Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

223results about How to "With balance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

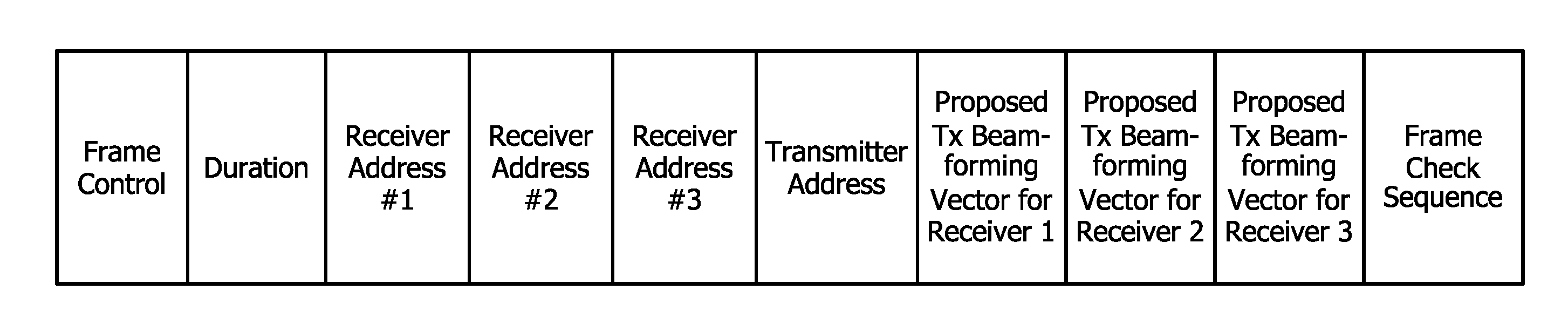

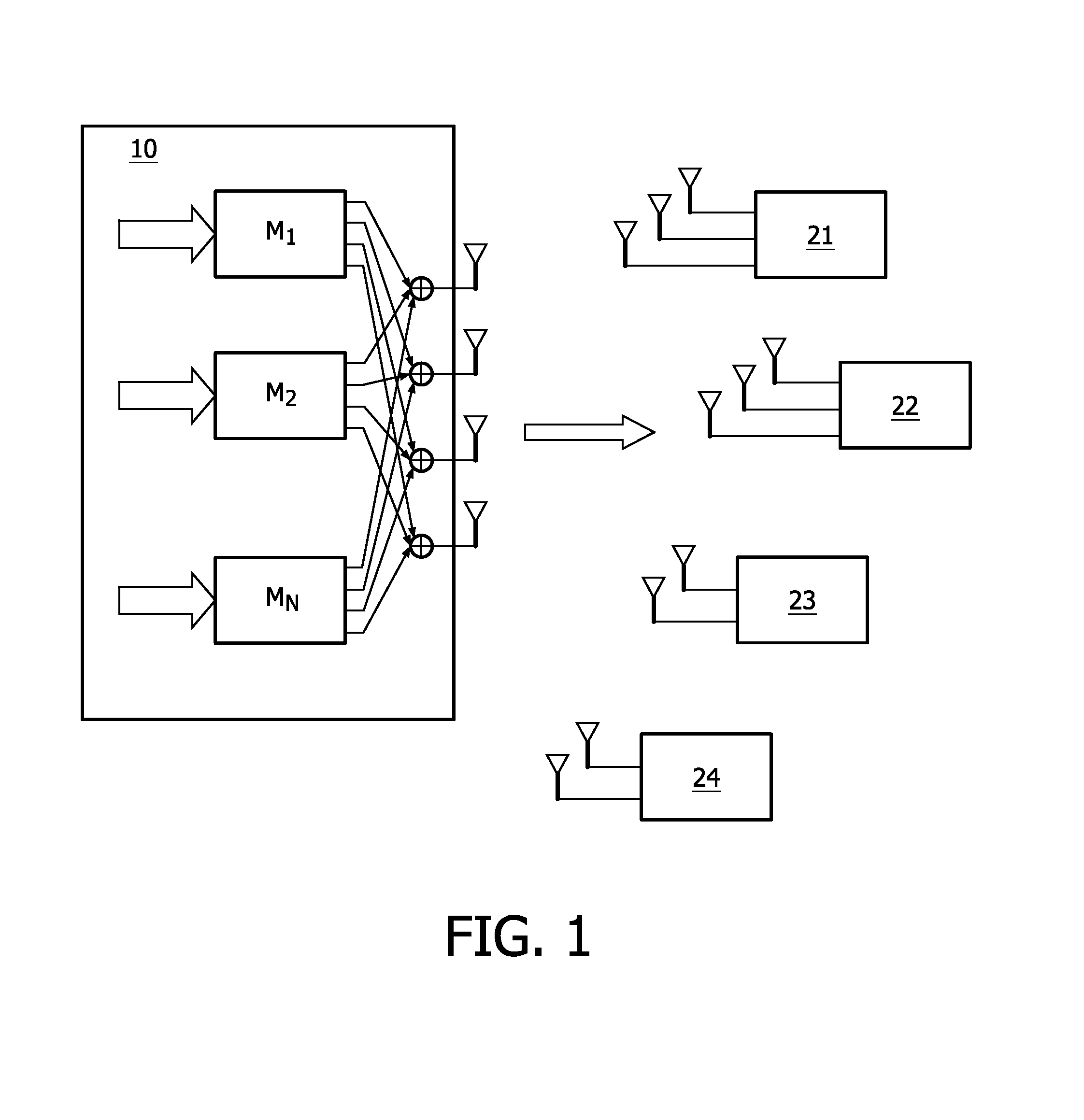

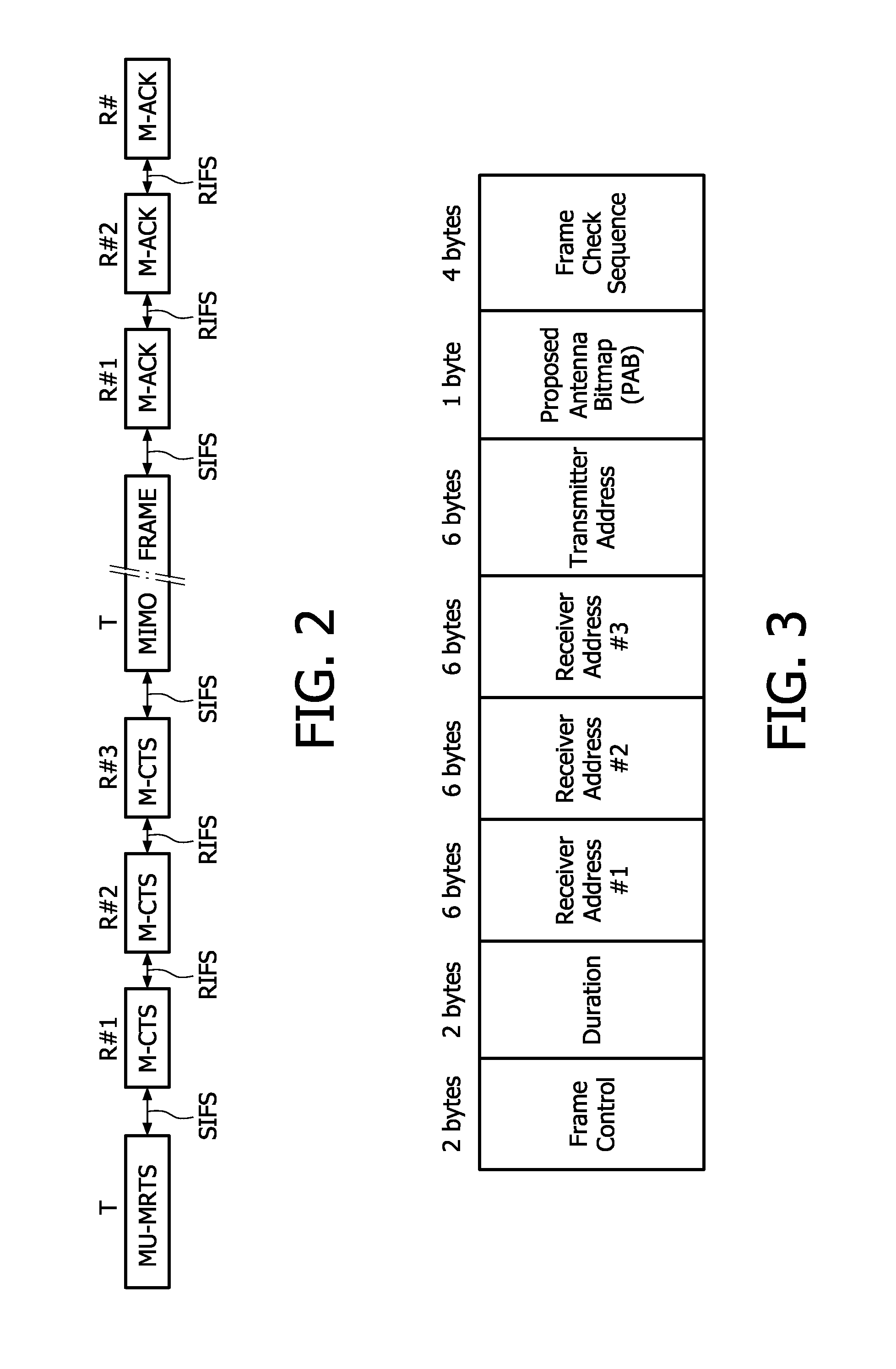

Enhanced multi-user transmission

ActiveUS20110150004A1Less modificationWith balanceReceivers monitoringNetwork traffic/resource managementMedia accessMedia access control

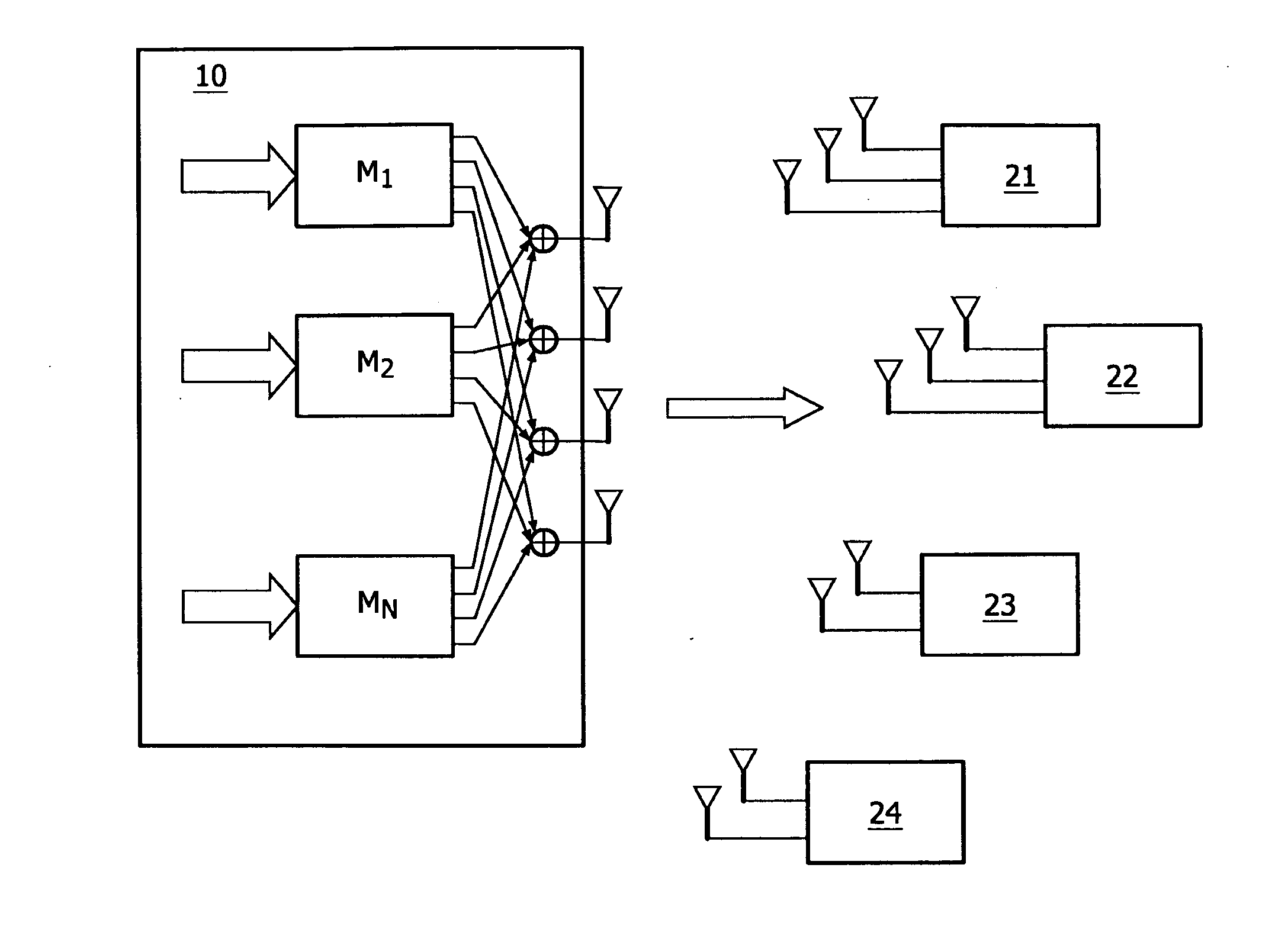

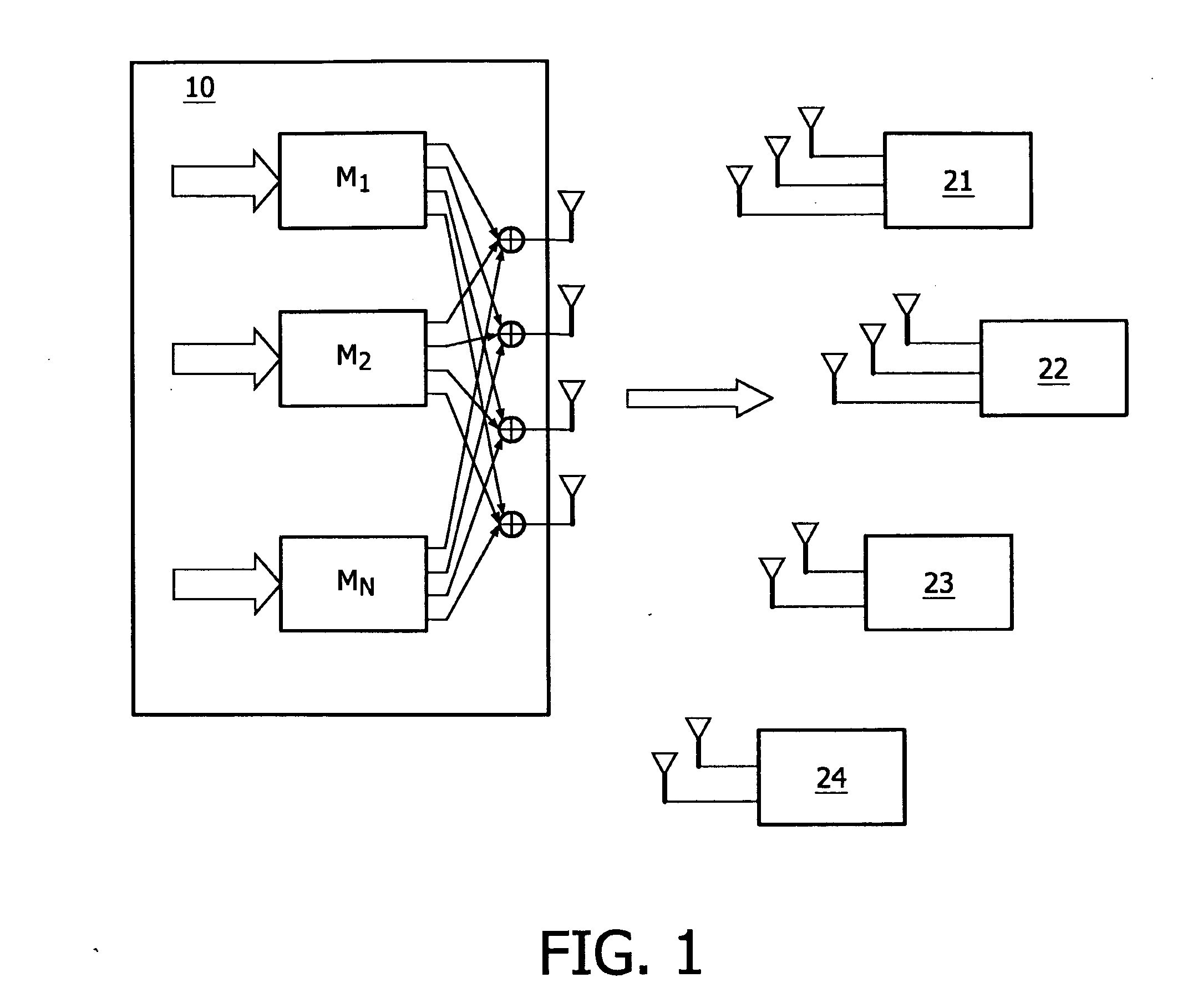

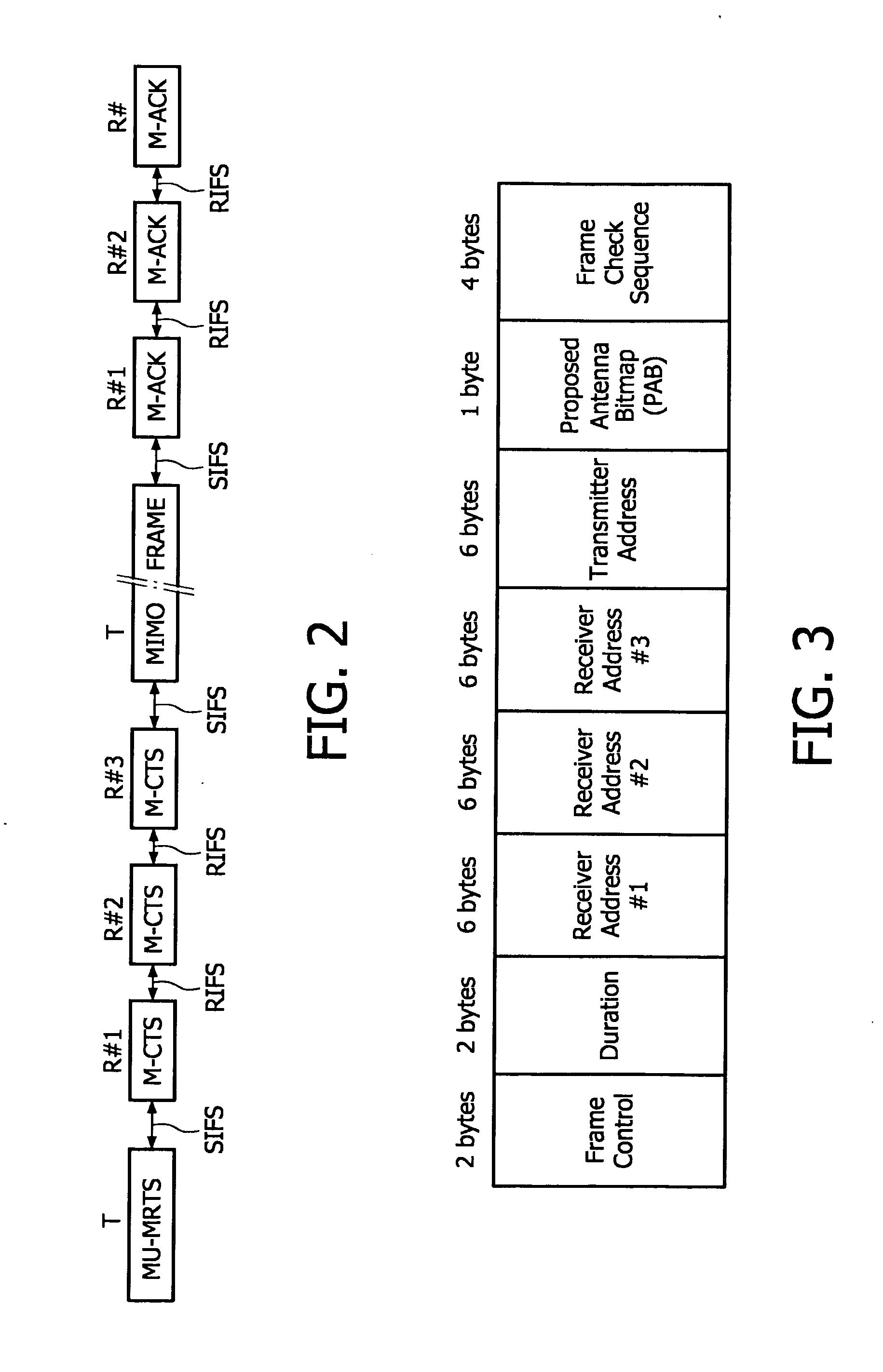

The present invention relates to a transmitting apparatus, a receiving apparatus, a system and a method of performing multi-user transmission to a plurality of other transmission ends (21-24), wherein a request for transmission is broadcast to said plurality of other transmission ends (21-24), and the request is provided with a Medium Access Control MAC frame which includes a list of at least two identifications of receiving ends which are requested to reply to the request.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Liquid crystal polymer film, laminate, method of making them and multi-layered parts-mounted circuit board

InactiveUS6274242B1With balanceImprove thermal conductivityLiquid crystal compositionsLamination ancillary operationsThermal deformationPolymer chemistry

A polymer film capable of forming an optically anisotropic melt phase is, after having been laminated on a base material capable of supporting the shape of the film during heat treatment, is heat-treated at a temperature of from the thermal deformation temperature Tdef of the film to a temperature lower by alpha (alpha=10 to 35° C.) than the melting point Tm of the film until the fusion peak temperature TA of the film attains a temperature which is higher by beta (beta=5 to 30° C.) than the melting point Tm of the film before the heat treatment and is subsequently heat-treated at a temperature of from a temperature not lower than the melting point Tm of the film to a temperature lower than the fuision peak temperature TA for a length of time over which the TA increases by gamma (gamma=5 to 20° C.), and thereafter the base material is removed to produce the film.

