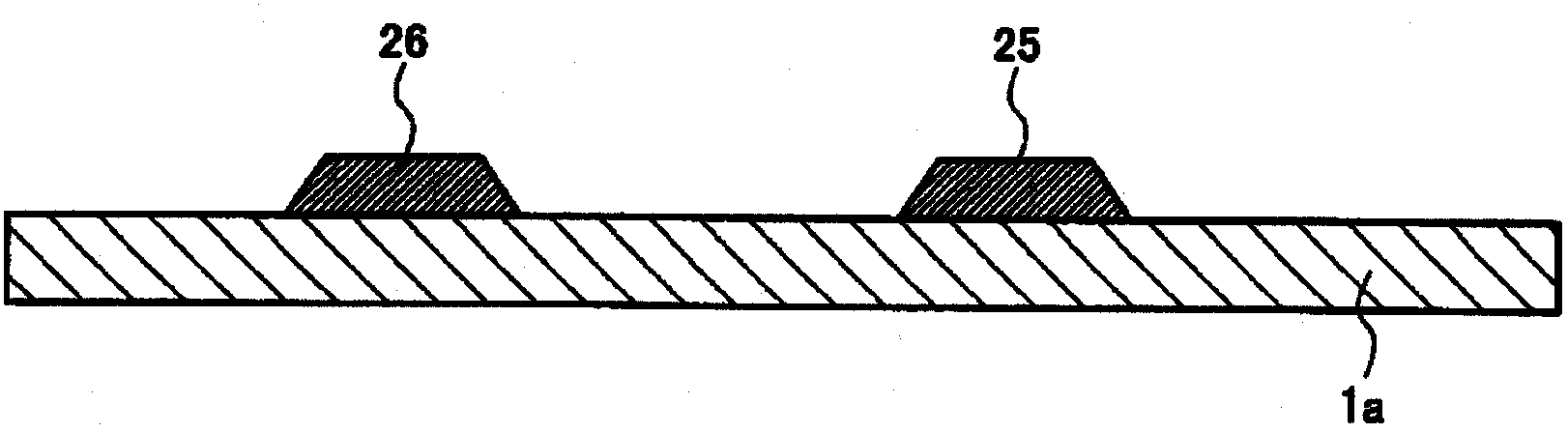

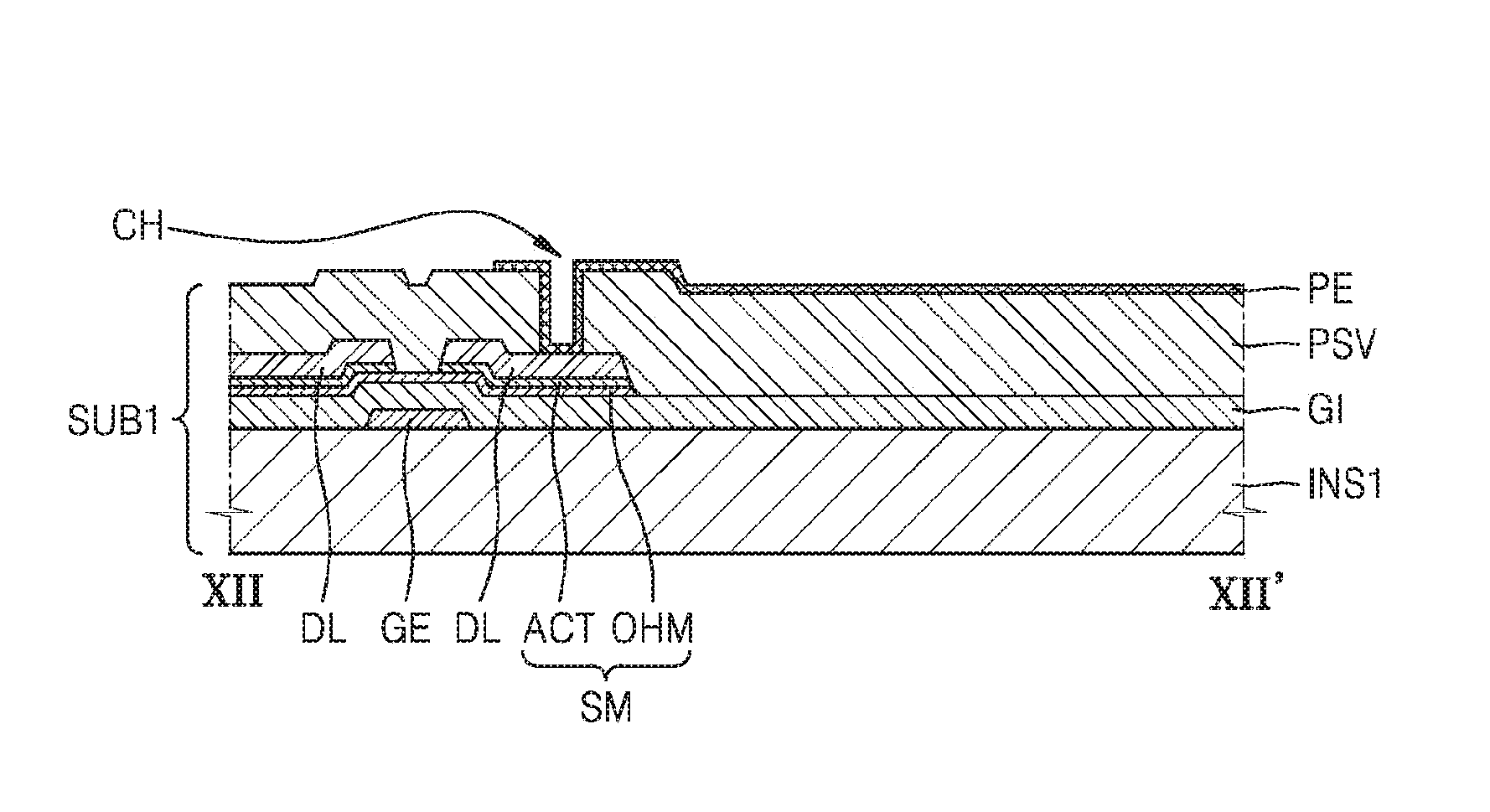

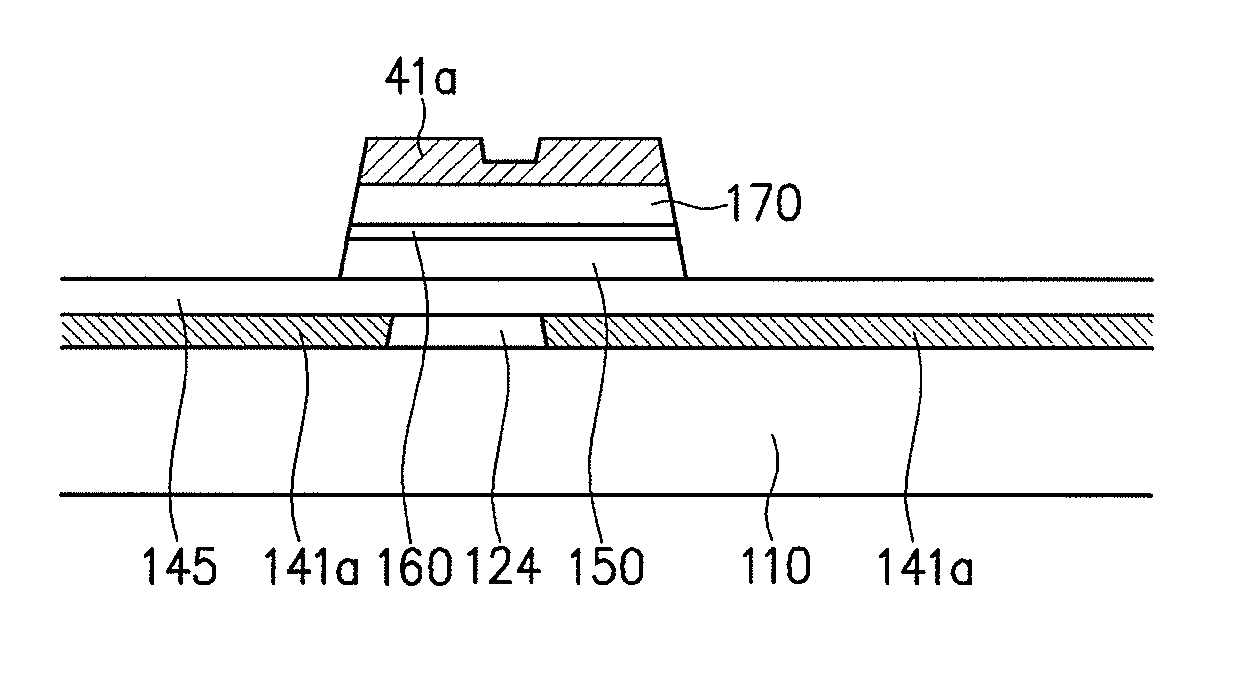

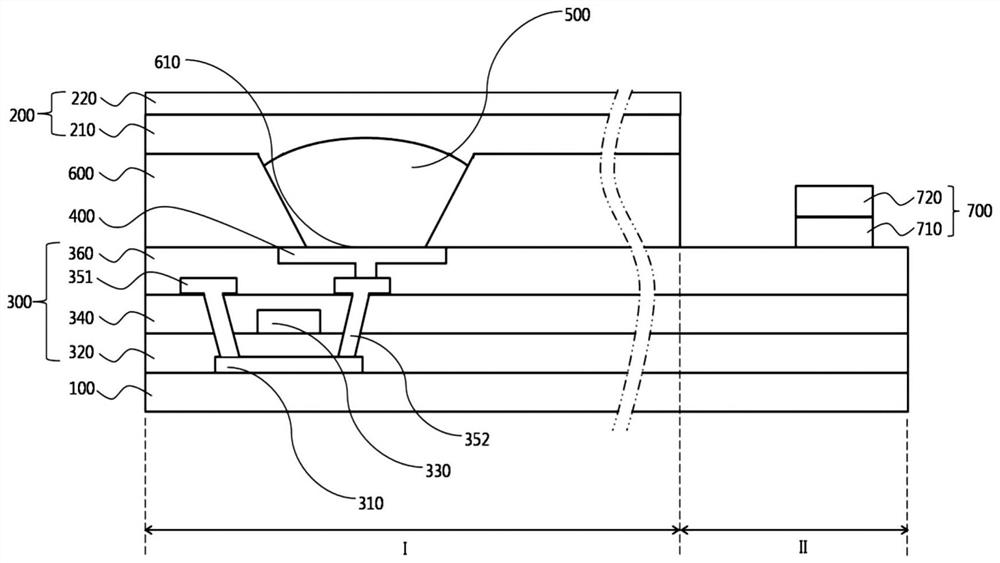

Display device, Cu alloy film for use in the display device, and Cu alloy sputtering target

