Metal film etchant composition and conductive pattern forming method using same

A conductive pattern and composition technology, which is applied in the field of metal film etching solution composition, can solve the problems of poor wiring side profile, wiring bulge or peeling, and no countermeasures are provided, and achieves reduction of bad pixels and excellent etching properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example

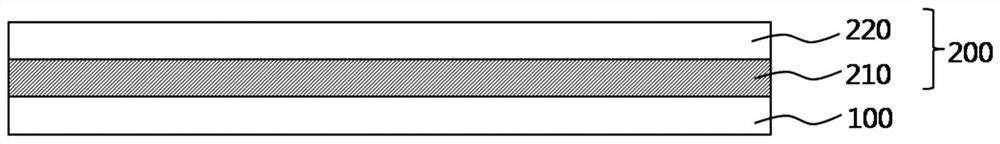

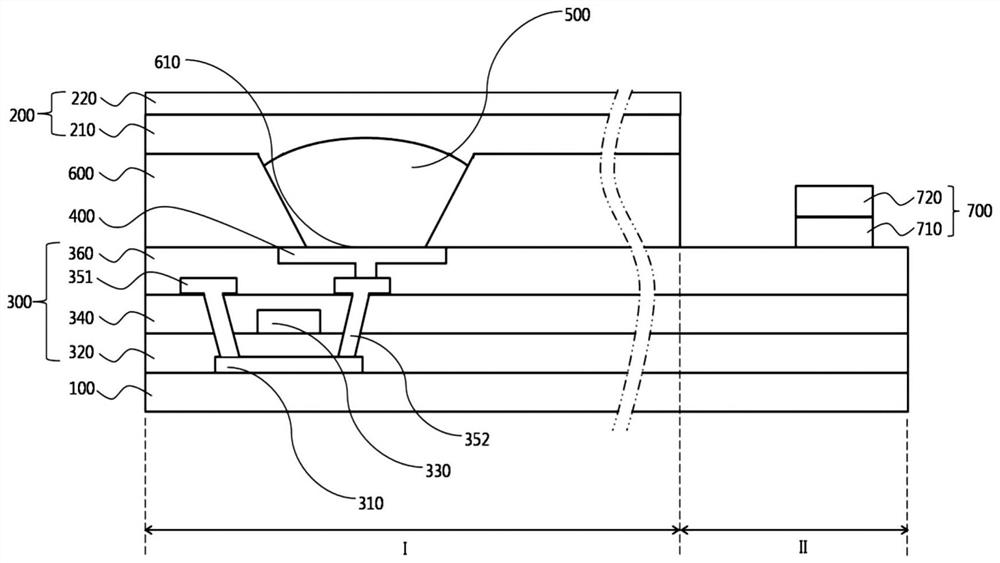

[0143] In order to test the performance of the metal film etchant composition, the following substrates are prepared: an organic insulating film is evaporated on the substrate, and the A substrate with a size of 680mm X 880mm obtained by vapor-depositing ITO / Ag / ITO three-layer film.

[0144] Afterwards, using the metal film etchant compositions of Examples and Comparative Examples, performance tests were performed as follows.

[0145] 1. Determination of critical dimension deviation (CD bias)

[0146] Put the metal film etchant compositions of the above-mentioned examples and comparative examples into the experimental equipment (model: ETCHER, K.C.Tech company) of the jet etching method respectively, set the temperature to 40° C. and heat it, and when the temperature reaches 40 At ±0.1°C, the above-mentioned etching process of the test piece was carried out. The total etching time was set to 100 seconds and implemented.

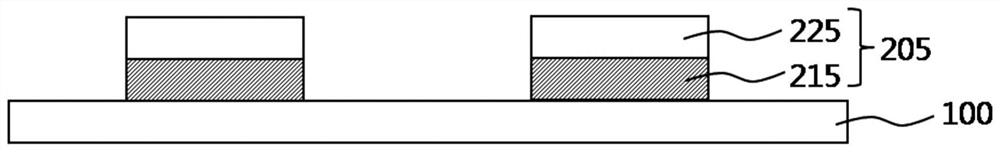

[0147] Specifically, a photoresist pattern is forme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com