Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

66results about How to "Reduce resin content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

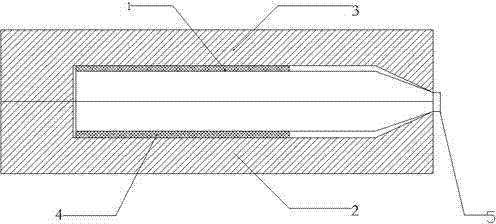

Manufacturing method of carbon fiber composite material rectangular hollow pipe for mechanical arm

The invention provides a manufacturing method of a carbon fiber composite material rectangular hollow pipe for a mechanical arm, and the obtained rectangular hollow pipe. A carbon fiber composite material serves as a raw material and is carbon fiber prepreg; the prepreg comprises one-way and fabric prepregs and the rectangular hollow pipe is manufactured by a mould pressing inflation forming method. According to the manufacturing method of the carbon fiber composite material rectangular hollow pipe, a rectangular thin-walled hollow pipe is manufactured by performing mould pressing inflation combined forming on the carbon fiber prepreg serving as the raw material. Compared with the prior art, the invention has the advantages that the carbon fiber composite material rectangular hollow pipe has high bearing capacity, high rigidity and light weight; during operation, the arm is more stable in action and moves and stops more quickly; the arm can be quickly positioned by the vibration damping characteristic of the carbon fiber composite material; the carbon fiber composite material is applicable to precision equipment due to the zero thermal expansion coefficient; equipment investment is small; a mould is simple to manufacture; production energy consumption is low; production period is short; automatic production is realized.

Owner:HENGSHEN

Sizing agent special for ultra-low adsorption resin concentration chopped roving

The invention discloses a special size of chopped twistless roving with ultra-low resin absorbing-capacity, comprising coupling agent, lubricant, antistatic agent A, antistatic agent B, film forming agent A, film forming agent B, film forming agent C and a pH value regulator; all the materials respectively accounts for 1 to 10 percent, 1 to 10 percent, 1 to 5 percent, 1 to 5 percent, 10 to 80 percent, 80 to 10 percent, 1 to 5 percent and 0.1 to 5 percent and water as the rest; the content of the water accounts for 85 to 95 percent of the total weight of the size; the coupling agent adopts silane coupling agent, the lubricant adopts water-soluble grease lubricant, the antistatic agent A adopts organic salt substance with good water absorptivity, the antistatic agent B adopts inorganic salt substance with good water absorptivity, the film forming agent A, the film forming agent B and the film forming agent C respectively adopts one of epoxy emulsion, polyester emulsion, polyvinyl acetate (PVAc) emulsion and polyurethane emulsion; the film forming agent C selects compound with low degree of polymerization, the pH value regulator adopts acid and the pH value of the size is 3 to 11. The size can improve the penetration velocity under the situation of meeting the requirements of the chopped technique, achieves the high content of the glass fibre and ultra-low content of resin, improves the production efficiency of the client and reduces the production cost.

Owner:JUSHI GRP CO

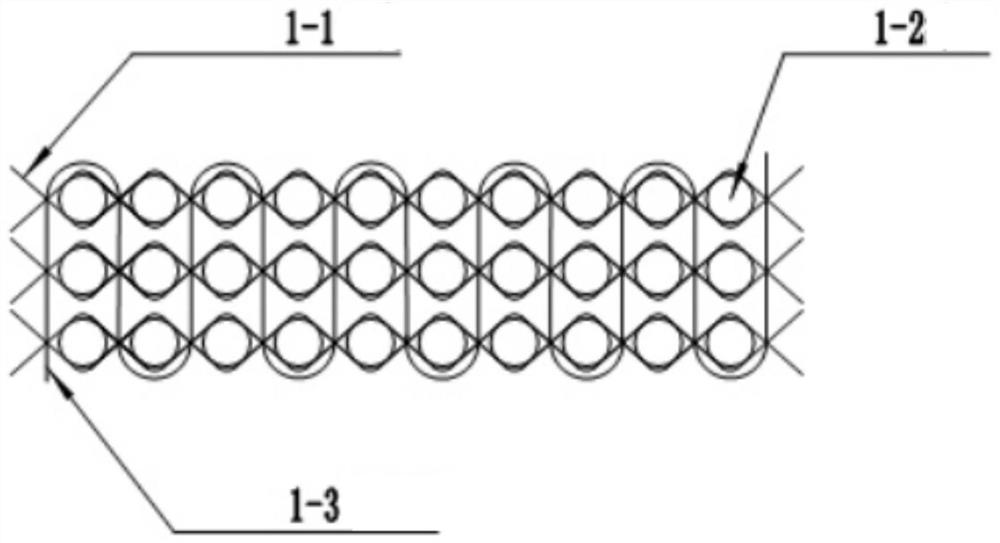

Thermoforming method of co-woven continuous fiber reinforced thermoplastic structural plate

The invention discloses a thermoforming method of a co-woven continuous fiber reinforced thermoplastic structural plate. The method comprises: first co-weaving prepreg into sheet or band prepreg on a braiding machine; spreading the prepreg on a die and conducting sealing with a vacuum bag or a polyester film; then raising the temperature, carrying out vacuum pumping to maintain a vacuum negative pressure, when the temperature reaches the melting point of thermoplastic resin, preserving the heat for a period of time, then performing cooling for molding; finally dismounting the vacuum bag or the polyester film so as to obtain a structural plate. The structural plate produced by the co-weaving method can expel air among the internal layers of the prepreg. Pressure is transmitted uniformly through fibers, so that shift in fiber direction can be avoided, and the structural plate also can be reinforced based on original enhanced fibers, thus substantially saving cost.