InactiveCN102119230AImprove adhesionExcellent etching propertiesTransistorSemiconductor/solid-state device detailsDisplay deviceBottom gate

Disclosed is a Cu alloy film for a display device that has high adhesion to a glass substrate while maintaining low electric resistance characteristic of Cu-based materials. The Cu alloy film is wiring in direct contact with a glass substrate on a board and contains 0.1 to 10.0 atomic% in total of one or more elements selected from the group consisting of Ti, Al, and Mg. Also disclosed is a display device comprising a thin-film transistor that comprises the Cu alloy film. In a preferred embodiment of the display device, the thin-film transistor has a bottom gate-type structure, and a gate electrode and scanning lines in the thin-film transistor comprise the Cu alloy film and are in direct contact with the glass substrate.

Owner:KOBE STEEL LTD

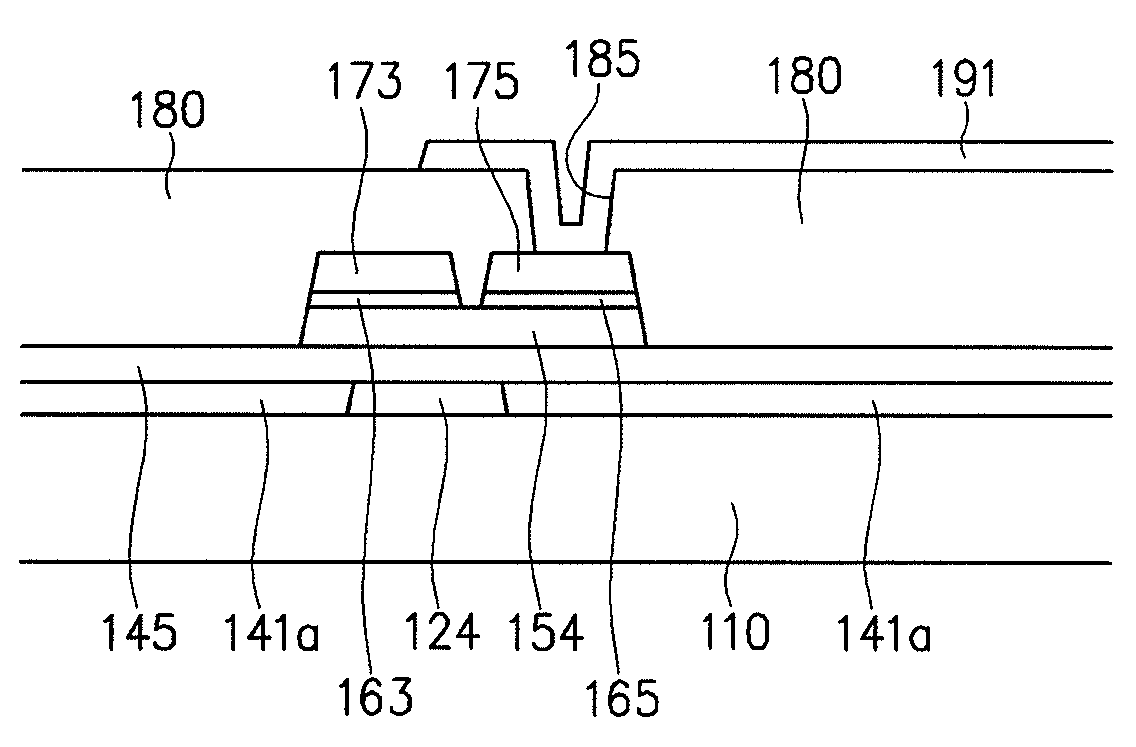

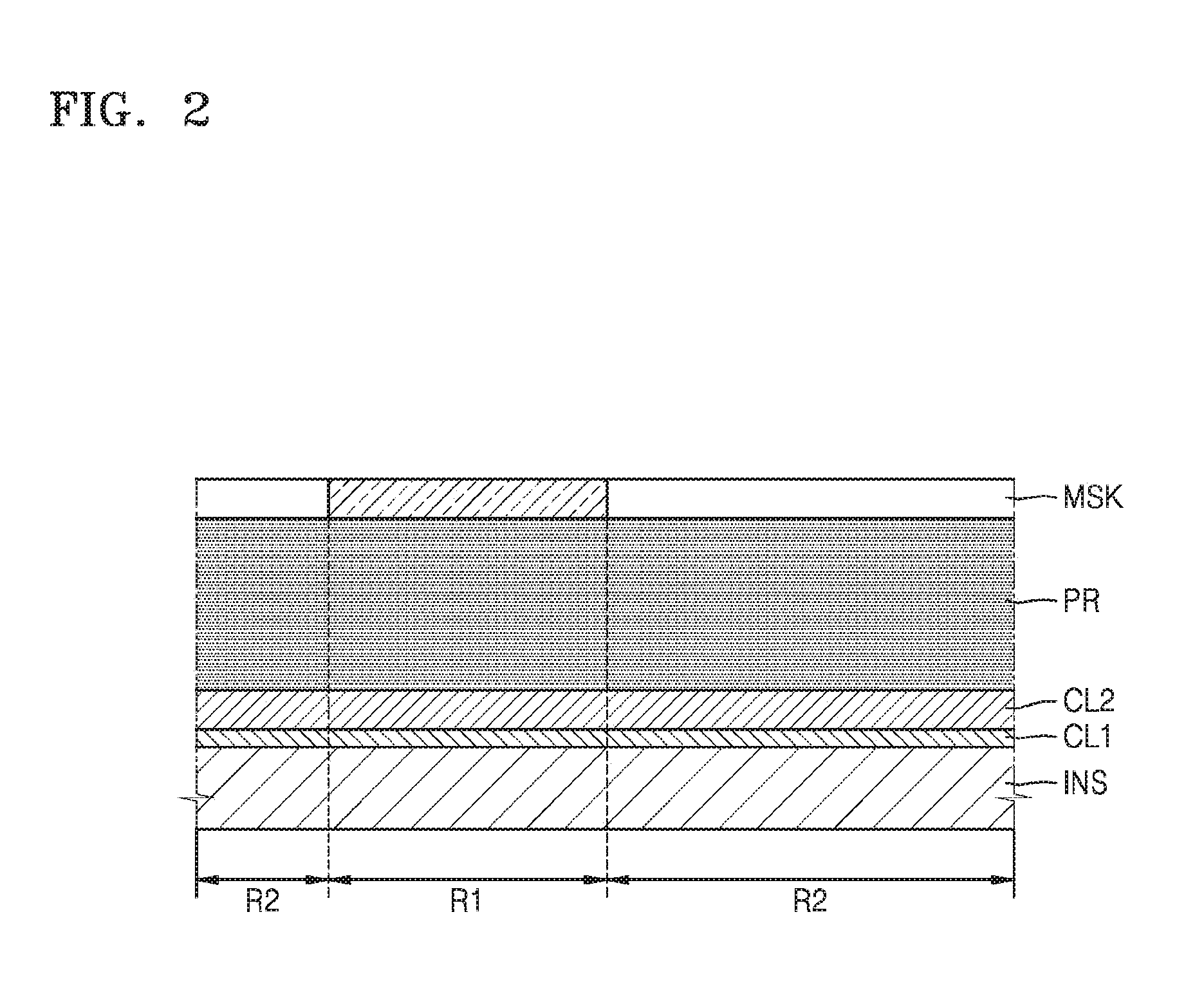

Etchant composition, and method of fabricating metal pattern and thin film transistor array panel using the same

ActiveUS20100120209A1Excellent etch profileExcellent productivityDecorative surface effectsSolid-state devicesPhosphoric acidChemistry

An etchant composition is provided. The etchant composition includes about 40 to about 65 wt % of phosphoric acid, about 2 to about 5 wt % of nitric acid, about 2 to about 20 wt % of acetic acid, about 0.1 to about 2 wt % of a compound containing phosphate, about 0.1 to about 2 wt % of a compound simultaneously containing an amino group and a carboxyl group, and a remaining weight percent of water for the total weight of the composition.

Owner:SAMSUNG DISPLAY CO LTD +1

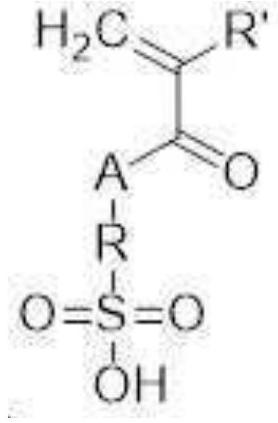

Etchant composition and method of manufacturing a thin film transistor substrate by using the same

ActiveUS20170029958A1Excellent etching propertiesSolid-state devicesSemiconductor/solid-state device manufacturingWater basedOrganic acid

An etchant composition includes an etchant composition that includes about 0.5 wt % to about 20 wt % of persulfate, about 0.01 wt % to about 2 wt % of a fluorine compound, about 1 wt % to about 10 wt % of an inorganic acid, about 0.5 wt % to about 5 wt % of a cyclic amine compound, about 0.1 wt % to about 5 wt % of a chlorine compound, about 0.1 wt % to about 10 wt % of an aliphatic sulfonic acid, about 1 wt % to about 20 wt % of an organic acid or an organic acid salt, and water based on a total weight of the etchant composition.

