Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32results about How to "Excellent etch profile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

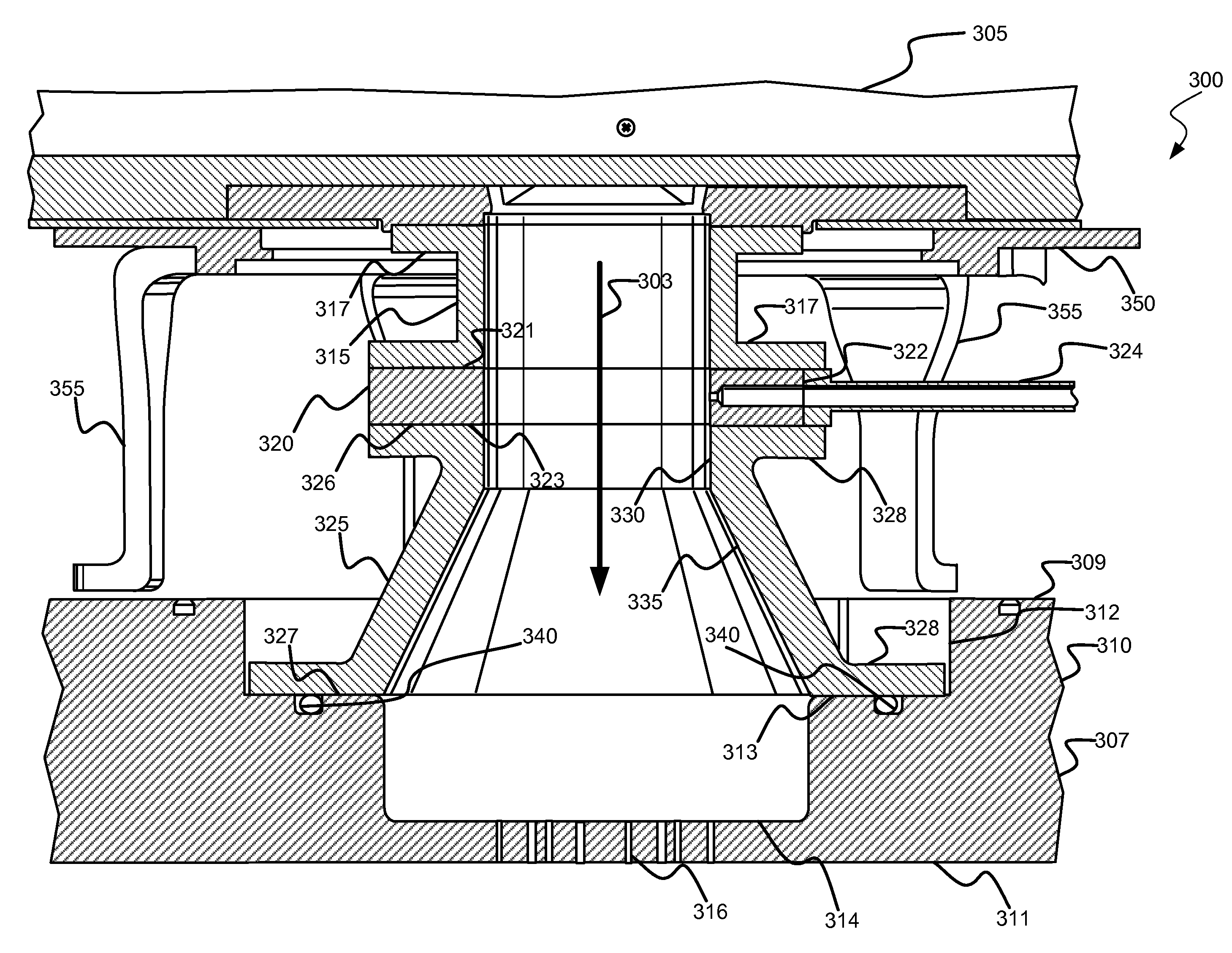

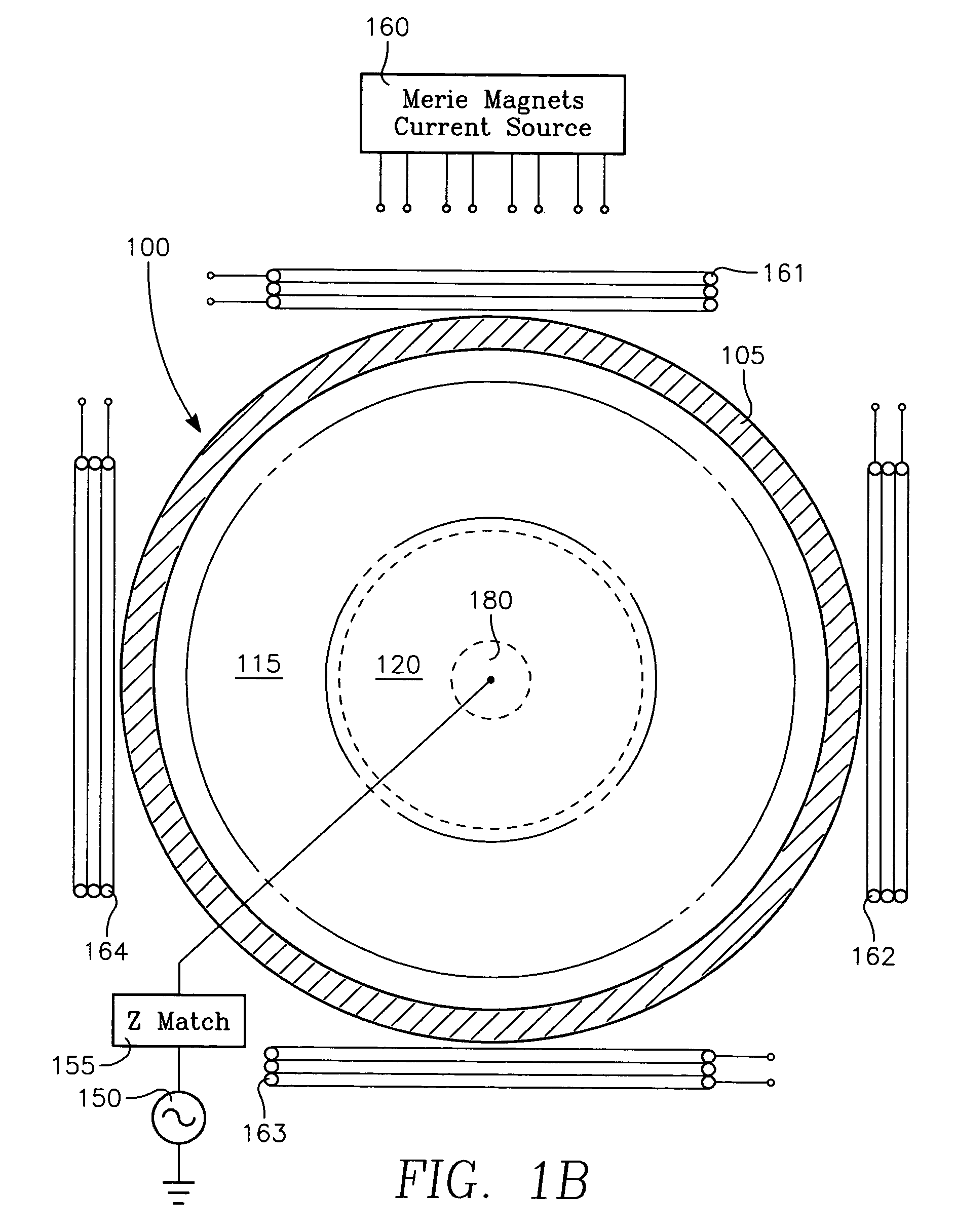

Semiconductor system assemblies and methods of operation

InactiveUS9287095B2Excellent etch profileReduce deliveryElectric discharge tubesSemiconductor/solid-state device manufacturingRemote plasmaInjection port

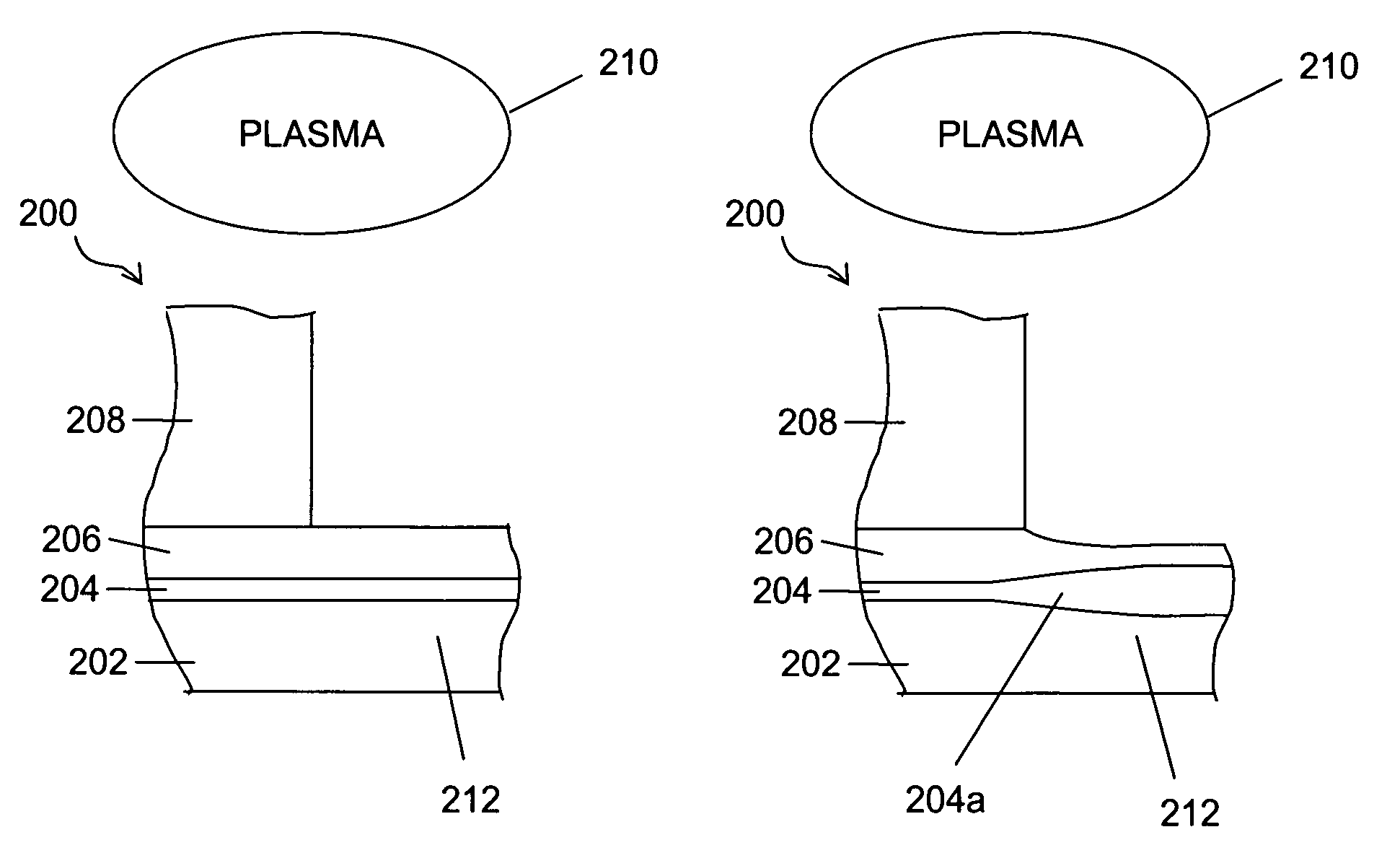

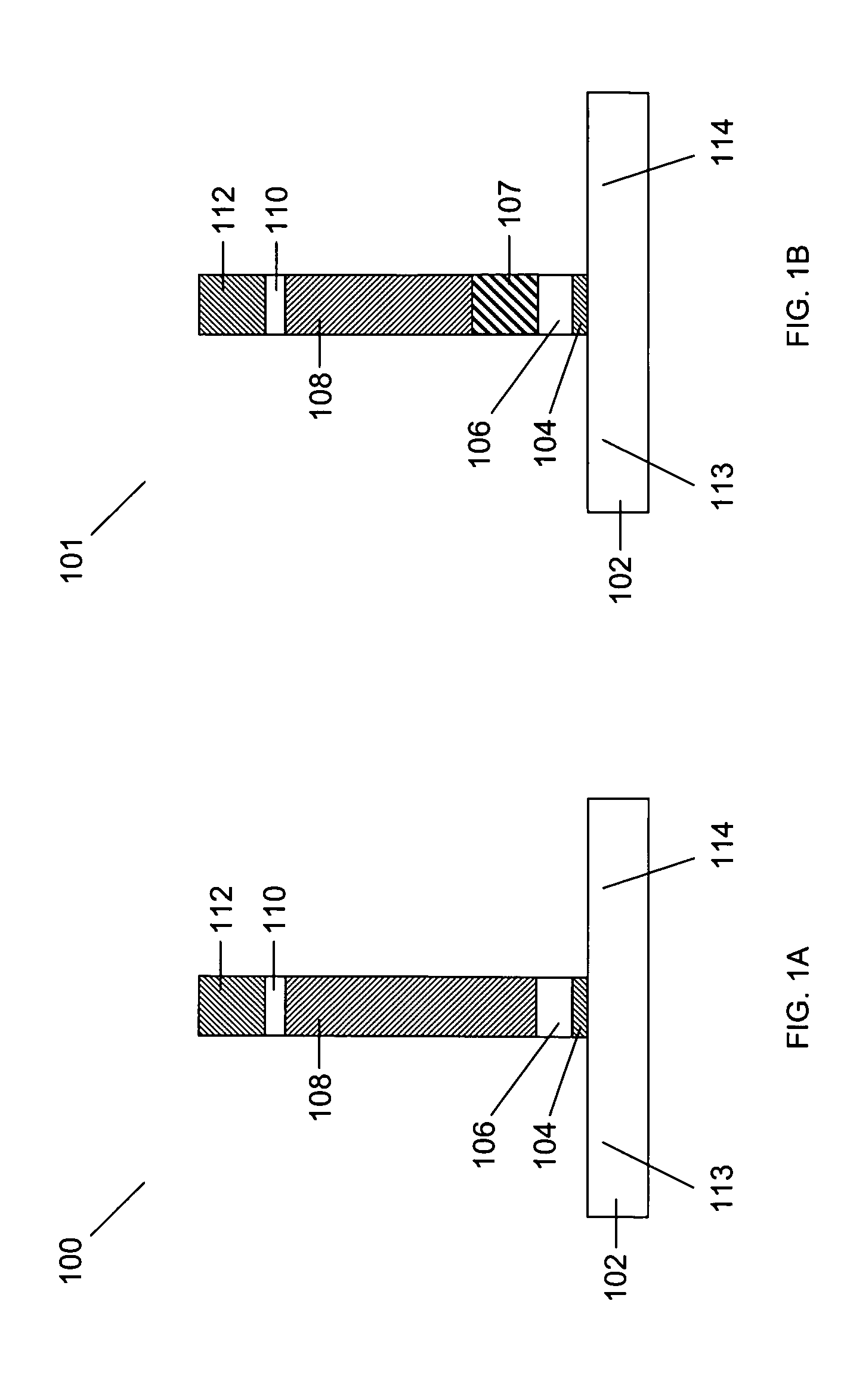

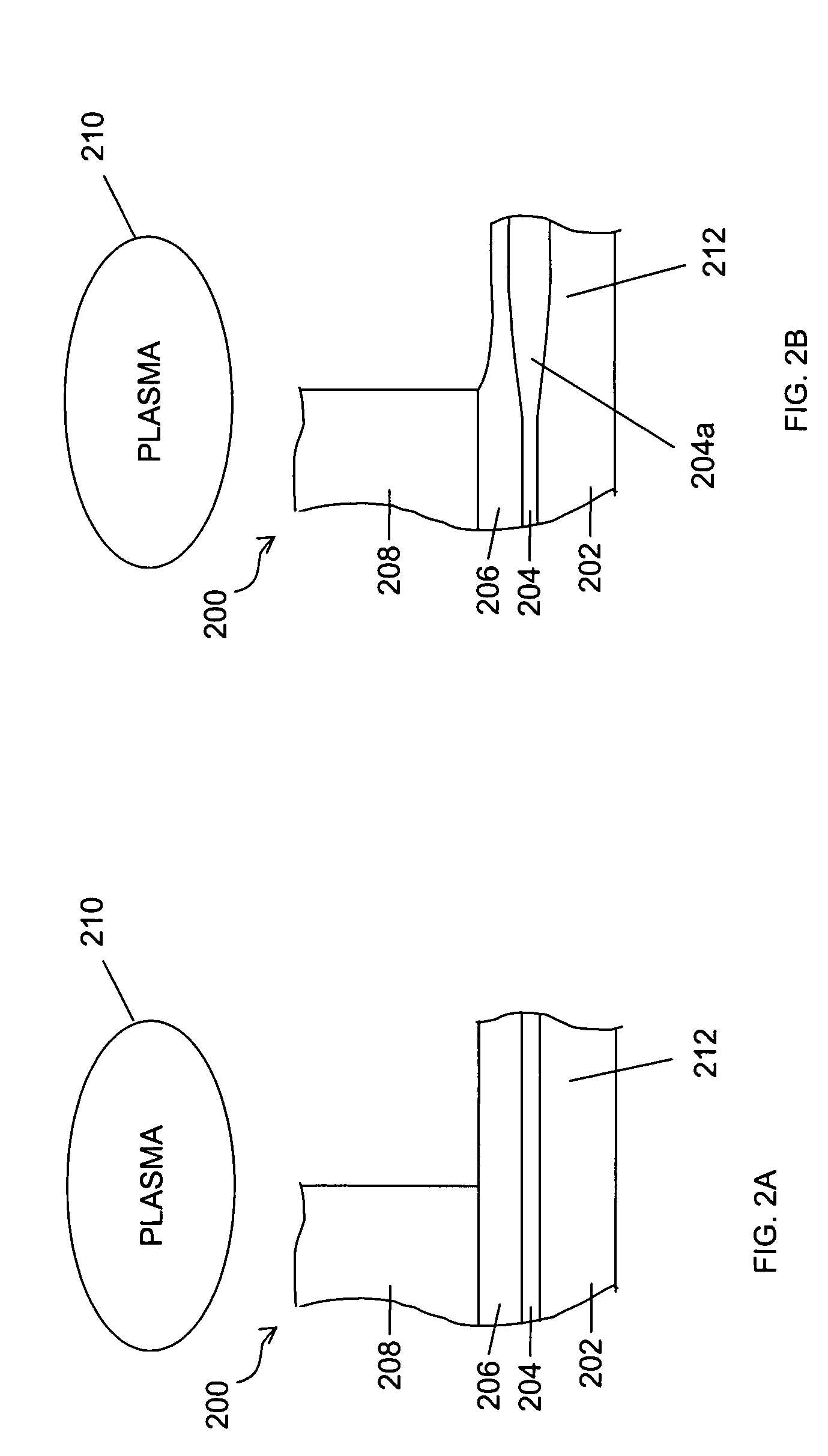

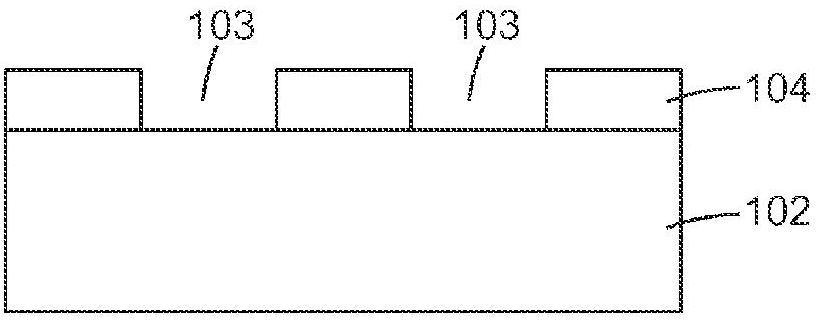

An exemplary semiconductor processing system may include a remote plasma source coupled with a processing chamber having a top plate. An inlet assembly may be used to couple the remote plasma source with the top plate and may include a mounting assembly, which in embodiments may include at least two components. The inlet assembly may further include a precursor distribution assembly defining a plurality of distribution channels fluidly coupled with an injection port.