Owner:LIAONING LIAOJIE SCI & TECH

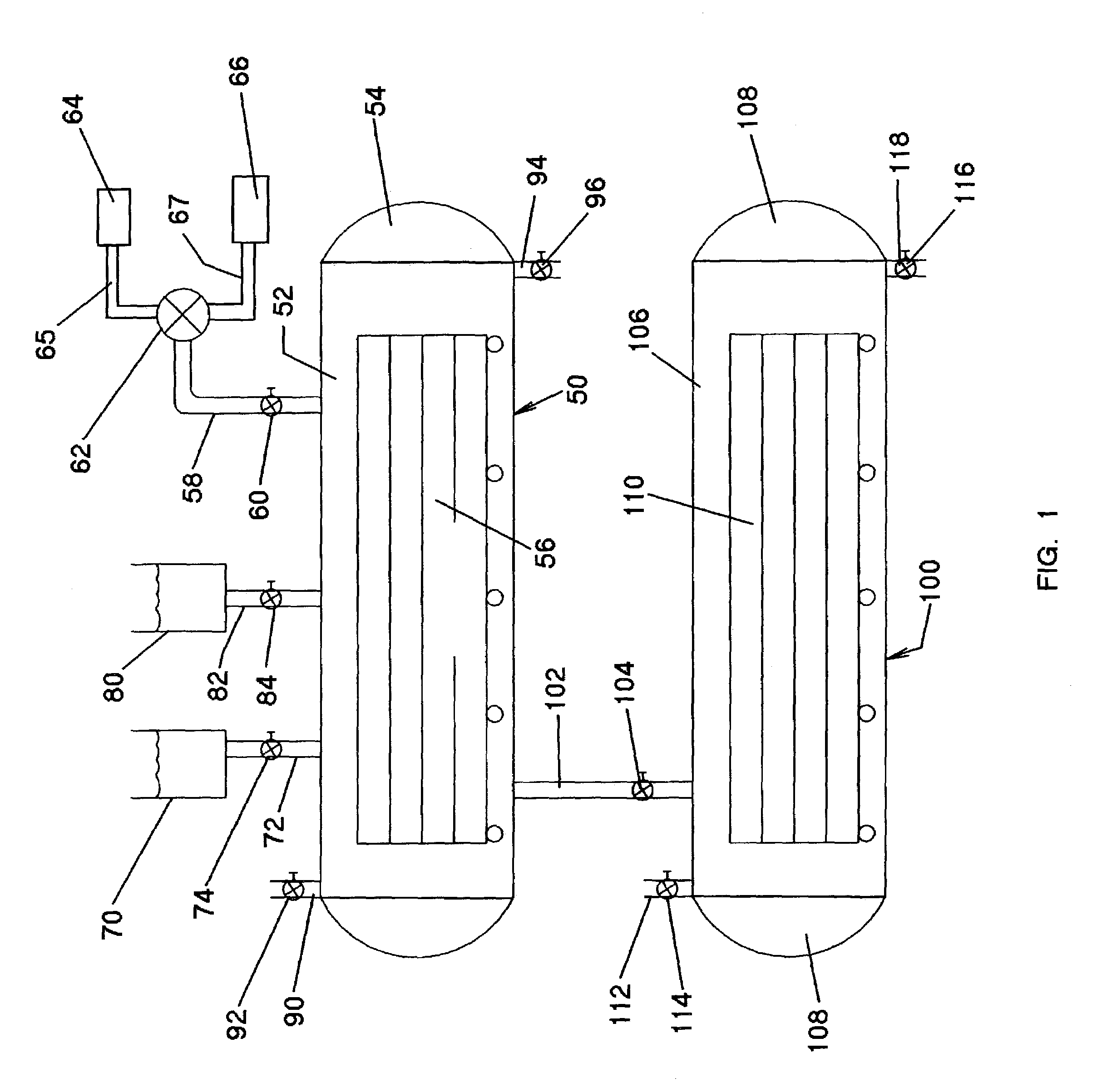

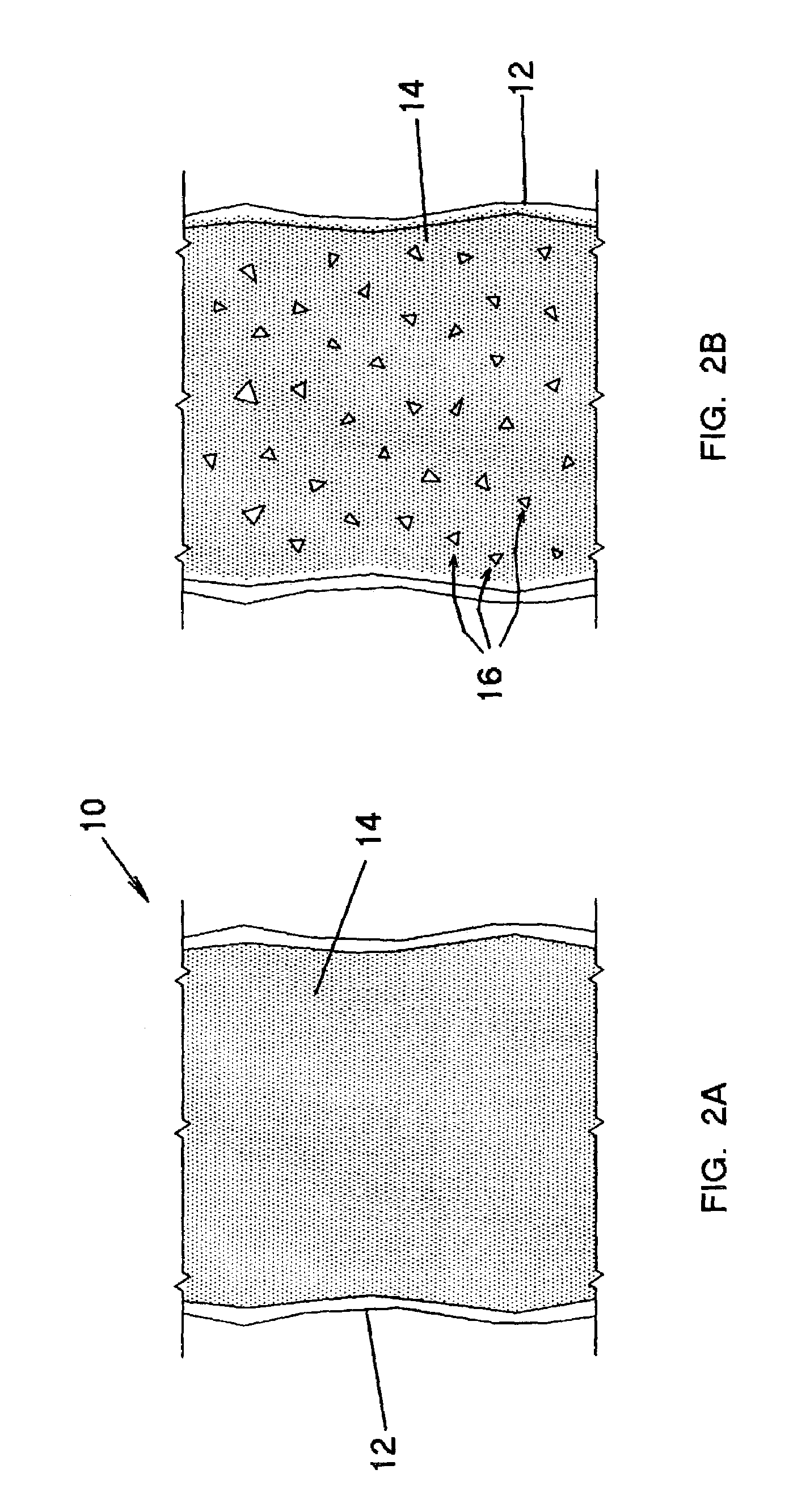

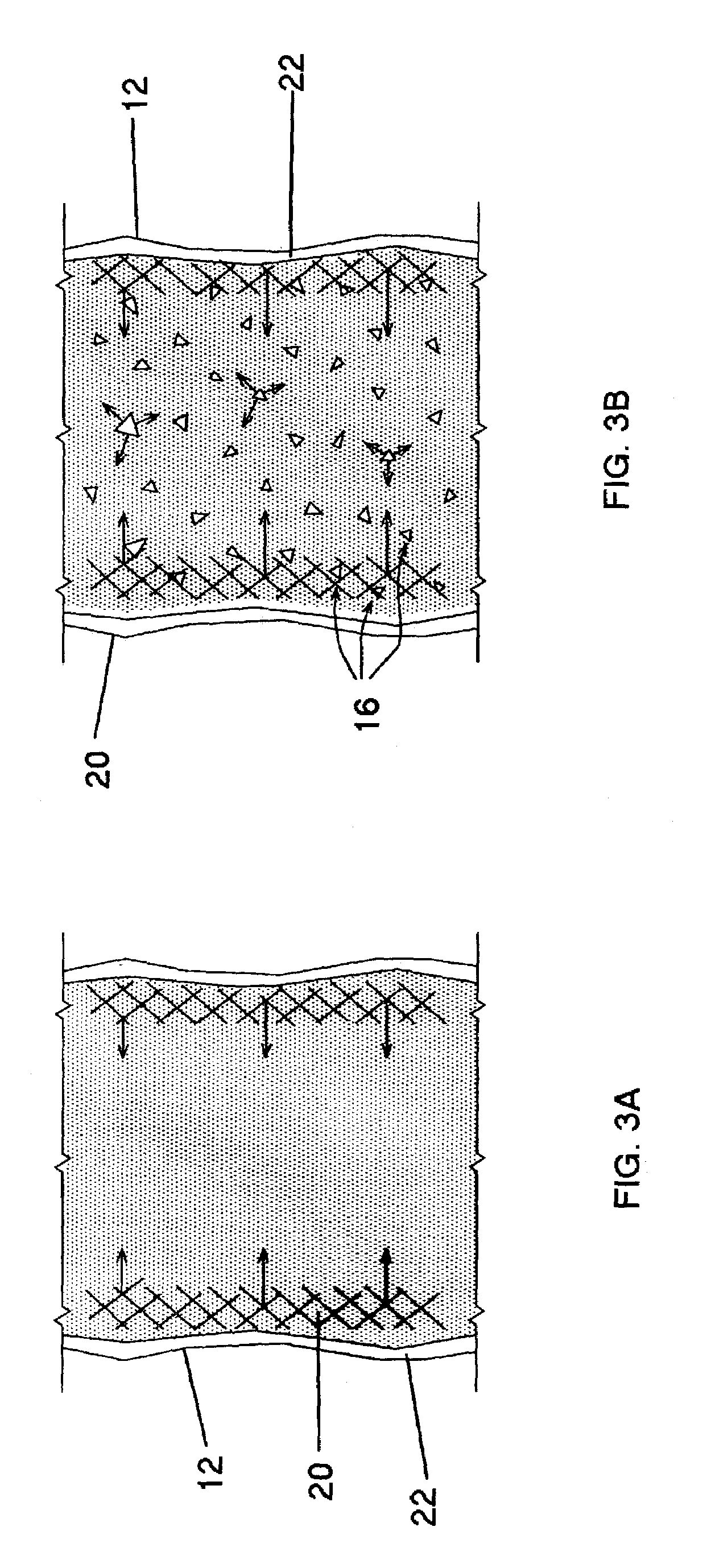

Woven fabric with a modified ester resin for use as a wet friction liner

InactiveUS20040213980A1Low costHigh glass transition temperatureLiquid surface applicatorsSynthetic resin layered productsYarnOligomer

Woven fabric of continuous, untwisted carbon yarn is impregnated with a modified cyanate ester resin or oligomer, preferably at least about 10% by weight of the combined weight of the cured resin and fabric. The cured fabric may be employed as a wet friction material suitable for use in transmission fluid couplings, and the like. The cured composite sheet can be backed with an adhesive film or liquid bonding paste for ease of bonding to one side of the metal portion of the transmission or clutch. Where thicker material is required, two or more cured composite sheets can be bonded together for applications such as transmissions.

Owner:J D LINCOLN

Epoxy heating fiberglass mould and preparation method thereof

PendingCN110053279ASolve the deformationSolve the strength problemDomestic articlesTemperature controlEpoxy

The invention provides an epoxy heating fiberglass mould and a preparation method thereof. The preparation method comprises the following steps including female mould manufacturing, mould structural manufacturing; gel coat manufacturing; topcoat manufacturing; heating layer manufacturing; structural reinforcing layer manufacturing; heat preservation layer manufacturing; framework support manufacturing; temperature control system manufacturing; and silica gel surface mould manufacturing. The epoxy heating mould meets the requirements that the high temperature deformation temperature is above 120 DEG C, the shrinking percentage is low, and heating is uniform, and the technical problem that local overheating damages the mould is solved.

Owner:XIAMEN HANSHENG YACHT BUILDING

Method of increasing latent heat storage of wood products

InactiveUS6933016B1Improve heat storage capacityIncrease heat releaseWood treatment detailsPretreated surfacesLatent heat storageEngineering

The heat storage capacity of natural cellulosic products is increased by injecting nucleating products and / or heat storing material into unfilled cells thereby increasing the amount of material that can undergo phase change for transferring latent heat.

Owner:SYKES JR MARVIN E

Method for pulping through needlebush pre-conditioning refiner chemical alkaline peroxide mechanical pulp (P-RC APMP)

InactiveCN102926253AImprove chemical performancePromote dissolutionPulping with inorganic basesFiberChemical treatment

The invention relates to the technical field of pulping and papermaking, in particular to a method for pulping through needlebush pre-conditioning refiner chemical alkaline peroxide mechanical pulp (P-RC APMP), wherein the first period of extrusion processing of needlebush pieces after being steamed is subjected, the first period of chemical processing is subjected after chemical liquid A is added, the chemical liquid A contains sodium dodecyl benzene sulfonate and octyl phenol polyoxyethylene ether (10), the second period of extrusion processing is subjected, the second period of chemical processing is subjected by adding chemical liquid B after the second period of extrusion, the chemical liquid B contains the sodium dodecyl benzene sulfonate and the octyl phenol polyoxyethylene ether (10), the first period of defibrination is subjected after processing and stops, and then the second period of defibrination and eliminate hidden processing are subjected to obtain needlebush P-RC APMP paper pulp. The method for pulping through needlebush P-RC APMP strengthens chemical action of impregnation liquid and dissolution of reactants, softens fiber materials, reduces subsequent pulping energy consumption, improves fiber quality, increases pulp whiteness, reduces pulp resin content, and reduces resin obstacle.

Owner:QILU UNIV OF TECH

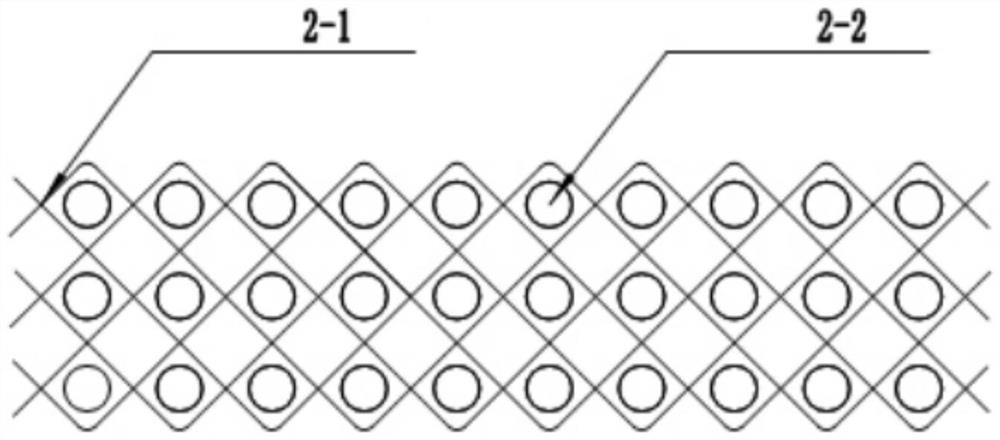

Preparation method of integrally-woven friction material

The invention provides a preparation method of an integrally-woven hot-pressed friction material. According to the method, metal fibers, inorganic fibers and / or organic fibers are made into plied yarns; the plied yarns are woven into cloth through a multi-layer integral weaving method; the cloth is soaked in resin and then dried, so that a blank can be obtained; the blank is cut and then placed ina hot-pressing mold; hot-pressing curing is conducted to obtain a semi-finished product; and the semi-finished product is subjected to heat treatment, machining and other procedures, so that a finished product can be obtained. As the friction material takes the integrally woven cloth as a framework, the fiber content of thefriction material is high, and the resin content of the friction materialis low. The finished product is high in strength and low in hardness, has certain flexibility, and can assist in solving the problems of an existing friction material.