Owner:SAMSUNG DISPLAY CO LTD +1

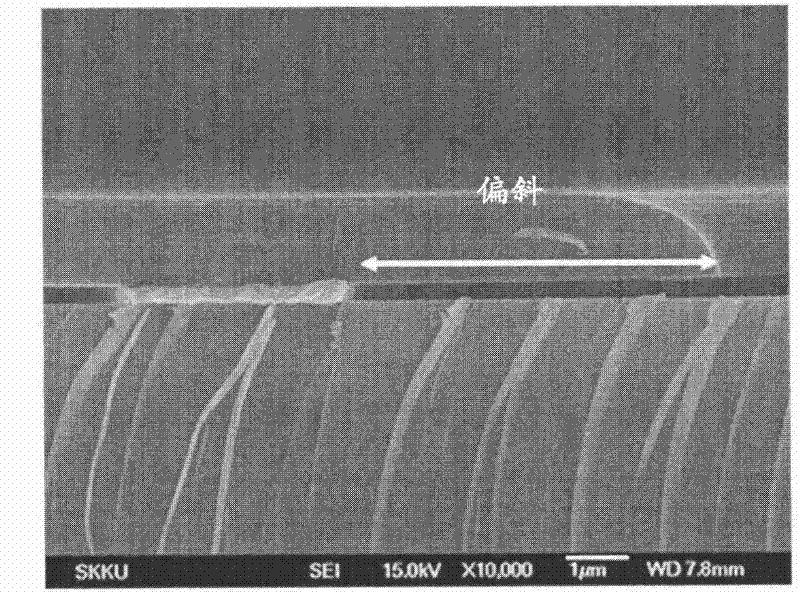

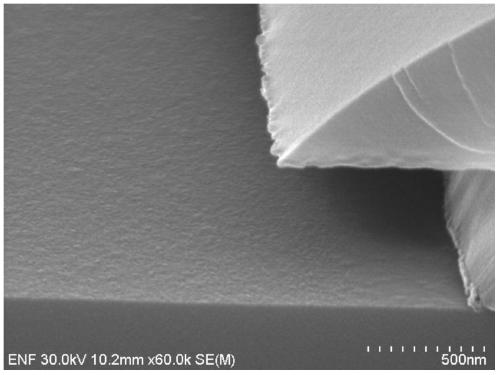

Etching liquid composition for copper-and-molybdenum-containing film

InactiveCN109136925ASide erosion can be controlledExcellent etching propertiesPhotomechanical apparatusSurface treatment compositionsAlloyCopper

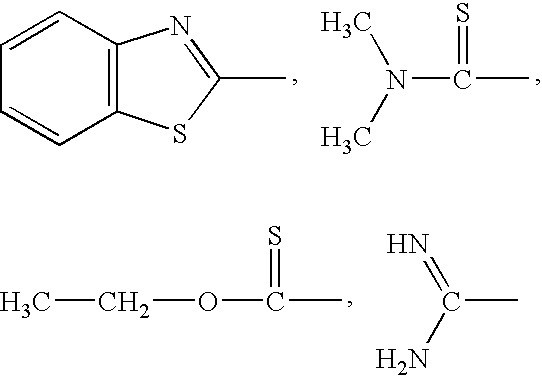

The invention relates to an etching liquid composition which is used for controlling lateral erosion of a molybdenum film or a molybdenum alloy film to realize stable etching processes when a copper-and-molybdenum-containing film is etched. The etching liquid composition can improve etching characteristics such as an etching taper angle, etching deviation, etching straightness and the like. The etching liquid composition comprises 10 to 30 weight% of a hydrogen peroxide, 0.1 to 5 weight% of an etching inhibitor, 0.1 to 5 weight% of a chelating agent, 0.1 to 5 weight% of an etching additive, 0.01 to 2 weight% of fluoride and 0.01 to 2 weight% of lateral erosion inhibitor; the total weight is enabled to be 100 weight% of water.

Owner:ENF TECH

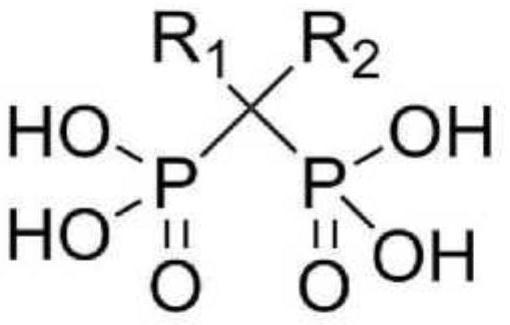

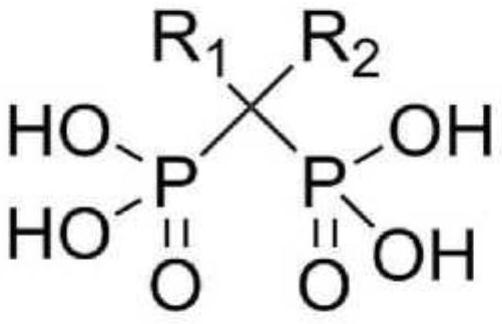

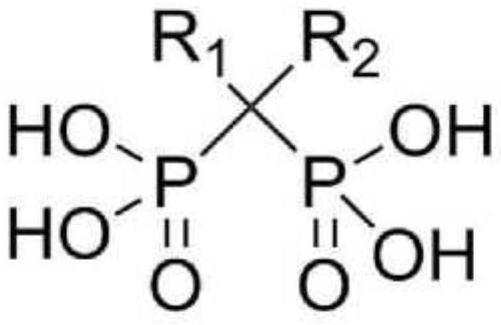

Metal film etching solution composition and method for forming conductive pattern using same

ActiveCN108660458AReduce dead pixelsReduce electrical short circuitSolid-state devicesSemiconductor/solid-state device manufacturingAcetic acidPhosphate

The present invention relates to a metal film etching solution composition and a method for forming a conductive pattern using the same, and more particularly, to a metal film etching solution composition comprising: 40 to 60% by weight of phosphoric acid; 3 to 8% by weight of nitric acid; 5 to 20% by weight of acetic acid; 0.1 to 3% by weight of phosphate; and 0.1 to 6 by weight of an anti-adsorbent comprising at least one of a diol-based compound and a compound containing a plurality of phosphate group; and the balance of water, thereby effectively preventing etched metal from being adsorbedon the substrate again. A lower film is not damaged, and the composition has excellent etching characteristics for a film to be etched.

Owner:DONGWOO FINE CHEM CO LTD

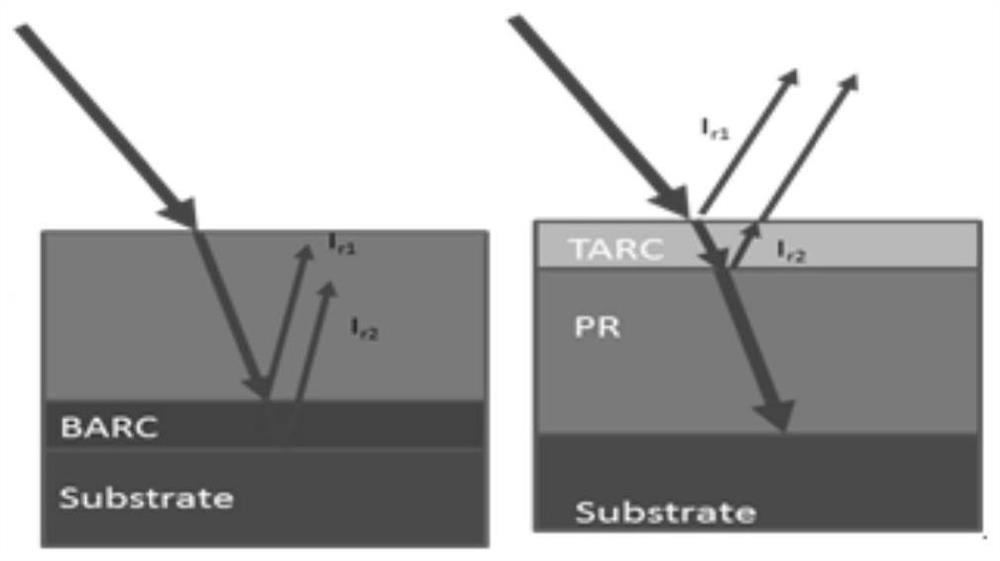

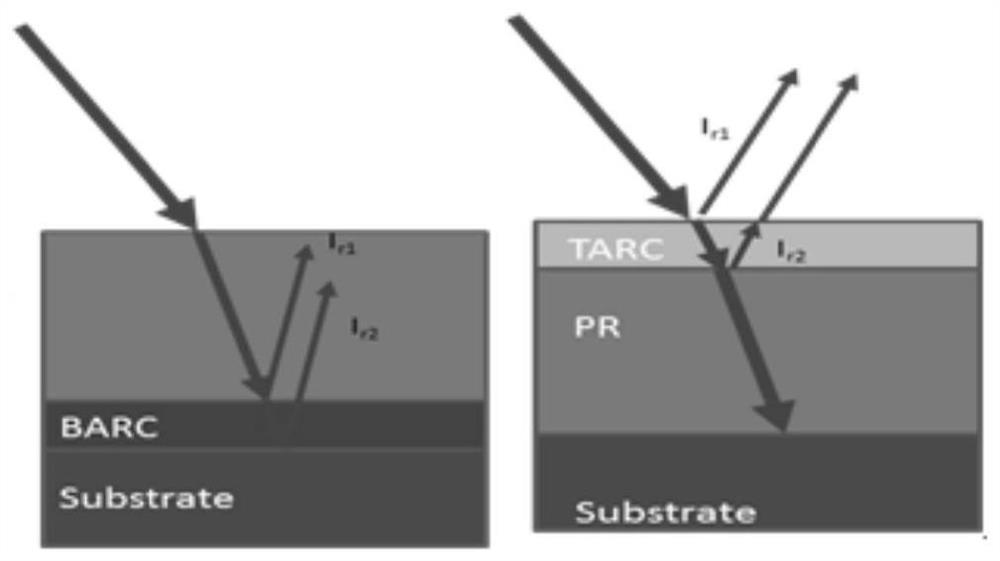

Antireflection coating composition and application thereof

ActiveCN112680052AImprove coating qualityEasy transferPhotomechanical apparatusAnti-reflective coatingsAnti-reflective coatingSolid component

