Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Uniform surface temperature distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

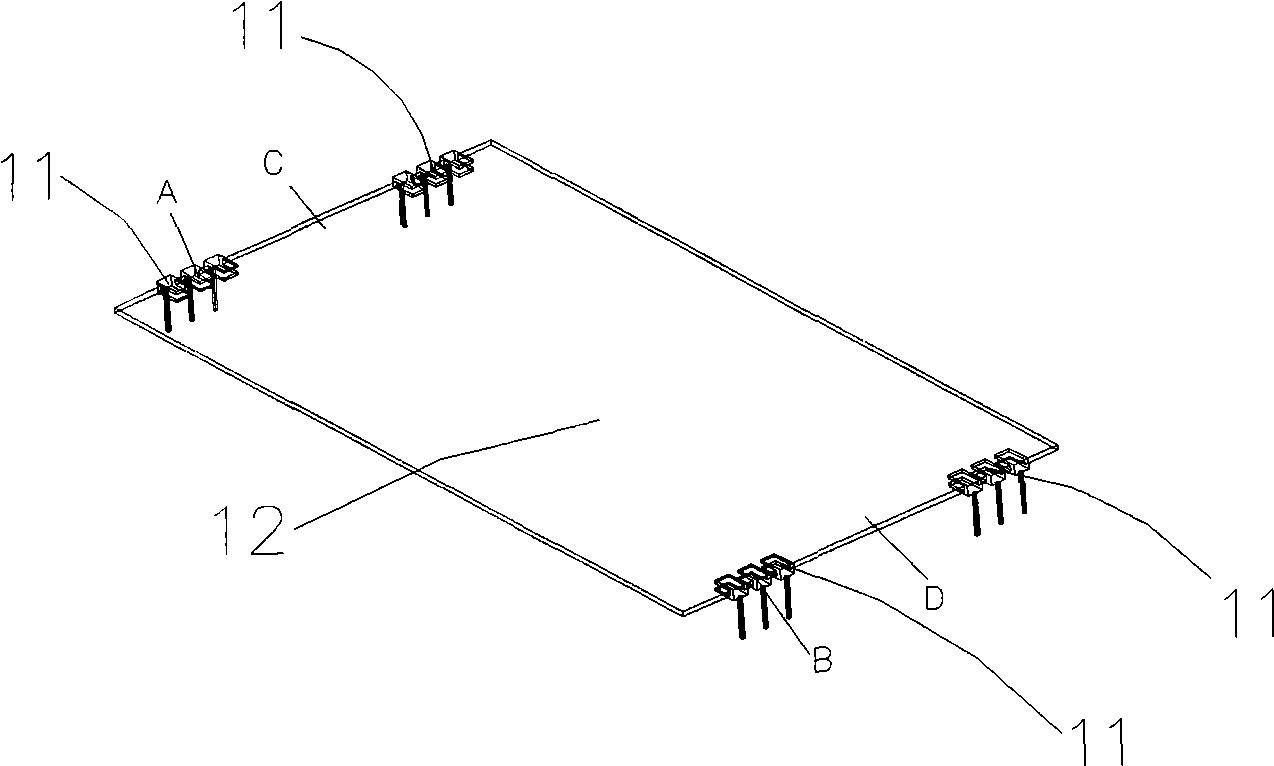

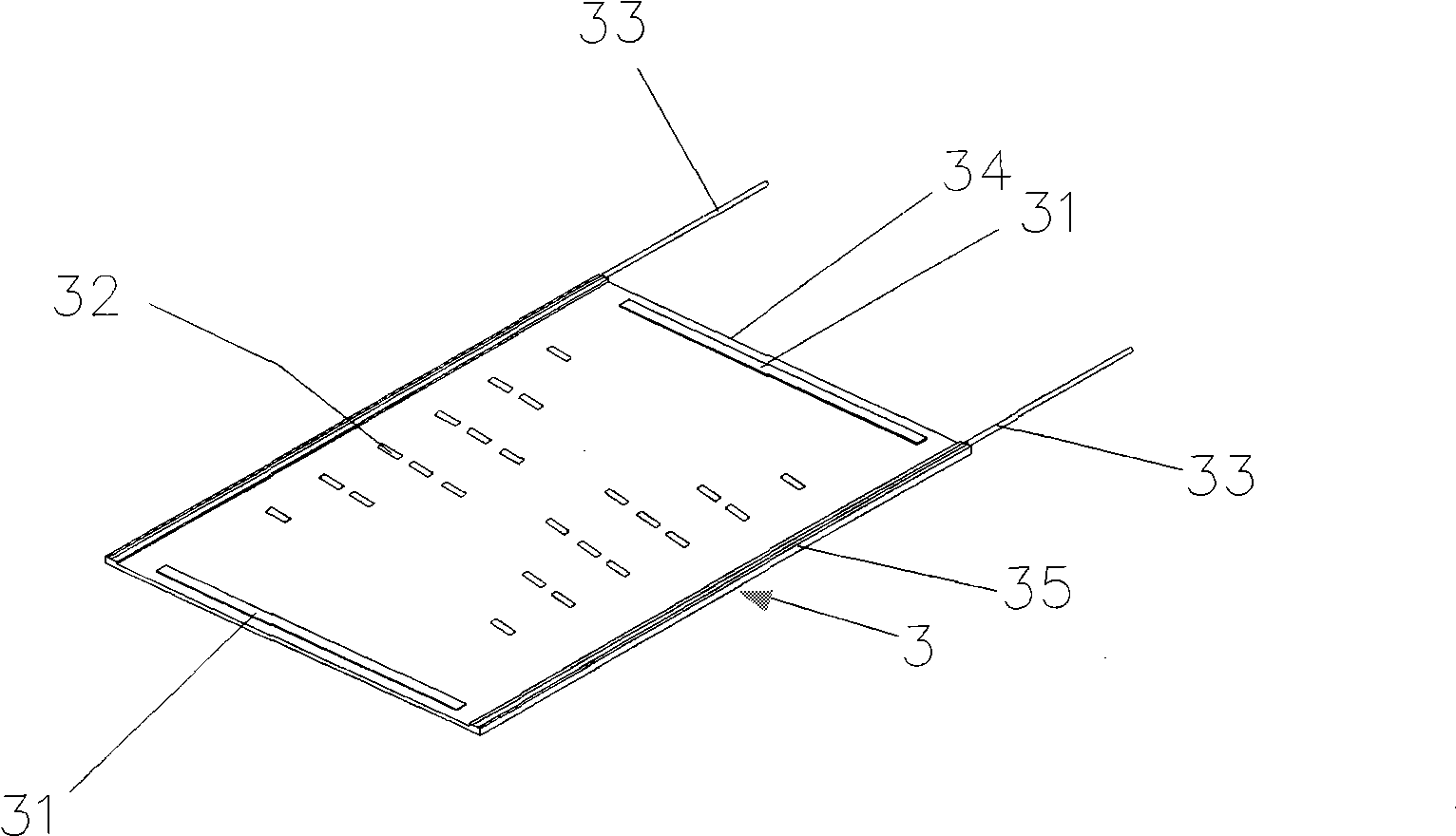

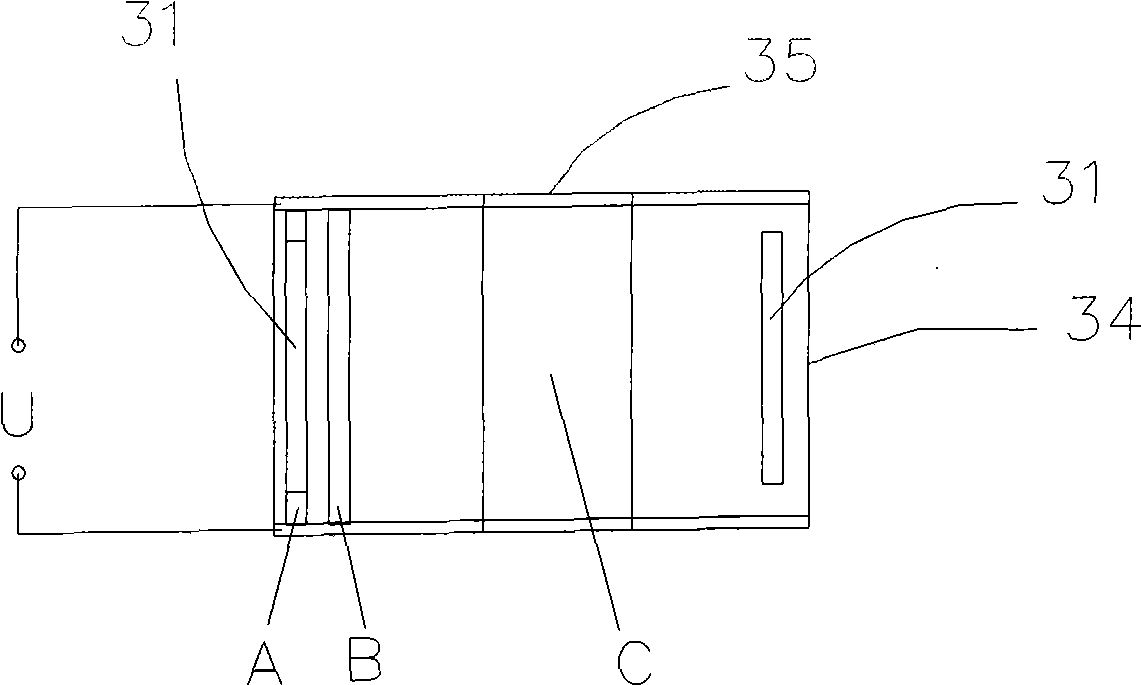

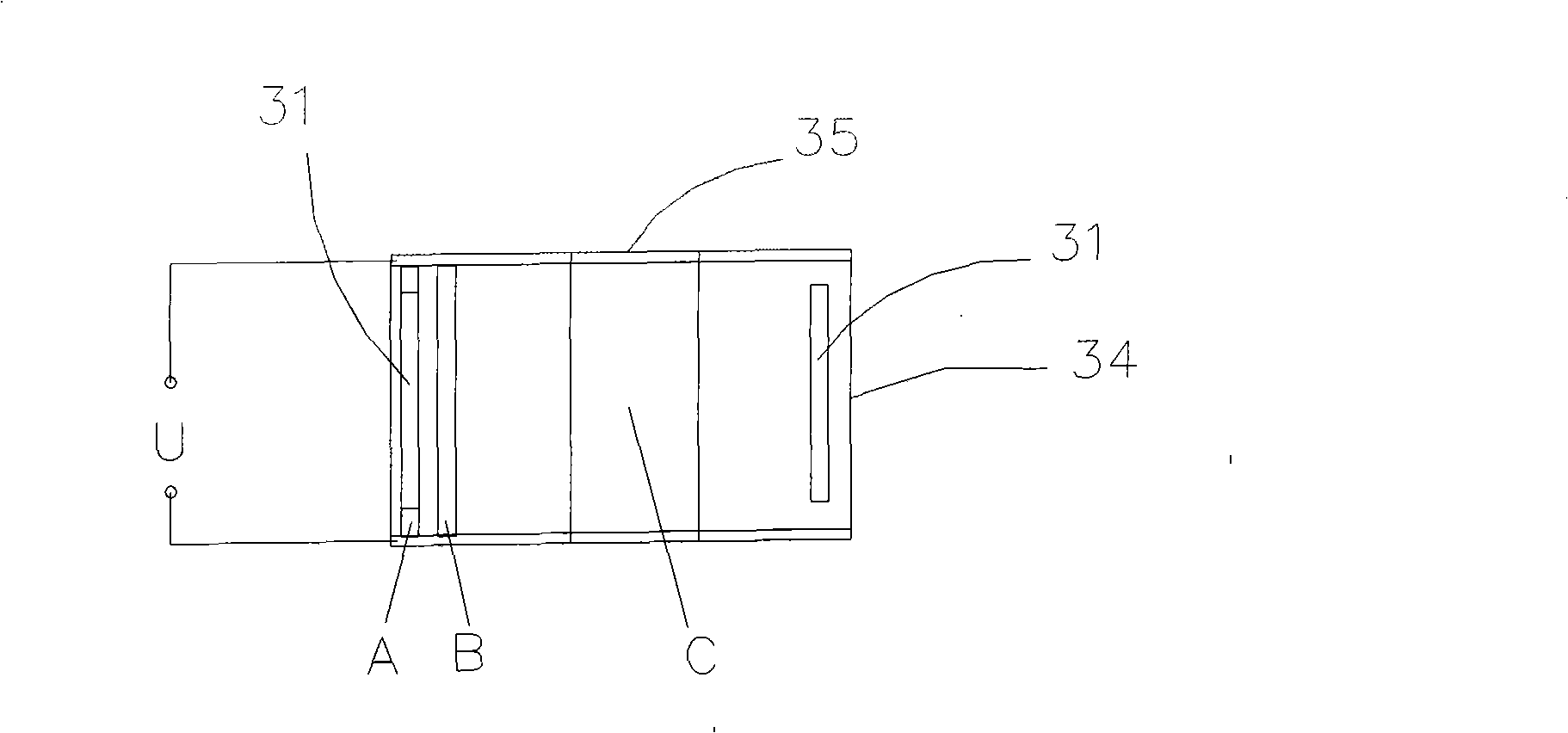

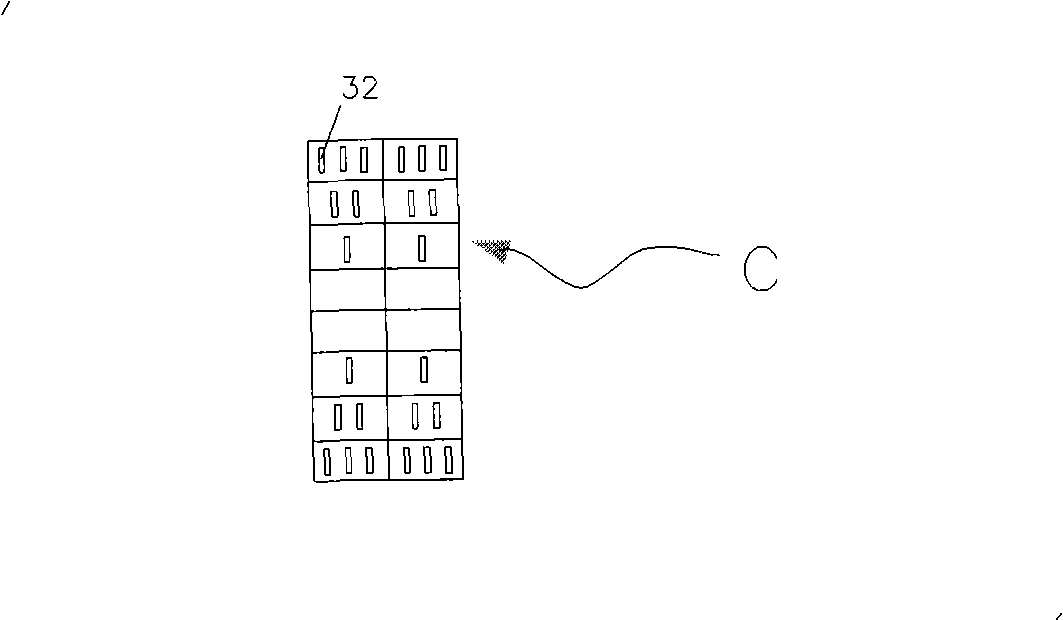

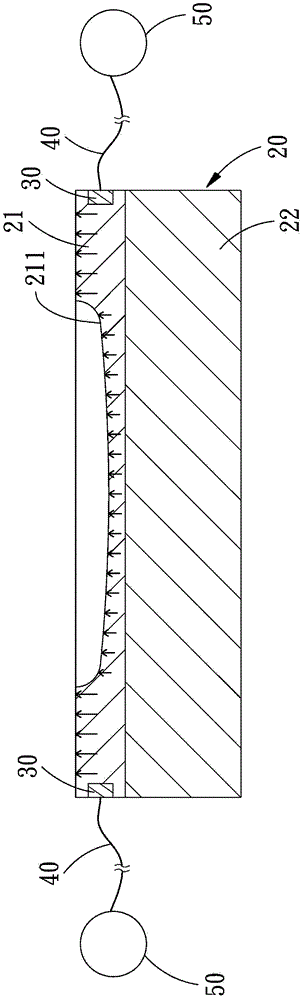

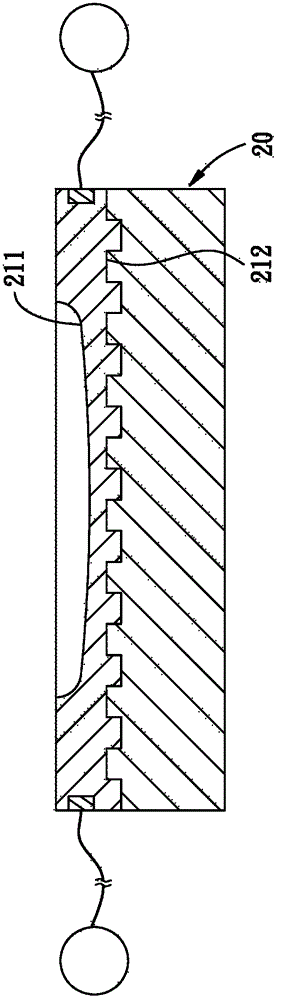

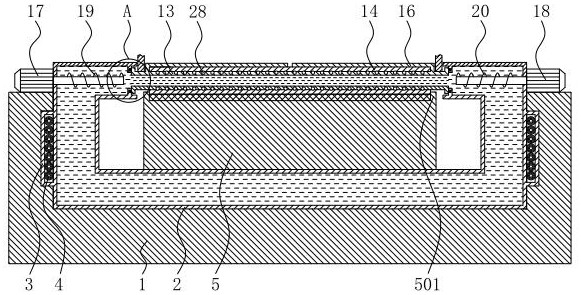

ITO heater and heating method of LCD

ActiveCN101510020AUniform surface temperature distributionStatic indicating devicesElectricityElectrical resistance and conductance

The invention is applicable to a liquid crystal display, providing an ITO heater and a heating method of the liquid crystal display. The ITO heater comprises an ITO glass substrate which is provided with two opposite long edges and two opposite short edges, wherein, two opposite edges are electrically connected with connecting terminals along the direction from one edge to the other edge; and the ITO glass substrate is divided into a plurality of areas, each area is etched with an ITO pattern, and the ITO area of the etched edge part is larger than that of the central part. As for the ITO heater of the invention, the closer to the edge area, the stronger the resistance is; therefore, the heat output of areas closer to the edge is more than that of the central part, while heat of the edge is discharged fast, therefore, offset effect is achieved; the ITO heater can be used for the heating of liquid crystal display modules, and the temperature is evenly distributed on the surface of the ITO heater.

Owner:芜湖天马汽车电子有限公司

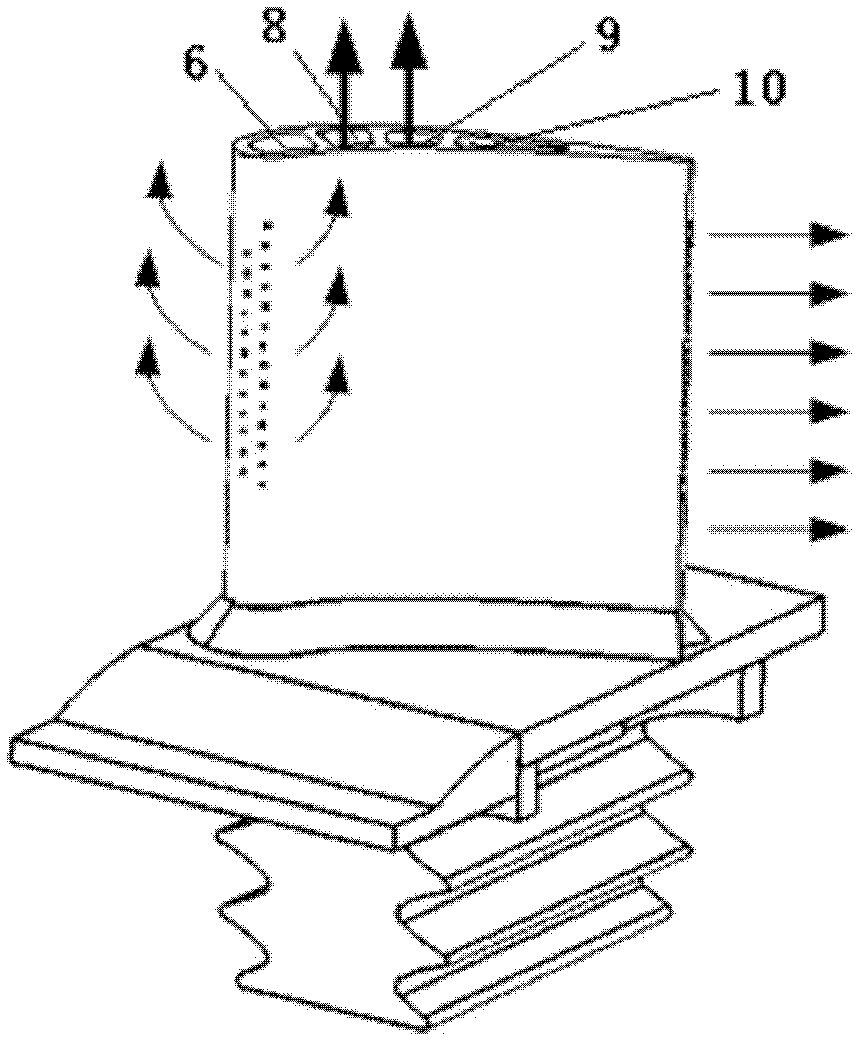

Electrothermal combined using device for solar cell

InactiveCN1988183AUniform surface temperatureImprove photoelectric conversion efficiencyPhotovoltaicsPhotovoltaic energy generationElectricityWorking fluid

This invention discloses a common use device for electricity and heat of a solar cell including a liquid container with heat collection working fluid, in which, hot tubes are set on the side walls of the container and set with phase change heat- carry working fluid, a solar cell is connected with the tubes in the container fixedly, an inlet is set at the bottom of the container and an outlet is set at the top of the container, the bottom face is transmissive, heat preservation materials are set at outside of the top and outside of the side wall of the container. This invention can carry away solar heat not changed to electricity quickly by dipping a solar cell in a heat-collection working fluid and connecting to the hot tubes.