Owner:TALFRI BRAKES

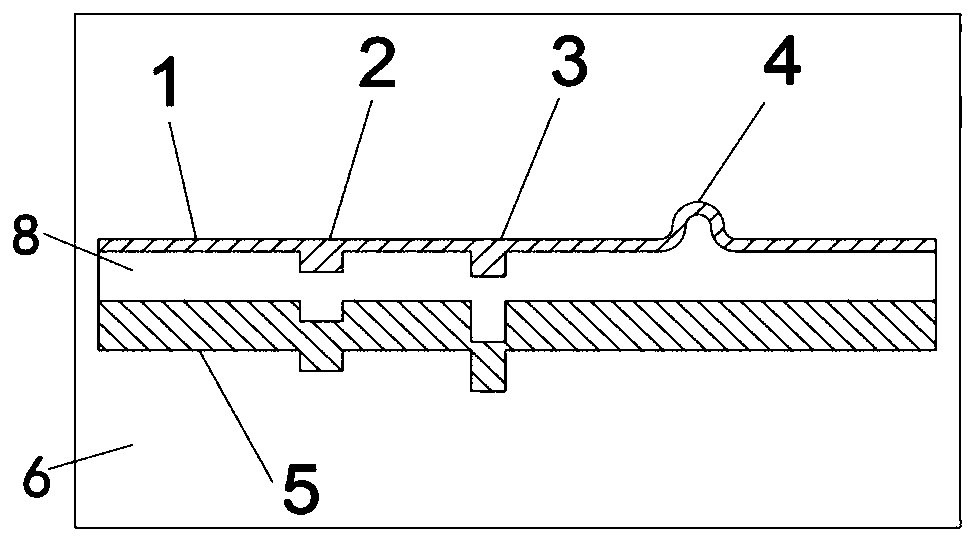

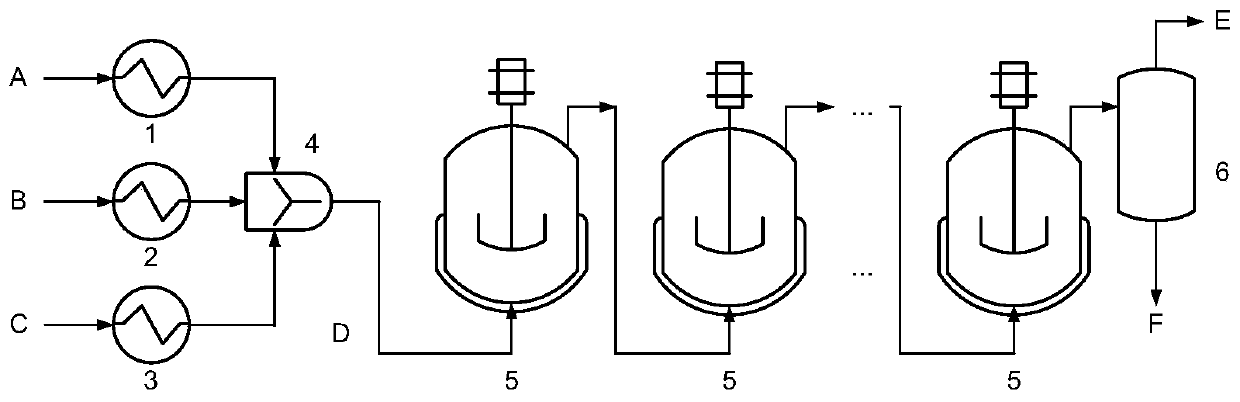

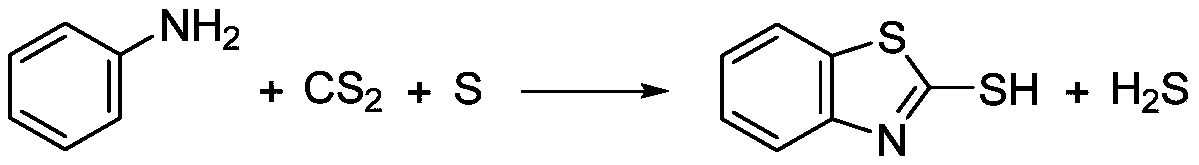

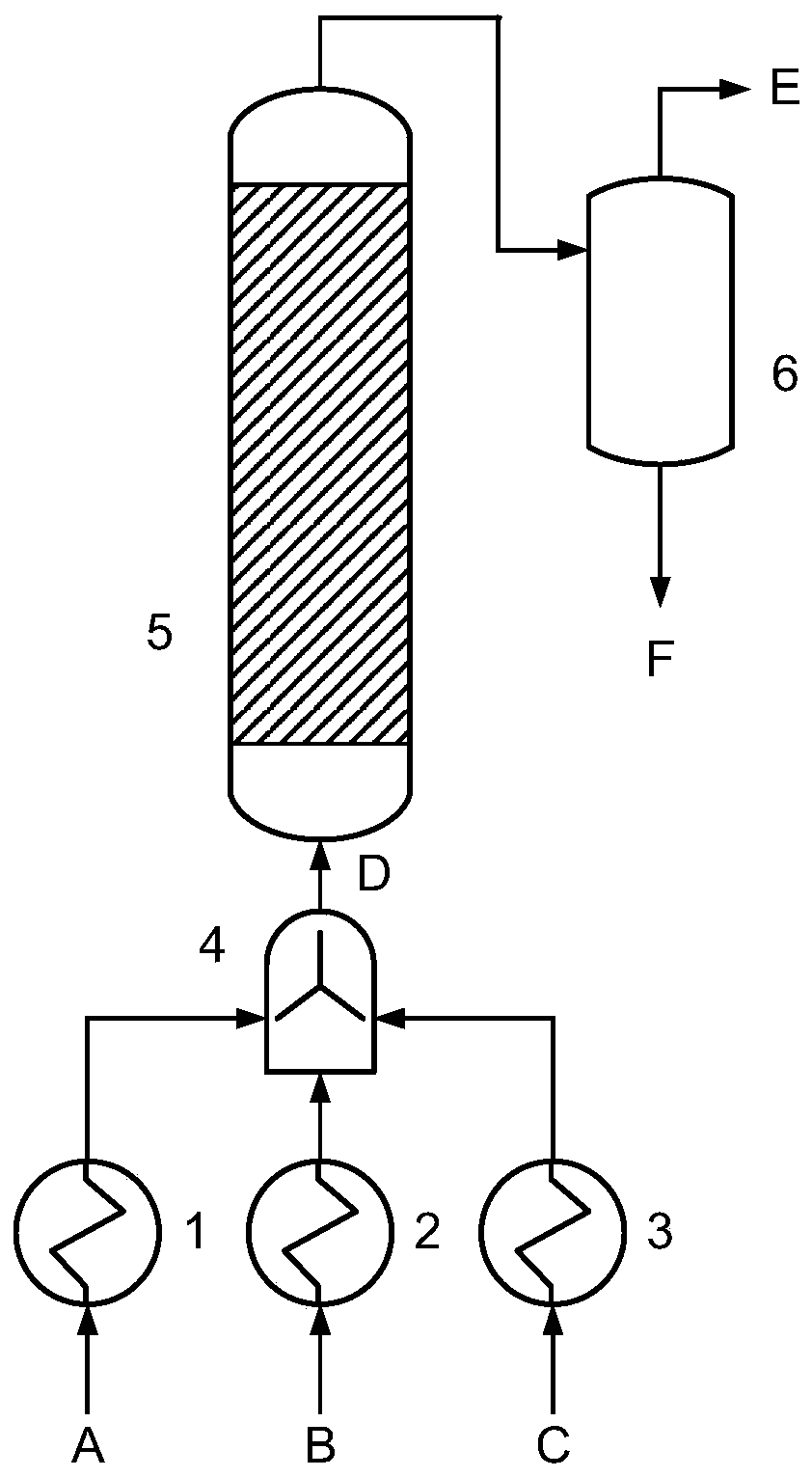

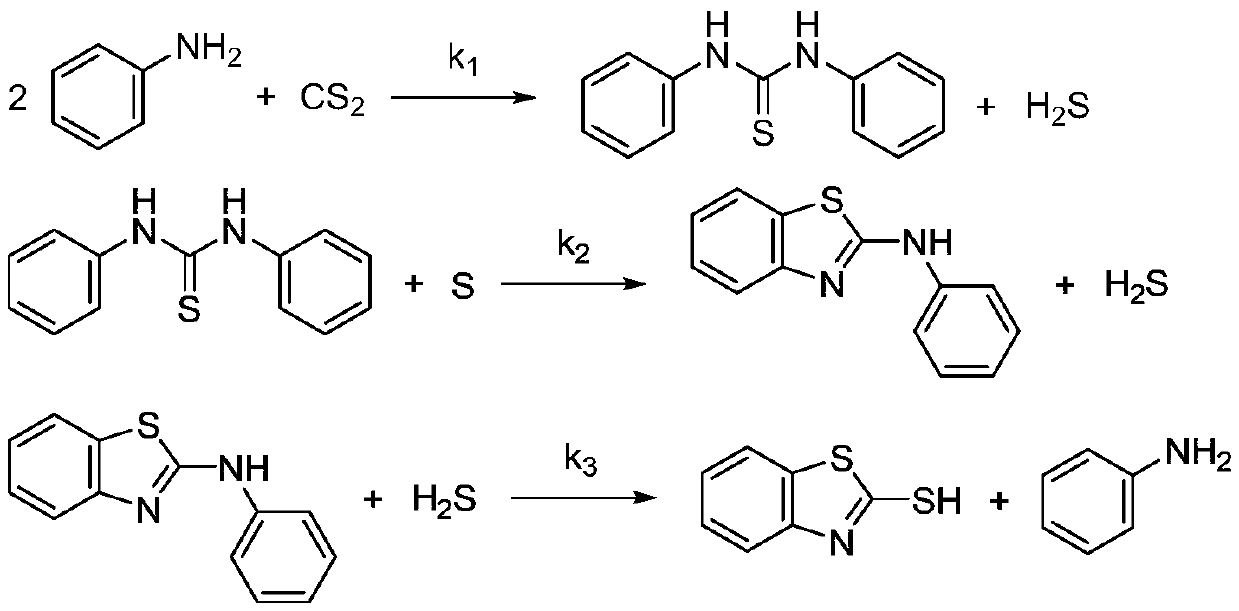

Reaction device for continuous synthesis of 2-mercaptobenzothiazole

The invention discloses a reaction device for continuous synthesis of 2-mercaptobenzothiazole. The reaction device comprises a raw material preheater, a micromixer, multistage reaction kettles and a stripping tower which are connected in series and sequentially complete the preheating, mixing, reacting and phase separating processes of raw materials; the raw materials comprise aniline, carbon disulfide and sulphur which are heated to the respective initial temperatures in the preheating device and then are subjected to insulation mixing in the micromixer, a raw material mixture sequentially enters from the bottom of the multi-stage reaction kettles which are connected in series, leaves from the tops of the multi-stage reaction kettles, and is subjected to multi-stage reaction to generate the 2-mercaptobenzothiazole; and the top of the last-stage reaction kettle communicates with the stripping tower, and the stripping tower is used for separating the reacted materials into tail gas anda 2-mercaptobenzothiazole coarse product. Continuous production can be achieved by using the reaction device, the yield of the 2-mercaptobenzothiazole reaches 92% or above, the resin content is less than 4%, the production efficiency is high, and the product stability is good.