Owner:KURARAY CO LTD

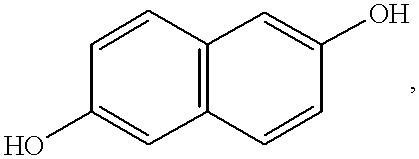

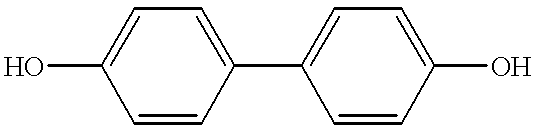

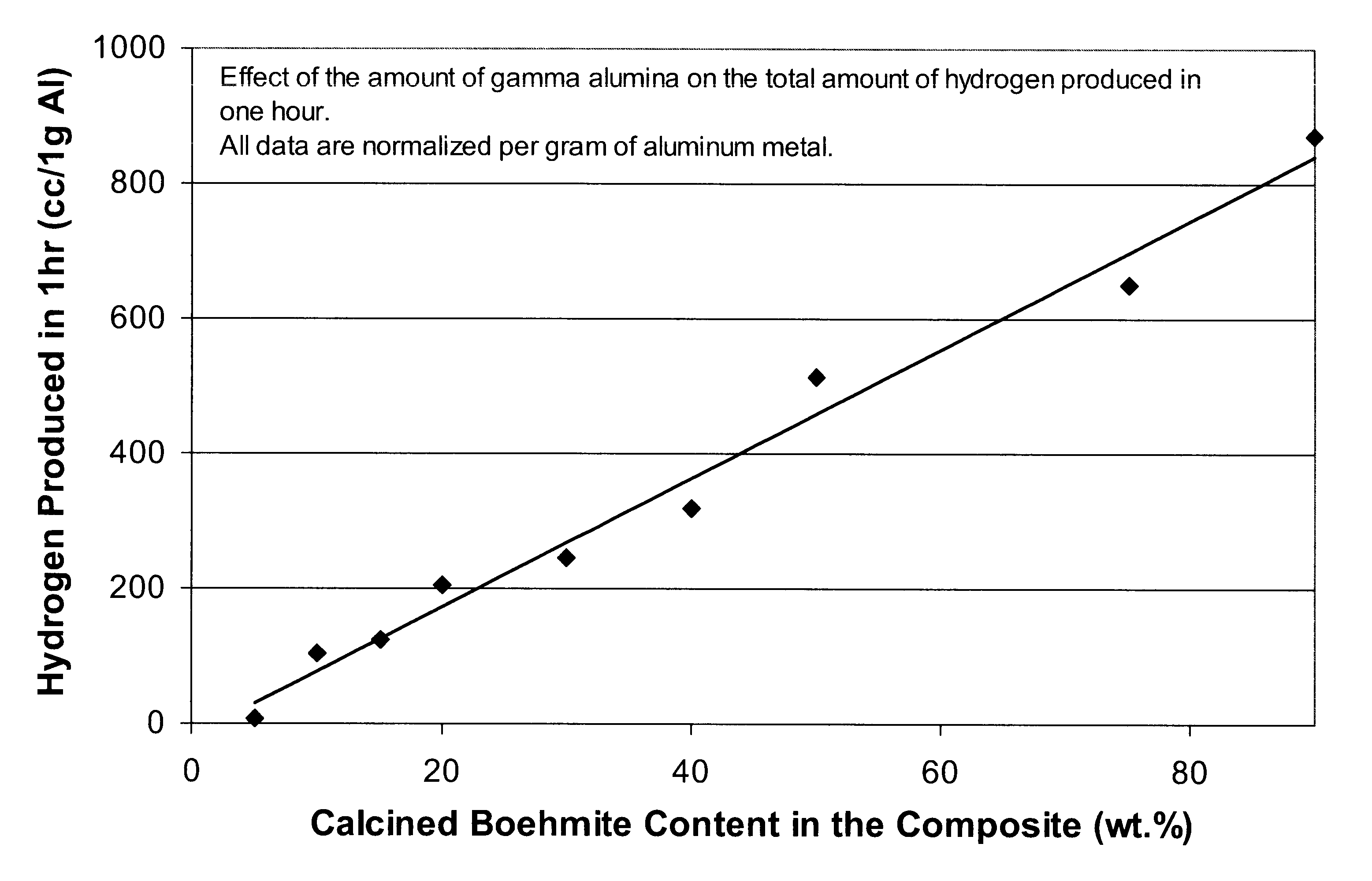

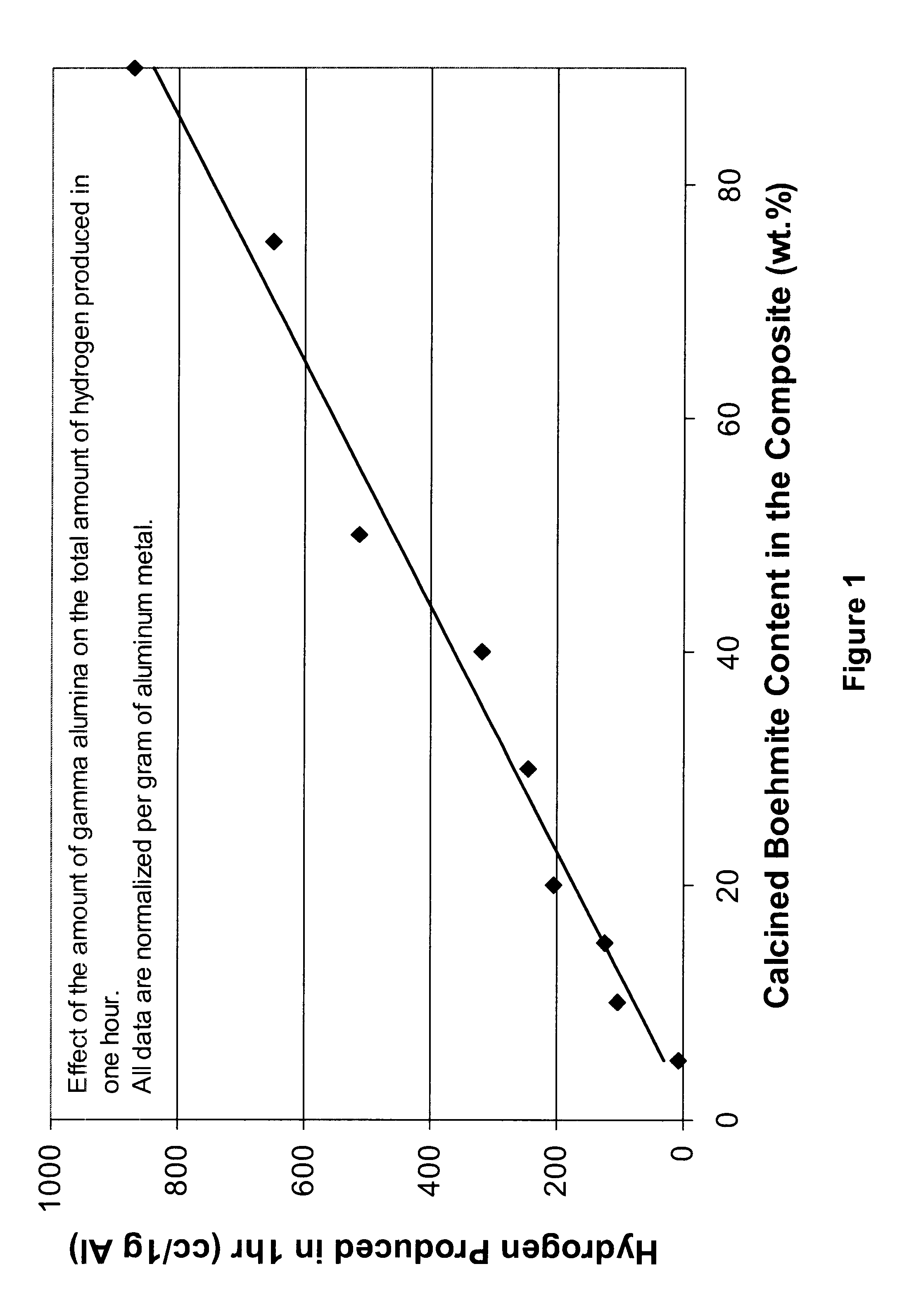

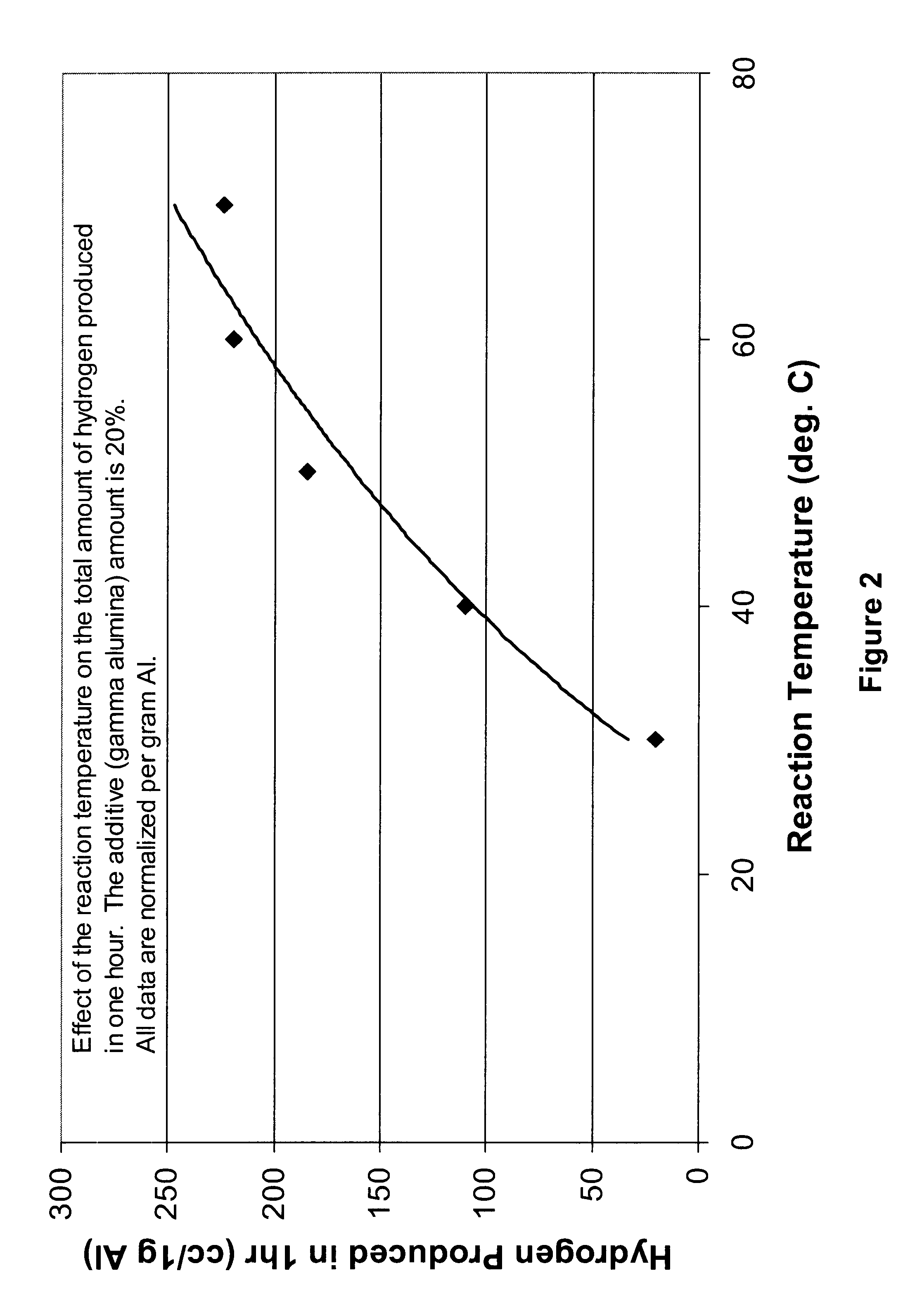

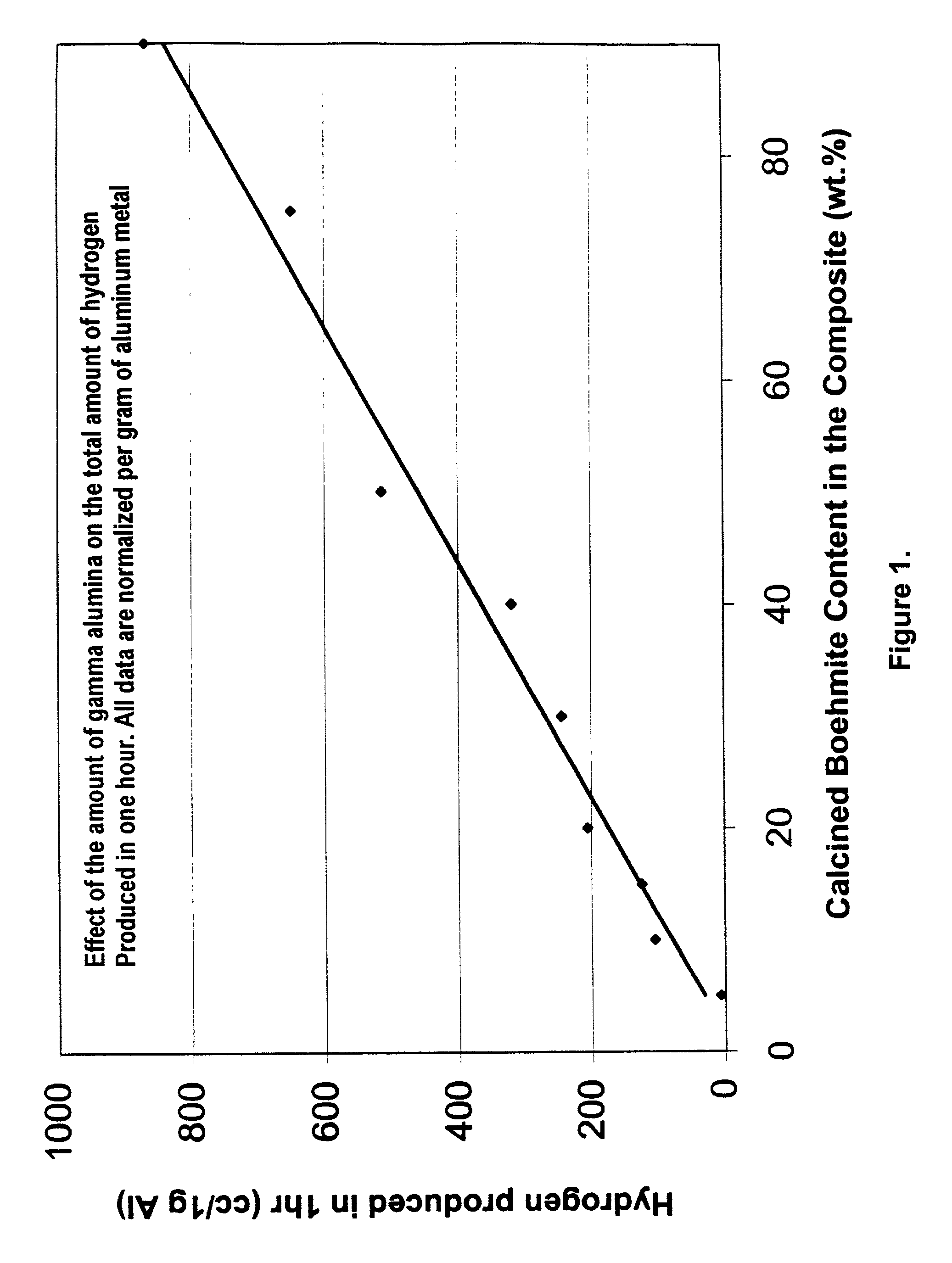

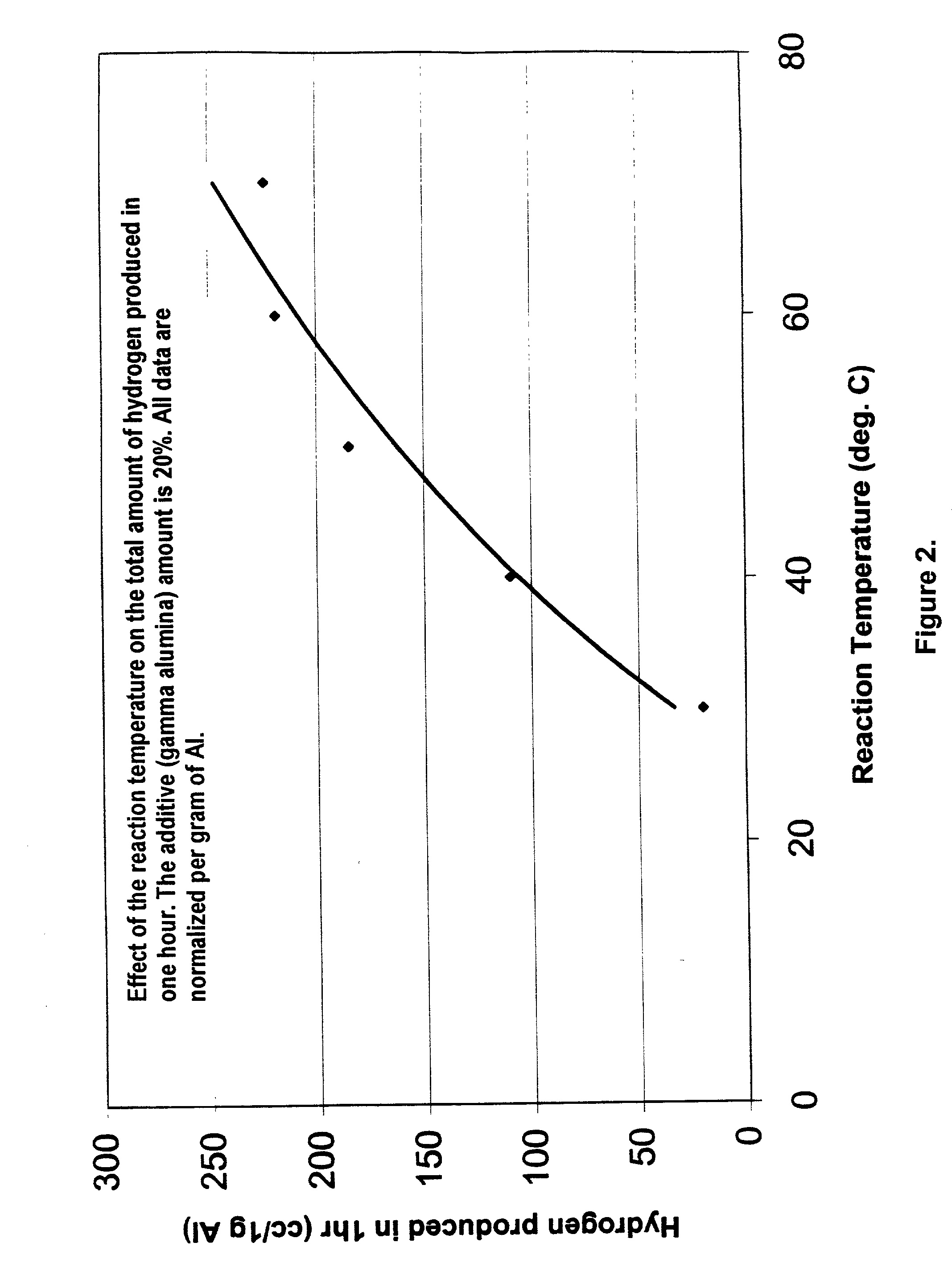

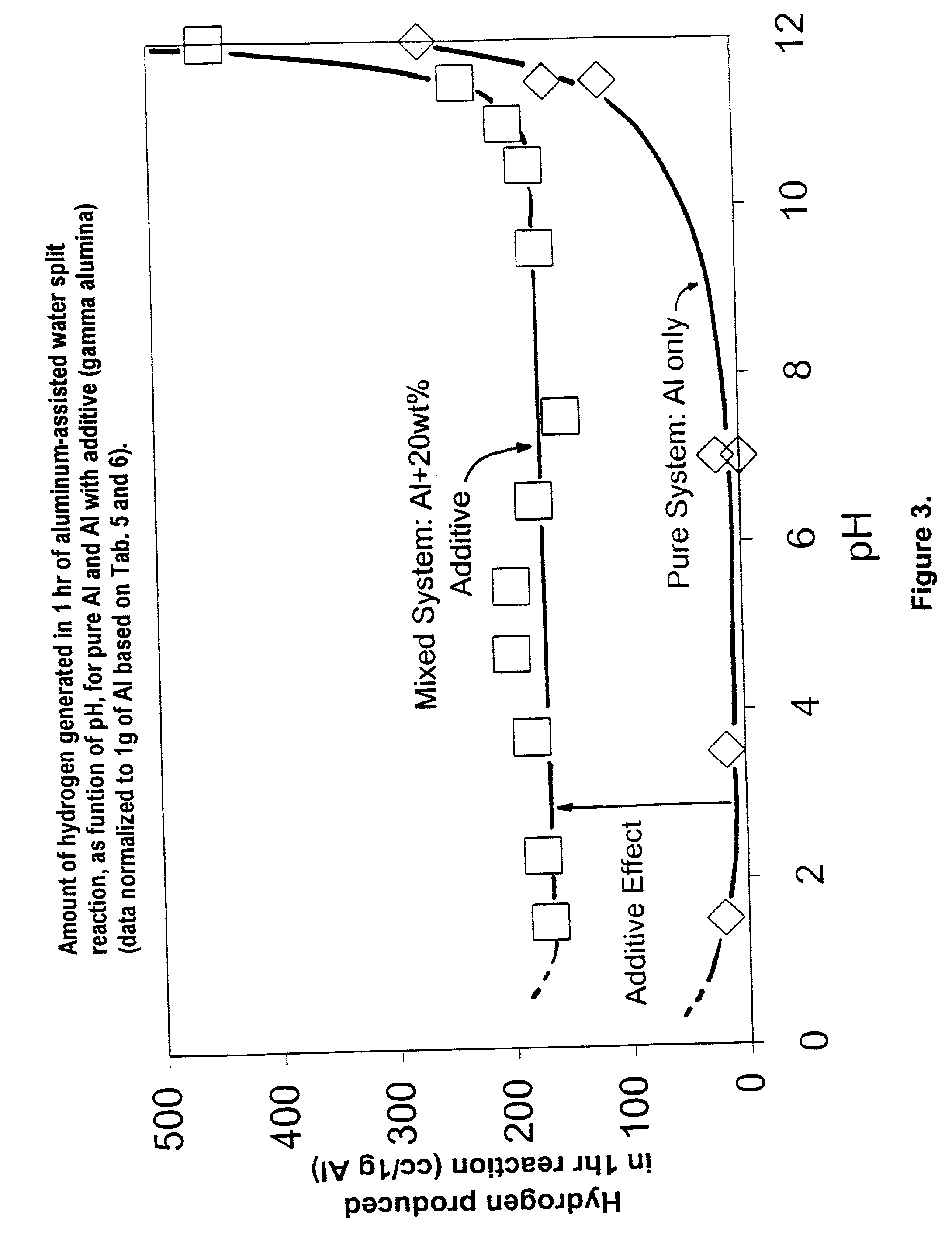

Hydrogen generation from water split reaction

A method of producing Hydrogen by reacting a metal selected from the group consisting of Aluminum (Al), Magnesium (Mg), Silicon (Si) and Zinc (Zn) with water in the presence of an effective amount of a catalyst at a pH of between 4 and 10 to produce Hydrogen. The catalyst or other additive is selected to prevent or slow down deposition of the reaction products on the (impair reactions with the) metal that tend to passivate the metal and thereby facilitates the production of said Hydrogen.

Owner:THE UNIV OF BRITISH COLUMBIA

Hydrogen generation from water split reaction

A method of producing Hydrogen by reacting a metal selected from the group consisting of Aluminum (Al), Magnesium (Mg), Silicon (Si) and Zinc (Zn) with water in the presence of an effective amount of a catalyst at a pH of between 4 and 10 to produce Hydrogen. The catalyst or other additive is selected to prevent or slow down deposition of the reaction products on the (impair reactions with the) metal that tend to passivate the metal and thereby facilitates the production of said Hydrogen.