The present invention provides an antireflective coating composition. Theantireflective coating composition can strongly absorb radiation of 100-300 nm by using the extinction resin of the present invention, particularly has high light absorption performance at 248 nm, and has an extinction coefficient K of 0.4 or more or 0.5 or more, thereby allowing the use of a thinner coating layer and a shorter etching time, and the prepared antireflective coating material is easy to remove, and is particularly suitable for being used in thin-layer photoresist to obtain a high-resolution photoetching pattern; meanwhile, the BARC layer provided by the invention also has an improved plasma etching rate relative to a photoresist material, so that an image can be completely transferred to a substrate to obtain a good photoresist image. Further, through the interaction of the solid components, the interference effect in the photoresist can be eliminated; and through the combined action of a catalyst, a crosslinking agent and extinction resin, the antireflection coating composition with good storage stability and high differential solubility after curing is obtained.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

Etchant composition, and method of fabricating metal pattern and thin film transistor array panel using the same

ActiveUS7968000B2Excellent etching propertiesExcellent etch profileDecorative surface effectsSolid-state devicesAcetic acidPhosphate

An etchant composition is provided. The etchant composition includes about 40 to about 65 wt % of phosphoric acid, about 2 to about 5 wt % of nitric acid, about 2 to about 20 wt % of acetic acid, about 0.1 to about 2 wt % of a compound containing phosphate, about 0.1 to about 2 wt % of a compound simultaneously containing an amino group and a carboxyl group, and a remaining weight percent of water for the total weight of the composition.

Owner:SAMSUNG DISPLAY CO LTD +1

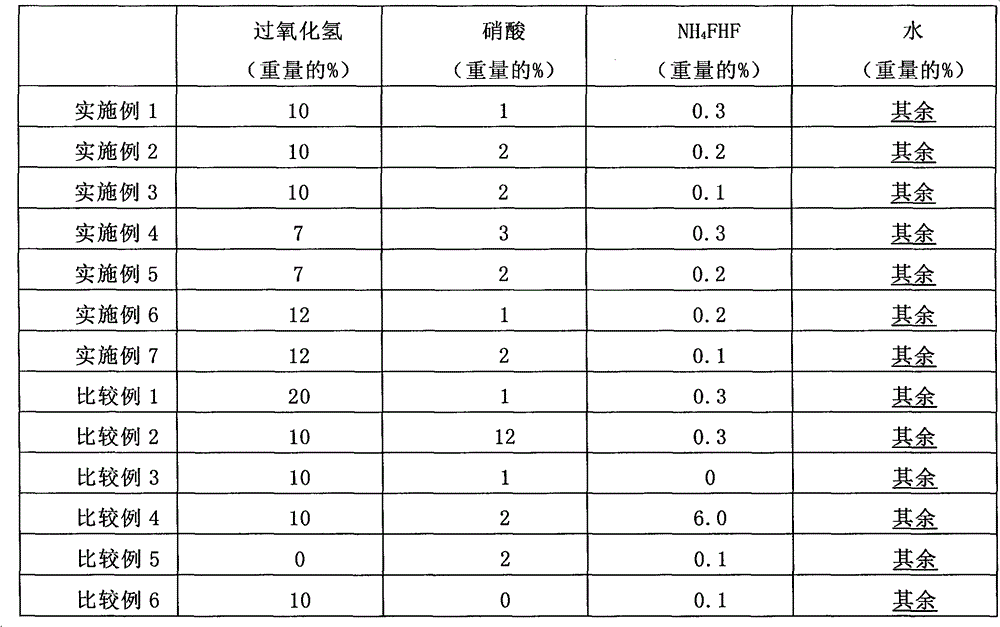

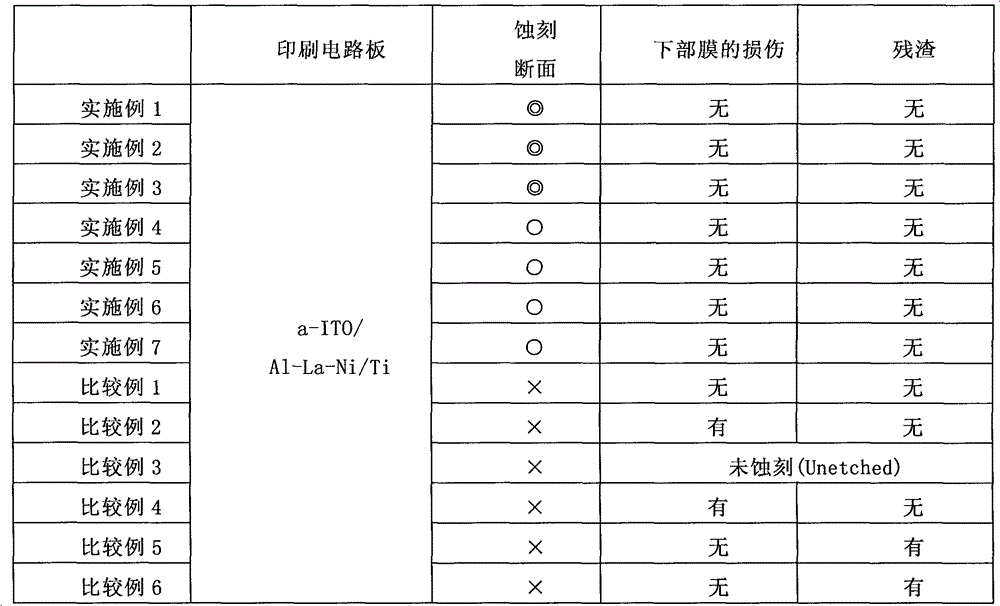

Etchant composition

ActiveCN102753652AExcellent etching propertiesPhenomena such as upper curling will not occurSurface treatment compositionsIndiumAlloy

The present invention relates to an etchant composition for etching a triple film consisting of an indium-based metal film, an aluminum-lanthanum-based alloy film, and a titanium-based metal film, wherein the etchant composition comprises: 1 to 15 wt % of hydrogen peroxide; 0.1 to 10 wt % of inorganic acid; and 0.01 to 5 wt % of a fluorine compound, with the remainder being water.

Owner:DONGWOO FINE CHEM CO LTD +1

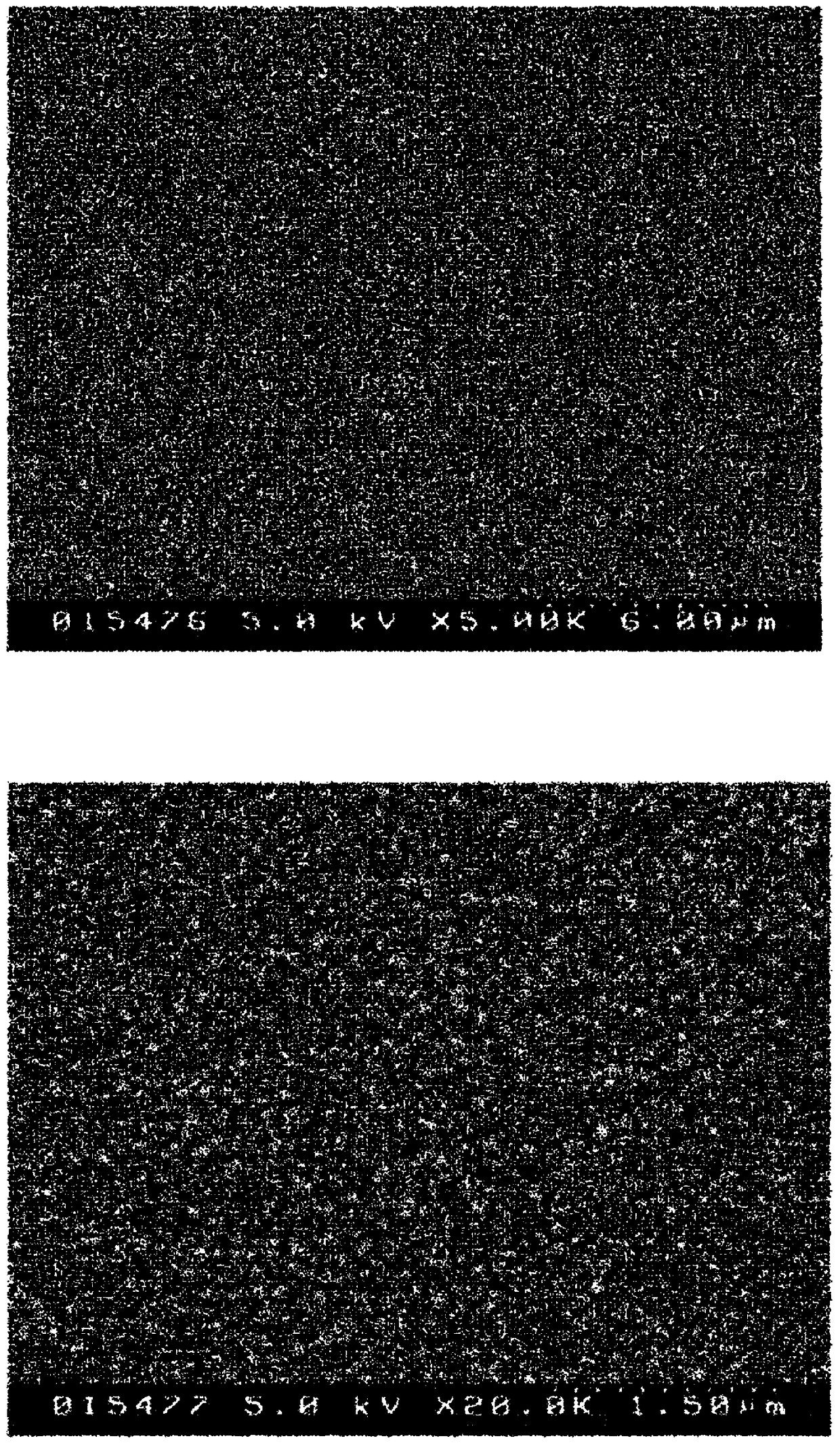

Two-layer flexible substrate

ActiveUS8568856B2Excellent etching propertiesAdherence to resistInsulating substrate metal adhesion improvementSynthetic resin layered productsResistAdhesive

The invention provides a two-layer flexible substrate free of surface defects and having excellent etching characteristics and adherence to a resist.The two-layer flexible substrate has a copper layer provided on one or both faces of an insulator film without using an adhesive, wherein the surface roughness (Ra) of the copper layer is 0.10 to 0.25 μm, and wherein the average crystal grain size [of copper] is no greater than 0.8 μm at 1 μm from the insulator film in the cross-section of the copper layer. Preferably, the insulator film is a polyimide film.