Owner:WILLING NEW MATERIALS TECH CO LTD +1

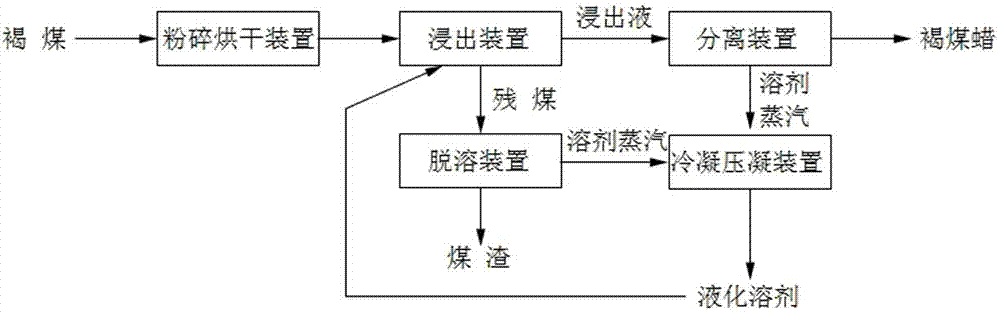

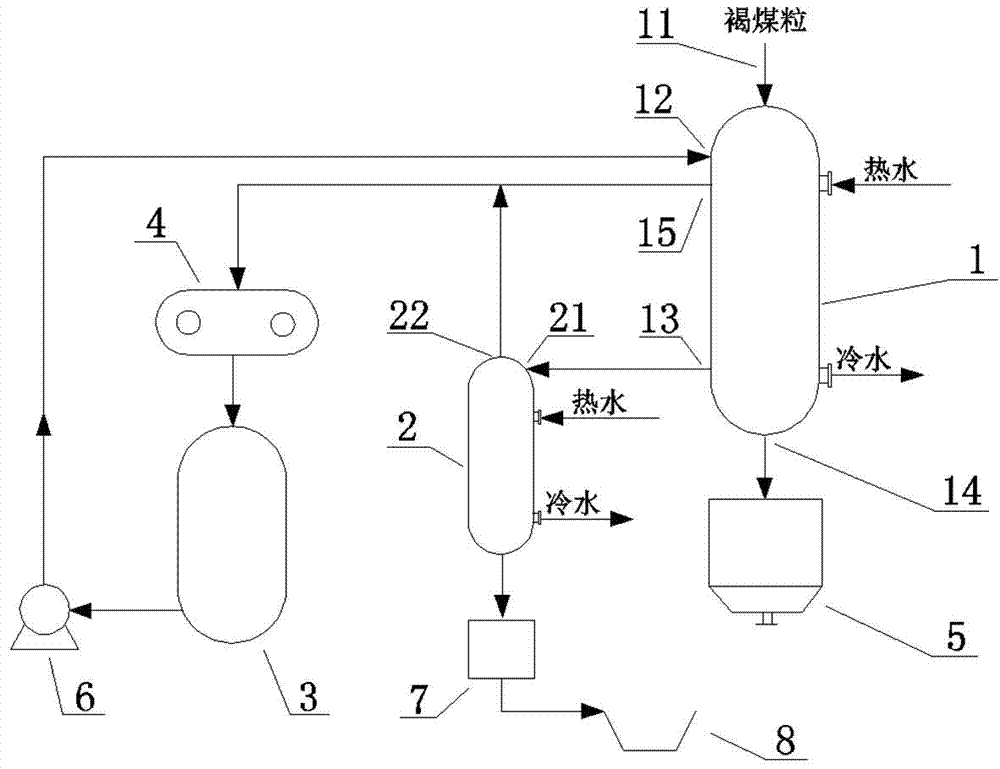

Method and device for leaching high-quality lignite wax

ActiveCN103881752AReduce resin contentHigh resin contentMineral wax recovery/refiningSolid solvent extractionPARAFFIN HYDROCARBONSResidual solvent

The invention discloses a method and a device for leaching high-quality lignite wax. The leaching method comprises the followings steps: smashing lignite, sieving by use of a sieve with the hole size of 1.0-8.0 millimeters, and drying until the water content is 15-25 percent; loading the dried lignite and a straight-chain paraffin solvent into a leaching device at a temperature of 0.5-1.5MPa at a material-liquid ratio of (1:2)-(1:5) (kg / L), soaking at the temperature of 10-40 DEG C for 3-6 hours, and performing material-liquid separation to obtain leach liquor and residual lignite; putting the leach liquor into a separating device, and heating to 30-60 DEG C or reducing the pressure to 30-60KPa for evaporating the solvent to obtain lignite wax and a solvent; putting the leached residual lignite into a desolventizer, and heating or evaporating the residual solvent under reduced pressure under the conditions of the step C to obtain lignite residues and the solvent. The leaching device comprises a leacher, a fluid wax evaporation-separation tank and a solvent storage tank. According to the method, low-toxicity straight-chain paraffin is taken as a leaching solvent, and a leaching process is performed at the room temperature or a temperature higher than the room temperature, so that energy conservation and environmental protection are facilitated, and the resin content and asphalt content of the wax are low.

Owner:QUJING ZHONGYI FINE CHEMICAL INDUSTRY CO LTD

Method for grading quartz sand by clamping quartz sand with glass-fiber reinforced plastic quartz-sand clamping tube through adopting wet process

The invention discloses a method for grading quartz sand by clamping the quartz sand with a glass-fiber reinforced plastic quartz-sand clamping tube through adopting the wet process. The method comprises the following steps of: taking 15 parts by weight of accessory in a first group, wherein the accessory in the first group is quartz sand with the particle size of 0.6-0.9mm; taking 29 parts by weight of accessory in a second group, wherein the accessory in the second group is quartz sand with the particle size of 0.5-0.56mm; taking 25 parts by weight of accessory in a third group, wherein the accessory in the third group is quartz sand with the particle size of 0.45mm; taking 21 parts by weight of accessory in a fourth group, wherein the accessory in the fourth group is quartz sand with the particle size of 0.355mm; taking 8 parts by weight of accessory in a fifth group, wherein the accessory in the fifth group is quartz sand with the particle size of 0.3mm; taking 2 parts by weight of accessory in a sixth group, wherein the accessory in the sixth group is quartz sand with the particle size of 0.25mm; and mixing the six groups of accessories uniformly according to the corresponding parts. The quartz-sand clamping layer of a product has low content of resin and is highly compact, thus the stable quality of the product is guaranteed, and the cost of the product is lowered.

Owner:浙江新世管道股份有限公司

Cured resin for artificial quartz and preparation of artificial quartz

The invention provides a cured resin for artificial quartz and the artificial quartz prepared by the cured resin, which relate to the cured resin for the artificial quartz and the artificial quartz prepared by the cured resin, in particular to a method for preparing the artificial quartz which has easy formability and appearance similar to marmoreal. The cured resin for the artificial quartz is in liquid state at normal temperature, and is prepared by a condensation reaction of polylol, saturated acid and unsaturated acid; an alcohol acid reaction system comprises the following components in percentage by weight: 37 to 47 percent of the polylol, 35 to 40 percent of saturated acid or estolide, and 18 to 23 percent of unsaturated acid or estolide, wherein 30 to 45 percent of cross-linking agent is added into the alcohol acid reaction system; the saturated acid or estolide is phthalic acid or phthalic anhydride; and the unsaturated acid or estolide is maleic acid or maleic anhydride. The cured resin for the artificial quartz can be used for preparing the artificial quartz, has sufficient curing, small internal stress inside the product and performance capable of reaching maximum.

Owner:上海新天和树脂有限公司 +1

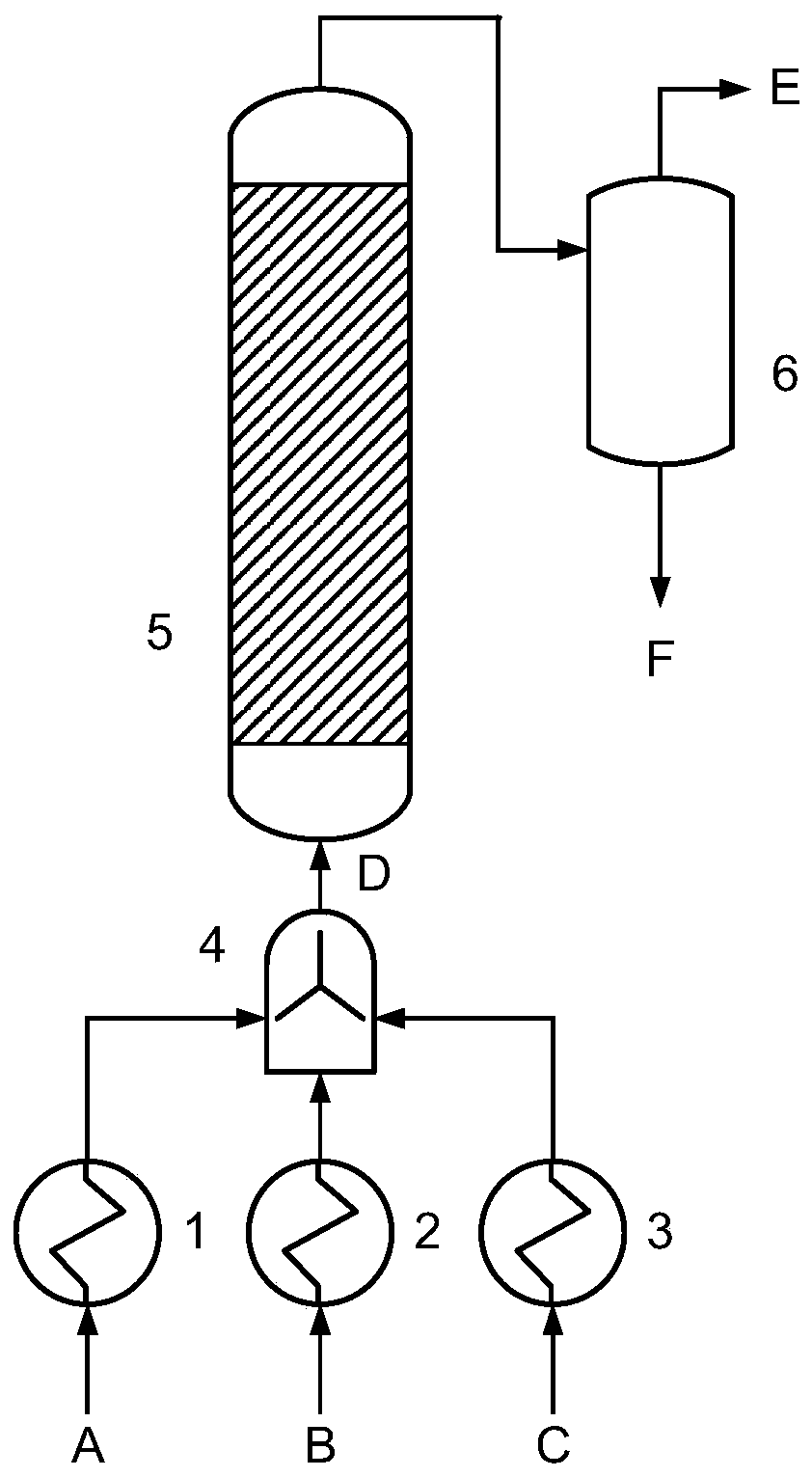

Tower type microreactor for continuous synthesis of 2-mercaptobenzothiazole

ActiveCN109701470AHigh yieldImprove heat utilizationOrganic chemistryChemical/physical/physico-chemical processesAnilineMicromixer

The invention discloses a microreactor for continuous synthesis of 2-mercaptobenzothiazole. The microreactor comprises a raw material preheater, a micromixer, a filling material reaction tower and a stripping tower which are connected in series to successively complete the processes of preheating, mixing, reaction and phase separation of raw materials, wherein the raw materials comprise aniline, carbon disulfide and sulfur, are separately heated to a respective initial temperature in the raw material preheater, and then mixed in the micromixer in a heat-insulation manner; the micromixer is placed at the bottom part of the filling material reaction tower; a raw material mixture enters from the bottom part of the filling material reaction tower for a reaction; and a product leaves from the top part of the filling material reaction tower to enter the stripping tower, and is separated into tail gas and a crude 2-mercaptobenzothiazole product in the stripping tower. By use of the microreactor provided by the invention, continuous production can be realized; the yield of the 2-mercaptobenzothiazole can achieve 95% or above; the content of resin is less than 2%; and high production efficiency and good product quality are achieved.

