Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Uniform distribution of fibers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gel electrolyte film of lithium battery and preparation method of gel electrolyte film

InactiveCN102170021ASolve the problem of mechanical strengthIncrease fluid retentionFinal product manufactureElectrolyte accumulators manufactureFiltrationPhysical chemistry

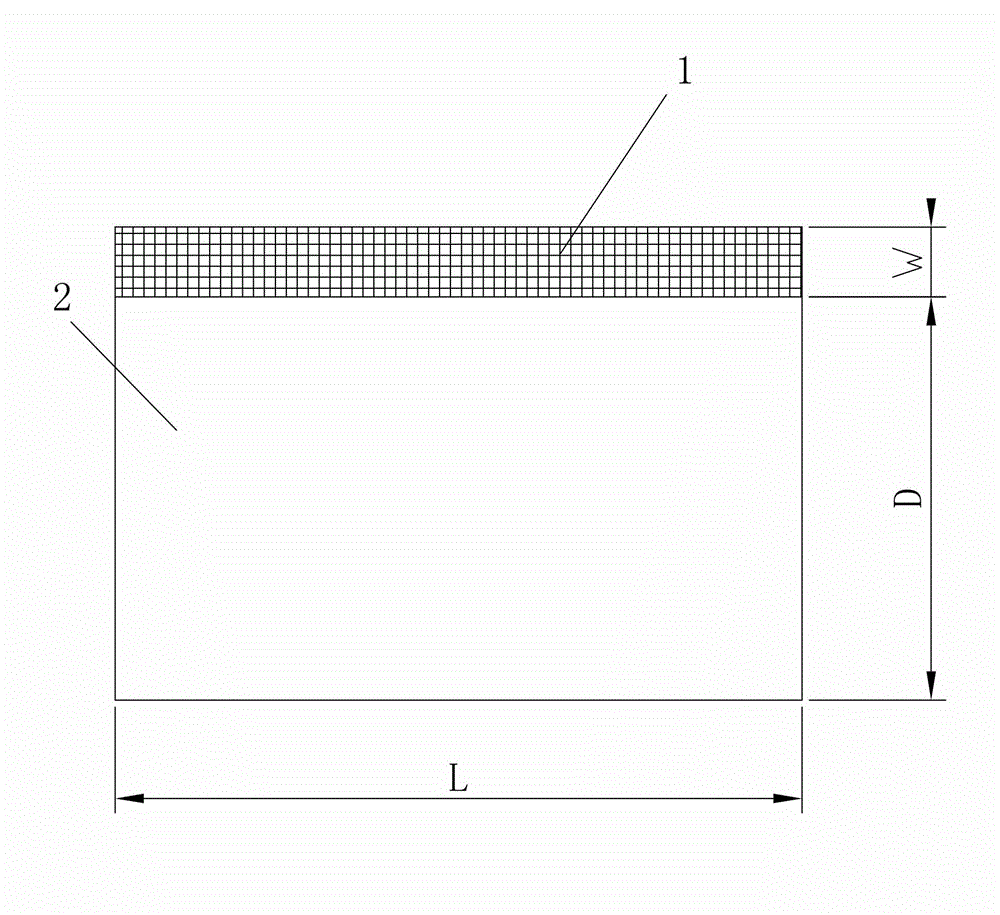

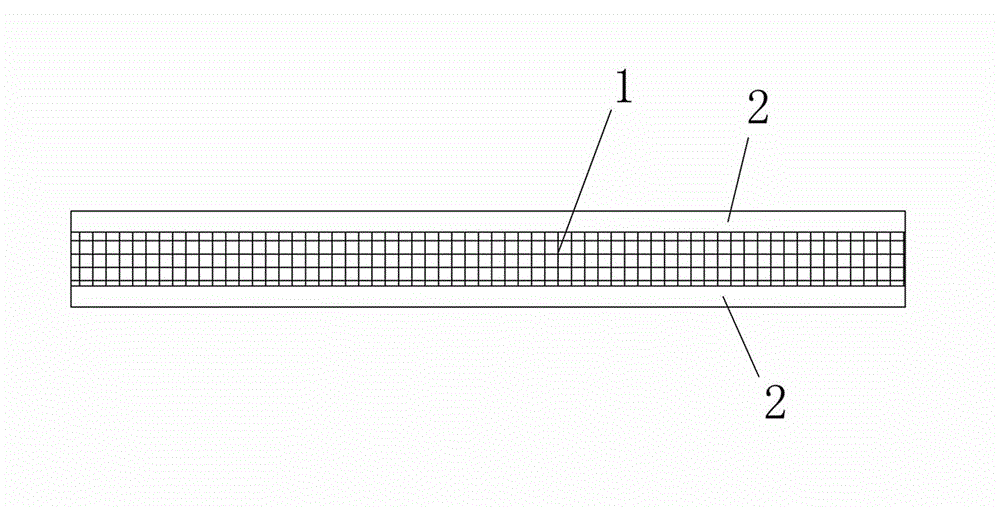

The invention relates to a gel electrolyte film of a lithium battery and a preparation method of the gel electrolyte film. The preparation method comprises the following steps of: making bacterial cellulose neutral; producing bacterial cellulose pulp by beating and dispersion; and performing suction-filtration, dehydration and electrolyte soaking to obtain the gel electrolyte film. The gel electrolyte film of the lithium battery provided by the invention has good ion conductivity and mechanical strength and effectively solves the problem of poor mechanical strength of the gel electrolyte film. By the preparation method of the gel electrolyte film, the thickness of the gel electrolyte film is reduced by means of beating and suction filtration, the surface smoothness of the gel electrolyte film of the lithium battery is improved, fibre distribution is more uniform, arrangement is dense, physical property is relatively strong, an application range is expanded, a preparation process is simple, and industrial production is easy to carry out.

Owner:海南椰国热带水果食品加工有限公司 +1

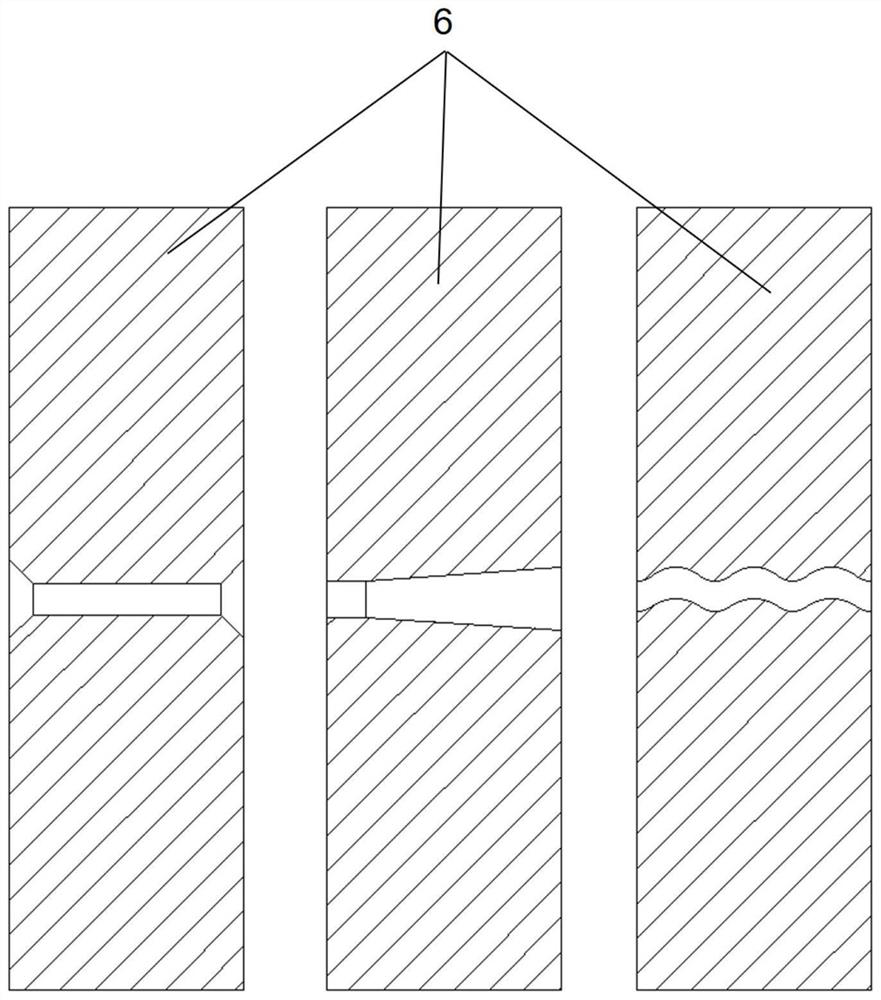

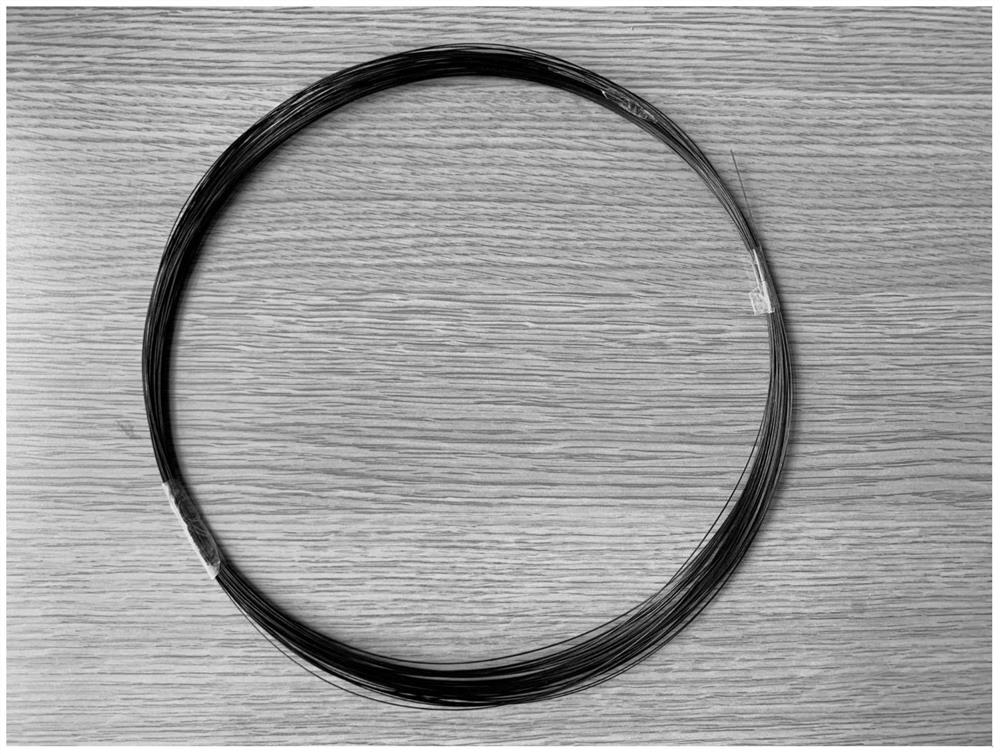

Tungsten-based plasma facing material and preparation method thereof

ActiveCN102560292ALow sputtering yieldLow hydrogen isotope retentionMelting Point TemperaturePlasma-facing material

The invention discloses a tungsten-based plasma facing material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing tungsten powder and tungsten fiber by a powder mixing method which does not damage the tungsten fiber; and sintering to prepare a bulk fiber toughened tungsten-based material by a hot isostatic pressing process. The tungsten powder is one of pure tungsten powder, tungsten-rhenium alloy powder, and tungsten powder doped with carbide and oxide; and the tungsten fiber is a pure tungsten wire, a tungsten-rhenium alloy wire or the like. The tungsten-based plasma facing material has the advantages of high thermal conductivity, high melting point temperature, low sputtering yield, low hydrogen isotope retention and low vapor pressure, as well as low cost and greater toughness.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

Hybrid composite flywheel rim and its manufacturing method

InactiveUS7080573B2Uniform distribution of fibersMechanical energy handlingDomestic articlesGlass fiberCarbon fibers

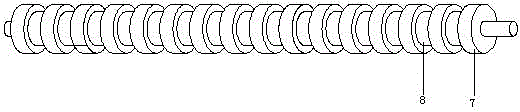

A composite flywheel rim has multiple fiber layers in each of a plurality of radially contiguous zones. The layers in the intermediate zones each have a mixture of carbon fiber tows and glass fiber tows. The ratio of carbon fiber tows to glass fiber tows in each layer of any single zone is constant and the ratio incrementally increases zone-by-zone radially toward the outside of the rim, and the distribution of carbon fiber tows is macroscopically uniform in each zone. The flywheel rim is made by winding a band of fiber tows, impregnated with wet resin, onto a mandrel. The macroscopically uniform distribution can be achieved by controlling the correlation between lead rate of the fiber band as it is wound onto the mandrel per mandrel revolution and the winding length. Carbon fiber tow spacing and position in the band, and a width of a carbon fiber tow also affect the lay up pattern, however, the most effective and the easiest way to change the lay up pattern with constant parameters is by controlling the winding length.

Owner:BEACON POWER LLC

Technique for splitting silk

InactiveCN106521643AUniform distribution of fibersImprove mechanical propertiesDe-gumming silkAnimal fibresNanofiberEnzyme

The invention discloses a technique for splitting silk, and relates to the technical field of processing treatment of silk. The technique for splitting silk comprises the following steps: carrying out enzyme degumming on natural silk to obtain silk fibroin; soaking the silk fibroin in a sodium carbonate solution for 30-60 min, wherein the soaking temperature is controlled to be 40-50 DEG C; carrying out splitting treatment on the soaked silk fibroin by ultrasonic waves at the temperature of 48-50 DEG C, wherein ultrasonic wave treatment power is 50-60 W, the frequency is 5-8 KHz, and the treating time is 1-2 h; and removing soaking liquid, cleaning the silk fibroin in water at the temperature of 40-50 DEG C, and then cleaning the silk fibroin with cold water to obtain fibroin nanofibers. The problem that the yield of existing fibroin nanofibers is low is solved.