Owner:APPLIED MATERIALS INC

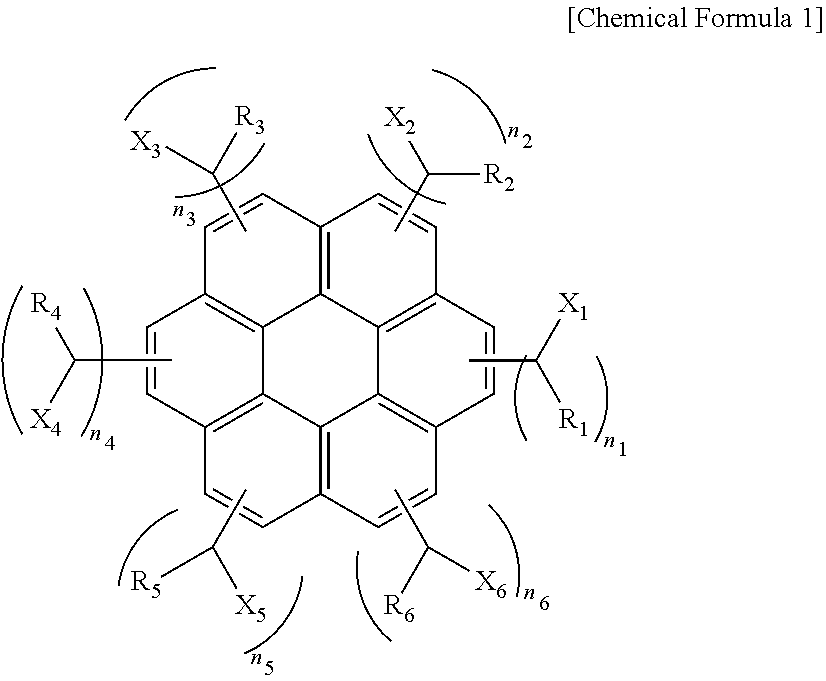

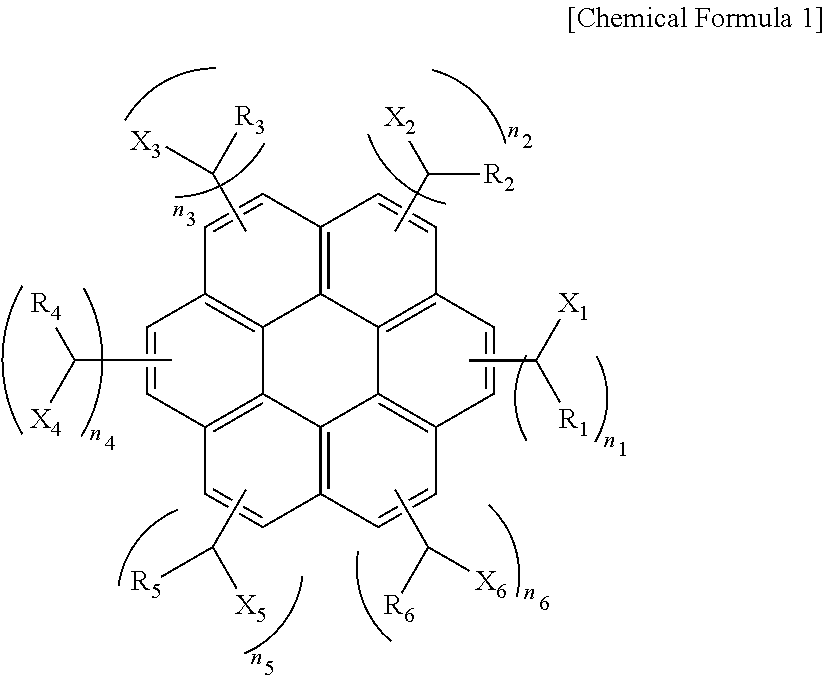

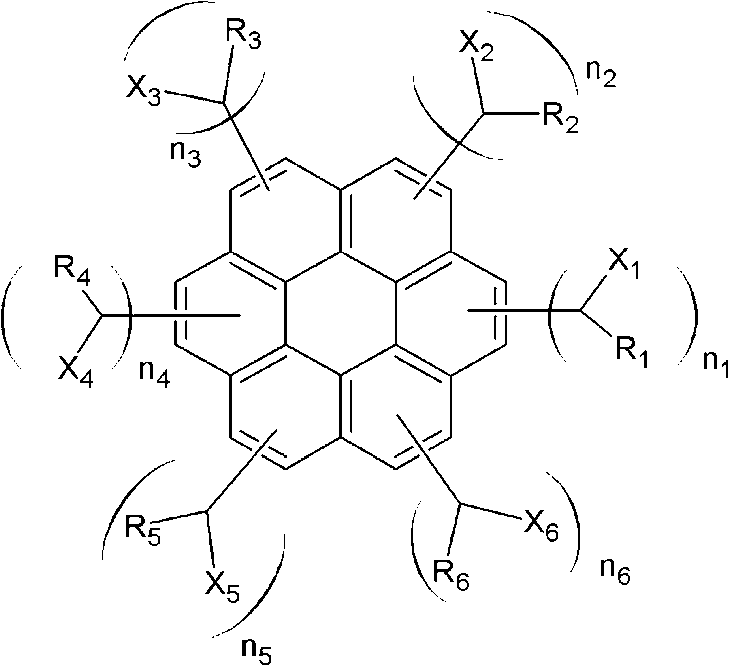

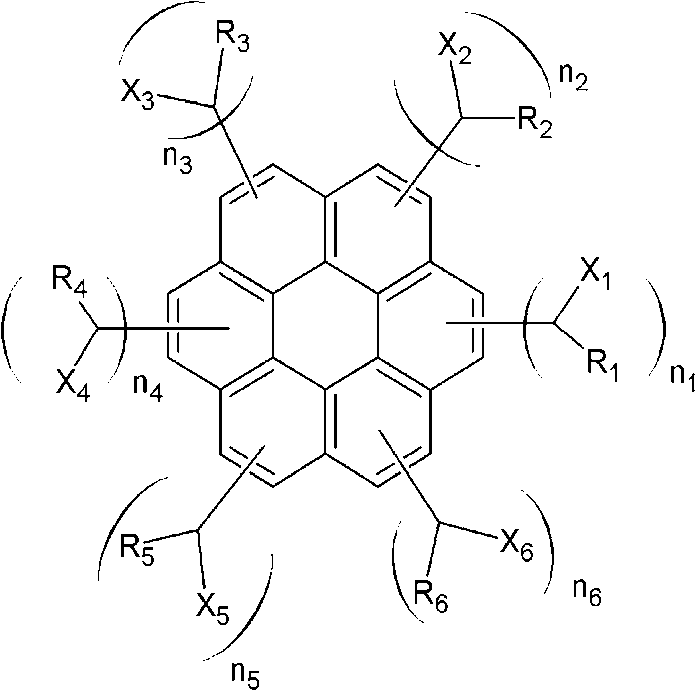

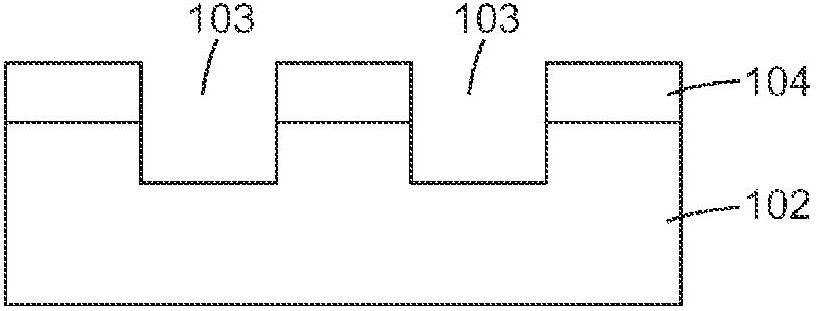

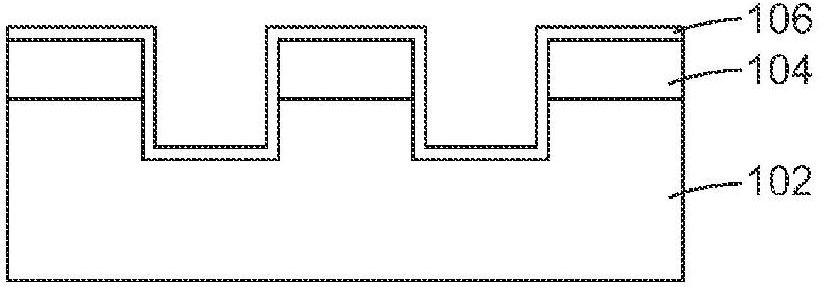

Aromatic ring-containing compound for a resist underlayer and resist underlayer composition

ActiveUS20110155944A1Excellent lithographic structureImprove etch selectivityOrganic chemistryMagnetic paintsResistAlkoxy group

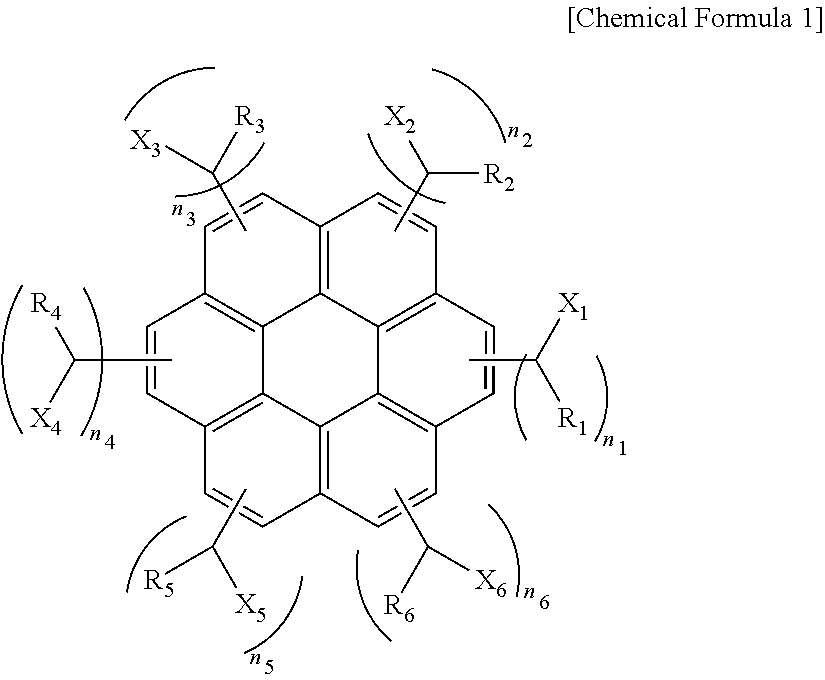

An aromatic ring-containing compound for a resist underlayer and a resist underlayer composition, the aromatic ring-containing compound being represented by the following Chemical Formula 1:wherein, in Chemical Formula 1, R1 to R6 are each independently a substituted or unsubstituted C1 to C10 alkyl group, a substituted or unsubstituted C5 to C20 aromatic ring group, a substituted or unsubstituted C3 to C20 cycloalkyl group, a substituted or unsubstituted C3 to C20 cycloalkenyl group, a substituted or unsubstituted C2 to C20 heteroaryl group, or a substituted or unsubstituted C2 to C20 heterocycloalkyl group, X1 to X6 are each independently hydrogen, a hydroxy group (—OH), a substituted or unsubstituted alkyl amine group, a substituted or unsubstituted alkoxy group, or an amino group (—NH2), n1 to n6 are each independently 0 or 1, and 1≦n1+n2+n3+n4+n5+n6≦6.

Owner:CHEIL IND INC

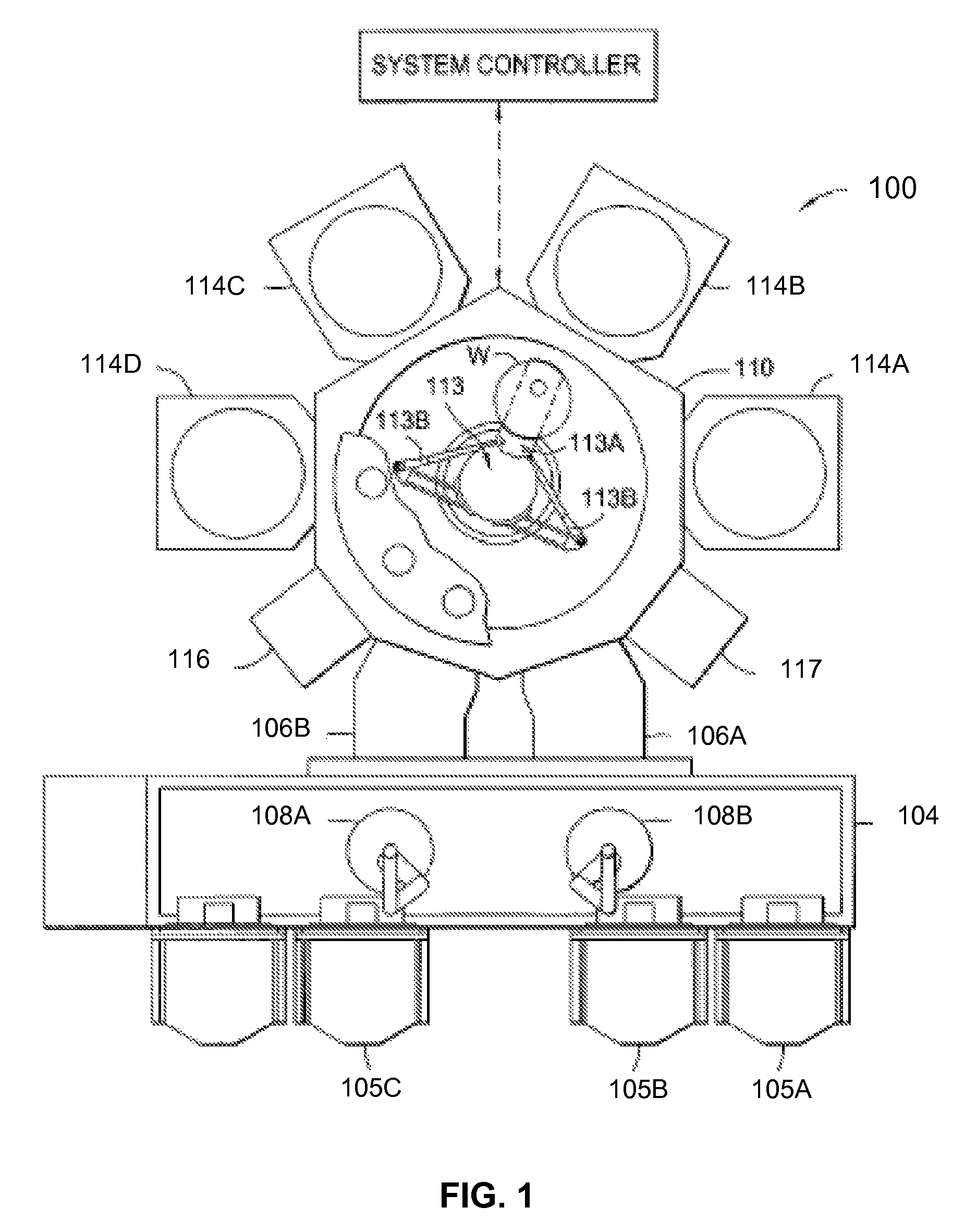

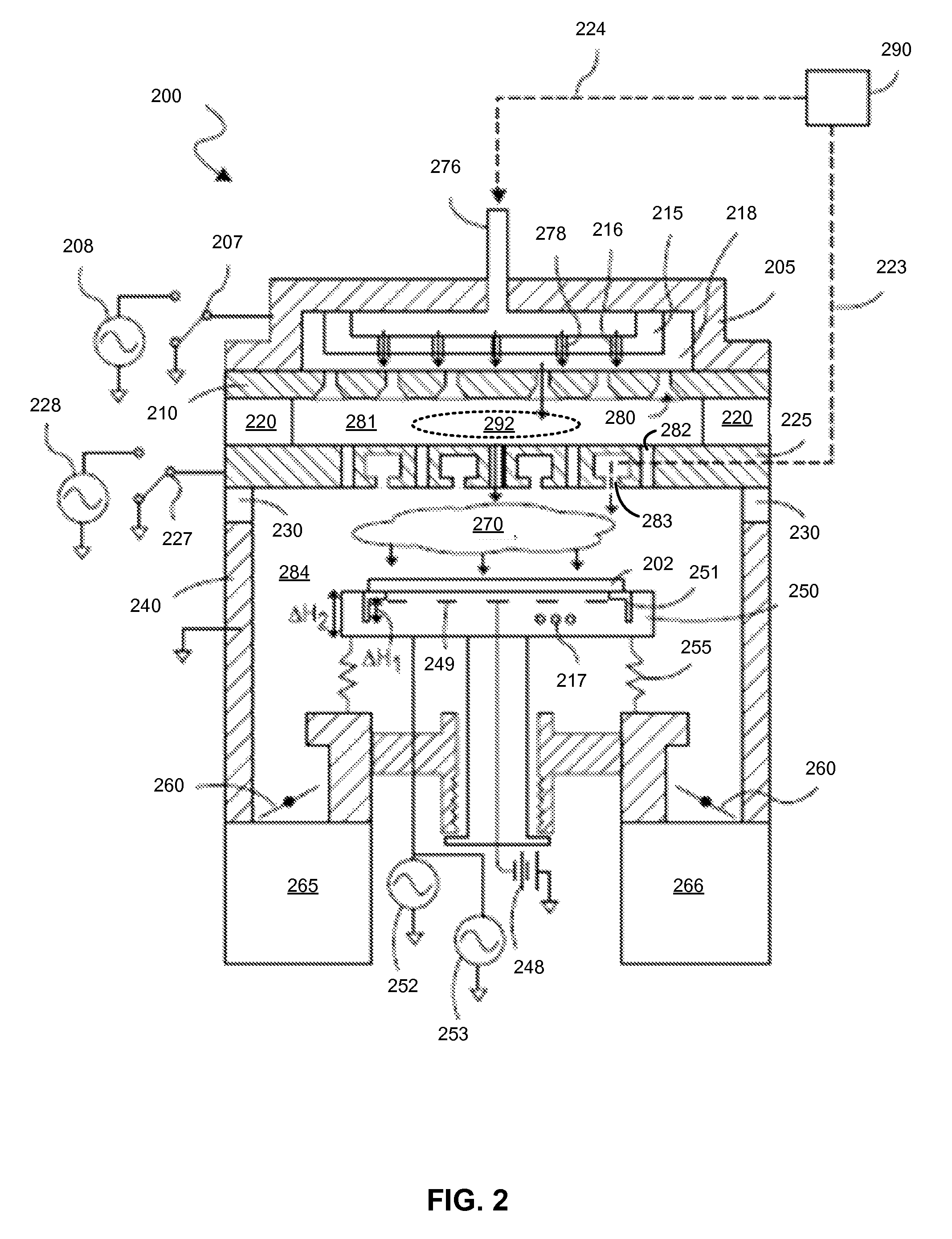

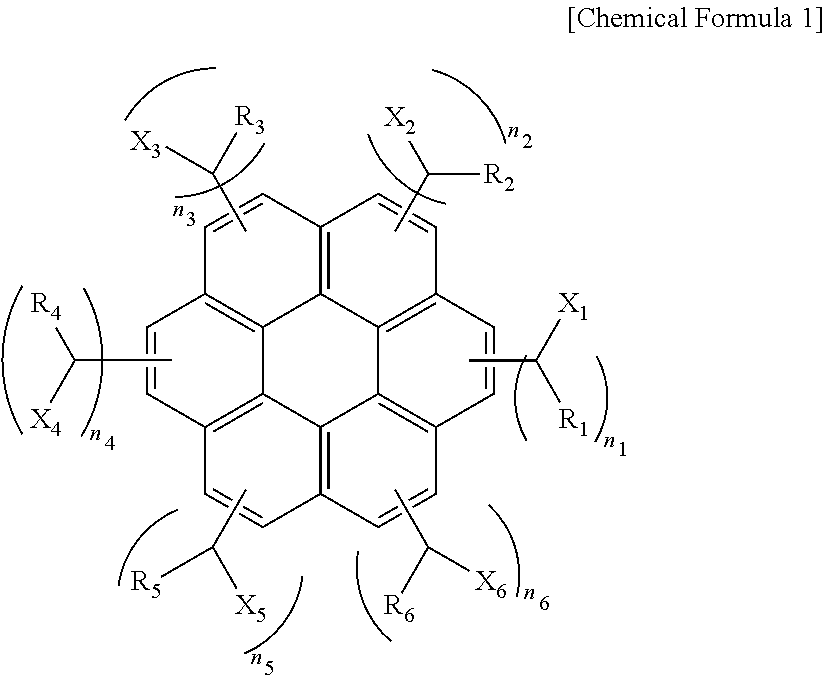

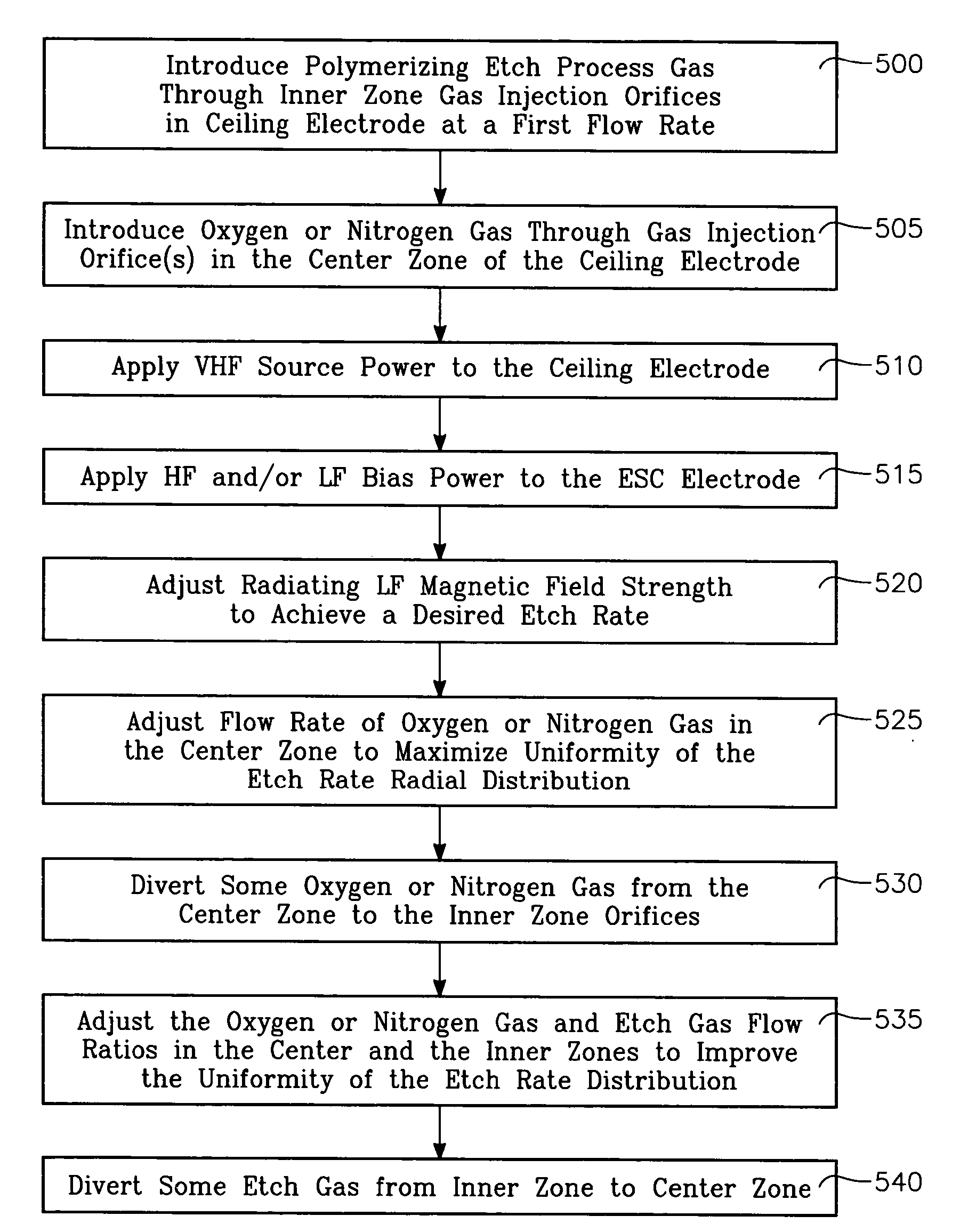

Plasma etch process using polymerizing etch gases with different etch and polymer-deposition rates in different radial gas injection zones with time modulation

ActiveUS7431859B2Increase etch rateIncrease deposition rateElectric discharge tubesVacuum gauge using ionisation effectsChemical speciesProduct gas

A plasma etch process includes injecting process gases with different compositions of chemical species through different radial gas injection zones of an overhead electrode to establish a desired distribution of chemical species among the plural gas injection zones.