Owner:WILLING NEW MATERIALS TECH CO LTD +1

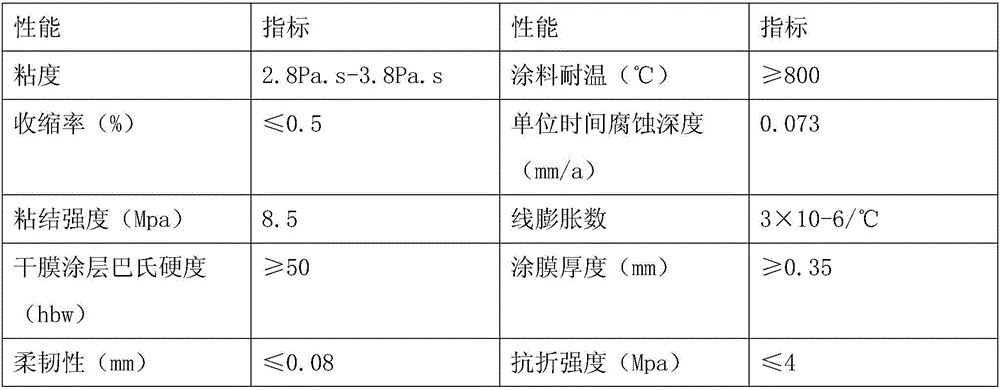

Epoxy vinyl ester micro compound resin and preparing method thereof

InactiveCN106349889AReduce resin contentLarge coating thicknessAnti-corrosive paintsEpoxy resin coatingsDefoaming AgentsChemistry

The invention relates to an epoxy vinyl ester micro compound resin and preparing method thereof. The resin is characterized by that epoxy vinyl ester micro compound resin mainly comprises epoxy vinyl ester resin, quartz sand, dispersant, defoaming agent and leveling agent. The preparing method of epoxy vinyl ester micro compound resin comprises the following step: (1) Weighting raw materials according to claim 2 formula; (2) mixing and stirring raw materials after the raw materials are added into mixing tank; (3) adding the raw materials into high-speed dispersing machine for dispersion; (4) adding the raw materials into grinding miller for grinding; (5) packaging all raw materials in different packages and placing them in cool and dry place for later use. In the preparing method, high-speed dispersing can mix the chemical materials with quartz powder completely and evenly, grinding can open the particles of original resin to make the particles form a new combination with the high-speed dispersed mixture which is added later, in order to form epoxy vinyl ester micro compound resin.

Owner:南丹县南方有色金属有限责任公司

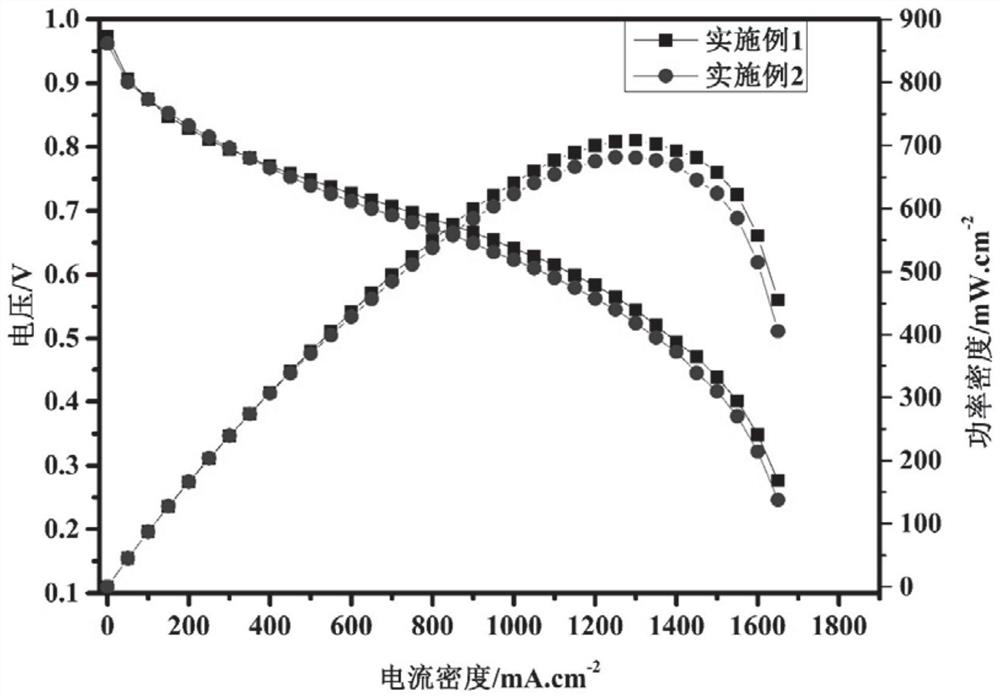

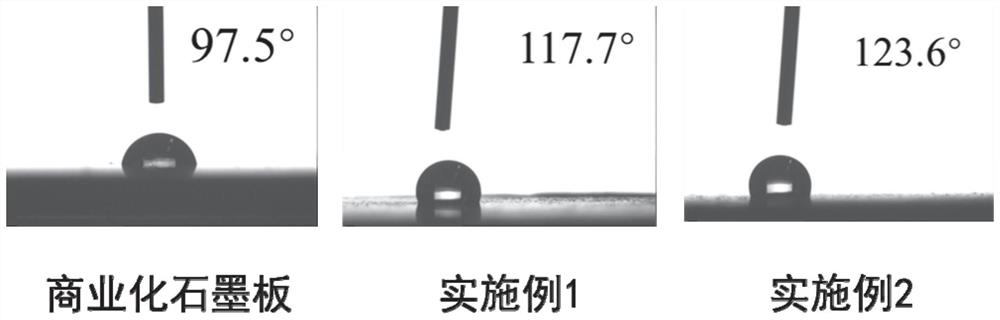

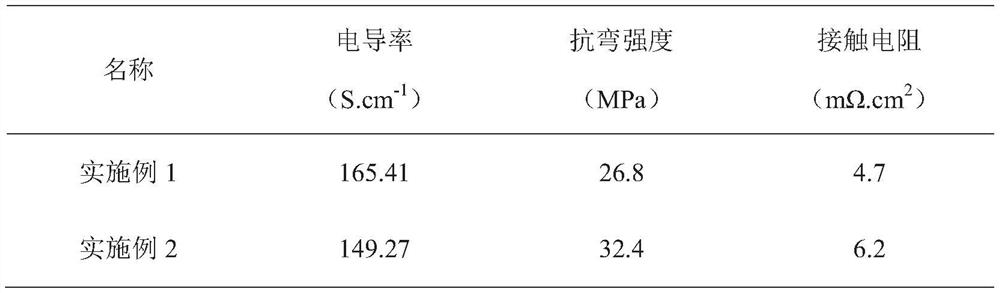

Carbon-plastic composite bipolar plate for fuel cell as well as preparation and application thereof

PendingCN112993294AHigh mechanical strengthImprove mechanical propertiesFuel cellsChemical stabilityComposite material

The invention belongs to the field of fuel cells, and discloses a carbon-plastic composite bipolar plate for a fuel cell as well as preparation and application of the carbon-plastic composite bipolar plate. The composite bipolar plate is a carbon-plastic composite plate composed of polyphenylene sulfide, polyvinylidene fluoride, a hydrogenated ethylene-butylene-styrene triblock copolymer, a conductive filler and reinforced fibers. The selected filler is good in heat-conducting property, high in strength, good in chemical stability, very high in corrosion resistance and very high in electrical conductivity, and the mechanical property, the electrical conductivity and the heat-conducting property of the composite bipolar plate can be greatly improved. The body resistance and contact resistance of the bipolar plate can be greatly reduced, and the total battery performance is improved.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