Owner:TIANJIN UNIV

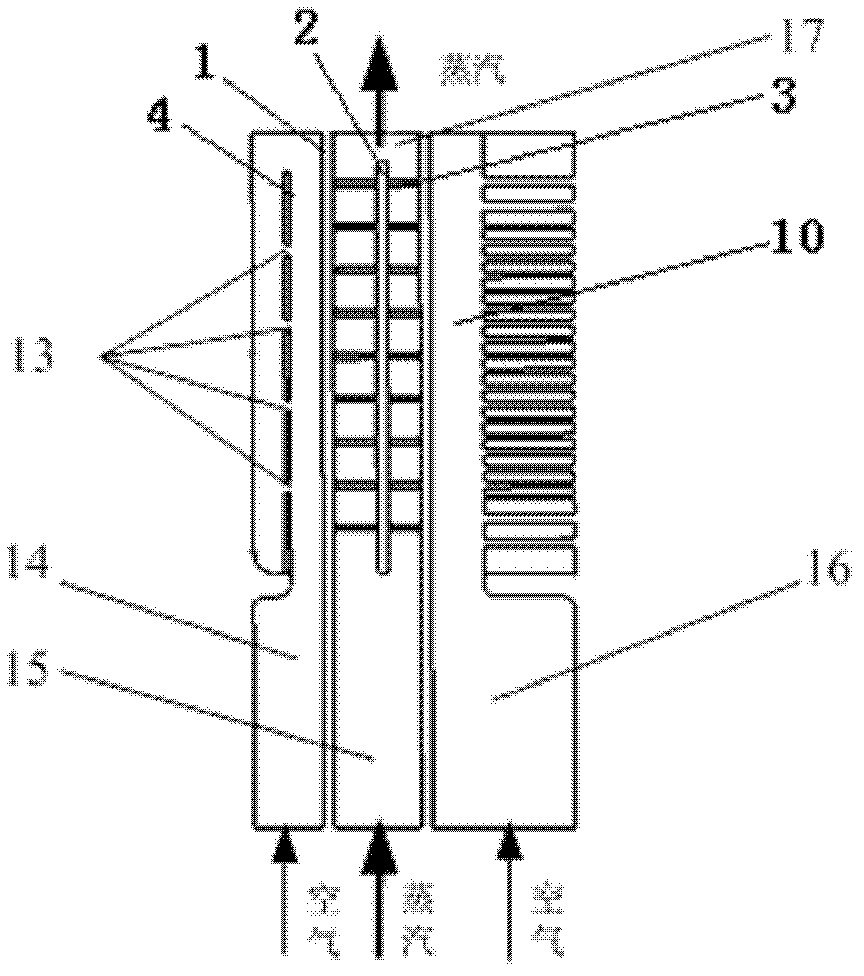

Heavy-type combustion engine high-temperature turbine double-medium cooling blade

ActiveCN102425459AUniform surface temperature distributionExtend your lifeTurbine/propulsion engine coolingBlade accessoriesCombustionCooling effect

The invention relates to a heavy-type combustion engine high-temperature turbine double-medium cooling blade, which is characterized in that: a first separation plate and a third separation plate are sequentially arranged from the front edge and the end edge of a blade inner cavity to divide the blade inner cavity into a front cooling space, a middle cooling space and a rear cooling space to be independent from one another along the radial direction of the blade, the blade front cooling space is divided by a fourth separation plate into a first cooling cavity and a second cooling cavity, impact cooling holes are equally distanced to one another to be arranged on the fourth separation plate, the front edge of the blade is provided with four rows of gas film cooling holes which are alternatively arranged, spoiler ribs which are arranged at equal intervals are arranged on a blade inner wall B of the middle cooling space, the middle cooling space is divided by a second separation plate into a third cooling cavity and a fourth cooling cavity, which are communicated with each other, the rear cooling space is a fifth cooling cavity, and the fifth cooling cavity is connected through fin-shaped vent holes which are equally distanced to one another; and the middle cooling space adopts a steam closed-type cycling cooling way to be combined with the air cooling way of the front and the rear cooling spaces, so the cooling fluid has high heat exchanging coefficient on each position of the blade, the cooling effect can be improved, and the unit heat efficiency can be improved.