Owner:THE UNIV OF BRITISH COLUMBIA

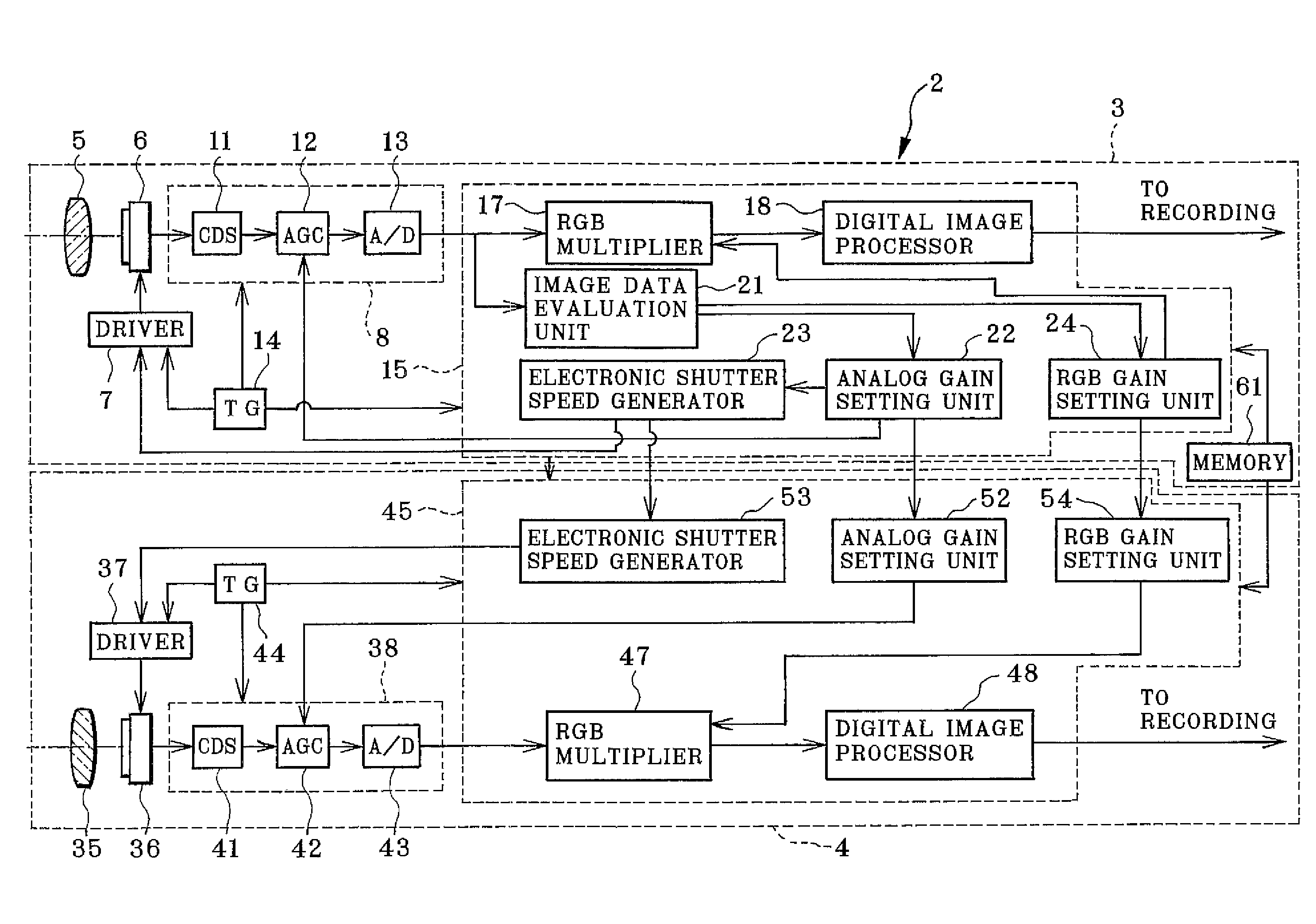

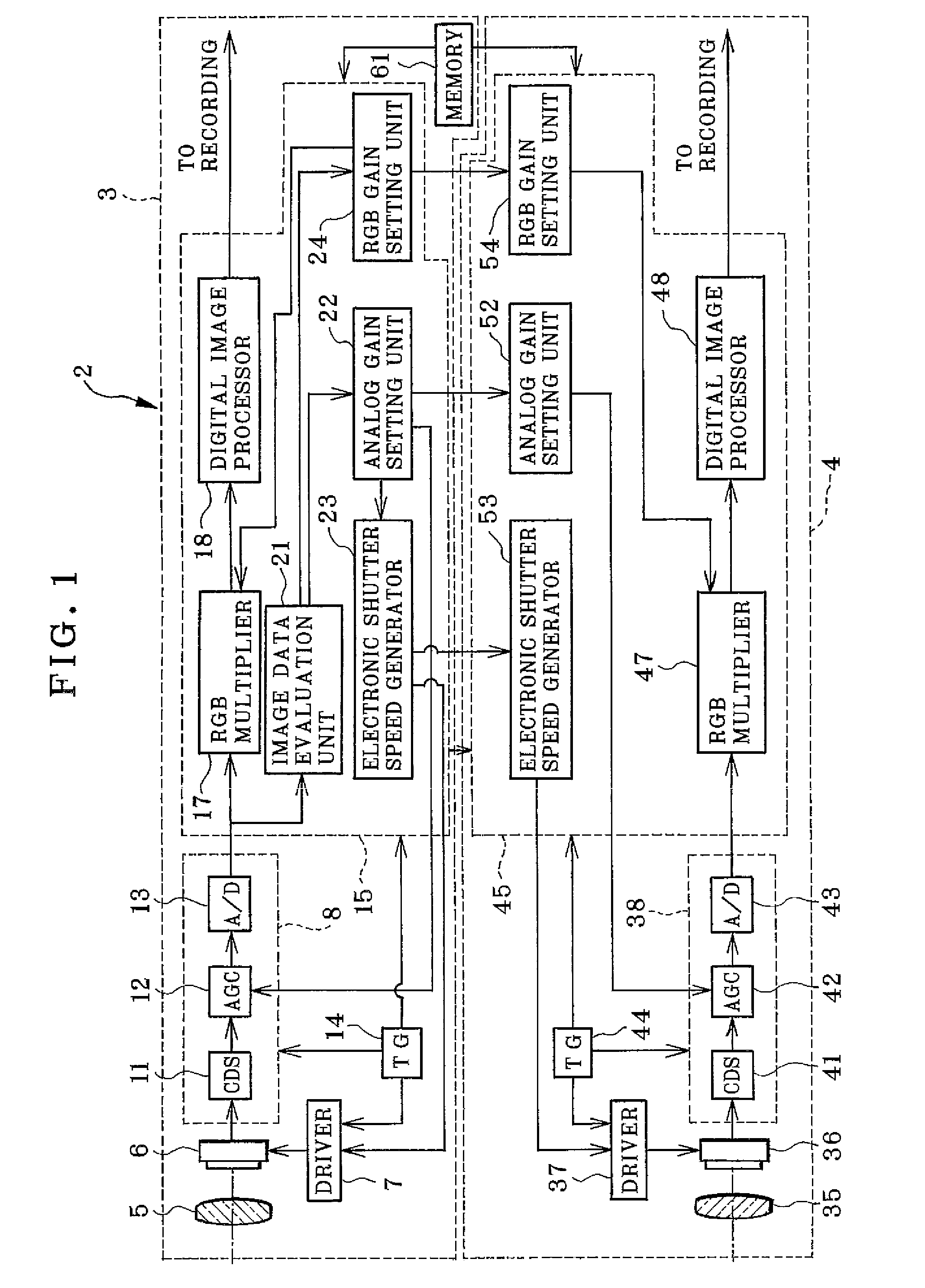

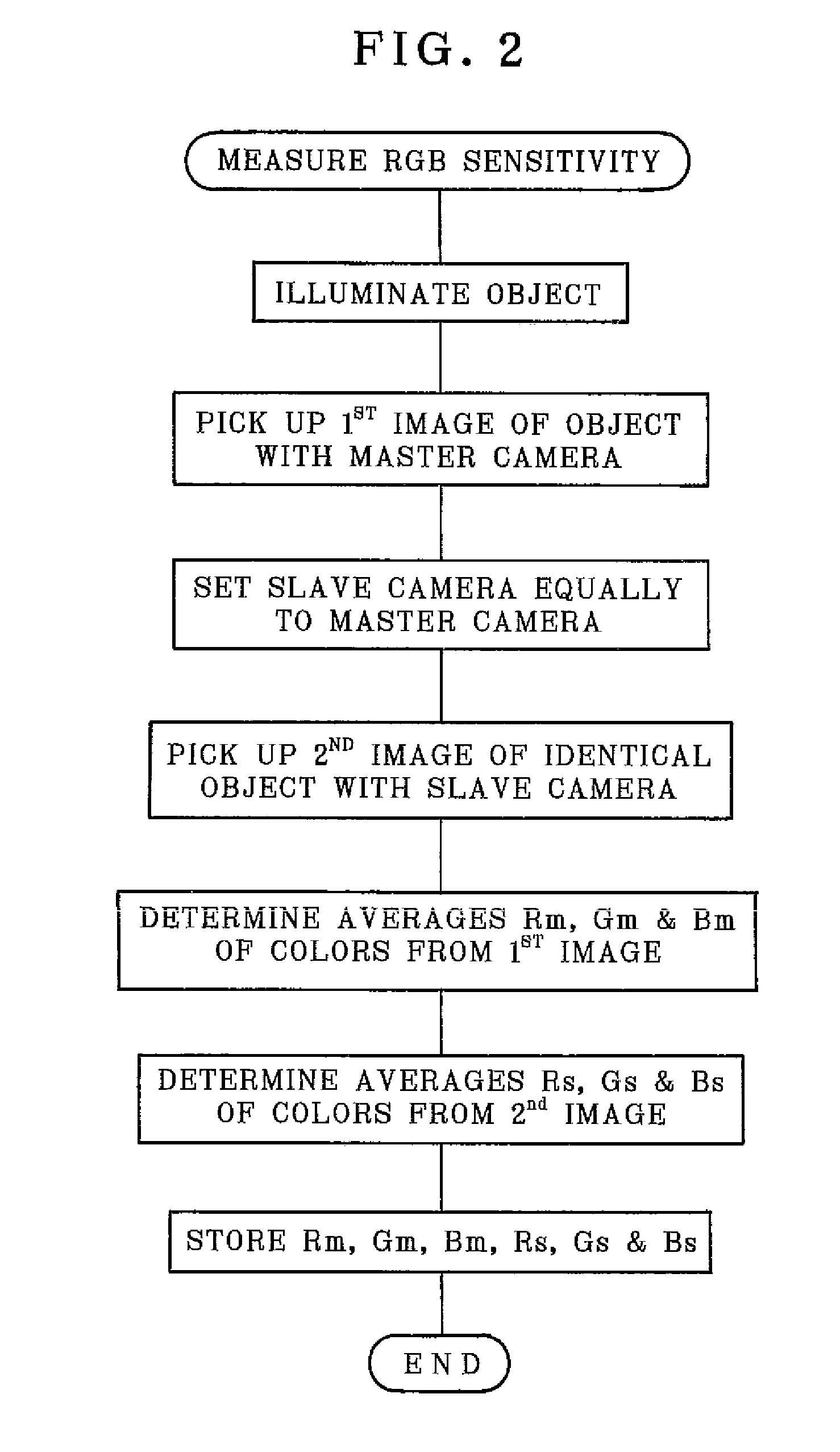

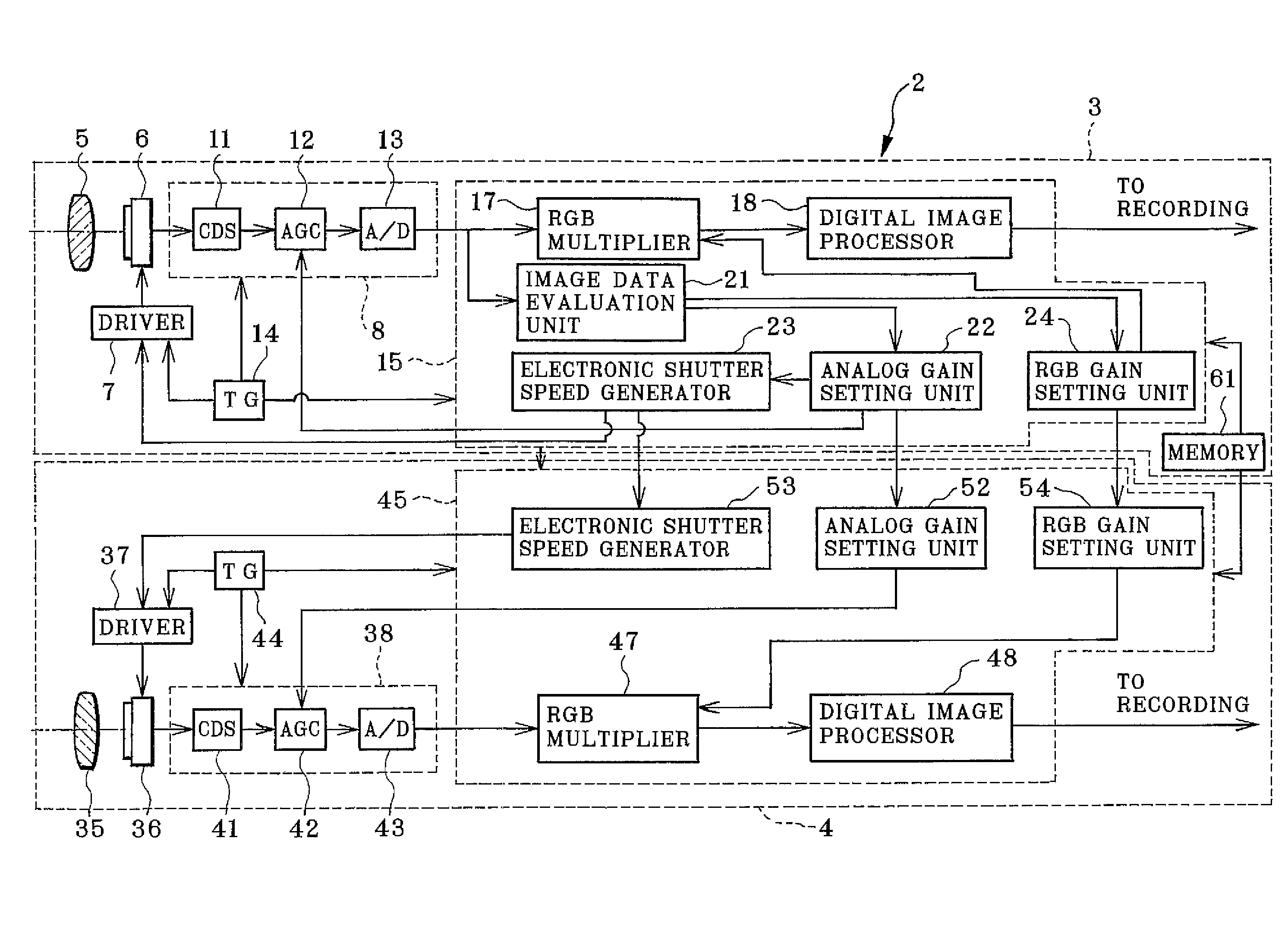

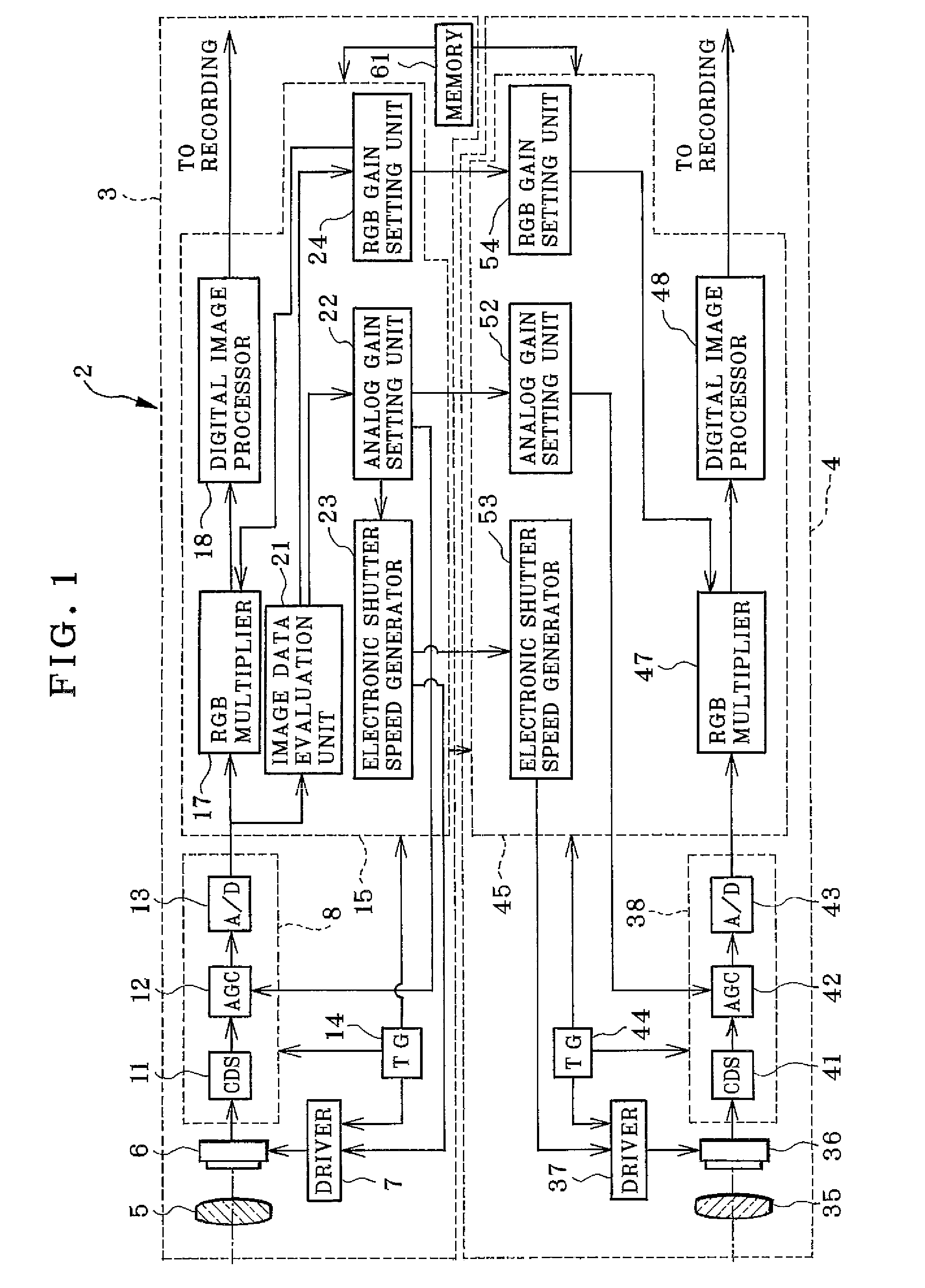

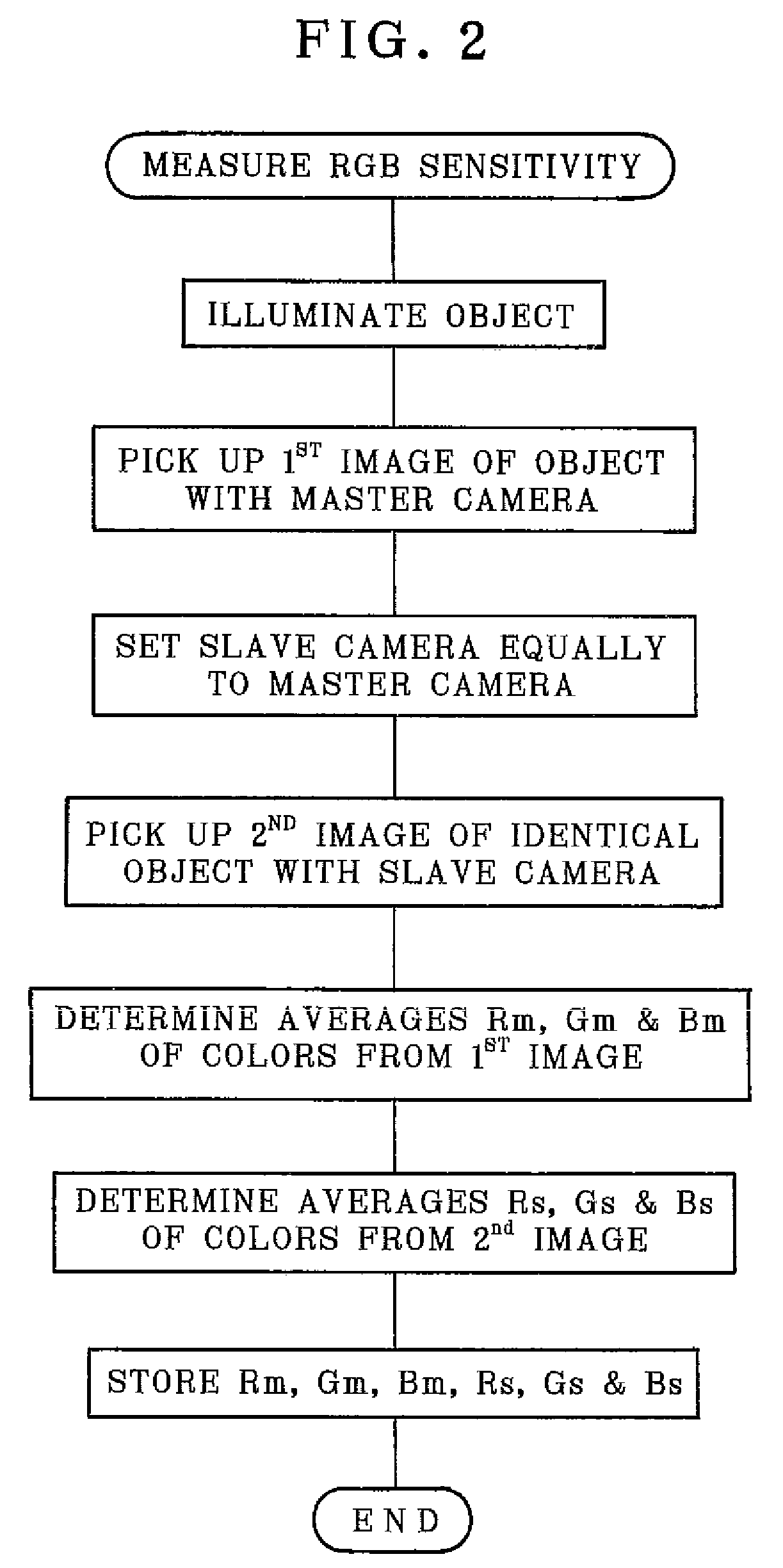

Multi-eye image pickup apparatus and adjusting method

InactiveUS20090015689A1With balanceImprove the level ofTelevision system detailsColor signal processing circuitsStereo cameraPhotoelectric conversion

A stereoscopic camera includes a master camera for photoelectric conversion of object light to generate a first image signal with three color components G, R and B. A slave camera generates a second image signal. In an adjusting method, a first gain Dmr, Dmg and Dmb of the color components is determined according to the first image signal to correct a brightness level and white balance of the master camera, to adjust the first image signal by use thereof. A second gain Dsr, Dsg and Dsb of the color components is determined according to the first gain and color calibration information predetermined according to color sensitivity of the master and slave cameras in relation to the color components. The second image signal is adjusted by use thereof, for color matching between the first and second image signals to set equal the brightness level and the white balance.

