Etchant compositions for metal oxide layers

A composition and etchant technology, applied in the direction of surface etching compositions, chemical instruments and methods, electrical components, etc., can solve problems such as poor uniformity, poor performance, complex processes, etc., and achieve good etching performance and good etching Contouring, preparation for simple effects

Active Publication Date: 2018-07-20

DONGWOO FINE CHEM CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] Compared with a-Si TFT, polysilicon thin film transistors (hereinafter referred to as "poly-Si TFT") with excellent performance usually have tens to hundreds of cm 2 / Vs high mobility, thus exhibiting the ability to be suitable for high-definition displays, which is difficult to achieve with the existing a-Si TFT

In addition, compared with a-Si TFT, the aforementioned poly-Si TFT almost never has the problem of device performance deterioration

However, compared with a-Si TFT, for the manufacture of poly-Si TFT, a more complicated process is required, which will increase the additional cost of poly-Si TFT

Thus, although the aforementioned poly-Si TFT is suitable for application to products such as OLEDs (Organic Light Emitting Diodes) or for realizing high definition of displays, poly-Si TFTs are inferior to existing a-Si TFTs in terms of cost, therefore, poly -Si TFT is limited in its application

At the same time, for poly-Si TFTs, due to technical problems (such as limitations of manufacturing equipment, poor uniformity, etc.), the manufacturing process using large substrates with a size greater than 1m has not been realized in practice. Therefore, making poly -Si TFT is difficult to apply in TV products

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 to Embodiment 12 and comparative Embodiment 1 to comparative Embodiment 3

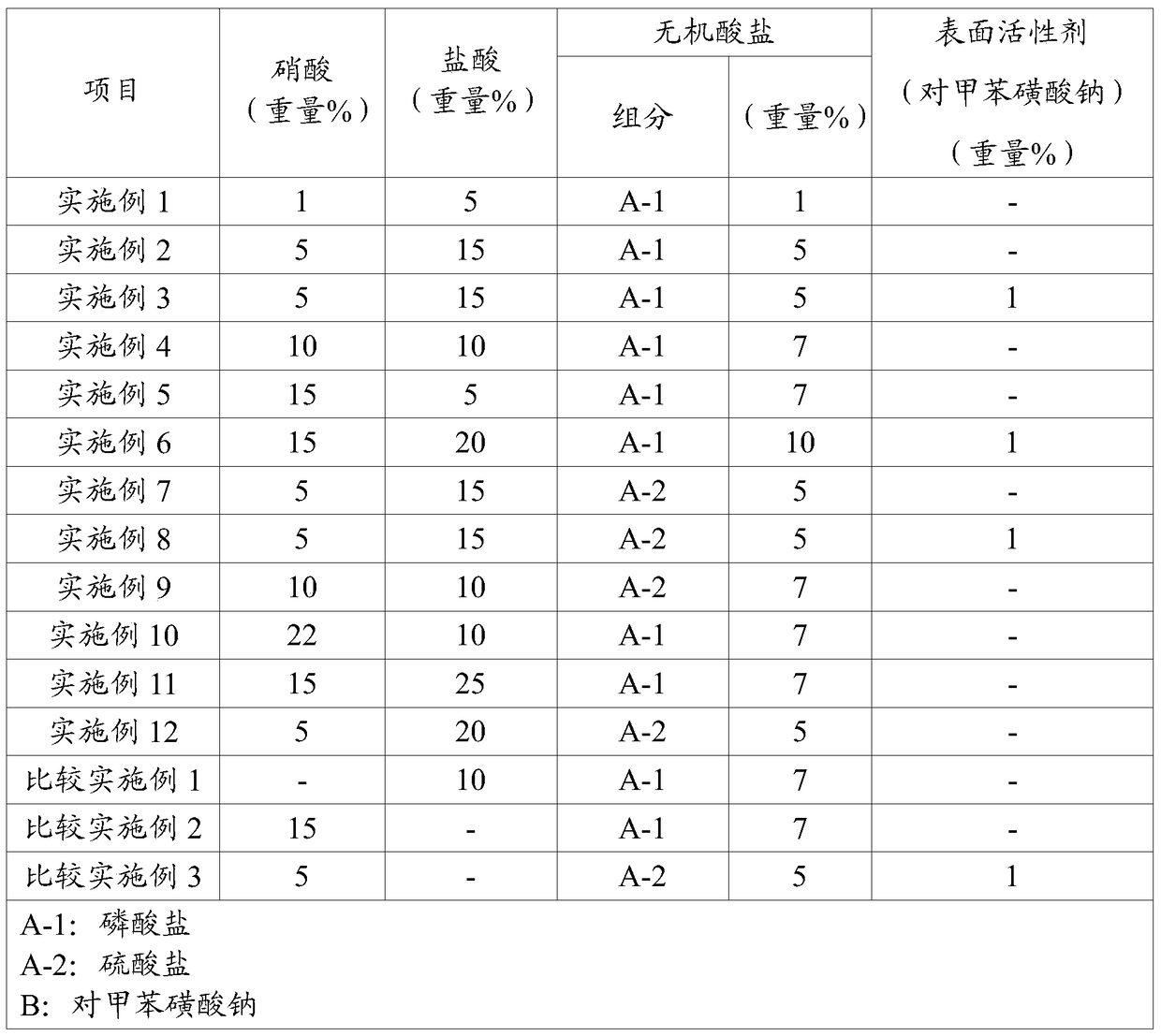

[0058] An etchant composition for a metal oxide layer was prepared by using the components listed in Table 1 in the corresponding contents (% by weight) and adding the balance of water.

[0059] [Table 1]

[0060]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses an etchant composition for a metallic oxide layer. The etchant composition for the metallic oxide layer includes nitric acid, hydrochloric acid, organic acid and water. The composition can rapidly and uniformly etch the metallic oxide layer (transparent oxide semiconductor), and is simple in preparation and easy to control.

Description

technical field [0001] The present invention relates to an etchant composition for a metal oxide layer capable of rapidly and uniformly etching a metal oxide layer (transparent oxide semiconductor). Background technique [0002] Thin film transistors (TFTs) are used in a large number of applications, in particular, for switching devices and driving devices in the field of displays. [0003] In the recent environment of TV (television) panels mainly composed of liquid crystal displays (LCDs), the use of organic light emitting displays in TVs is also rapidly developing. Technological developments in TV displays are increasingly meeting market demands. Market needs may include large TV or Digital Information Display (DID), low price, high definition (ie, image quality) (eg, motion image expression, high resolution, brightness, contrast range, color reproduction), etc. In order to meet such demands as described above, improved TFTs suitable for switching and driving devices of...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C09K13/04

CPCC09K13/04H01L21/465

Inventor 金童基田玹守郑敬燮

Owner DONGWOO FINE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com