Owner:XI AN JIAOTONG UNIV

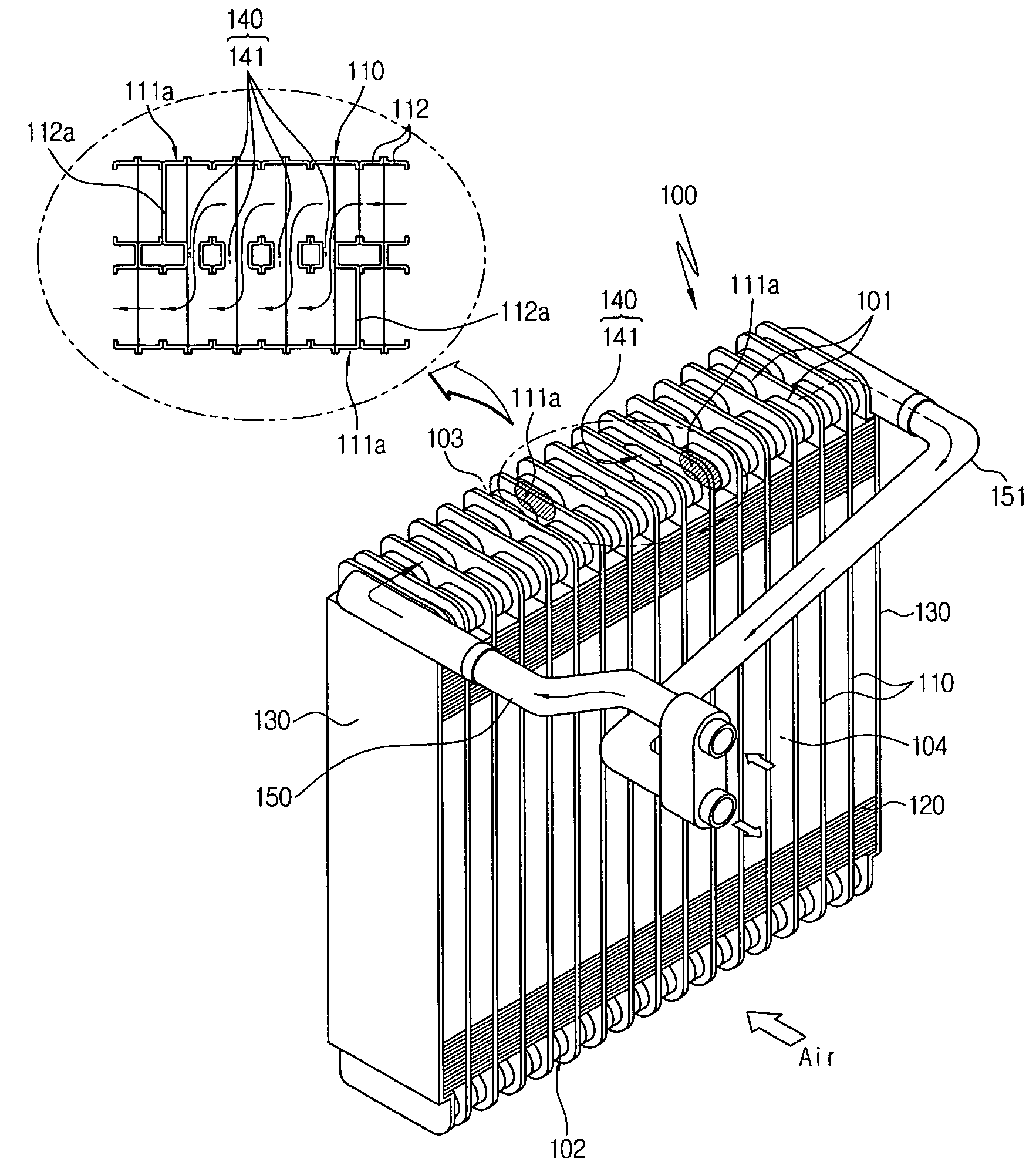

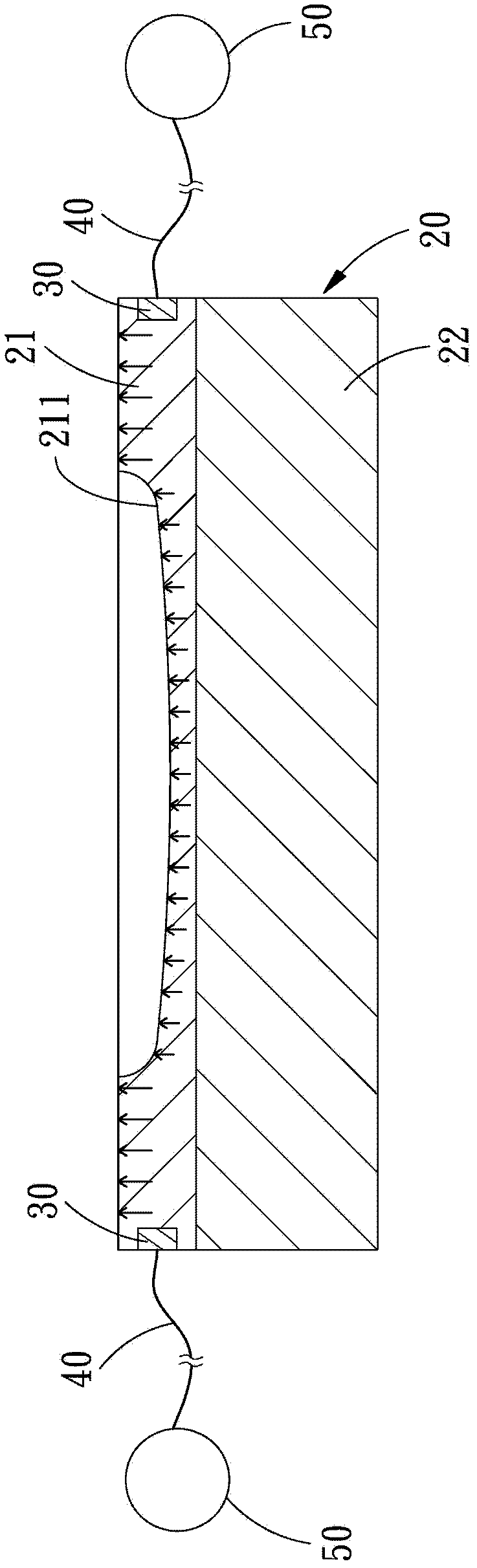

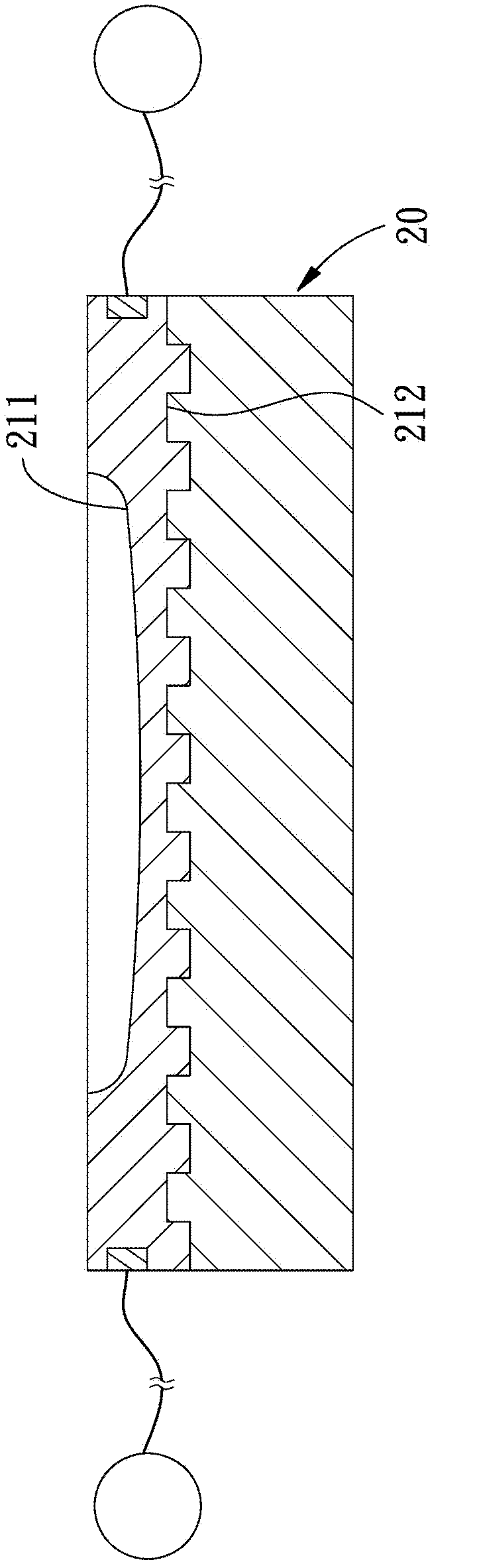

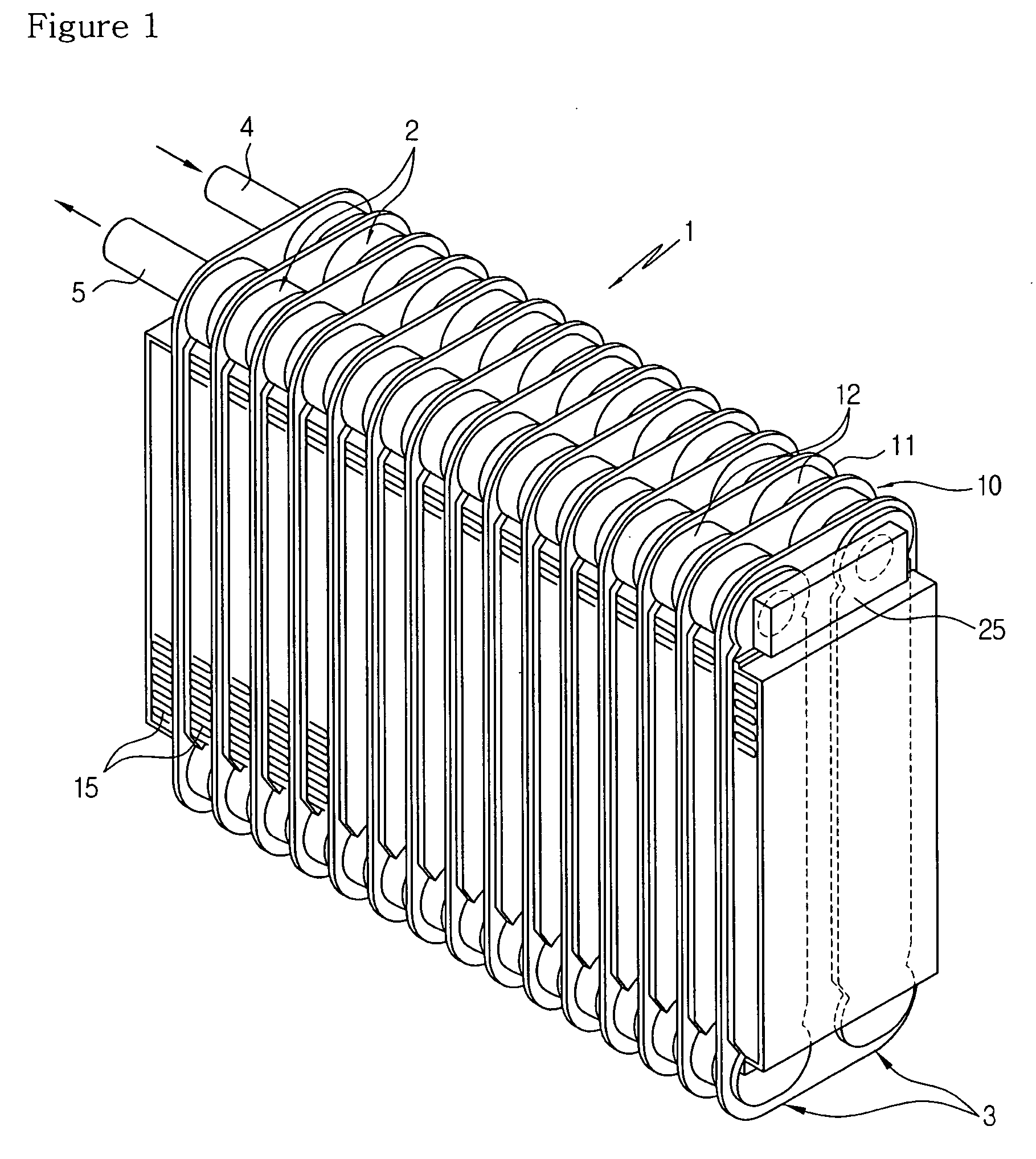

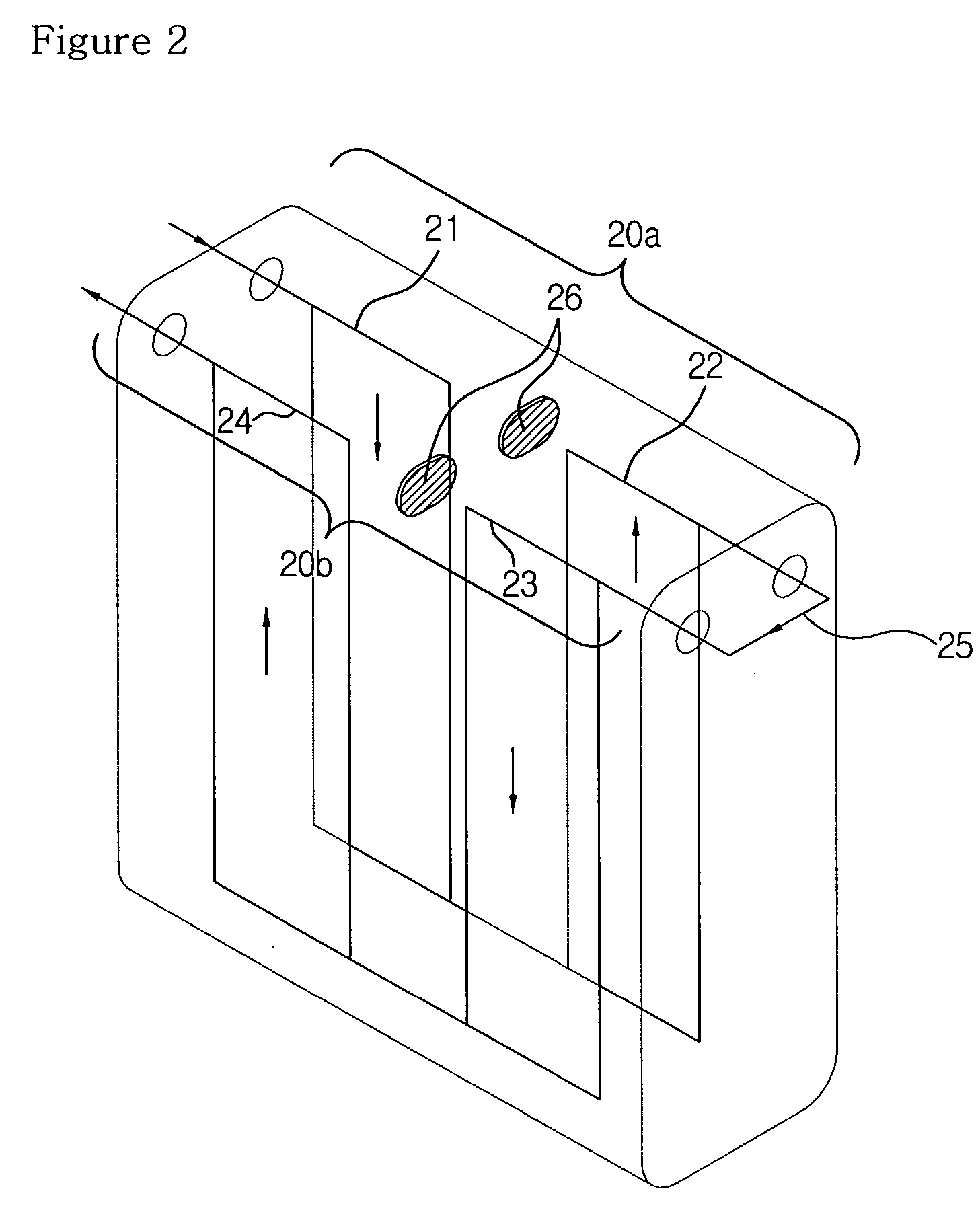

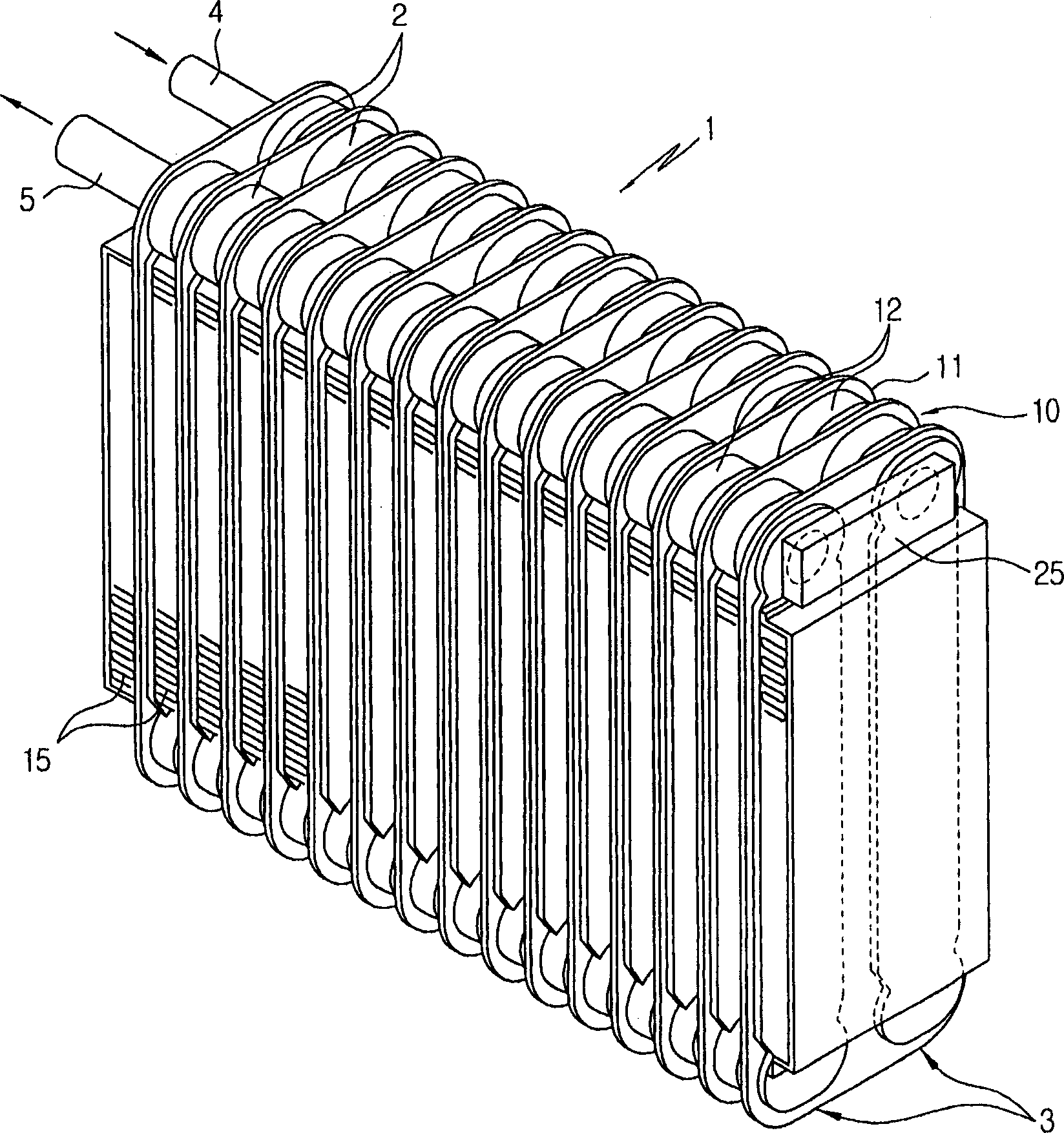

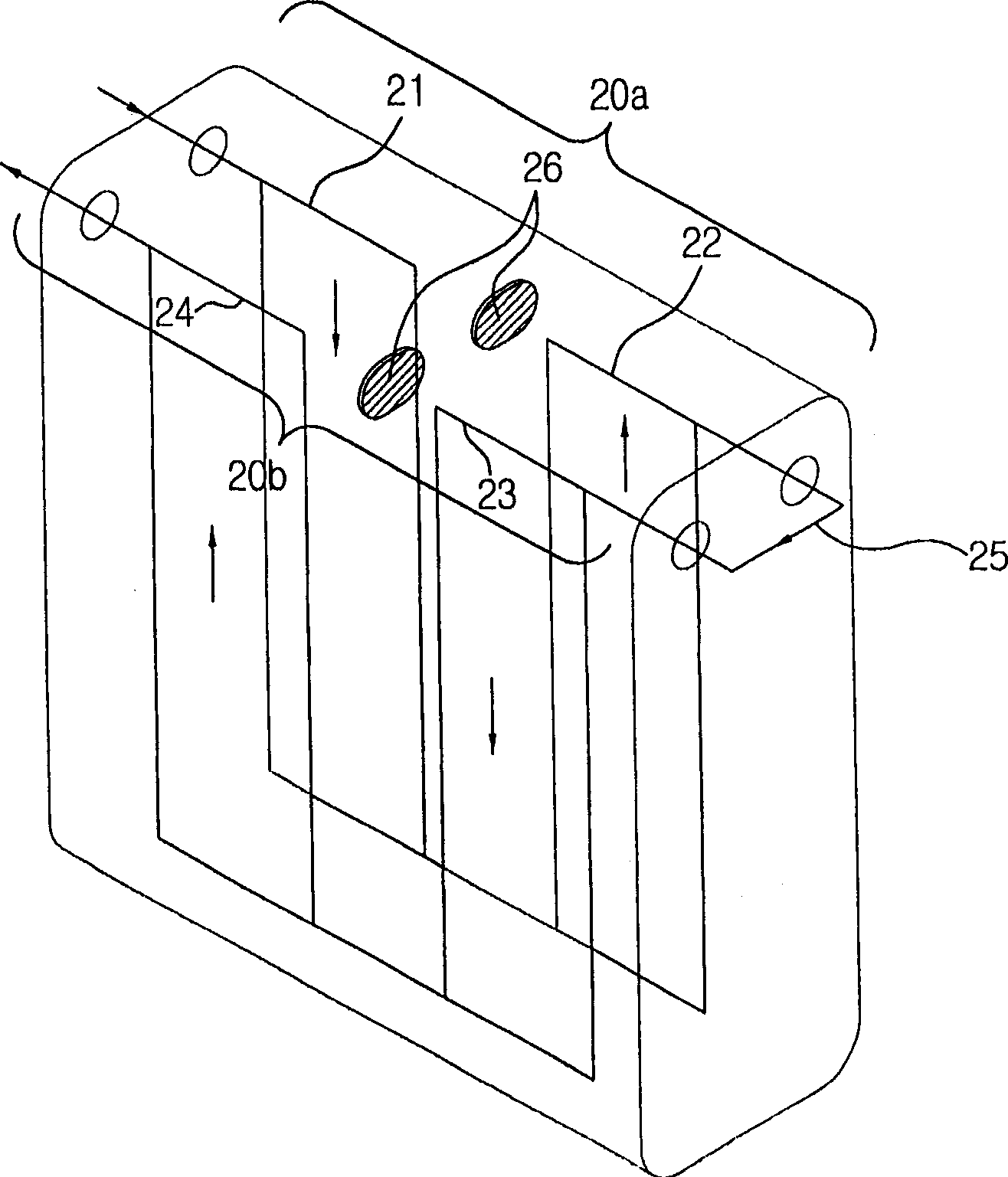

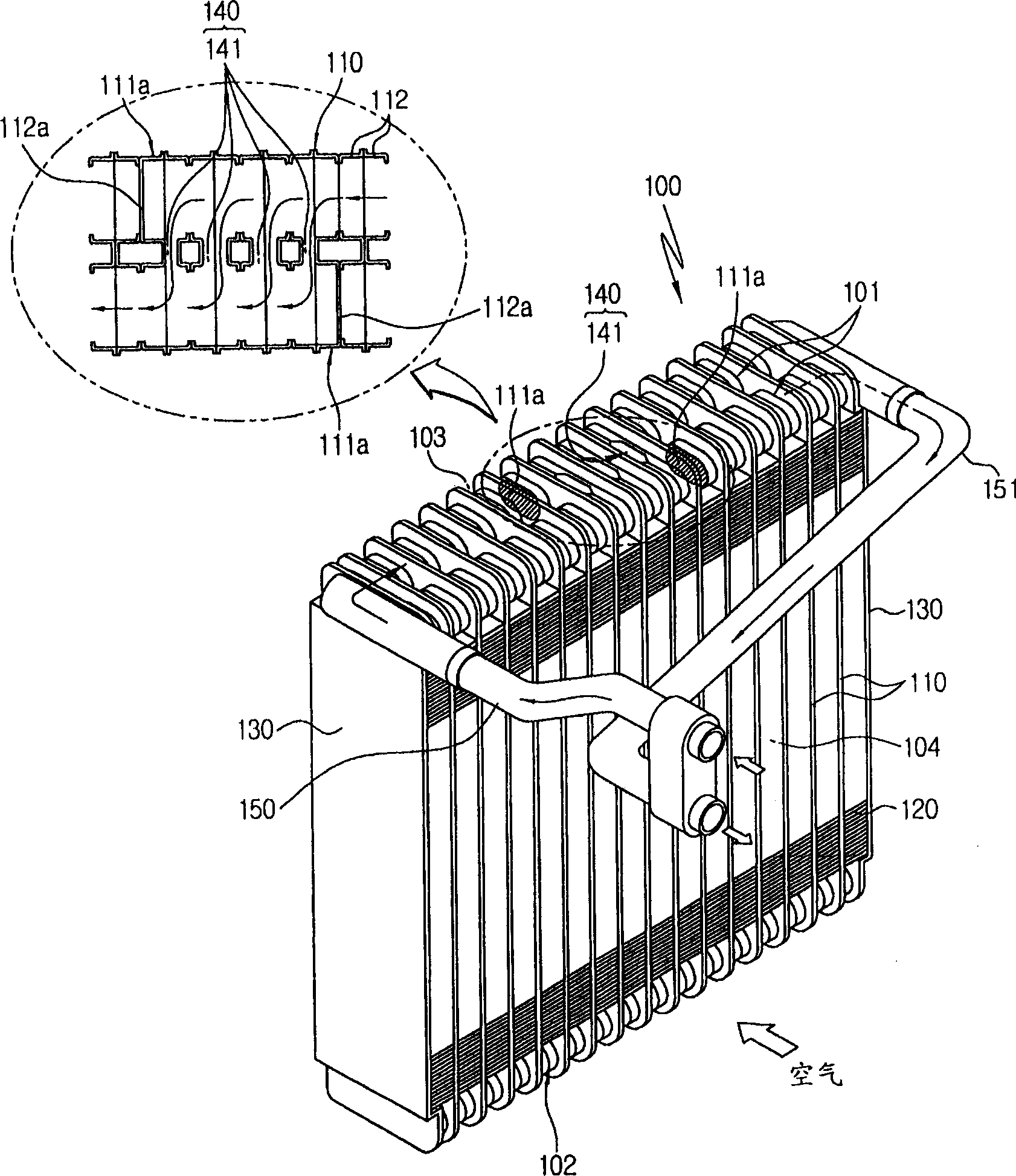

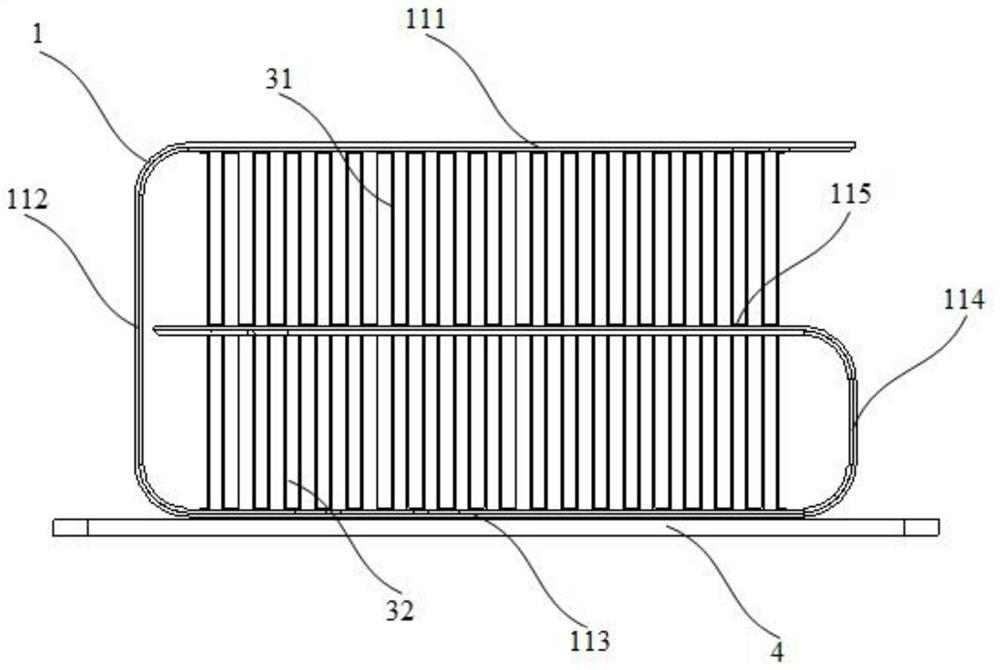

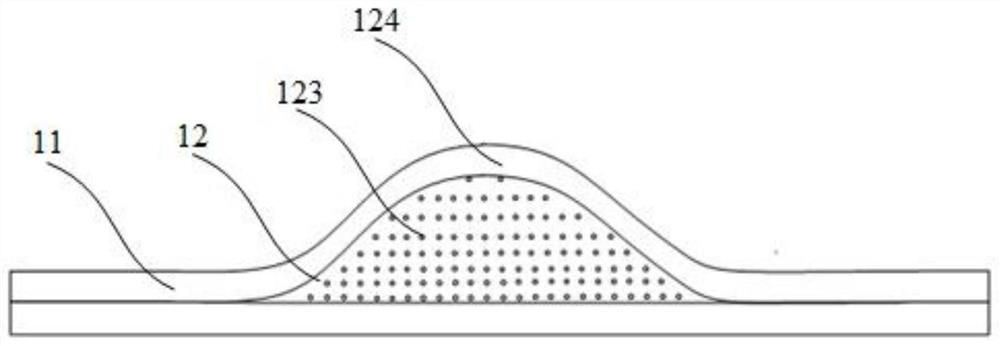

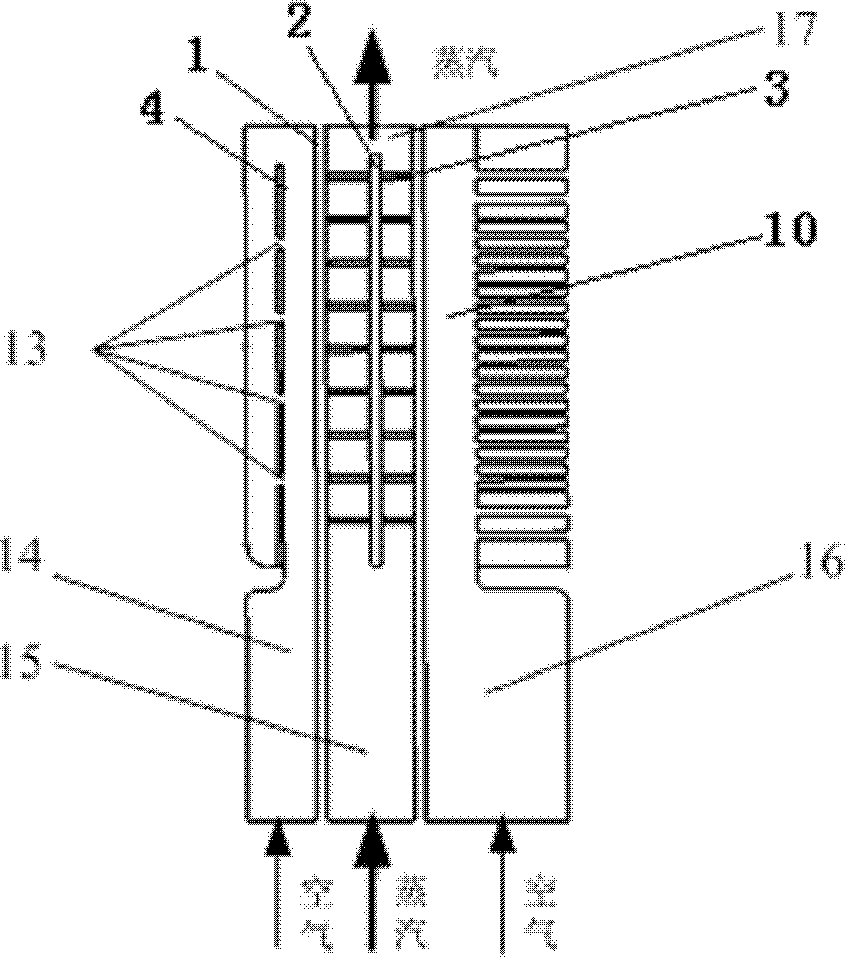

Heat exchanger

ActiveUS7523781B2Improve heat transfer efficiencySmall sizeStationary conduit assembliesHeat exchanger casingsPlate heat exchangerEngineering

The present invention relates to a heat exchanger, in which inlet and outlet side heat exchange parts are communicated with each other and have the same refrigerant flowing direction by communicating pairs of cups with each other which are located at a predetermined area of the center of the heat exchanger, thereby being easily reduced in size, providing uniform surface temperature distribution and improving heat exchange efficiency by reducing the preponderance and the pressure drop rate of refrigerant and inlet and outlet pipes being easily arranged forward.

Owner:HANON SYST

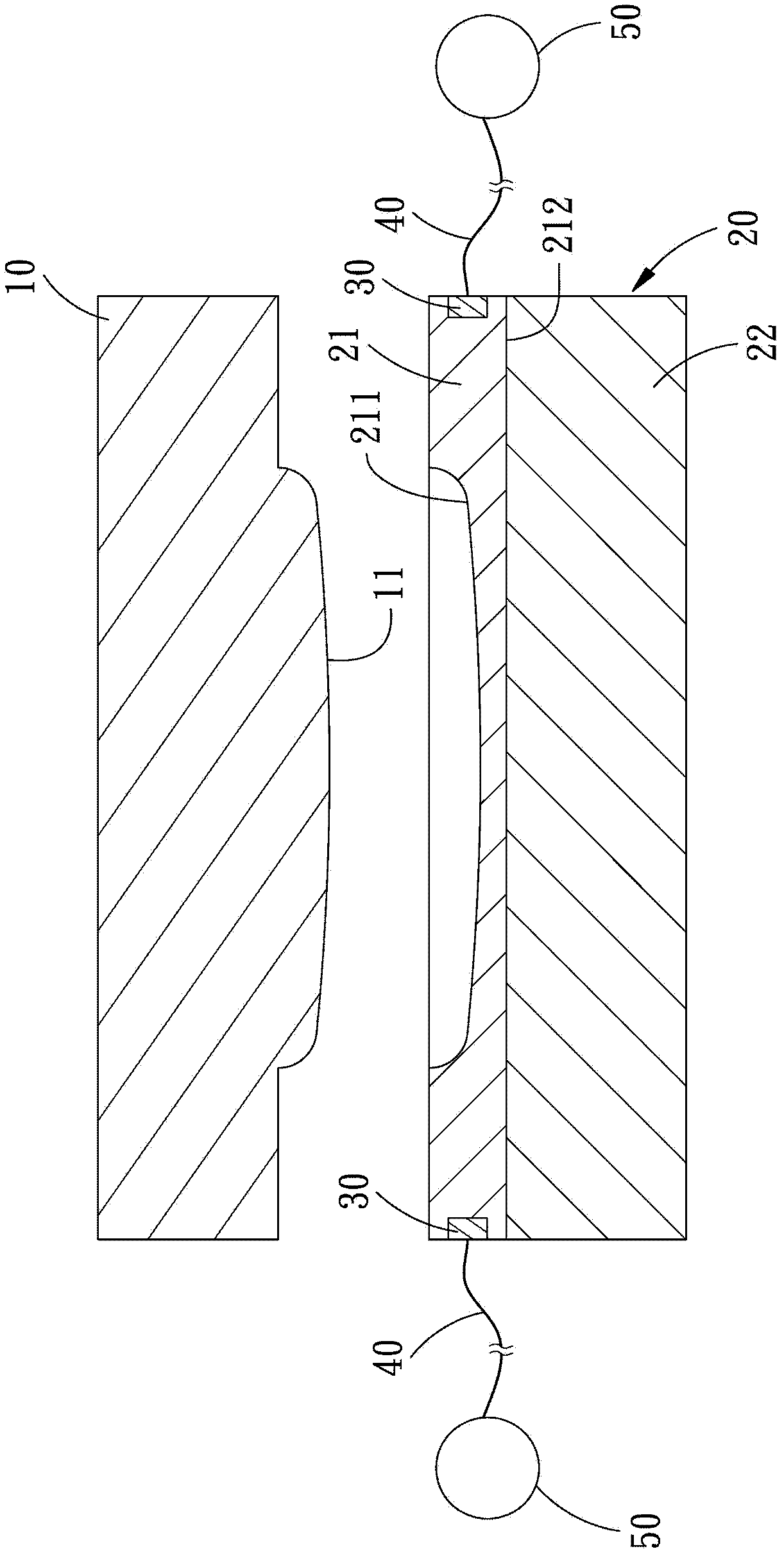

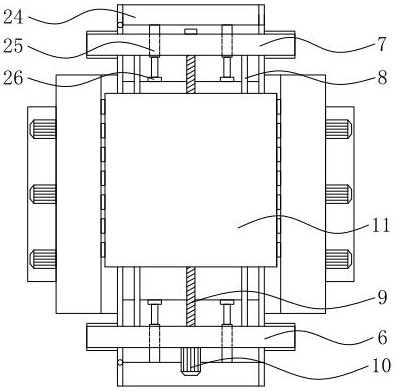

Die with heating device

InactiveCN103072222ASimple structureUniform surface temperature distributionPower flowRoom temperature

The invention discloses a die with a heating device. Main points of the invention are as follows: an insulating layer and a conducting layer which are electrically isolated are arranged on an upper die or a lower die or simultaneously arranged on the upper die and the lower die, the surface of the conducting layer is an interface between the die and a material, current is directly switched on the conducting layer so as to allow the current to crowd on the surface of the conducting layer of the upper die, or the lower die, or the upper die, the lower die and the like, and the surface of the conducting layer is preheated to an operating temperature from room temperature. Thus, the die provided by the invention may be only composed of the upper die, the lower die, a current conducting plate and a conductor wire and electrical insulation is carried out on the conducting layer and the insulating layer of the upper die, or the lower die, or the upper die and the lower die so as to achieve effects of the prior art, thereby realizing the purpose of cost reduction; moreover, since current only crowds on the surface of the conducting layer of the upper die, or the lower die, or the upper die and the lower die, uniform distribution of surface temperature of the die can be realized regardless of changing of the shape of the surface of the conducting layer.