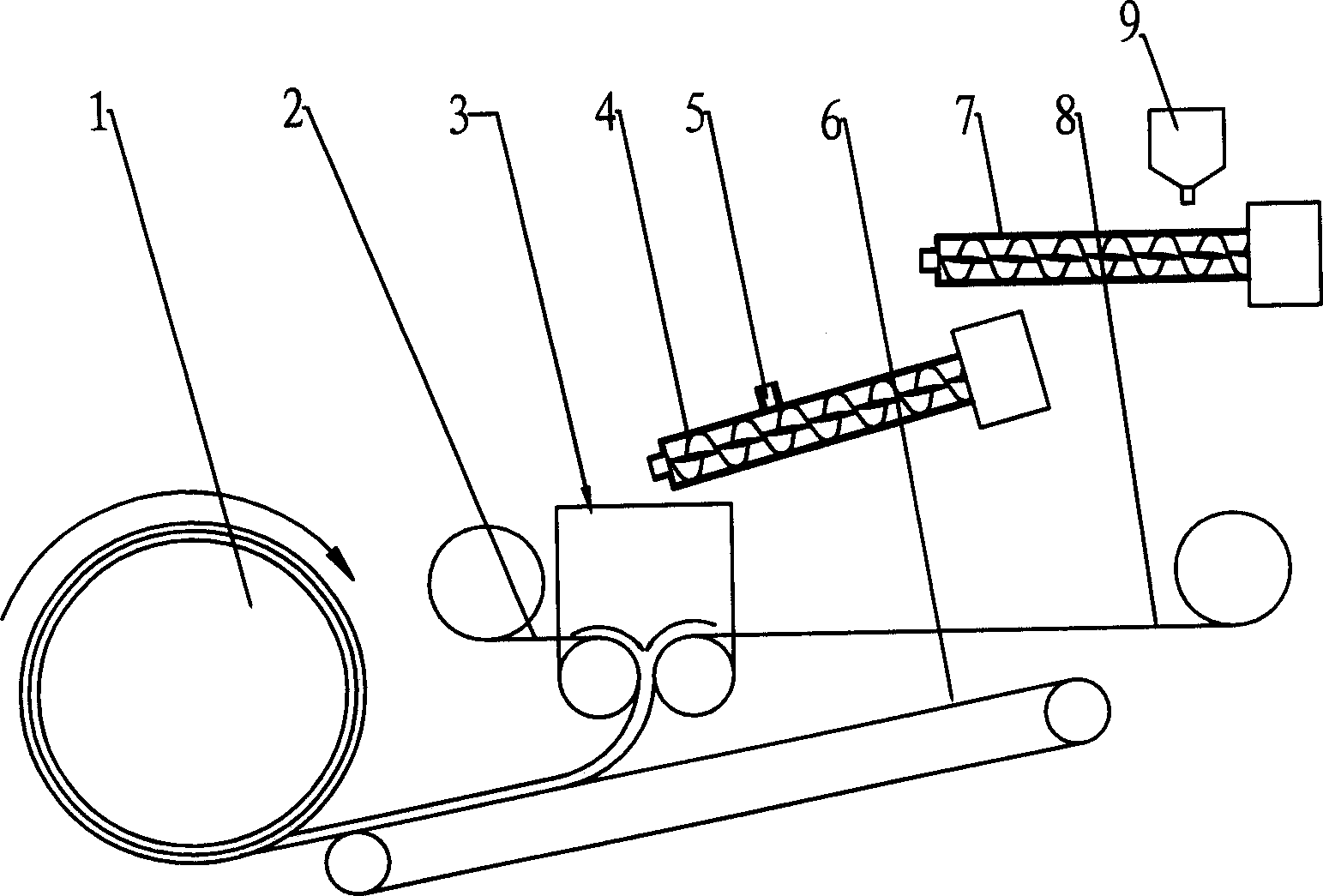

Resin quartz sand premixing equipment

A kind of facilities of preliminary mixing for manufacturing the glass fiber reinforced thermal-setting resin sand-inclusion piping. Including: the sand box, the transporting device, its characteristic lies in: a measure feed transporting machinery is linked to the outlet of the sand box, at the exit of the transporting machinery is linked with a premixing device, a rolling device is linked to the outlet of the preliminary mixture, the said rolling device includes the two parallel rolls, two parallel cloth sand-hood. After the pressing device, it establishes the belt conveyer which matches with a rotating mold. The beneficial result of the invention is that it lowers the resin content effectively, economizes direct material cost of the product. It is advantageous to control the product quantity, the resin is soaking well, the mezzanine sand layer density is high, raising the quantity of the product effectively.

Owner:周永清 +1

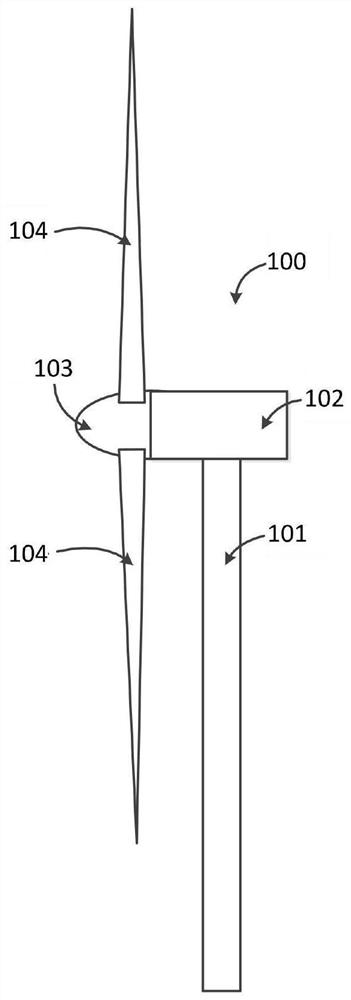

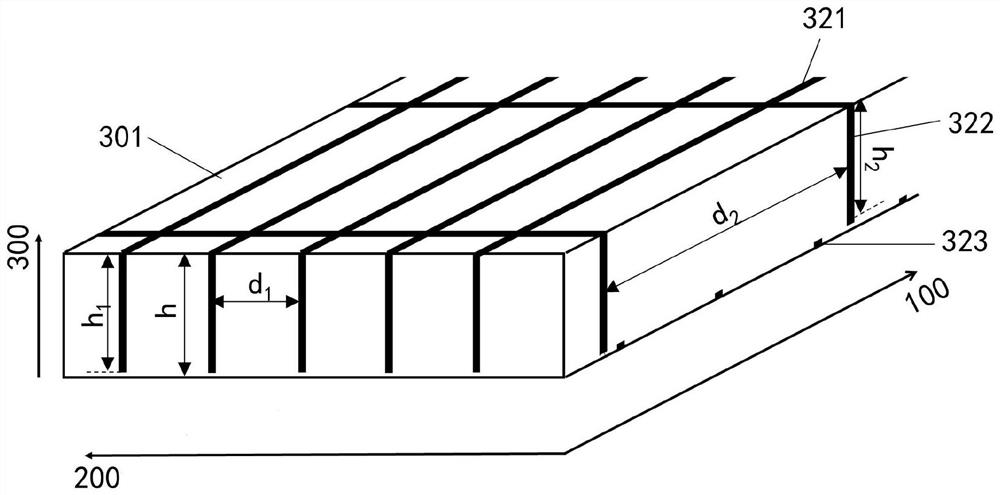

Core material structure and fan blade

PendingCN114673627AIncrease flexibilityReduce design weightMachines/enginesEngine componentsClassical mechanicsStructural engineering

The invention discloses a core material structure. The core material structure comprises a main body and grooves distributed in the main body, wherein the grooves comprise at least one first groove which is formed in the first surface of the main body and extends in the length direction of the fan blade; and the at least one second groove is formed in the first surface of the main body and extends in the chordwise direction of the fan blade.

Owner:YUANJIAN WIND POWER JIANGYINENVISION ENERGY CO LTD

Processing technology of PCB plug hole board

ActiveCN109429432AWill not lead to scrappingHigh resin contentPrinted circuit aspectsPrinted element electric connection formationPetroleum engineeringScrap

The invention relates to a processing technology of a PCB plug hole board. The processing technology is used for manufacturing a PCB. During green-oil printing of the PCB, green oil is formed by mixing special plug hole oil and welding surface-resistant oil according to a mass ratio being 1:1, the special plug hole oil is high in content and does not have developing performance, the saturation ofink in a hole can be ensured by a plug hole, the welding surface-resistant oil is high in developing performance and low in resin content, rework can be ensured when the plug hole is unfavorable, theresin content of the ink of a new plug hole can be ensured when the special plug hole oil and the welding surface-resistant oil are matched to form the plug hole according to a proportion being 1:1, meanwhile, the oil developing performance of the new plug hole is also satisfied, the saturation condition of the plug hole is ensured, rework also can be performed when unfavorable condition occurs, and the scrap of a PCB cannot be caused.

Owner:LONGTENG ELECTRONICS TECH CO LTD

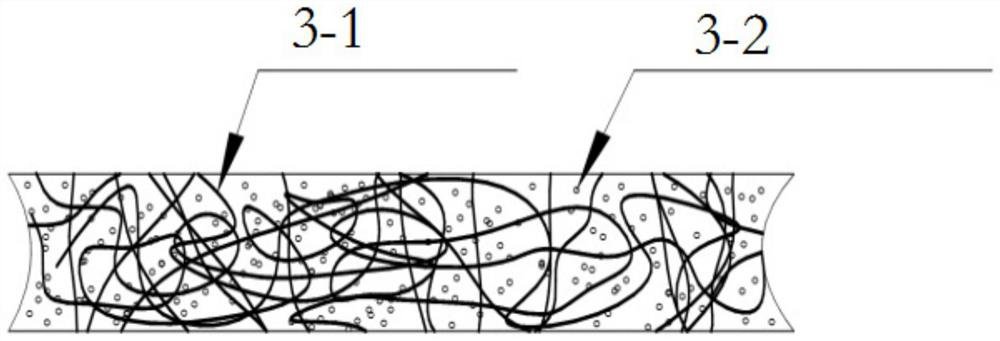

Preparation and application of high-wettability epoxy resin composite material

The invention discloses a high-wettability epoxy resin composite material and an application. The high-wettability epoxy resin composite material is prepared from the raw materials including epoxy resin, a curing agent, an accelerant and an antifoaming agent. Based on the antifoaming effect of the antifoaming agent on the epoxy resin and a perfect wetting effect on carbon fiber when the proportion of the antifoaming agent in the epoxy resin system is over 1% and with the supplemented synergistic effect between appropriate curing agent and accelerant and excellent mechanical properties of the epoxy resin, the composite material shows good wetting property on the carbon fiber in use, and a carbon fiber prepreg with low resin content can be prepared; and moreover, the preparation method of the carbon fiber prepreg with low resin content has the advantages of easiness, high efficiency, low cost and huge potential of industrial production while the product has the characteristics of low porosity, high strength and the like.

Owner:JIANGSU ZHAOJUN NEW MATERIAL CO LTD

Ecological environment-friendly foaming lightweight wallboard and preparation method thereof

InactiveCN107501687ALow costSave resourcesConstruction materialAntifouling/underwater paintsGlass fiberEcological environment

The invention provides an ecological environment-friendly foaming lightweight wallboard. The ecological environment-friendly foaming lightweight wallboard comprises a foaming matrix and a sealing layer outside the foaming matrix, and the raw materials comprise wood powder, polyethylene particles, an environment-friendly coating and other additives. The invention also provides a preparation method of the ecological environment-friendly foaming lightweight wallboard. The preparation method of the ecological environment-friendly foaming lightweight wallboard comprises the following steps: 1, pretreating the wood powder, the polyethylene particles and glass fiber; 2, mixing the glass fiber and the polyethylene particles to obtain glass fiber modified polyethylene; 3, adding the additives into the glass fiber modified polyethylene and stirring uniformly to obtain a molten mixture, dividing and dispersing the molten mixture into a powder material groove in a pelletizer material distributing device to adhere to the wood powder, and cooling and performing consolidation forming; 4, performing melt extrusion on the mixed materials and then performing forming, layer sealing and cutting processes to obtain the ecological environment-friendly foaming lightweight wallboard. The foaming wall body has the advantages of corrosion resistance, insect prevention, dampproof property, flame retardance and the like, has stripy wood texture, and has relatively good market promotion value.

Owner:HENAN INST OF ENG

Cured resin for artificial quartz and preparation of artificial quartz

The invention provides a cured resin for artificial quartz and the artificial quartz prepared by the cured resin, which relate to the cured resin for the artificial quartz and the artificial quartz prepared by the cured resin, in particular to a method for preparing the artificial quartz which has easy formability and appearance similar to marmoreal. The cured resin for the artificial quartz is in liquid state at normal temperature, and is prepared by a condensation reaction of polylol, saturated acid and unsaturated acid; an alcohol acid reaction system comprises the following components in percentage by weight: 37 to 47 percent of the polylol, 35 to 40 percent of saturated acid or estolide, and 18 to 23 percent of unsaturated acid or estolide, wherein 30 to 45 percent of cross-linking agent is added into the alcohol acid reaction system; the saturated acid or estolide is phthalic acid or phthalic anhydride; and the unsaturated acid or estolide is maleic acid or maleic anhydride. Thecured resin for the artificial quartz can be used for preparing the artificial quartz, has sufficient curing, small internal stress inside the product and performance capable of reaching maximum.

