Quick resin forming method based on LCD (liquid crystal display) selective regional light transmission principle

A molding method and selective technology, applied in the field of photocuring molding, can solve the problems of large investment, high cost of parts manufacturing, high operating cost of the system, hindering the promotion and application of advanced technology and system, etc., achieving short molding time, simple and convenient replacement, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

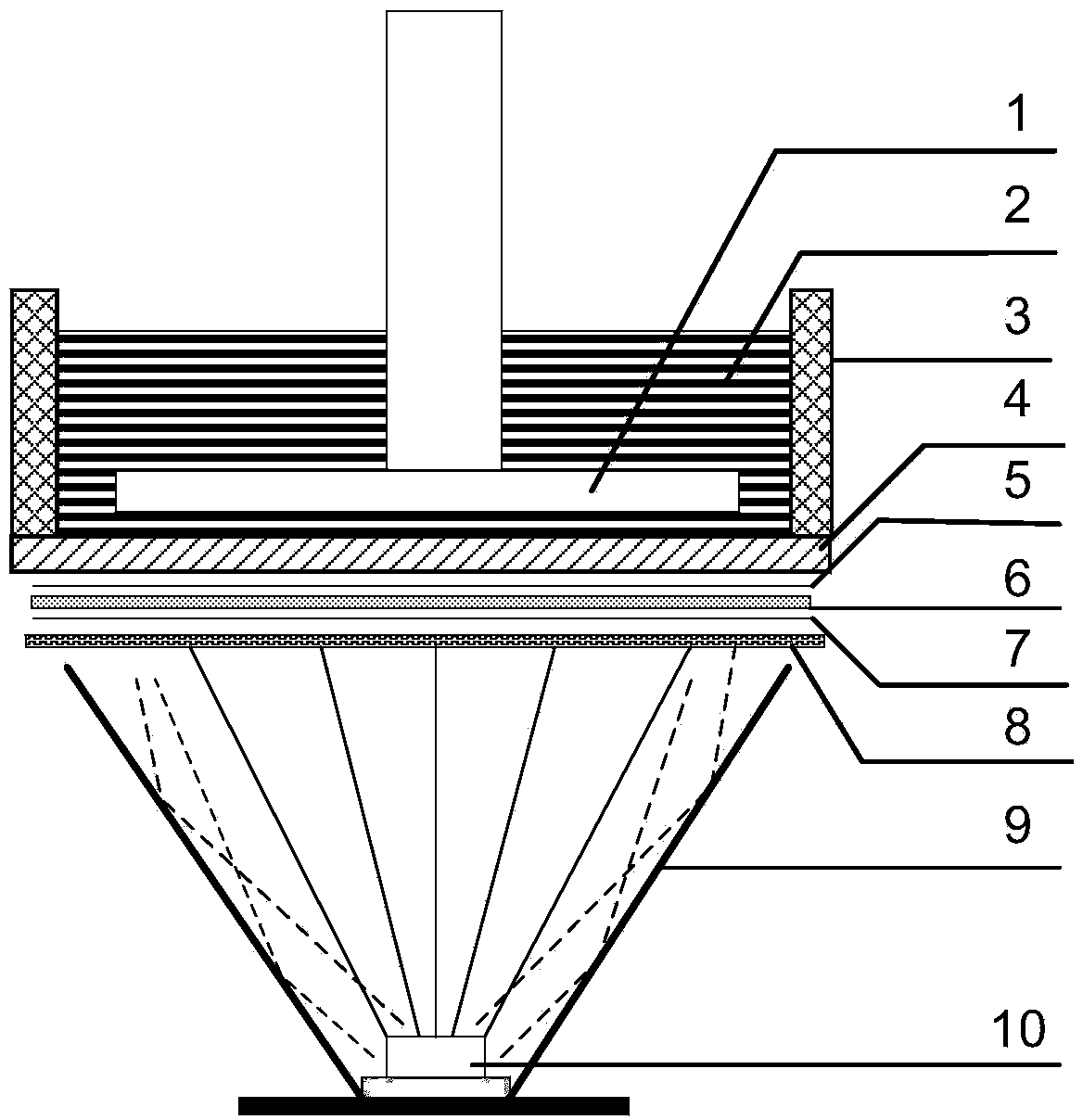

[0035] The invention adopts the principle of LCD selective area light transmission, and uses high-power 405nm LED light source for exposure molding; uses a stepping motor to control Z-axis movement; selects photosensitive resin with a peak photosensitive wavelength of 405nm as the material to be cured; and selects a five-pointed star model.

[0036] This example is carried out as follows: clean the resin storage tank, add resin after drying, and place it on the processing platform; use 3Dmax to draw the closed curve of the five-pointed star, and generate a three-dimensional model by lofting, with a height of 1.0cm, and save it as OBJ format; import the file into professional software to slice and discretize the surface model, adjust the slicing accuracy to about 200 μm, save the image of each surface model in jpg format; import these image files into the control software; set the light source exposure time to 3s, and Z-axis movement The system rises by 200 μm after each exposur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com