Owner:KUNSHAN YURONG ELECTRONICS +1

Heat exchanger

ActiveUS20060162911A1Easily reduced in sizeUniform surface temperature distributionStationary conduit assembliesHeat exchanger casingsEngineeringRefrigerant

The present invention relates to a heat exchanger, in which inlet and outlet side heat exchange parts are communicated with each other and have the same refrigerant flowing direction by communicating pairs of cups with each other which are located at a predetermined area of the center of the heat exchanger, thereby being easily reduced in size, providing uniform surface temperature distribution and improving heat exchange efficiency by reducing the preponderance and the pressure drop rate of refrigerant and inlet and outlet pipes being easily arranged forward.

Owner:HANON SYST

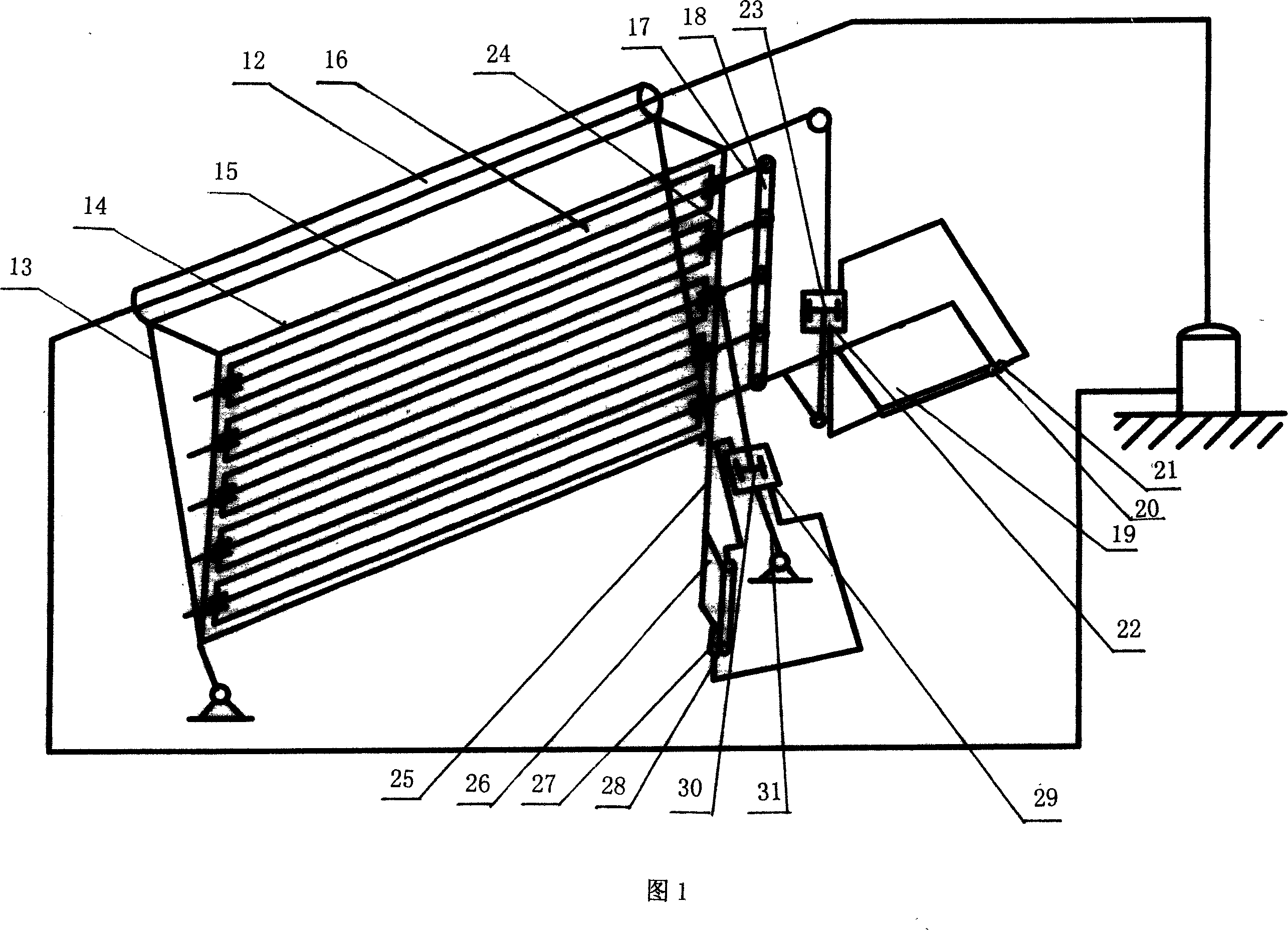

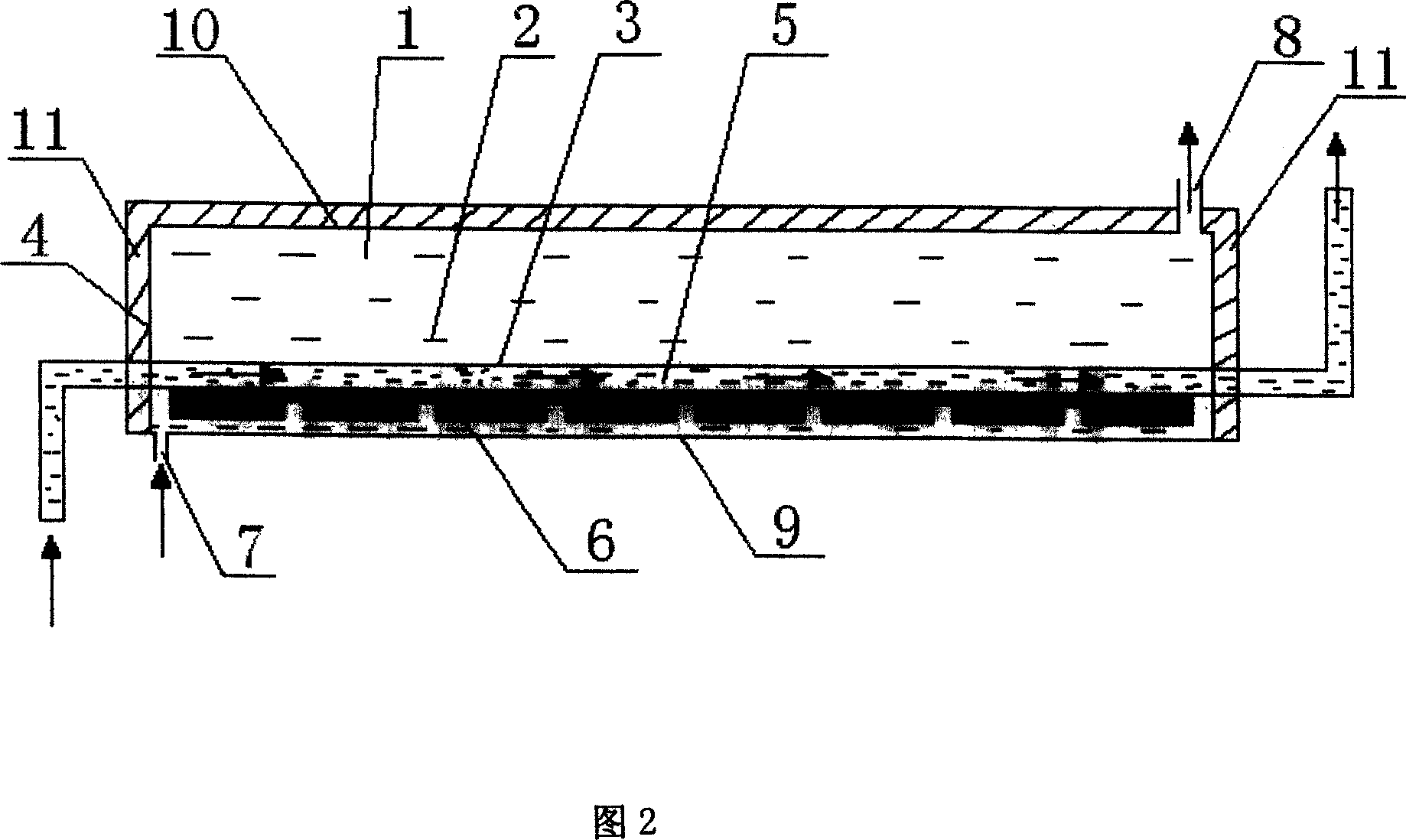

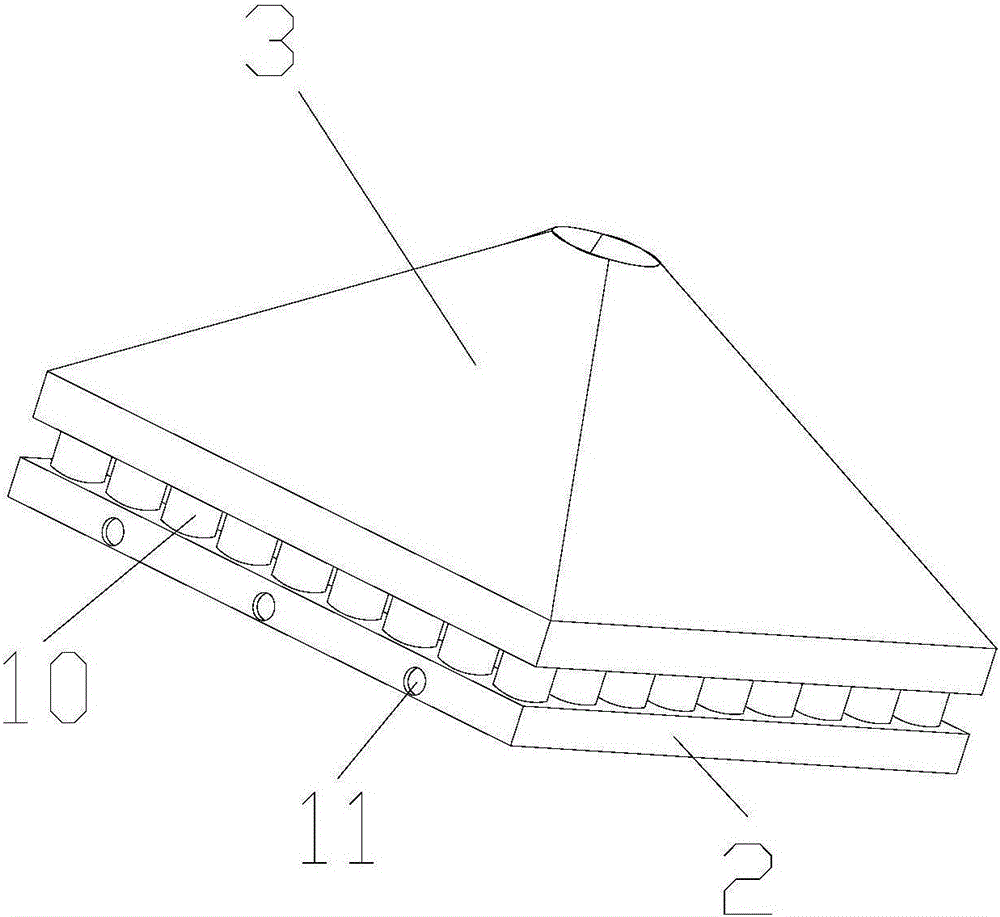

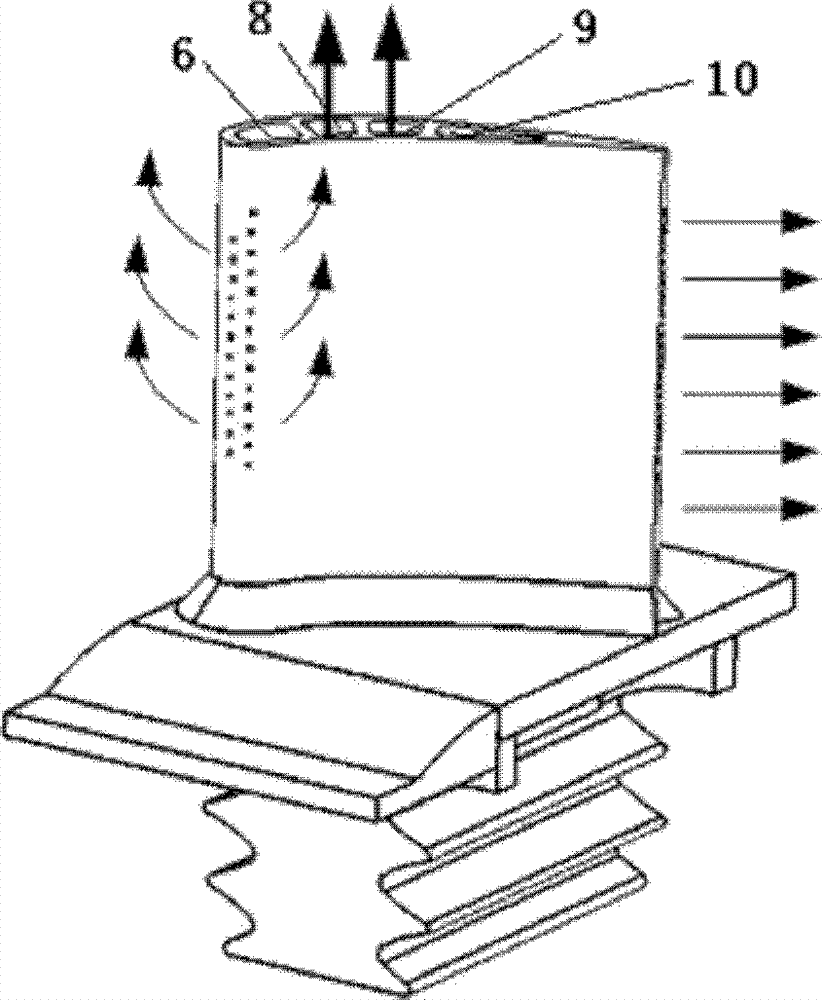

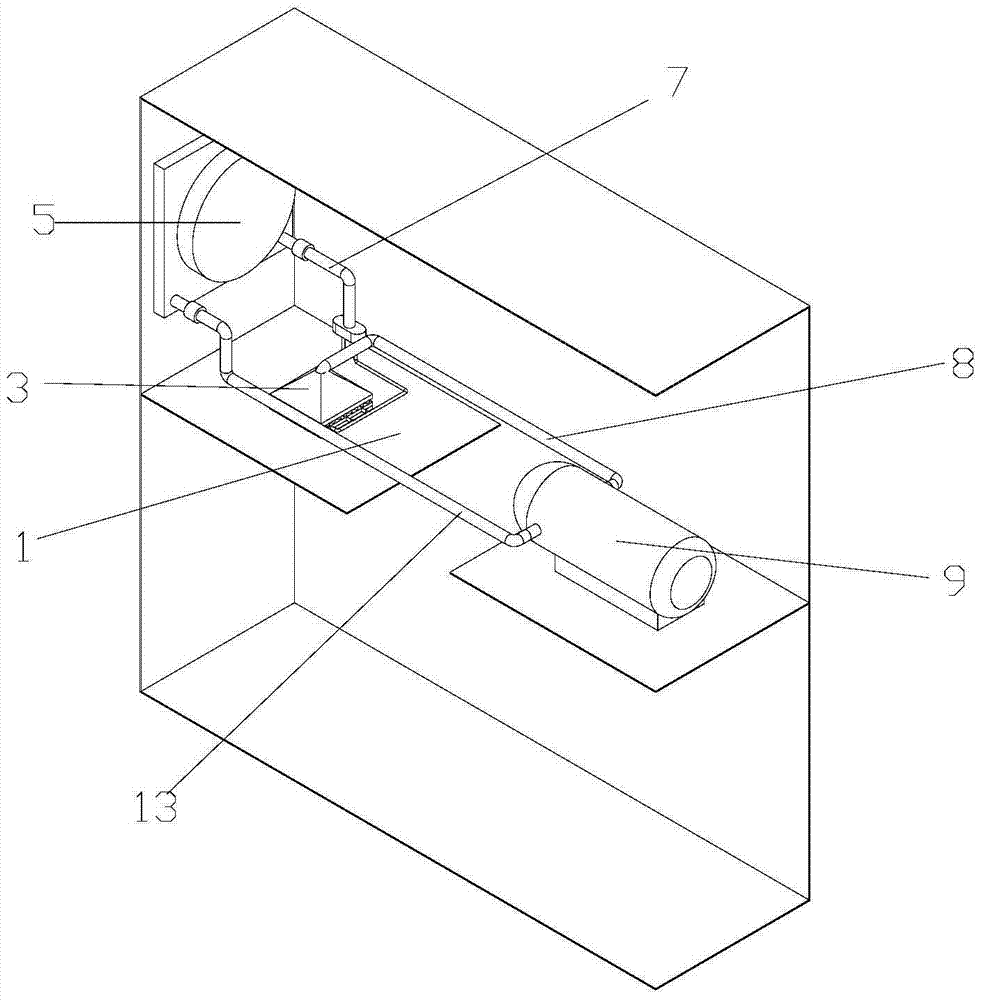

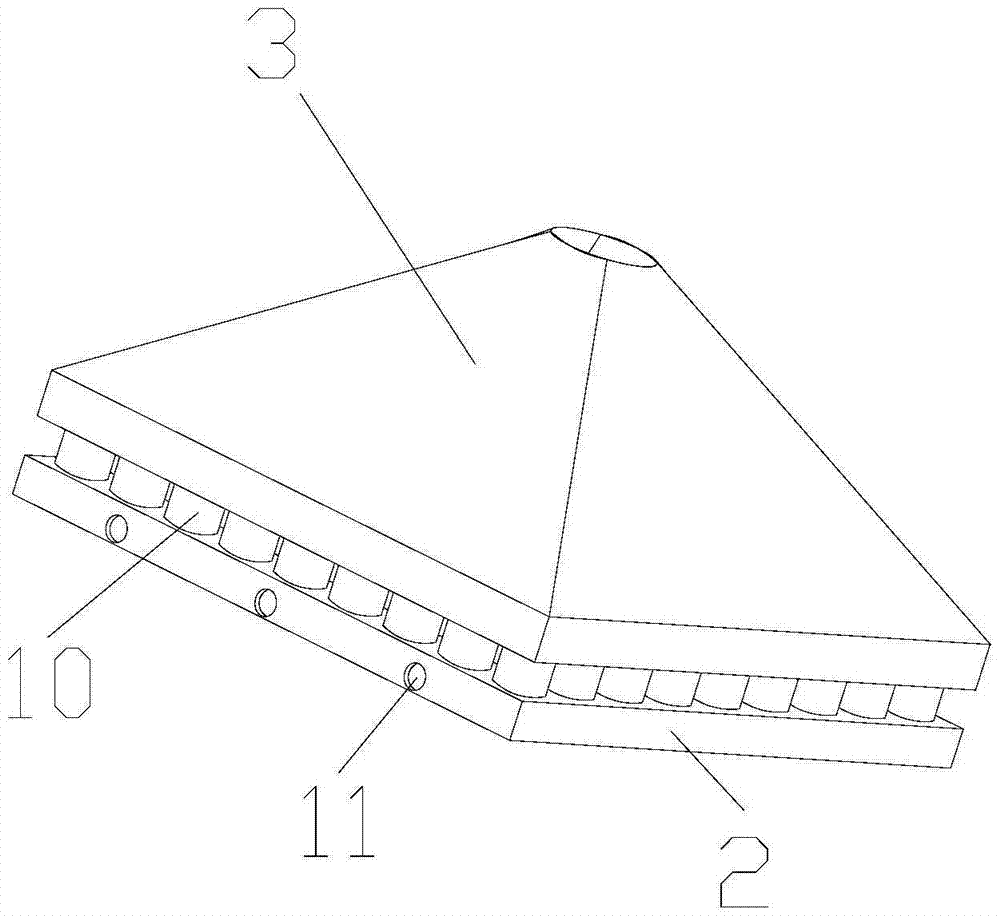

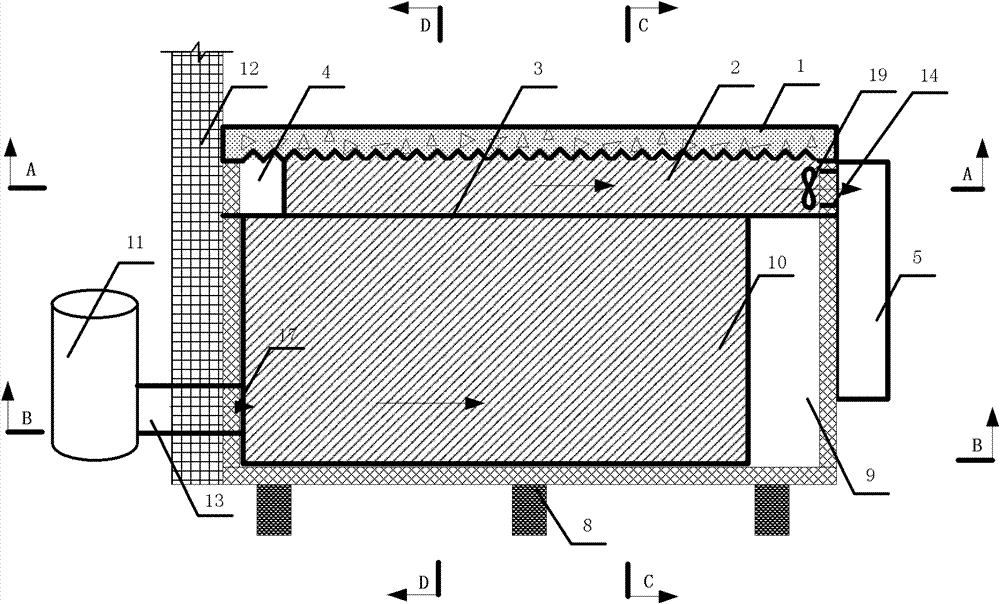

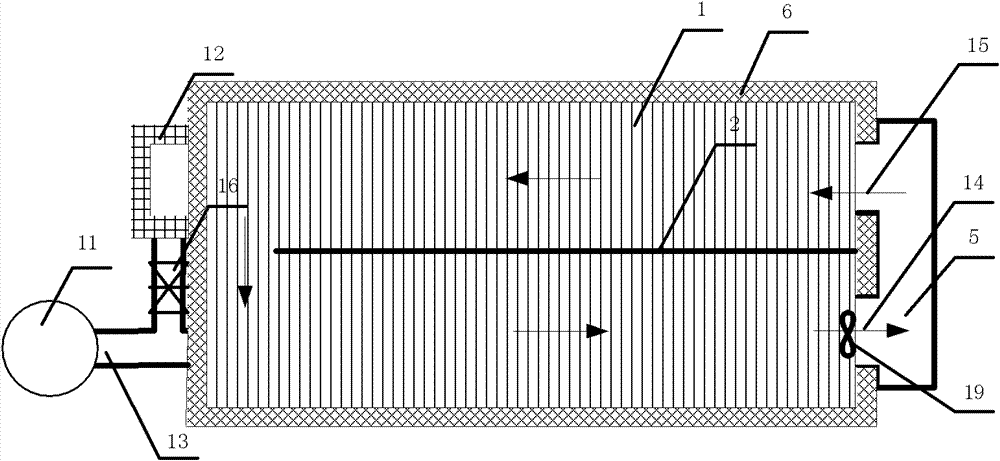

Energy-saving kang with double flow channels

ActiveCN101984297ALow-cost and high-efficiency solar heat utilization at low temperatureLow running costLighting and heating apparatusCombustion-air/flue-gas circulation for stovesFlueBiomass

An energy-saving kang with double flow channels belongs to the technical fields of the utilization of solar energy and biomass energy and the building energy conservation. The energy-saving kang with double flow channels contains not only a stove, a kang plate, a flue baffle plate, a flue gas inlet, a flue gas circulation channel, a flue gas outlet, a chimney and other parts of the traditional kang, but also a solar air heat collecting system. In the energy-saving kang, the folded metal plate on the lower surface of the upper kang plate is utilized to increase the heat-transfer intensity of the air and the kang plate and the uniformity of the temperature distribution of the kang surface; the baffle plate is used to effectively separate the air and the flue gas circulation channel; and the solar energy and the heat of the flue gas can be utilized simultaneously, and the solar heat collecting device can not be damaged. All the parts in the energy-saving kang are prepared from common materials and by common preparation technology, thus the energy-saving kang has the advantages of simple production technology, low production cost and the like. The energy-saving kang is mainly used in the single building of a village in Northern China, can solve the indoor heating problem in winter and can reduce the coal consumption while lowering the environment pollution.