Owner:JX NIPPON MINING & METALS CORP

Etchant composition for the formation of a metal line

ActiveCN102471686AImprove productivityUniform etchingSemiconductor/solid-state device manufacturingSurface treatment compositionsProduction rateDisplay device

The present invention relates to an etchant composition for the formation of a metal line. The etchant composition can wet-etch, in a batch, a single-layer film formed of one or more metals selected from a group consisting of titanium, titanium alloy, aluminum, and an aluminum alloy, or a multilayer film including a double-layer film, thus simplifying the etching process and improving productivity. Further, the etchant composition of the present invention has a high etching rate, prevents damage to a lower film and equipment, enables uniform etching, provides excellent etching characteristics, eliminates the need for expensive equipment, is advantageous when used for large display devices, and provides remarkable economical advantages.

Owner:DONGWOO FINE CHEM CO LTD

Etchant composition and method of manufacturing a thin film transistor substrate by using the same

ActiveUS10465296B2Excellent etching propertiesSolid-state devicesSemiconductor/solid-state device manufacturingOrganic acidWater based

An etchant composition includes an etchant composition that includes about 0.5 wt % to about 20 wt % of persulfate, about 0.01 wt % to about 2 wt % of a fluorine compound, about 1 wt % to about 10 wt % of an inorganic acid, about 0.5 wt % to about 5 wt % of a cyclic amine compound, about 0.1 wt % to about 5 wt % of a chlorine compound, about 0.1 wt % to about 10 wt % of an aliphatic sulfonic acid, about 1 wt % to about 20 wt % of an organic acid or an organic acid salt, and water based on a total weight of the etchant composition.

Owner:SAMSUNG DISPLAY CO LTD +1

Etching solution composition for silver-containing metal layer

The present invention provides an etching solution composition for a silver-containing metal film, which comprises nitric acid, polysulfonic acid, organic acid and water. The etching solution composition according to the present invention contains nitric acid, polysulfonic acid, organic acid, and water, and for a silver (Ag) or silver alloy metal film used as a reflector or wiring of a display device, damage to the lower film is suppressed, and during formation of fine wirings, it is possible to minimize the occurrence of undesirable deviations and debris or precipitates, and can exhibit excellent etching characteristics.

Owner:ENF TECH

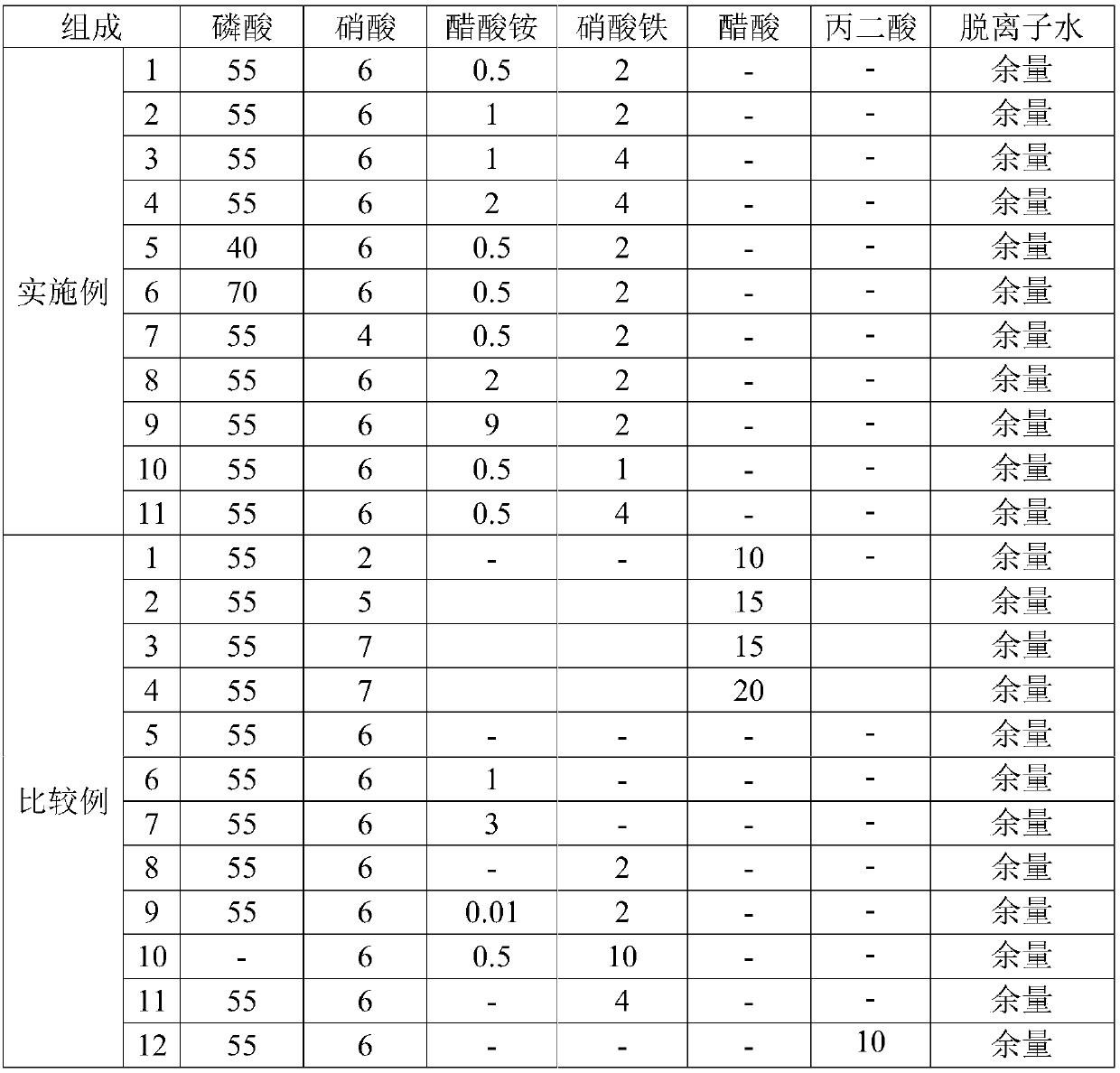

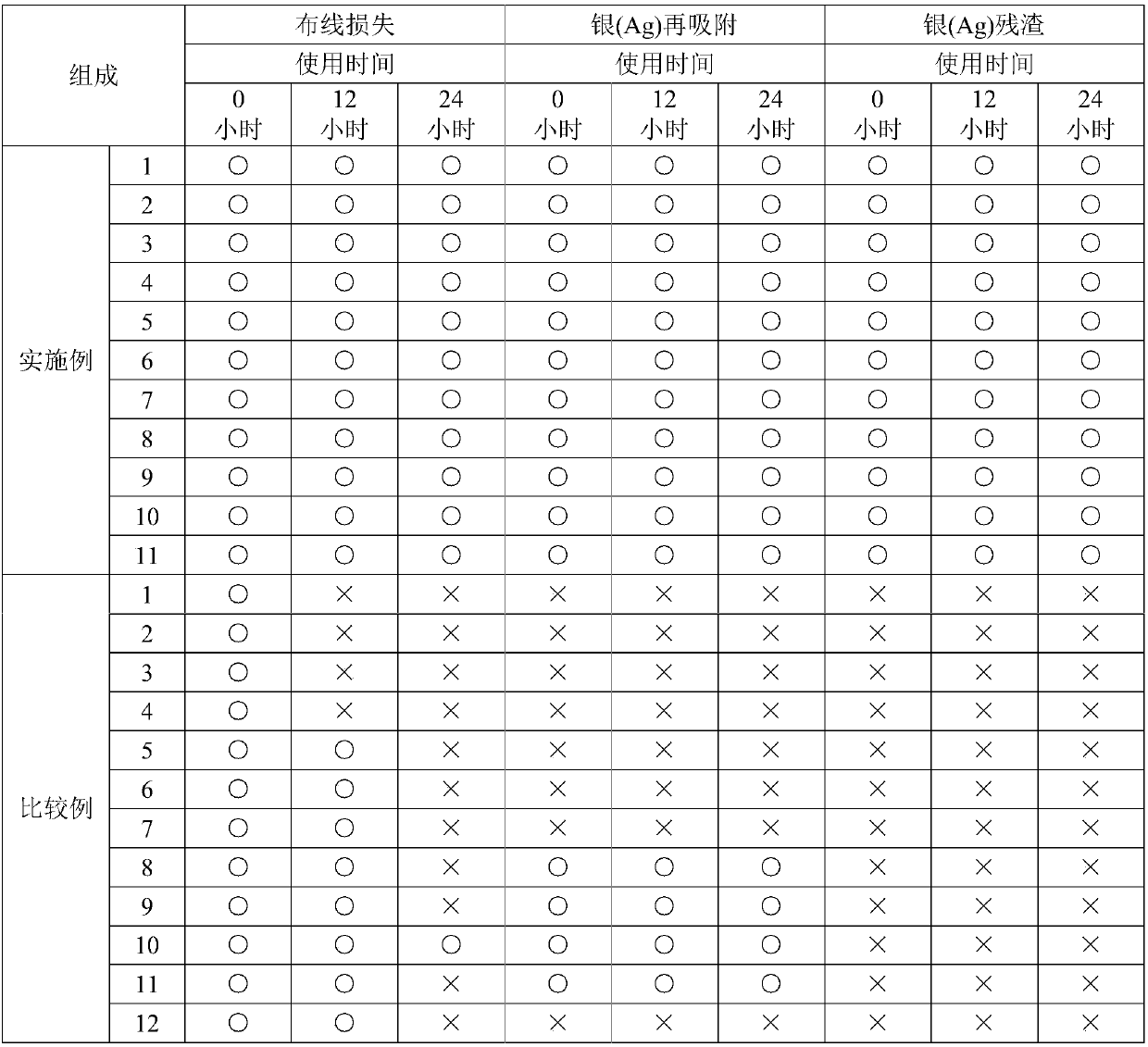

Etchant composition for silver thin layer and ehting method and mehtod for fabrication metal pattern using the same