Owner:广西环江意桐茧丝绸有限公司

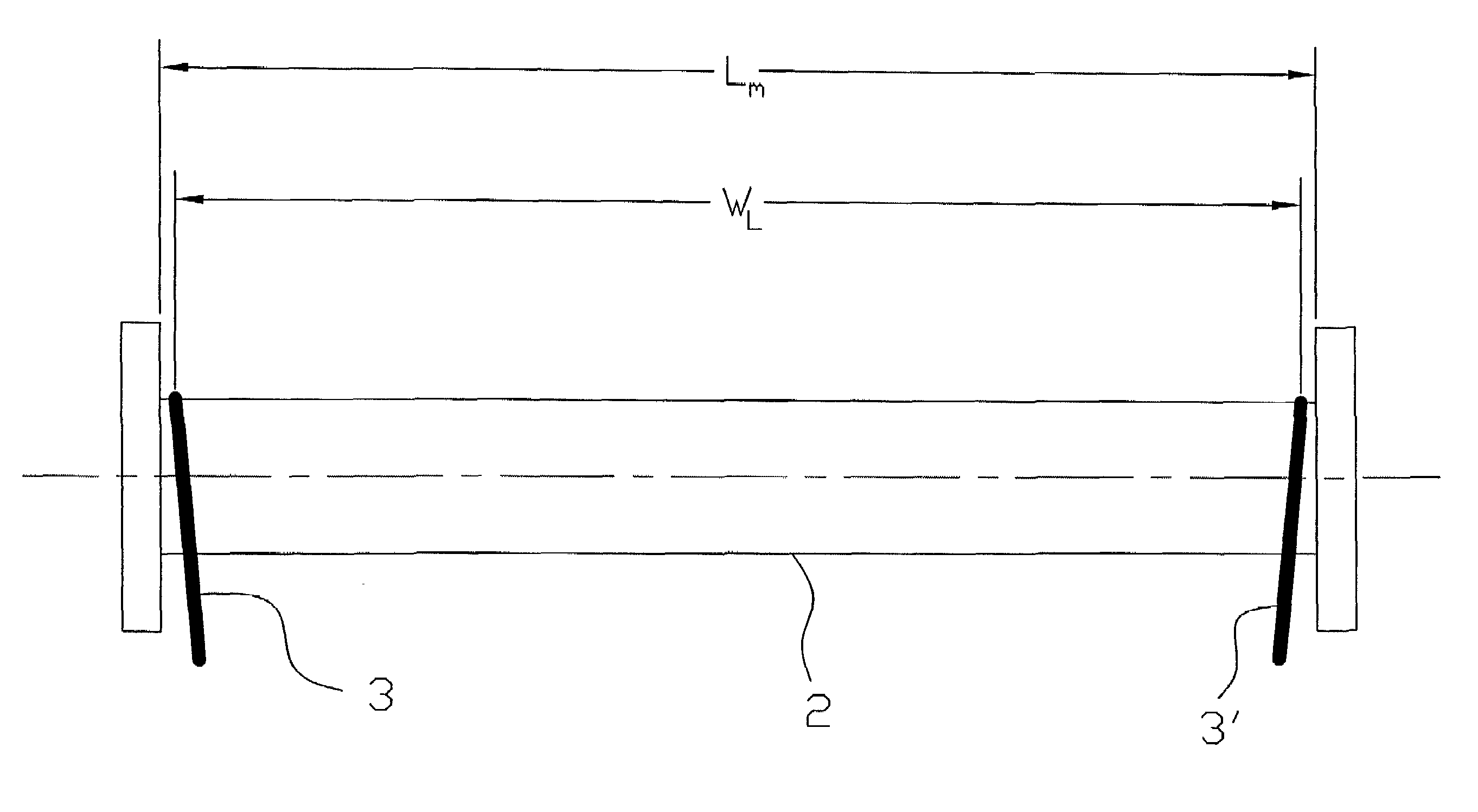

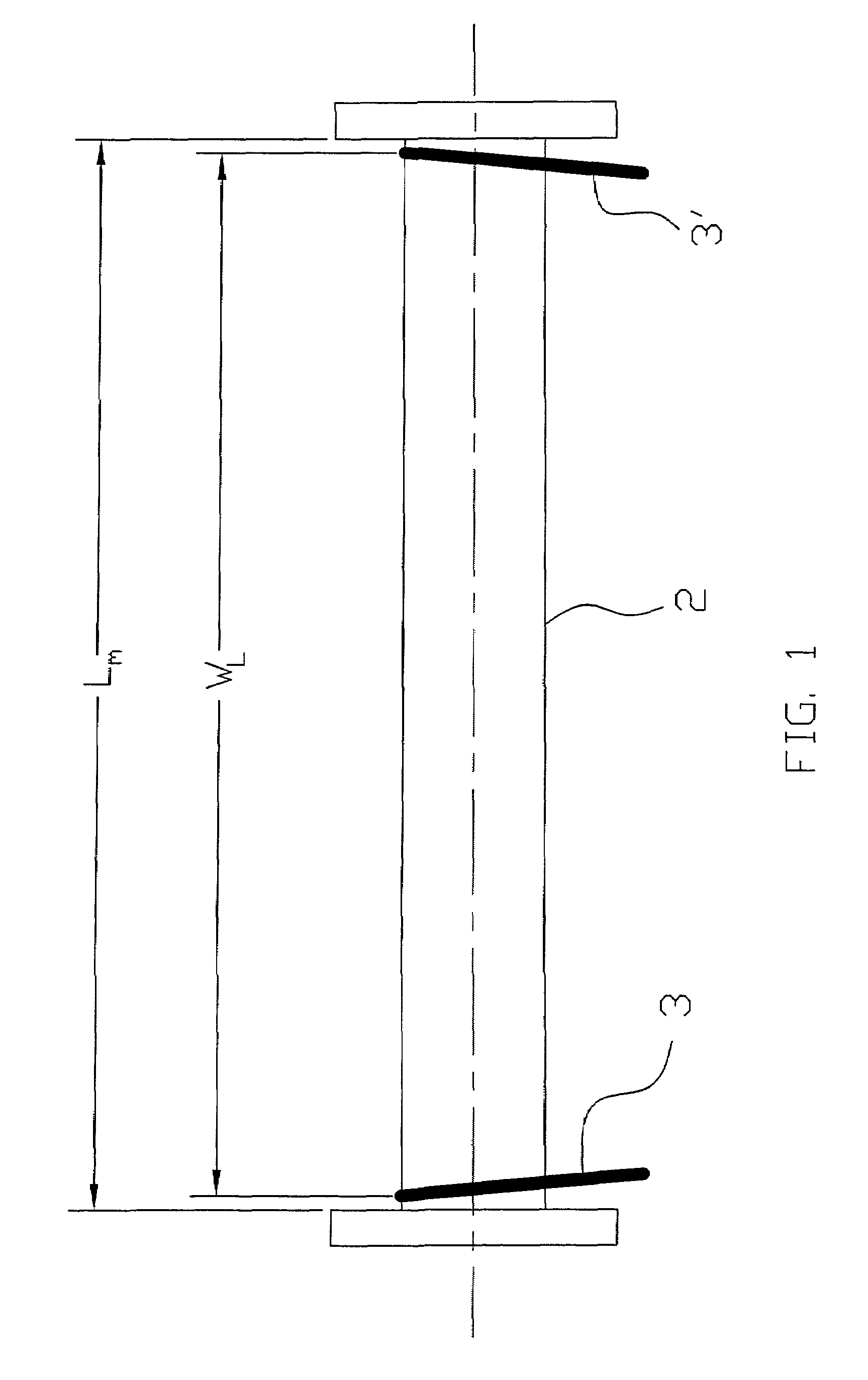

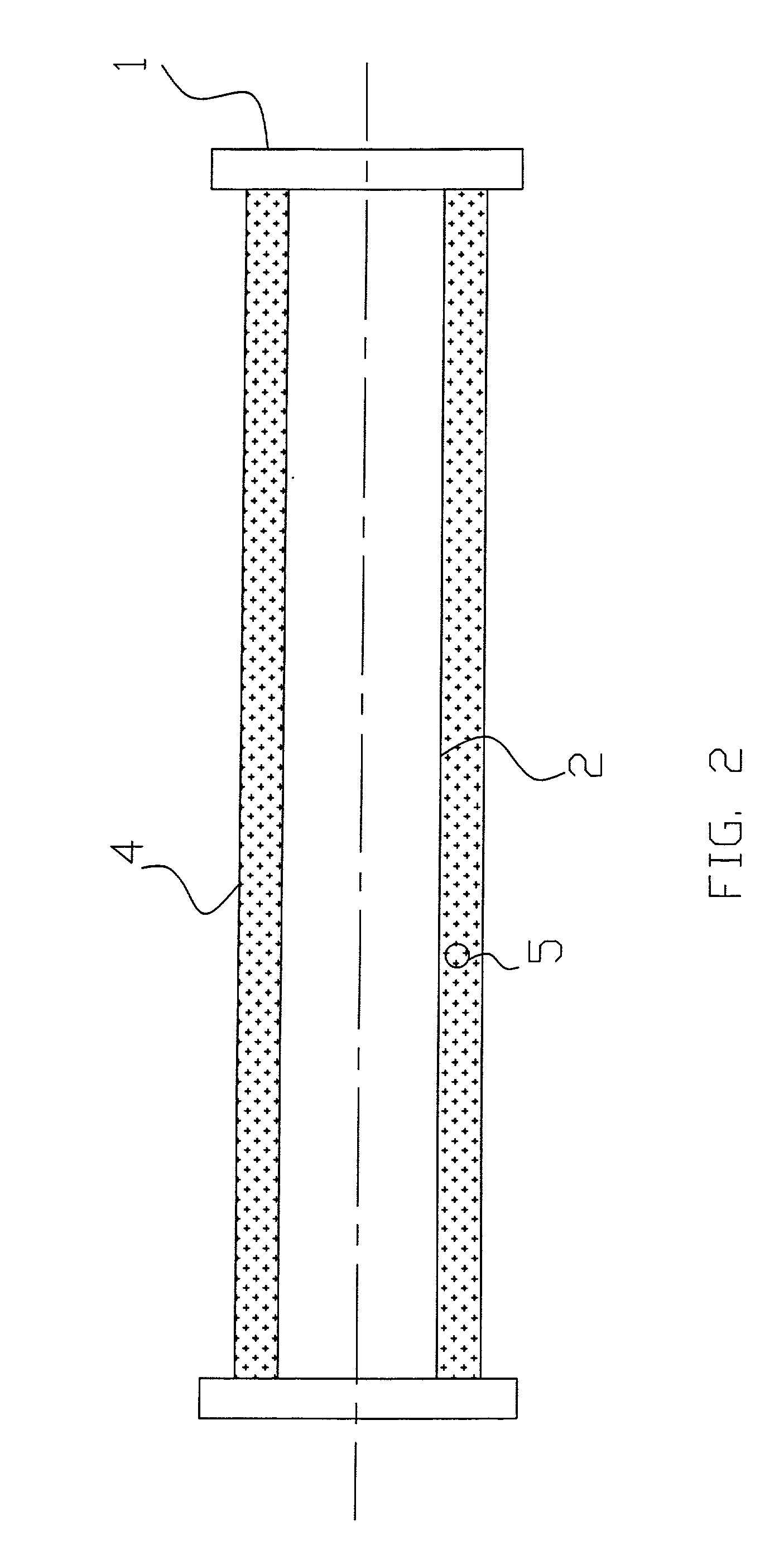

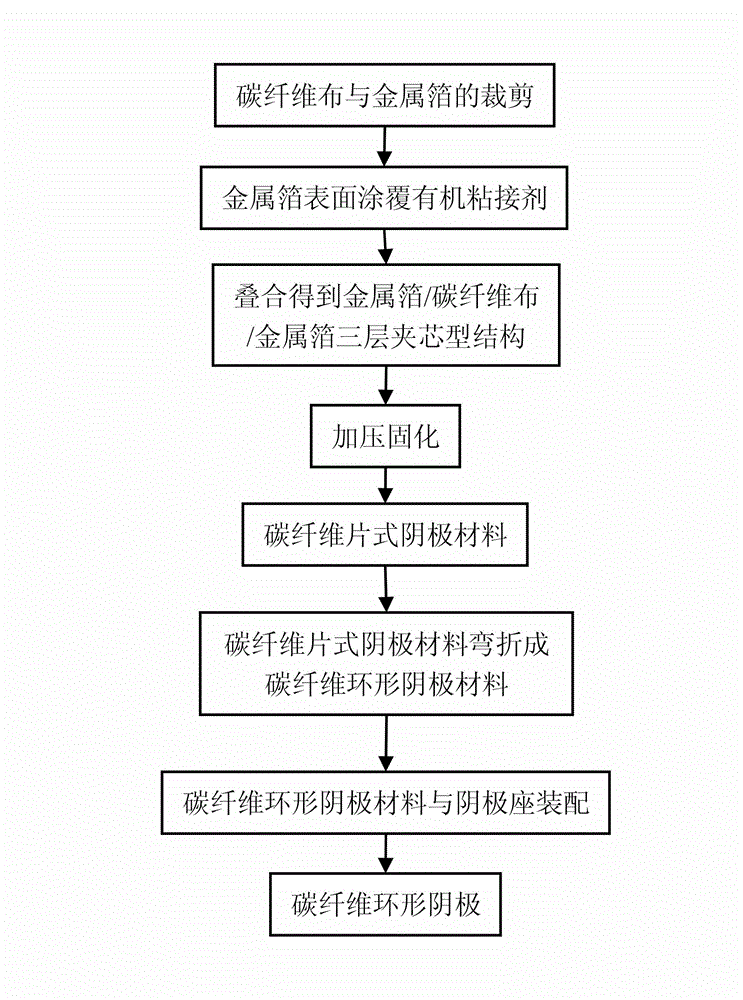

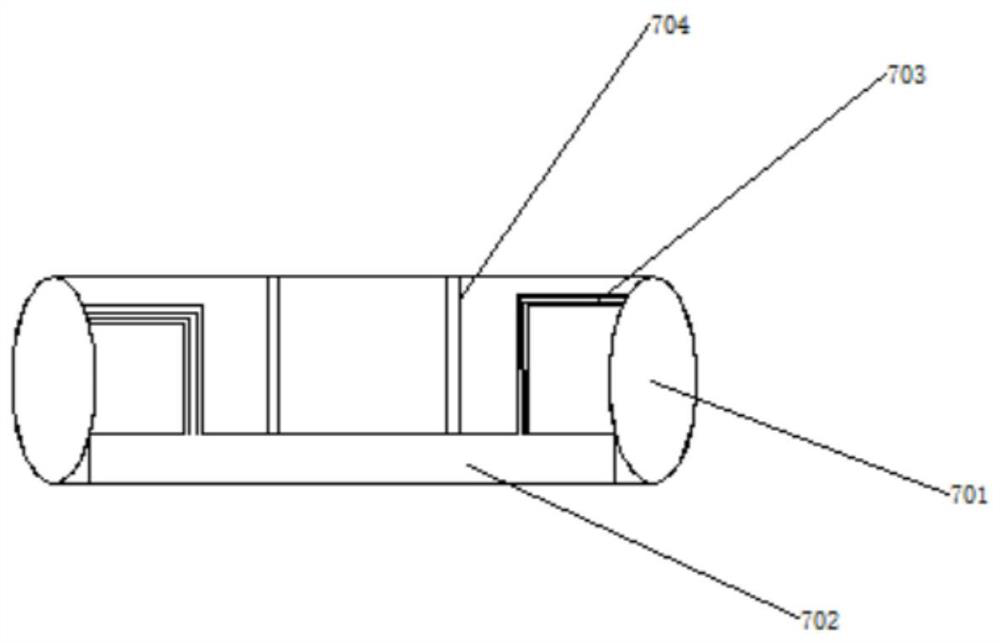

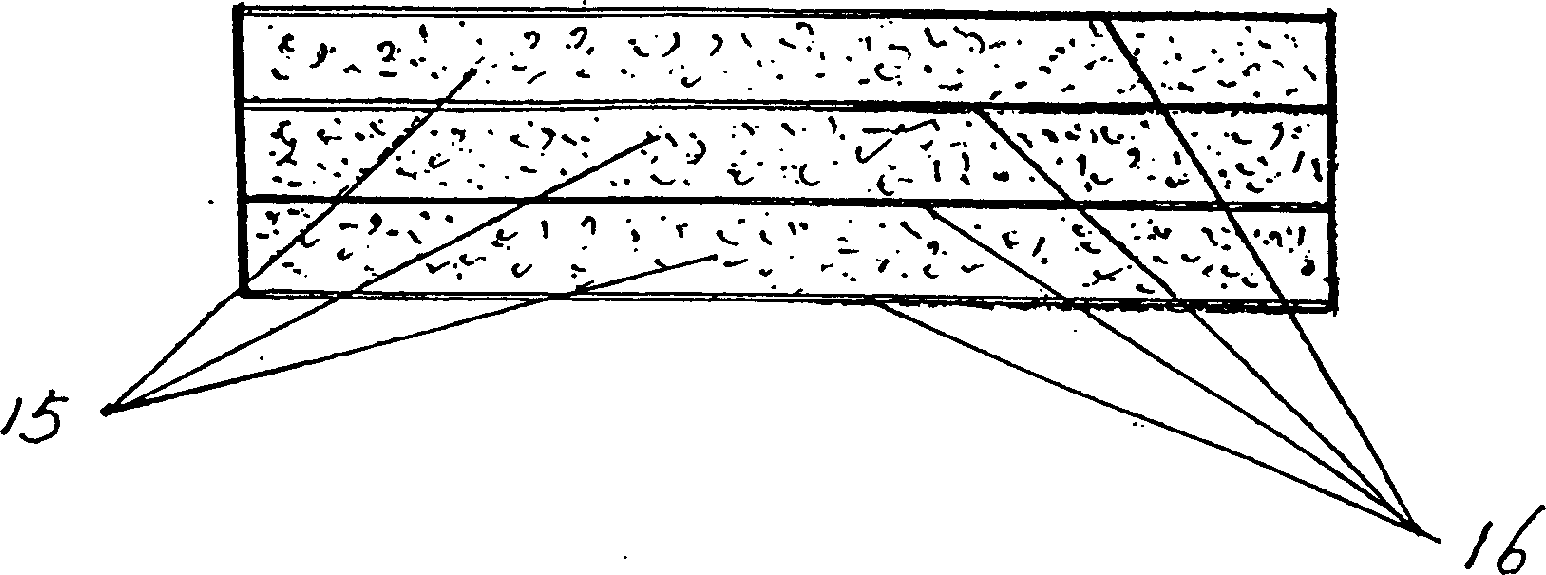

Preparation method for carbon fiber annular cathode

InactiveCN103065906AUniform distribution of fibersGuaranteed directionality and uniformityCold cathode manufactureMetal foilFiber

The invention discloses a preparation method for a carbon fiber annular cathode. The carbon fiber annular cathode is made through directly installing and clamping a fashioned carbon fiber annular cathode material on a cathode base and the fashioned carbon fiber annular cathode material is made through bending a carbon fiber sheet cathode material to an annular shape along the length direction. The carbon fiber sheet cathode material is of a three-layer composite sandwich-type structure, and the three-layer composite sandwich-type structure comprises two metal foil sheets on the outer sides and carbon fiber cloth clamped between the two metal foil sheets. By means of the preparation method for the carbon fiber annular cathode, the carbon fiber annular cathode is enabled to have strong designability, evenly distributed carbon fibers along the axial direction of an electron emission end guarantee the directionality and uniformity of emitted electrons. The preparation method for the carbon fiber annular cathode is simple in technique, low in cost, high in operability and capable of meeting emission requirements on property of different electrons.

Owner:NAT UNIV OF DEFENSE TECH

Agricultural rock wool for vegetable cultivation and seedling culture

The invention relates to agricultural rock wool for vegetable cultivation and seedling culture and belongs to the technical field of agricultural rock wool. The agricultural rock wool comprises a component A and a component B. The component A is prepared from, by weight, 90-95 parts of basalt, 3-4 parts of dolomite and 1-7 parts of silicon dioxide. The component B is prepared from, by weight, 80-90 parts of environment-friendly nontoxic resin, 300-360 parts of refined filtration water, 5-8 parts of a hydrophilic agent, 2-3 parts of a silane coupling agent and 8-10 parts of ammonium hydroxide. The agricultural rock wool has various buffering functions for soil cultivation, is very good in water absorbing quality, water retaining property and breathability, good in fiber forming effect, uniform in fiber distribution, soft and uniform in texture and beneficial to growth of the root systems of crops.

Owner:盛和深

A kind of carbon fiber mat reinforced inorganic polymer matrix composite material and preparation method thereof

The invention provides a carbon fiber felt reinforcement inorganic polymer matrix composite and a preparation method of the carbon fiber felt reinforcement inorganic polymer matrix composite, and relates to an inorganic polymer matrix composite and a preparation method of the inorganic polymer matrix composite, in particular to the carbon fiber felt reinforcement inorganic polymer matrix composite and a preparation method of the carbon fiber felt reinforcement inorganic polymer matrix composite. The problems that an existing inorganic polymer material is poor in mechanical performance and low in toughness and the operation for adding short carbon fiber is complex are solved. The product is prepared through inorganic polymer material pulp and carbon fiber felt. The inorganic polymer material pulp is prepared through potassium hydroxide, silica sol and aluminosilicate powder. The method includes the steps of firstly, preparing the inorganic polymer material pulp; secondly, washing the carbon fiber felt; thirdly, preparing a prefabricated material blank; fourthly, preparing the carbon fiber felt reinforcement inorganic polymer matrix composite. The method is simple in process, low in cost, environmentally friendly and capable of being use for large-area preparation, and the prepared composite is good in mechanical property and wider in application range.

Owner:HARBIN INST OF TECH

Raw tipping paper capable of reducing injuries and resisting oxidization and preparation method thereof

InactiveCN104005293AModerate sizingHigh tensile strengthFlexible coversWrappersFiberOxidation resistant