Owner:FUJIFILM CORP

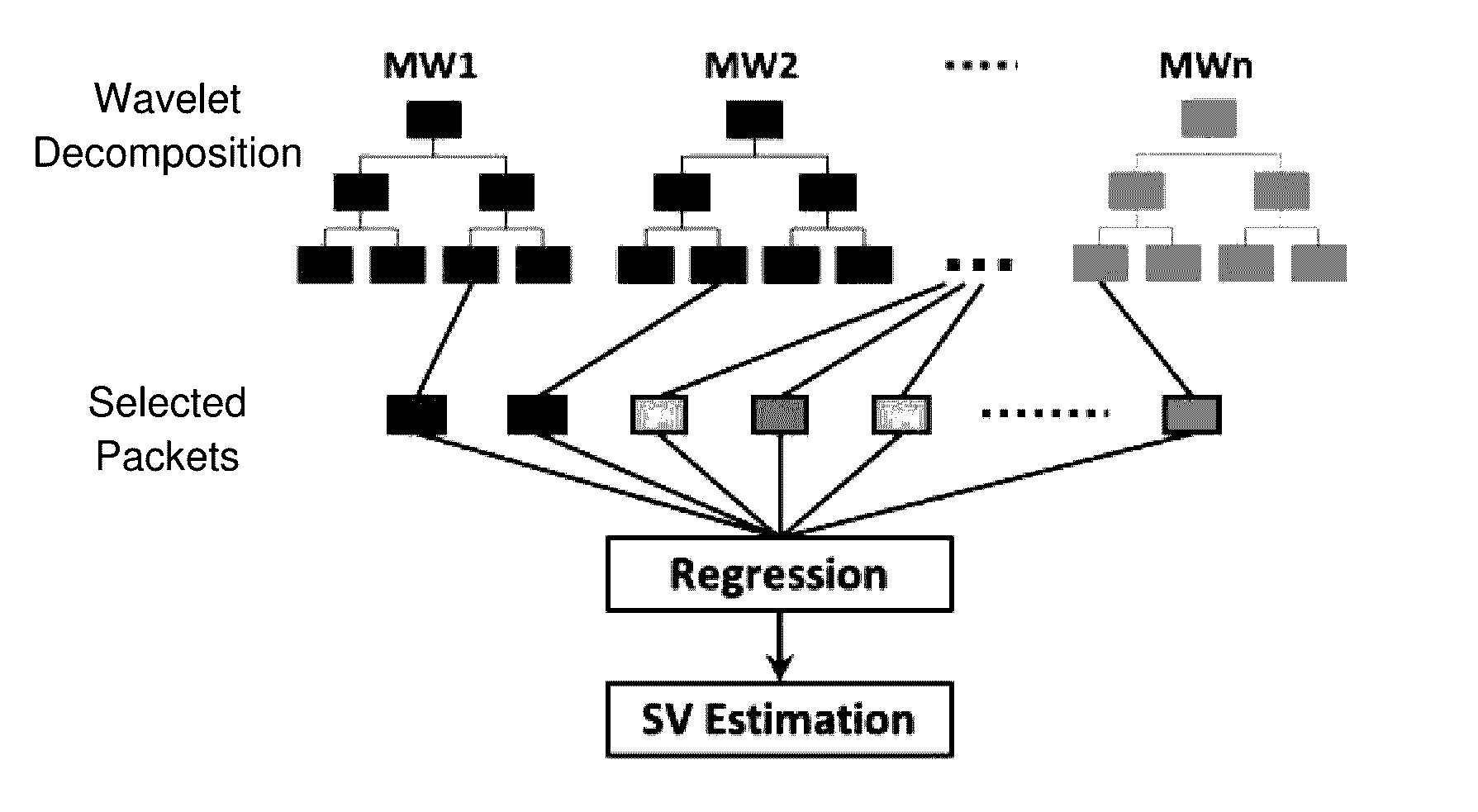

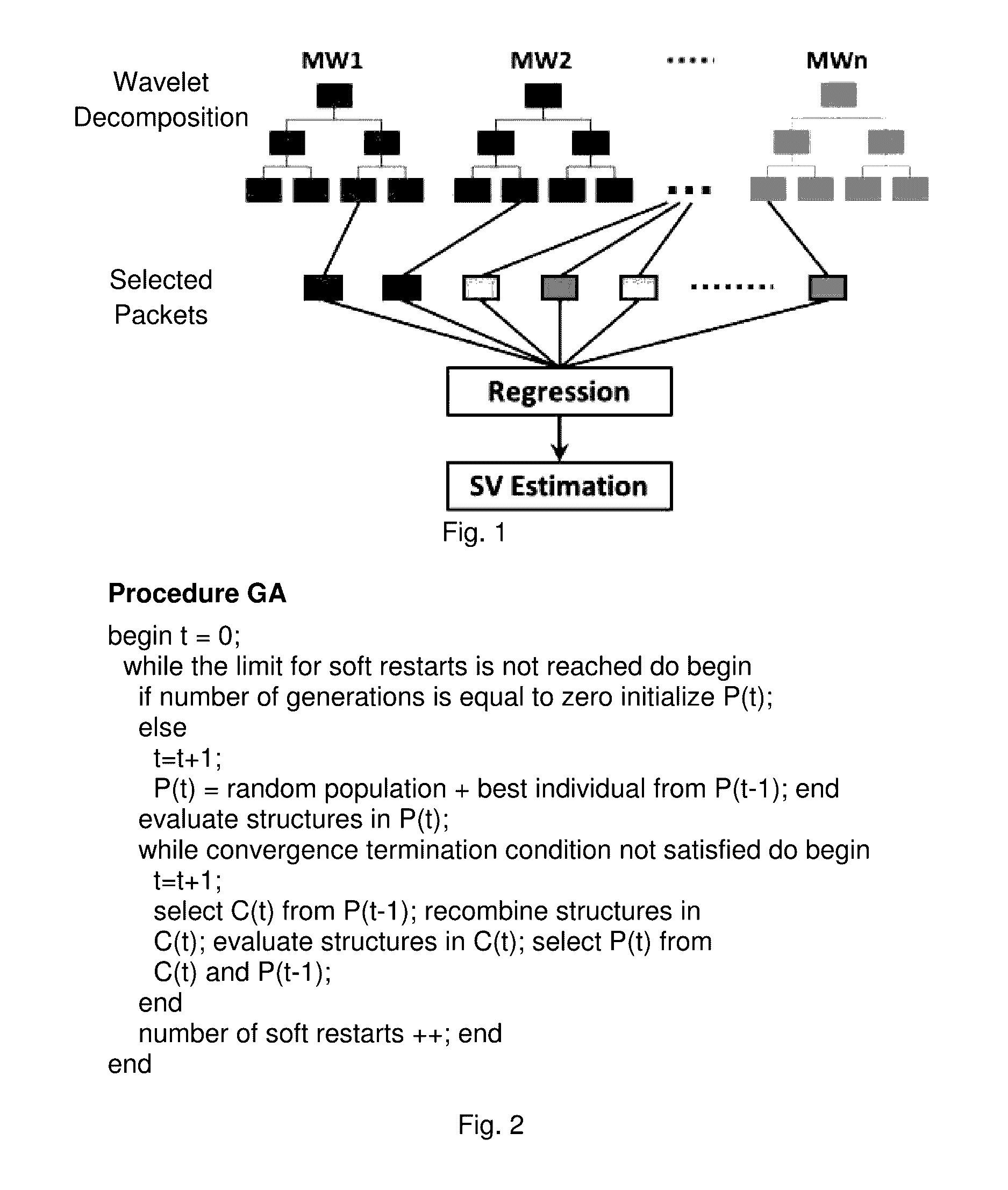

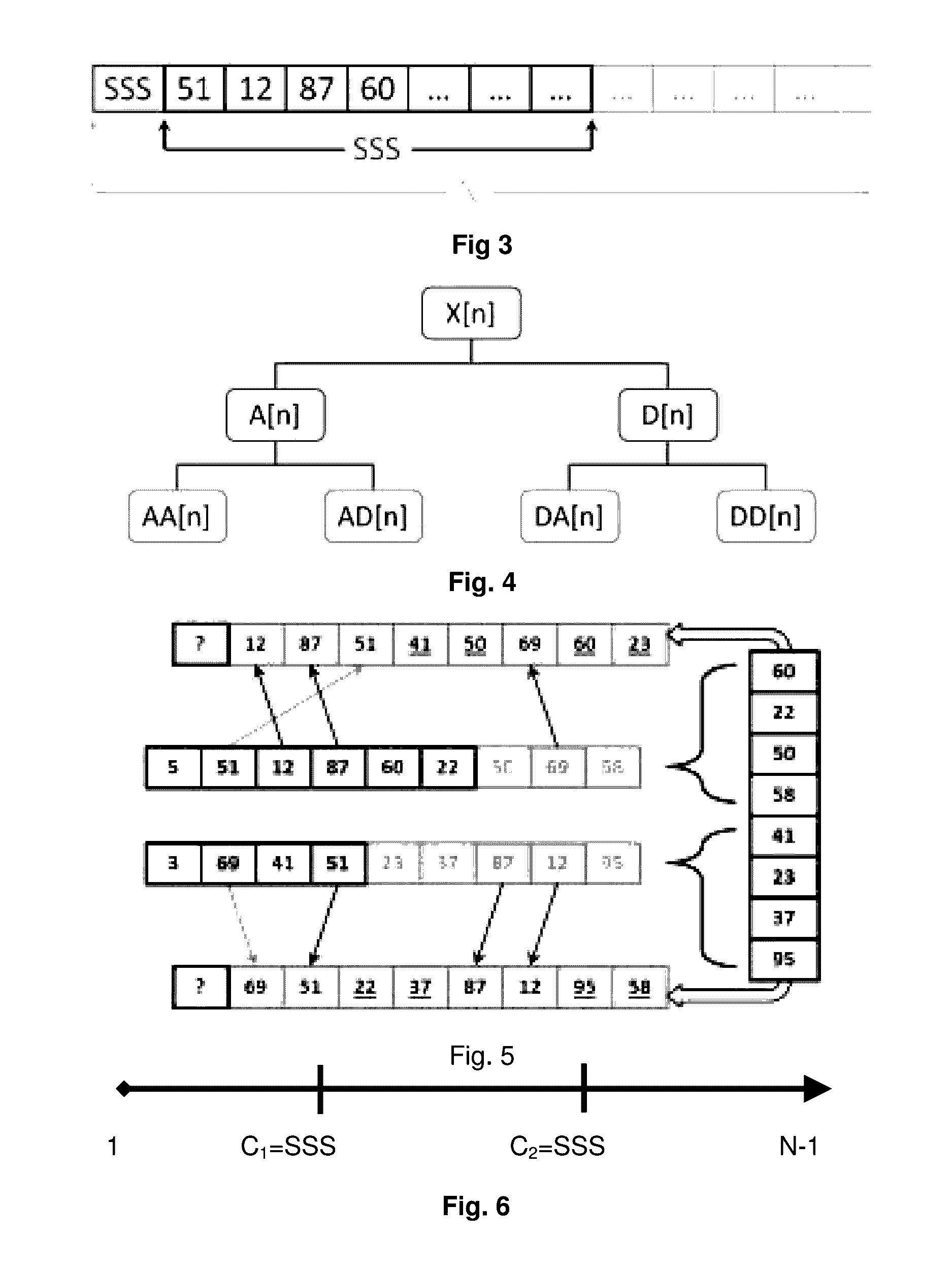

System and method for infrasonic cardiac monitoring

ActiveUS20160361041A1With balanceHigh and good performanceBlood flow measurement devicesHealth-index calculationVentricular contractionCardiac monitoring

Cardiac Output (CO) has traditionally been difficult, dangerous, and expensive to obtain. Surrogate measures such as pulse rate and blood pressure have therefore been used to permit an estimate of CO. MEMS technology, evolutionary computation, and time-frequency signal analysis techniques provide a technology to non-invasively estimate CO, based on precordial (chest wall) motions. The technology detects a ventricular contraction time point, and stroke volume, from chest wall motion measurements. As CO is the product of heart rate and stroke volume, these algorithms permit continuous, beat to beat CO assessment. Nontraditional Wavelet analysis can be used to extract features from chest acceleration. A learning tool is preferable to define the packets which best correlate to contraction time and stroke volume.