Owner:TSINGHUA UNIV

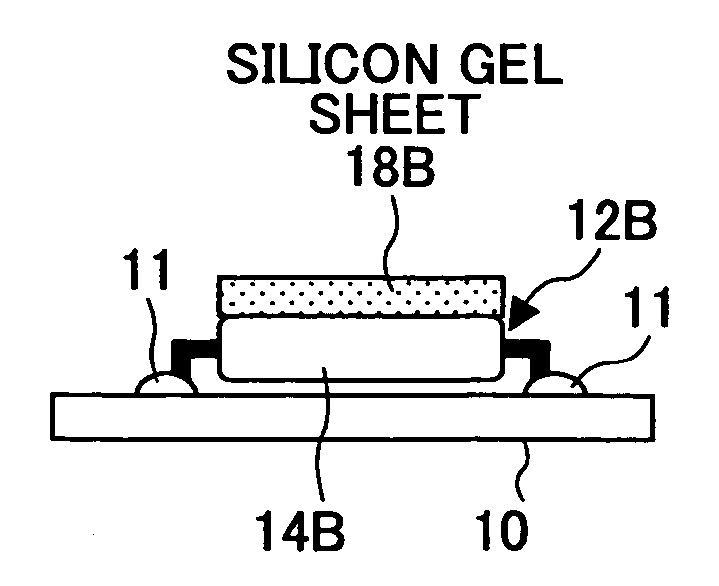

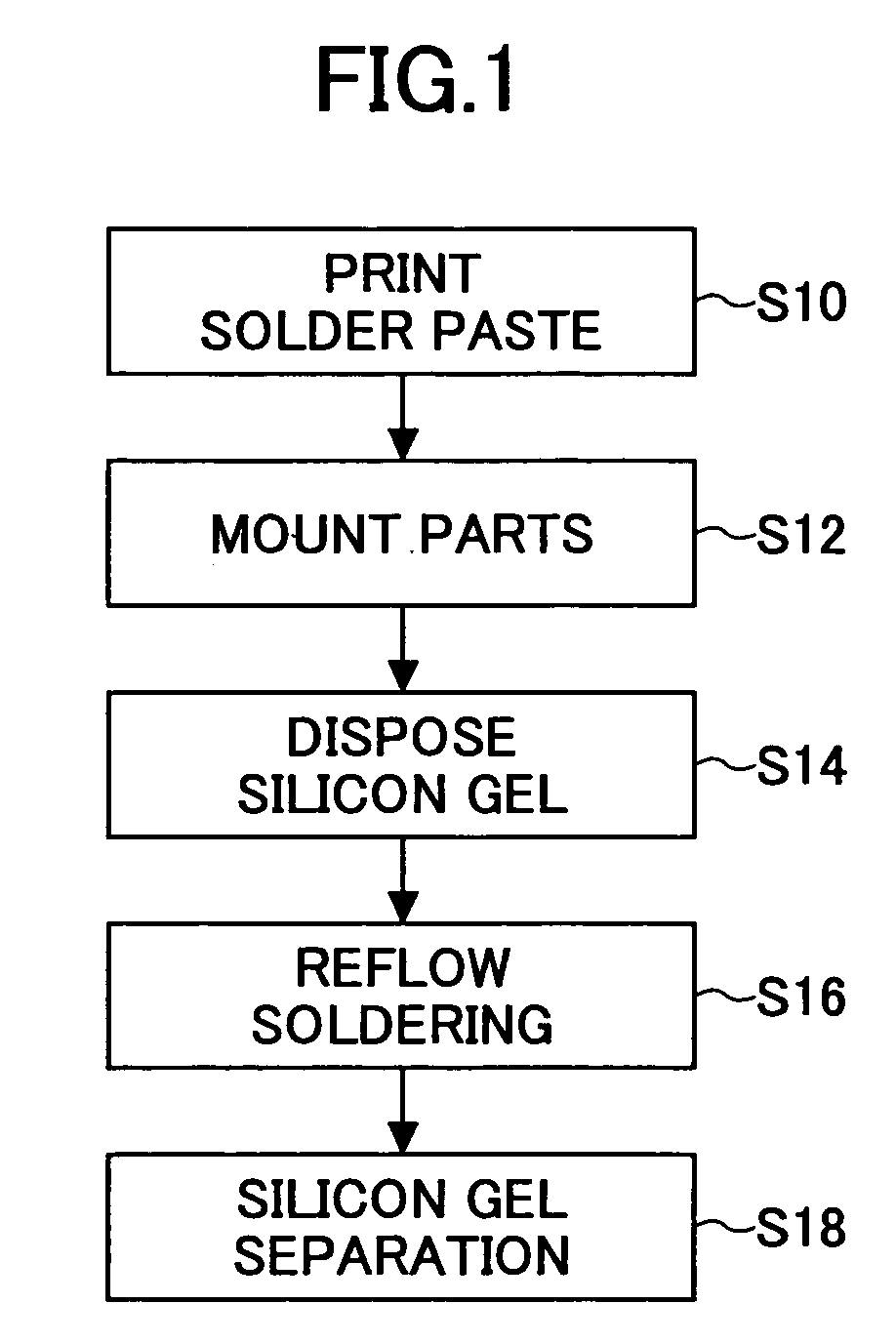

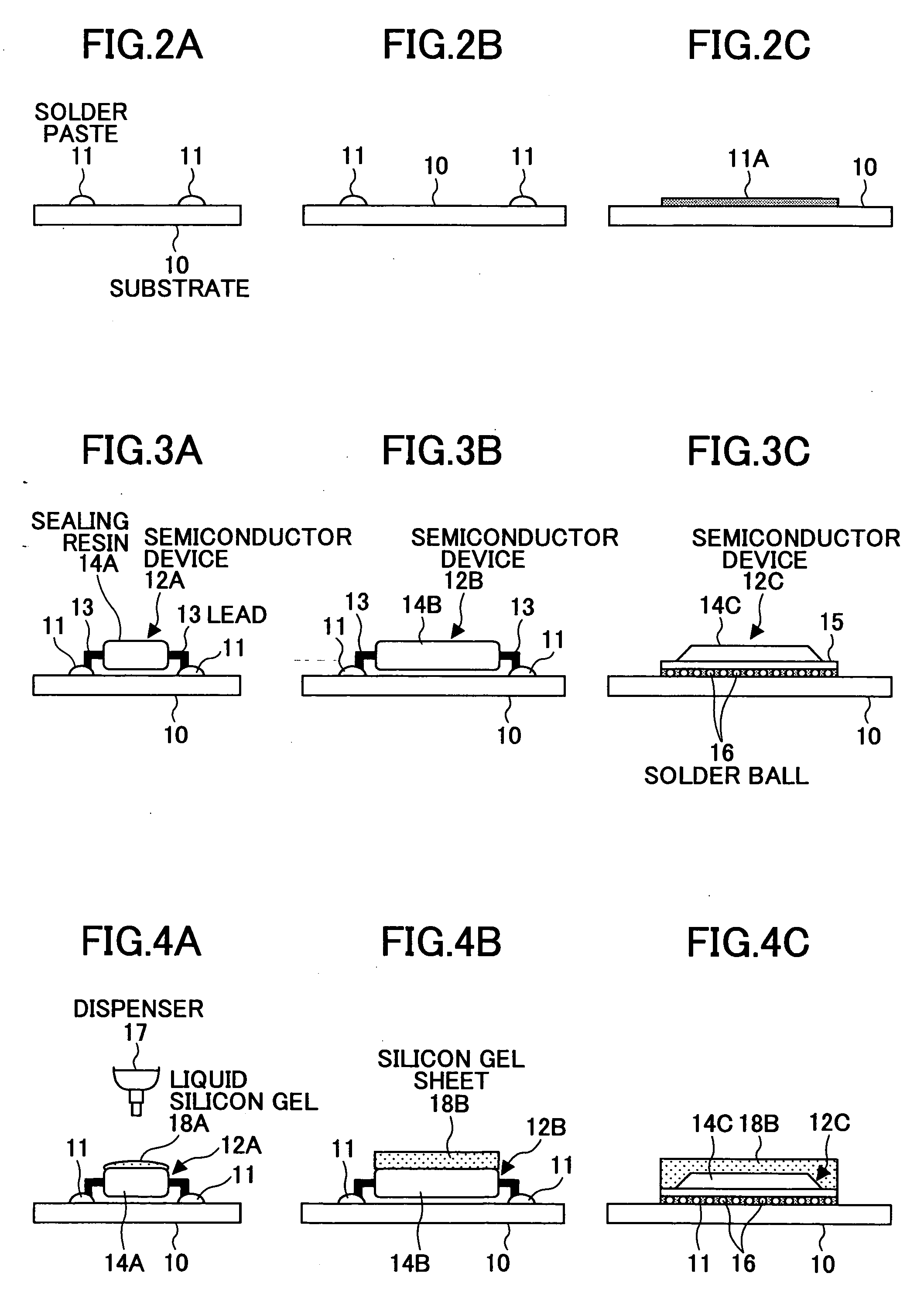

Soldering method, electronic part, and part-exchanging method

InactiveUS20060266806A1Easy temperature controlAvoid defectsPrinted circuit aspectsSolid-state devicesSolder pasteHeat capacity

A soldering method for soldering an electronic part on a substrate by reflow soldering is disclosed that includes the steps of applying a solder paste on the substrate; mounting the electronic part on the substrate by using the solder paste; disposing a heat capacity enhancing member on the electronic part, the heat capacity enhancing member including a gel-like material able to enhance the heat capacity of the electronic part; and soldering the electronic part onto the substrate by reflow soldering with the heat capacity enhancing member being applied thereon.

Owner:FUJITSU LTD

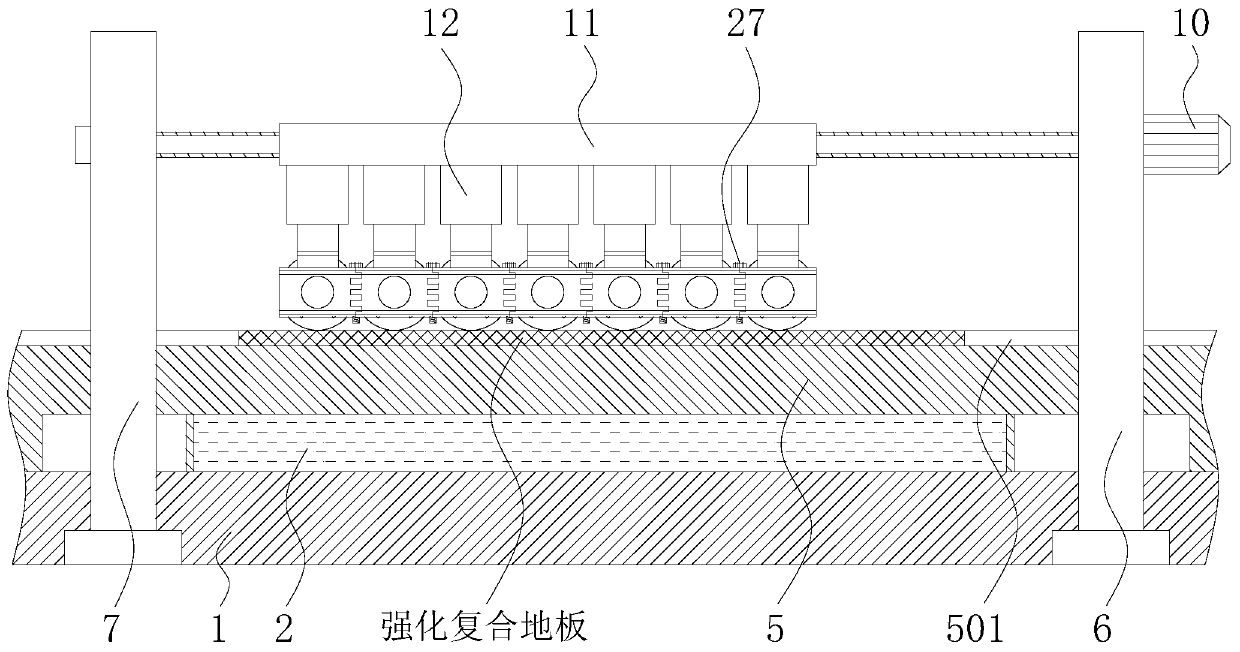

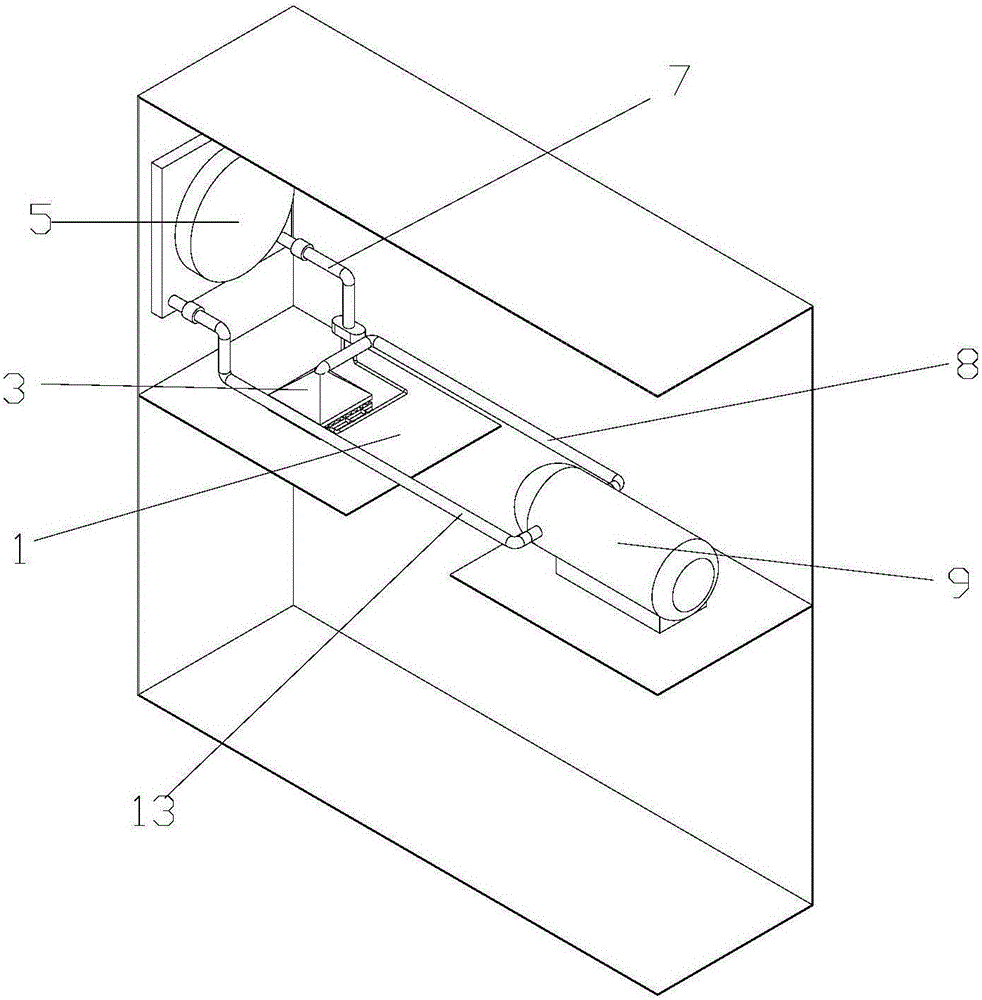

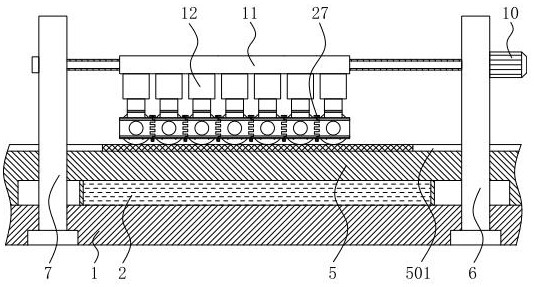

Reinforced composite floor hot press

InactiveCN110614682AImprove the effect of hot pressingUniform surface temperature distributionPlywood pressesVeneer pressesFuel tankEngineering

The invention belongs to the technical field of floor manufacturing equipment, and particularly relates to a reinforced composite floor hot press. The reinforced composite floor hot press comprises abase, an oil storage tank is fixedly installed on the base, and through holes are formed in the two end surfaces of the oil storage tank. A pressure-bearing platform is fixedly installed on the base,and a guiding rail is arranged on the pressure-bearing platform. A first bracket and a second bracket are fixedly arranged on the base, a limiting rod and a lead screw are connected between the firstbracket and the second bracket, and an installation plate parallel to the top surface of the pressure-bearing platform is matched with the lead screw in a threaded mode. A first air cylinder is installed on the bottom surface of the installation plate, the end part of a piston rod of the air cylinder is clamped to the two ends of a hot oil pipe, and a pressing roller is rotatably matched with theouter side wall of the hot oil pipe. The two ends of the hot oil pipe are fixedly connected with a sealing plate mutually matched with the end surface, and an opening with the same size as the longitudinal section of the hot oil pipe is formed in the middle part of the sealing plate. According to the reinforced composite floor hot press, a hot pressing roller is adopted to replace a traditional hot pressing plate to conduct the hot pressing on the reinforced composite floor, and a better hot pressing effect is achieved.