The invention discloses raw tipping paper capable of reducing injuries and resisting oxidization. The raw tipping paper is characterized by being prepared from following raw materials in parts by weight: 40-45 parts of cotton pulp, 52-56 parts of softwood pulp, 0.7-1 part of tocopheryl acetate, 2-3 parts of ethanol, 0.8-1.1 parts of tween-600, 0.6-0.8 part of sodium hydrogen carbonate, 0.3-0.6 part of nano-selenium, 3-5 parts of asparaguses, 2-4 parts of garcinia mangostana peels, 4-6 parts of portulaca oleracea, 0.5-0.7 part of moringa oil, 1-2 parts of sodium alginate, 1-1.4 parts of locust bean gum, 2-3 parts of cationic starch, 3-4 parts of diatomite, 1-2 parts of an auxiliary agent and suitable amount of water. According to the raw tipping paper, a glue application degree is moderate and the tensile strength is great; the raw tipping paper cannot be cracked easily and has uniformly-distributed fibers; tocopheryl acetate, moringa oil and the like which have strong oxidization-resisting components are added; the nano-selenium can be used for removing free radicals in a human body so as to reduce injuries to the human body caused by tar, carbon monoxide and the like in cigarettes.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

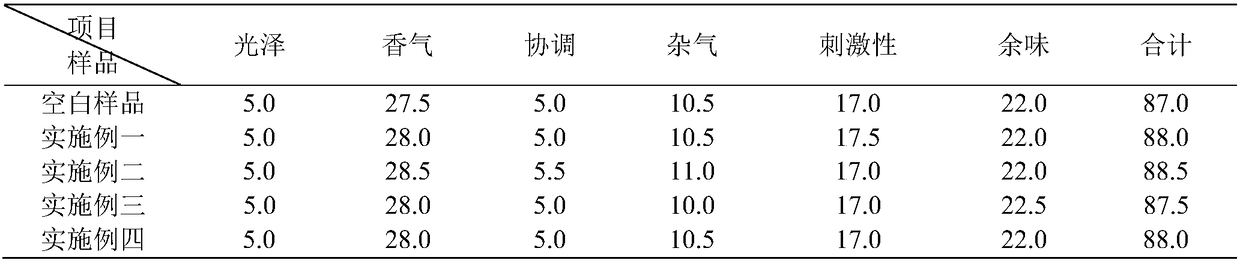

Milky sweet flavor characteristic of cordyceps for cigarette tipping paper and application and preparation method thereof

PendingCN109135923AHighlight the underlying styleCoordinating incenseTobacco smoke filtersEssential-oils/perfumesPunchingSweet flavor

The invention discloses a milky sweet flavor characteristic of cordyceps for cigarette tipping paper, which comprises the following components in parts by weight: 1-10 parts of cordyceps extract, 10-30 parts of vanillin, 1-5 parts of heliotropin, 0.1-0.5 parts of dihydrocoumarin, 10-35 parts of 95% ethanol and 20-80 parts of propylene glycol. The milky sweet cigarette tipping paper with cordycepscharacteristics is the milky sweet flavor with cordyceps characteristics added to a printing ink. The preparation method comprises the following steps: the raw materials of cordyceps sinensis are crushed, refluxed and concentrated to obtain cordyceps extract; all the components are mixed according to the volume ratio, and fully stirred; the milky sweet flavor is added into the printing ink of thecigarette tipping paper, the printing ink is printed onto the tipping paper base paper, and then the milky sweet and fragrant cigarette tipping paper with the characteristics of the cordyceps is obtained through the processes of gilding, slitting and punching. In the method, the soft and comfortable milky sweet aroma style is imparted to the cigarette, the suction quality is improved, the smoke issoft and comfortable, the taste is improved, the delicate smoke is improved, at the same time, the pharmacological and healthcare effects of the cordyceps are provided, so that the comprehensive quality and the safety of the cigarette are improved.

Owner:INNER MONGOLIA KUNMING CIGARETTE CO LTD

Preparation method of chopped carbon fiber reinforced photosensitive resin

The invention discloses a preparation method of a chopped carbon fiber reinforced photosensitive resin. The method comprises the following steps: (a) performing ball milling on the chopped carbon fiber with a small amount of nano silica, a coupling agent, an acrylate oligomer to obtain a first mixture; (b) stirring the first mixture with the acrylate oligomer, a reactive monomer, an anti-settlingaid and an anti-foaming agent to obtain a second mixture; and (c) oscillating the second mixture to prepare the photosensitive resin finished product. The method has the following beneficial effects:the chopped carbon fiber is evenly distributed in the photosensitive resin, and a photo-curable rapid-formed chopped carbon fiber reinforced photosensitive resin-based composite material is prepared;and the chopped carbon fiber has a relatively high proportion in the photosensitive resin, and the dispersion effect is good, so that a high-toughness resin product with uniform fiber distribution canbe obtained in the layer-by-layer photo-curing shaping process of the photosensitive resin, mechanical properties are good, and application prospects are broad.