Owner:THE RES FOUND OF STATE UNIV OF NEW YORK

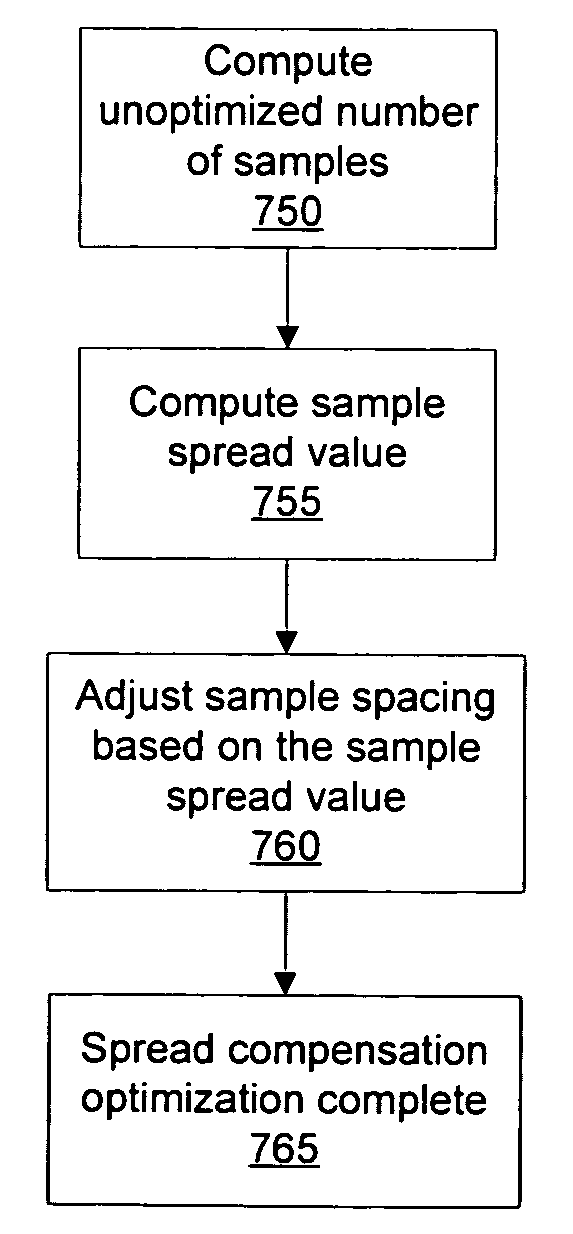

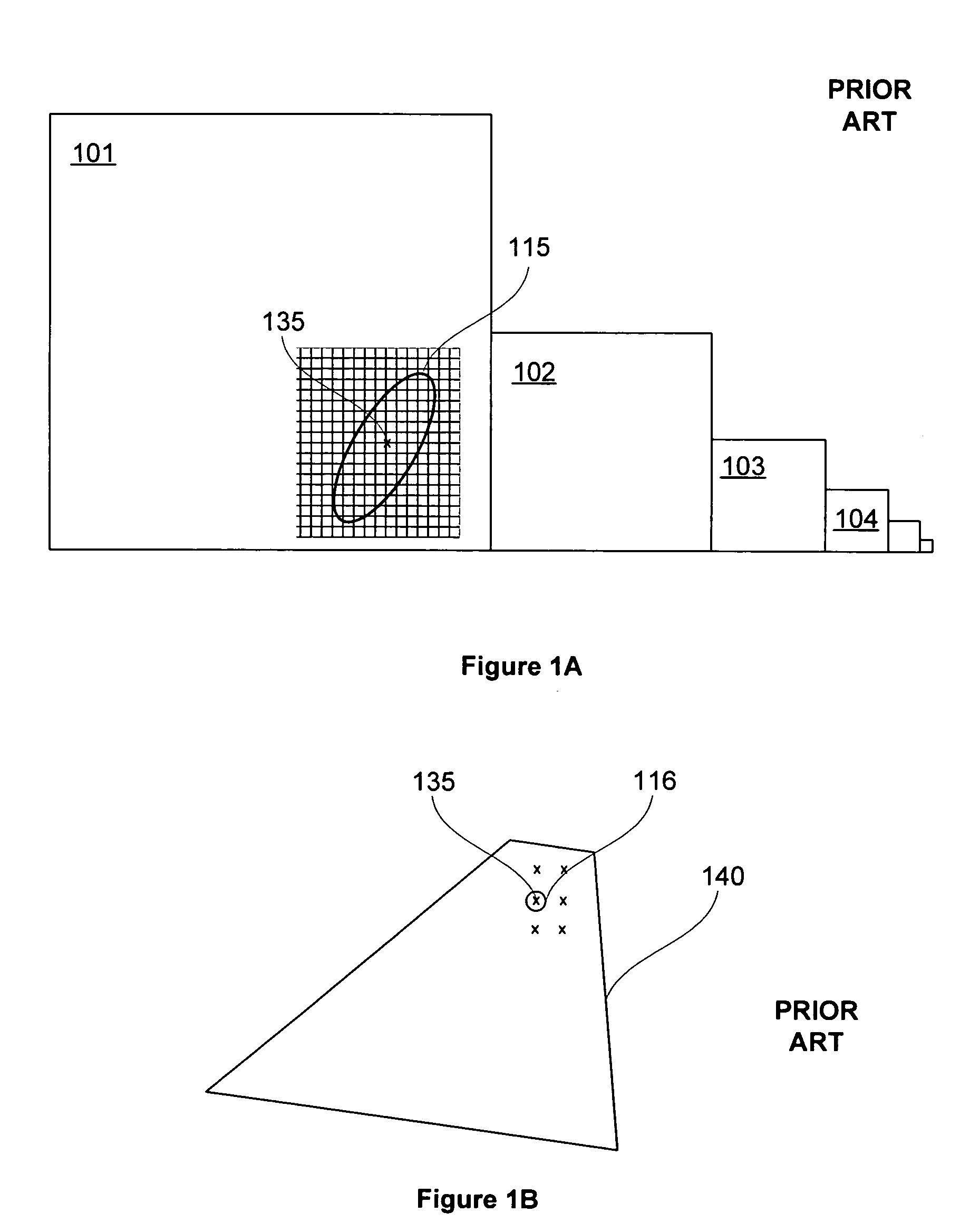

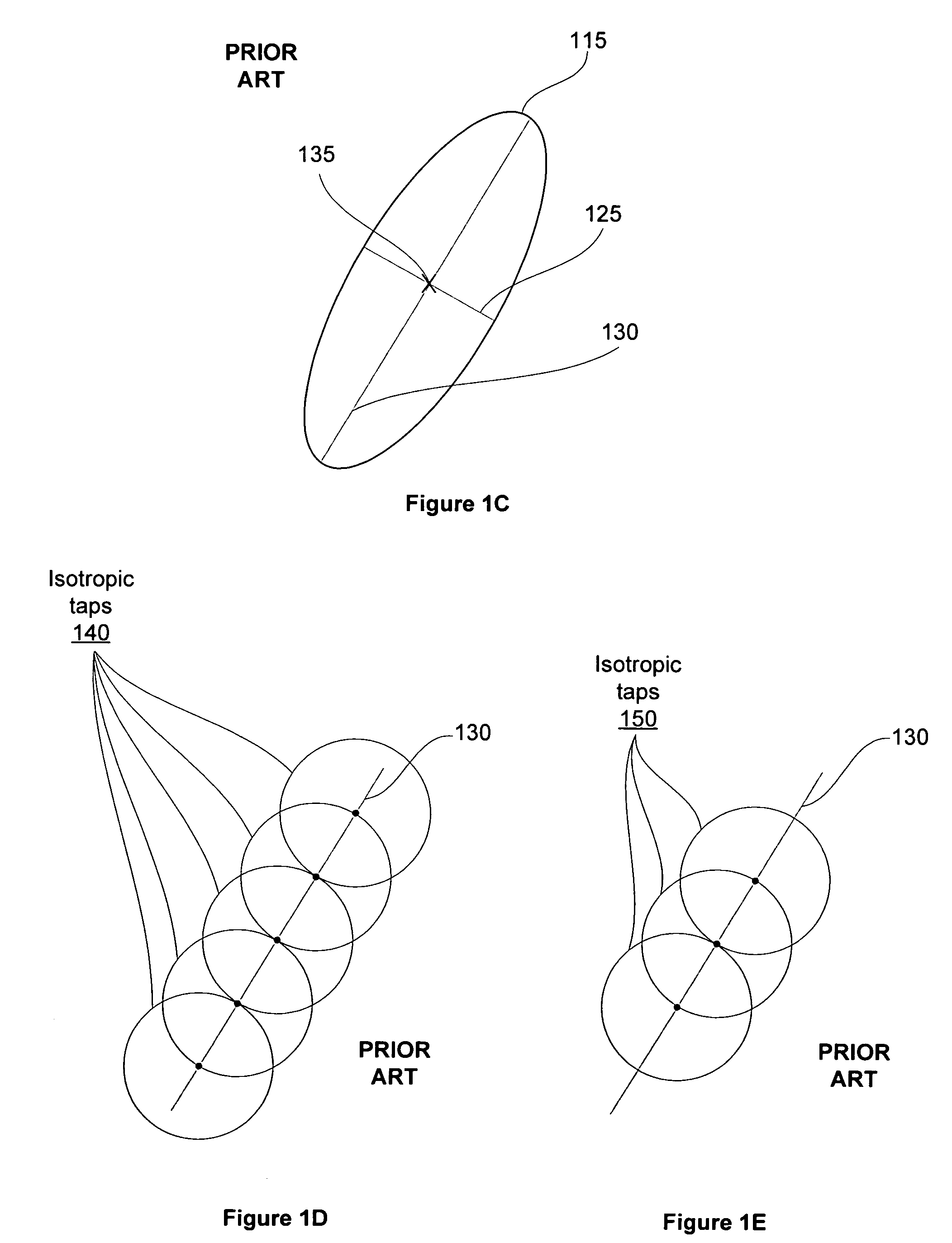

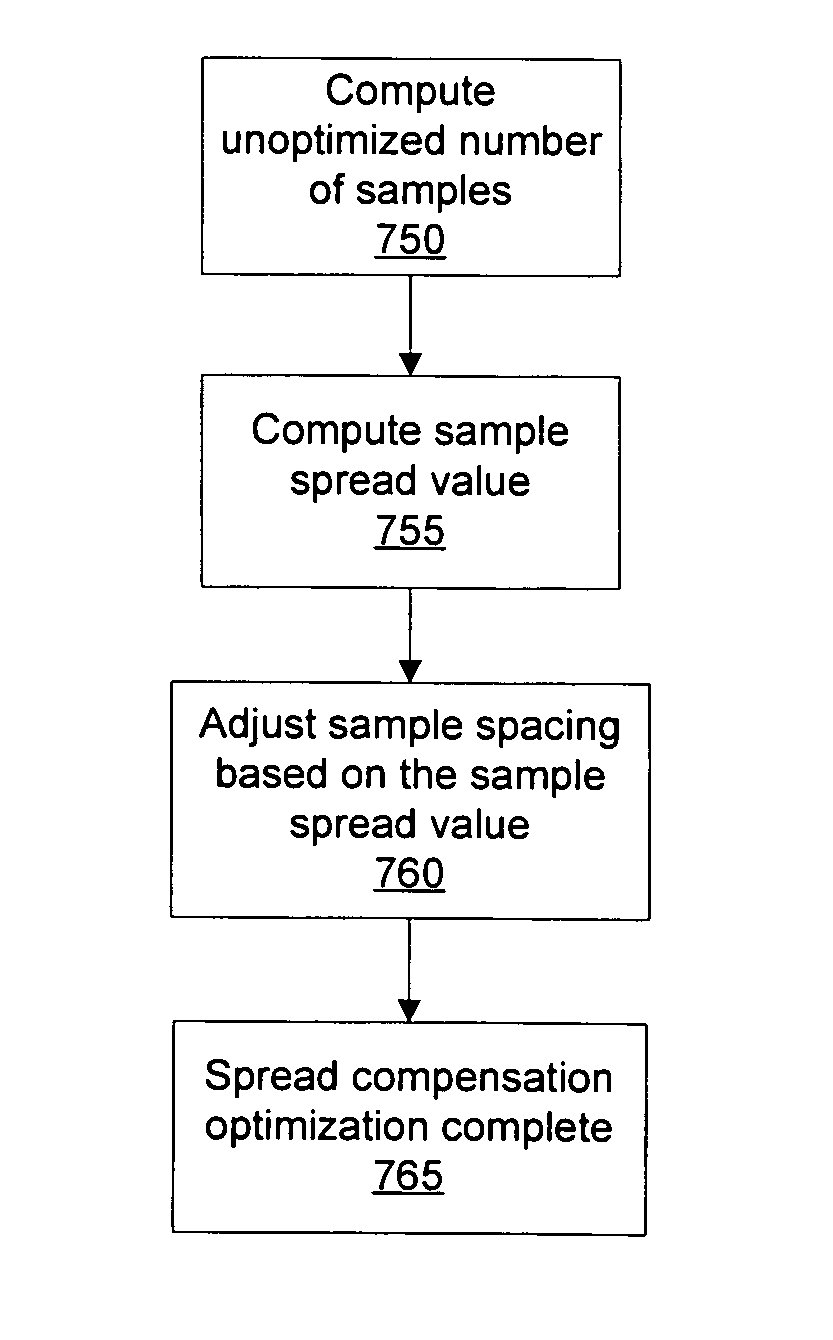

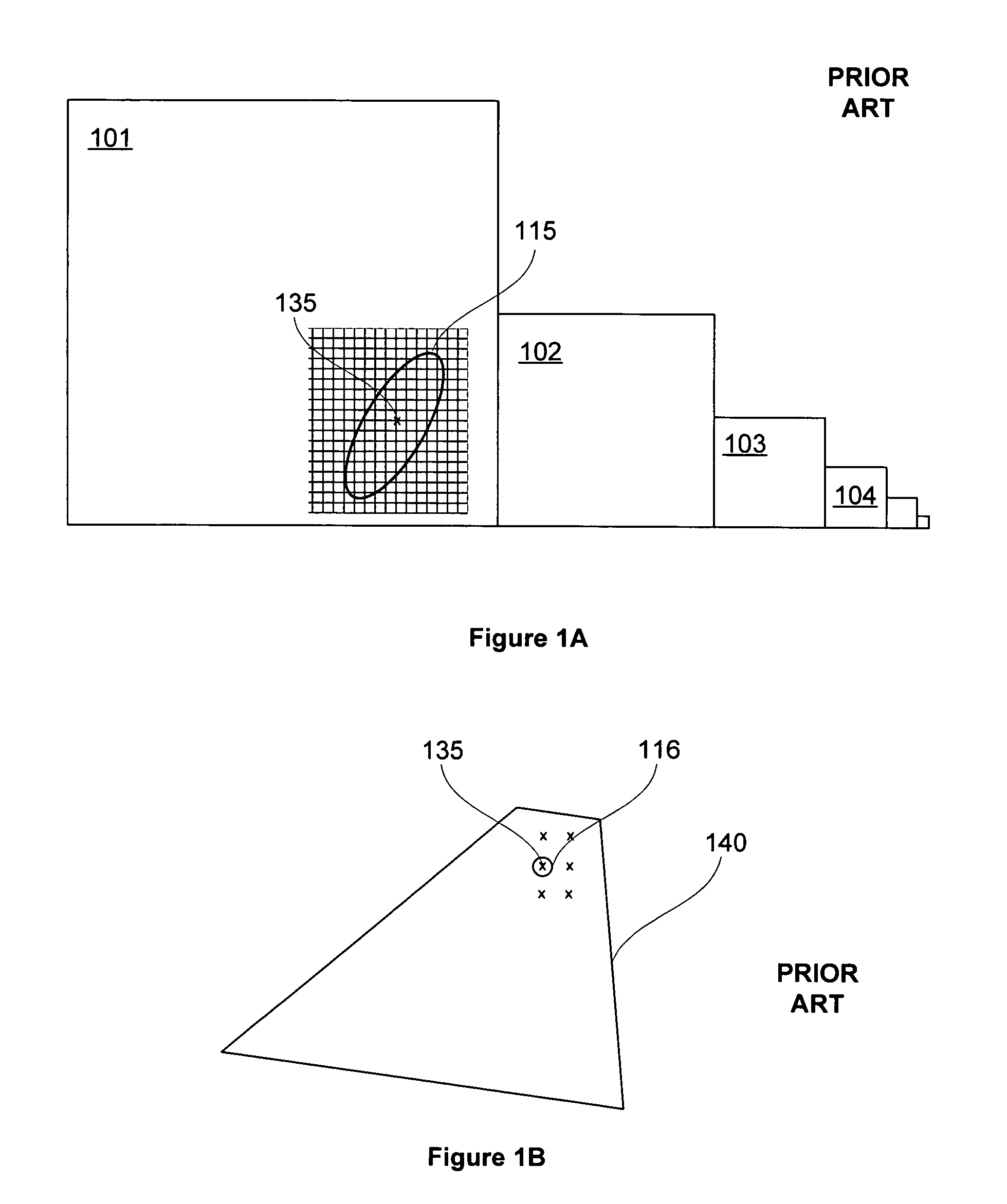

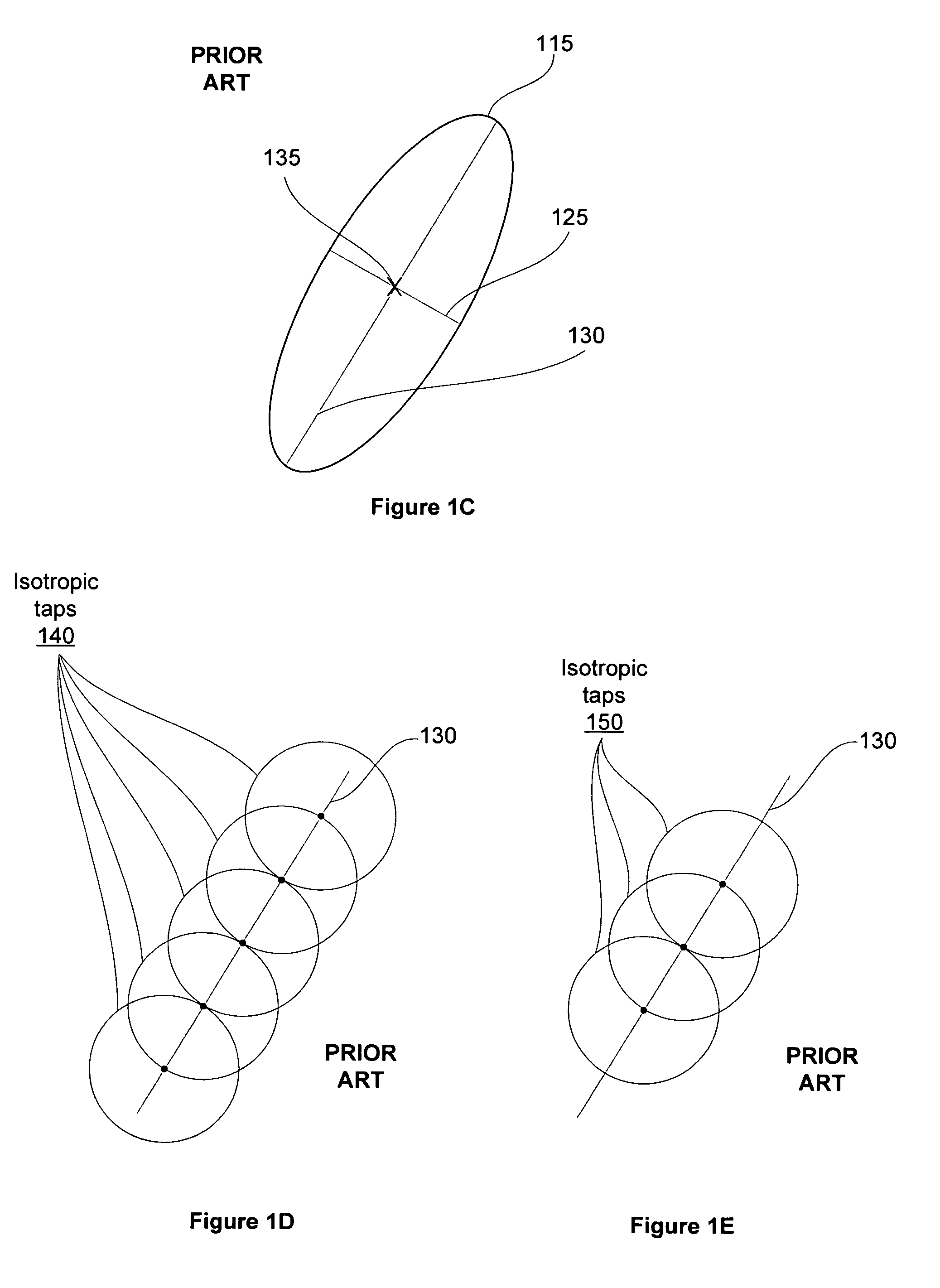

Optimized anisotropic texture sampling

ActiveUS7339594B1Quality and performance be balanceIncrease and decrease numberTexturing/coloringCathode-ray tube indicatorsState variableAnisotropic filtering

Systems and methods for determining the number of texture samples used to produce an anisotropically filtered texture mapped pixel may improve texture mapping performance or image quality. The number of texture samples may be increased or decreased based on texture state variables that may be specific to each texture map. Furthermore, the texture samples may be positioned along an axis of anisotropy to approximate an elliptical footprint, ensuring that the texture samples span the entire axis of anisotropy. A graphics driver may load the texture state variables and configure a system to modify the number of texture samples and / or position the texture samples used to produce the anisotropically filtered texture mapped pixel.

