Susceptor for vapor-phase growth apparatus

a technology of vapor-phase growth and susceptor, which is applied in the direction of polycrystalline material growth, crystal growth process, chemically reactive gas growth, etc., can solve the problems of poor production efficiency of the device, and achieve the effect of preventing the localized raise of the dopant concentration at the most outer peripheral portion of the grown epitaxial layer and raising the dopant concentration in the epitaxial layer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiments

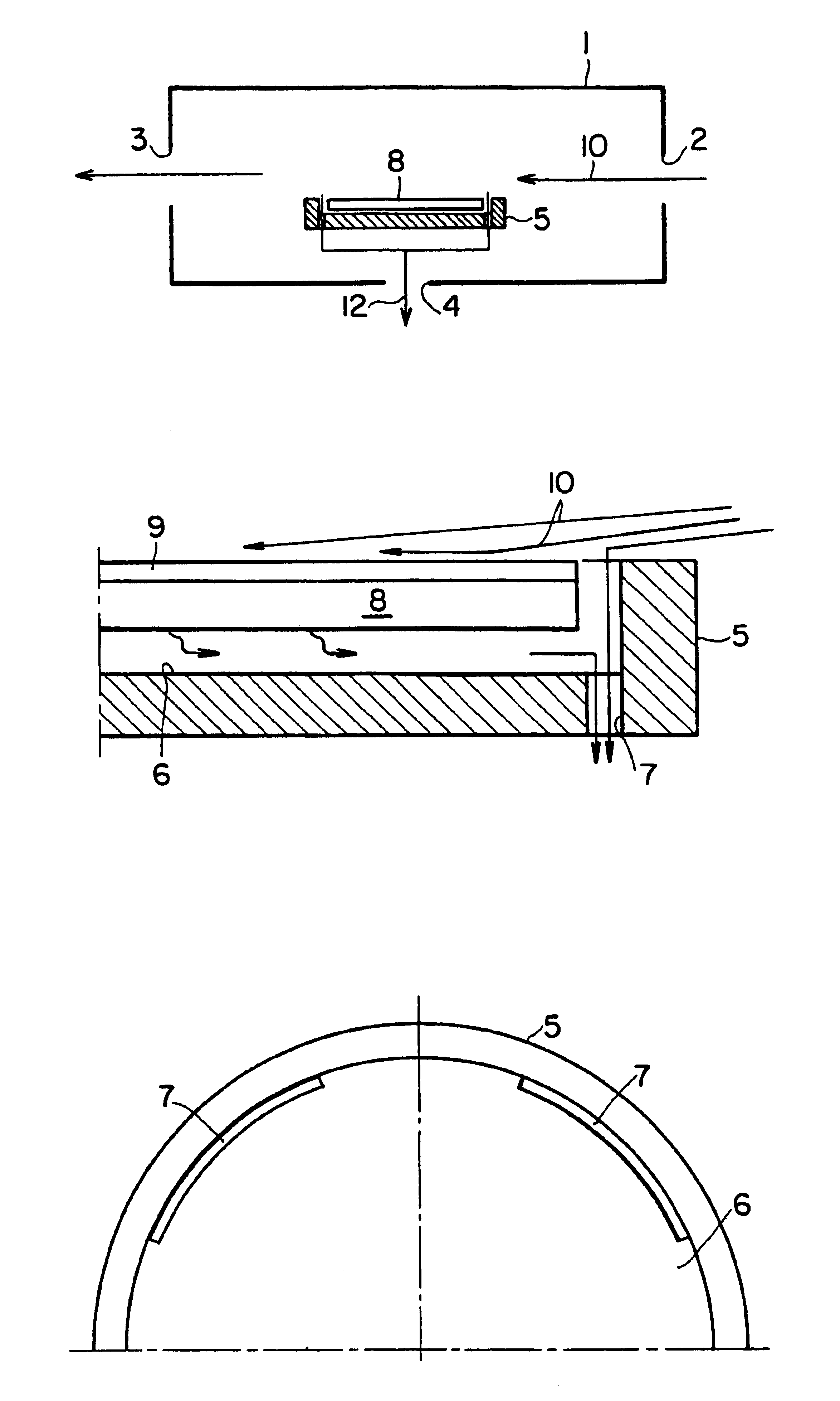

[0027]Using the horizontal single wafer type vapor-phase growth apparatus with a lamp-heating method as seen in FIG. 1, an epitaxial film with the film thickness of about 10 pm was formed at a reaction temperature of 1,150° C. onto the P++ type (100) plane silicon semiconductor base plate (with 200 mm diameter) having the specific resistance of 5 mΩcm using SiHCl3 diluted with hydrogen as the silicon supplying source gas. Two tests were conducted; one was with susceptor having the through-hole of the present invention and the other was with the conventional type of susceptor without any through-holes as seen in FIG. 3.