Owner:宁波哈勒姆电子科技有限公司

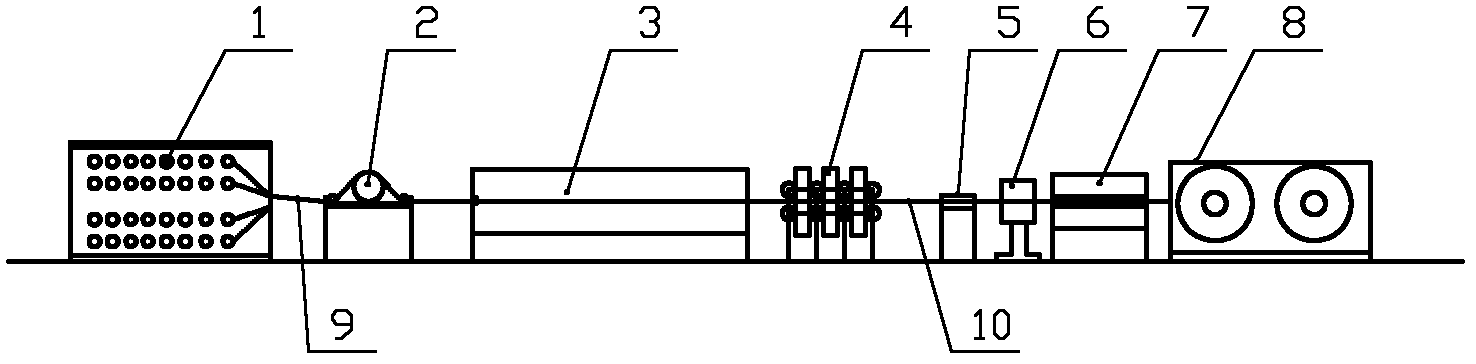

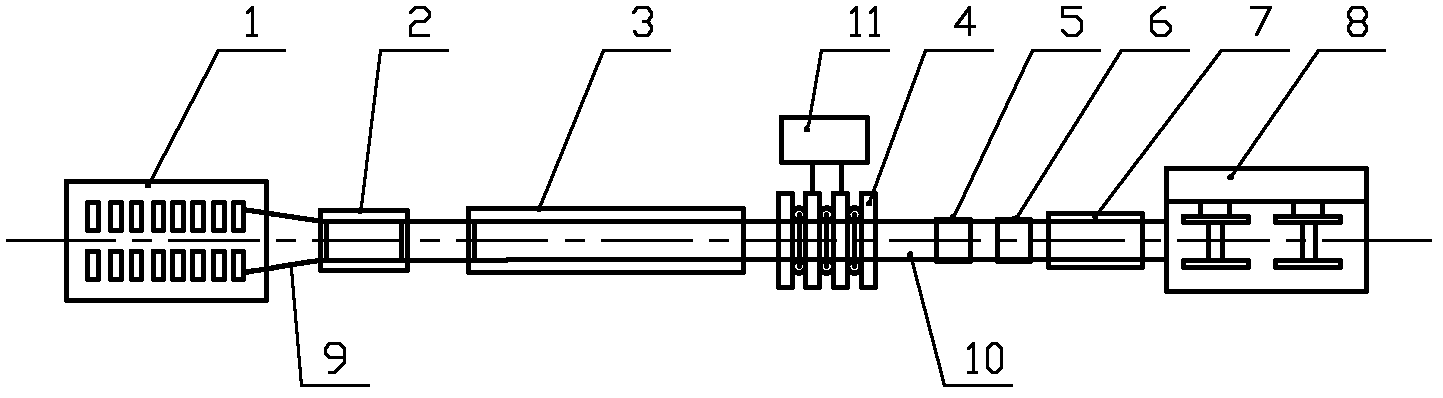

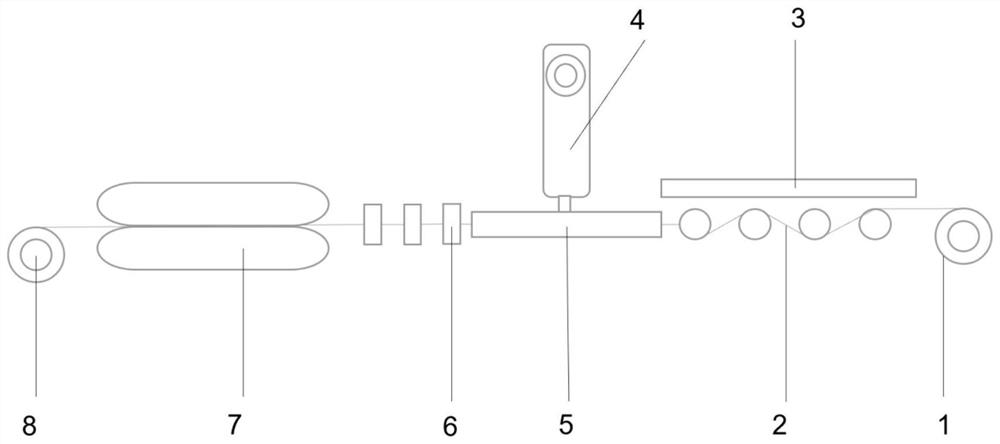

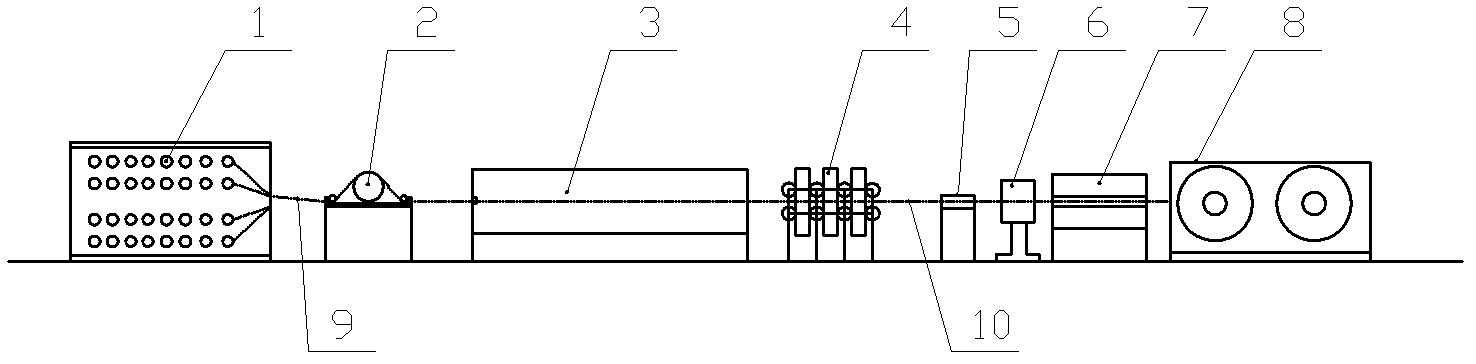

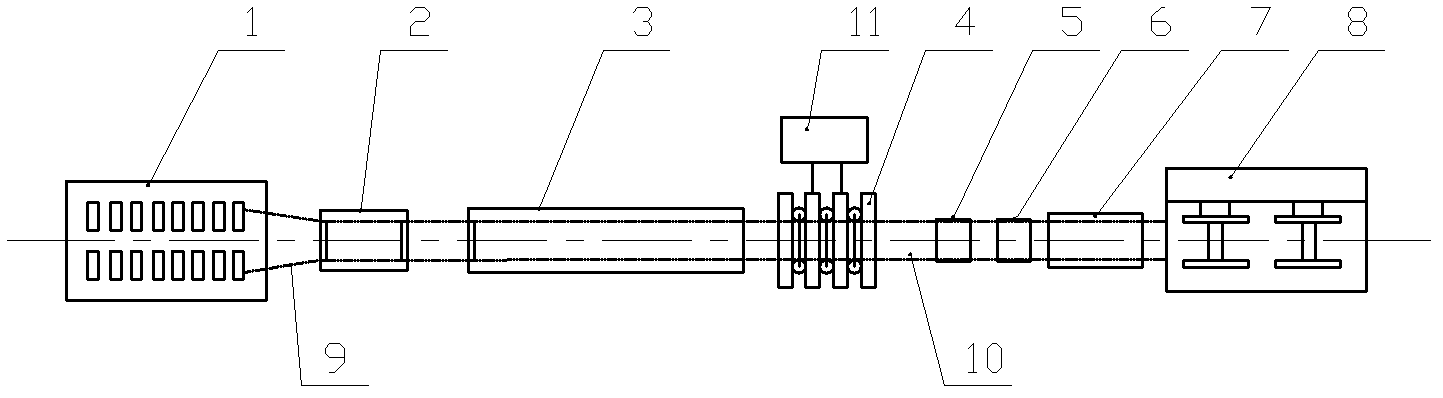

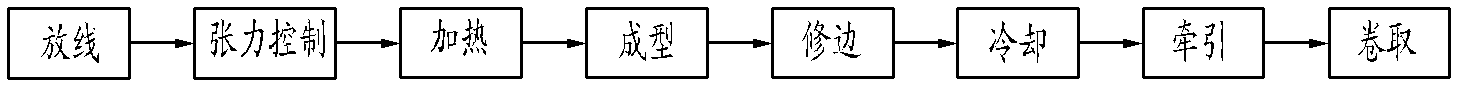

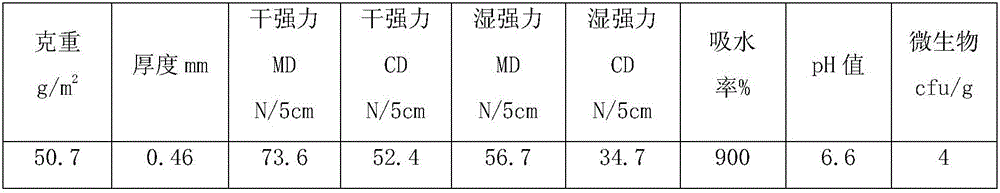

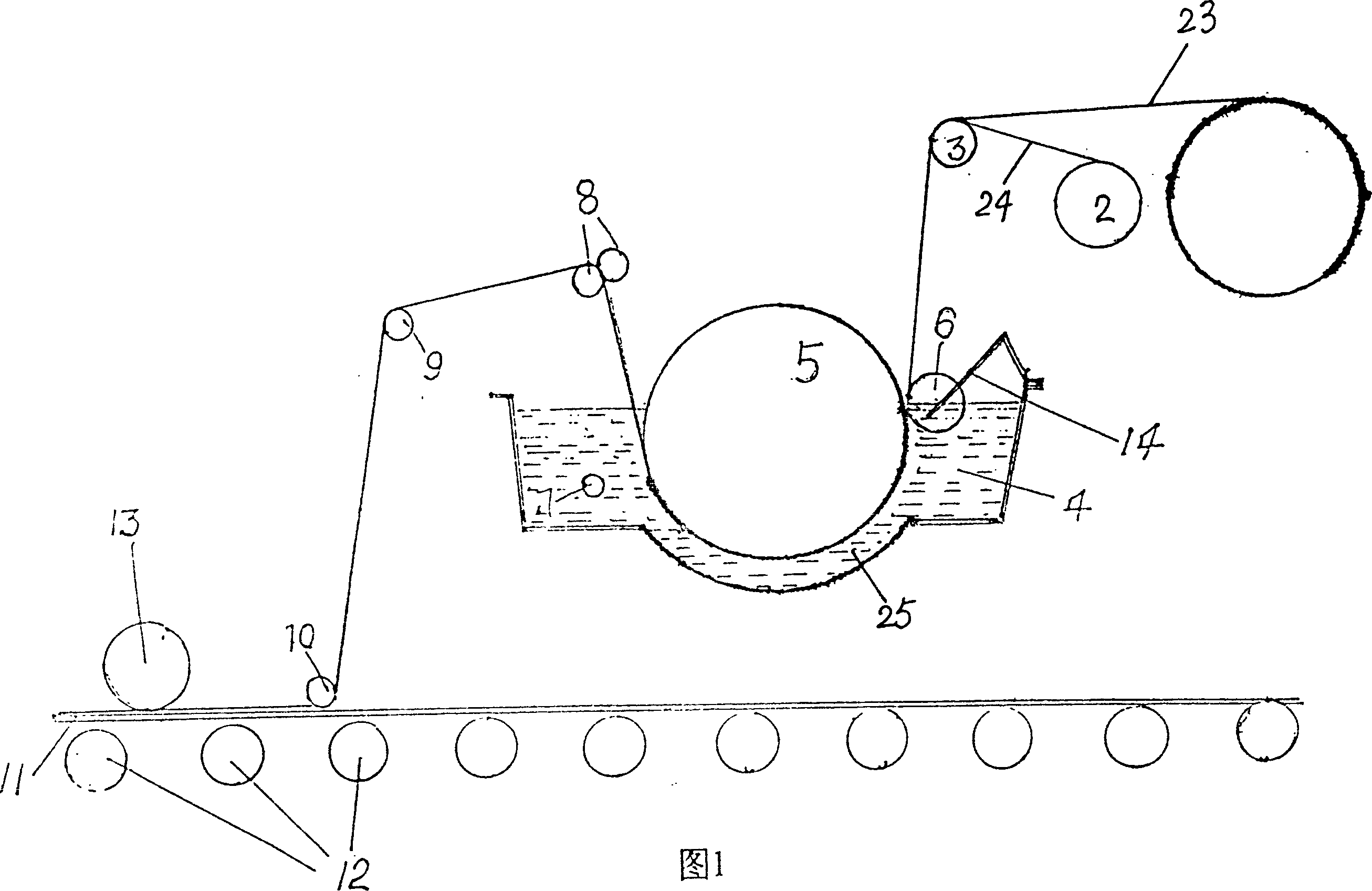

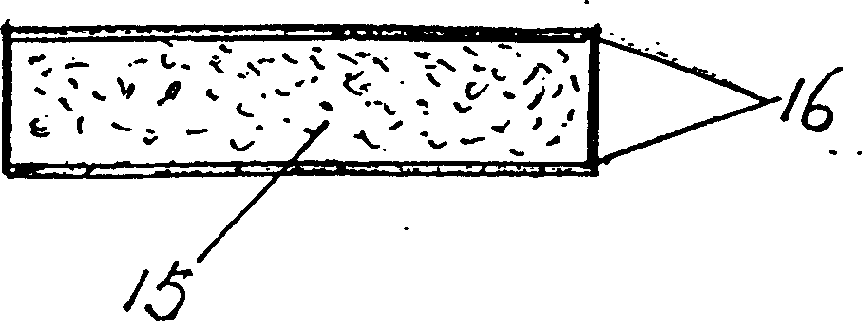

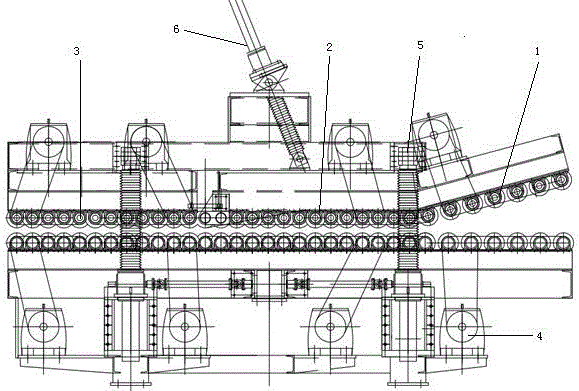

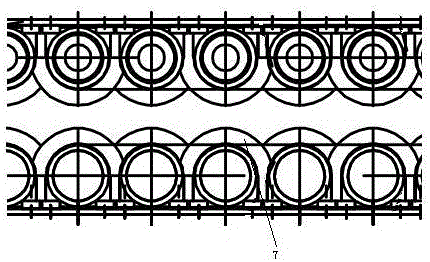

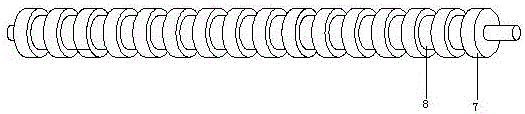

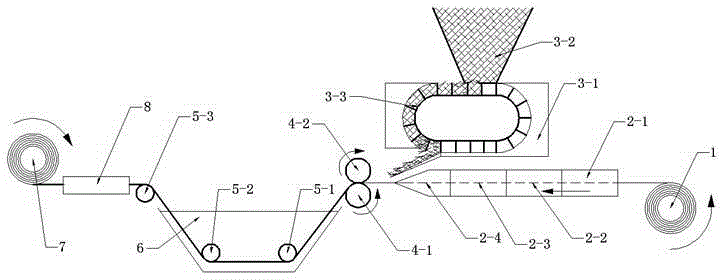

Production process and device of high-fiber ultra-thin plastic-covered reinforcing band

The invention discloses a production process of a high-fiber ultra-thin plastic-covered reinforcing band, and the plastic-covered fiber reinforcing band is prepared by heating and melting a plastic-covered fiber rope and then performing press forming. The invention further discloses a production device of the high-fiber ultra-thin plastic-covered reinforcing band, and the production device comprises a pay-off frame, a tension control device, a heating device, a forming roller group, a cold air machine, a traction machine and a winding machine which are sequentially connected in series. The device is reasonable in structure, simple in process and low in production cost, the plastic-covered fiber rope is directly adopted for preparing the reinforcing band, the fiber distribution is uniform, the fiber content is high and controllable, the production is stable and reliable, and the high-fiber ultra-thin plastic-covered reinforcing band can be continuously manufactured.