Owner:NVIDIA CORP

Nickel-base alloy

Owner:ATI PROPERTIES

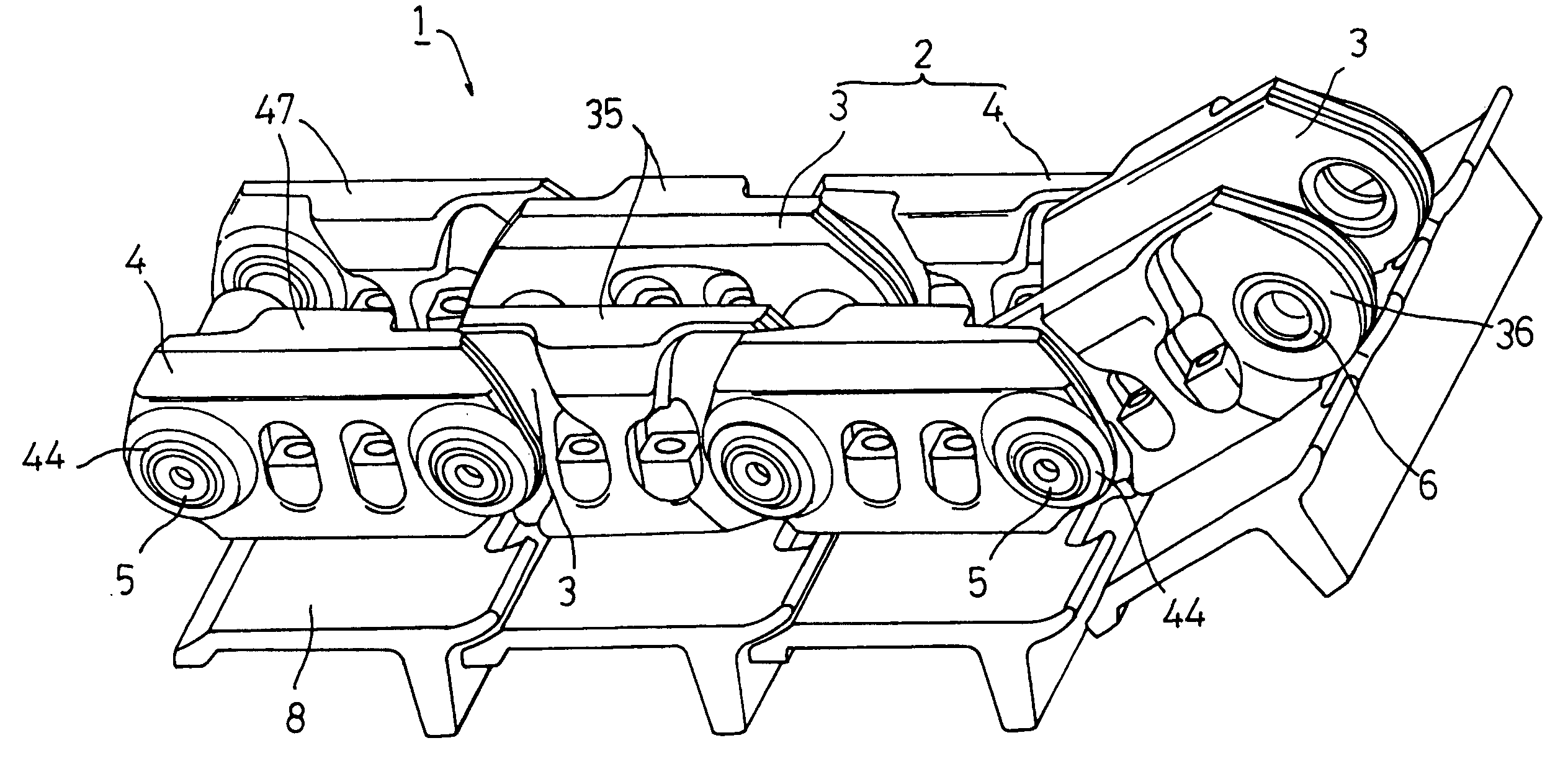

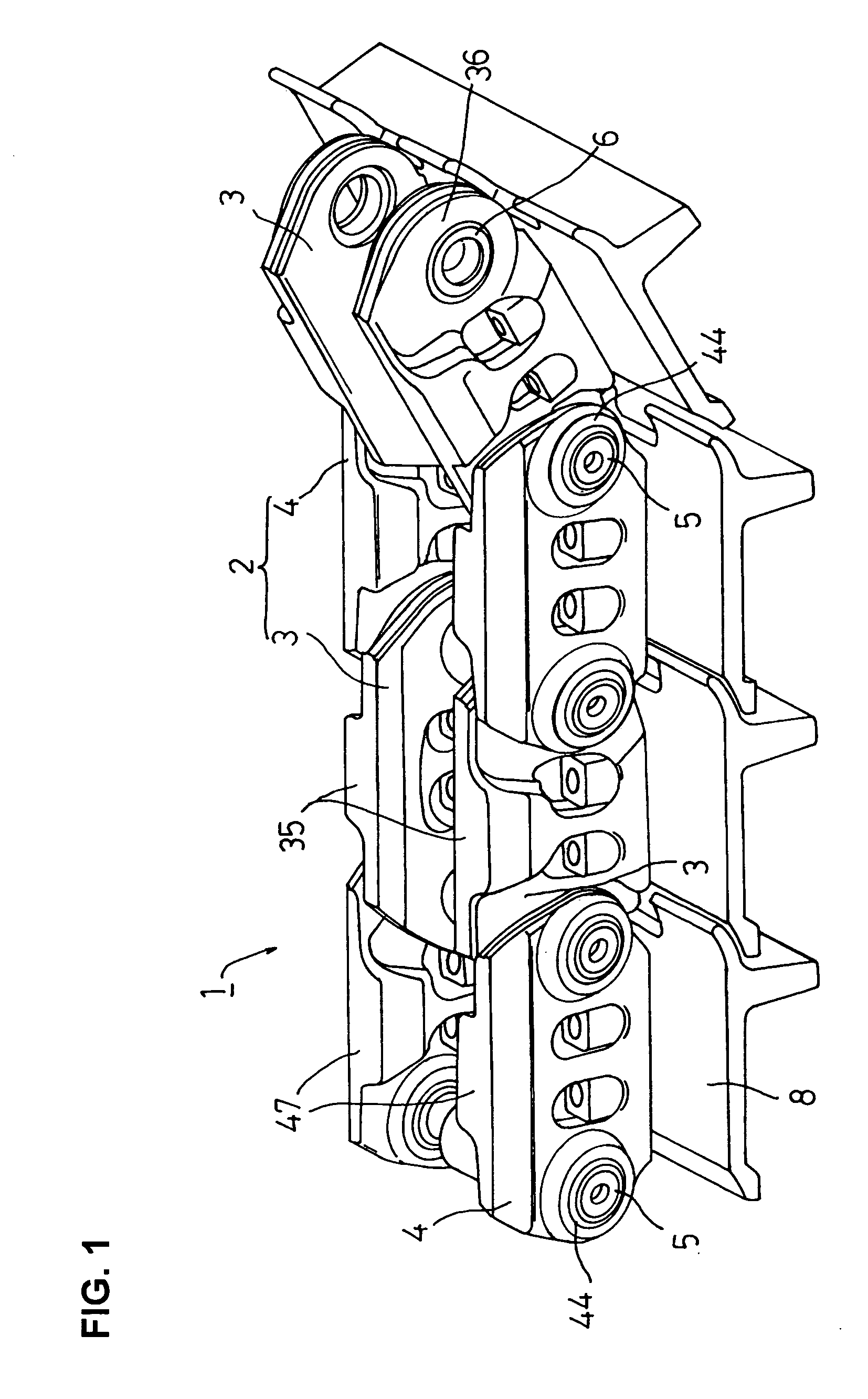

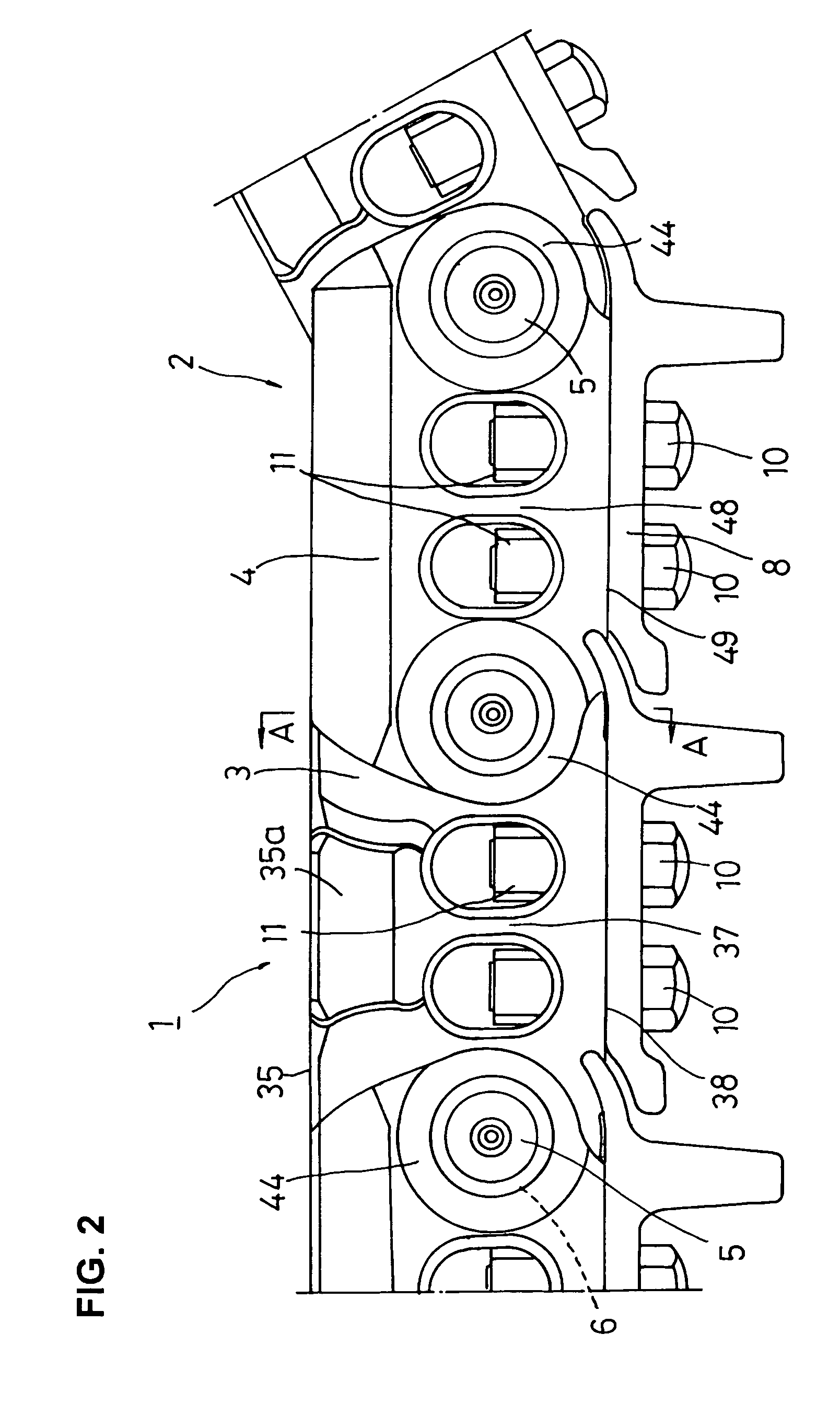

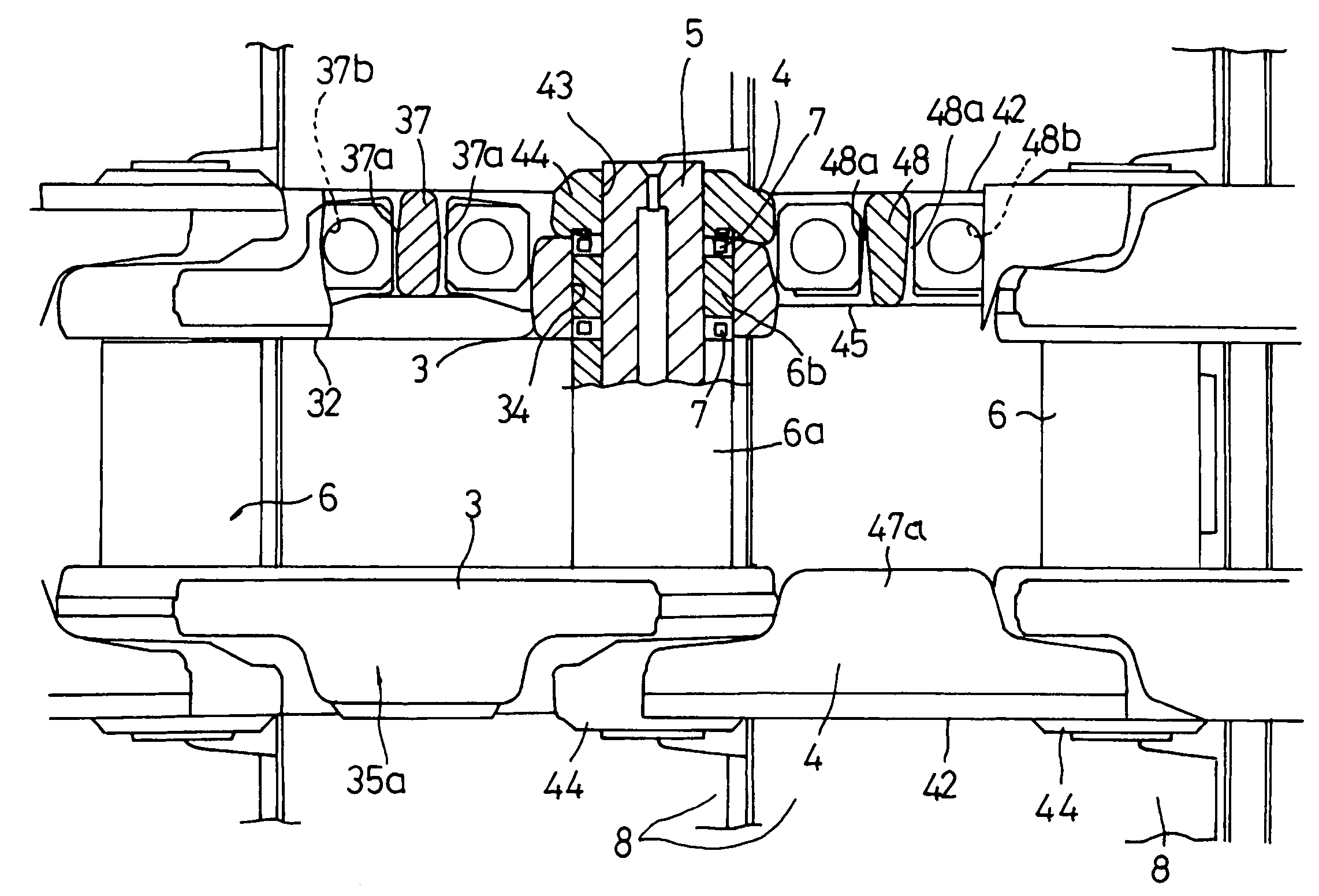

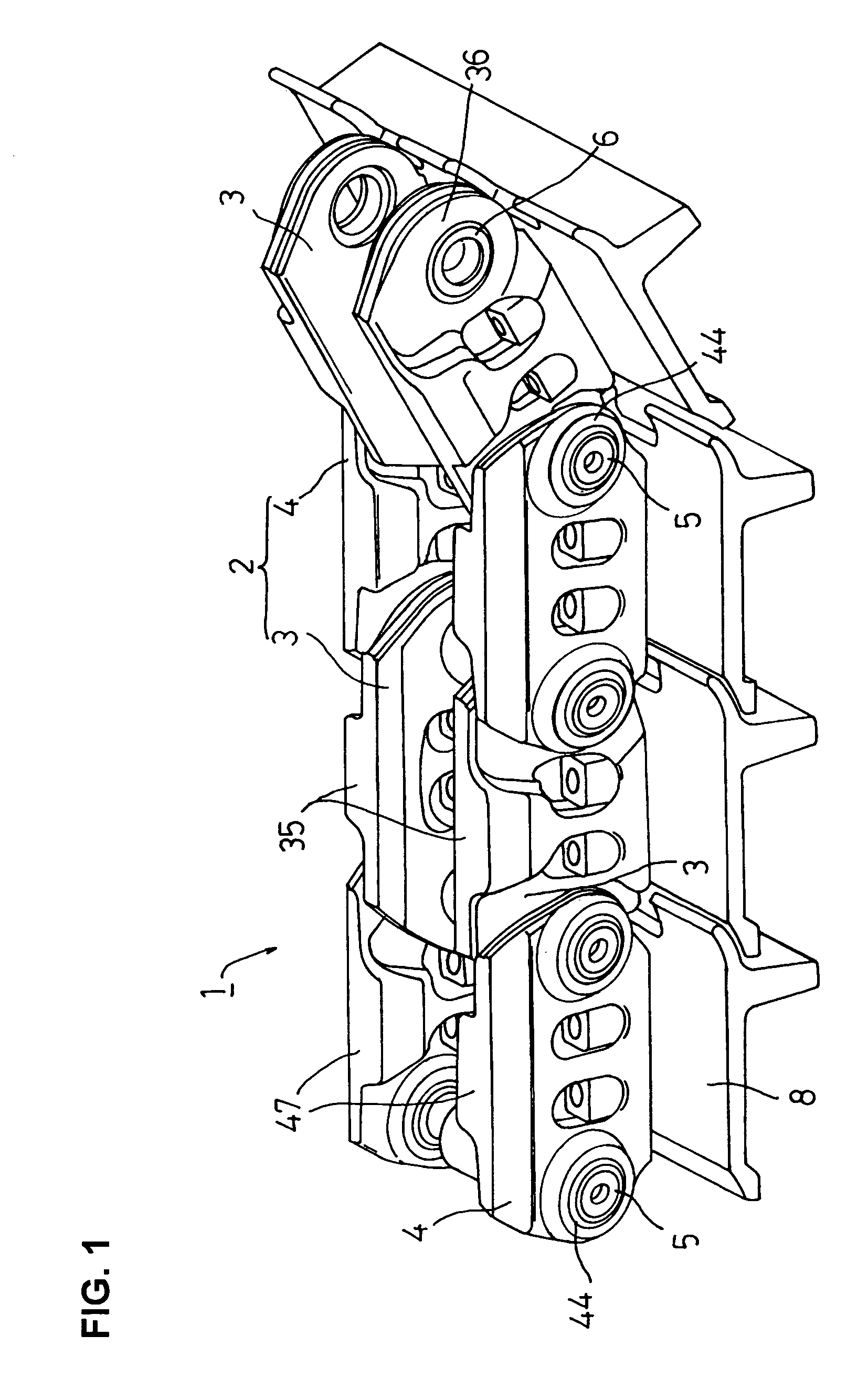

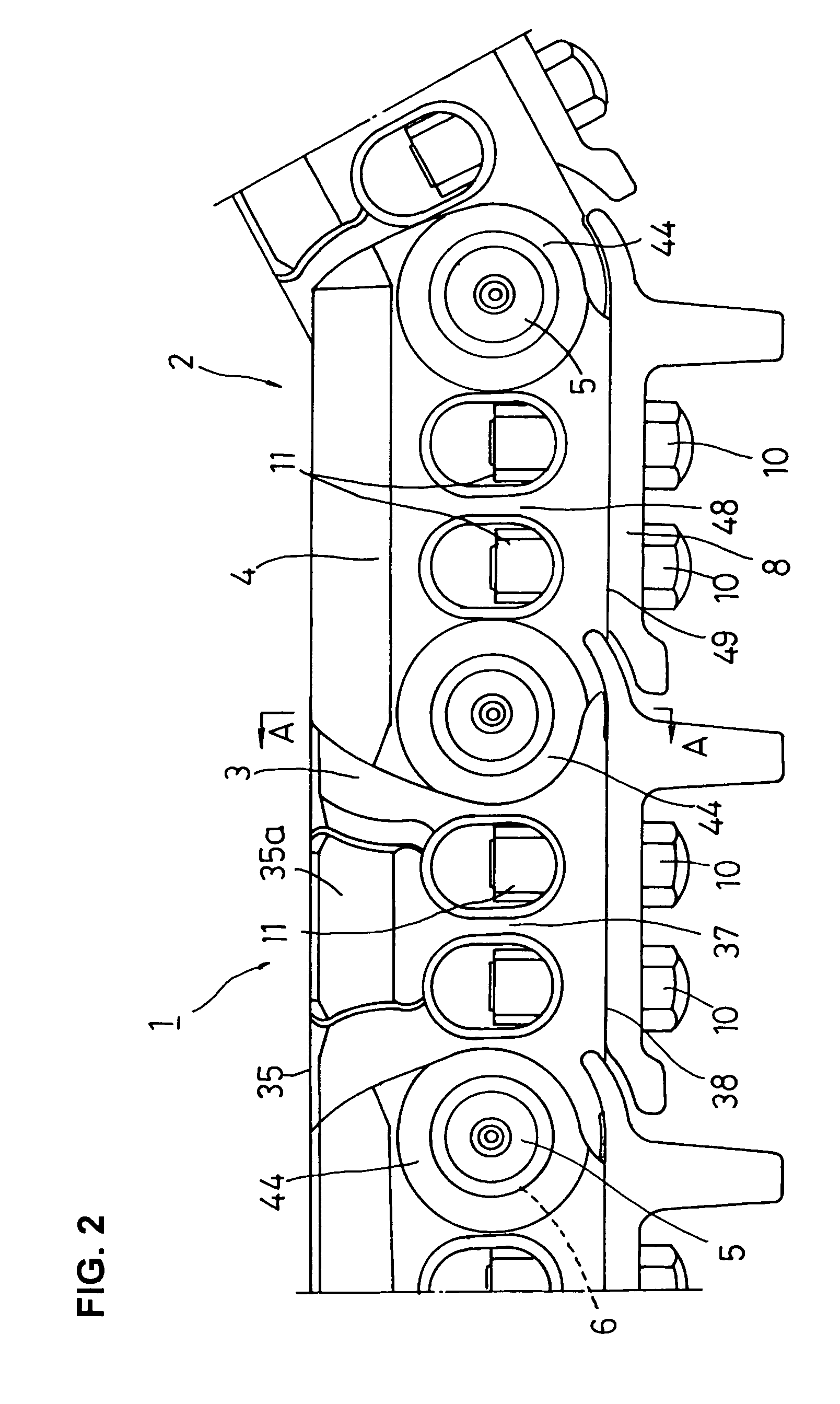

Track having rotatable bushing and link for the same

ActiveUS20050040708A1Occurrence of internal deformation be preventSmoothly transmit powerHingesVehicle design optimisationSprocketEngineering

In a track with a rotatable bushing which is brought into engagement with a sprocket of a track-type vehicle, it is intended that strength is enhanced rationally by link functionality sharing and by combination of such assigned functional tasks for achieving further improvements in rotatable bushing function. To this end, a track link comprises a combination of an external link and an internal link; a coupler pin hole is provided through the external link; a bushing hole is provided through the internal link, and the thickness dimension of a bushing hole formation part of the internal link is made greater than that of a coupler pin formation part of the external link.

Owner:KOMATSU LTD

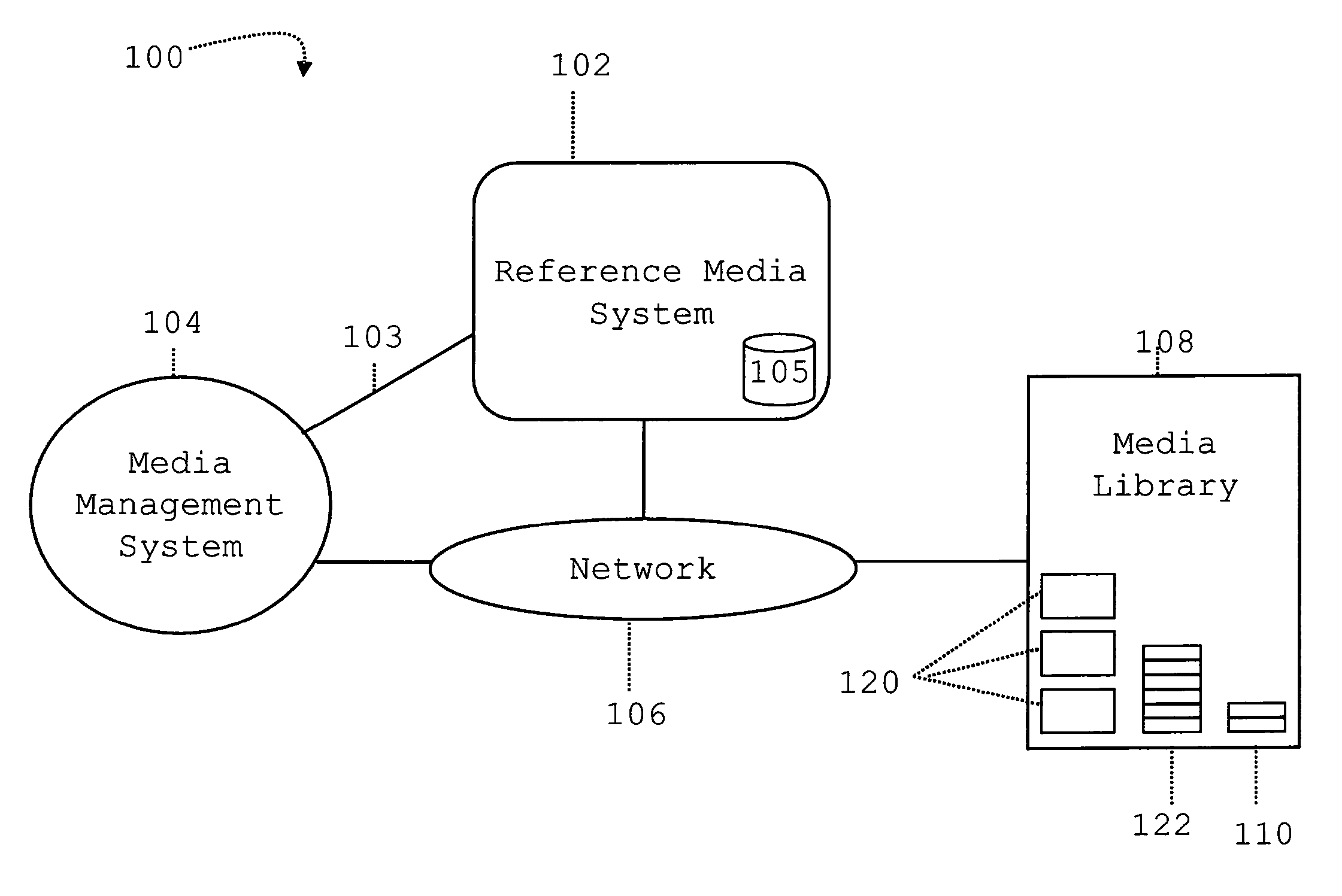

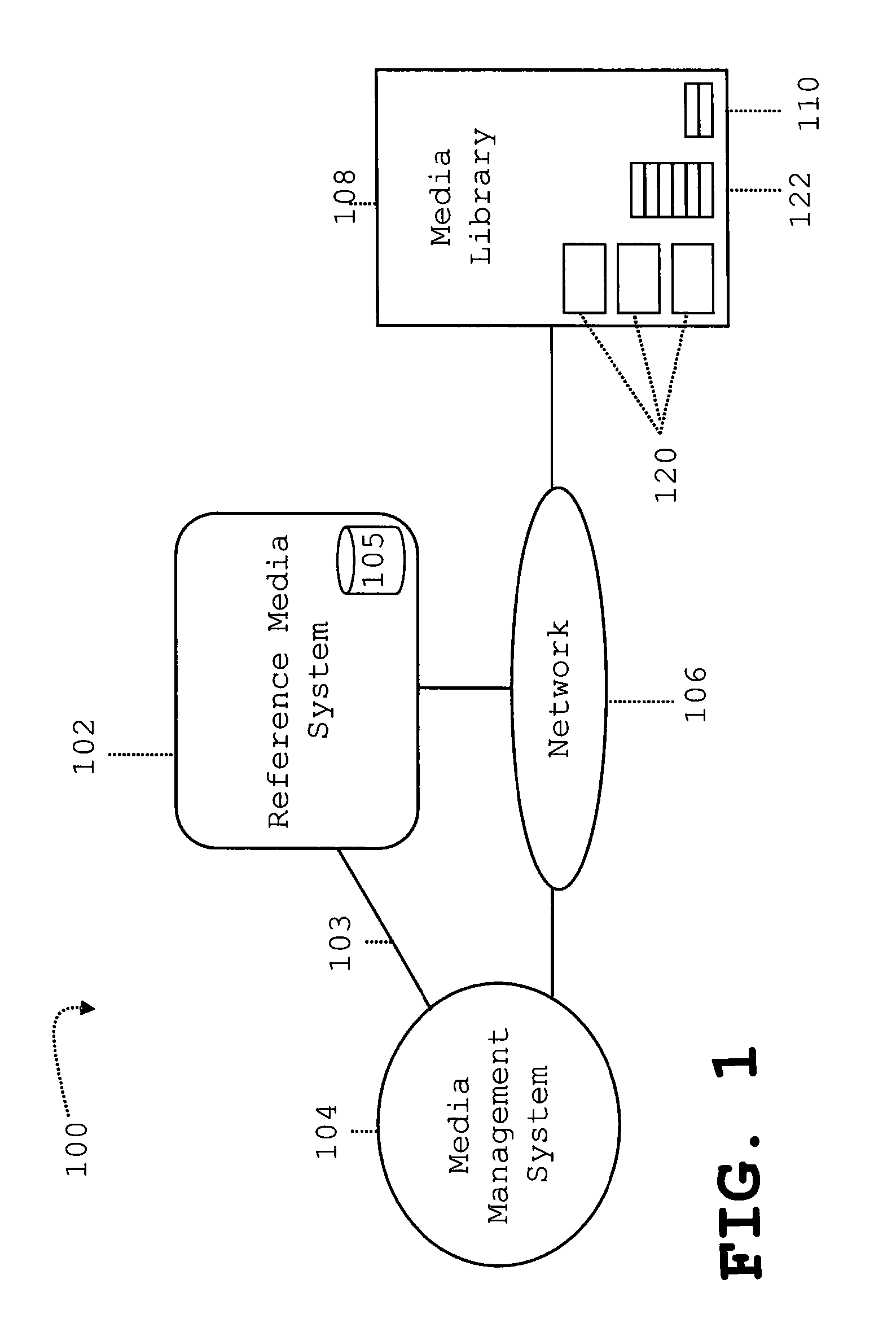

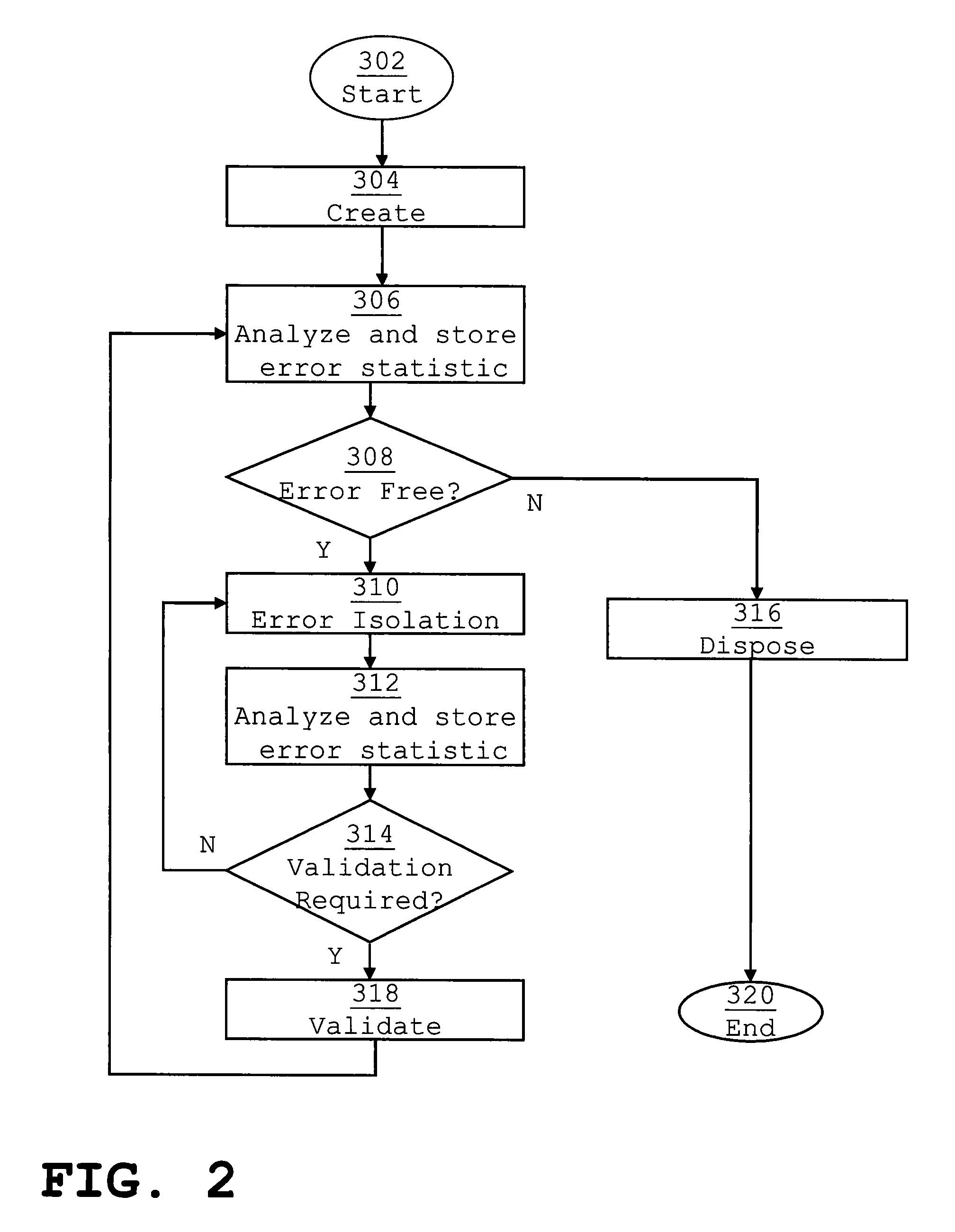

Monitoring and Analyzing the Storage Quality and the Drive Hardware Performance of a Media Library

InactiveUS20090059757A1Clearly markedWith balanceCombination recordingOptical discsManagement systemRemovable media

A method and infrastructure are provided for monitoring and analyzing the storage media quality and the drive hardware performance of a media library. The media library comprises a plurality of removable storage media, a plurality of drive units for said storage media and means for moving said storage media to and from appropriate drive units. The media library is