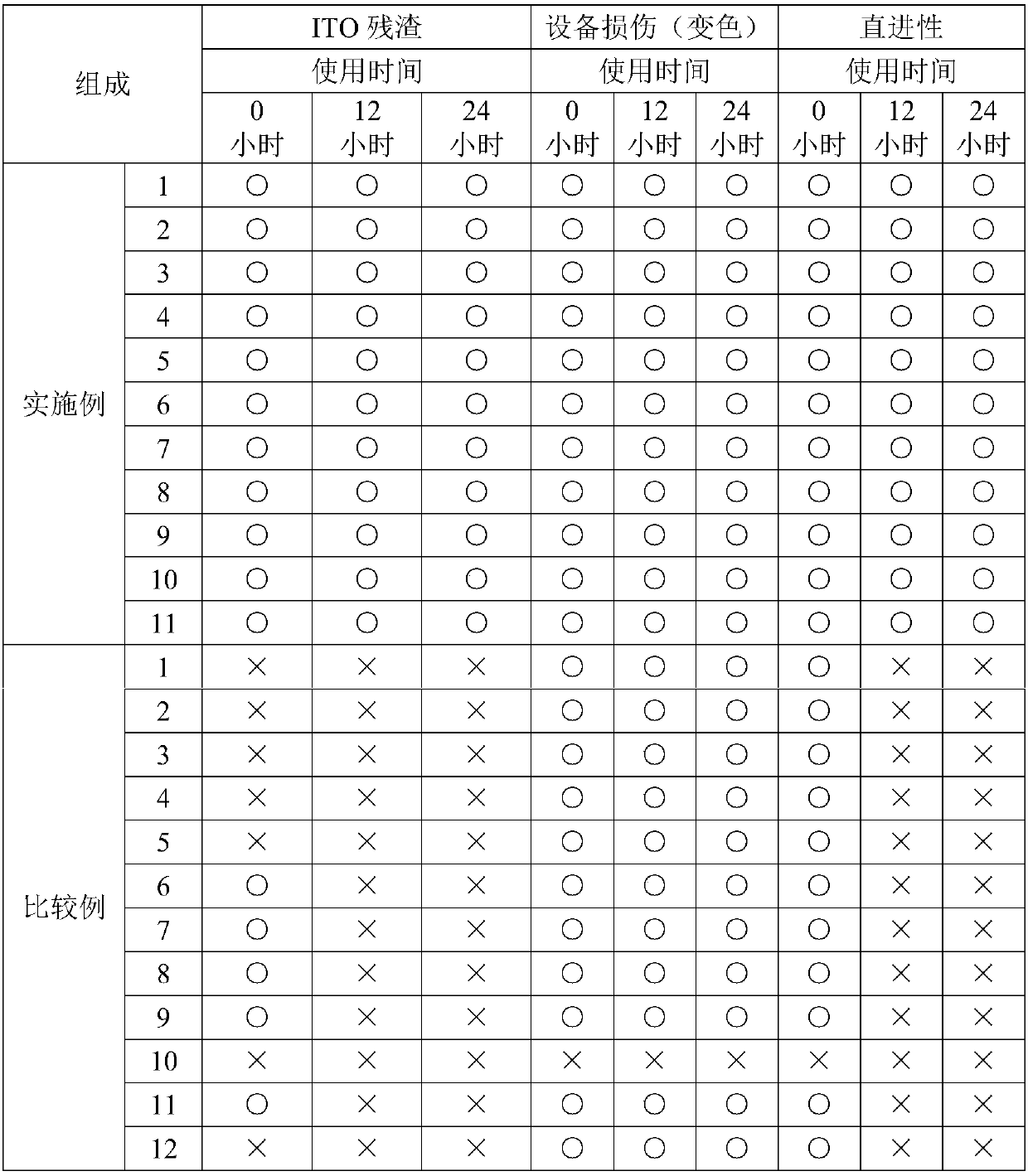

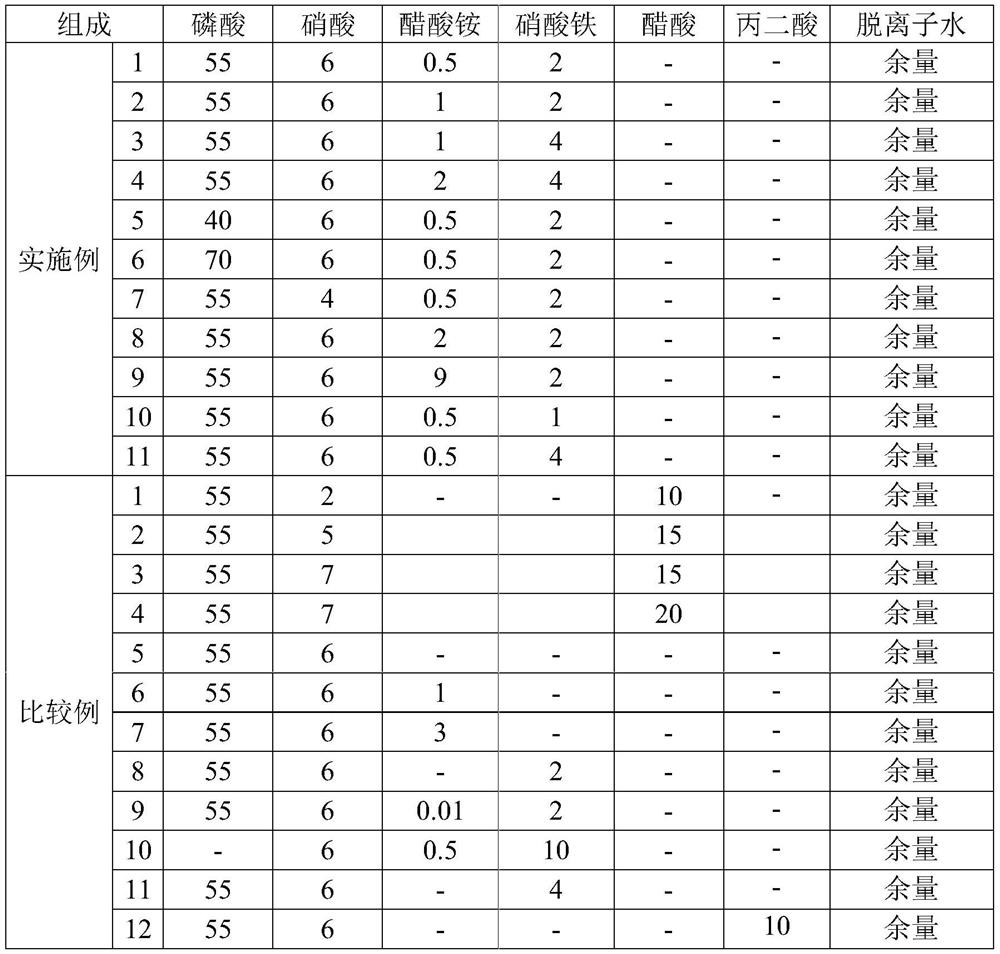

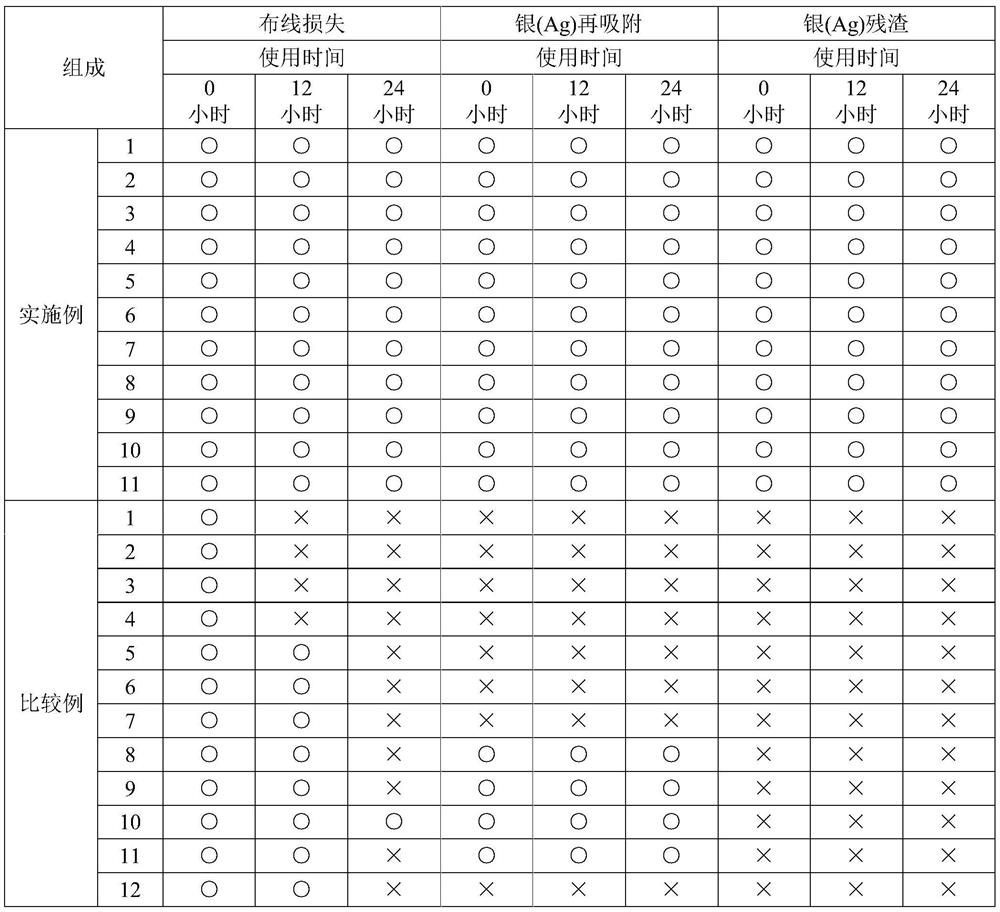

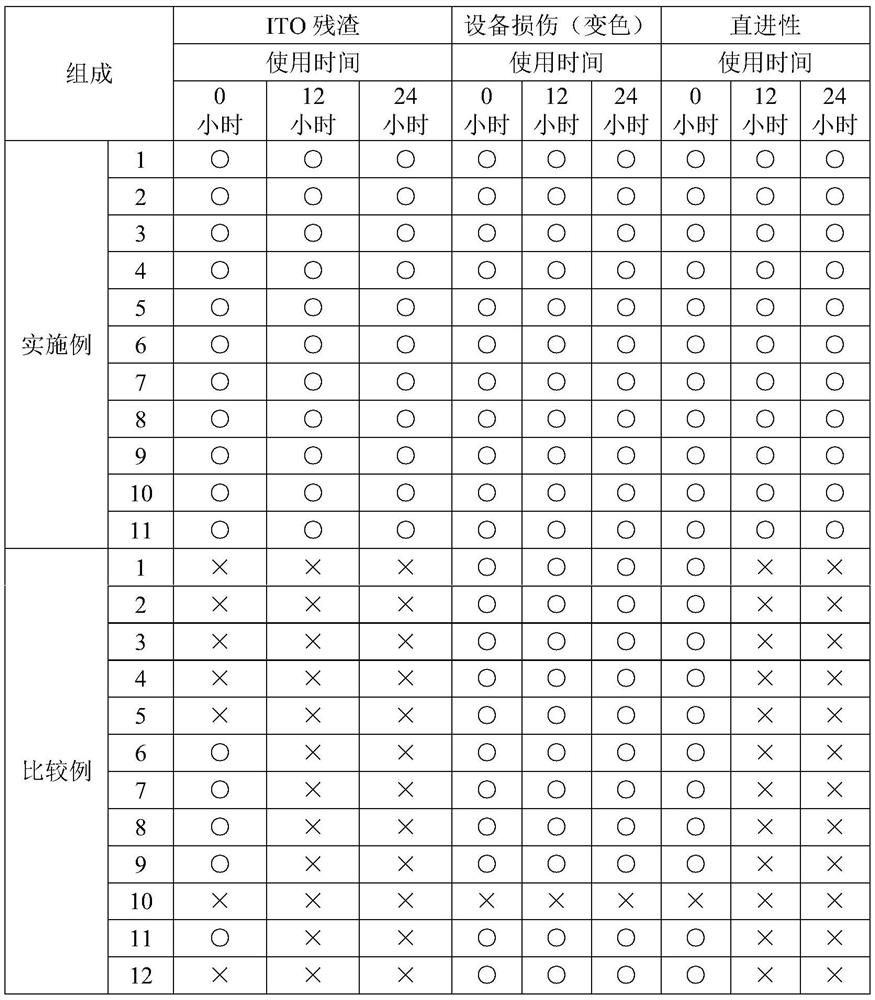

ActiveCN109797397ADoes not cause discoloration issuesExcellent etching straightnessSurface treatment compositionsThin layerPhosphoric acid

The present invention relates to a silver etching solution composition, an etching method using the same, and a method of forming a metal pattern, the silver etching solution composition comprising 30to 70% by weight of phosphoric acid, 2 to 9 by weight with respect to the total weight of the composition % of nitric acid, 0.1 to 9% by weight of the acetate compound, 0.1 to 10% by weight of ferricnitrate, and the balance of the total weight of the composition to 100% by weight of water.

Owner:DONGWOO FINE CHEM CO LTD

Silver etchant composition, etching method using same, and metal pattern forming method

ActiveCN109797397BDoes not cause discoloration issuesImprove uniformitySurface treatment compositionsO-Phosphoric AcidPhysical chemistry

The present invention relates to a silver etchant composition, an etching method utilizing it and a method for forming a metal pattern. The silver etchant composition contains 30 to 70% by weight of phosphoric acid, 2 to 9% by weight relative to the total weight of the composition. % nitric acid, 0.1 to 9% by weight of an acetate compound, 0.1 to 10% by weight of ferric nitrate and the balance of water making the total weight of the composition 100% by weight.

Owner:DONGWOO FINE CHEM CO LTD

Aluminum material, method of manufacturing aluminum material , electrolytic capacitor and anode material

InactiveCN1942984BReliable removalExcellent etching propertiesAnodisationElectrolytic capacitorsElectrolysisSurface layer

