Manufacturing method of carbon fiber composite material rectangular hollow pipe for mechanical arm

A technology of composite materials and manufacturing methods, applied in applications, household appliances, tubular objects, etc., can solve problems such as uncontrollable resin content, uneven resin distribution, harsh production environment, etc., to save auxiliary material costs, provide longitudinal strength and Shear strength, effect of ensuring surface finish

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred implementation cases of the present invention will be described in detail below with reference to the accompanying drawings.

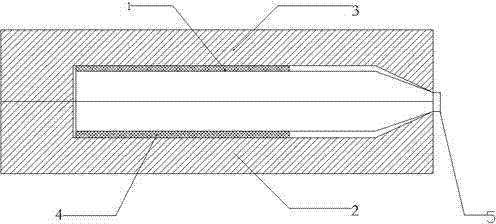

[0031] Such as figure 1 As shown, this embodiment provides a method for manufacturing a carbon fiber composite rectangular hollow tube for a robot arm. The carbon fiber composite material is used as a raw material, and the carbon fiber composite material is a carbon fiber prepreg. The prepreg includes unidirectional and fabric. The prepreg is made into a rectangular hollow tube by means of compression and inflation molding. The resin used in the prepreg is a toughened epoxy resin, and the resin content in the prepreg is 35%-45%. The inner and outer layers of the rectangular hollow tube are made of fabric prepreg, and the middle part of the rectangular hollow tube is made of unidirectional prepreg.

[0032] The upper mold 2 and the lower mold 3 are fixed on the press, and the carbon fiber prepreg is used to lay up the preform 4 on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com