Owner:GUANGZHOU ADVANCE TECH

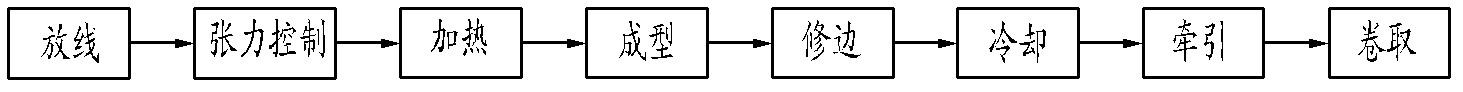

Air shower for cleaning workshop

InactiveCN111842334AImprove practicalityImprove cleanlinessDispersed particle filtrationTransportation and packagingFiberAir filter

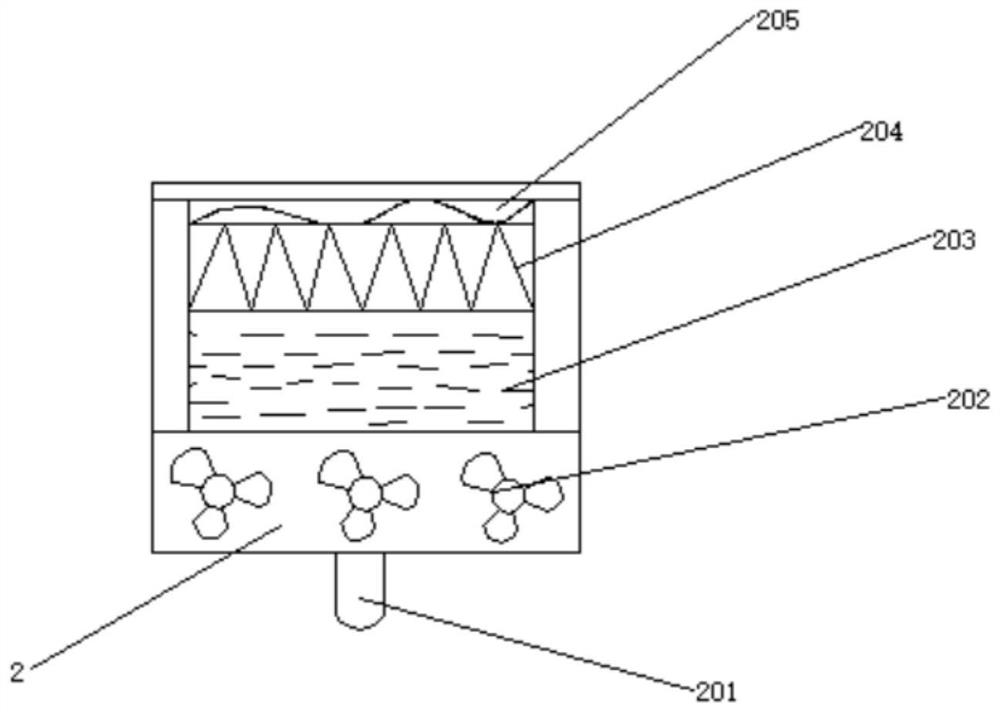

The invention discloses an air shower for cleaning a workshop. The air shower comprises an air shower device body, an efficient air filter, an ultraviolet germicidal lamp and a light sensor. A water collecting pore plate is arranged at the bottom of the air shower device body and fixedly connected with the air shower device body. An air outlet is formed in the top of the water collecting pore plate and fixedly connected with the water collecting pore plate. A fan is arranged at the top of the air outlet and fixedly connected with the air outlet. The efficient air filter is arranged so that tiny dust can be effectively filtered out, a filter layer has the characteristics of being uniform in fiber distribution, extremely large in dust holding capacity, small in resistance and the like, and thus the service life of the efficient air filter is prolonged; the filter does not need to be replaced frequently, so that people use the air shower conveniently, and the practicability of the air shower for the workshop is effectively improved; and when people enter the air shower, a large amount of bacteria and dust can be brought in, and the air shower is suitable for being used in the field ofventilation cabinets and has wide application prospects in the future.