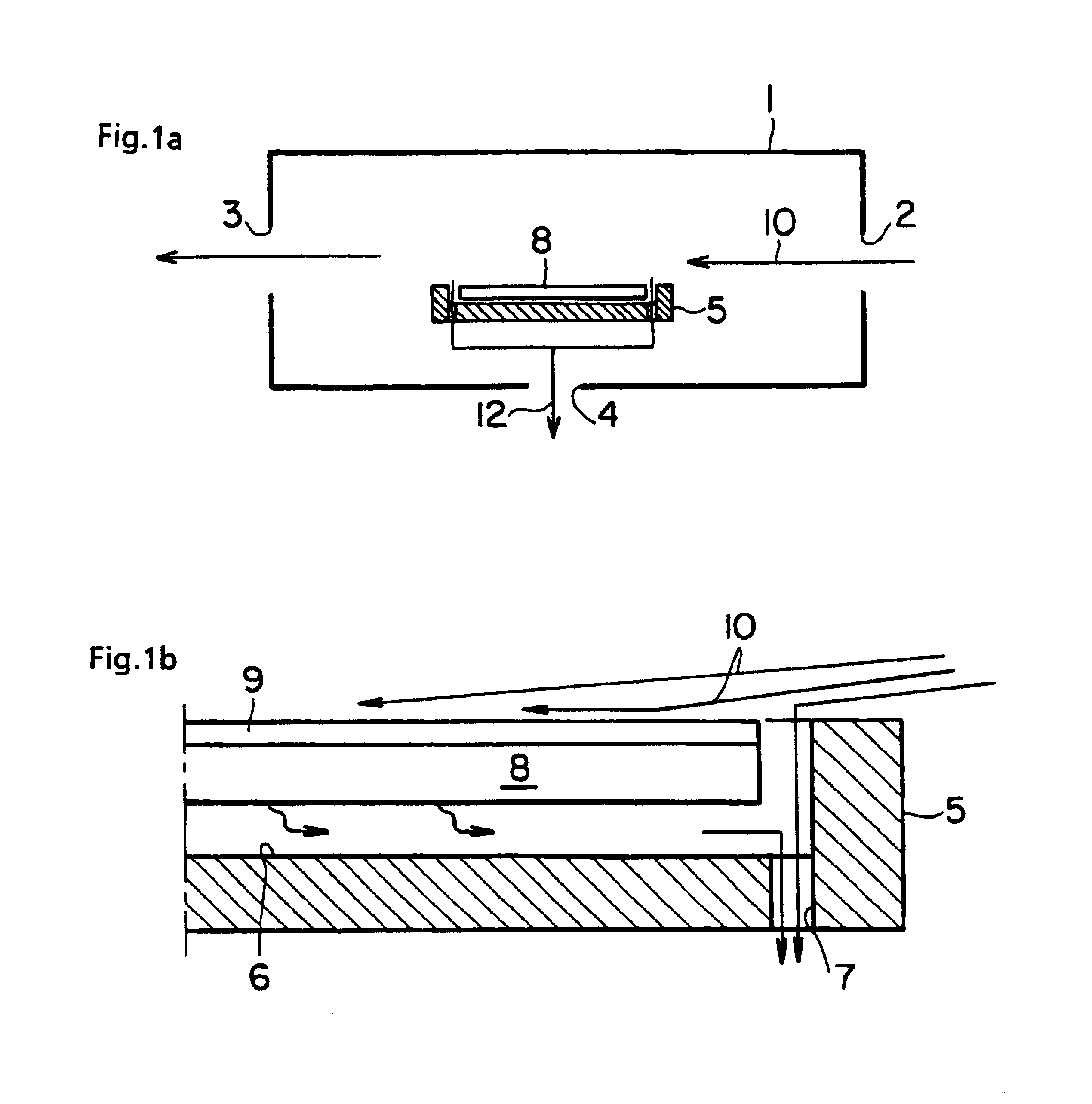

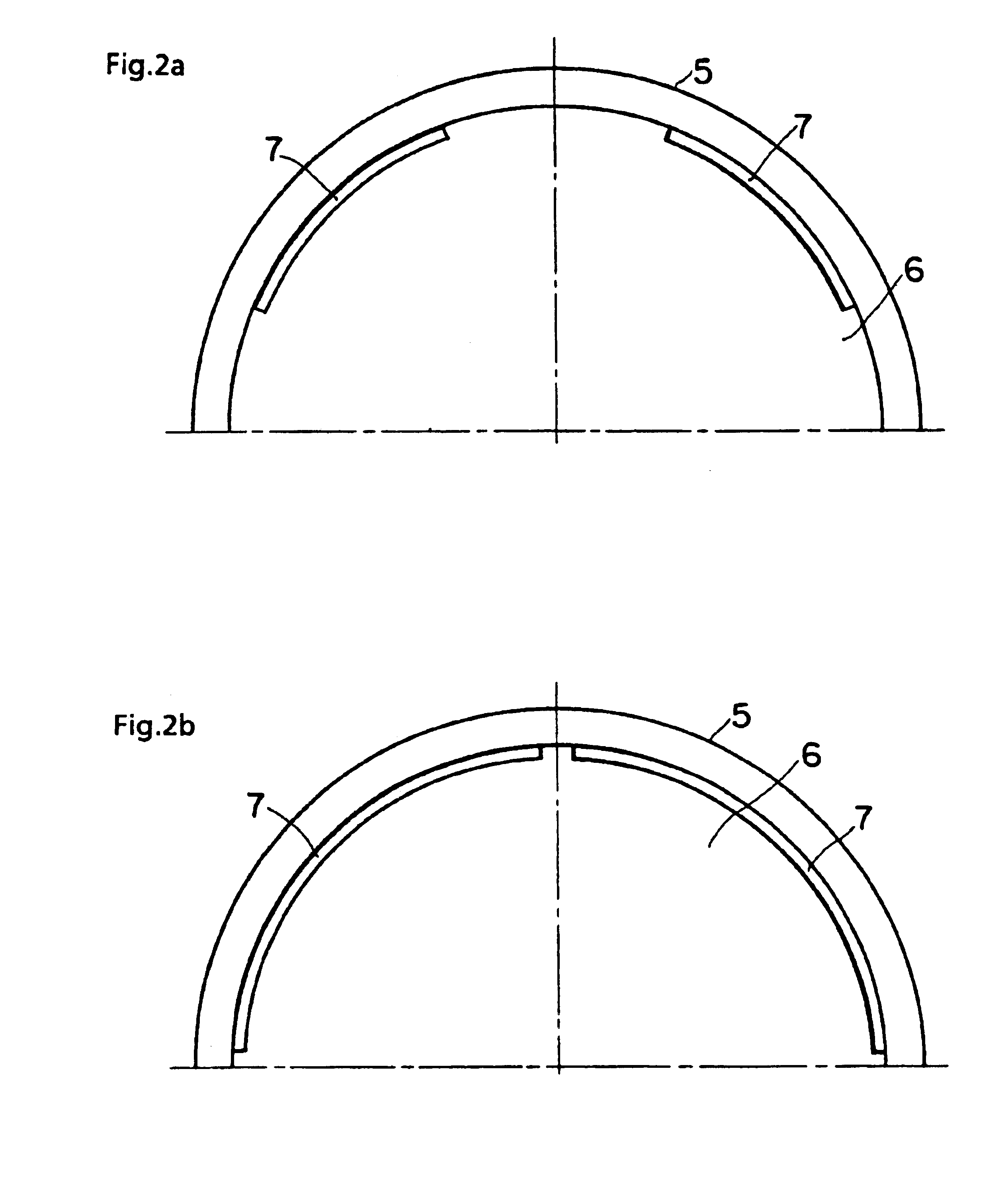

[0028]As seen in FIGS. 2a and 2b, the suscpetor according to the present invention has an arcshaped groove-type through-hole portion 7 at the most outer peripheral portion of the wafer pocket 6. In FIG. 2a, four locations are installed with the through-hole portions 7 leaving the connecting area of 75 mm on its peripheral portion. On the other hand, in FIG. 2b, four lo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com