Carbon-plastic composite bipolar plate for fuel cell as well as preparation and application thereof

A bipolar plate, carbon plastic technology, applied in the direction of fuel cells, circuits, electrical components, etc., can solve the problems of reduced bipolar plate cost, low production efficiency, high production cost, and achieve good product quality, low cost, and resin reduction. The effect of content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

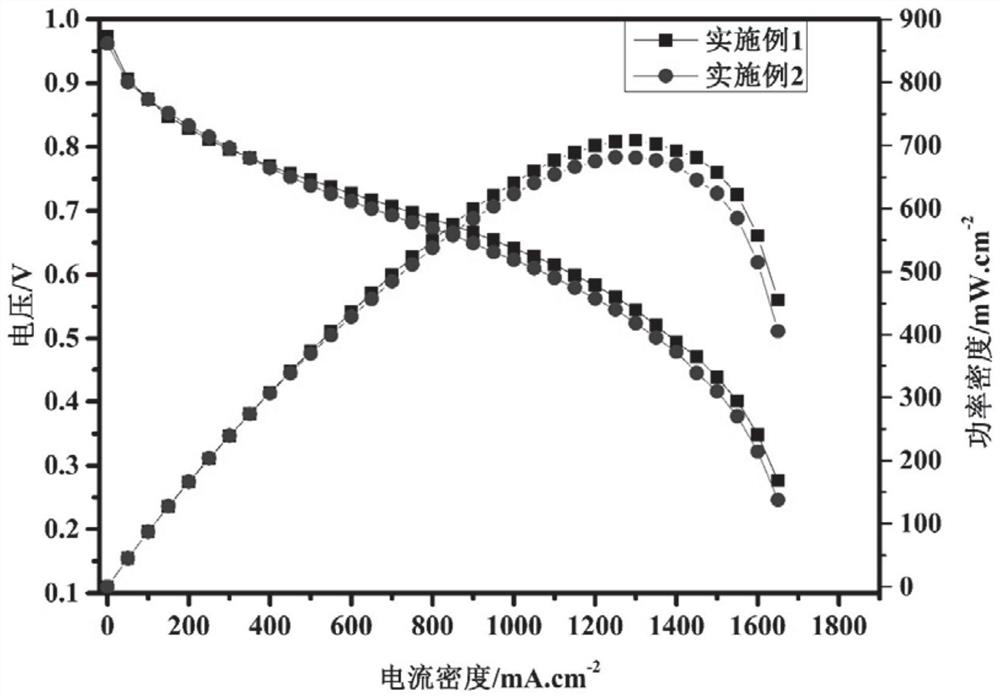

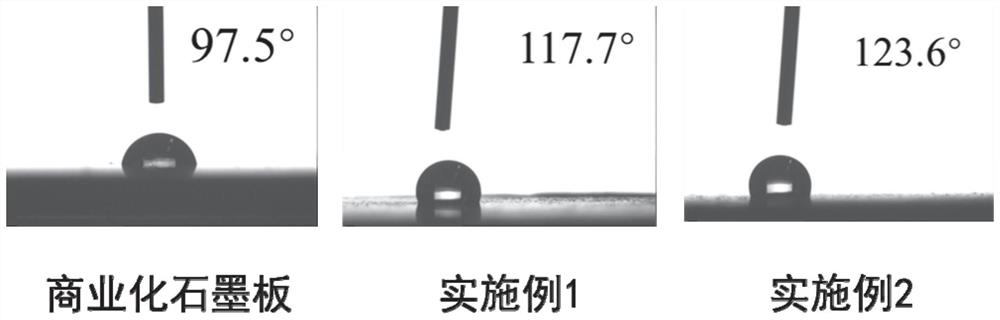

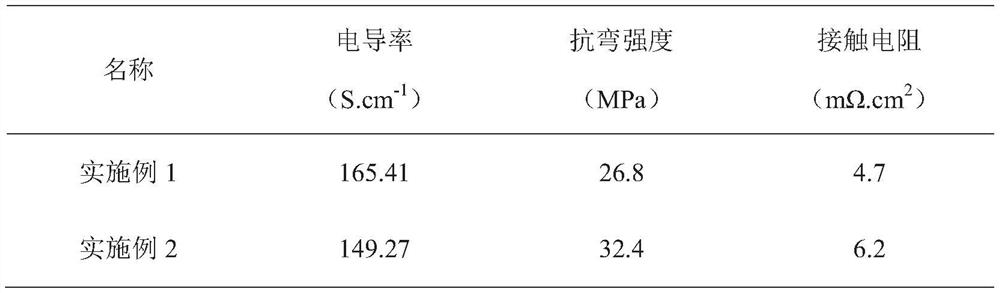

[0031] Weigh respectively PPS resin (molecular weight is 100,000) 1.0kg, PVDF resin (molecular weight is 300,000) 0.8kg, SEBS resin (styrene content 15%, melt index is 6g / 10min under 200 ℃) 0.2kg, natural flake graphite Powder (purity 99.0%, 400 mesh) 8.5kg, carbon fiber (diameter is 5 μm, aspect ratio is 20) 0.4kg, join in the ball mill, ball milling temperature is room temperature 25 ℃, ball milling speed is 50r / min, ball milling time 20min. Then the uniformly mixed material was transferred to a mold with a flow field, the pre-compression pressure was 60MPa, the molding temperature was 320°C, the molding pressure was 120MPa, and the molding time was 20min. Finally, the temperature of the mold was lowered to room temperature 25°C by circulating water cooling, and the carbon / polymer composite bipolar plate was obtained by releasing the pressure and demoulding. The operating conditions of the single cell are: the platinum loading of the cathode and anode is 0.4 / 0.2mg cm -2 , t...

Embodiment 2

[0033] Take by weighing PPS resin (molecular weight is 100,000) 1.5kg, PVDF resin (molecular weight is 300,000) 0.75kg, SEBS resin (styrene content 20%, melt index is 10g / 10min under 200 ℃) 0.2kg, natural flake graphite Powder (purity 99.0%, 400 mesh) 9.0kg, carbon fiber (diameter is 5 μm, aspect ratio is 20) 0.5kg, join in the ball mill, ball milling temperature is room temperature 25 ℃, ball milling speed is 80r / min, ball milling time 15min. Then the uniformly mixed material was transferred to a mold with a flow field, the pre-compression pressure was 80MPa, the molding temperature was 350°C, the molding pressure was 100MPa, and the molding time was 30min. Finally, the temperature of the mold was lowered to room temperature 25°C by circulating water cooling, and the carbon / polymer composite bipolar plate was obtained by releasing the pressure and demoulding.

[0034] The steps of applying the prepared composite bipolar plate to the fuel cell and the battery performance test ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com