Owner:上海军裕实业有限公司

Light focusing type solar energy electrothermal combined using device

InactiveCN1988184AImprove photoelectric conversion efficiencyExtend your lifeSolar heating energySolar heat collector controllersElectricitySolar light

This invention discloses a light-gathering solar light-electricity-heat on-line device, which is connected with a solar condenser by a connecting bar, the electricity-heat on-line of the solar cell includes a liquid container with heat-collection working fluid, hot tubes are set on the side walls of the container and includes phase-change heat working fluid, the cell is connected with the hot tubes in the container fixedly, an inlet is set at the bottom and an outlet at the top, and the bottom face is transmissive, the outsides of the top face and the side walls are set with heat preservation material, which dips solar cells in a heat-collection working fluid and hot tube can carry solar heat not changed to electricity away quickly and guarantee uniform temperature of the cell surface to increase the photo-electric conversion rate.

Owner:TIANJIN UNIV

ITO heater and heating method of LCD

ActiveCN101510020BUniform surface temperature distributionStatic indicating devicesElectricityElectrical resistance and conductance

The invention is applicable to a liquid crystal display, providing an ITO heater and a heating method of the liquid crystal display. The ITO heater comprises an ITO glass substrate which is provided with two opposite long edges and two opposite short edges, wherein, two opposite edges are electrically connected with connecting terminals along the direction from one edge to the other edge; and theITO glass substrate is divided into a plurality of areas, each area is etched with an ITO pattern, and the ITO area of the etched edge part is larger than that of the central part. As for the ITO heater of the invention, the closer to the edge area, the stronger the resistance is; therefore, the heat output of areas closer to the edge is more than that of the central part, while heat of the edge is discharged fast, therefore, offset effect is achieved; the ITO heater can be used for the heating of liquid crystal display modules, and the temperature is evenly distributed on the surface of the ITO heater.

Owner:芜湖天马汽车电子有限公司

Electric automobile and power battery thereof

PendingCN110492201ASpecial heating characteristicsImprove securitySecondary cellsPower batteryGraphene

The invention relates to a power battery. The power battery comprises a shell, a battery pack, a first graphene heating sheet surrounding the battery pack and a second graphene heating sheet arrangedin the battery pack, and after the first graphene heating sheet is electrified, the battery pack can be heated from outside to inside. Moreover, the first graphene heating sheet is encircled to form aring shape and coats the outer side of the battery pack, so that heat can be diffused from the periphery of the battery pack to the inside of the battery pack. The second graphene heating sheet is clamped between the adjacent battery cells and can heat the battery pack from inside to outside after being electrified. Therefore, when the power battery starts to heat, heat can be transferred from inside to outside and from outside to inside at the same time. Moreover, the first graphene heating sheet and the second graphene heating sheet heat on the whole surface, the heating area is large, andthe surface temperature distribution is balanced. Therefore, the power battery can be used for uniformly heating the internal battery cell. In addition, the invention further provides an electric automobile.

Owner:长沙优力电驱动系统有限公司

Enhanced heat abstractor employing pulsating flow and foam metal plate

ActiveCN105097735ALittle flow resistance lossIncrease contact areaSemiconductor/solid-state device detailsSolid-state devicesCavitationHeat transfer efficiency

The invention discloses an enhanced heat abstractor employing pulsating flow and a foam metal plate. The enhanced heat abstractor comprises a pulsating pump, a heat sink chamber, an accumulated liquid cavity and a cooler, wherein the pulsating pump conveys a cooling liquid into the accumulated liquid cavity through a liquid inflow pipe; the accumulated liquid cavity sprays the cooling liquid into the heat sink chamber; the heat sink chamber conveys the liquid which is subjected to heat transfer into the cooler to cool through a liquid discharge pipe; the pulsating pump sucks in the cooled cooling liquid from the cooler through a connecting pipe; the heat sink chamber comprises the foam metal plate, a heat transfer support plate and a cover board; the heat transfer support plate is connected with a high-heating flux device; the foam metal plate is fixedly connected with the heat transfer support plate; and a dispenser is vertically connected with the top of the cover board. The pulsating flow of the enhanced heat abstractor is matched with a dual-layer foam metal structure, so that transverse and longitudinal disturbance and mixing of working mediums can be increased; a thermal boundary layer is continuously recombined; and meanwhile, cavitation and vortex formation are caused by pressure change in the disturbance process, therefore, the heat transfer efficiency can be greatly improved.

Owner:常州贺斯特科技股份有限公司

Method for preparing thermal barrier coating on surface of engine turbine blade

ActiveCN114015980AControl surface temperatureAvoid overheating damageMolten spray coatingVacuum evaporation coatingPlasma jetTurbine blade

The invention discloses a method for preparing a thermal barrier coating on the surface of an engine turbine blade. The method comprises the following steps: arranging a winding and plating shielding object at a position with a certain distance on the surface of the turbine blade, so that plasma jet flow firstly bypasses the winding and plating shielding object and then reaches the surface of the turbine blade when being sprayed on the surface of the turbine blade; and a PS-PVD process is used for spraying the surface of the turbine blade.

Owner:BEIHANG UNIV +2

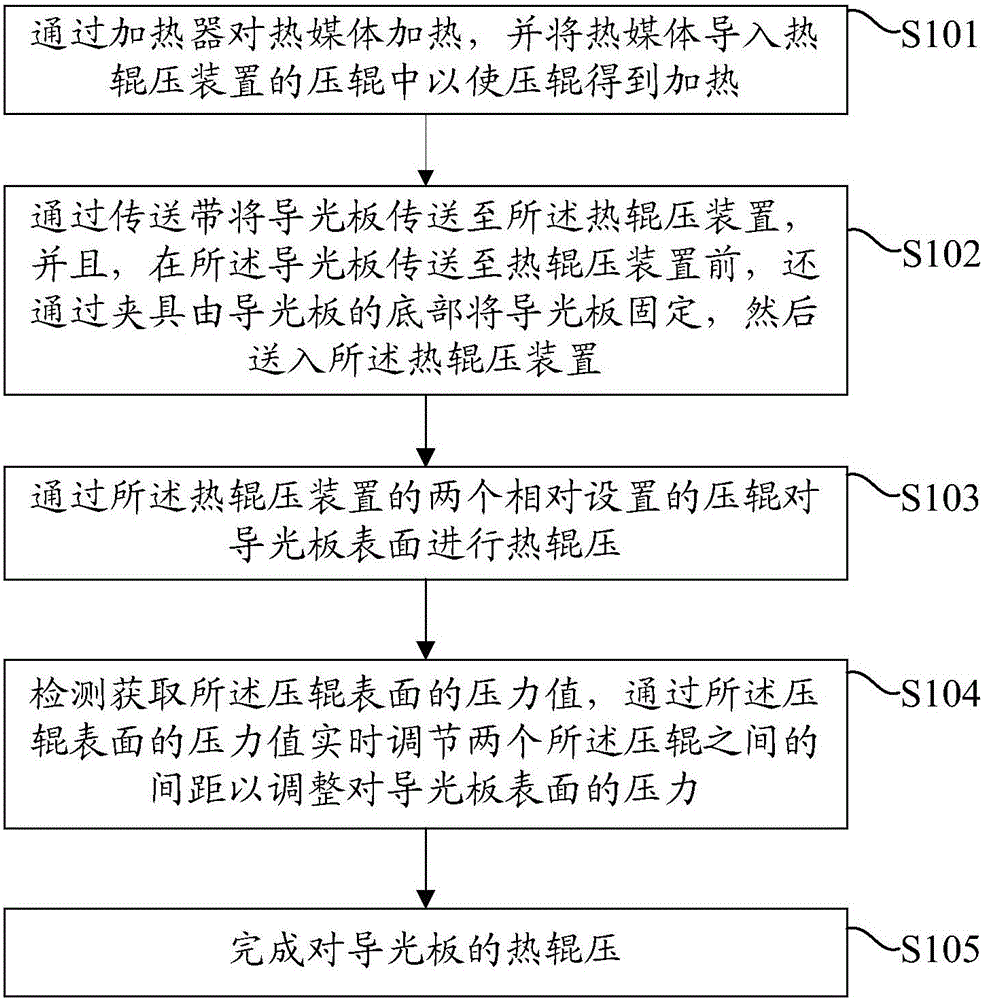

Hot rolling method of light guide plate

The invention relates to a hot rolling method of a light guide plate. The method comprises steps that a heat conduction medium is heated through a heater and is guided into pressing rollers of a hot rolling device so as to enable the pressing rollers to be heated; the light guide plate is conveyed to the hot rolling device through a conveying belt, and before the light guide plate is conveyed to the hot rolling device, the light guide plate is fixed through a clamp from the bottom of the light guide plate, and then the light guide plate is conveyed to the hot rolling device; the two oppositely-arranged pressing rollers of the hot rolling device carry out hot rolling on the surface of the light guide plate; and a pressure value of the surfaces of the pressing rollers is obtained, and according to the pressure value of the surfaces of the pressing rollers, the distance between the two pressing rollers is adjusted in real time, and therefore the pressure on the surface of the light guide plate is adjusted. According to the hot rolling method, the surface temperature distribution of the pressing rollers is more uniform, pressing on the surface of the light guide plate is more balanced, the number of bad points on the surface of the light guide plate is effectively reduced, bending generated in the hot rolling process of the light guide plate is effectively avoided, and the product yield is greatly improved.

Owner:SHENZHEN DIXIAN ELECTRONICS

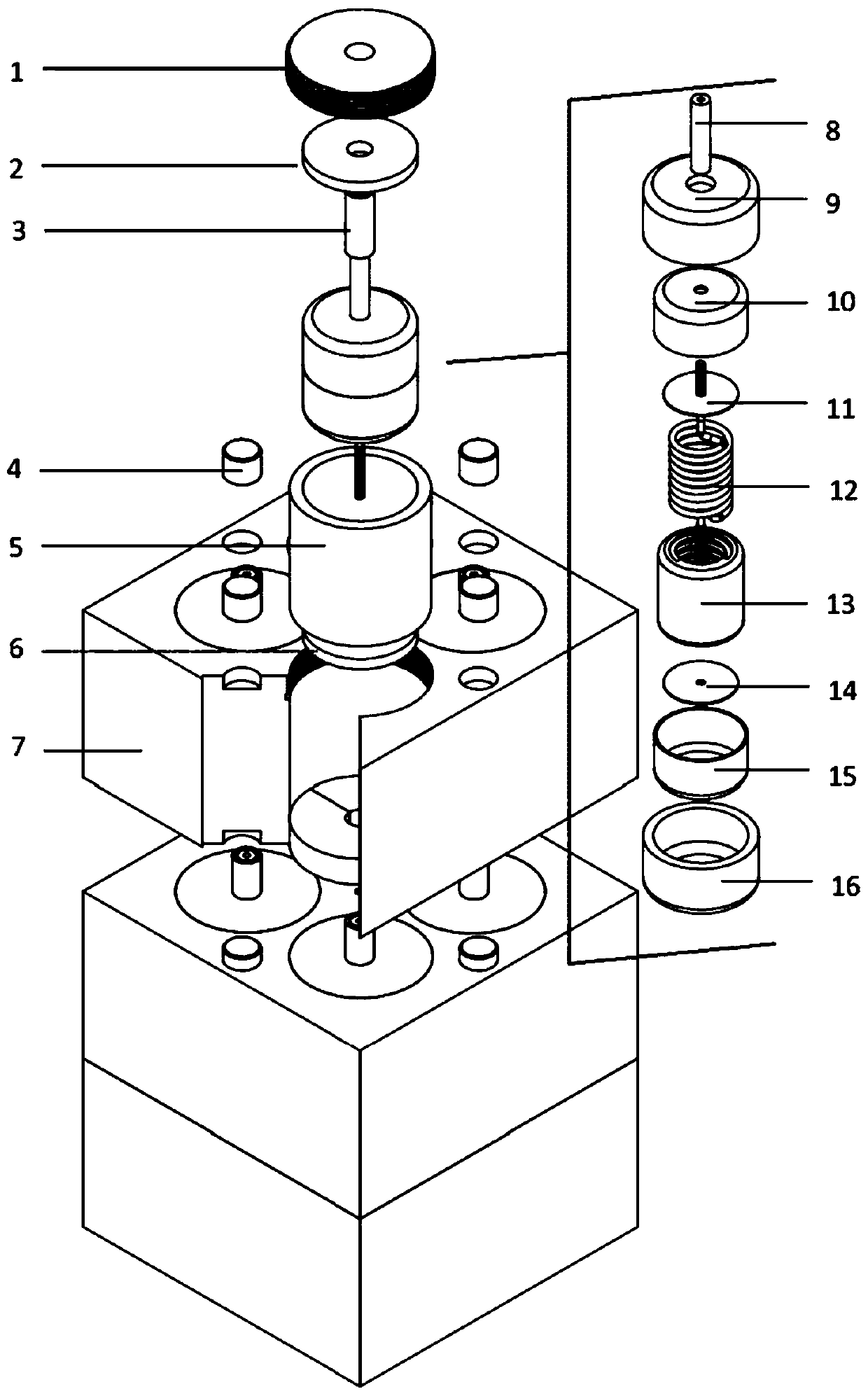

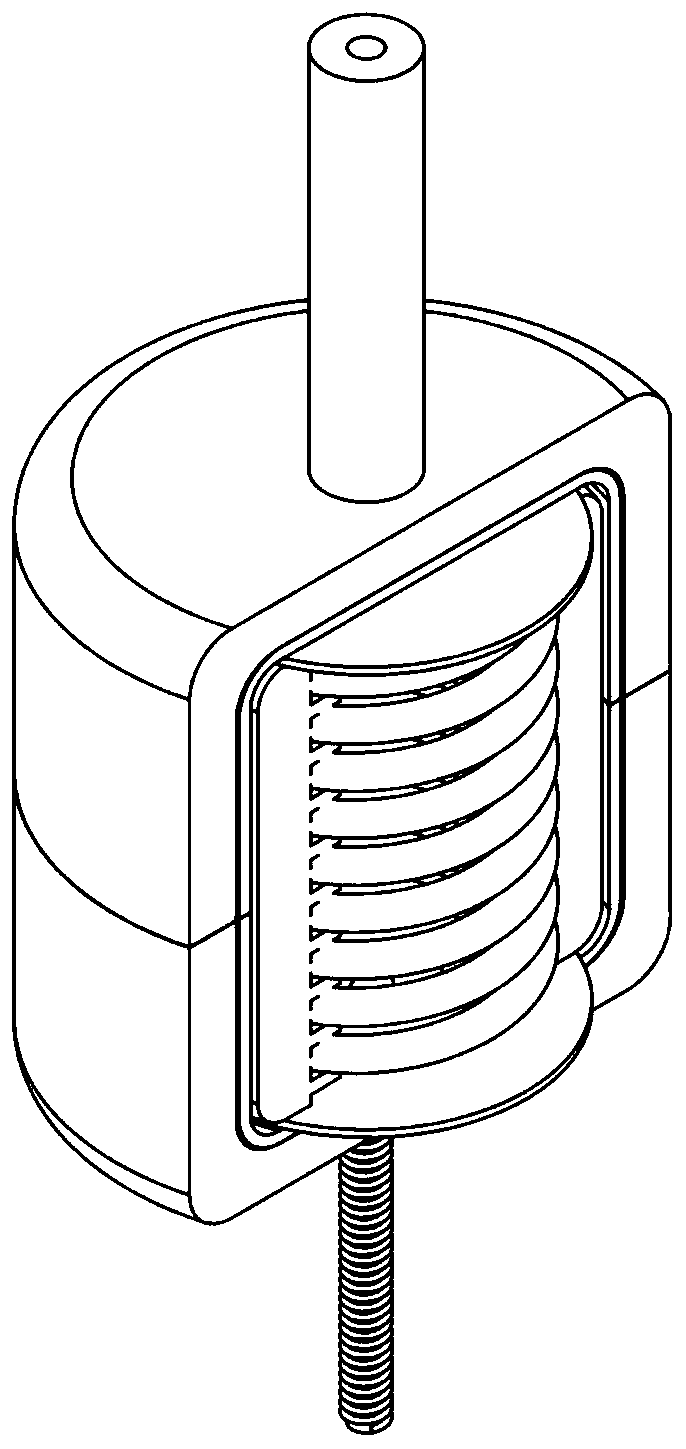

Modular electric heating simulation heat source for ETG

ActiveCN110927775AHeat flow path is the sameUniform surface temperature distributionThermometers using electric/magnetic elementsUsing electrical meansInsulation layerThreaded pipe

The invention relates to a modular electric heating simulation heat source for ETG. The modular electric heating simulation heat source comprises at least two stacked modules. The module comprises a module box and an electric heating unit arranged in the module box. The electric heating unit is wrapped with a heat insulation layer. The electric heating unit comprises a cladding, a coil holding threaded pipe and a resistance wire spiral coil. The coil holding threaded pipe is mounted in the cladding. The resistance wire spiral coil is installed in the coil maintaining threaded pipe, and the coil maintaining threaded pipe is provided with internal threads matched with the resistance wire spiral coil. The beneficial effects of the heat souorce are as follows: the spiral coil simulates the radioactive source for heating, it is guaranteed that the heat flow path of the electric heating unit and the heat flow path of the radioactive source fuel pellet single body are basically the same, surface temperature distribution is basically consistent, overall temperature distribution is also basically consistent, a radioactive source is replaced to test and verify the performance of the generator, early-stage research cost is greatly reduced, and the research progress is accelerated.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Double-cooling section cooling water blowing apparatus for special-shaped blank continuous casting and uses method

ActiveCN101367118BUniform surface temperature distributionQuality improvementMetallurgyTemperature difference

The invention discloses a beam blank continuous casting double cold leg cooling water blowing device. In the device, a gas pipeline(1) is overlapped with a vertical and symmetrical plane(16) of a ventral plate and is parallel to the surface of a beam blank ventral plate(6); and a gas nozzle(2) blows gases towards a beam blank internal arc side ventral plate pressed mark (4) of the beam blank(11).With the technical proposal, the gas nozzle of the water blowing machine blows compressed air or other inert gases towards the water accumulation area of the beam blank ventral plate so as to reduce the accumulated water and to ensure that the accumulated water is evenly distributed over high-temperature parts of the casting blank, so that the surface temperature of the beam blank is more evenly distributed, and the return range of the surface temperature is reduced below 80 DEG C / meter, and the transverse temperature difference on the surface of the ventral plate is reduced below 200 DEG C / meter; the quality of the beam blank is greatly improved, and the incidence rate of the surface crack is reduced below 1 percent; meanwhile, the device and the corresponding application method are simple, easy in operation and are low in cost.