Owner:义乌市裕晨科技有限公司

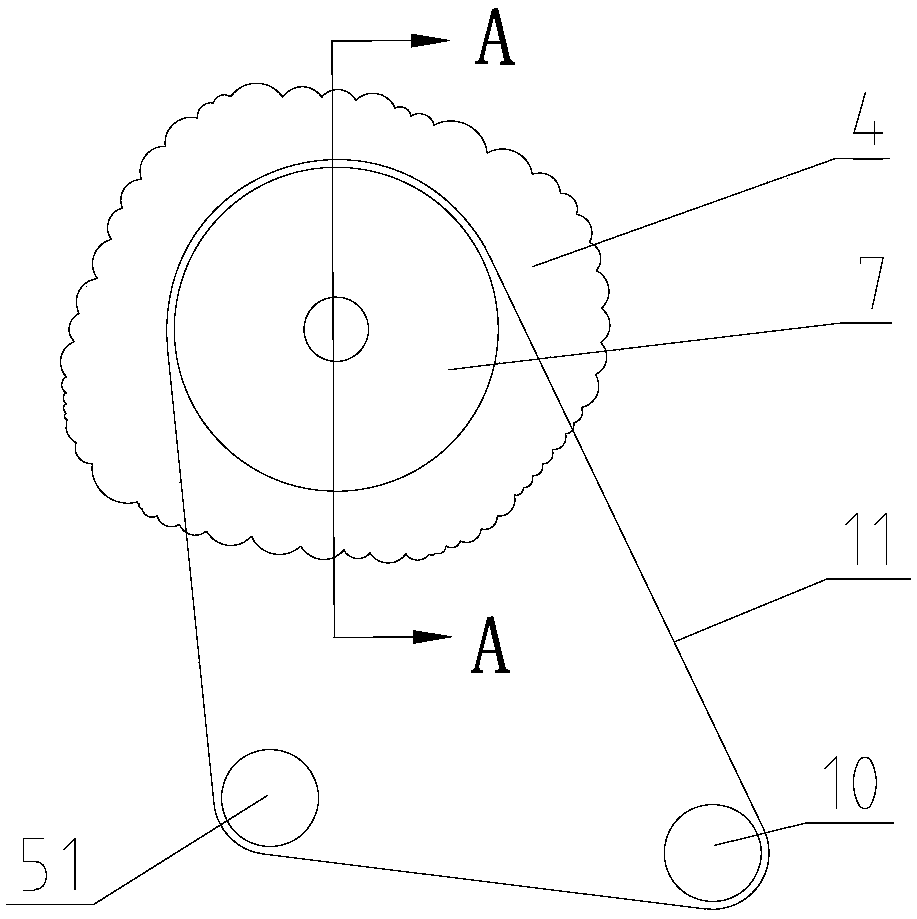

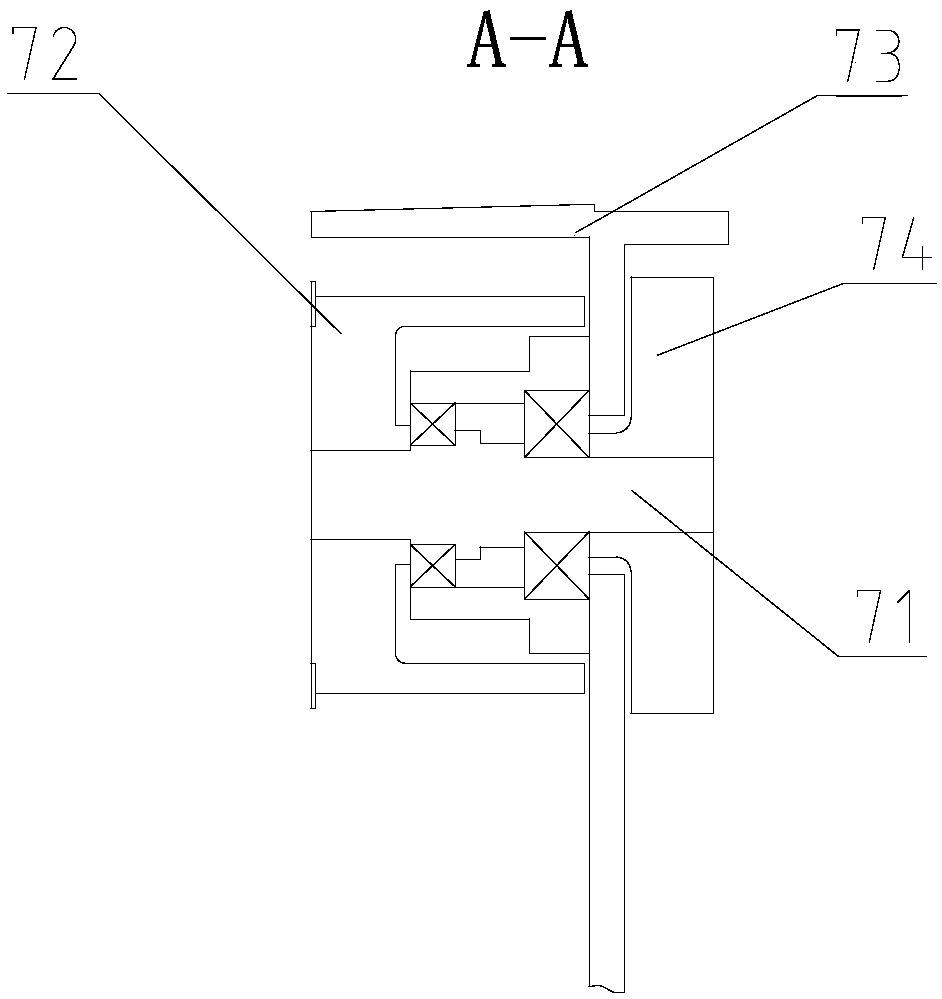

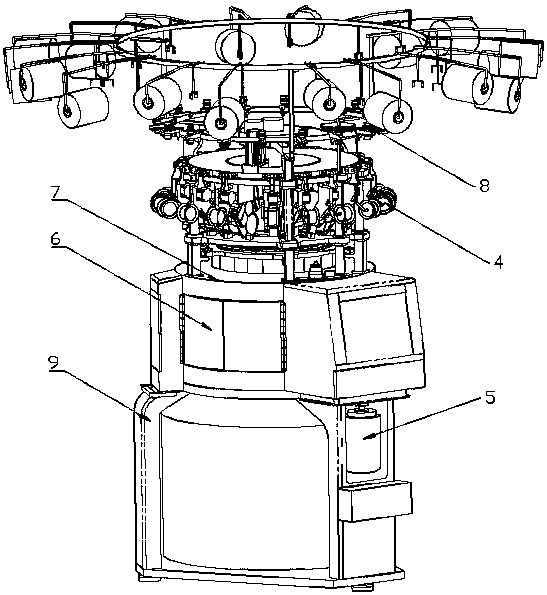

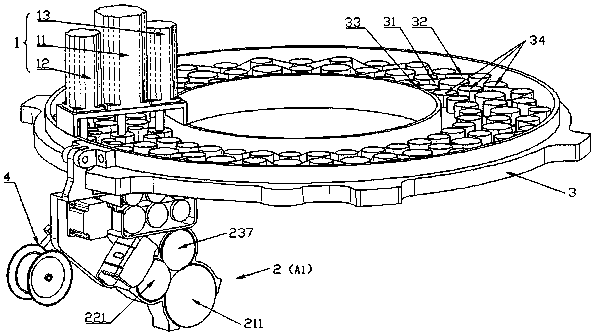

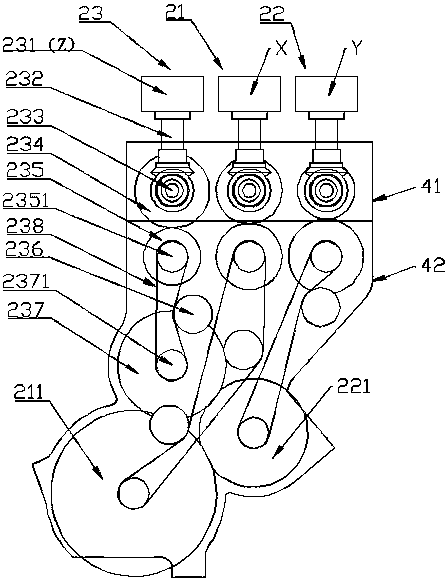

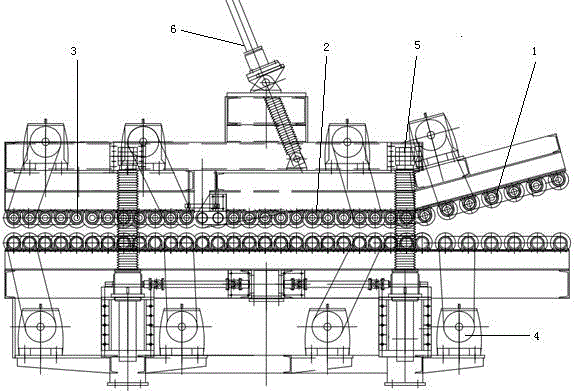

Miniature combing device used for artificial fur machine and provided with multi-speed working roll

PendingCN109295604AUniform distribution of fibersEffectively break upWeft knittingCarding machinesWoolCombing

The invention relates to a miniature combing device used for an artificial fur machine and provided with a multi-speed working roll. The technical problem is solved that an existing combing device isnot uniform in disperse fiber distribution during combing. The miniature combing device is provided with a fur feeding roller, a cylinder, a doffer and a new working roll assembly, wherein the new working roll assembly is provided with two or more roll segments, and all the roll segments can rotate at different rotating speeds. The miniature combing device can be widely applied to combing of fibers roved into wool tops into the disperse fibers.

Owner:WEIHAI PENGYUAN TEXTILE TECH

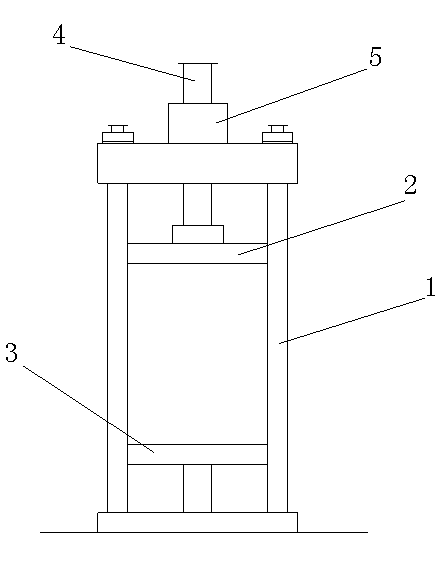

Paper sheet pressing machine with graphite press plates

The invention discloses a paper sheet pressing machine with graphite press plates. The paper sheet pressing machine comprises a bracket, a stainless steel nut, a screw rod, an upper press plate and a lower press plate; and both the upper press plate and the lower press plate are respectively of a steel steel-lining graphite structure, in each steel lining graphite structure, the inner part is full of graphite, and the outer side is coated by steel. The paper sheet pressing machine with the graphite press plates, disclosed by the invention, has corrosion resistance, ensures that the upper and lower press plates are smooth, is long in service life, and ensures that after being pressed, a wet paper sheet manufactured and sheeted in a lab is characterized by uniformly-reduced moisture, evenly-distributed fibers, and flat surface.

Owner:南通华信敷料有限公司

Preparation method of fiber-reinforced thermoplastic composite filaments for 3D printing

InactiveCN113858482AImprove mechanical propertiesUniform distribution of fibersAdditive manufacturing apparatusCoatings3d printPolymer science

The invention provides a preparation method of fiber-reinforced thermoplastic composite filaments for 3D printing, and belongs to the technical field of 3D printing. The preparation method comprises the following steps of firstly spreading carbon fiber tows, then preheating the fiber tows, performing fiber and thermoplastic resin impregnating, and finally sizing, cooling and rolling through a sizing mold to obtain the continuous fiber 3D printing filaments. By means of the preparation method, the continuous fiber composite 3D printing filaments are prepared by homogenizing the fiber tows through thermoplastic resin, the composite filaments have the advantages of high strength and high modulus, and a prepared 3D printing sample piece has the advantages of high mechanical property and the like. The method can be used for efficiently and continuously preparing the 3D printing filaments.

Owner:UNIV OF SCI & TECH BEIJING

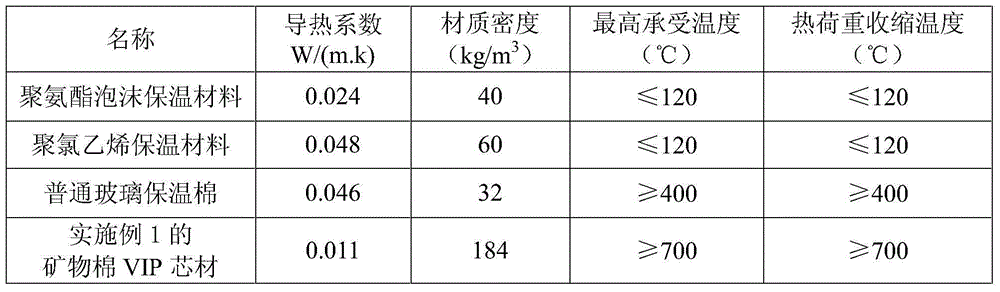

Preparation method of mineral wool vacuum insulation panel core material

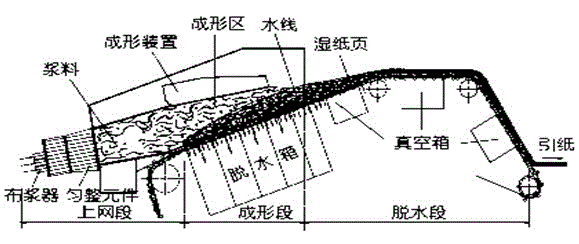

The invention discloses a novel method for preparing a mineral wool Vacuum Insulation Panel (VIP) core material. The method comprises steps of step 1, adding rock wool to a fluffer, adding sulfuric acid and water for dispersion, dispersing the rock wool to be in a diameter of less than 1.5 mu m, feeding the dispersed rock wool to a storage stirring pool, adding the sulfuric acid and the water, and obtaining slurry of the potential of hydrogen (PH) value from 3.5 to 4.5 and of 3-4% of mass concentration; step 2, diluting the slurry obtained in the step 1 to be in 0.2-0.4% of mass concentration, removing slag, conveying the obtained slurry to an inclined net former for wet forming, obtaining wet paper, and conducting suction dehydration for the wet paper on the condition of 0.01-0.05 Mpa of vacuum degree; and step 3, drying the wet paper obtained in the step 2 at the temperature from 200 DEG C to 300 DEG C. The VIP core material prepared through the method is low in thermal coefficient and cost, uniform in fiber distribution and neat.