managed by a management system being connected to said media library. At least one reference medium of a known and proven quality to compare the performance of at least one of said storage media in a given drive unit with the performance of said reference medium in said given drive unit and / or to test the performance of at least one given drive unit of said media library when acting on said reference medium.

Owner:IBM CORP

Eating five-element corn-vegetable-fruit health product

InactiveCN101971985AClear mechanismClarify the mechanism of health careFood preparationBiotechnologyUncooked Foods

The invention relates to an eating five-element corn-vegetable-fruit health product comprising more than 40 raw materials, such as naked oat flour, cichory flour, bitter almonds, coixseeds, white lablab seeds, burdocks, white turnips, white fungi, yam, ginkgo, coconuts, highland barley, brassica campestris, green tea powder, cowberries, green apples, peas, green beans, spinach, cacti, spirulina, Chinese goosebeeries, black tartary buckwheats, agaricus blazei murill, blackcurrant, mulberry powder, black kerneled rice, teata glycinis, niger seeds, dried purple seaweed, mushrooms, black fungi, Tibetan red beans, and the like, which is white, green, black, red or yellow corn-vegetable-fruit grains or integrative five-color corn-vegetable-fruit grains prepared by a specific technology. The eating five-element corn-vegetable-fruit health product is produced on the basis of a traditional Chinese medical five-element theory and a modern nutriology theory, has excellent raw materials, edible safety, pure taste and rich nutrition, is especially used for raw foods, provides complete, balanced and reasonably-matched nutrients for a human body, has obvious opsonization for sub-health physiques and various chronic diseases, is easy to industrially popularize and has positive social and economic benefits.