Owner:APPLIED MATERIALS INC

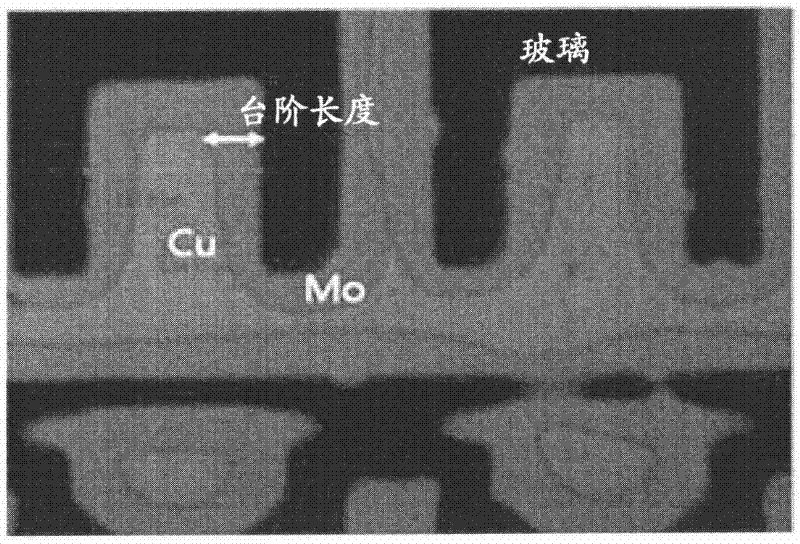

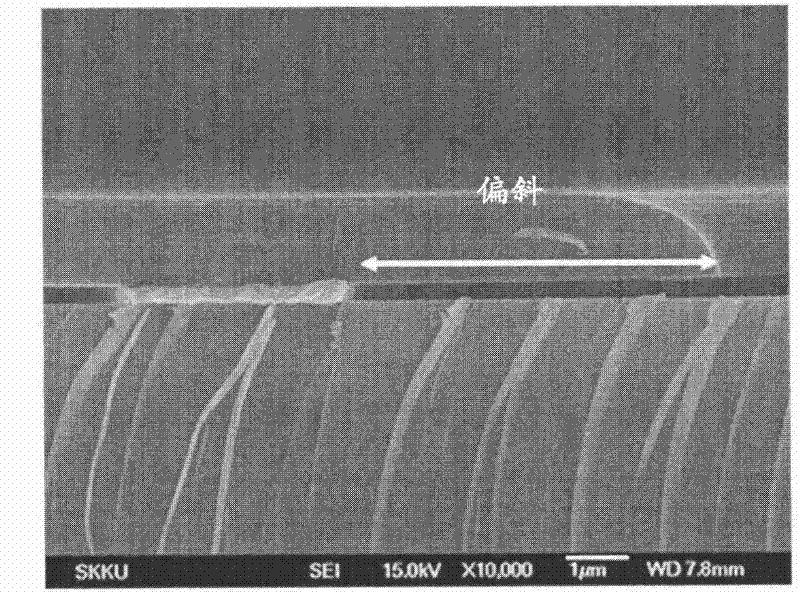

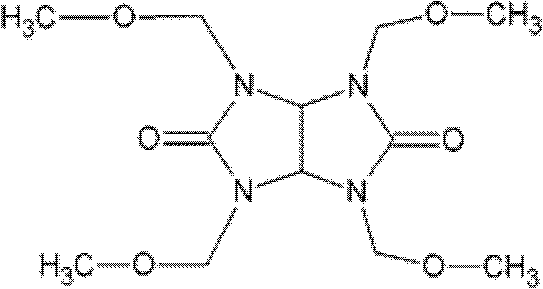

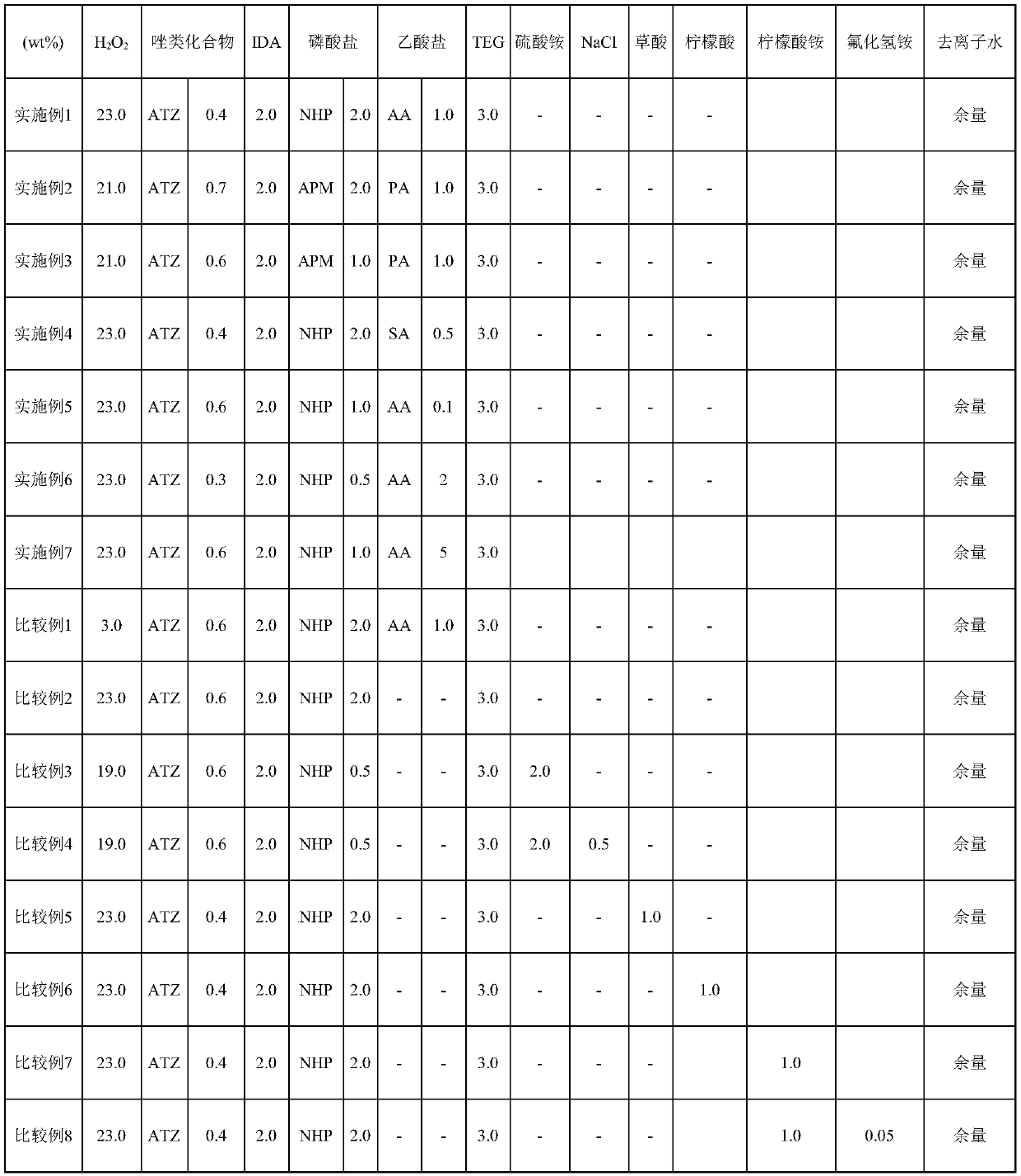

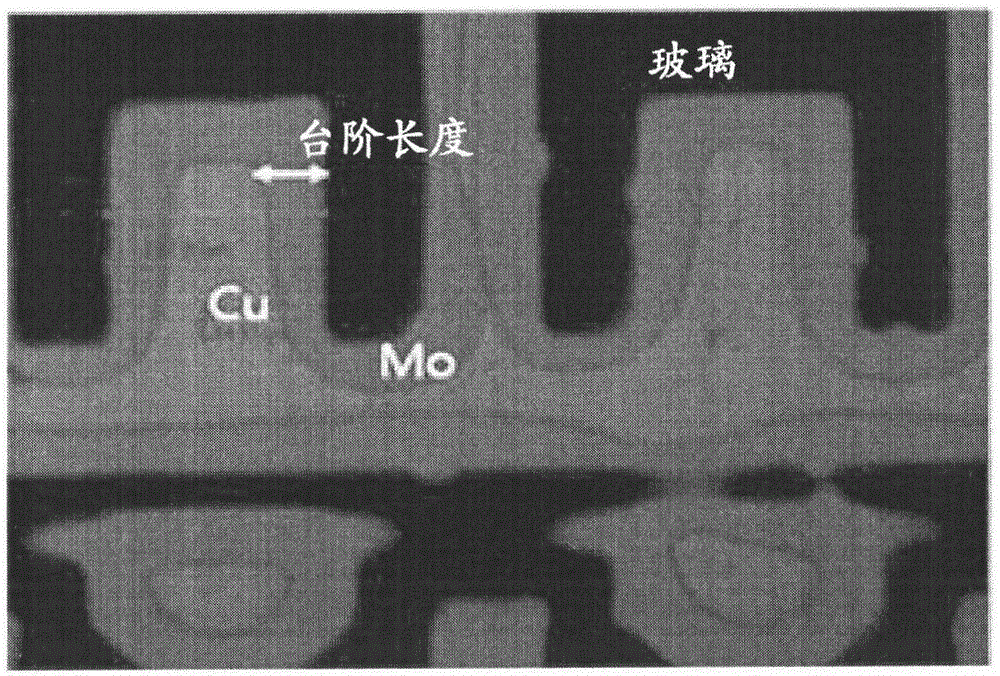

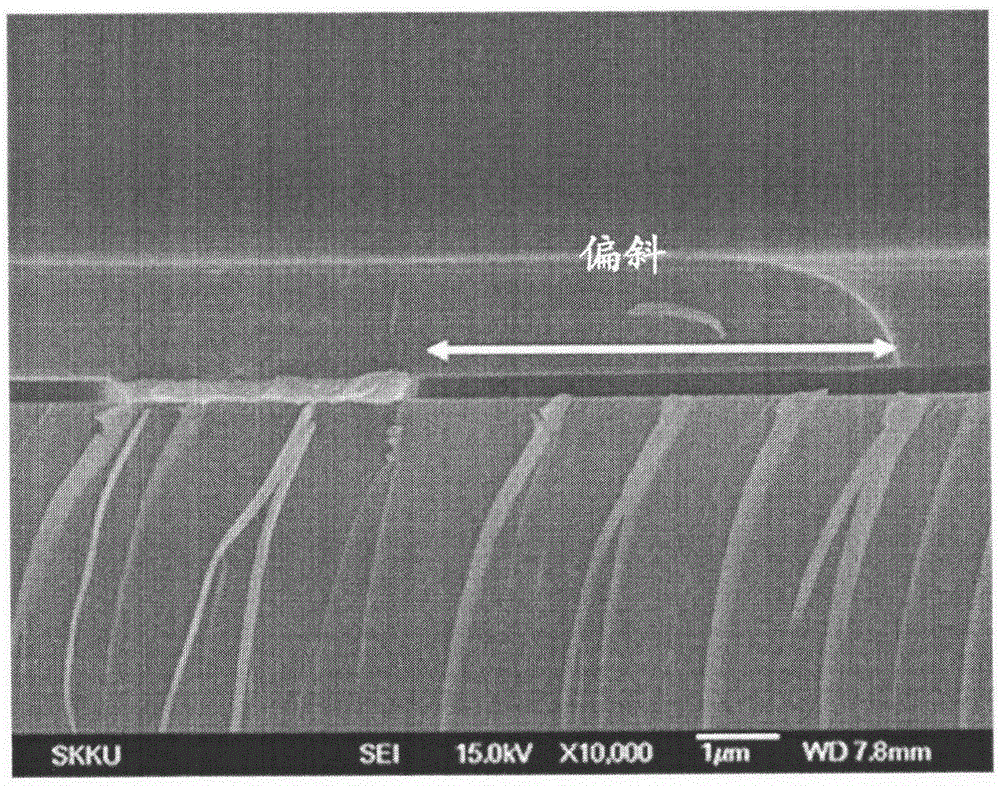

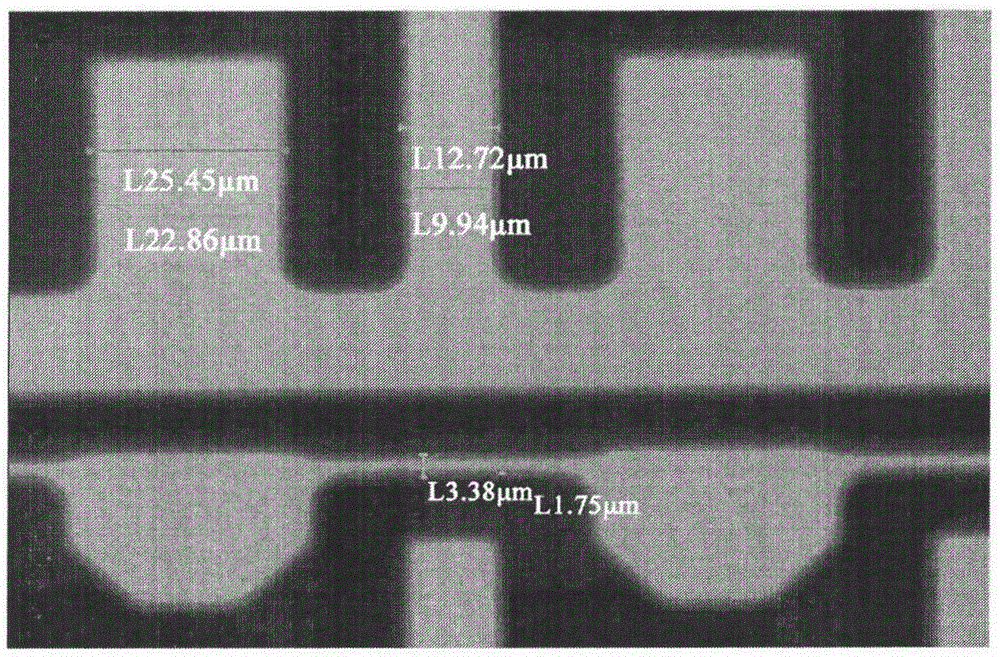

Etching Agent Composite Used For Etching Conductive Multi-layer Film And Etching Method Using The Same

InactiveCN102409342AReduce manufacturing costShorten production timeSemiconductor/solid-state device manufacturingSurface treatment compositionsAcetic acidPhosphoric acid

The invention discloses an etching agent composite used for etching conductive multi-layer film and an etching method using the same. The etching agent composite includes, by weight, 50 to 80 percents phosphoric acid of a total weight of the composite, 0.5 to 10 percents nitric acid, 5 to 30 percents acetic acid, 0.01 to 5 percents imidazole, and the rest is water. The multi-layer film includes at least one copper or copper alloy layer, and at least one molybdenum or molybdenum alloy layer. The multi-layer film can be a Cu / Mo lamination film, a Cu / Mo alloy lamination film or a Cu alloy / Mo alloy lamination film. The multi-layer film can be etched by the etching agent composite efficiently and well. Besides, a constitutional layer of the multi-layer film can be etched in batch. The imidazole is an annexing agent working as a reaction control agent of a Cu / Mo primary battery.