Owner:宣汉正原微玻纤有限公司

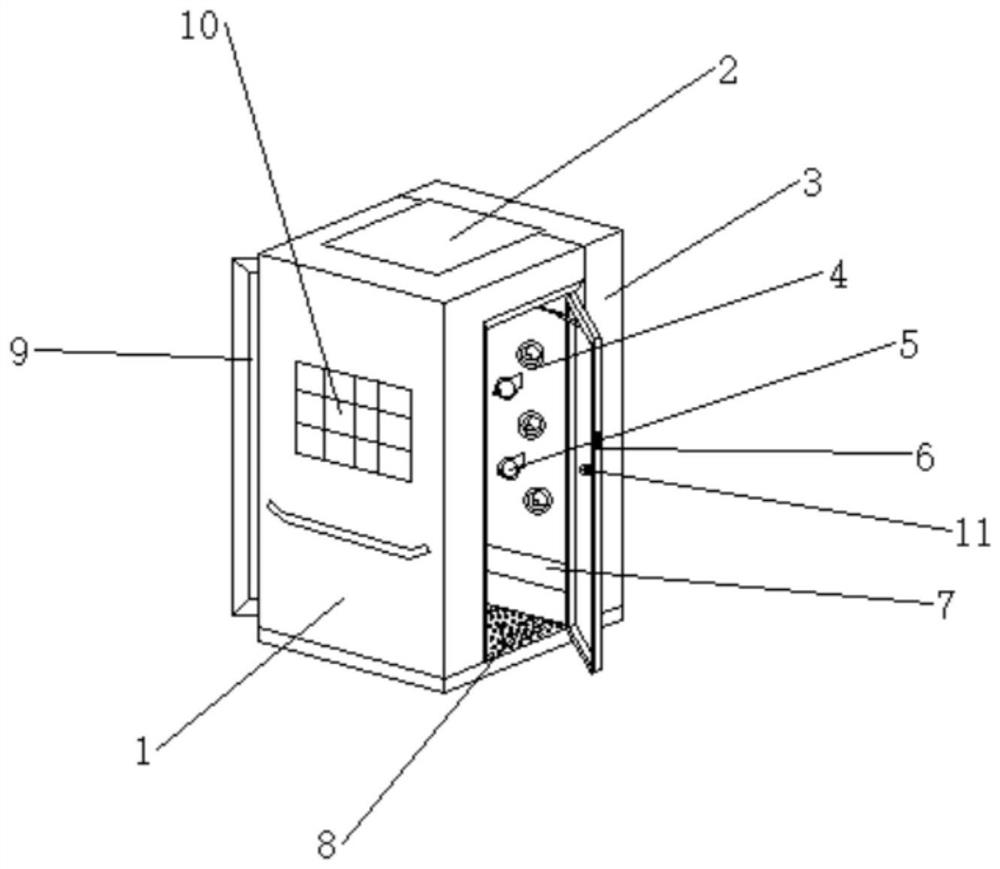

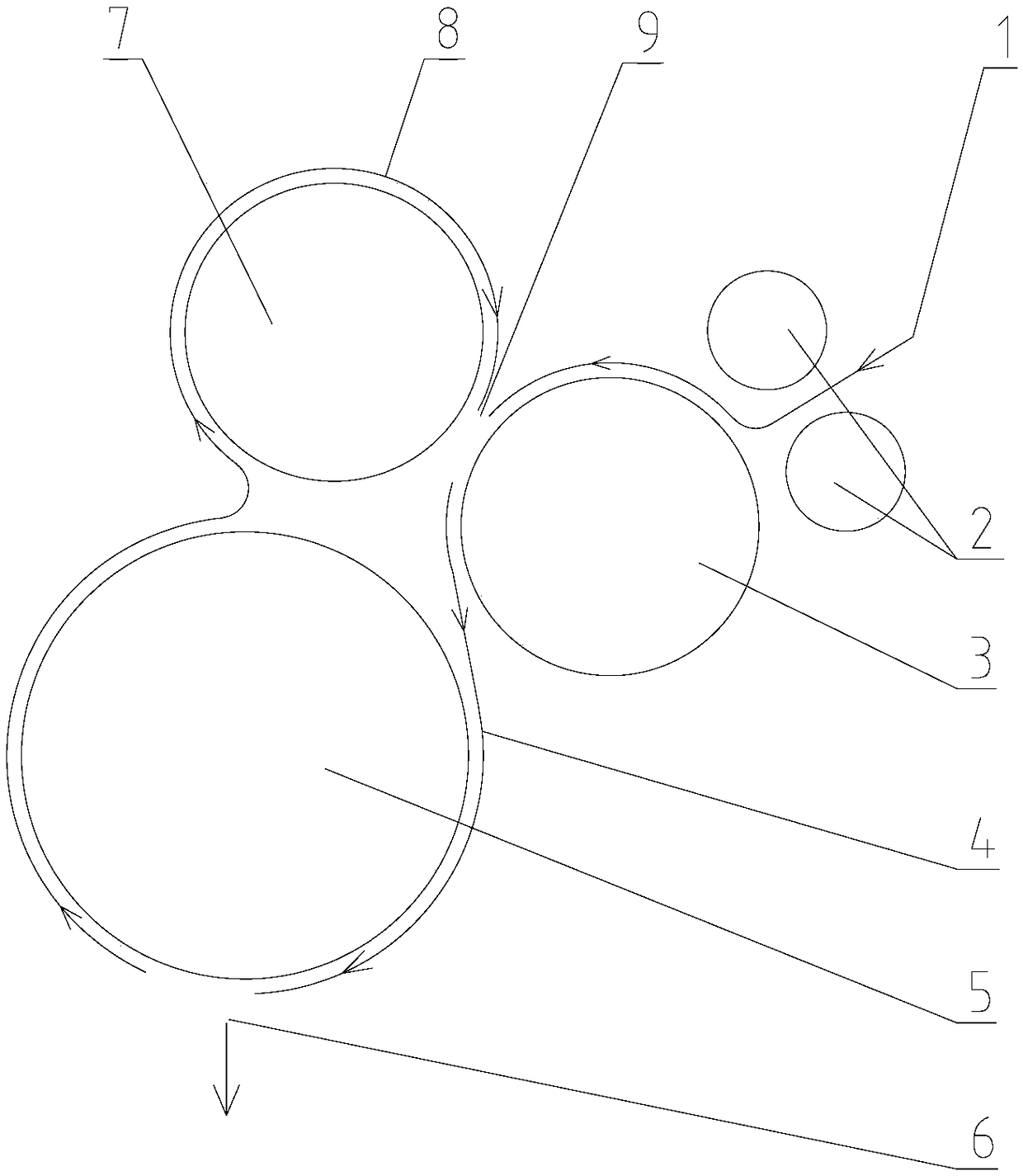

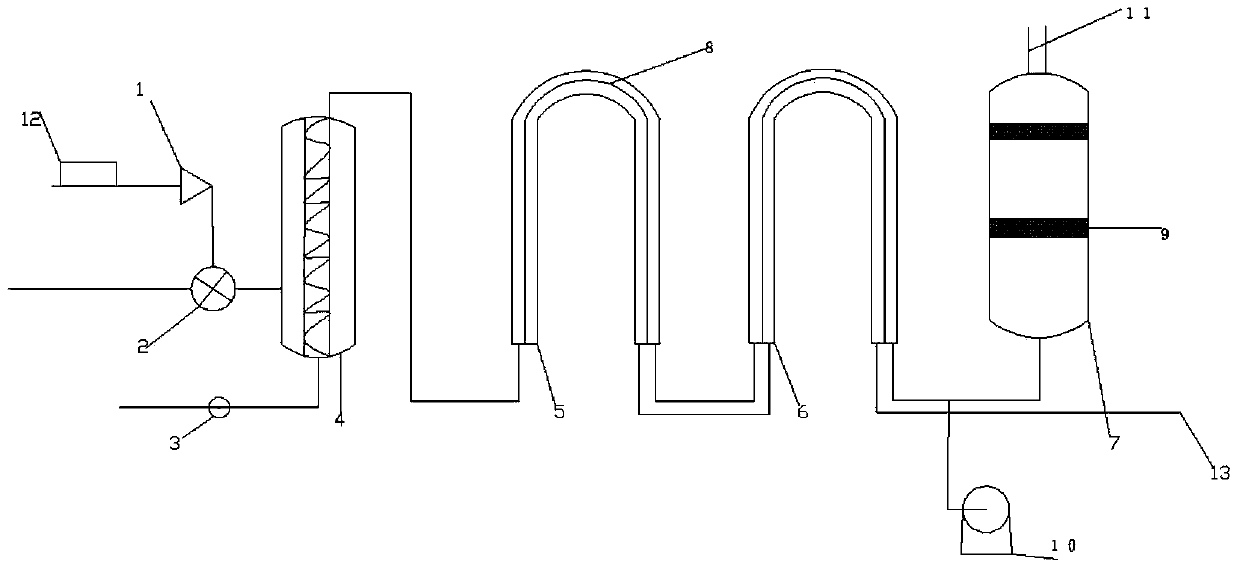

Device for processing high-concentration ammonia nitrogen in rare-earth wastewater by using surfactant

InactiveCN104211247AUniform distribution of fibersImprove textureMultistage water/sewage treatmentHigh concentrationRare earth

The invention relates to a device for processing high-concentration ammonia nitrogen in a rare-earth wastewater by using a surfactant, and belongs to the field of sewage treatment. The device comprises an air compressor (1), a high-pressure pump (2), a high-pressure steam pump (3), a heat exchanger (4), a first-stage denitrification device (5), a second-stage denitrification device (6), a catalytic reduction pot (7), quartz glass fiber membranes (8), a heavy metal catalyst (9), a draught fan (10), an air outlet (11), a spray tank (12) and a wastewater outlet (13); the air compressor (1), the high-pressure pump (2), the high-pressure steam pump (3) and the heat exchanger (4) are connected with one another; and the quartz glass fiber membranes are arranged inside the first-stage denitrification device (5) and the second-stage denitrification device (6). The quartz glass fiber membranes adopt hollow fiber membrane elements, the fibers are evenly distributed, and are fine and smooth in grain and strong in hydrophilicity, the device is simple to operate, and high in removal rate, the production cost is saved, the ammonia nitrogen removal rate of the high-concentration ammonia nitrogen wastewater which is processed by the device reaches over 99.9%, and the environmental pollution is greatly relieved.

Owner:CHANGZHOU UNIV

Novel artificial fur weaving machine

The invention provides a novel artificial fur weaving machine which comprises a machine body, a yarn conveyer, a combing device, a weaving device, a cloth coiling device and a main control motor, wherein the yarn conveyer, the weaving device and the cloth coiling device are driven by the main control motor to operate; the combing device comprises a driving platform and a plurality of combing headswhich are connected with the driving platform; each combing head comprises a plurality of working wheel groups; each group of the working wheel groups of same functions are connected with one power device and are driven by the power device to move; the power devices are independent from one another. According to the novel artificial fur weaving machine provided by the invention, structures and transmission modes inside the combing heads can be changed, the transmission speed ratios of the working wheels can be independently adjusted, linear adjustment can be achieved, then weaving at an optimal speed ratio can be implemented according to fur strips of different types, different specifications and different fiber lengths, the adaptability to different raw materials can be improved, and theproblem of ghosting images caused by uneven fiber distribution can be finally solved.

Owner:威海市创为针织机械有限公司

Production process and device of high-fiber ultra-thin plastic-covered reinforcing band

The invention discloses a production process of a high-fiber ultra-thin plastic-covered reinforcing band, and the plastic-covered fiber reinforcing band is prepared by heating and melting a plastic-covered fiber rope and then performing press forming. The invention further discloses a production device of the high-fiber ultra-thin plastic-covered reinforcing band, and the production device comprises a pay-off frame, a tension control device, a heating device, a forming roller group, a cold air machine, a traction machine and a winding machine which are sequentially connected in series. The device is reasonable in structure, simple in process and low in production cost, the plastic-covered fiber rope is directly adopted for preparing the reinforcing band, the fiber distribution is uniform, the fiber content is high and controllable, the production is stable and reliable, and the high-fiber ultra-thin plastic-covered reinforcing band can be continuously manufactured.

Owner:GUANGZHOU ADVANCE TECH

Corn fiber ecological mask spunlaced material and preparation method thereof

InactiveCN106245223AGood hygroscopicityImprove breathabilityNon-woven fabricsNonwoven fabricFibrous corn

The invention relates to a corn fiber ecological mask spunlaced material and a preparation method thereof, belonging to the technical field of non-woven materials. The corn fiber ecological mask spunlaced material is characterized by being prepared from 100% corn fibers, wherein the specification of the corn fibers is 12mm*1.6D. The corn fiber ecological mask spunlaced material is soft and smooth, has good hygroscopicity and breathability, good fitness with the skin, high strength and small thickness, is fully degradable and is uniform in fiber distribution. The preparation method of the corn fiber ecological mask spunlaced material has the advantages of short process flow, low defective rate and high production efficiency.

Owner:绍兴柯桥天圣无纺有限公司

Composite wall plate with waste textile fibre reinforced concrete side surface and its producing method

InactiveCN1173105CImproves breakage resistanceUniform distribution of fibersLayered productsBuilding componentsTextile fiberGlass fiber

The composite wall plate has one middle layer of porous plastic, rock wool, honeycomb structure, foamed concrete or other heat insulating and sound isolating material and waste fiber reinforced concrete surface layers combined firmly via vibration and rolling. The present invention features that the surface layer is formed by soaking felt of waste textile fiber and at least one outer alkali resisting glass fiber cloth with cement slurry. During soaking, the felt and glass fiber cloth is extruded to eliminate air and the cement slurry is vibrated with a inserted vibrating pump. The wall plate has strong bending resistance, no rust and low cost, and the present invention solves the waste fabric disposing problem.

Owner:龚卓夫

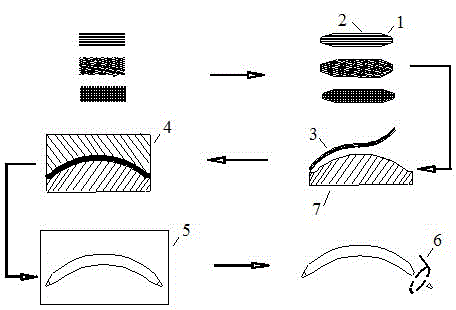

Method for manufacturing fiber reinforced plastic plate type spring

ActiveCN102785372BHigh strengthIntensity controllableCoatingsHeat stabilityUltimate tensile strength

The invention relates to a method for manufacturing a fiber reinforced plastic plate type spring. The method comprises the following steps of prepreg preparing, clipping, layering, heat forming and post-processing. The implementation process includes clipping a unidirectional fiber prepreg and a bidirectional fiber prepreg into needed shapes, and attaching the clipped unidirectional fiber prepreg and the bidirectional fiber prepreg on a die to be manufactured into a preformed body according to a set layering mode. The preformed body can be one layered through one or more of the unidirectional fiber prepreg and the bidirectional fiber prepreg. The preformed body can be manufactured into a needed composite material plate type spring through lamination forming, post heat treatment and mechanical processing. Heat forming of plate springs is controlled through temperature, time and pressure. The composite material plate type spring has the advantages of being high in strength, light in quality, fatigue resistant, good in heat stability and small in deformation.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

A method for manufacturing a seedbed

InactiveCN104529176BImprove mechanical propertiesGood heavy metal contentGlass making apparatusGrowth substratesFiberMagma

The invention discloses a preparation method of a novel seedling bed. The preparation method comprises the following steps: preparing a mixed raw material from the following raw materials in parts by weight: 25-35 parts of ferrotitanium stone, 35-45 parts of basalt, 5-8 parts of limestone, 3-5 parts of slag, 20-30 parts of coke and 3-5 parts of auxiliary materials; feeding the mixed raw material to a cupola furnace, fusing into magma, forming fibers, collecting cotton, and laying cotton; pressing on a three-dimensional cotton presser; and solidifying and trimming, so as to prepare the novel seedling bed. The novel seedling bed prepared by adopting the method has black to black brown color similar to the color of soil, and has a good mechanical property.

Owner:GUANGDE SKD ROCKWOOL MFG

Tungsten-based plasma facing material and preparation method thereof

The invention discloses a tungsten-based plasma facing material and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing tungsten powder and tungsten fiber by a powder mixing method which does not damage the tungsten fiber; and sintering to prepare a bulk fiber toughened tungsten-based material by a hot isostatic pressing process. The tungsten powder is one of pure tungsten powder, tungsten-rhenium alloy powder, and tungsten powder doped with carbide and oxide; and the tungsten fiber is a pure tungsten wire, a tungsten-rhenium alloy wire or the like. The tungsten-based plasma facing material has the advantages of high thermal conductivity, high melting point temperature, low sputtering yield, low hydrogen isotope retention and low vapor pressure, as well as low cost and greater toughness.

Owner:INST OF PLASMA PHYSICS CHINESE ACAD OF SCI

A kind of tipping paper base paper with heat-clearing and alcohol-relieving functions and preparation method thereof

ActiveCN104005254BHas health benefitsLarge adsorption capacityCoatings with pigmentsPulp beating methodsFiberAlcohol poisonings

The invention discloses a tipping paper base paper with functions of clearing away heat and relieving alcohol, which is characterized in that it is prepared from the following raw materials in parts by weight: 3-4 parts by weight of ashweed, 1-2 parts of nigella seed oil, and 41 parts by weight of pomegranate pulp -46, cork pulp 52-55, pterygium 2-4, mannitol 1-1.5, Hovenia dulcis 1-2, taurine 0.5-0.7, activated clay 3-4, iron oxide yellow 1-2, Carboresin 2-3, Ammonium Bicarbonate 1-1.6, Calcium Peroxide 2-2.5, Calcium Propionate 1-2, Auxiliary 1-2, appropriate amount of water; the present invention adds Pterocephala clearing heat and detoxifying, Hovenia dulcis Alcohol poisoning, the production of tipping paper base paper has certain health effects, suitable for social use, adding additives, not only can increase the amount of tar adsorption, but also has a natural fragrance, fresh and pleasant, reducing bad breath, and the fiber distribution of the product of the present invention Uniform, small fluctuations in thickness, tightness, air permeability and other indicators, easy to print.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

An extrusion system device for processing reinforced materials

The invention provides an extrusion system device for machining reinforced materials. By means of the extrusion system device, a machined product is good in isotonicity, the liquidity of the product in the die pressing process is good, and the load of a threaded rod is reduced. The extruder system device for producing the reinforced materials comprises a twin-screw extruder; the twin-screw extruder comprises a hopper-shaped feeding port; continuous filaments are from a continuous filament supporting rack; part of the continuous filaments enter a fixed-length cutting machine for being subjected to fixed-length cutting, the other part of the continuous filaments are heated through heating equipment, and then the heated continuous filaments and the fixed-length cut filaments enter the twin-screw extruder through the hopper-shaped feeding port to be mixed with and dispersed with thermoplastics polymers. The continuous filaments entering the twin-screw extruder are twisted to broken and dispersed through the threaded rod inside the twin-screw extruder. The continuous filaments twine with one another and are overturned and bent inside the twin-screw extruder, the isotropy of the product is guaranteed, the flatness is good, the liquidity of the product in the die pressing process is increased through the fixed-length cut filaments, the filaments are distributed more uniformly in the product, and the bearing capacity of the produced product is higher.