Owner:上海新天和树脂有限公司 +1

Phenolic resin additive, phenolic resin with the additive and its prepn process

The phenolic resin adhesive additive is prepared through mixing 3-25 % concentration sodium carbonate solution in 70-80 weight portions and fenugreek slag powder in 20-30 weight portions, heating to 70-80 deg.c to react for 3-6 hr, cooling to 30 deg.c to obtain fenugreek adhesive with viscosity 200-400 mPa.s as the additive for phenolic resin adhesive. Alkaline water soluble phenolic resin and the fenugreek adhesive in the weight ratio of 50-90 to 10-50 are mixed to obtain the phenolic resin adhesive. The phenolic resin adhesive has low production cost, high adhesion strength and low formaldehyde releasing amount.

Owner:BEIJING FORESTRY UNIVERSITY

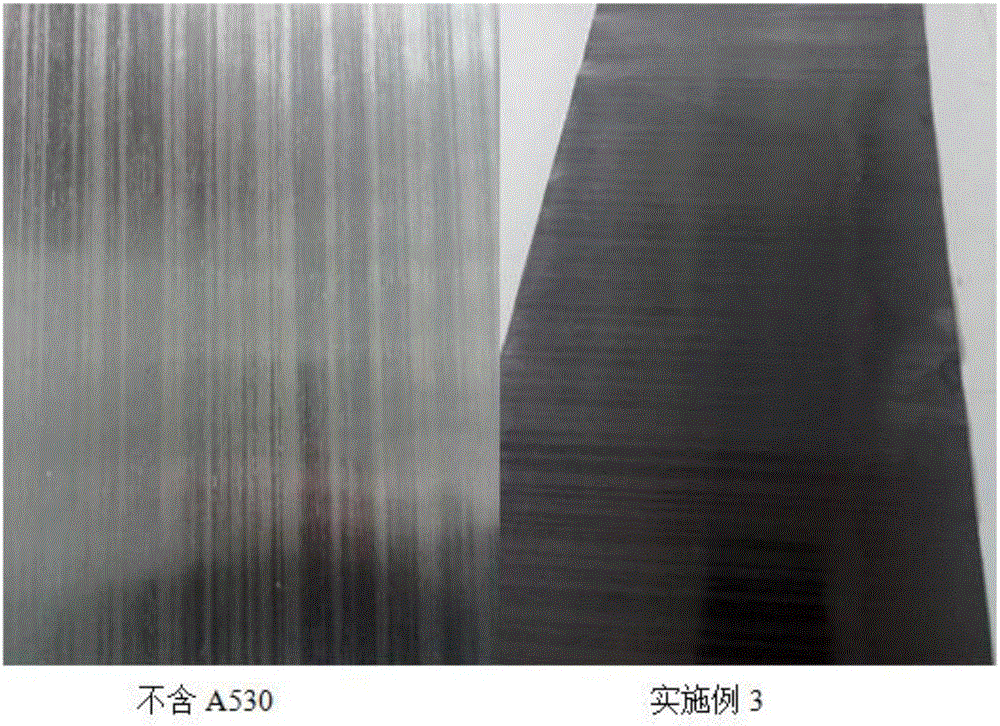

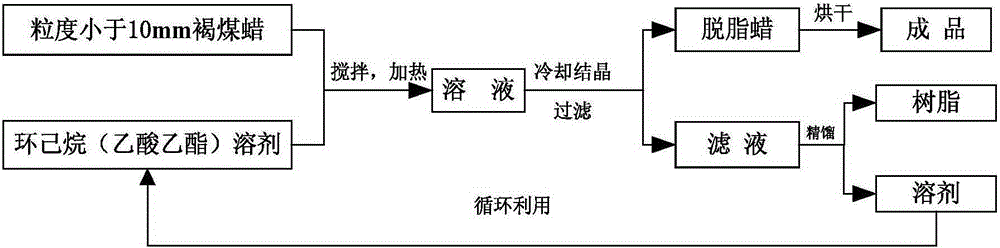

Solvent and method for removing resin in montan wax by crystallization method

InactiveCN104312627BRemove completelyHigh yield of pure waxMineral wax recovery/refiningAcetic acidEcological environment

The invention discloses a solvent and method for removing resin from lignite wax by virtue of a crystallization process, belonging to methods for removing resin from lignite wax. The method comprises the following steps: (1) heating and dissolving, namely putting lignite wax particles into a crystallization kettle, injecting a cyclohexane solvent or an acetic ester solvent according to a material-liquid mass ratio of 1:(5-50), stirring, heating the crystallization kettle by using steam, and controlling the pressure of the container to be 1.0-5.0 MPa until the lignite wax particles are dissolved; (2) cooling and crystallizing, namely after the lignite wax particles are dissolved, stopping heating, performing water cooling on the crystallization kettle until the temperature is between -10 and 20 DEG C, and keeping the low temperature for crystallization for 10-50 minutes; (3) filtering and drying, namely after crystallization, filtering to separate filter residues and filtrate, performing reduced pressure drying on the filter residues at 40 DEG C in a vacuum drying machine, and then performing press forming; and (4) recovering the filtrate, namely recovering by virtue of rectification, and separating the solvent and resin for recycling. The solvent adopted in the method disclosed by the invention is cyclohexane or acetic ester, and the two solvents are nontoxic, cause small harm to human bodies, are not corrosive, can be recycled, are harmless to the ecological environment and are environment-friendly.

Owner:CHINA UNIV OF MINING & TECH

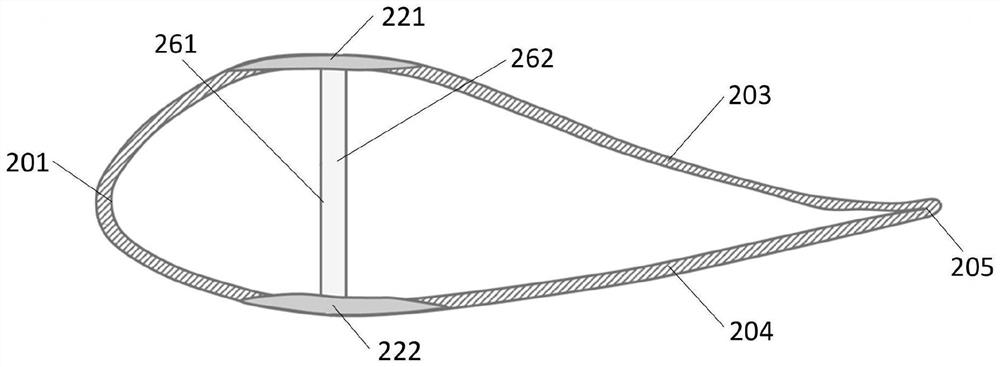

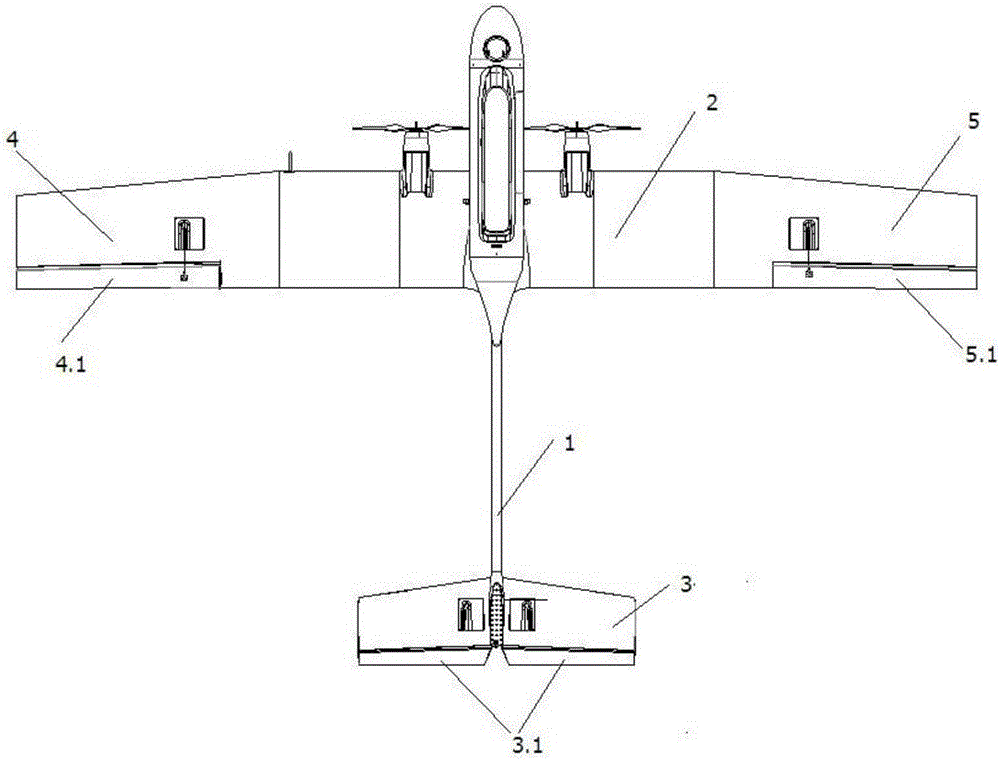

Unmanned aerial vehicle body prepared from composite material, and preparation method thereof

InactiveCN106741823AReduce weightHigh strengthSynthetic resin layered productsGlass/slag layered productsFiberCarbon fibers

The invention provides an unmanned aerial vehicle body prepared from a composite material, and a preparation method thereof. The unmanned aerial vehicle body comprises an airframe and a wing group, wherein the wing group comprises a main wing and a tail wing arranged on two sides of the airframe respectively; two sides of the main wing are connected with a first or second side wing; materials of the airframe and the wing group are of a laminated structure; the material of the airframe comprises first carbon fiber cloth, second carbon fiber cloth, first polyvinyl chloride cloth and third carbon fiber cloth which are sequentially connected in a laminated manner; materials of the main wing and the first and second side wings respectively comprise first carbon fiber cloth, first polyvinyl chloride cloth and second carbon fiber cloth which are sequentially connected in a laminated manner; a material of the tail wing comprises first carbon fiber cloth, first polyvinyl chloride cloth and second carbon fiber cloth which are sequentially connected in a laminated manner. The composite material used for the airframe and the wings of the unmanned aerial vehicle body is light, the tensile strength and tear resistance of the materials of the airframe and the wings are improved, and the structural strength of the unmanned aerial vehicle can be ensured.