Owner:PLANSEE SE

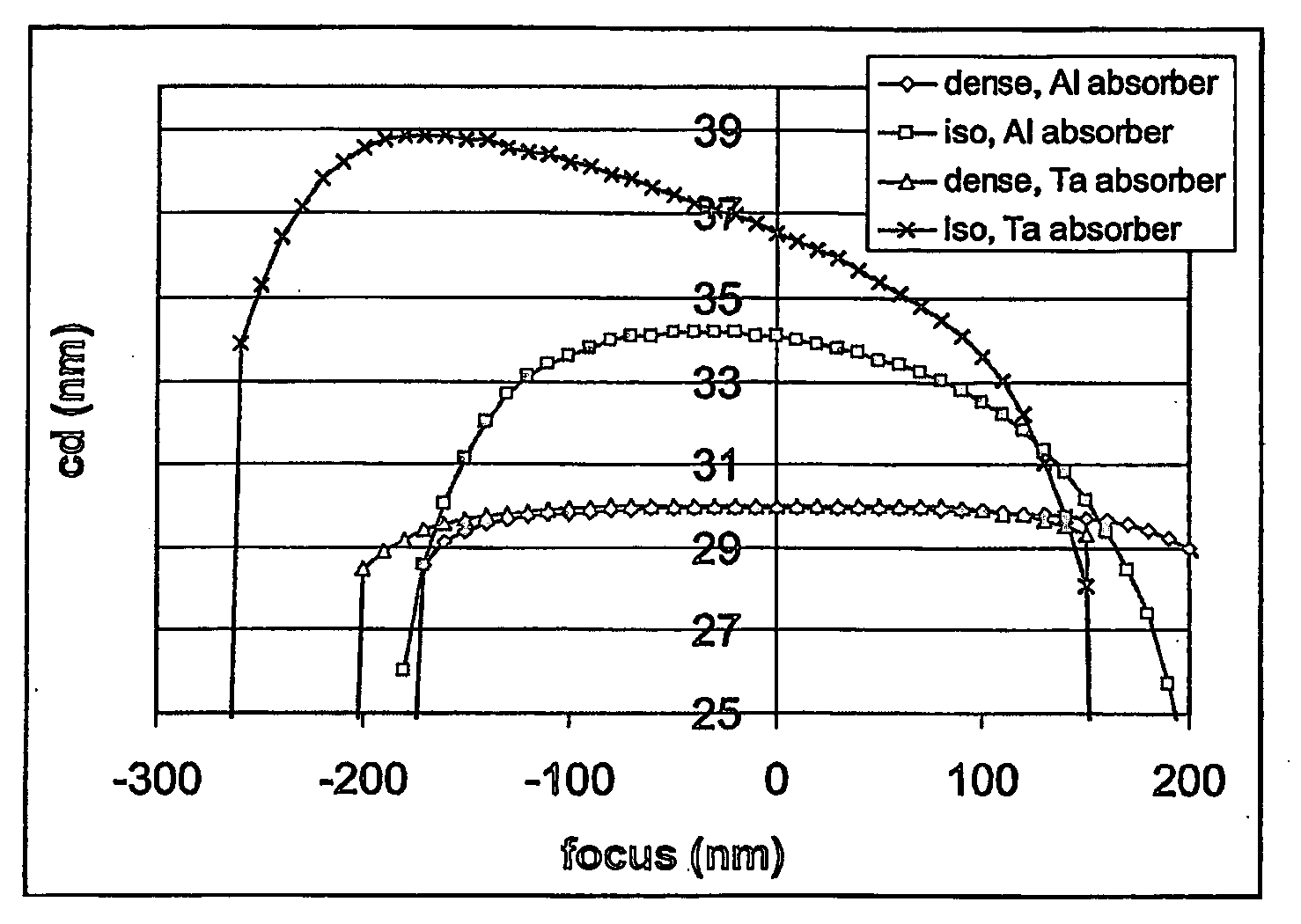

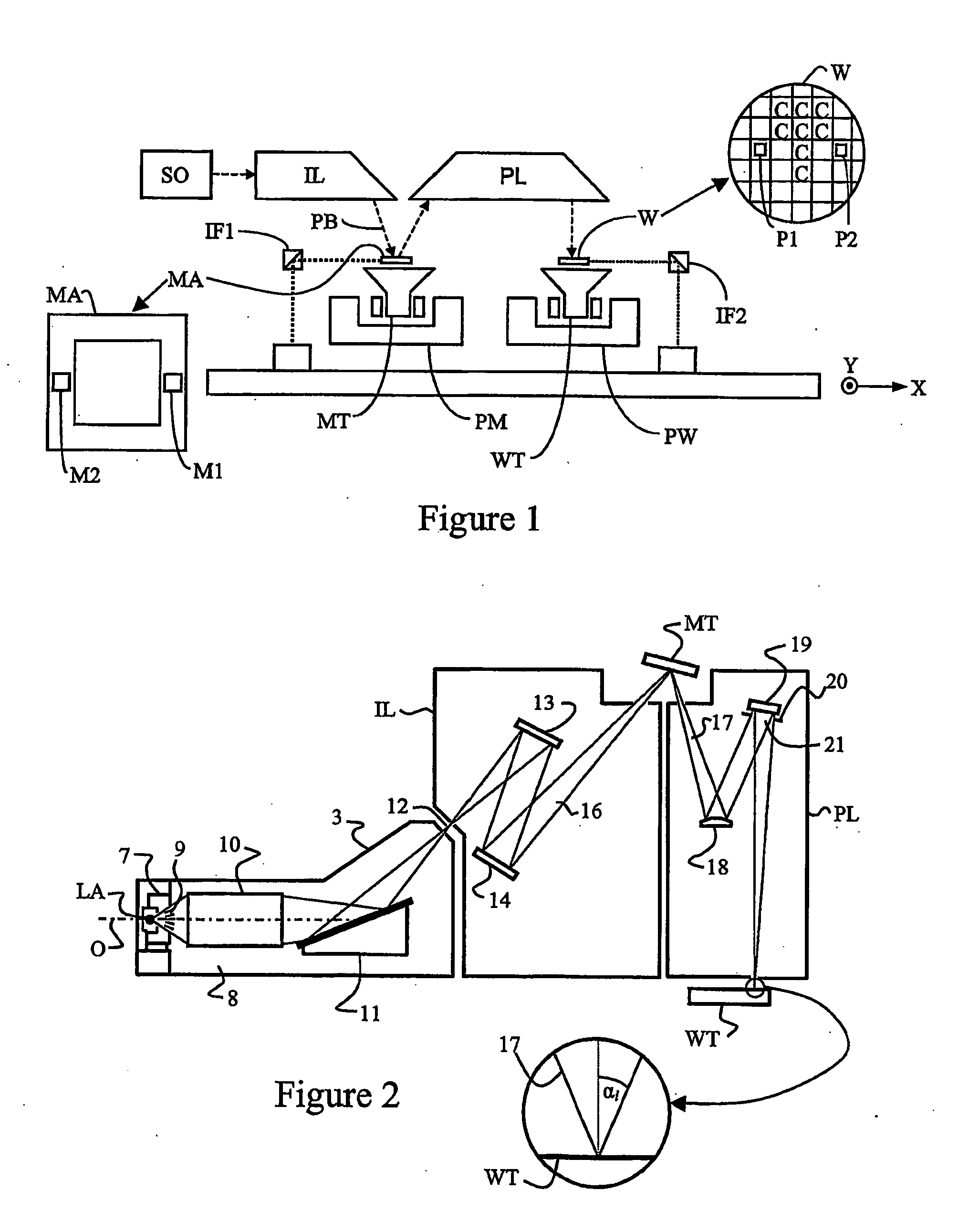

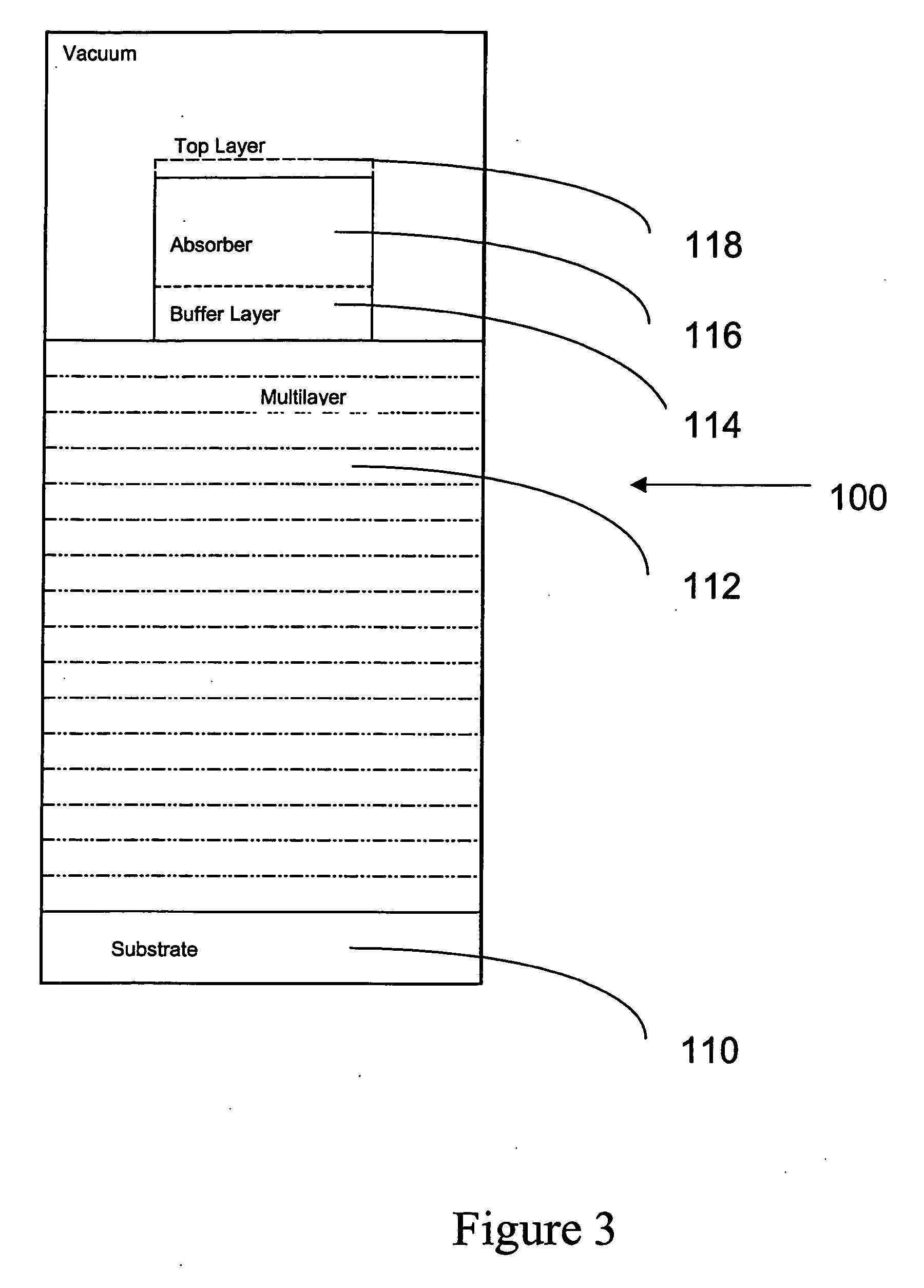

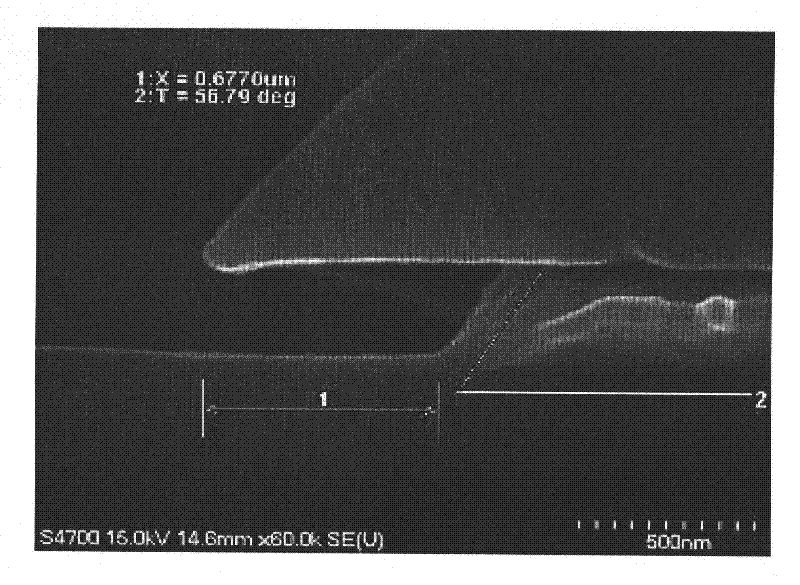

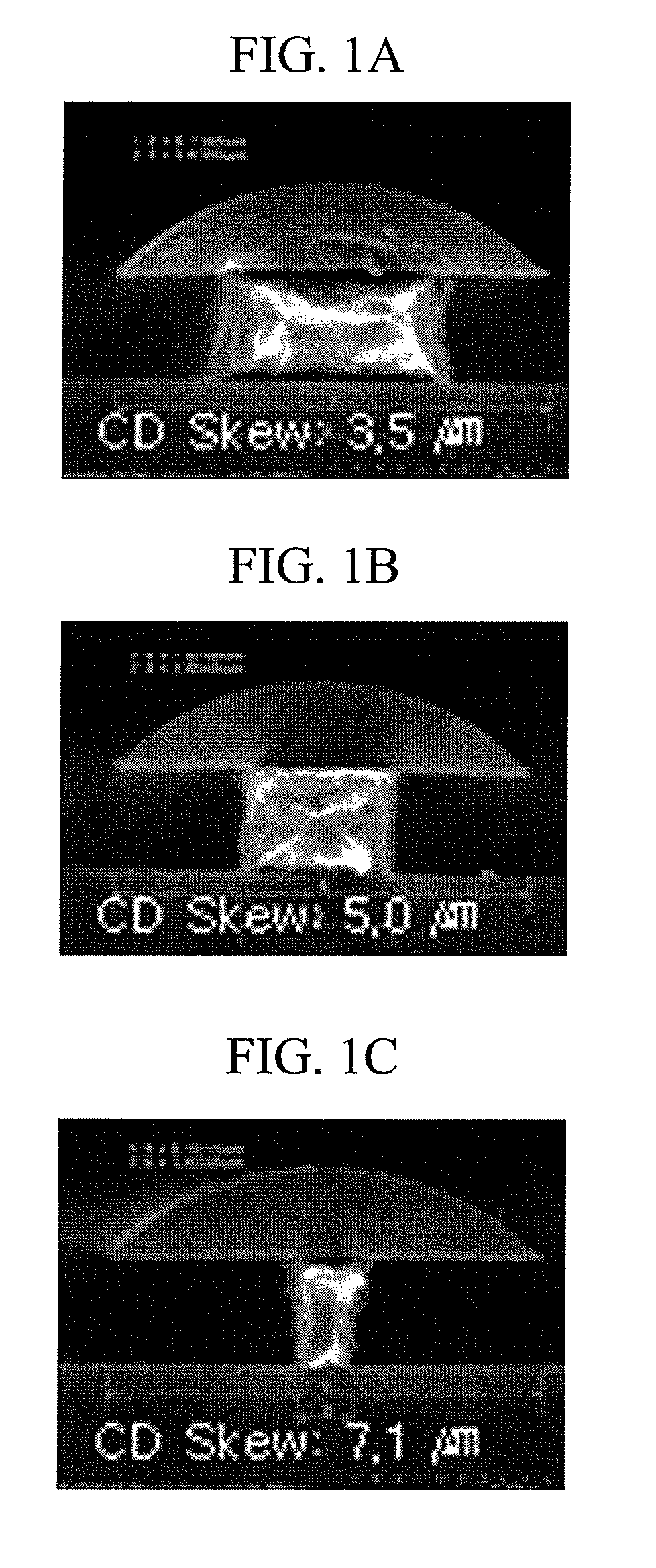

Use of a reticle absorber material in reducing aberrations

InactiveUS20050221238A1Enhance the imageMinimize formationPhoto-taking processesNanoinformaticsLight beamReticle

Owner:ASML NETHERLANDS BV

Etchant composition for forming copper interconnects

InactiveCN102471688AMinimize damageExcellent etch profileSemiconductor/solid-state device manufacturingSurface treatment compositionsCopper interconnectTitanium

The present invention relates to a wet etchant composition to a multilayer film comprising a copper-based metal layer and a titanium-based metal layer. The etchant composition of the present invention provides an excellent etching profile in case of etching said multilayer film, and minimizes the damage of a glass substrate and a lower insulating layer and the generation of residue, thereby enabling the stable performance of a subsequent process.

Owner:DONGWOO FINE CHEM CO LTD

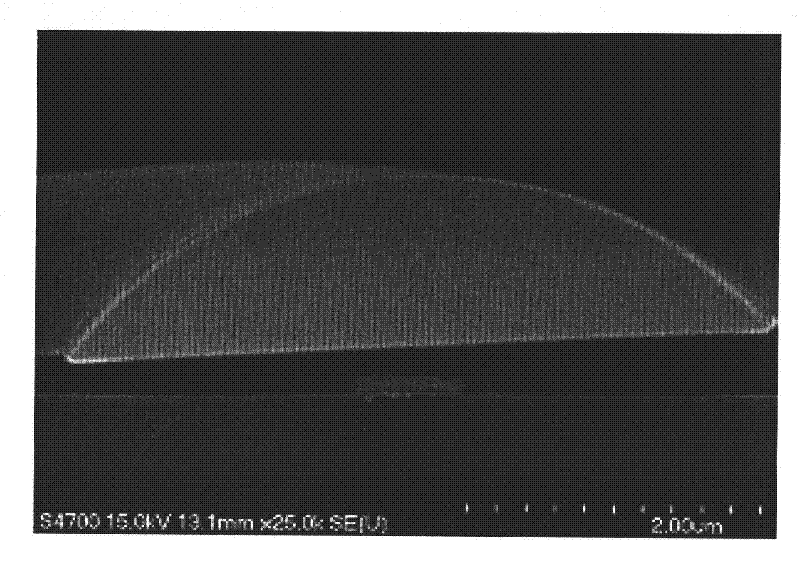

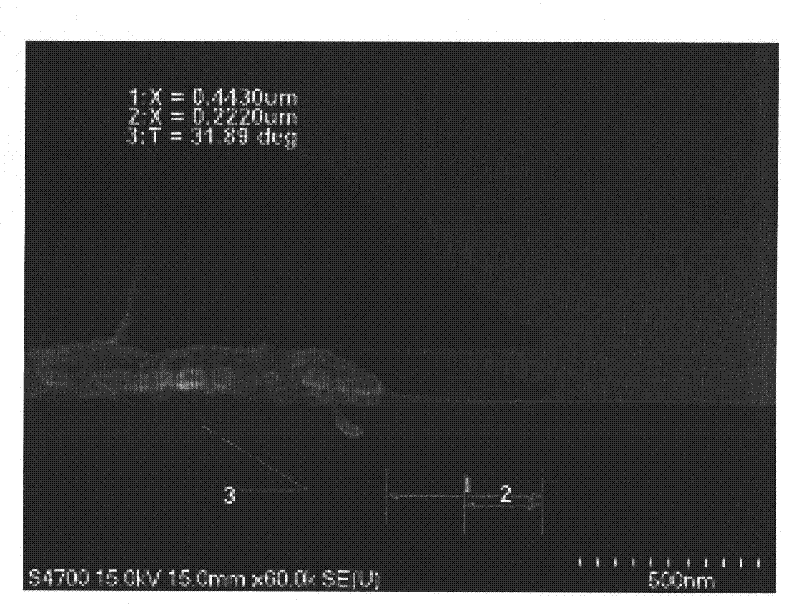

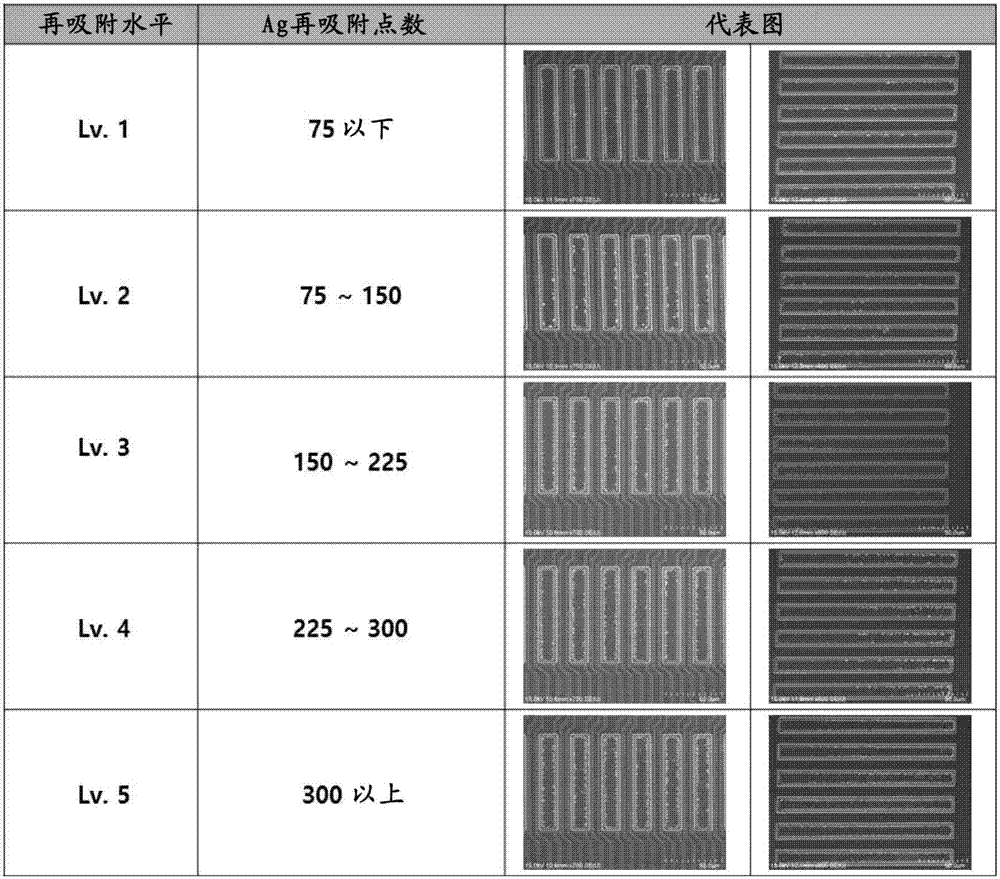

Etching solution composition for silver-containing layer and a display substrate using the same

InactiveCN107419270APrevent resorptionMaintain etch uniformityNon-linear opticsSurface treatment compositionsPhosphoric acidSolution composition

The invention relates to the etchant composition and display substrate using the same of the argentiferous thin film, more specifically, the phosphoric acid 45 about the total weight of composition, through 55 weight%, the nitric acid 2 through 9 weight%, the acetic acid 5 through 15 weight%, and the potassium nitrate 1 through 5 weight%, the etchant composition of the argentiferous thin film including the residual water, and the display substrate using the same.

Owner:DONGWOO FINE CHEM CO LTD

Aromatic ring-containing compound for a resist underlayer and resist underlayer composition

ActiveCN102115426AImprove etch selectivityReflectivity minimizationOrganic chemistryOrganic compound preparationLithography processLength wave

The present invention discloses an aromatic ring-containing compound represented by a following chemical formula 1 and a resist underlayer composition containing the compound. In the chemical formula 1, each substituted group is defined as embodiments. The aromatic ring-containing compound may has excellent optical performance, mechanical characteristics and etching selection characteristics, and may be applied by a rotary coating method. The aromatic ring-containing compound is useful for a lithography process using short wavelength and shows minimal content of remaining acid. The invention also provides a method of patterning elements using the resist underlayer composition.