Owner:ZHENGZHOU LINGYU NEW MATERIALS

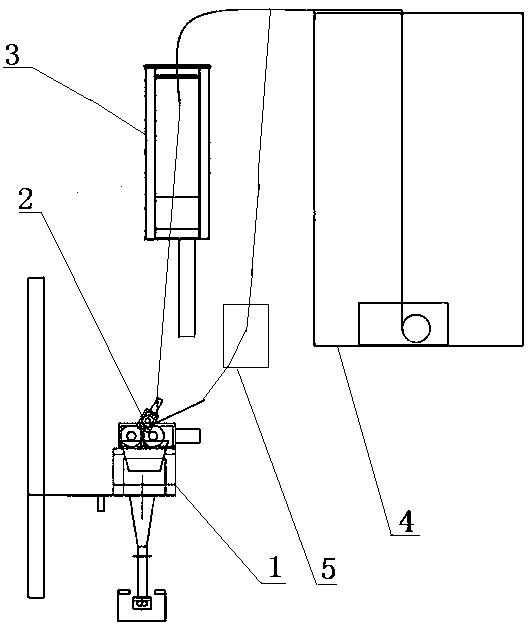

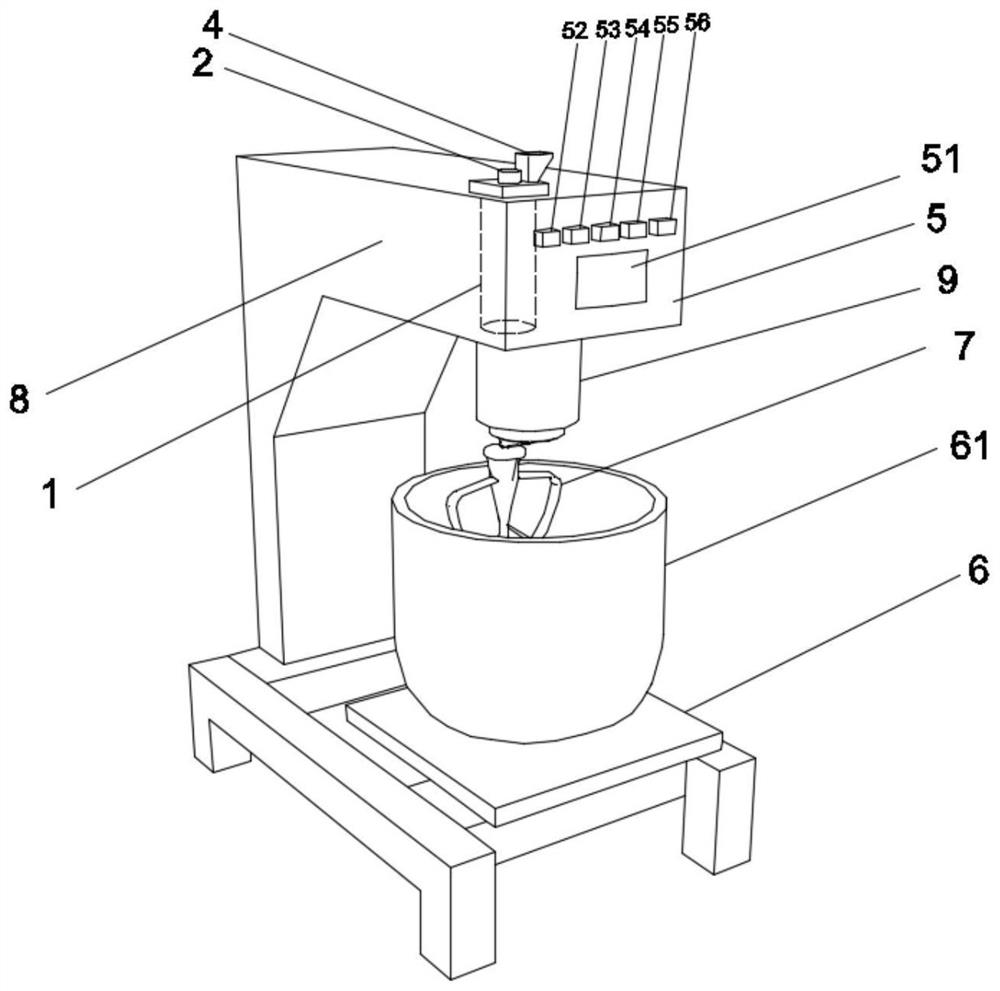

Asphalt mixture stirring device capable of automatically feeding fibers

PendingCN113215923AUniform distribution of fibersLittle variabilityRoads maintainencePitch blendeAsphalt

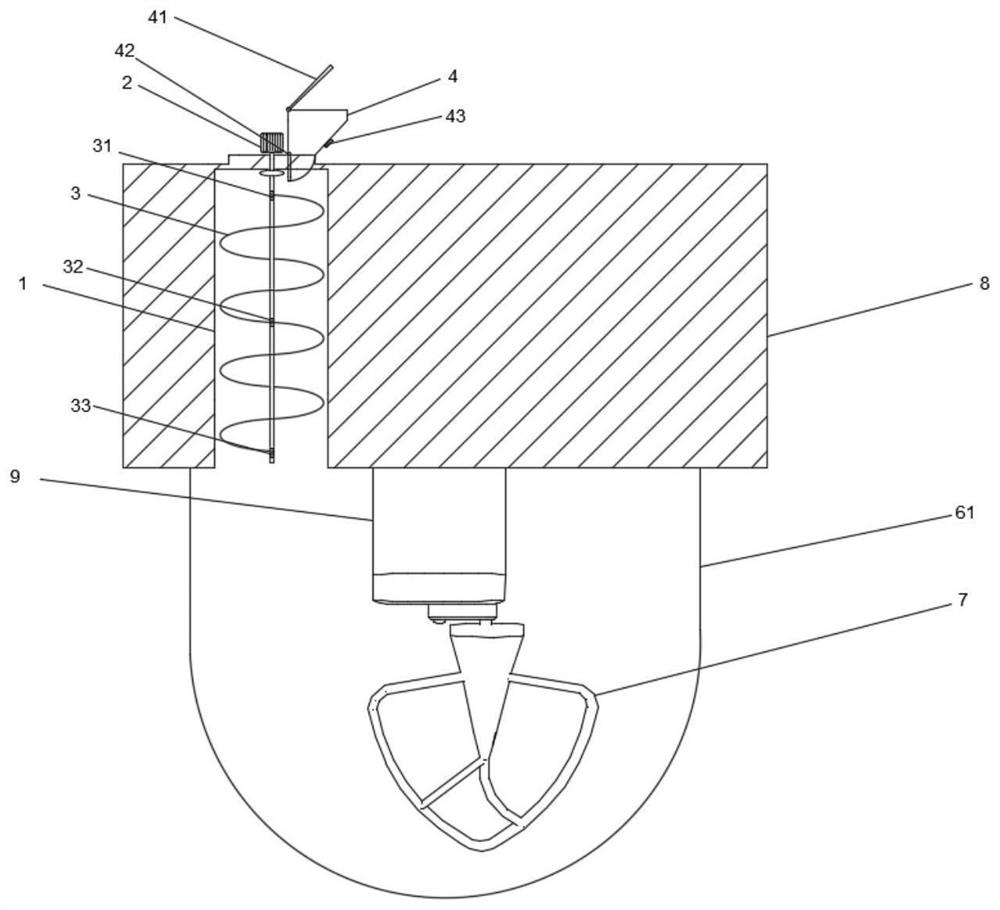

The invention discloses an asphalt mixture stirring device capable of automatically feeding fibers, fibers in a fiber asphalt mixture are uniformly distributed, and performance variability of the mixture is low. The invention discloses an asphalt mixture stirring device capable of automatically feeding fibers. The asphalt mixture stirring device comprises a liftable platform (6) with a supporting arm (8), a heating and stirring pot (61) arranged on the liftable platform (6), and a stirring blade (7) of which an upper end is connected with a gearbox (9) arranged at an upper end of the supporting arm (8), wherein a fiber bin (4) and a fiber stirring cavity (1) are further arranged at an upper end of the supporting arm; an upper opening of the fiber stirring cavity (1) is connected with a lower opening of the fiber bin (4), and a lower opening of the fiber stirring cavity (1) faces an upper opening of the heating and stirring pot (61); a fiber stirring blade (3) is arranged in the fiber stirring cavity (1), and an upper end of the fiber stirring blade (3) is connected with a fiber stirring motor (2).

Owner:YANGZHOU UNIV

A kind of high-quality tipping paper base paper with good bursting resistance and its preparation method

ActiveCN104005298BImprove the level ofImprove spicy tasteFlexible coversWrappersBeta-CaroteneFluff pulp

The invention discloses raw tipping paper with high quality and good breaking resistance degree. The raw tipping paper is characterized by being prepared from following raw materials in parts by weight: 45-48 parts of pine pulp, 53-56 parts of fluff pulp, 4-6 parts of phoenix tree barks, 1-2 parts of gelonium, 2-3 parts of polyvinylpyrrolidone, 1-2 parts of alums, 2-3 parts of calcium carbonate, 2-4 parts of a zeolite molecular sieve, 1-3 parts of silicone rubber, 0.8-1 part of beta-carotene, 1-2 parts of lithopone, 2-3 parts of carboxymethylcellulose, 1-2 parts of an auxiliary agent and suitable amount of water. According to the raw tipping paper, prepared phoenix tree bark fibers are added into papermaking pulp so that a product has white fibers which are uniformly distributed; a paper sheet is firm and durable, has good breaking resistance degree and is smooth and fine; the raw tipping paper has a good printing ink leveling performance; the auxiliary agent is added so that the raw tipping paper has a certain adsorption effect, has a pleasant aroma and can be used for improving the spicy taste of smoke.

Owner:CHUZHOU CIGARETTE MATERIALS FACTORY

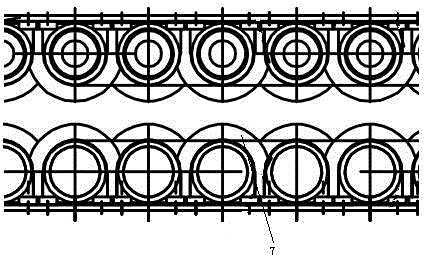

A kind of non-adhesive bonding composite filter material manufacturing device and using method thereof

InactiveCN103706183BImprove breathabilitySolve the need for frequent replacementFiltration separationFiberFilter paper

The invention relates to a glue-bonding-free composite filter material manufacturing device and an application method thereof. The device mainly comprises a heat-resistant fiber filter material roller, a filter material heating component, a short fiber paving component, a hot rolling roller, a guiding roller, a cooling water tank, a composite filter material roller, and an oven. The application method comprises the following steps: making a heat-resistant fiber filter material go through the heating component so as to heat the surface of the filter material to a certain temperature; rapidly paving the short fibers on the surface of the heat-resistant fiber filter material through feeding the short fibers into a groove, a gear-shaped conveying belt, and the short fiber paving component, making the short fibers be melt and attached on the filter material; then making the filter material coated by the short fibers go through the hot rolling roller so as to strengthen the adhesion effect; then making the filter material go through the guiding roller which can immediately soaking the composite filter material into the cooling water so as to make the composite filter material be tightly adhered, and finally placing the wet composite filter material in the oven to carry out a drying treatment so as to obtain the finished composite filter material. The composite filter paper is prepared through a glue-bonding-free technology, the filter material void fraction is largely improved, the one-time service life and filter efficiency of the filter material are increased, and the manufacturing method of the filter material has the advantages of reasonable design, high production efficiency, simple technology, and even fiber thickness of composite layer.

Owner:TONGJI UNIV

Preparation method of novel seedling bed

InactiveCN104529176AImprove mechanical propertiesGood heavy metal contentGlass making apparatusGrowth substratesFiberMagma

The invention discloses a preparation method of a novel seedling bed. The preparation method comprises the following steps: preparing a mixed raw material from the following raw materials in parts by weight: 25-35 parts of ferrotitanium stone, 35-45 parts of basalt, 5-8 parts of limestone, 3-5 parts of slag, 20-30 parts of coke and 3-5 parts of auxiliary materials; feeding the mixed raw material to a cupola furnace, fusing into magma, forming fibers, collecting cotton, and laying cotton; pressing on a three-dimensional cotton presser; and solidifying and trimming, so as to prepare the novel seedling bed. The novel seedling bed prepared by adopting the method has black to black brown color similar to the color of soil, and has a good mechanical property.

Owner:GUANGDE SKD ROCKWOOL MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com