A method for manufacturing an aluminum material for electrolytic capacitor electrodes of the present invention, comprising the steps of heating an aluminum material in an oxidative atmosphere, removing the surface layer of the aluminum material by washing the heated aluminum material and subjecting the washed aluminum material obtained by washing to final annealing.

Owner:SHOWA DENKO KK

Etching liquid composition and preparation method thereof

PendingCN114657564AAvoid it happening againImprove residueSolid-state devicesSemiconductor/solid-state device manufacturingMetal membraneNanotechnology

The present invention relates to an etchant composition for etching silver (Ag) or a silver-containing film and a method for preparing the same. According to the etchant composition of the present invention, in an etching step of silver or a silver-containing metal film, by improving residues and preventing the generation of deposits without damaging the underlayer film, deviation defects during the formation of fine wiring can be minimized, thereby improving etching characteristics.

Owner:ENF TECH

Metal film etchant composition and conductive pattern forming method using same

ActiveCN108660458BReduce dead pixelsReduce electrical short circuitSolid-state devicesSemiconductor/solid-state device manufacturingAcetic acidO-Phosphoric Acid

The present invention relates to a metal film etching solution composition and a method for forming a conductive pattern using the same. More specifically, it relates to the following metal film etching solution composition. The total weight of the composition includes: 40-60% by weight of phosphoric acid; 3-8% by weight of nitric acid; 5-20% by weight of acetic acid; 0.1-3% by weight of phosphate; 0.1-6% by weight of anti-adsorption agent containing at least one of diol-based compounds and compounds containing multiple phosphoric acid groups; And the remaining water, so as to effectively prevent the etched metal from re-adsorbing on the substrate, without damaging the lower film, and show excellent etching characteristics for the etching target film.