Owner:EWATT TECH CO LTD

Method for knitting high-strength rope from high-strength polyethylene fibers

The invention relates to a new production method for knitting a high-strength rope from high-strength polyethylene fibers, which is superior to the current production method for ropes. The method of the invention comprises the following concrete steps: selecting high-strength large-tow polyethylene fibers; by homogenizing tension by a fiber tension device, twisting and stranding multiple tows of fibers; homogenizing the tension of multiple strands of twisted fibers according to the specification requirements of the rope, combining the multiple strands of twisted fibers, and then homogenizing the tension of the combined single-strand tows; knitting 12 strands of ropes by a knitting machine; and coating resin on the surface, drying and shaping to form a high-strength polyethylene fiber rope. The rope produced by the invention has the advantages of convenient use, high strength, corrosion resistance, wear resistance, excellent toughness and flexibility, long service life and the like, and can be widely applied to the fields of industries, national defense, physical education, oceans and the like.

Owner:NINGBO DACHENG ADVANCED MATERIAL

Method for APMP (Alkaline Peroxide Mechanical Pulp) pulping of needlebush

InactiveCN102926252AImprove qualityHigh whitenessPulping with inorganic basesPulping with organic solventsFiberChemical treatment

The invention relates to the technical field of APMP (Alkaline Peroxide Mechanical Pulp) pulping, in particular to a method for the APMP pulping of a needlebush. The method comprises steps as follows: extruding a steamed needlebush piece at the first section; adding chemical medicine liquid A to the extruded piece for chemical processing at the first section, wherein the chemical medicine liquid A includes sodium dodecyl benzene sulfonate and octyl phenol polyoxyethylene ether; extruding at the second section after the first chemical processing; chemically processing after the extruding at the second section, wherein the chemical medicine liquid B includes sodium dodecyl benzene sulfonate and octyl phenol polyoxyethylene ether; then washing after the processing; grinding into pulp; and depositing so as to obtain the needlebush APMP pulping. According to the method, a chemical effect of dipping liquid is improved, a reaction product is deposited, a fiber material is softened, so that energy consumption in follow-up pulping is reduced, quality of the fiber is greatly improved, whiteness of the pulp is improved, content of resin of paper pulp is reduced, and a resin barrier is decreased.

Owner:QILU UNIV OF TECH

Treatment method for surface of carbon fiber resin-based composite material

The invention discloses a treatment method for the surface of a carbon fiber resin-based composite material. The treatment method comprises the following steps that S1, the carbon fiber resin-based composite material is roughly ground and polished by using sandpaper with the mesh number of 200-799; S2, the surface of the carbon fiber resin-based composite material is finely ground and polished for1-n times by using sandpaper with the mesh number of 800-6999 until the surface roughness Ra is less than or equal to 0.8 micron, the sandpaper is replaced each time, the mesh number of the sandpaperis increased, and first angles of the sandpaper polishing direction are changed to remove the last polished traces; and S3, the surface of the carbon fiber resin-based composite material is finely ground and polished for 1-m times by using sandpaper with the mesh number of 7000 or more, the sandpaper is replaced each time, the mesh number of the sandpaper is increased, and second angles of the sandpaper polishing direction are changed to remove the last polished traces. According to the treatment method, the micro defects on the surface of the composite material can be treated under the condition that the carbon fibers are not damaged, so that the resin content of the composite material is reduced, and the surface beauty and the reprocessing effect of the composite material are improved;and the operation is simple, the cost is low, and the time consumption is short.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

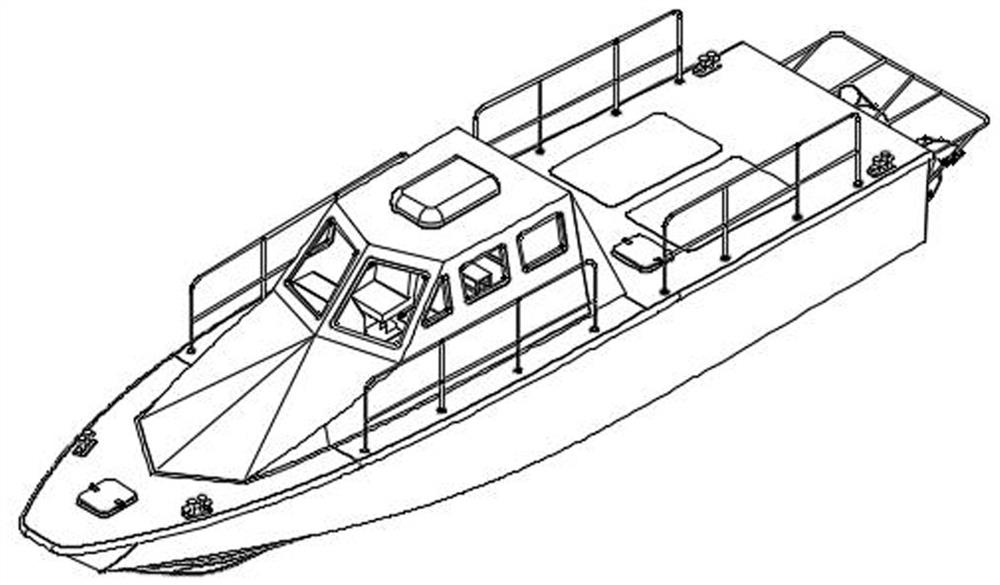

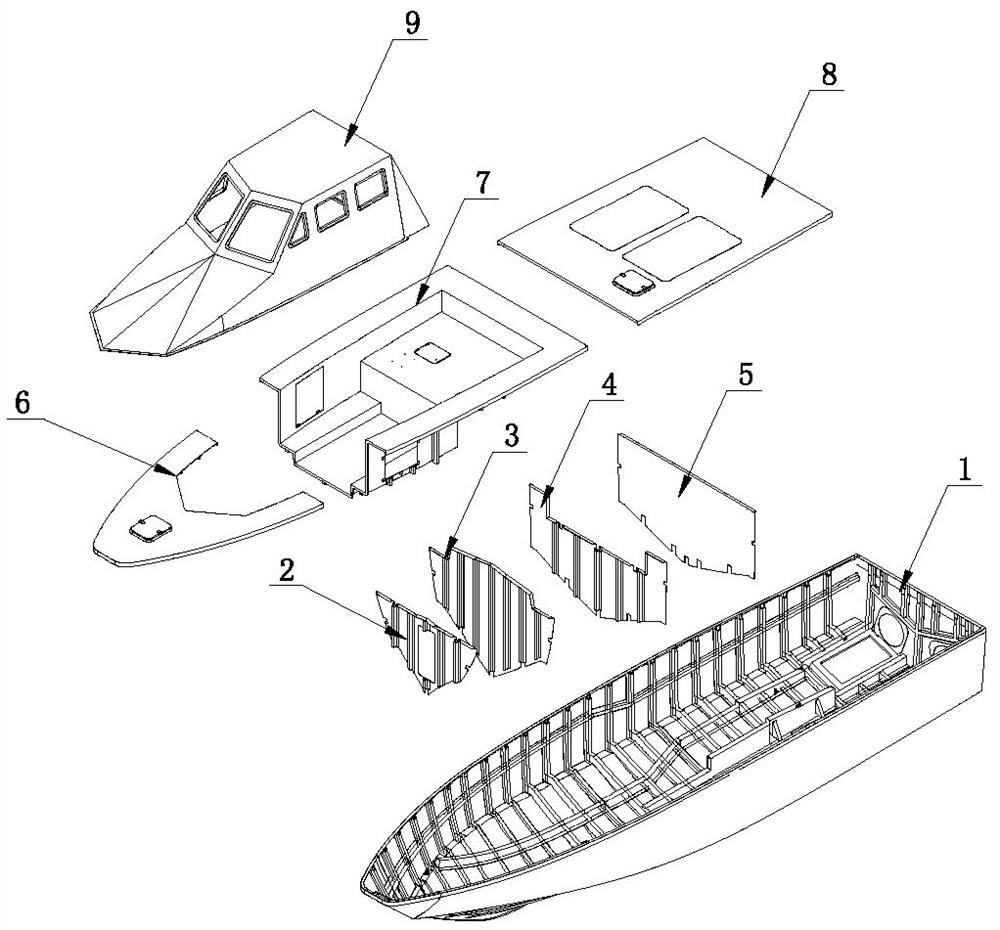

Composite material unmanned ship body forming method

PendingCN114536809AReduce weightReduce porosityWatercraft hull designDomestic articlesManufactured materialMechanical engineering

The invention discloses a composite material unmanned ship body forming method which comprises the following steps: 1) preparing a mold and equipment, and enabling a ship body structure to comprise nine composite material parts; (2) paving the composite material part; 3) autoclave curing molding; according to the method, the boat body is divided into nine parts by adopting a prepreg paving autoclave curing forming process, the number of the parts is reduced, the parts are cut by utilizing an automatic cutting machine to be paved with the shape-following prepreg, the utilization rate of raw materials is effectively improved, and the utilization rate of the raw materials and the production efficiency are remarkably improved.

Owner:JIANGSU XINYANG NEW MATERIALS CO LTD

Woven fabric with a modified ester resin for use as a wet friction liner

InactiveUS6875473B2Improve adhesionHigh glass transition temperatureLiquid surface applicatorsSynthetic resin layered productsYarnOligomer

Woven fabric of continuous, untwisted carbon yarn is impregnated with a modified cyanate ester resin or oligomer, preferably at least about 10% by weight of the combined weight of the cured resin and fabric. The cured fabric may be employed as a wet friction material suitable for use in transmission fluid couplings, and the like. The cured composite sheet can be backed with an adhesive film or liquid bonding paste for ease of bonding to one side of the metal portion of the transmission or clutch. Where thicker material is required, two or more cured composite sheets can be bonded together for applications such as transmissions.

Owner:J D LINCOLN

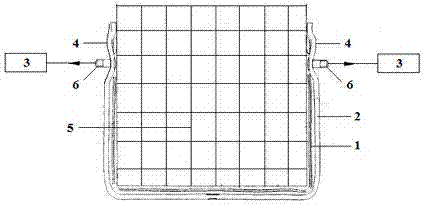

Method for fabricating glass fiber reinforced plastic square box

ActiveCN101791865ASolve difficultySolve the shortcomings of easy deformationSynthetic resin layered productsGlass/slag layered productsGlass fiberWhole body

The invention relates to a method for fabricating a glass fiber reinforced plastic square box. Panels of the square box are prefabricated first and then are spliced into the square box. The splicing method is that the side panels of the square box are hoisted to a bottom panel, and splicing joints between the bottom panel and the side panels and between the side panels are manually pasted for reinforcement. The fabrication steps of the panels are that: (1) the fabricating glass fiber reinforced plastic inner layer with thickness of 5-10mm is fabricated; (2) the fine aggregate mortar interlayer of the panel is fabricated; and (3) the surface of the fine aggregate mortar is ground, the surface is leveled by using resin putty and finally the glass fiber reinforced plastic outer layer of the panel is fabricated. The invention has the advantages that the production preparation tasks are simplified, the overall rigidity is enhanced, the assembling is rapid and simple because the panels are fixed into a whole body in a splicing way, the large square box can be spliced in the field and the transportation difficulty is reduced. Moreover, the invention solves the defects that the fabrication of the glass fiber reinforced plastic square box is very difficult and the square box is apt to be deformed, the cost is reduced because low-cost fine aggregate mortar is used for substituting for the glass fiber reinforced plastic layer, the overall rigidity of the square box is improved and the safety in use is improved.

Owner:LIANYUNGANG ZHONGFU LIANZHONG COMPOSITES GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com