Etching solution composition and method for manufacturing array substrate for display device

A composition and etching solution technology, applied in the directions of surface etching compositions, chemical instruments and methods, instruments, etc., can solve problems such as interface erosion when etching multilayer films, and achieve excellent etching profile and side etching variation characteristics. excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9 and comparative example 1~8

[0094] Examples 1-9 and Comparative Examples 1-8. Preparation of Etching Solution Composition

[0095] 180 kg of etching liquid composition was manufactured according to the composition and content (weight%) described in the following Table 1.

[0096] [Table 1]

[0097]

[0098] Note) In the above table 1,

[0099] NHP: sodium dihydrogen phosphate

[0100] PPM: potassium dihydrogen phosphate

[0101] APM: Ammonium Phosphate

[0102] SS: sodium sulfate

[0103] PS: potassium sulfate

[0104] AS: Ammonium sulfate

[0105] TEG: Triethylene glycol (triethylene glycol)

[0106] Phosphite: sodium phosphite (sodium phosphite)

experiment example

[0107] Evaluation of Etching Properties of Etching Solution Composition

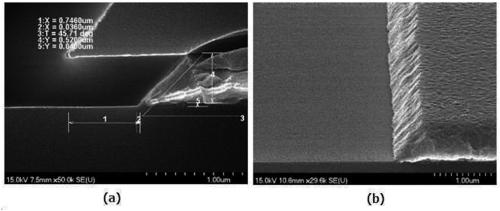

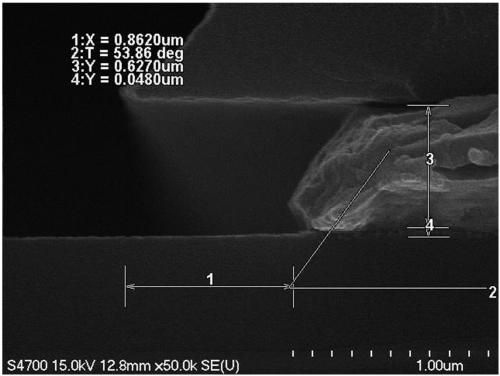

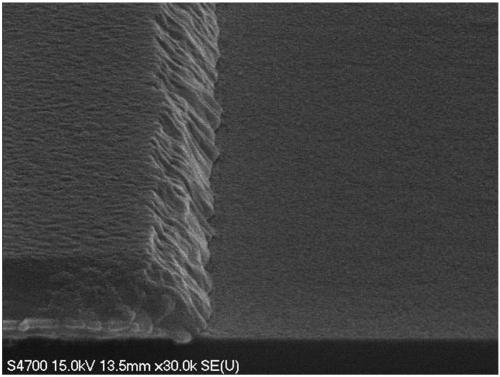

[0108] The etching process was implemented using the etching liquid composition of Examples 1-9 and Comparative Examples 1-8, respectively. The temperature of the etchant composition in the etching process was set to about 33° C. using a spray etching method experimental device (model name: ETCHER (TFT), SEMES). The etching time may vary depending on the etching temperature, but is usually performed at about 110 seconds. The profile cross section of the copper-based metal film etched in the above etching step was examined by SEM (Hitachi Corporation, model name S-4700), and the results are shown in Table 2 below.

[0109] The test piece (Cu / MoNb) used in the etching process used the following test piece: a molybdenum-niobium alloy film was deposited on a glass substrate (100mm×100mm), and a copper film was deposited on the above film, followed by a photolithography process. , forming a photoresist wit...

experiment example 1

[0110] Experimental example 1. Etching rate evaluation

[0111] Measure the end point detection (End Point Detection, EPD) with naked eyes, and obtain the etching rate (E / R, Etch Rate) at different times, and the etching rate is only evaluated by the vertical etching rate. If the thickness of the etched metal film is divided by the EPD, it can be calculated per second (time) (thickness) The etching rate was evaluated according to the following criteria, and the results are shown in Table 2.

[0112]

[0113] ○: good

[0114] Х: Poor (less than or more than )

[0115] Unetch: Unetchable

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com