Owner:MAANSHAN IRON & STEEL CO LTD

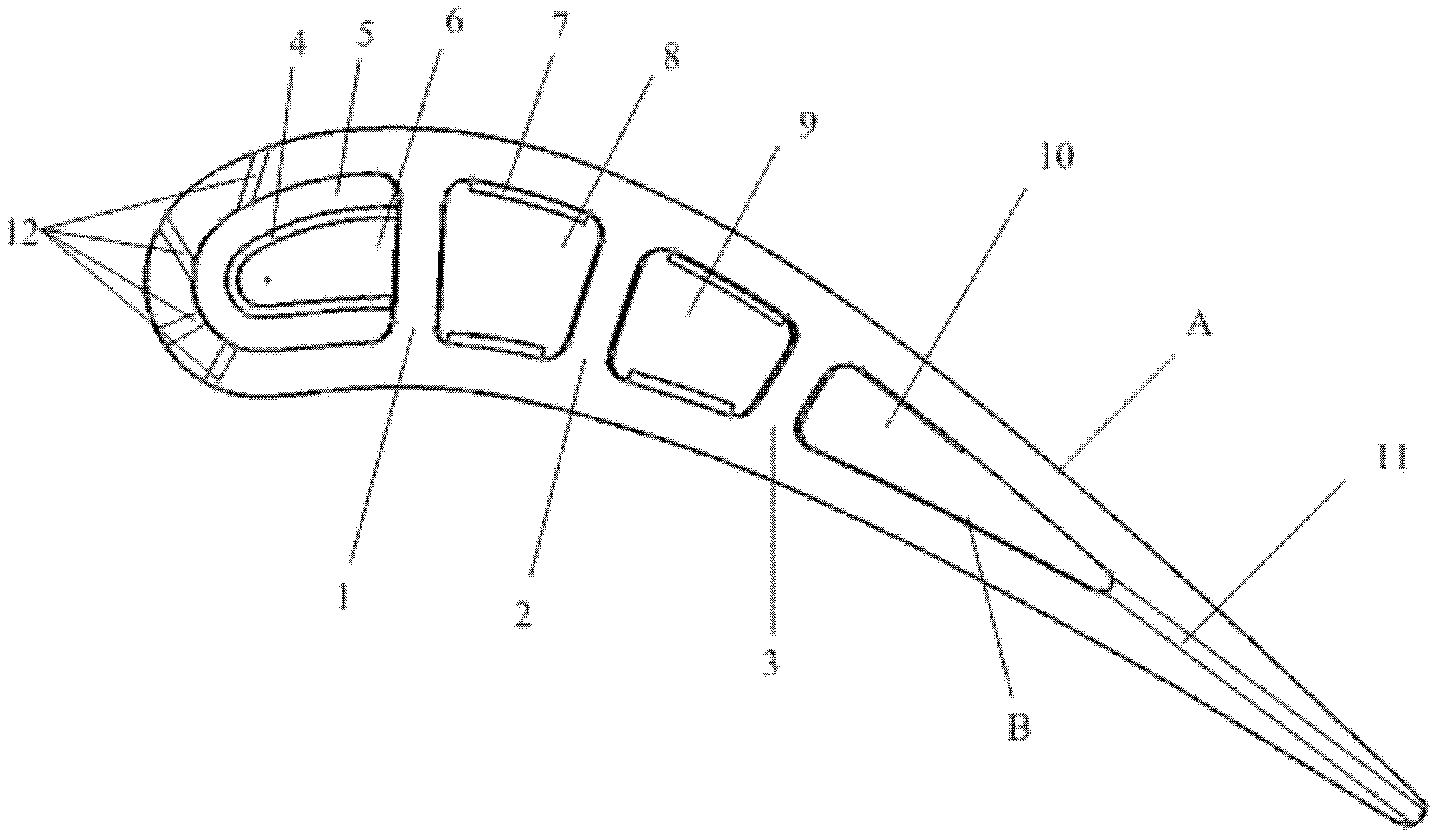

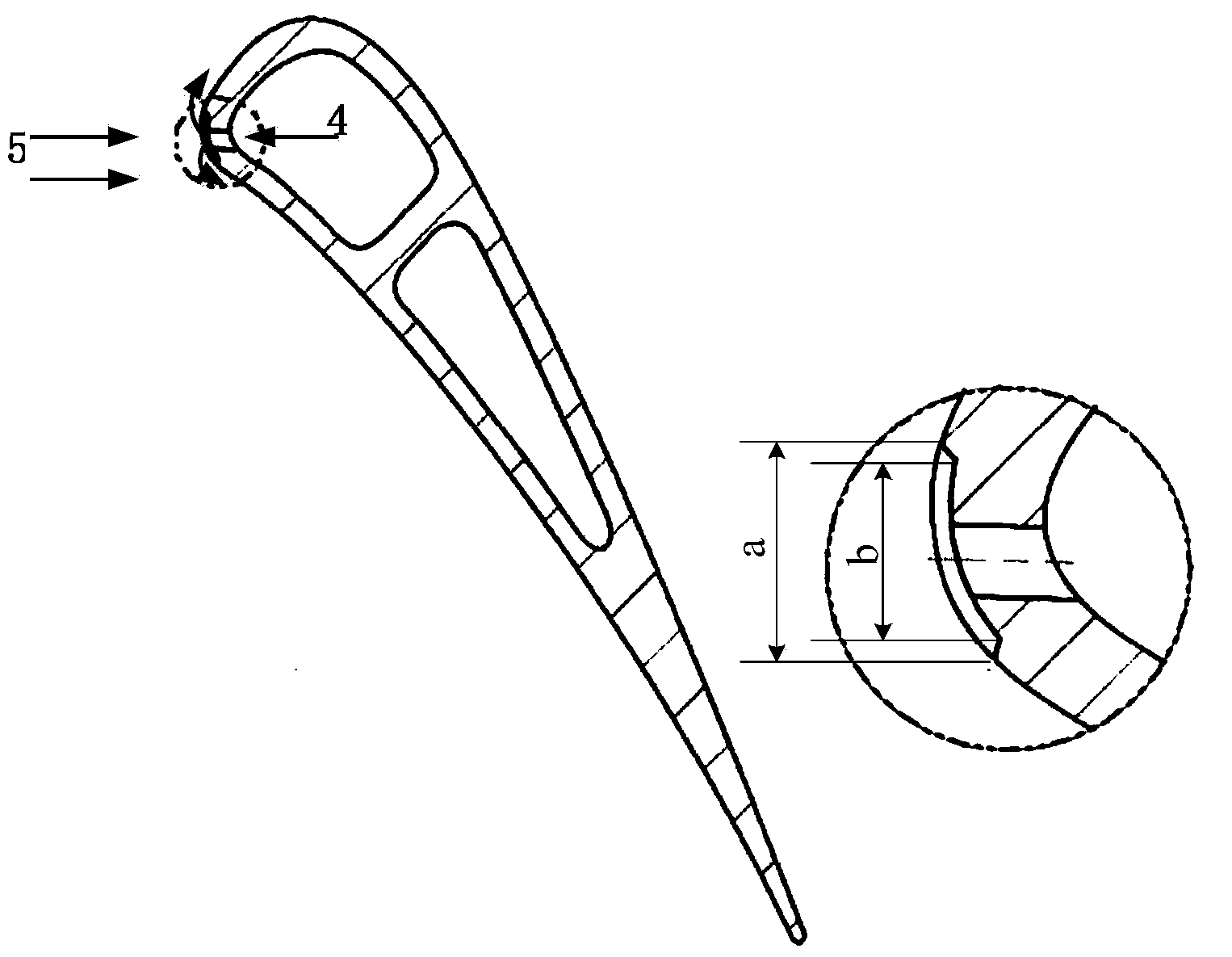

Turbine blade with leading-edge concaved cavity

InactiveCN103806952AImprove cooling efficiencyExtend your lifeBlade accessoriesMachines/enginesLeading edgeTurbine blade

The invention discloses a turbine blade with a leading-edge concaved cavity. The turbine blade with the leading-edge concaved cavity is suitable for gas turbine engines and comprises a blade base body, the leading-edge concaved cavity and a gas film hole. The turbine blade with the leading-edge concaved cavity is characterized in that a stationary point line is used as a center line by the leading edge of the turbine blade, the molded surface of the leading edge of the blade serves as a reference molded surface, and the concaved cavity with the depth of 1 mm to 2 mm is cut inwards. With the structure of the novel blade, the temperature distribution conditions of the leading edge of the turbine blade can be improved, and the cooling effect can be improved.

Owner:BEIHANG UNIV +1

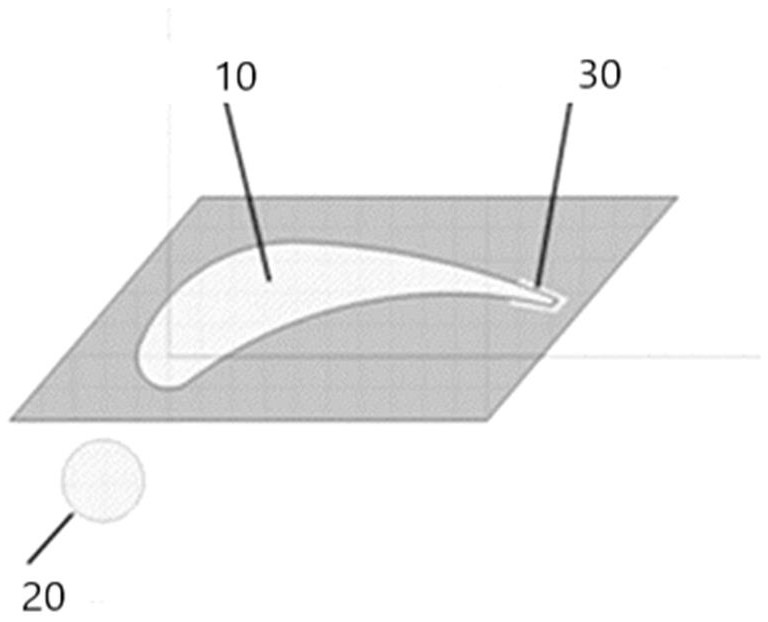

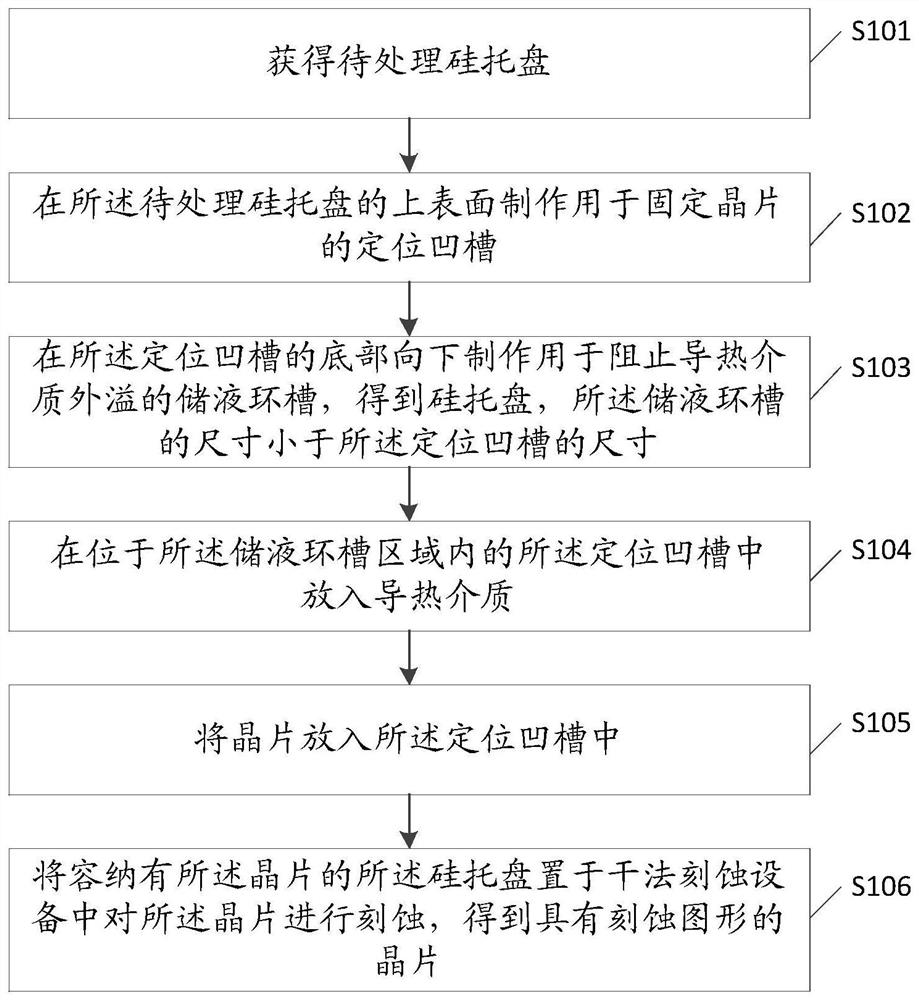

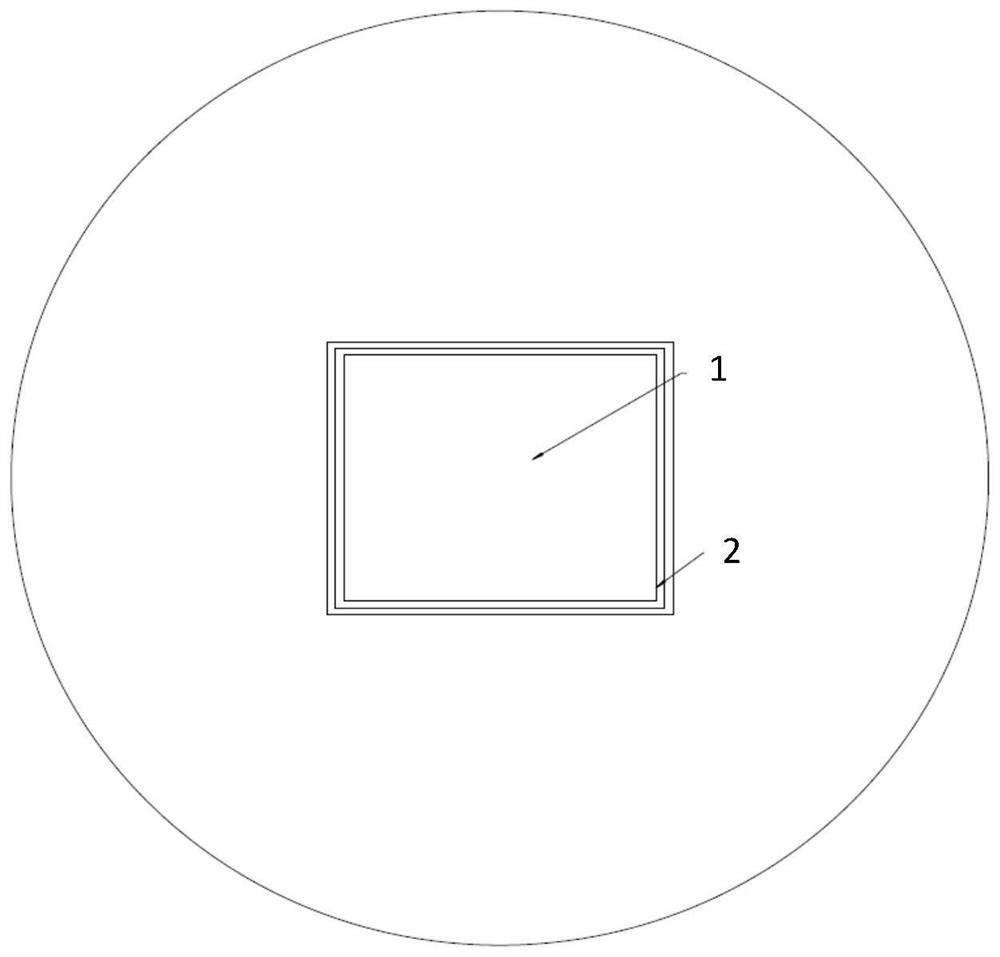

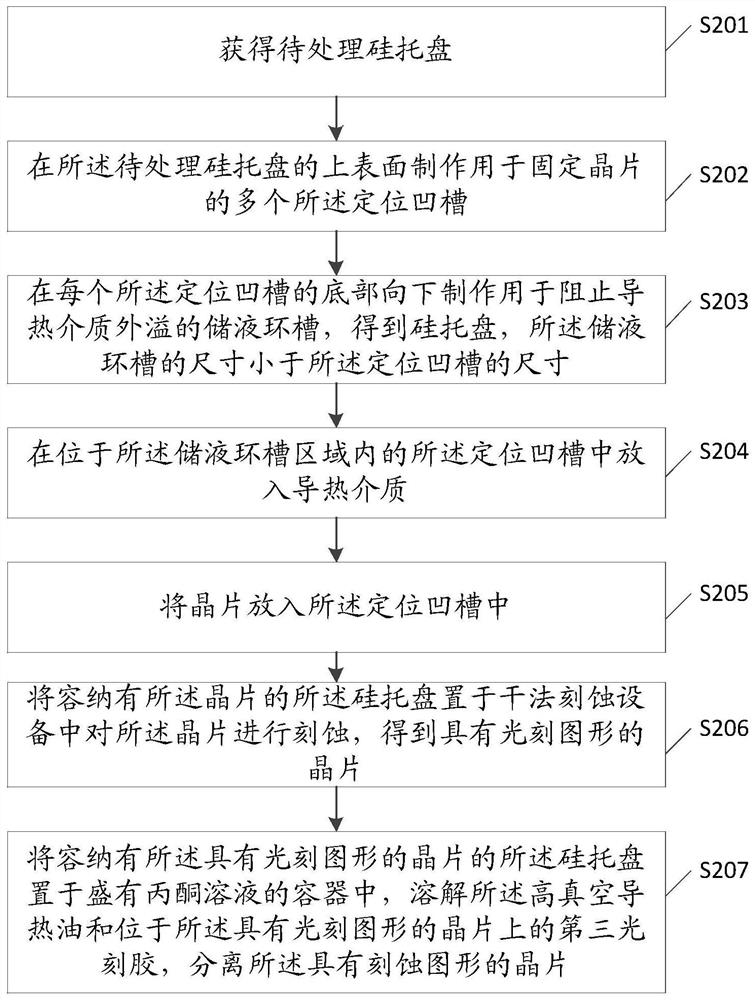

Wafer etching method

ActiveCN111816604ALow costWon't overflowElectric discharge tubesSemiconductor/solid-state device manufacturingWaferingEngineering

The invention discloses a wafer etching method. The wafer etching method comprises the steps: obtaining a to-be-processed silicon tray; manufacturing a positioning groove for fixing a wafer in the upper surface of the to-be-processed silicon tray; manufacturing a liquid storage annular groove used for preventing the heat conduction medium from overflowing in the bottom of the positioning groove, and obtaining a silicon tray, wherein the size of the liquid storage annular groove is smaller than that of the positioning groove; putting a heat-conducting medium into the positioning groove positioned in the liquid storage annular groove area; putting the wafer into the positioning groove; and placing the silicon tray containing the wafer in dry etching equipment to etch the wafer to obtain thewafer with an etching pattern. The silicon tray with the positioning groove and the liquid storage annular groove is manufactured; the silicon tray is low in cost; the liquid storage annular groove isused for preventing the heat-conducting medium from overflowing, so that generation of impurities caused by reaction with the etching gas does not occur; the wafer is contained in the positioning groove, so that the wafer can be prevented from sliding; the wafer does not need to be pressed, so that the fragment rate is reduced; and the area where the wafer is located is not affected, and etchinguniformity is guaranteed.

Owner:北京智创芯源科技有限公司

Die with heating device

InactiveCN103072222BSimple structureUniform surface temperature distributionPower flowRoom temperature

Owner:KUNSHAN YURONG ELECTRONICS +1

Heat exchanger

ActiveCN1811317AShorten speedEasy Forward ArrangementEvaporators/condensersStationary conduit assembliesEngineeringHeat exchanger

The present invention relates to a heat exchanger, in which inlet and outlet side heat exchange parts are communicated with each other and have the same refrigerant flowing direction by communicating pairs of cups with each other which are located at a predetermined area of the center of the heat exchanger, thereby being easily reduced in size, providing uniform surface temperature distribution and improving heat exchange efficiency by reducing the preponderance and the pressure drop rate of refrigerant and inlet and outlet pipes being easily arranged forward.

Owner:HANON SYST

Electrothermal combined using device for solar cell

InactiveCN100424893CUniform surface temperatureImprove photoelectric conversion efficiencyPhotovoltaicsPhotovoltaic energy generationElectricityWorking fluid

This invention discloses a common use device for electricity and heat of a solar cell including a liquid container with heat collection working fluid, in which, hot tubes are set on the side walls of the container and set with phase change heat- carry working fluid, a solar cell is connected with the tubes in the container fixedly, an inlet is set at the bottom of the container and an outlet is set at the top of the container, the bottom face is transmissive, heat preservation materials are set at outside of the top and outside of the side wall of the container. This invention can carry away solar heat not changed to electricity quickly by dipping a solar cell in a heat-collection working fluid and connecting to the hot tubes.

Owner:TIANJIN UNIV

2U-shaped radiator

PendingCN112969354AImprove cooling effectReduce temperature riseCooling/ventilation/heating modificationsMechanical engineeringHeat spreader

The invention provides a 2U-shaped radiator. The 2U-shaped radiator comprises a phase change restraining, heat transfer and radiating fin, a first fin and a second fin, wherein the phase change restraining, heat transfer and radiating fin comprises a first section, a second section, a third section, a fourth section and a fifth section which are sequentially connected, the first section, the second section and the third section form a first U-shaped part, the third section, the fourth section and the fifth section form a second U-shaped part, the opening directions of the first U-shaped part and the second U-shaped part are opposite, and the fifth section is located in the first U-shaped part; and the first fin is located between the first section and the fifth section, and the second fin is located between the third section and the fifth section. The 2U-shaped radiator has the advantages of being low in cost, high in heat dissipation capacity, uniform in heat dissipation, small in temperature rise and the like, and has wide market prospects.

Owner:ZHEJIANG JIAXI TECH CO LTD

Heavy-type combustion engine high-temperature turbine double-medium cooling blade

ActiveCN102425459BUniform surface temperature distributionExtend your lifeTurbine/propulsion engine coolingBlade accessoriesCombustionCooling effect

The invention relates to a heavy-type combustion engine high-temperature turbine double-medium cooling blade, which is characterized in that: a first separation plate and a third separation plate are sequentially arranged from the front edge and the end edge of a blade inner cavity to divide the blade inner cavity into a front cooling space, a middle cooling space and a rear cooling space to be independent from one another along the radial direction of the blade, the blade front cooling space is divided by a fourth separation plate into a first cooling cavity and a second cooling cavity, impact cooling holes are equally distanced to one another to be arranged on the fourth separation plate, the front edge of the blade is provided with four rows of gas film cooling holes which are alternatively arranged, spoiler ribs which are arranged at equal intervals are arranged on a blade inner wall B of the middle cooling space, the middle cooling space is divided by a second separation plate into a third cooling cavity and a fourth cooling cavity, which are communicated with each other, the rear cooling space is a fifth cooling cavity, and the fifth cooling cavity is connected through fin-shaped vent holes which are equally distanced to one another; and the middle cooling space adopts a steam closed-type cycling cooling way to be combined with the air cooling way of the front and the rear cooling spaces, so the cooling fluid has high heat exchanging coefficient on each position of the blade, the cooling effect can be improved, and the unit heat efficiency can be improved.