Owner:CHEIL IND INC

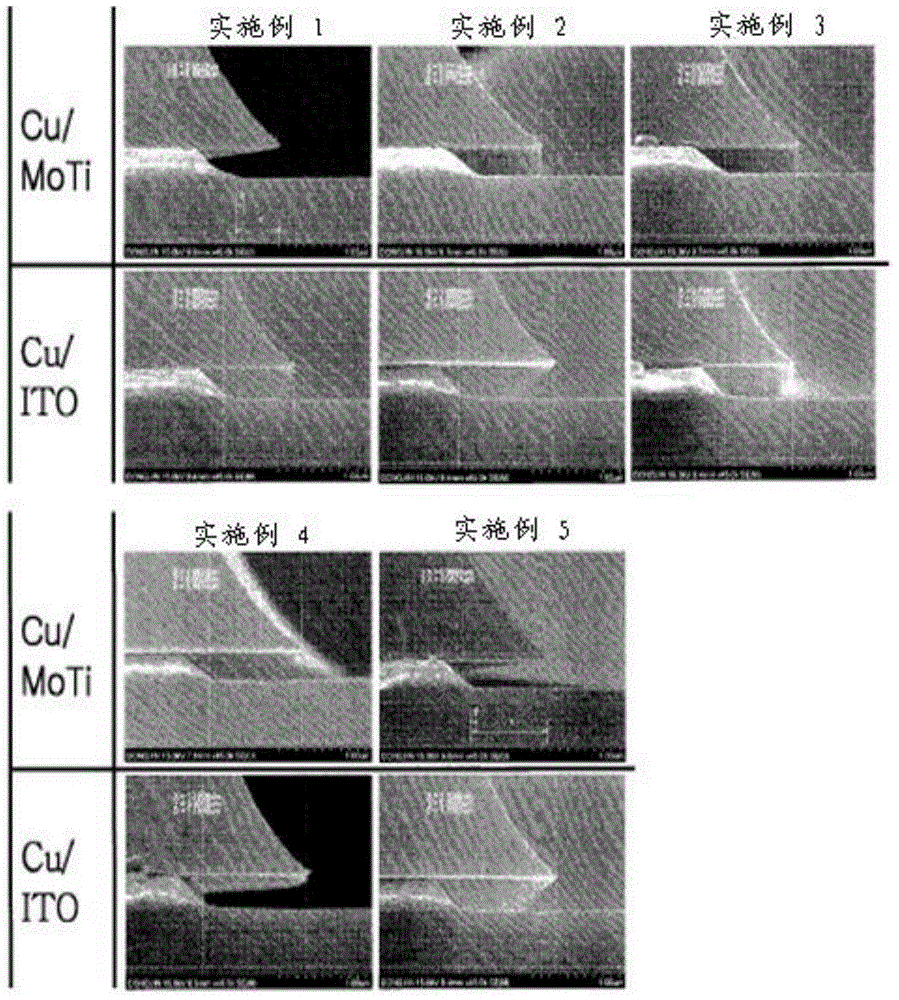

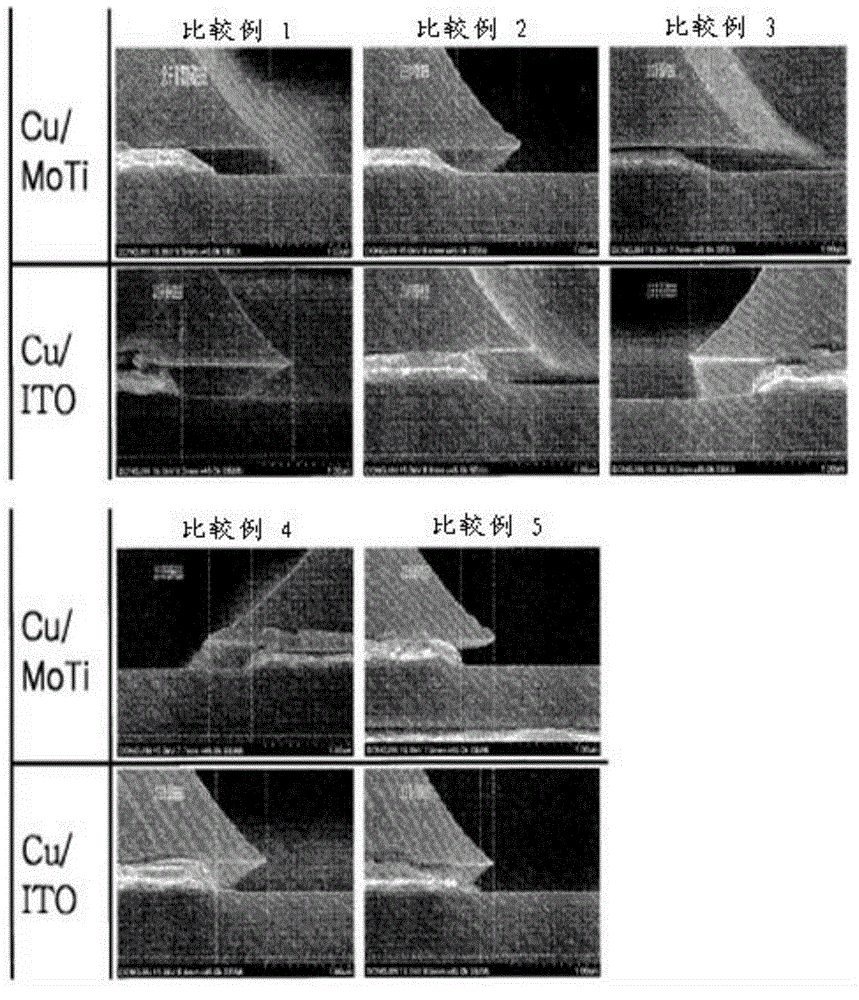

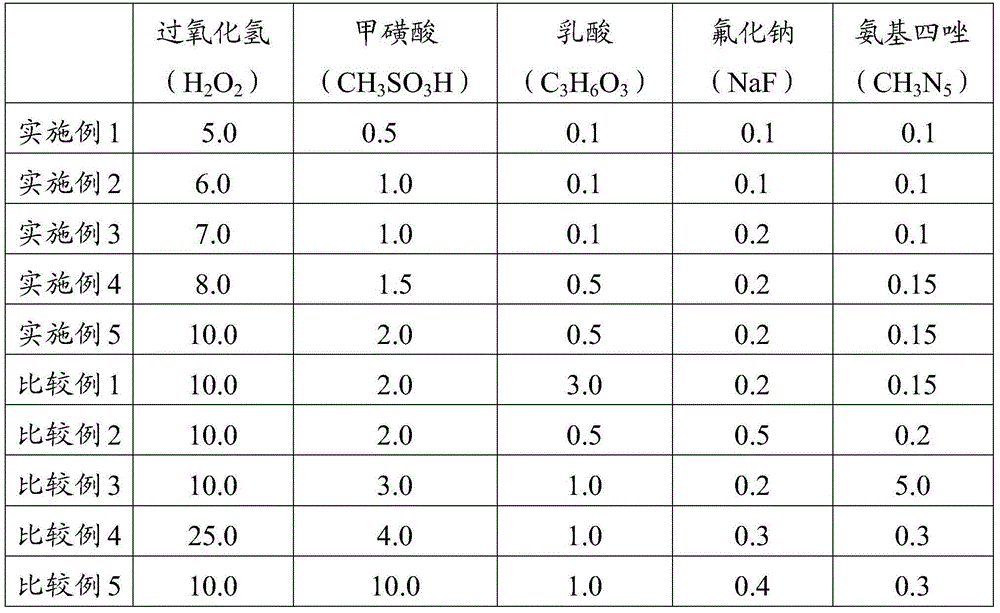

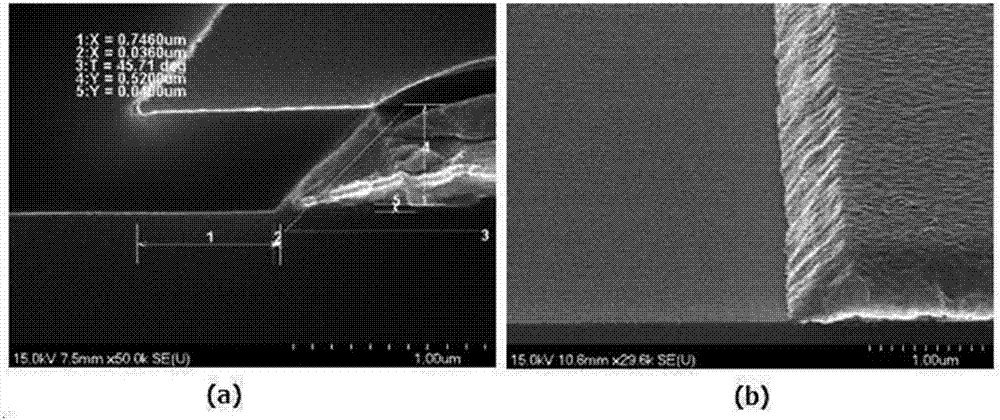

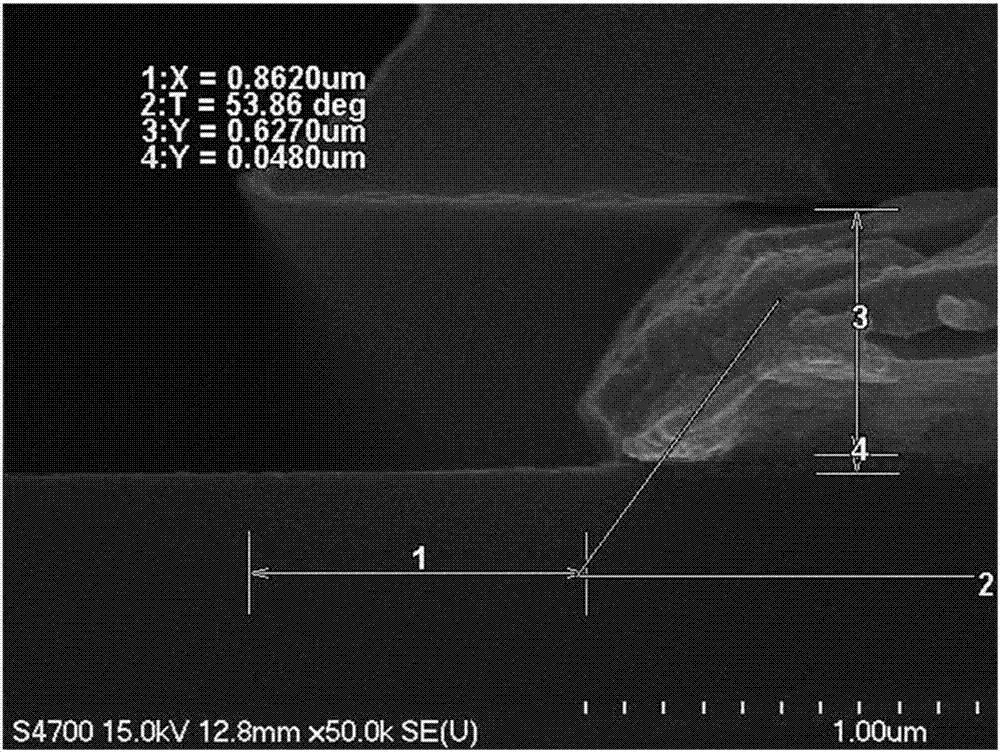

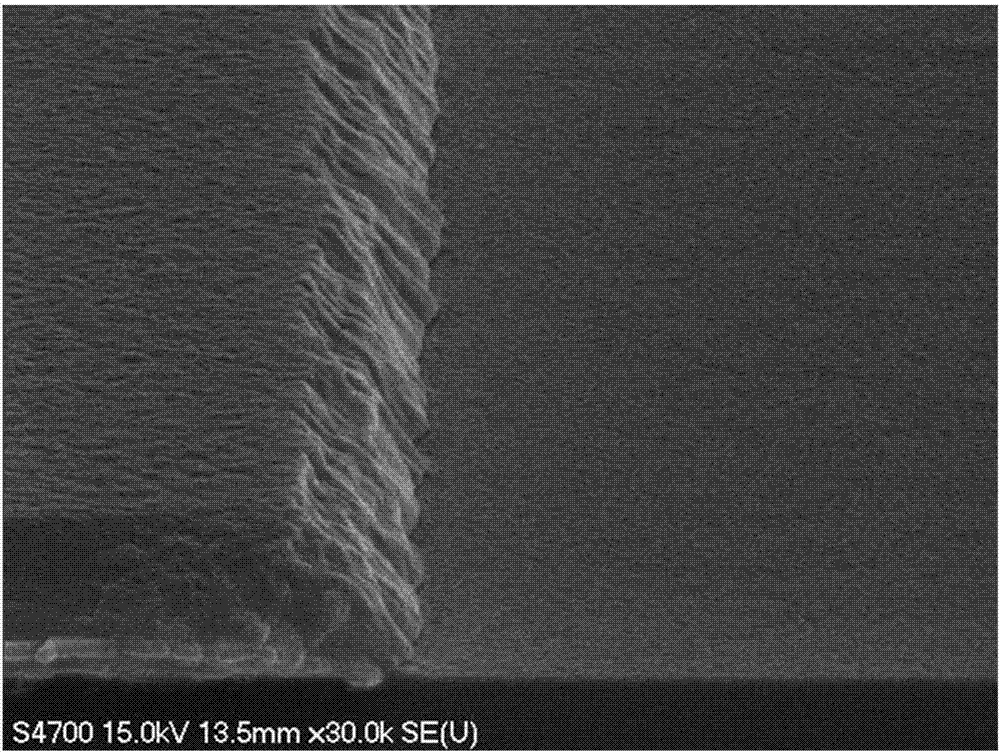

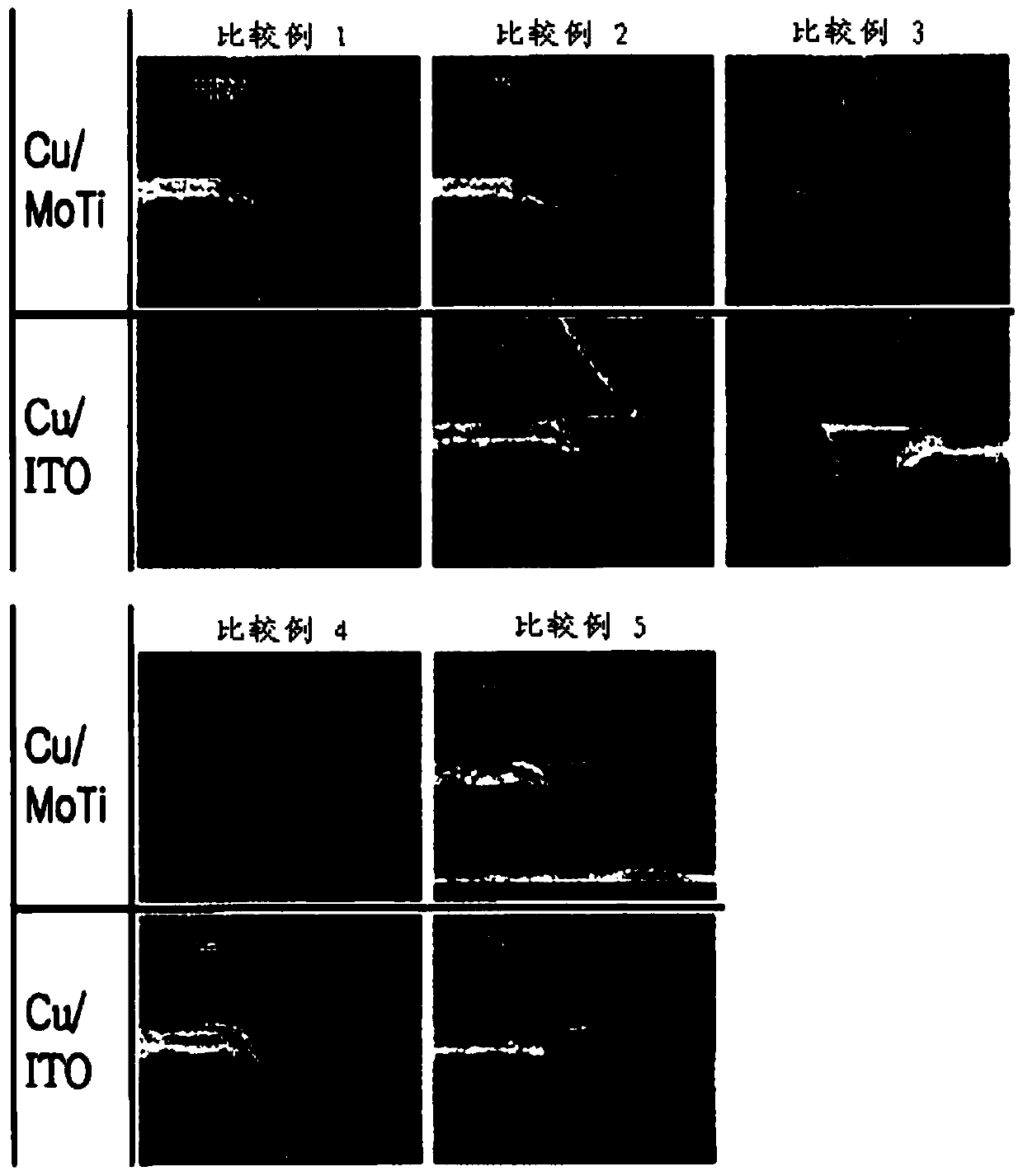

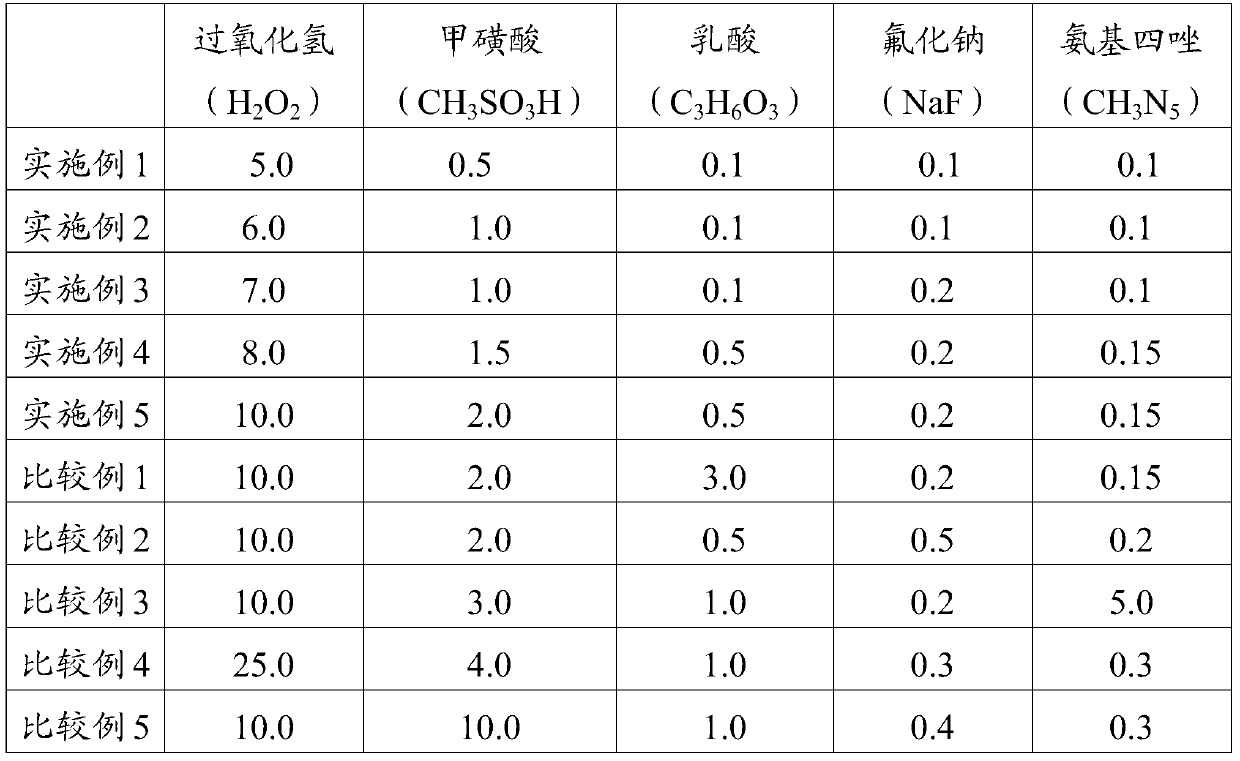

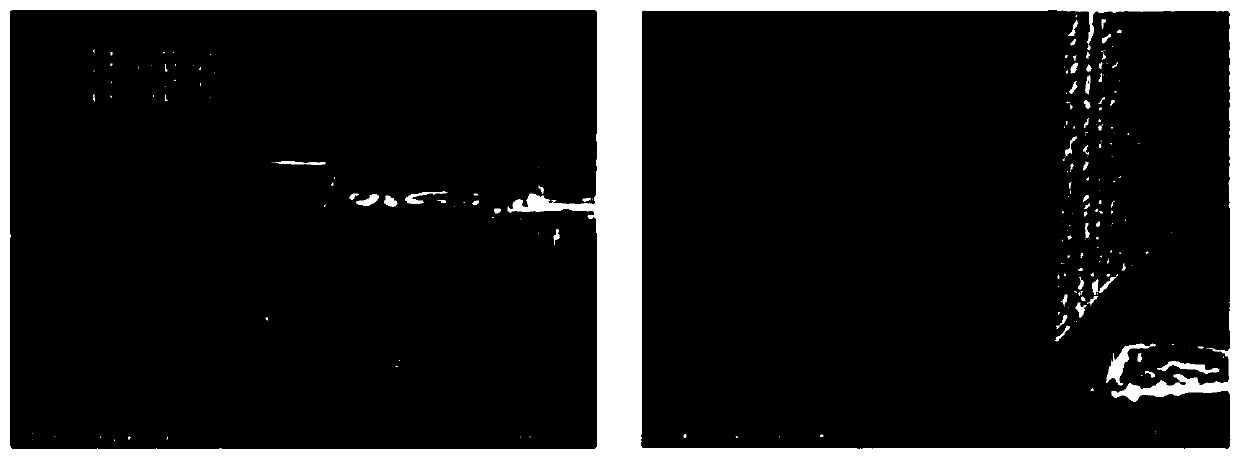

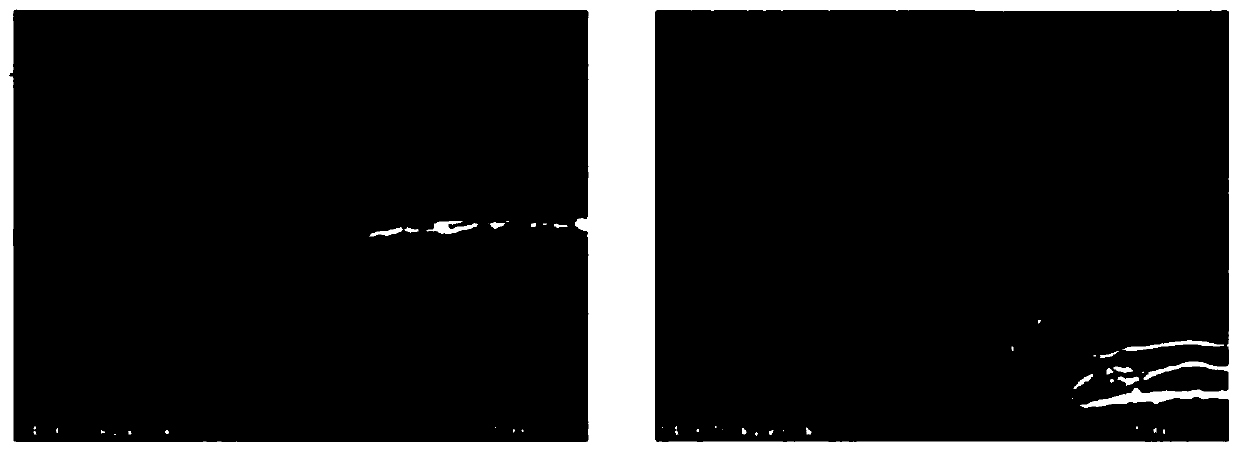

Metal-film etching-solution composition and etching method using same

ActiveCN104838040AExcellent etch profileImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesOrganic acidIndium tin oxide

Provided are: an etching-solution composition whereby it is possible to simultaneously etch a double film of a copper film and an indium tin oxide film or a double film of a copper film and a metal film; and an etching method using same. The etching-solution composition comprises between 5 and 20 wt.% of hydrogen peroxide, between 0.1 and 5 wt.% of a sulphonic acid compound, between 0.1 and 2 wt.% of a carbonyl based organic acid compound, between 0.1 and 0.4 wt.% of a fluorine compound, between 0.01 and 3 wt.% of an azole based compound, and a remainder of water.

