Resin quartz sand premixing equipment

A technology of resin quartz and quartz sand, which is applied in the field of resin quartz sand grading premixing equipment, can solve the problem of not proposing the metering and supply of additives, and achieve the effects of saving direct material costs, good resin infiltration, and saving material volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

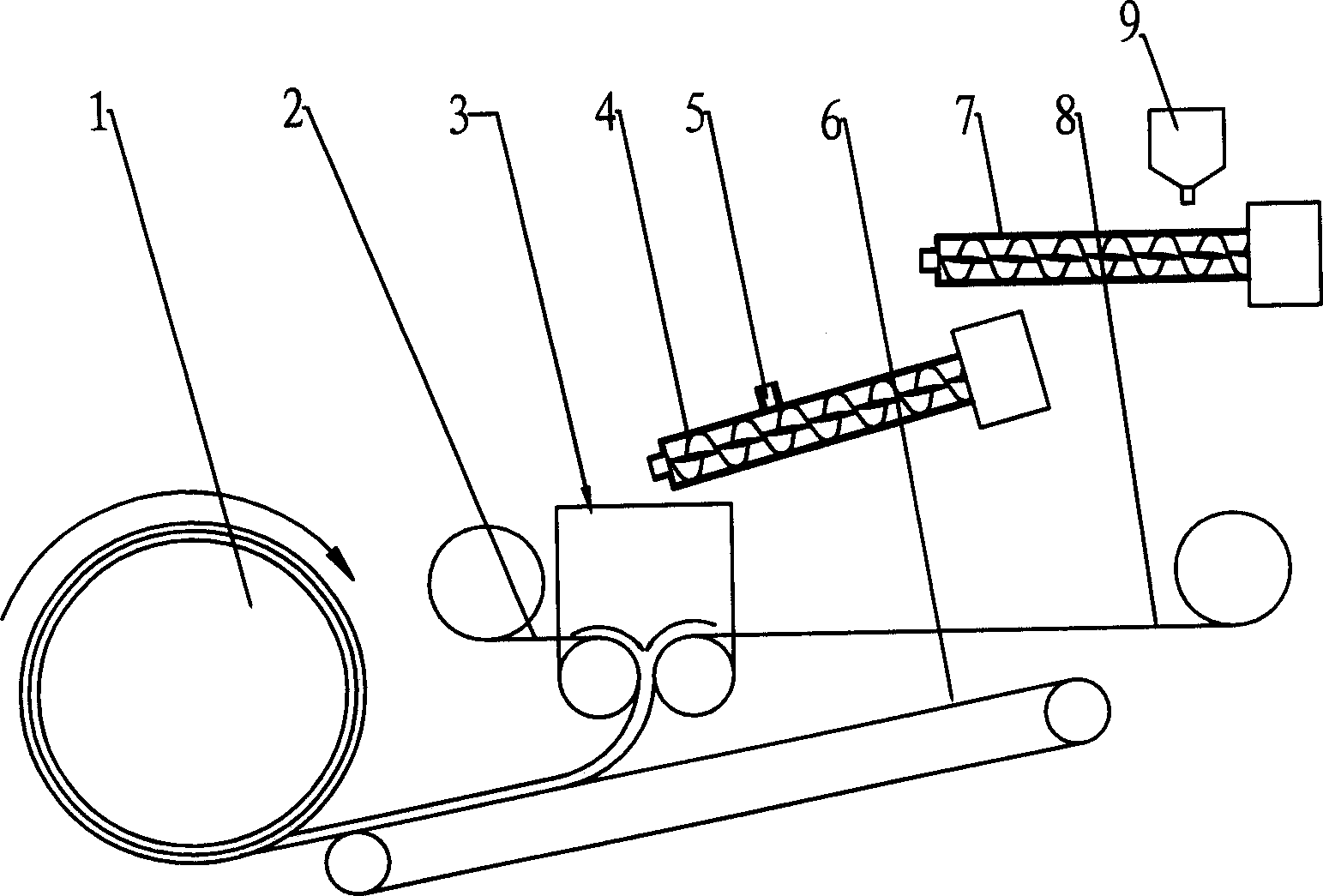

[0018] see figure 1 , a kind of resin quartz sand grading premixing equipment of the present invention comprises a sand conveying device; a premixing agitator 4 arranged downstream of the outlet end of the sand conveying device. The premix agitator 4 has a quartz sand inlet and at least one binder and auxiliary material injection port 5 and a stirring part arranged in the premix equipment, wherein the binder can be such as resin; the premix The mixing agitator 4 continuously conveys the quartz sand material during the stirring process; the adhesive and auxiliary material injection port 5 is arranged downstream of the quartz sand inlet; the premixing agitator 4 is provided with a mixing material outlet export port. The sand conveying device is a metering feed conveyor 7 . The metering supply conveyor 7 has a sand conveying shell, and a spiral part is arranged in the cylindrical shell, and the sand conveying shell and the spiral part form a sand conveying screw conveyor (commo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com