Owner:XI AN JIAOTONG UNIV

A heat dissipation device that adopts pulsating flow and foam metal plate to strengthen

ActiveCN105097735BIncrease disturbanceEnhanced blendingSemiconductor/solid-state device detailsSolid-state devicesCavitationWorking fluid

The invention discloses a device for strengthening heat dissipation by adopting pulsating flow and foamed metal plates, which comprises a pulsating pump, a heat sink chamber, a liquid accumulation chamber and a cooler. The liquid accumulation chamber sprays the cooling liquid into the heat sink chamber through the liquid separator, and the heat sink chamber sends the heat-exchanged liquid into the cooler through the liquid discharge pipe for cooling, and the pulsation pump sucks the cooled cooling liquid from the cooler through the connecting pipe. liquid; the heat sink chamber includes a foamed metal plate, a heat exchange carrier plate and a cover plate, the heat exchange carrier plate is connected to a high heat flux device, the foam metal plate is fixedly connected to the heat exchange carrier plate, and the liquid separator is connected to the heat exchange carrier plate The top of the cover plate is connected vertically. The pulsating flow in the present invention combined with the double-layer metal foam structure can increase the horizontal and vertical disturbance and mixing of the working fluid, and the thermal boundary layer is continuously reorganized. At the same time, the pressure change will lead to the formation of cavitation and vortex during the disturbance process. , can greatly improve the heat transfer efficiency.

Owner:常州贺斯特科技股份有限公司

Energy-saving kang with double flow channels

ActiveCN101984297BLow costLow running costLighting and heating apparatusCombustion-air/flue-gas circulation for stovesBuilding energyFlue gas

An energy-saving kang with double flow channels belongs to the technical fields of the utilization of solar energy and biomass energy and the building energy conservation. The energy-saving kang with double flow channels contains not only a stove, a kang plate, a flue baffle plate, a flue gas inlet, a flue gas circulation channel, a flue gas outlet, a chimney and other parts of the traditional kang, but also a solar air heat collecting system. In the energy-saving kang, the folded metal plate on the lower surface of the upper kang plate is utilized to increase the heat-transfer intensity of the air and the kang plate and the uniformity of the temperature distribution of the kang surface; the baffle plate is used to effectively separate the air and the flue gas circulation channel; and thesolar energy and the heat of the flue gas can be utilized simultaneously, and the solar heat collecting device can not be damaged. All the parts in the energy-saving kang are prepared from common materials and by common preparation technology, thus the energy-saving kang has the advantages of simple production technology, low production cost and the like. The energy-saving kang is mainly used in the single building of a village in Northern China, can solve the indoor heating problem in winter and can reduce the coal consumption while lowering the environment pollution.

Owner:TSINGHUA UNIV

A heat press machine for reinforced composite flooring

InactiveCN110614682BImprove the effect of hot pressingUniform surface temperature distributionPlywood pressesVeneer pressesThermodynamicsStructural engineering

The invention belongs to the technical field of floor manufacturing equipment, and particularly relates to a reinforced composite floor hot press. The reinforced composite floor hot press comprises abase, an oil storage tank is fixedly installed on the base, and through holes are formed in the two end surfaces of the oil storage tank. A pressure-bearing platform is fixedly installed on the base,and a guiding rail is arranged on the pressure-bearing platform. A first bracket and a second bracket are fixedly arranged on the base, a limiting rod and a lead screw are connected between the firstbracket and the second bracket, and an installation plate parallel to the top surface of the pressure-bearing platform is matched with the lead screw in a threaded mode. A first air cylinder is installed on the bottom surface of the installation plate, the end part of a piston rod of the air cylinder is clamped to the two ends of a hot oil pipe, and a pressing roller is rotatably matched with theouter side wall of the hot oil pipe. The two ends of the hot oil pipe are fixedly connected with a sealing plate mutually matched with the end surface, and an opening with the same size as the longitudinal section of the hot oil pipe is formed in the middle part of the sealing plate. According to the reinforced composite floor hot press, a hot pressing roller is adopted to replace a traditional hot pressing plate to conduct the hot pressing on the reinforced composite floor, and a better hot pressing effect is achieved.

Owner:上海军裕实业有限公司

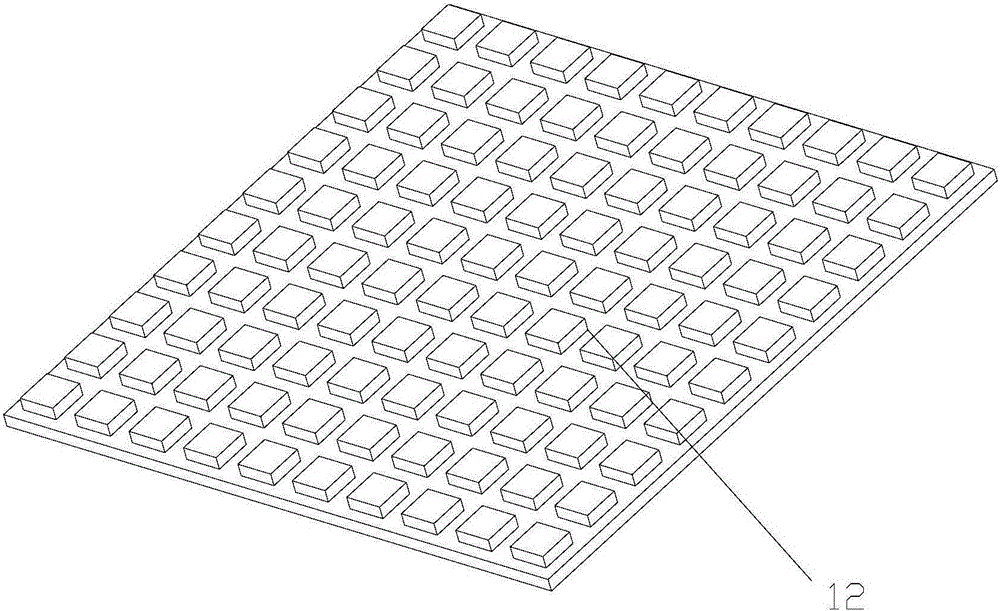

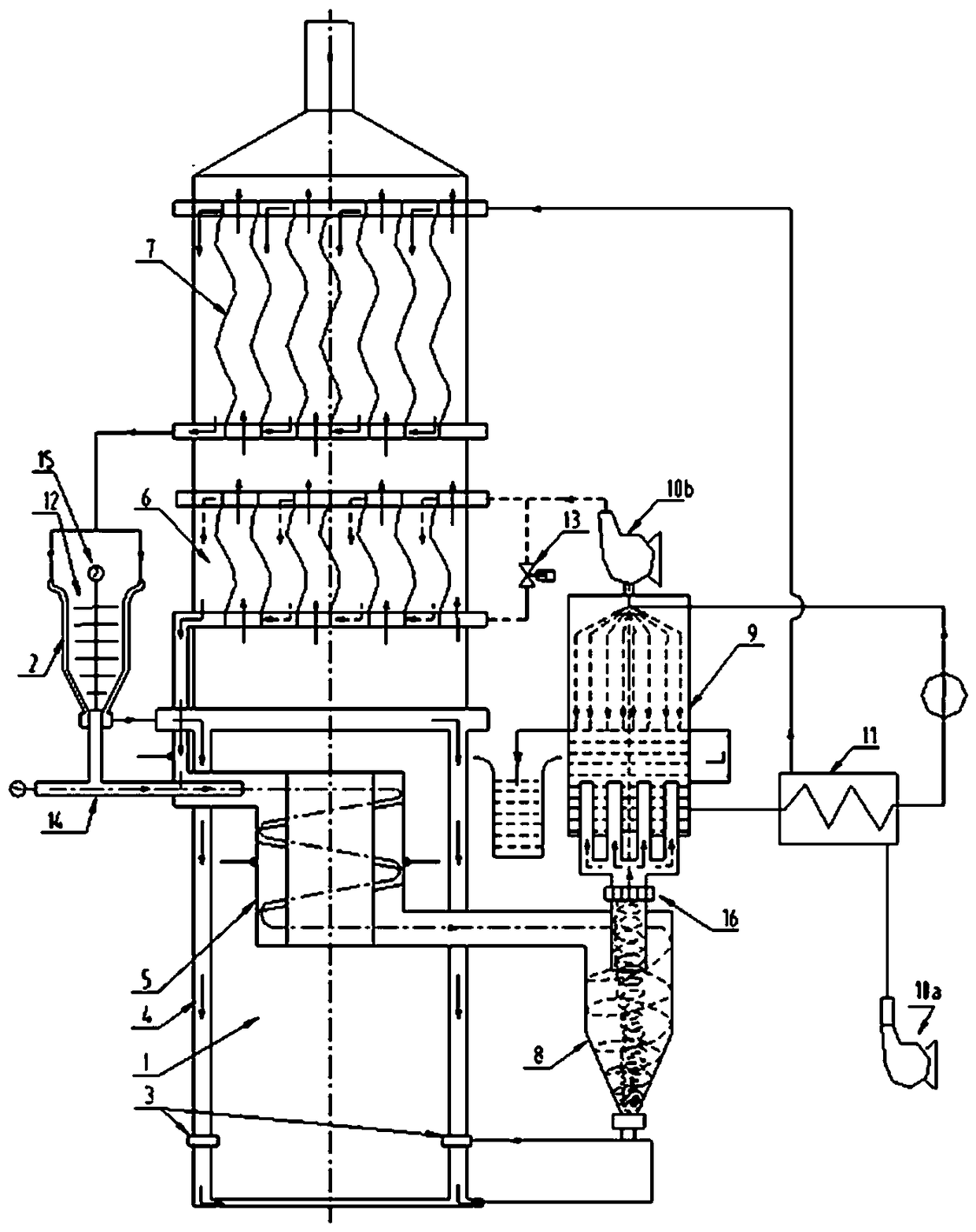

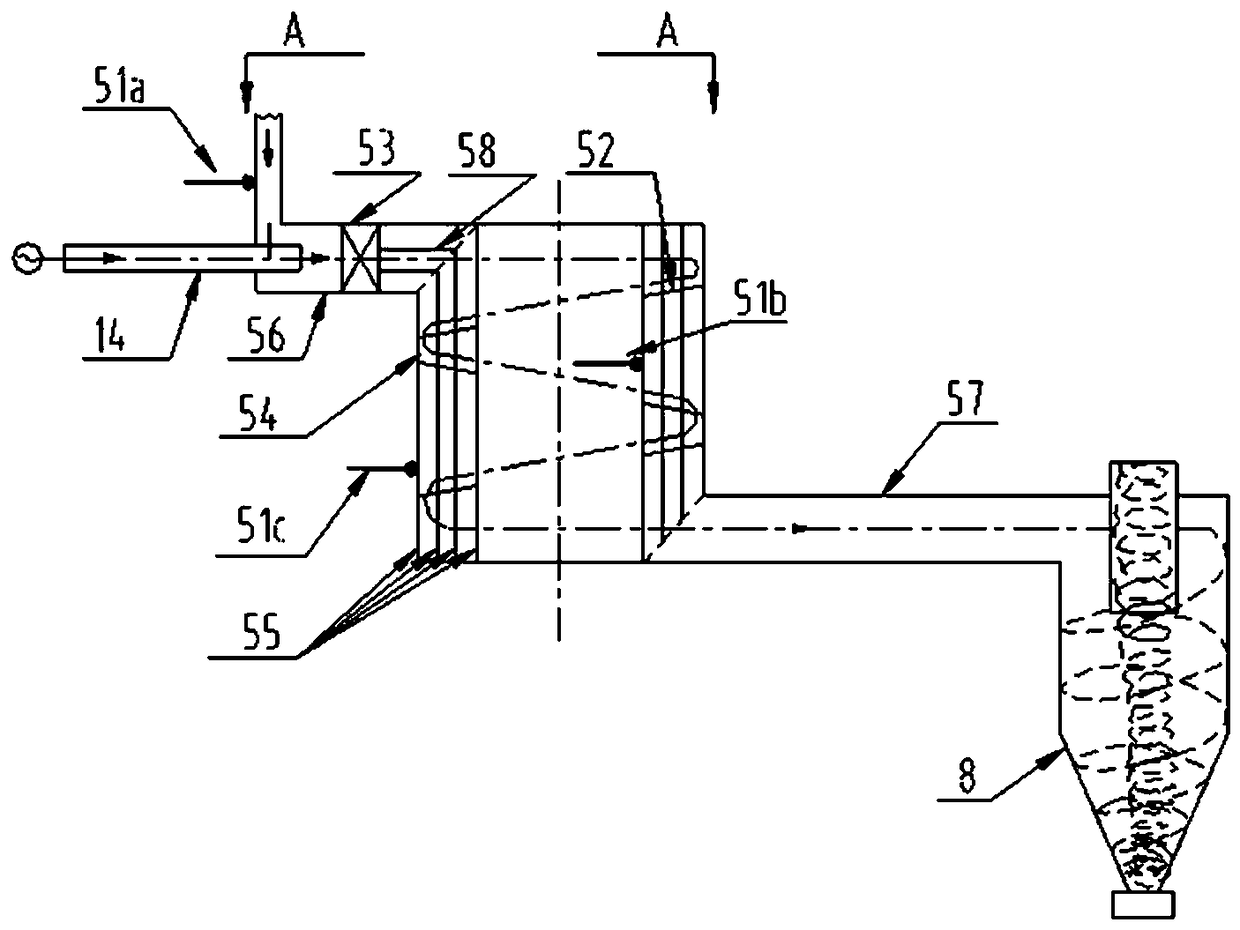

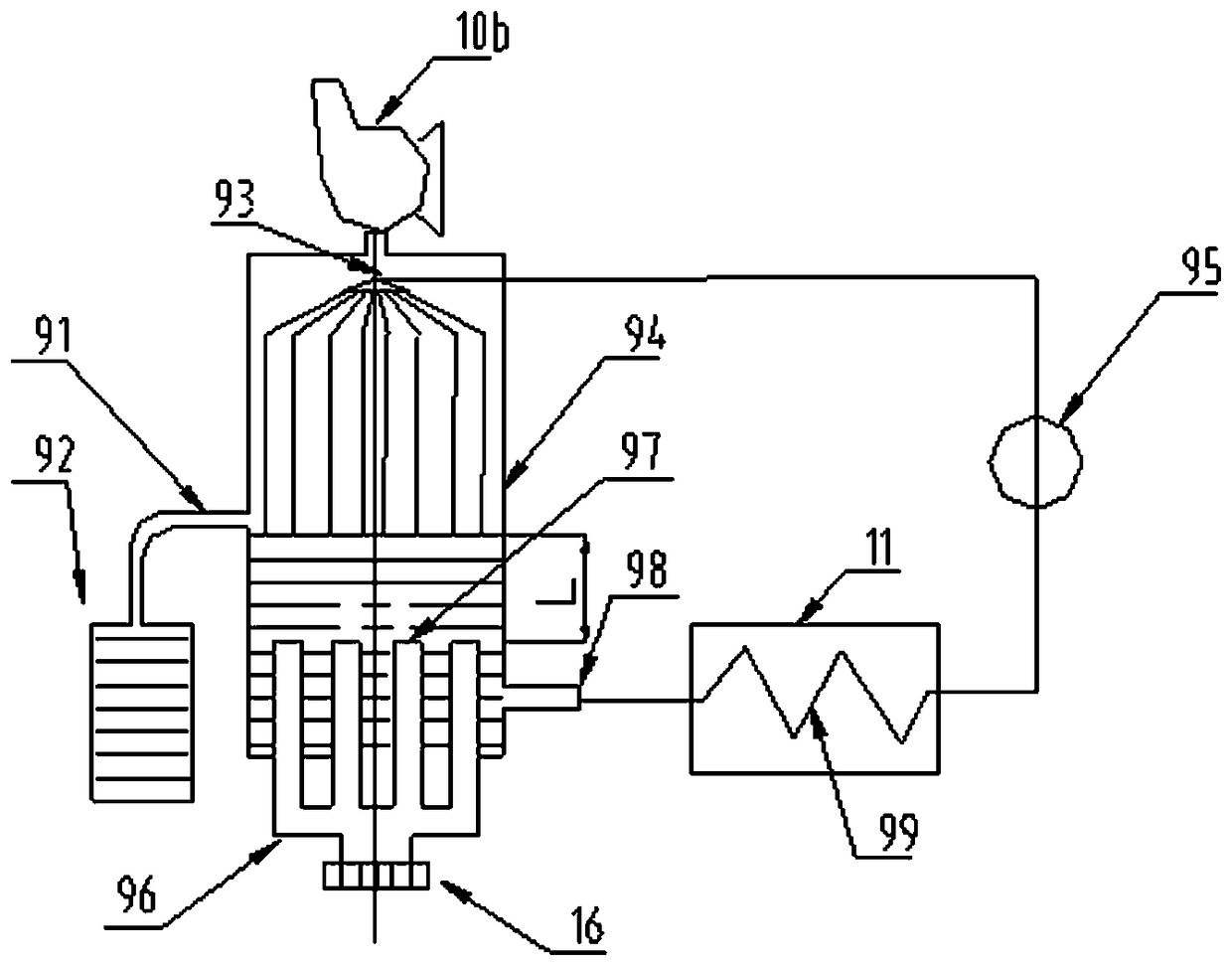

Low energy consumption biomass liquefying device

ActiveCN109161394AMeet heat absorption needsImprove utilization efficiencyLiquid hydrocarbon mixture productionAir preheaterMultiple stages

The invention belongs to the field of biomass fast pyrolysis liquefaction, particularly relates to a low energy consumption biomass liquefying device, and solves the problems of overhigh energy consumption and relatively low output proportion in the biomass pyrolysis liquefaction process. The device mainly comprises a feed bin heating jacket, a carbon powder burner, a multistage air preheater, a biomass pyrolysis reactor, a plate-type nitrogen preheater, a gas-solid cyclone separator, a fast condensing system, a metal filter and the like. According to the low energy consumption biomass liquefying device disclosed by the invention, the heating rate of biomass is greatly improved by use of rotating centrifugal force and a honeycomb channel; due to gas-liquid bubbling mixing, quick condensingis realized and the generation proportion of biomass oil is increased. Meanwhile, heat required by pyrolysis is mainly provided by burning biomass carbon particles, so that the self sufficiency of energy is realized; in addition, the heat of flue gas is recovered by multiple stages, so that heat loss of exhausted smoke is reduced, and heat efficiency of the whole set of device is improved. By adopting the low energy consumption biomass liquefying device disclosed by the invention, the oil yield of biomass fast pyrolysis liquefaction can be improved to 65 percent or above.

Owner:SHANXI UNIV

Method and device for improving critical dimension uniformity of wafer

PendingCN114253088AImprove critical dimension uniformityUniform surface temperature distributionPhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsProcess engineering

The invention provides a method and a device for improving the critical dimension uniformity of a wafer. The method comprises the following steps: acquiring first temperature distribution on the surface of a wafer in a drying process after coating; predicting second temperature distribution in the post-exposure drying process according to the first temperature distribution, wherein drying equipment adopted in the post-coating drying process and drying equipment adopted in the post-exposure drying process are manufactured by adopting the same process; and compensating exposure energy in an exposure process according to the second temperature distribution, and exposing the wafer by adopting the compensated exposure energy so as to improve the critical dimension uniformity of the wafer. The drying equipment adopted in the post-coating drying process and the drying equipment adopted in the post-exposure drying process are manufactured by adopting the same process, so that the second temperature distribution can be predicted by adopting the first temperature distribution, and the exposure energy in the exposure process is compensated according to the second temperature distribution; and the critical dimension uniformity of the wafer is improved.

Owner:YANGTZE MEMORY TECH CO LTD

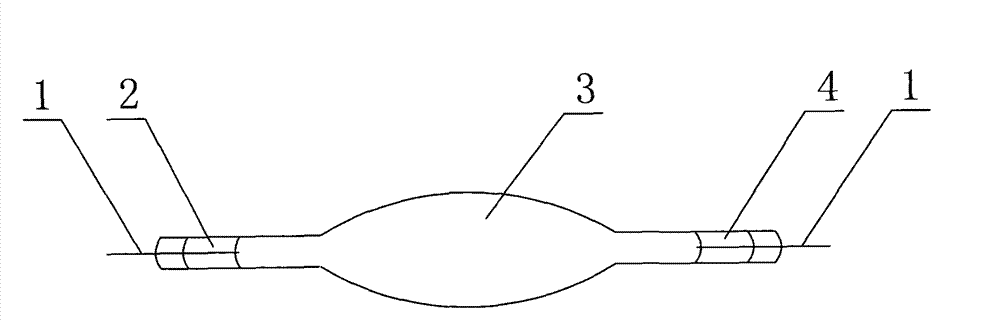

Exhaust-pipe-free UPS pulse metal halide lamp

InactiveCN101752192BHigh light efficiencyUniform surface temperature distributionGas discharge lamp detailsBiochemical engineeringMetal-halide lamp

The invention relates to an exhaust-pipe-free UPS pulse metal halide lamp, which comprises an electrode, a first clamp end which is used for clamping after the electrode is installed, an electric arc tube cell shell which is formed by a quartz tube through once forming and a second clamp end which is used for clamping after the electric arc tube cell shell is exhausted, wherein the electrode is arranged inside the first and the second clamp ends, the first clamp end is arranged on the left end of the electric arc tube cell shell, the second clamp end is arranged on the right end of the electric arc tube cell shell, and the first clamp end, the second clamp end and the electric arc tube cell shell are of an integrated structure. Since a cold end is not existed, the light efficiency is higher; the electric arc tube cell shell is free from reprocessing after being formed by the quartz tube at one time and can directly enter the following procedure to be produced, so the air leakage of the exhaust pipe is free from existing, the service life is longer, the energy can be saved, and the exhaust-pipe-free UPS pulse metal halide lamp is more energy-saving and more environment-friendly.

Owner:常州富邦节能技术服务有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com