Composite material unmanned ship body forming method

A composite material and molding method technology, applied in the direction of ship hull design, household appliances, other household appliances, etc., can solve the problems of large dispersion coefficient of mechanical properties, high resin content, easy generation of air bubbles, etc., and achieve uniform resin content and low porosity. , pressure and temperature uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

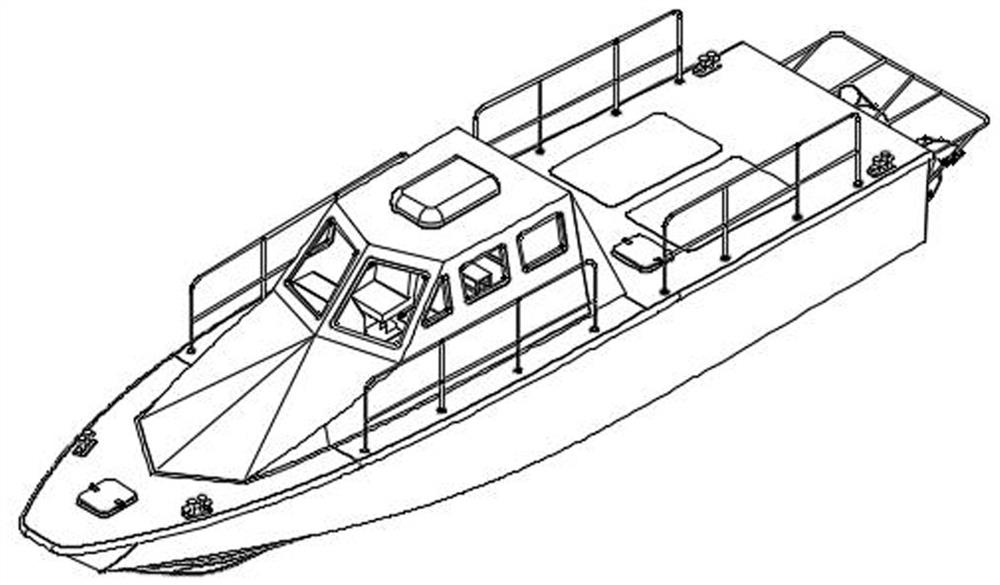

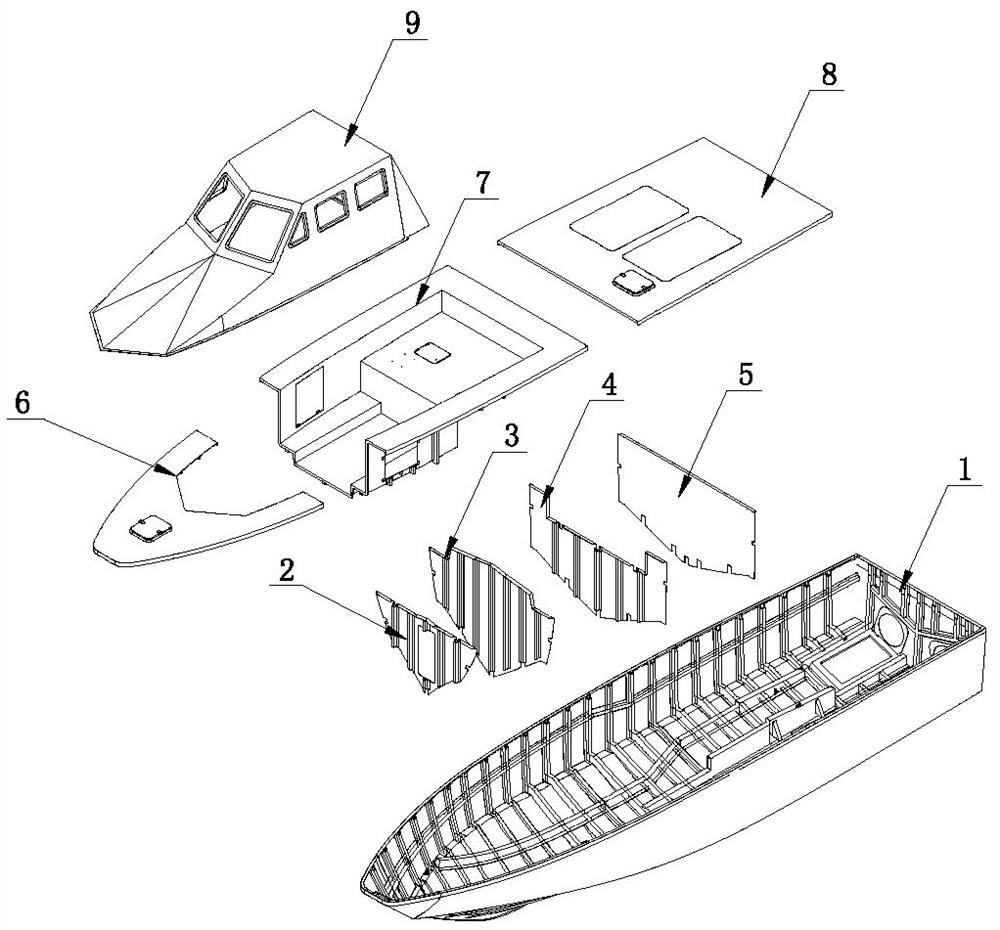

[0020] like figure 1 As shown, the technical parameters of the unmanned boat in this embodiment are that the length of the hull structure is 12.8 meters, the width is 3.2 meters, the height is 3.5 meters, the full water capacity is 13 tons, and the maximum speed is 36 knots; Alkali glass fiber yarn and 300g / m 2 The alkali-free glass fiber plain weave cloth is used as the reinforcing material, and the resin is selected from the medium temperature curing epoxy resin. The resin and glass fiber yarn and plain weave were made into the areal density of 373 g / m 2 of unidirectional fiber prepreg and 461g / m 2 The plain weave prepreg has a resin content of 33% and 35%, respectively.

[0021] 300g / m 2 The alkali-free glass fiber plain weave cloth is compounded with two epoxy resins of the same system, one is made into prepreg by autoclave process, and the other is made by vacuum introduction process to make mechanical properties test panels to test their mechanical properties, such a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com