Owner:DONGJIN SEMICHEM CO LTD

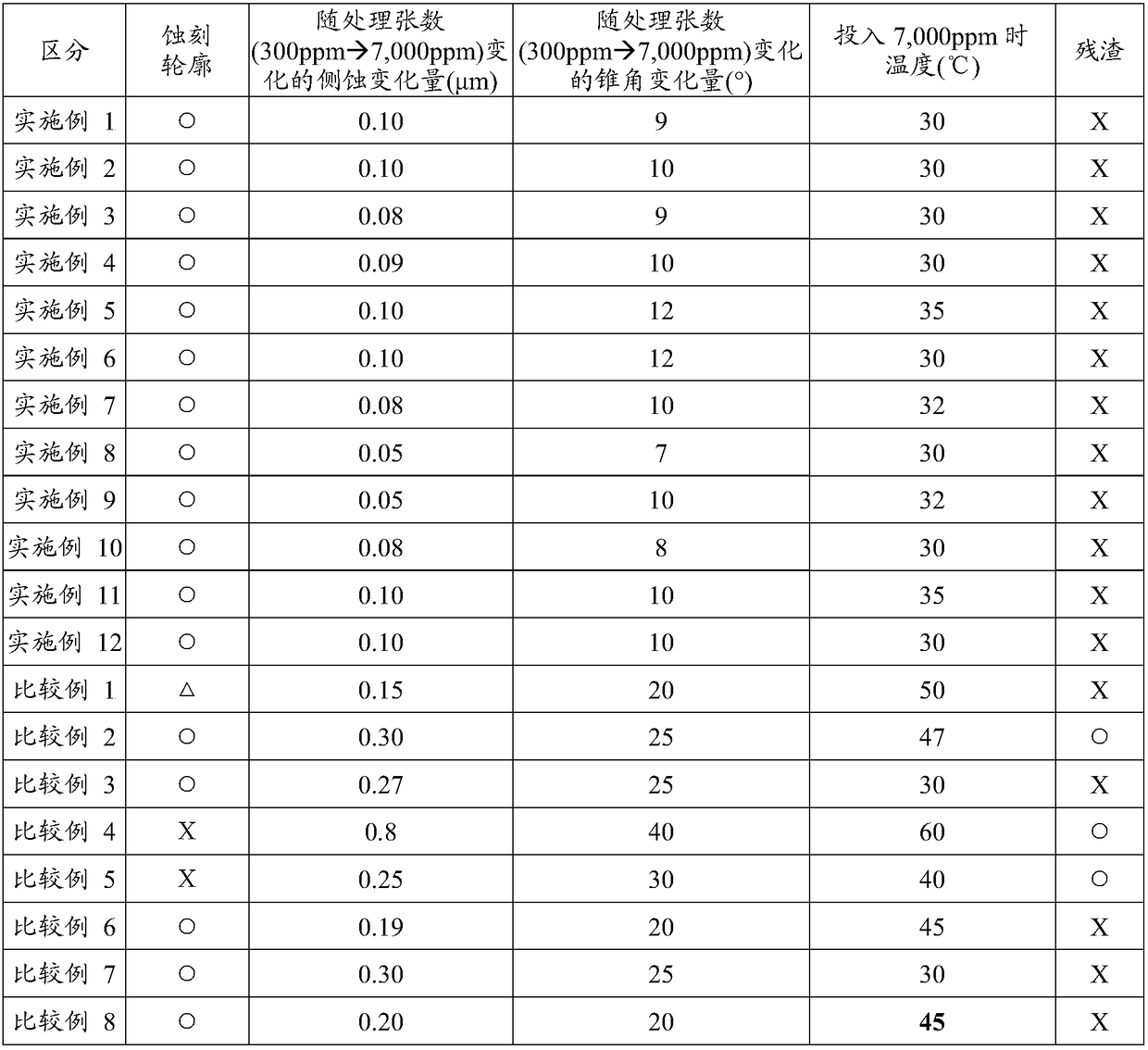

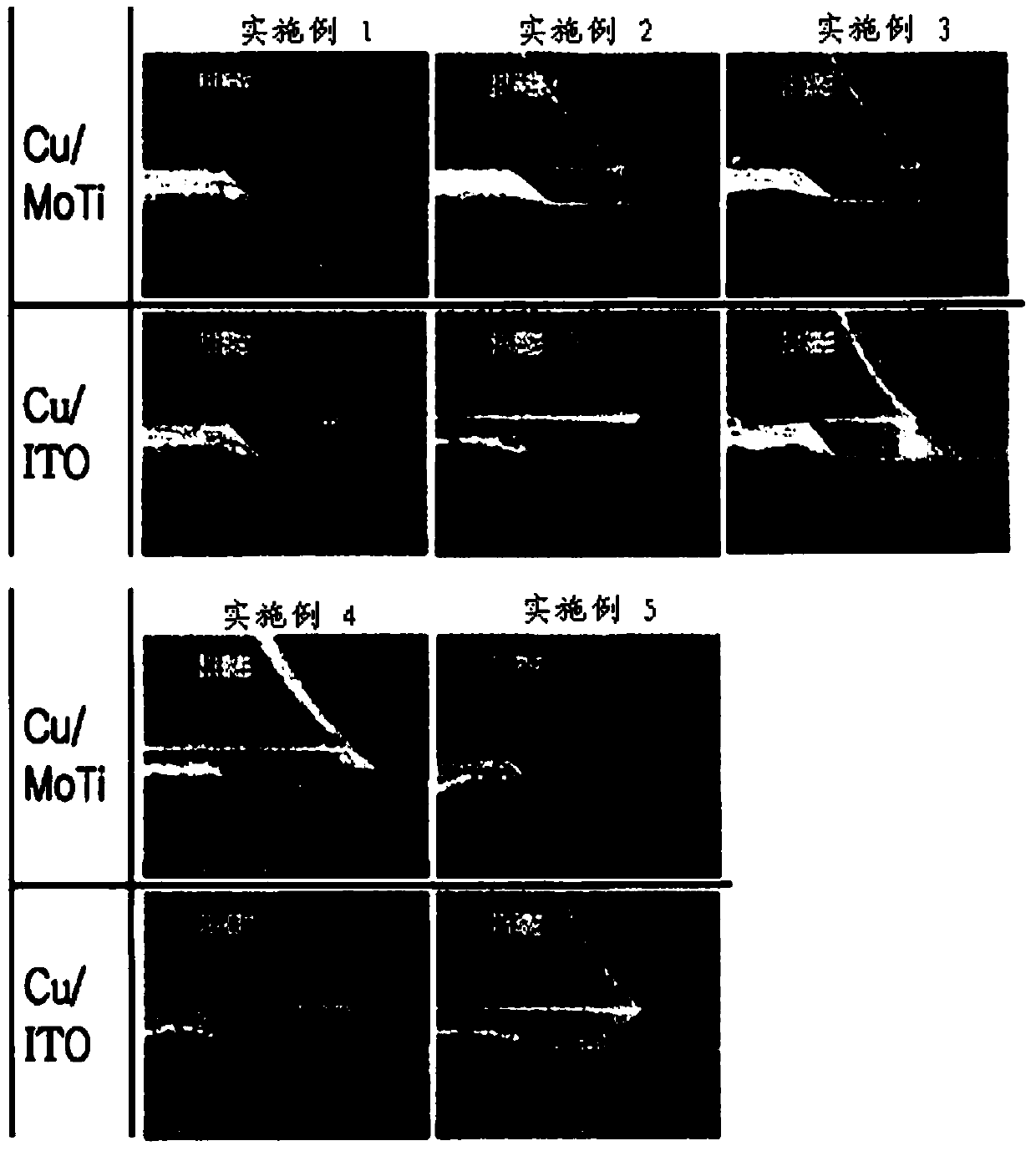

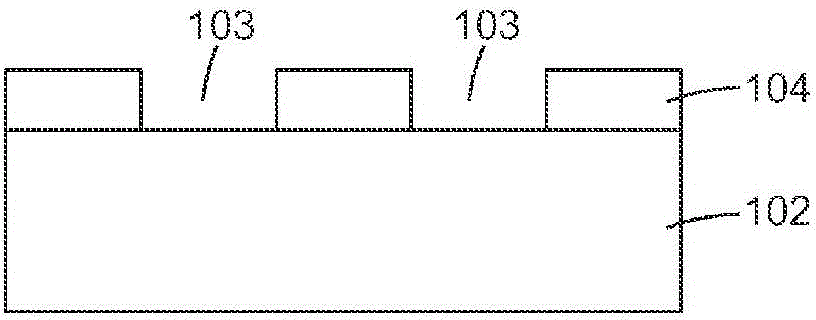

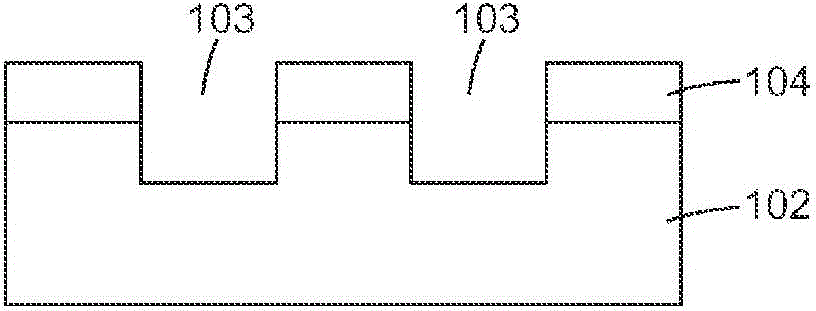

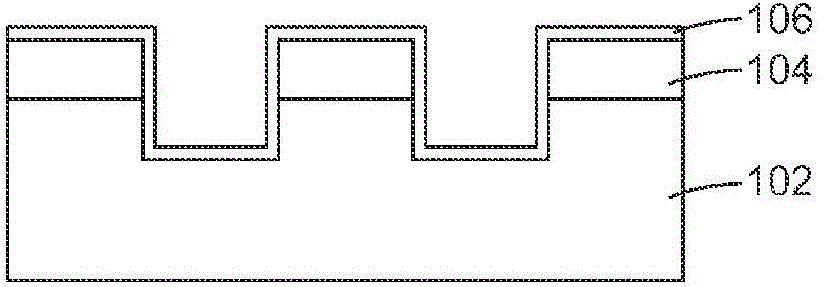

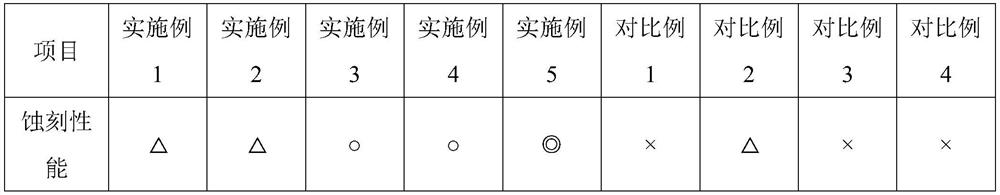

Etchant composition and manufacturing method of array substrate for display device

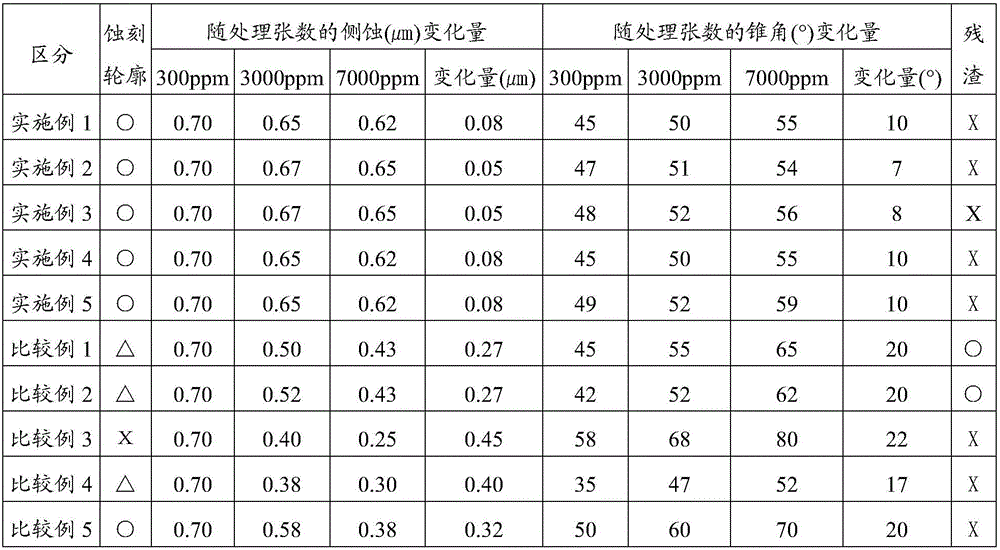

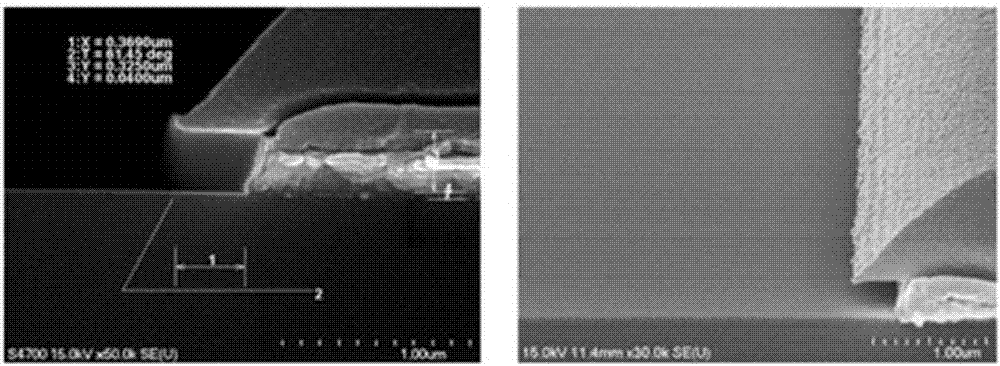

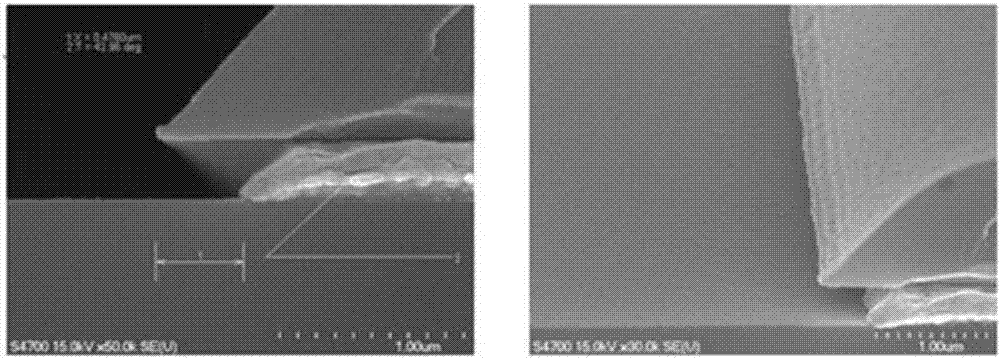

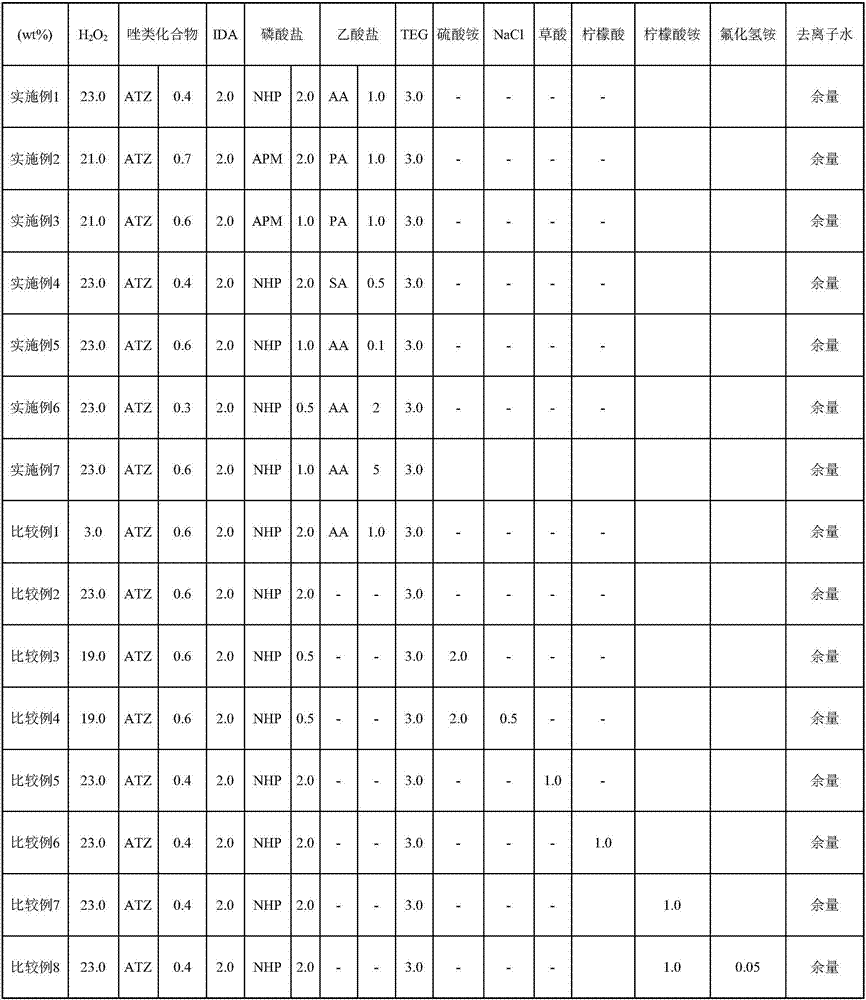

ActiveCN107988598AExcellent etch profileExcellent lateral erosion variation characteristicsSolid-state devicesNon-linear opticsWater solubleEtching

The invention relates to an etchant composition, and a method for manufacturing an array substrate for a display device, and an array substrate and a display device. More specifically, the invention provides an etchant composition of a metal film uniformly etching the metal film, having the excellent etching speed and an excellent taper angle characteristic, and having an excellent etching profileof an interface unit in a case of etching of a multilayer when manufacturing an array substrate for a display device, a method for manufacturing an array substrate for a display device and an array for a display device. The etchant composition of the metal film is characterized by containing, with respect to the total weight of the composition, 5 to 25 wt% of hydrogen peroxide, 0.01 to 1 wt% of afluorine compound, 0.1 to 5 wt% of an azole compound, 0.1 to 5 wt% of a water-soluble compound having a nitrogen atom and a carboxyl group in one molecule is by weight, 0.001 to 5 wt% of a phosphatecontaining alkali metal or alkaline earth metal, 0.01 to 5 wt% of a polyol-type surfactant, 0.1 to 5 wt% of sulfate comprising alkali metal or alkaline earth metal, and the balance of water, the weight ratio of phosphate to sulfate being 1:3 to 1:20.

Owner:DONGWOO FINE CHEM CO LTD

Aromatic ring-containing compound for a resist underlayer and resist underlayer composition

ActiveUS8637219B2Excellent lithographic structureImprove etch selectivityOrganic chemistryOrganic compound preparationResistHydrogen

An aromatic ring-containing compound for a resist underlayer and a resist underlayer composition, the aromatic ring-containing compound being represented by the following Chemical Formula 1:wherein, in Chemical Formula 1, R1 to R6 are each independently a substituted or unsubstituted C1 to C10 alkyl group, a substituted or unsubstituted C5 to C20 aromatic ring group, a substituted or unsubstituted C3 to C20 cycloalkyl group, a substituted or unsubstituted C3 to C20 cycloalkenyl group, a substituted or unsubstituted C2 to C20 heteroaryl group, or a substituted or unsubstituted C2 to C20 heterocycloalkyl group, X1 to X6 are each independently hydrogen, a hydroxy group (—OH), a substituted or unsubstituted alkyl amine group, a substituted or unsubstituted alkoxy group, or an amino group (—NH2), n1 to n6 are each independently 0 or 1, and 1≦n1+n2+n3+n4+n5+n6≦6.