Owner:DONGWOO FINE CHEM CO LTD

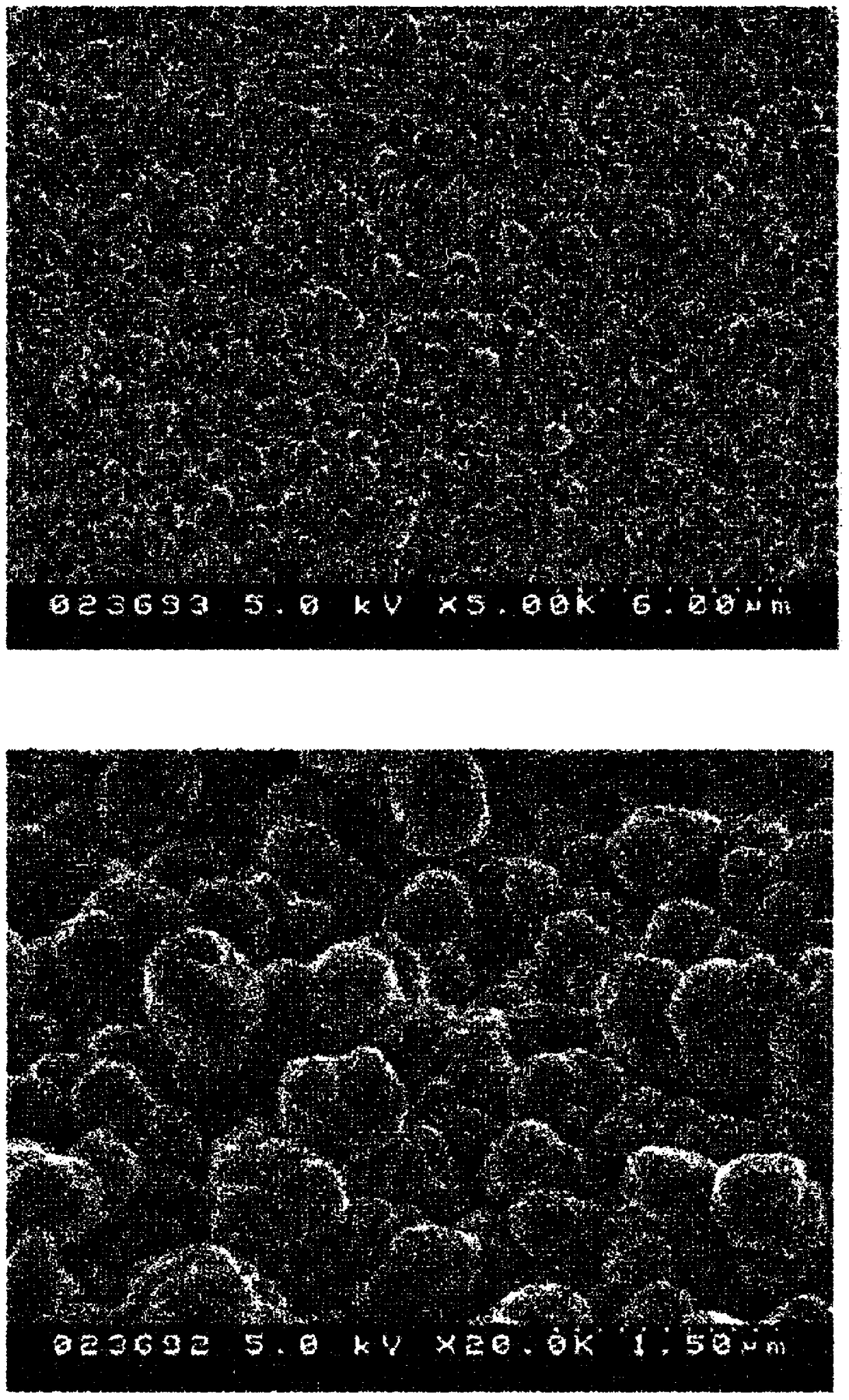

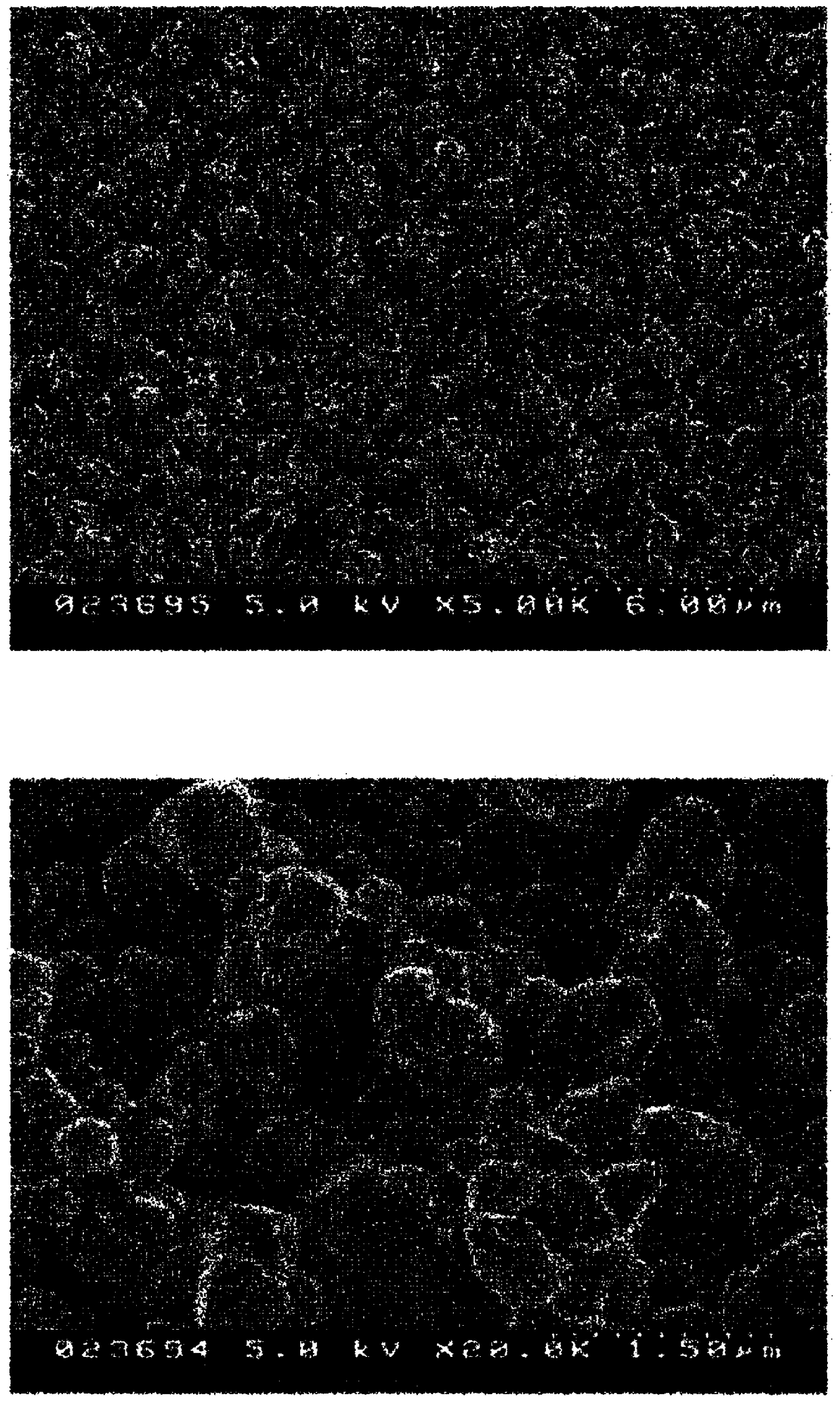

Blackened surface-treated copper foil, manufacturing method of blackened surface-treated copper foil, copper-clad laminate, and flexible printed circuit board

ActiveCN105008593BImprove detection accuracyShorten overetching timePrinted circuit aspectsPrinted circuit manufactureCopper foilMaterials science

The object of the present invention is to provide a copper foil for a printed wiring board, which has a blackened surface that can improve the visibility of the CCD in the terminal connection process and the detection accuracy of the AOI of the flexible printed wiring board. Appropriate roughness for flexible printed circuit board manufacturing, and has good etching properties. In order to achieve this object, the present invention adopts a blackened surface-treated copper foil for the manufacture of flexible printed wiring boards, etc., and the blackened surface-treated copper foil is a surface-treated copper foil having a roughened surface, and is characterized in that the roughened surface The surface is a black roughened surface having a maximum level difference (Wmax) of 1.2 μm or less, and a color tone having a lightness L* of L*a*b* colorimetric system of 30 or less.

Owner:MITSUI MINING & SMELTING CO LTD

Etching solution composition for copper and molybdenum containing film

ActiveCN104513981BSide erosion can be controlledExcellent etching propertiesPhotomechanical apparatusSurface treatment compositionsAlloyCopper

The invention relates to an etching liquid composition which is used for controlling lateral erosion of a molybdenum film or a molybdenum alloy film to realize stable etching processes when a copper-and-molybdenum-containing film is etched. The etching liquid composition can improve etching characteristics such as an etching taper angle, etching deviation, etching straightness and the like. The etching liquid composition comprises 10 to 30 weight% of a hydrogen peroxide, 0.1 to 5 weight% of an etching inhibitor, 0.1 to 5 weight% of a chelating agent, 0.1 to 5 weight% of an etching additive, 0.01 to 2 weight% of fluoride and 0.01 to 2 weight% of lateral erosion inhibitor; the total weight is enabled to be 100 weight% of water.

Owner:ENF TECH

A kind of copper-containing lamination etchant, etching method and application thereof

ActiveCN112342548BLow costReduce processing costsSolid-state devicesSemiconductor/solid-state device manufacturingChemical treatmentOrganic acid

The present invention relates to the field of chemical treatment of metal surfaces, more specifically, the present invention relates to a copper-containing lamination etchant, an etching method and its application. The etchant includes a main agent, and in parts by weight, the main agent includes 1 ‑20 parts of oxidizing agent, 0.01‑1 part of fluoride ion source, 0.01‑5 part of inorganic acid, 1‑15 part of organic acid, 1‑15 part of organic base, 0.01‑5 part of hydrogen peroxide stabilizer, 0.01‑1 part of metal corrosion inhibitor , make up 100 parts of solvent. The etchant provided by the invention has low cost, no phosphorus, is environmentally friendly, and has low waste treatment cost; it can effectively suppress cracks at the interface of different metals; it has high copper ion loading capacity; it has excellent etching characteristics, unilateral CD‑Loss<0.9um, the etching angle (taper) is 35‑45°; it can solve the problem of chamfering, effectively avoid bubbles in the insulating layer, and avoid the step of pre-dissolving copper.

Owner:江苏和达电子科技有限公司 +1

Etchant composition for silver layer and method for forming metal pattern and method for manufacturing display substrate using same

ActiveCN106702384BAvoid overetchingImprove wettabilityTransistorSolid-state devicesAcetic acidPropanoic acid

The present invention relates to an etchant composition for a silver layer, which comprises, based on the total weight of the composition: 30 to 70 wt % of phosphoric acid, 0.5 to 10 wt % of nitric acid, 5 to 20 wt % of propionic acid, 0.01 to 10 wt % % azole compounds, and the balance of water; using the etchant composition to form a metal pattern and using the etchant composition to manufacture a display substrate method. The etchant composition of the present invention can prevent overetching of silver or silver alloy to form lines with low S / E, and thus can be used for fine pattern formation. In particular, the etchant composition of the present invention includes propionic acid instead of acetic acid used in conventional etchant compositions for silver layers, thereby increasing wettability, thereby significantly improving etching characteristics.

Owner:DONGWOO FINE CHEM CO LTD

A kind of anti-reflection coating composition and its application

ActiveCN112680052BImprove coating qualityEasy transferPhotomechanical apparatusAnti-reflective coatingsAnti-reflective coatingPtru catalyst

The present invention provides an antireflection coating composition, which can strongly absorb radiation of 100 to 300 nm by using the matting resin of the present invention, especially has high light absorption performance at 248 nm, and the extinction coefficient K reaches 0.4 or more or 0.5 or more, thereby Allows the use of thinner coatings and shorter etching times, and the prepared anti-reflection coating material is easy to remove, and is particularly suitable for use in thin-layer photoresists to obtain high-resolution photolithographic patterns; at the same time, the present invention The BARC layer also has an improved plasma etch rate relative to the photoresist material, enabling the integrity of the image to be transferred to the substrate for a good photoresist image. Further, through the interaction of solid components, the interference effect in the photoresist can be eliminated; and through the joint action of the catalyst, the crosslinking agent and the matting resin of the present invention, a kind of photoresist with good storage properties can be obtained. Stable, highly differential solubility antireflective coating composition after curing.

Owner:SHANGHAI PHICHEM MATERIAL CO LTD

Titanium-copper alloy having plating layer

ActiveUS10092970B2Improve adhesionHigh bonding strengthProjector focusing arrangementSoldering apparatusTi-Cu alloyUltimate tensile strength

There is provided a titanium-copper alloy in which the adhesion strength with solder can be increased. The titanium-copper alloy comprises a base material and a plating layer provided on a surface of the base material, wherein the base material contains 1.5 to 5.0% by mass of Ti with a balance consisting of copper and unavoidable impurities, and the plating layer is selected from the group consisting of a Ni plating layer, a Co plating layer, and a Co—Ni alloy plating layer.

Owner:JX NIPPON MINING & METALS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com