Owner:CHEIL IND INC

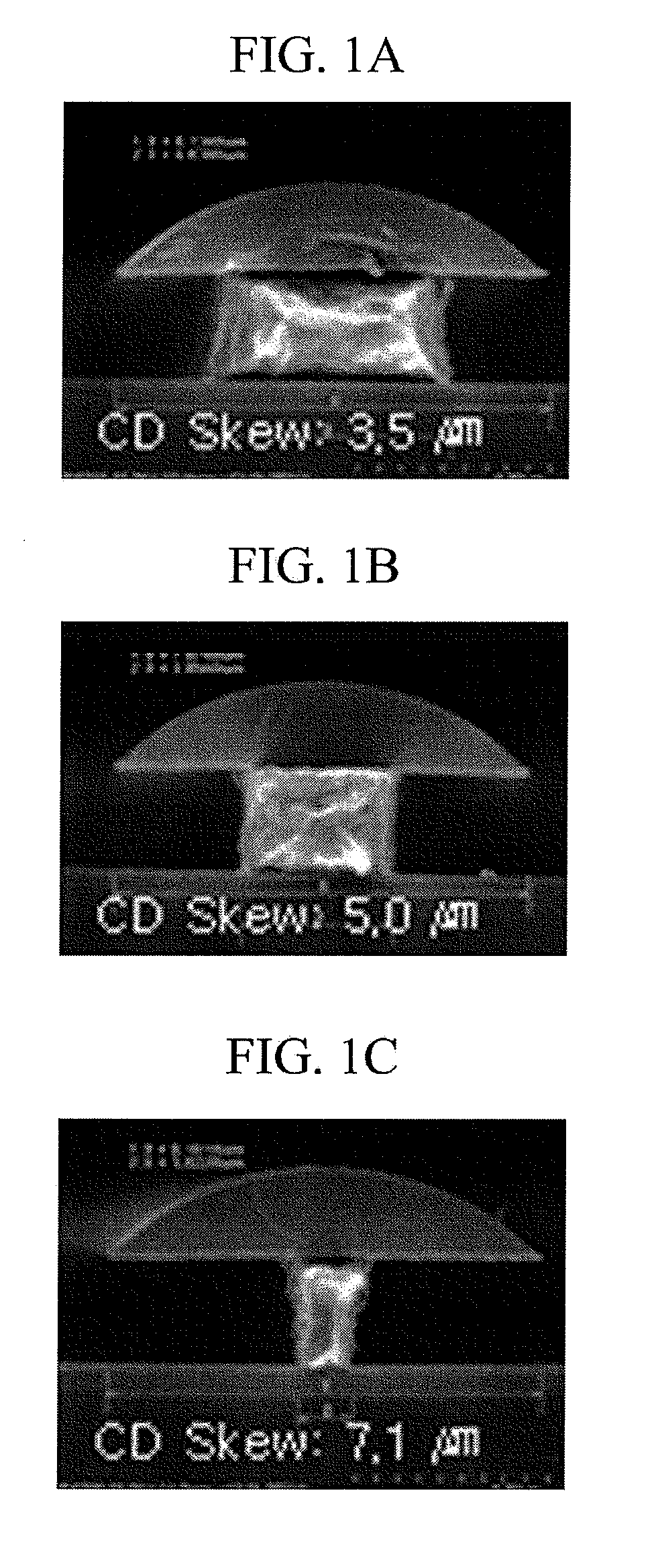

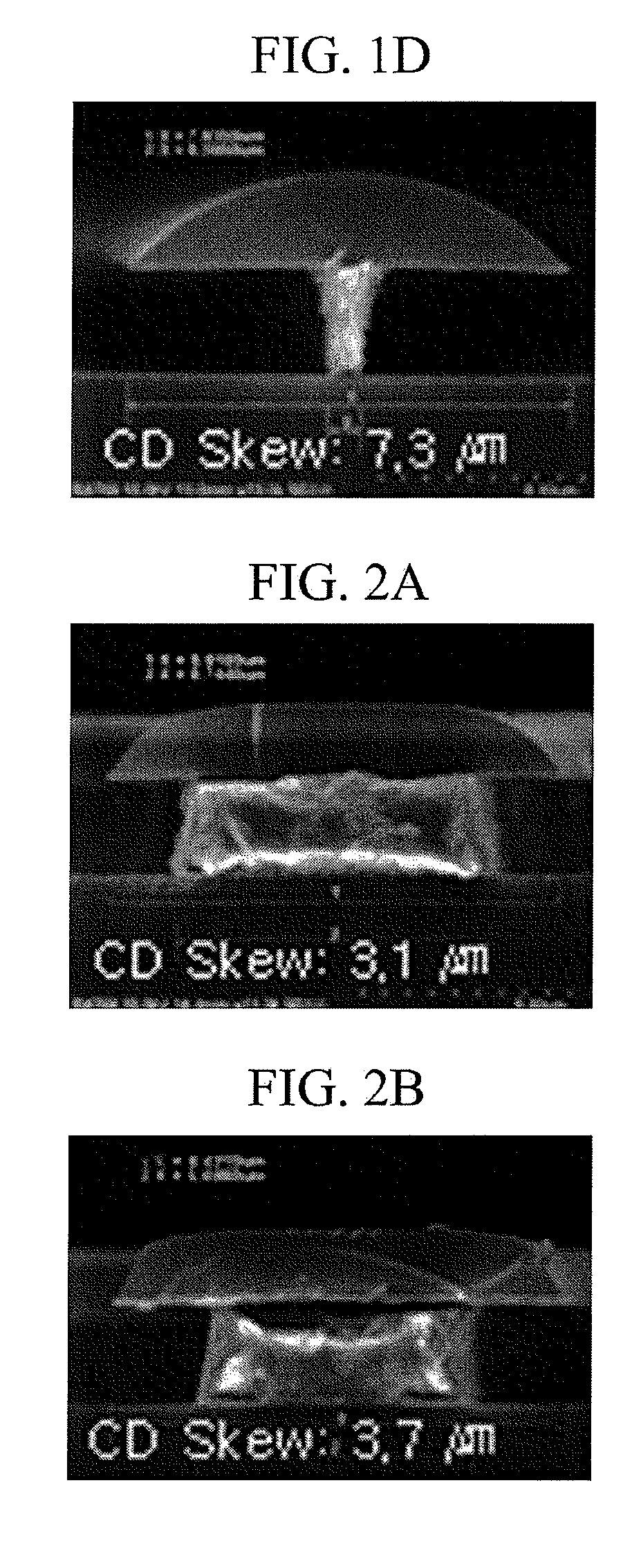

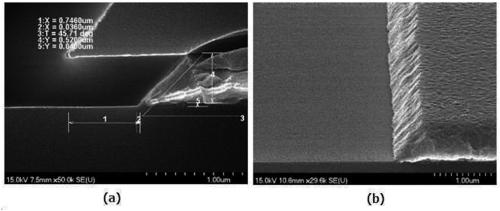

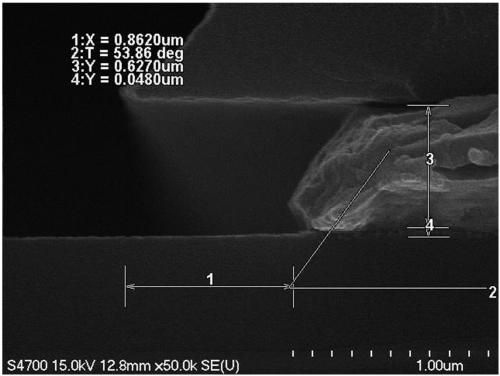

Dry etching method using polymer mask selectively formed by CO gas

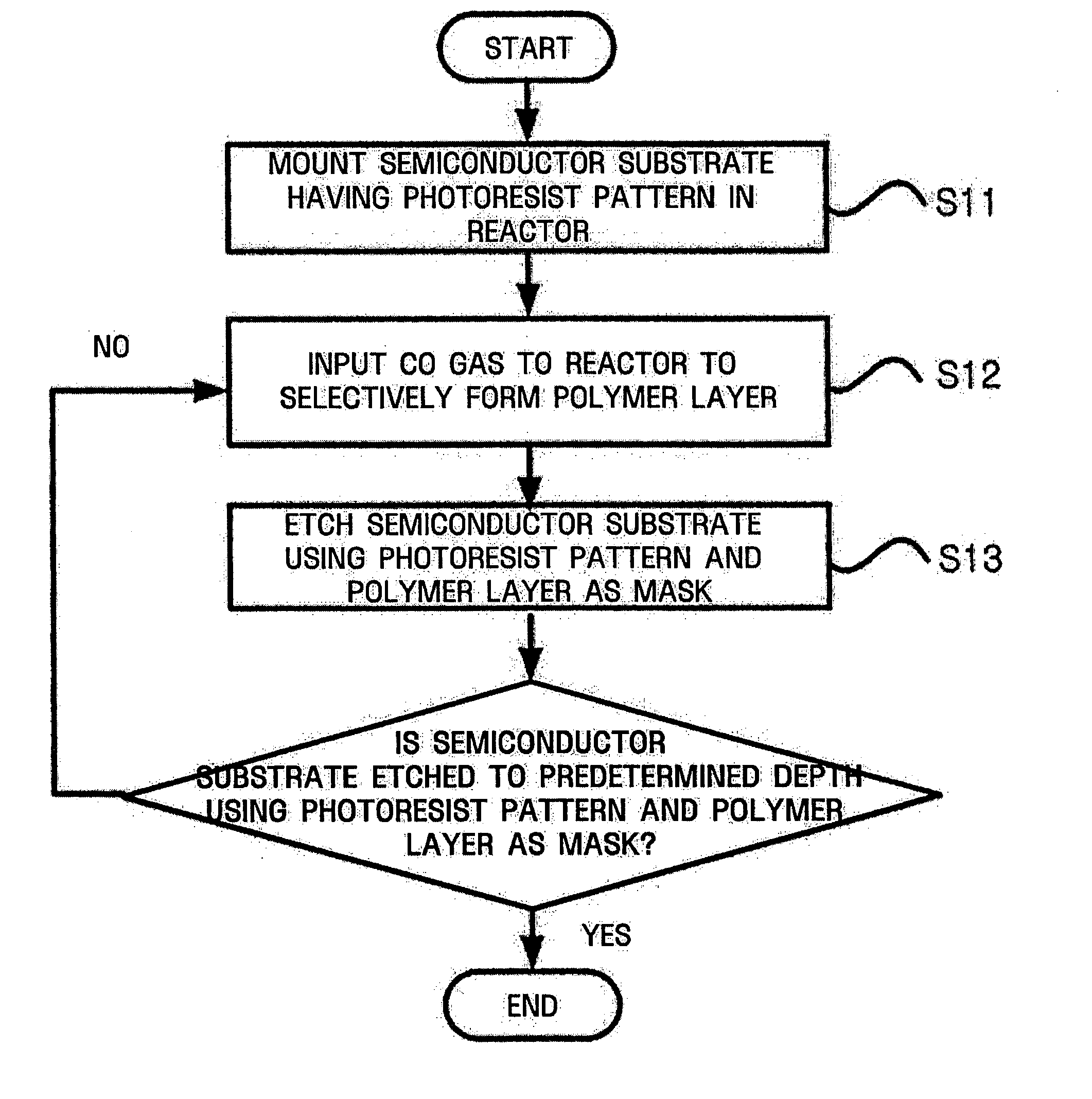

InactiveUS20060024971A1High resolutionExcellent etch profileSolid-state devicesSemiconductor/solid-state device manufacturingDry etchingCarbon monoxide gas

A dry etching method comprises placing a semiconductor substrate in a reactor, the semiconductor substrate comprising a photoresist pattern formed on an etching target layer, supplying carbon monoxide gas into the reactor to selectively deposit polymer on the photoresist pattern to form a polymer layer, and etching the etching target layer using the photoresist pattern and the polymer layer as an etch mask.

Owner:SAMSUNG ELECTRONICS CO LTD

Cross-linking and multi-phase etch pastes for high resolution feature patterning

InactiveUS20130092657A1Effectively encasesPrevent leakageMaterial nanotechnologyDecorative surface effectsEtchingMulti phase

Owner:MERCK PATENT GMBH

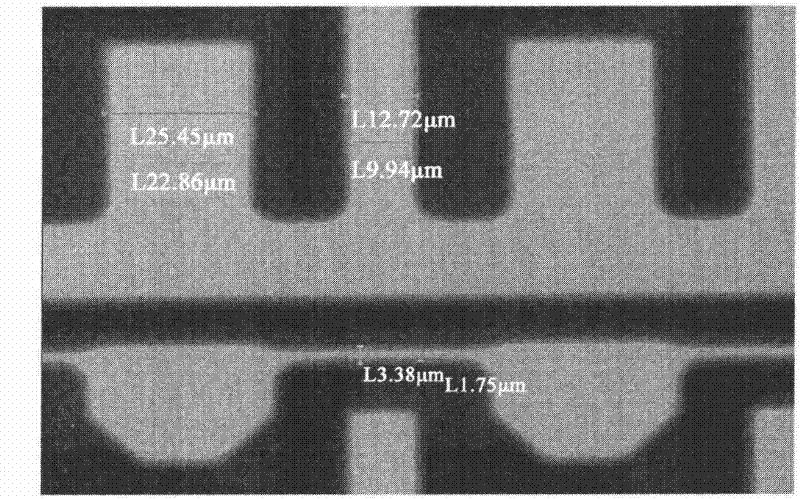

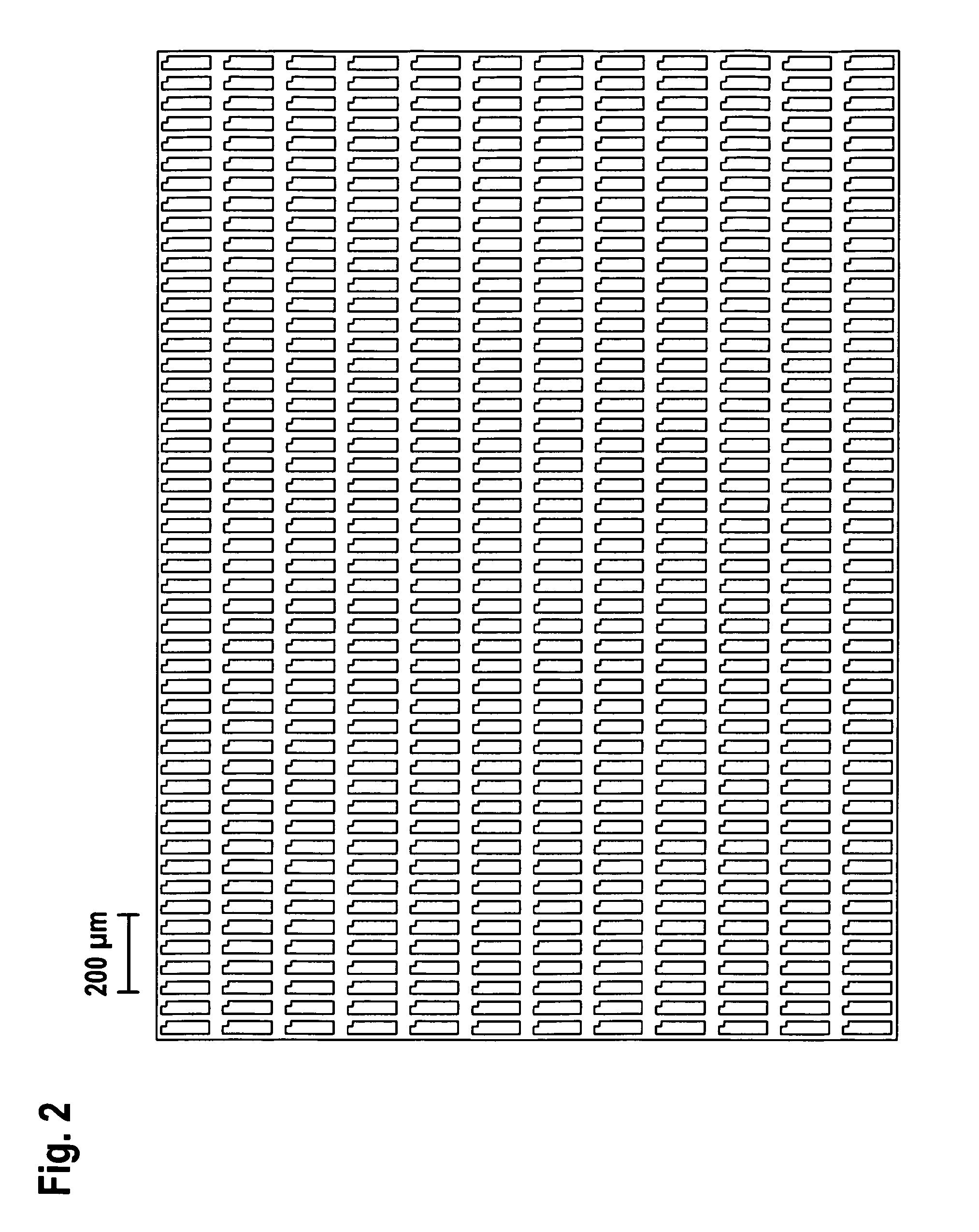

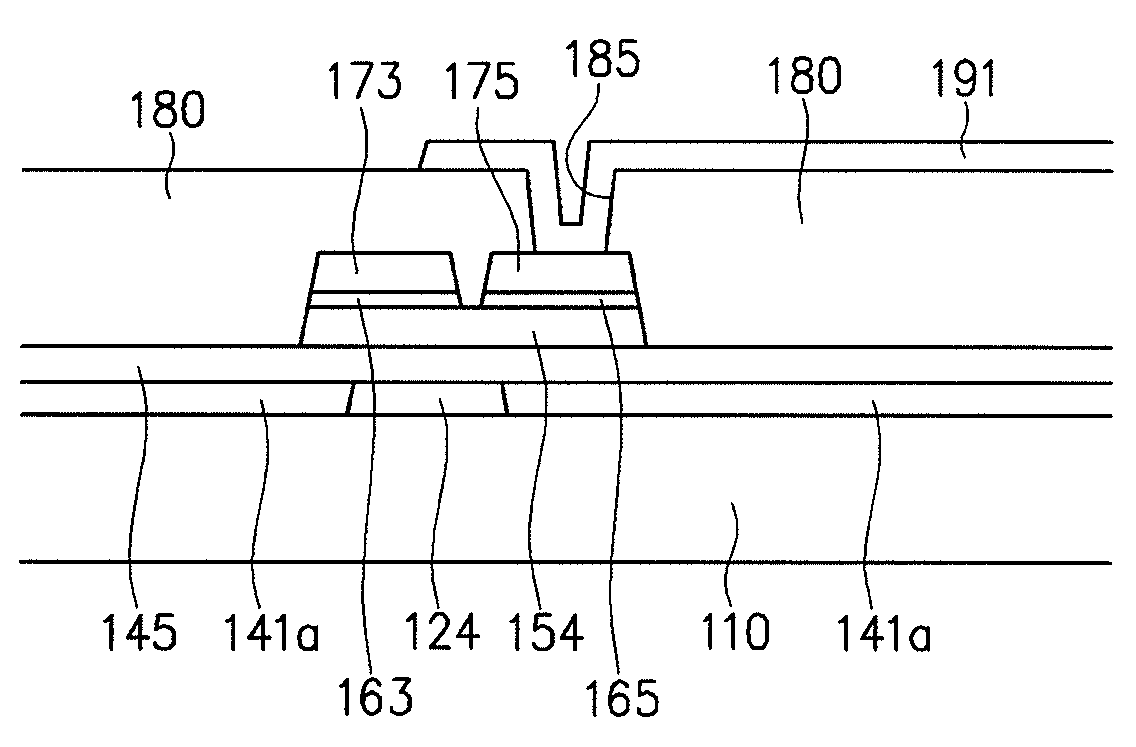

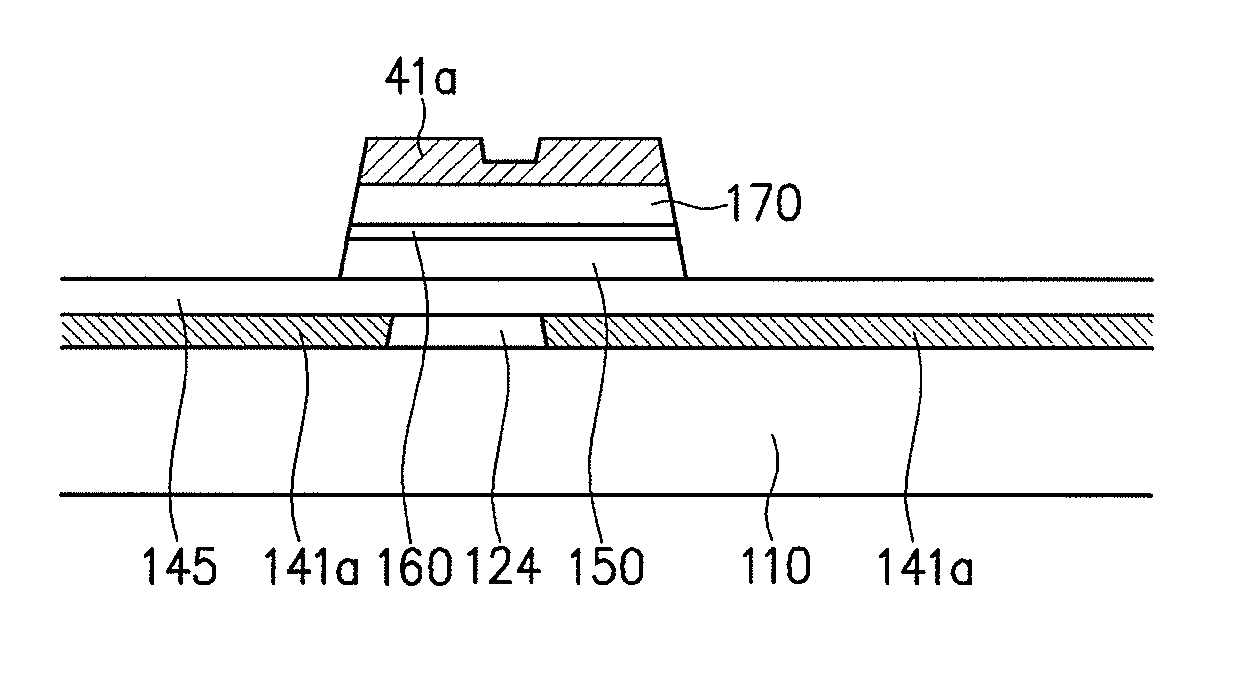

Etchant composition, and method of fabricating metal pattern and thin film transistor array panel using the same

ActiveUS20100120209A1Excellent etch profileExcellent productivityDecorative surface effectsSolid-state devicesPhosphoric acidChemistry

An etchant composition is provided. The etchant composition includes about 40 to about 65 wt % of phosphoric acid, about 2 to about 5 wt % of nitric acid, about 2 to about 20 wt % of acetic acid, about 0.1 to about 2 wt % of a compound containing phosphate, about 0.1 to about 2 wt % of a compound simultaneously containing an amino group and a carboxyl group, and a remaining weight percent of water for the total weight of the composition.

Owner:SAMSUNG DISPLAY CO LTD +1

Etching liquid composition for copper-based metal film, array substrate using the etching liquid composition for display device and manfuacutring method of the etching liquid composition

InactiveCN106611746AExcellent etch profileSolid-state devicesSemiconductor/solid-state device manufacturingPhosphateDisplay device

The invention relates to an etching liquid composition for a copper-based metal film, an array substrate using the etching liquid composition for a display device and a manfuacturing method of the etching liquid composition, particularly to an etching liquid composition for a copper-based metal film. The etching liquid composition for the copper-based metal film contains a ceertain content of the following substances: hydrogen peroxide, a fluorine compound, 5-methyl-1H-tetrazole, a compound having nitrogen atoms and carboxyl in a molecule, phosphate, sulfate, polyhydric alcohol surfactant and water, and the invention also relates to an array substrate for a display device which is manufactured by use of the composition, and a manufacturing method of the etching liquid composition.

Owner:DONGWOO FINE CHEM CO LTD

Etchant composition for copper-based metal layer, and method of manufacturing array substrate of display device

ActiveCN107236956AExcellent etch profileExcellent etch linearitySolid-state devicesSemiconductor/solid-state device manufacturingPhosphateDisplay device

The invention discloses an etchant composition for a copper-based metal layer comprising a predetermined amount of hydrogen peroxide, an azole compound, a water-soluble compound having a nitrogen atom and a carboxyl group in the molecule, a phosphate, an acetate, a polyol surfactant And water. There is also provided a method of manufacturing an array substrate for a display device using the etchant composition.

Owner:DONGWOO FINE CHEM CO LTD

Method and system for forming a feature in a high-k layer

InactiveUS7361608B2Improved operational and reliability characteristicReduce formationElectric discharge tubesSemiconductor/solid-state device manufacturingInterface layerPlasma processing

Owner:TOKYO ELECTRON LTD

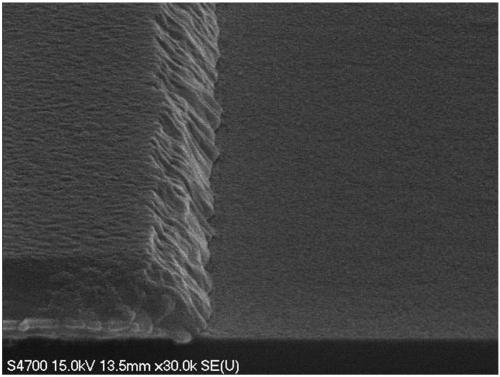

Process for anisotropic etching of semiconductors

InactiveCN102598223AExcellent etch profileSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsReactive gas

A method is provided for anisotropically etching semiconductor materials such as II-VI and III-V semiconductors. The method involves repeated cycles of plasma sputter etching of semiconductor material with a non-reactive gas through an etch mask, followed by passivation of the side walls by plasma polymerization using a polymer former. Using this procedure small pixels in down-converted light-emitting diode devices can be fabricated.

Owner:3M INNOVATIVE PROPERTIES CO

Etchant composition, and method of fabricating metal pattern and thin film transistor array panel using the same

ActiveUS7968000B2Excellent etching propertiesExcellent etch profileDecorative surface effectsSolid-state devicesAcetic acidPhosphate

An etchant composition is provided. The etchant composition includes about 40 to about 65 wt % of phosphoric acid, about 2 to about 5 wt % of nitric acid, about 2 to about 20 wt % of acetic acid, about 0.1 to about 2 wt % of a compound containing phosphate, about 0.1 to about 2 wt % of a compound simultaneously containing an amino group and a carboxyl group, and a remaining weight percent of water for the total weight of the composition.

Owner:SAMSUNG DISPLAY CO LTD +1

Etching solution

The etching liquid comprises the following components in percentage by mass: 12-22% of hydrogen peroxide; 0.5-4% by mass of a chelating agent; 0.1 to 2.5% by mass of an etching inhibitor; 0.1 to 5% by mass of an etching agent; 0.01-2% by mass of a residue removal agent; the etching agent can be used for etching a copper / molybdenum metal film layer with a multi-layer structure in a large area under the condition that the fluorine content does not need to be increased, not only can the phenomenon that copper metal is diffused on an insulating film be inhibited, but also molybdenum metal residues can be effectively removed, and the etching solution is stable in property, moderate in etching rate, good in etching outline and high in etching efficiency. And the yield of products can be effectively improved.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Etching solution composition and method for manufacturing array substrate for display device

ActiveCN107988598BExcellent etch profileExcellent lateral erosion variation characteristicsSolid-state devicesNon-linear opticsAlkaline earth metalEtching

Owner:DONGWOO FINE CHEM CO LTD

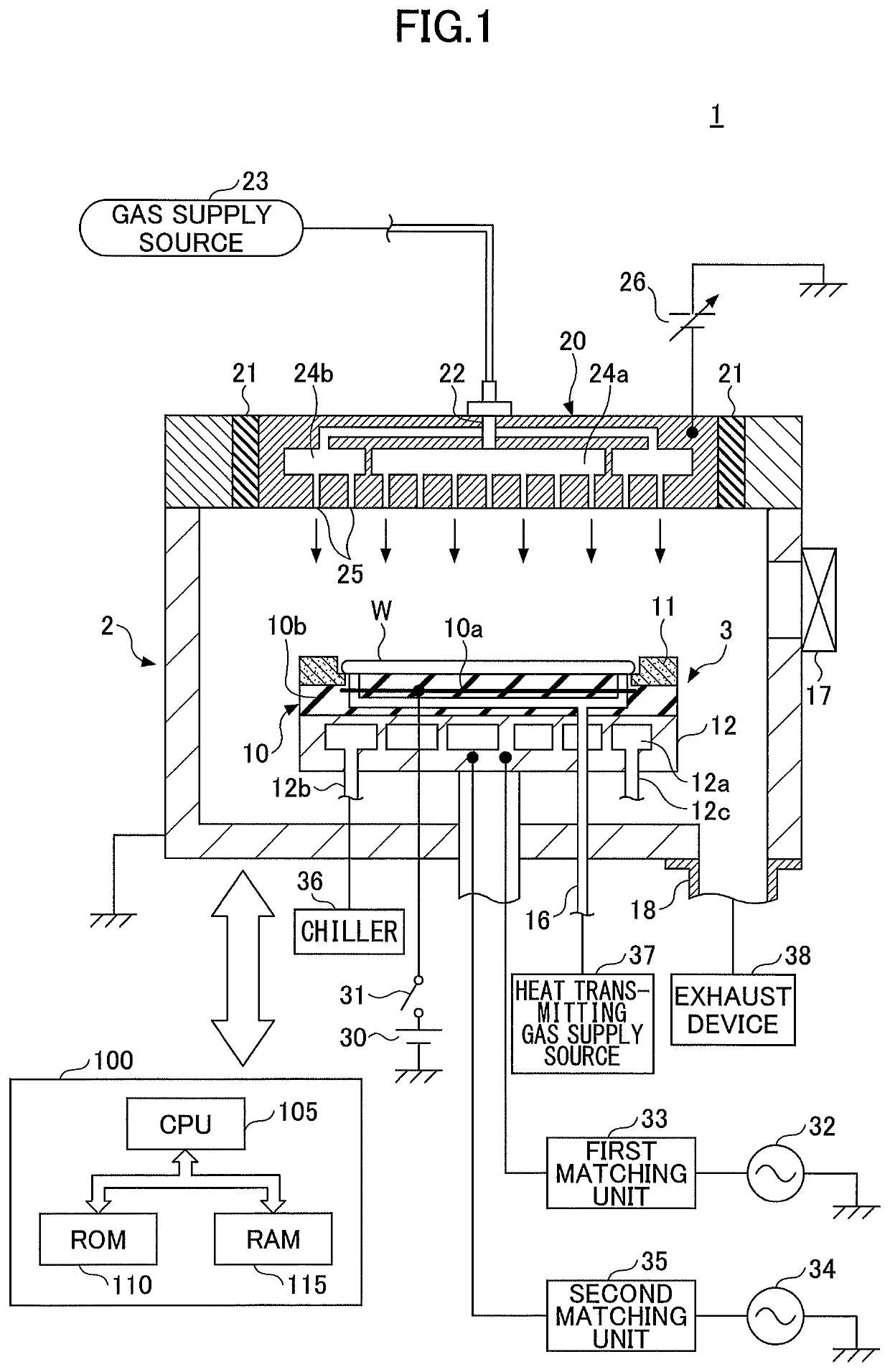

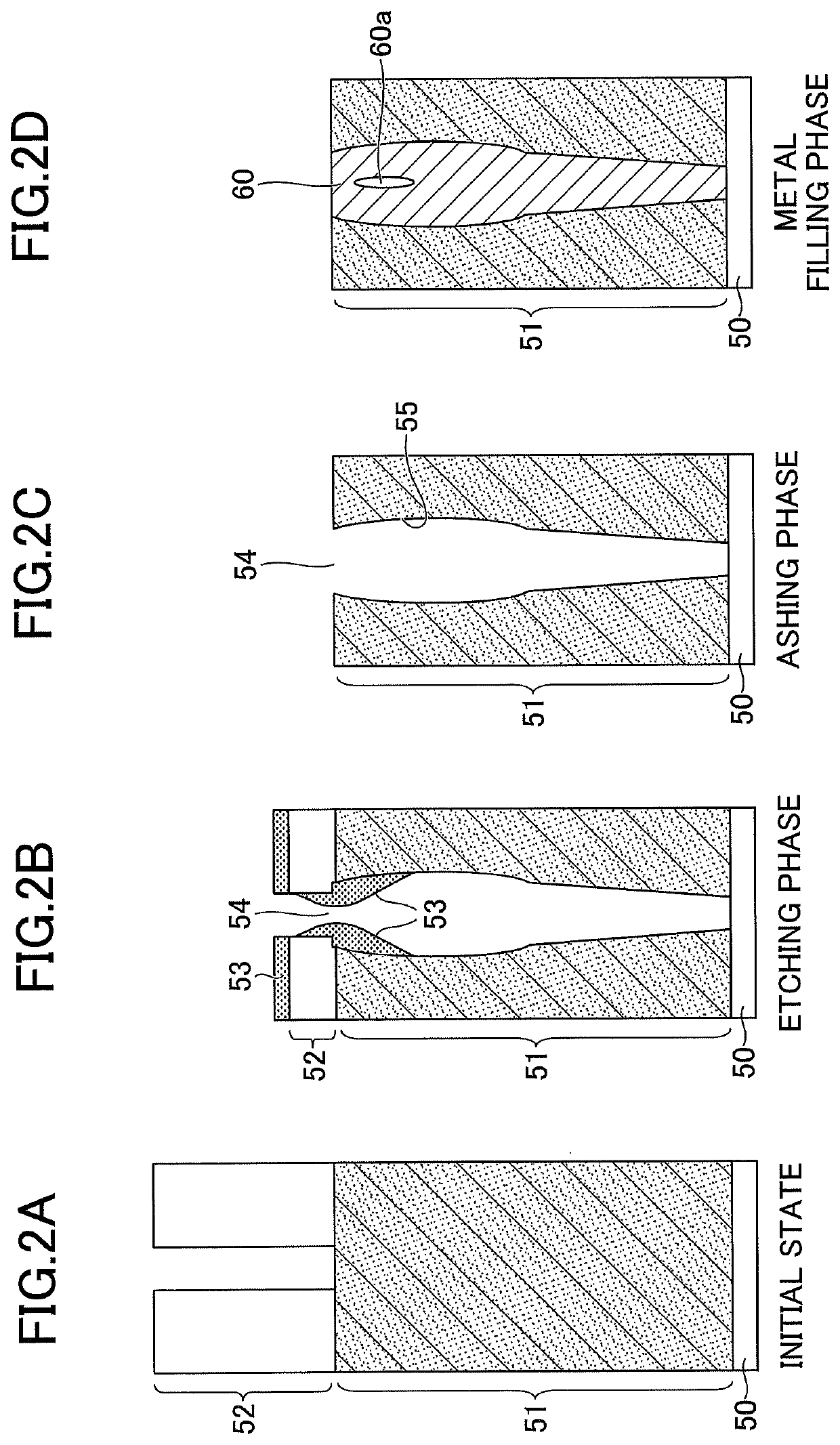

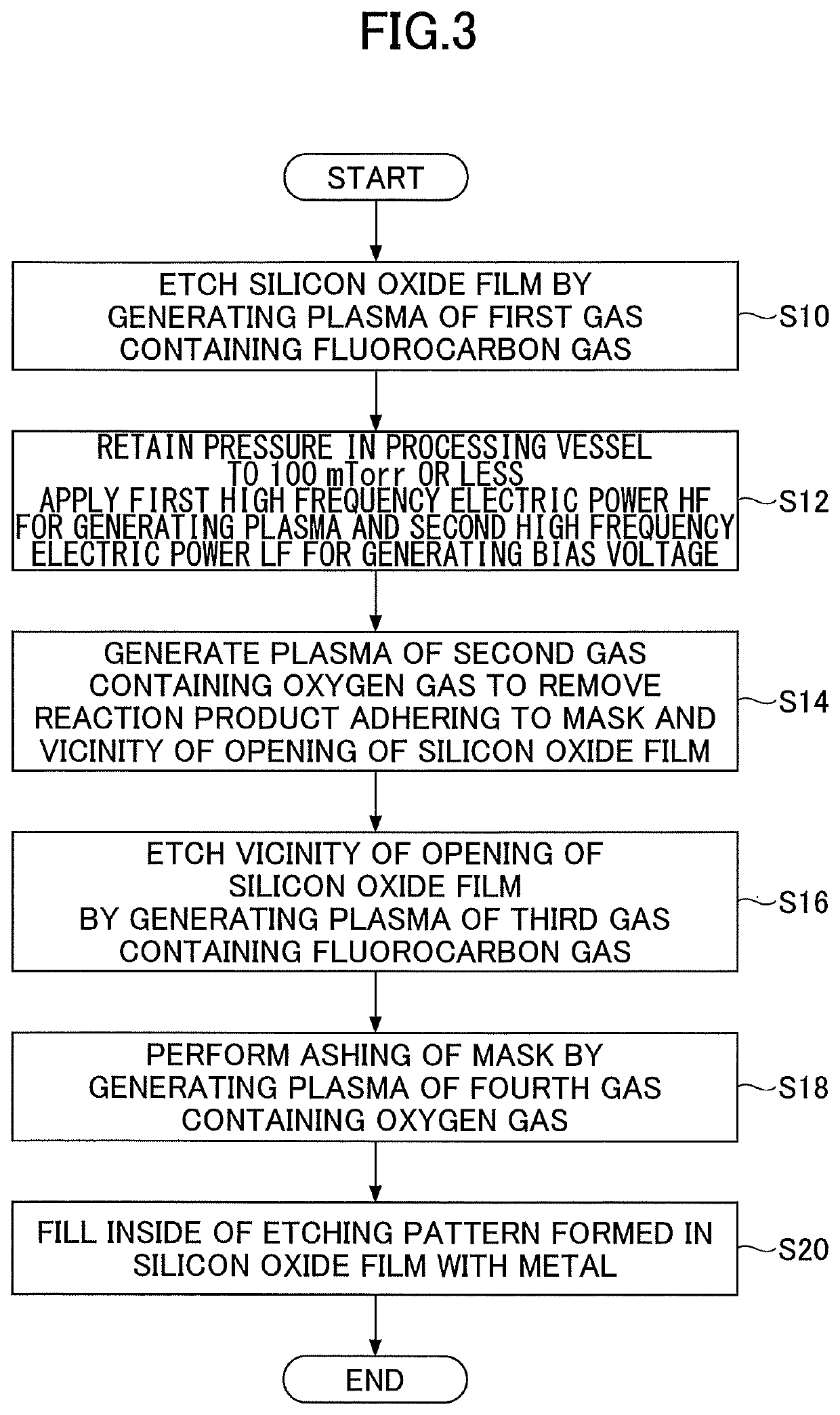

Etching method

ActiveUS10651077B2Excellent etch profileSemiconductor/solid-state device manufacturingEngineeringGas supply

An etching method of silicon-containing oxide film is provided. The etching method includes a first step of forming an etching pattern on the silicon-containing oxide film by etching the silicon-containing oxide film using a first plasma generated from a first gas supplied to the processing vessel, according to a pattern of a mask layered on the silicon-containing oxide film, and a second step of removing a reaction product adhering to vicinity of an opening of the etching pattern and to the mask using a second plasma generated from a second gas supplied to the processing vessel, by applying a first high frequency electric power for generating plasma and a second high frequency electric power for generating bias voltage.

Owner:TOKYO ELECTRON LTD

Etching solution composition, array substrate for display device and manufacturing method thereof

ActiveCN106835138BExcellent cone angle characteristicsExcellent etch profileSemiconductor/solid-state device manufacturingDisplay deviceLiquid composition

The invention relates to an etchant composition, an array substrate for a display device, and a manufacturing method thereof. More specifically, the invention relates to an etchant composition for a copper-based metal film, including hydrogen peroxide, fluorine compound, 5-methyl-1H-tetrazole, a water soluble compound in which one molecule has a nitrogen atom and hydroxy, sodium tripolyphosphate / disulfate, polyols type surfactant, and water with certain contents, an array substrate for a display device by employing the above etchant composition, and a manufacturing method thereof.

Owner:DONGWOO FINE CHEM CO LTD

Manufacturing method of array substrate for display device, etchant composition and etching method

ActiveCN106467969BExcellent etch profileImprove straightnessSolid-state devicesNon-linear opticsDisplay deviceLiquid composition

The present invention relates to a copper-based metal film etching liquid composition which includes (A) 5 to 30 weight percent of hydrogen peroxide (H2O2), (B) fluorine compound 0.01 to 3% by weight, (C) 0.01 to 3% by weight of 5- (alkyl of 1 to 5 carbon atoms) -1H-tetrazole, (D) 0.5 to 5% by weight of a water-soluble compound having a nitrogen atom and a carboxyl group in one molecule, (E) 0.05 to 1% by weight of sulfate compound, (F) 1 to 5% by weight of polyhydric alcohol type surfactant, and (G) a residual amount of water with regard to the total weight of the composition, a method of manufacturing an array substrate for a display device using an etchant composition and an etching method. It is possible to provide a metal film etching liquid composition which can prevent step coverage failure and the incidence of etch residues.

Owner:DONGWOO FINE CHEM CO LTD

Metal film etching solution composition and etching method using the same

ActiveCN104838040BExcellent etch profileImprove stabilitySemiconductor/solid-state device manufacturingSemiconductor devicesOrganic acidIndium tin oxide

The invention discloses an etching solution composition capable of simultaneously etching a double film of a copper film and an indium tin oxide film or a double film of a copper film and a metal film, and an etching method using the composition. The above etching solution composition comprises: 5 to 20% by weight of hydrogen peroxide; 0.1 to 5% by weight of sulfonic acid compounds; 0.1 to 2% by weight of carbonyl organic acid compounds; 0.1 to 0.4% by weight of fluorine compounds; 3% by weight of azole compounds; and, the remaining weight% of water.

Owner:DONGJIN SEMICHEM CO LTD

Etchant composition for copper-based metal layer and method for manufacturing array substrate of display device using same

ActiveCN107236956BExcellent etch profileExcellent etch linearitySolid-state devicesSemiconductor/solid-state device manufacturingPolyolActive agent

The invention discloses an etchant composition for a copper-based metal layer comprising a predetermined amount of hydrogen peroxide, an azole compound, a water-soluble compound having a nitrogen atom and a carboxyl group in the molecule, a phosphate, an acetate, a polyol surfactant And water. There is also provided a method of manufacturing an array substrate for a display device using the etchant composition.

Owner:DONGWOO FINE CHEM CO LTD

The etching composition for etching conductive multi -layer membrane and the etching method using it

InactiveCN102409342BReduce manufacturing costShorten production timeSemiconductor/solid-state device manufacturingSurface treatment compositionsAcetic acidEtching

The present invention discloses an etchant composition for etching a conductive multilayer film and an etching method using the same. The etchant composition contains 50-80% by weight of phosphoric acid, 0.5-10% by weight of nitric acid, 5-30% by weight of acetic acid, 0.01-5% by weight of imidazole, based on the total weight of the composition, and the balance is water. The multilayer film includes at least one copper or copper alloy layer and at least one molybdenum or molybdenum alloy layer. The multilayer film may be a Cu / Mo laminated film, a Cu / Mo alloy laminated film or a Cu alloy / Mo alloy laminated film. The multilayer film can be etched in an efficient and advantageous manner using the etchant composition. Furthermore, the constituent layers of the multilayer film can be etched simultaneously in a batch manner. Imidazole is an additive that acts as a reaction control agent for Cu / Mo primary cells.

Owner:PLANSEE SE

Process for anisotropic etching of semiconductors

InactiveCN102598223BExcellent etch profileSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductor materialsReactive gas

A method is provided for anisotropically etching semiconductor materials such as II-VI and III-V semiconductors. The method involves repeated cycles of plasma sputter etching of semiconductor material with a non-reactive gas through an etch mask, followed by passivation of the side walls by plasma polymerization using a polymer former. Using this procedure small pixels in down-converted light-emitting diode devices can be fabricated.

Owner:3M INNOVATIVE PROPERTIES CO

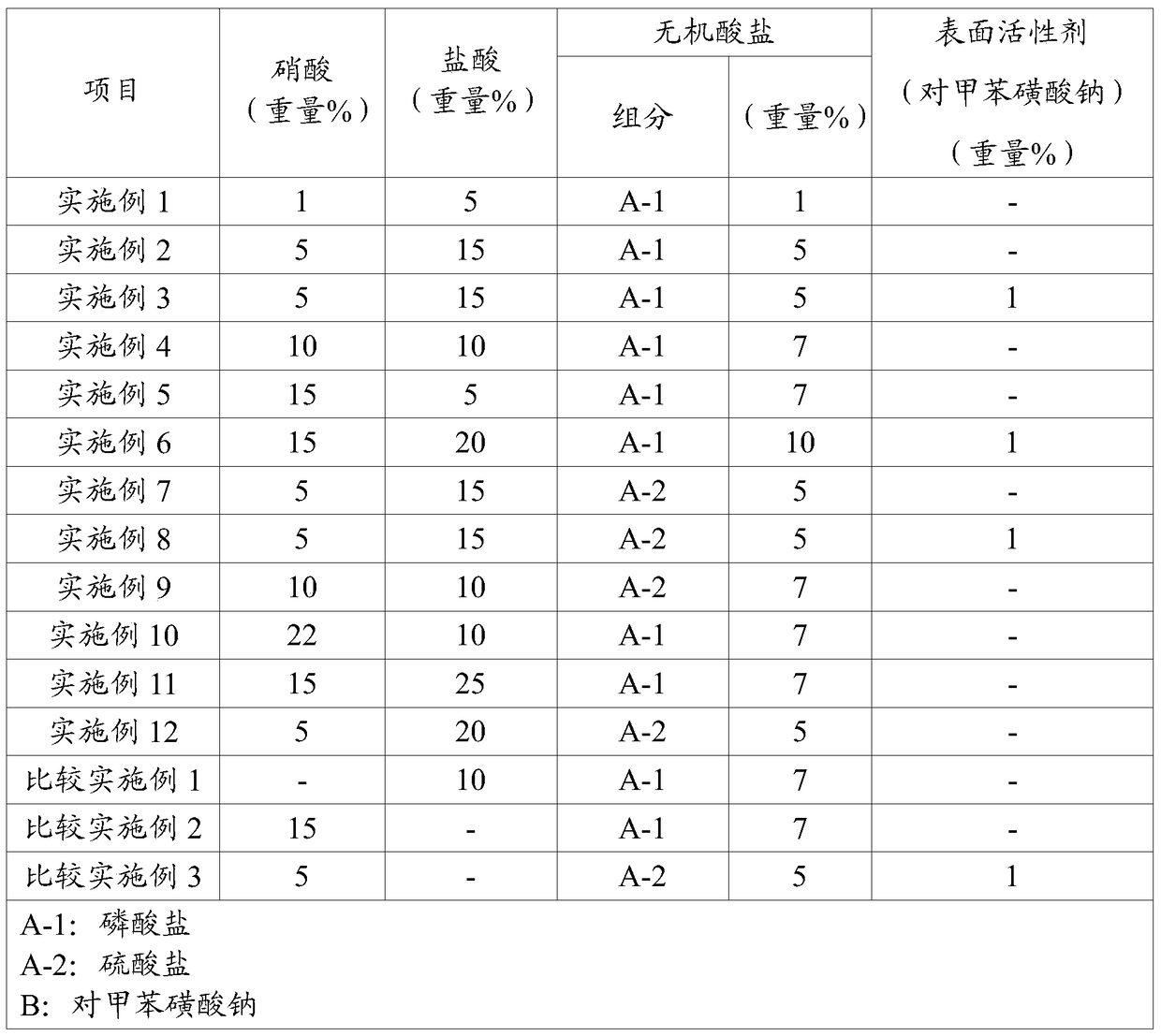

Etchant compositions for integrated circuits

ActiveCN110129056BAvoid breakingControllable etch rateSemiconductor/solid-state device manufacturingSurface treatment compositionsPhysical chemistryMetal electrodes

The invention provides an etchant composition for integrated circuits, belonging to the field of etching technology, comprising, based on the total weight of the etchant composition, 3-10wt% of nitric acid; 9-16wt% of hydrochloric acid; 0.01-1wt% jelly jelly; and the remainder of water. The etching method using the above etchant composition comprises the steps of: forming a metal oxide layer on a substrate; selectively leaving a photoreactive material on the metal oxide layer to expose a part of the metal oxide layer; and using an etching The agent composition etches the exposed metal oxide layer. The etchant composition of the present invention has the advantages of controllable etching rate, good etching effect, precise thickness etching and no etching residue, better etching uniformity and stability, can provide excellent etching profile, and exhibits excellent Good etching performance, the metal electrode structure is not easy to be damaged, and it is not easy to leave residues that cause electrical short circuits.

Owner:上海舸海科技有限公司

Etchant compositions for metal oxide layers

ActiveCN103911156BExcellent etch profileGood etchingSemiconductor/solid-state device manufacturingSurface treatment compositionsOrganic acidSemiconductor

The invention discloses an etchant composition for a metallic oxide layer. The etchant composition for the metallic oxide layer includes nitric acid, hydrochloric acid, organic acid and water. The composition can rapidly and uniformly etch the metallic oxide layer (transparent oxide semiconductor), and is simple in preparation and easy to control.

Owner:DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com