Owner:崔晓廷

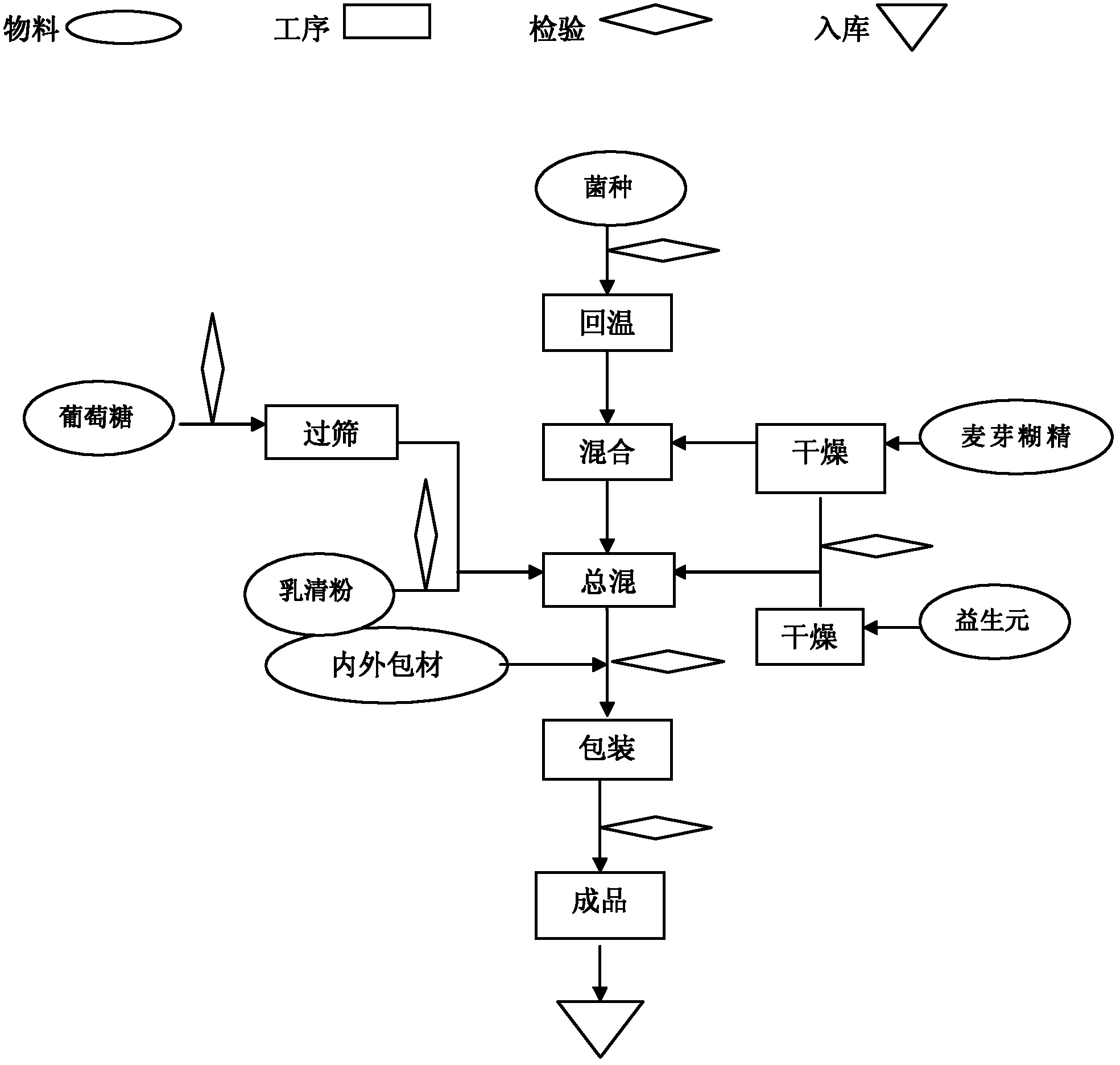

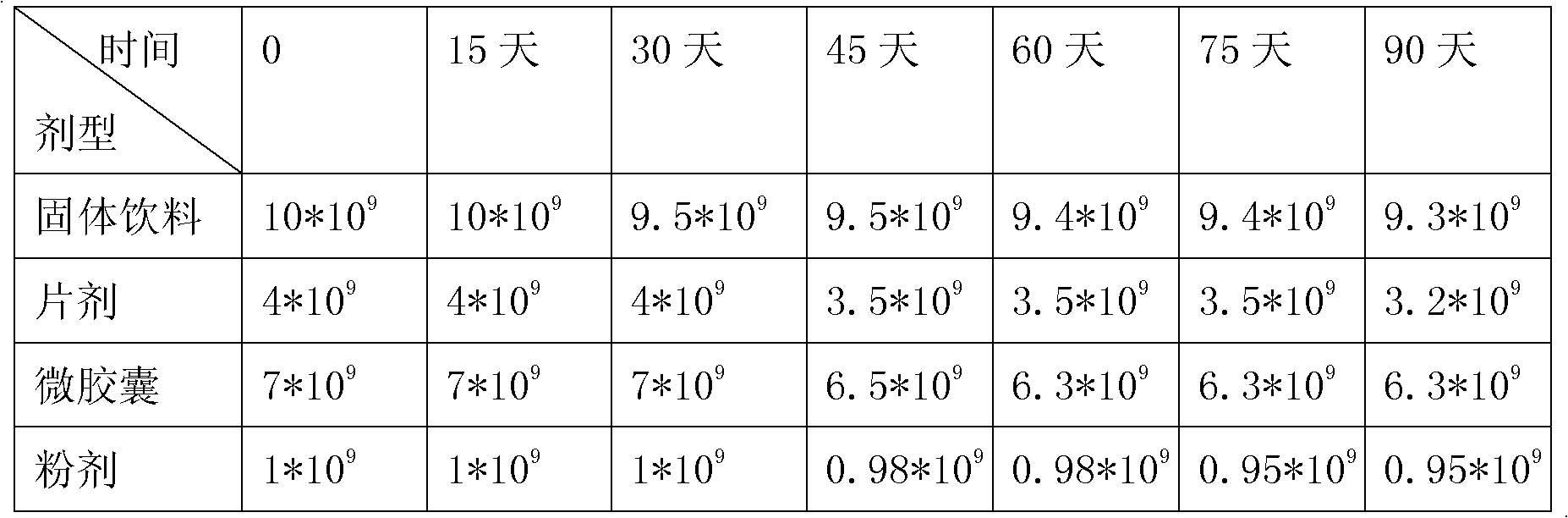

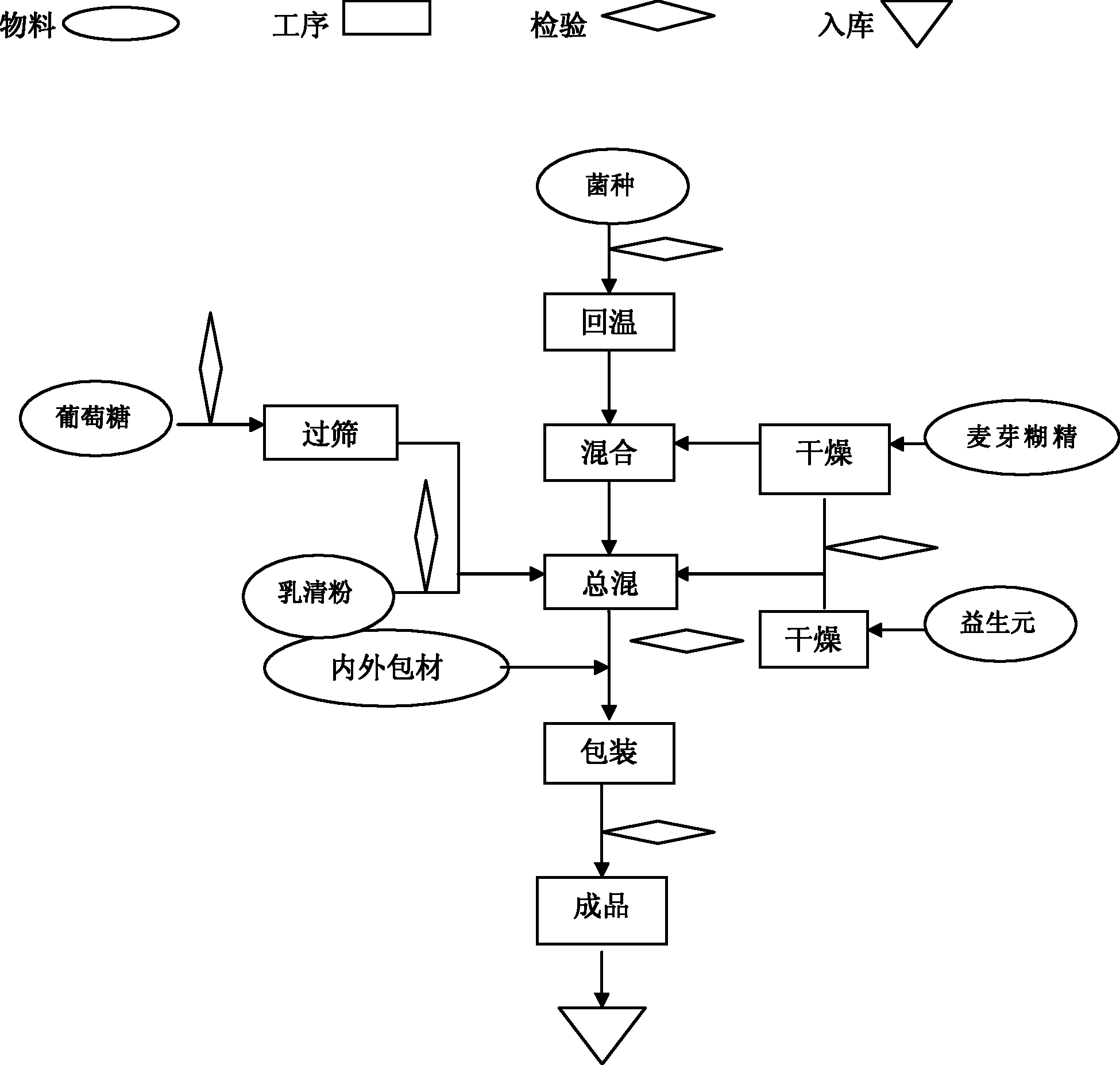

High-activity probiotic composition suitable for infants and preparation method thereof

The invention relates to a high-activity probiotic composition suitable for infants and a preparation method thereof. The composition contains the following active components of: by weight, 0.33-3.3% of bifidobacteria, 45-60% of maltodextrin, 10-20% of glucose, 10-20% of whey powder and 5-10% of prebiotics. The preparation method comprises the following steps of: (1) drying the auxiliary materials until water activity (Aw) is less than or equal to 0.1; (2) replacing the air in a mixer with dry medical nitrogen; and (3) adding a few maltodextrin, adding probiotics, mixing for 5 minutes, adding residual maltodextrin and other raw and auxiliary materials, uniformly mixing, and discharging. The composition provided by the invention and functional foods (including health products) prepared by the composition have advantages of high safety of the probiotic strains and raw and auxiliary materials, balanced combination and appropriate bacteria number, are more suitable for Chinese infants' intestinal tracts, and have effects of enhancing infant's immunity and promoting the health of intestinal tract.

Owner:杭州千岛湖康诺邦健康产品有限公司

Enhanced multi-user transmission

ActiveUS8842606B2Less modificationWith balanceSpatial transmit diversityReceivers monitoringMedia access controlBroadcasting

A transmitting and a receiving apparatus, a system and a method of performing multi-user transmission to other transmission ends include broadcasting a request for transmission to the other transmission ends. A request is provided with a Medium Access Control MAC frame which includes a list of at least two identifications of receiving ends which are requested to reply to the request.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Supporting acetylcholine function

InactiveUS20110015154A1Easy to operateRestore balanceOrganic active ingredientsBiocideMedicineAnticholinesterase Agents

This document provides methods and materials related to regulating inflammatory pathways. For example, compositions and kits containing two or more of an anticholinesterase compound, a choline compound, and a carnitine compound and methods for using the compositions and kits described herein to support acetylcholine function to regulate one or more inflammatory pathways are provided.

Owner:NEUROSCI INC

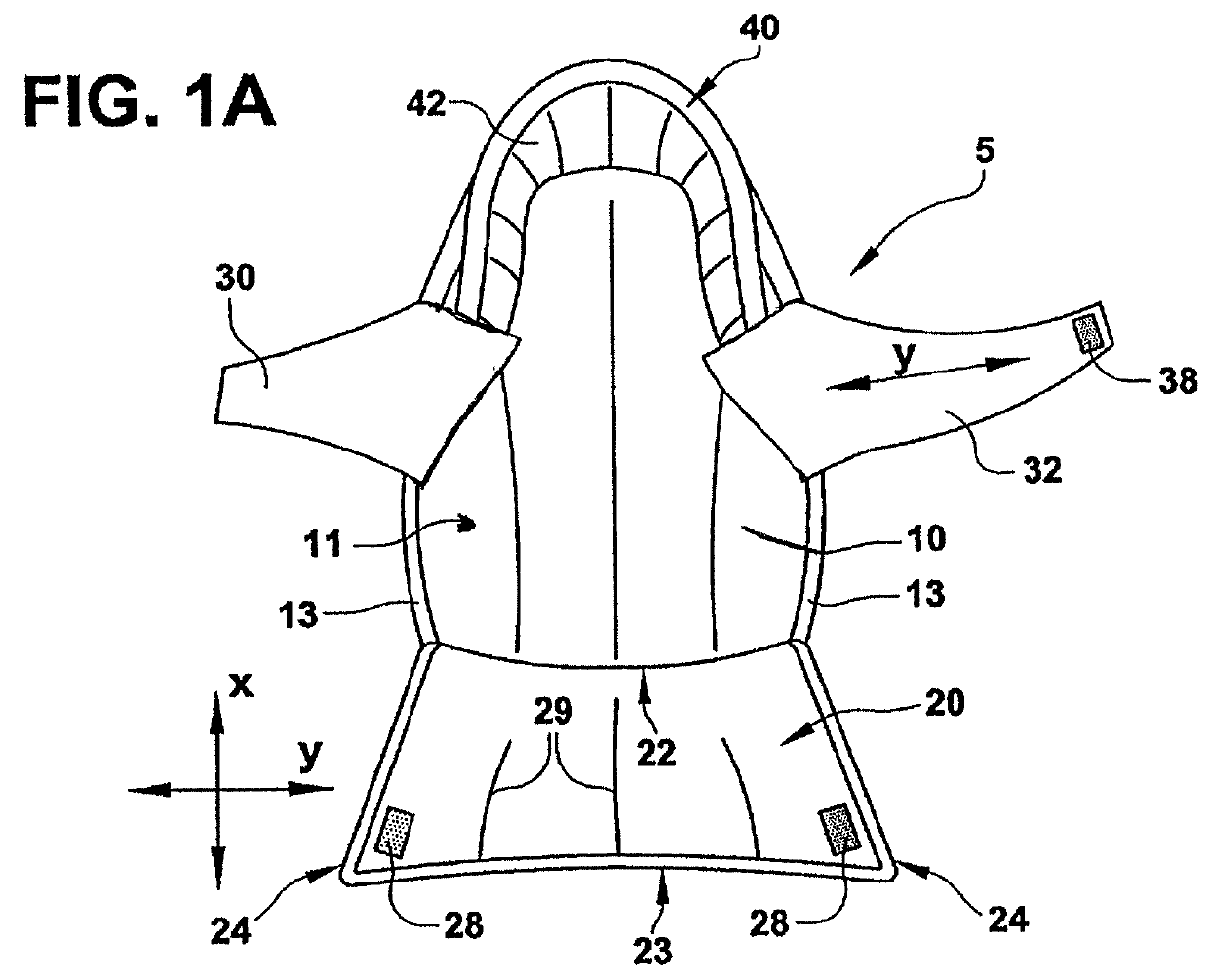

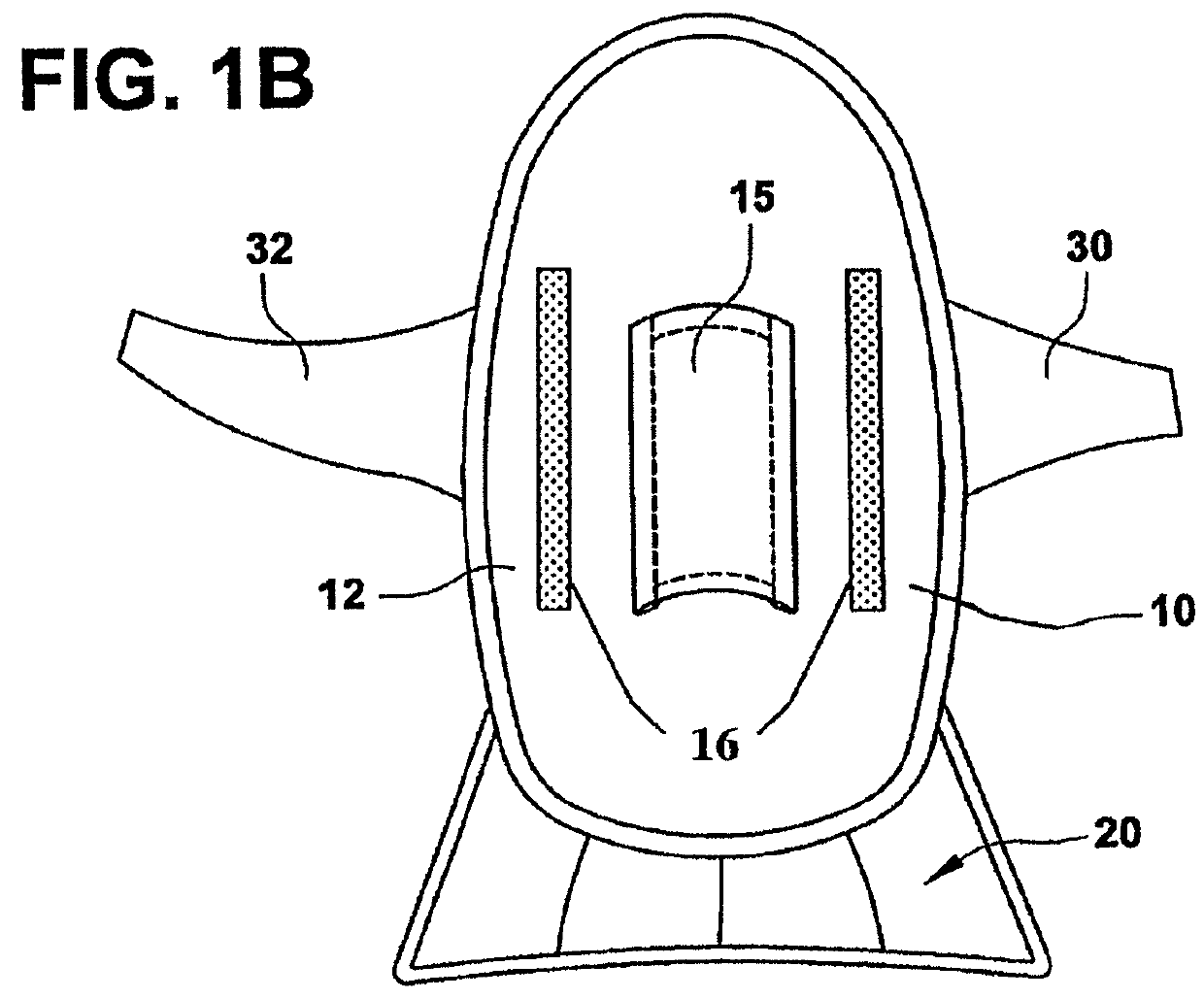

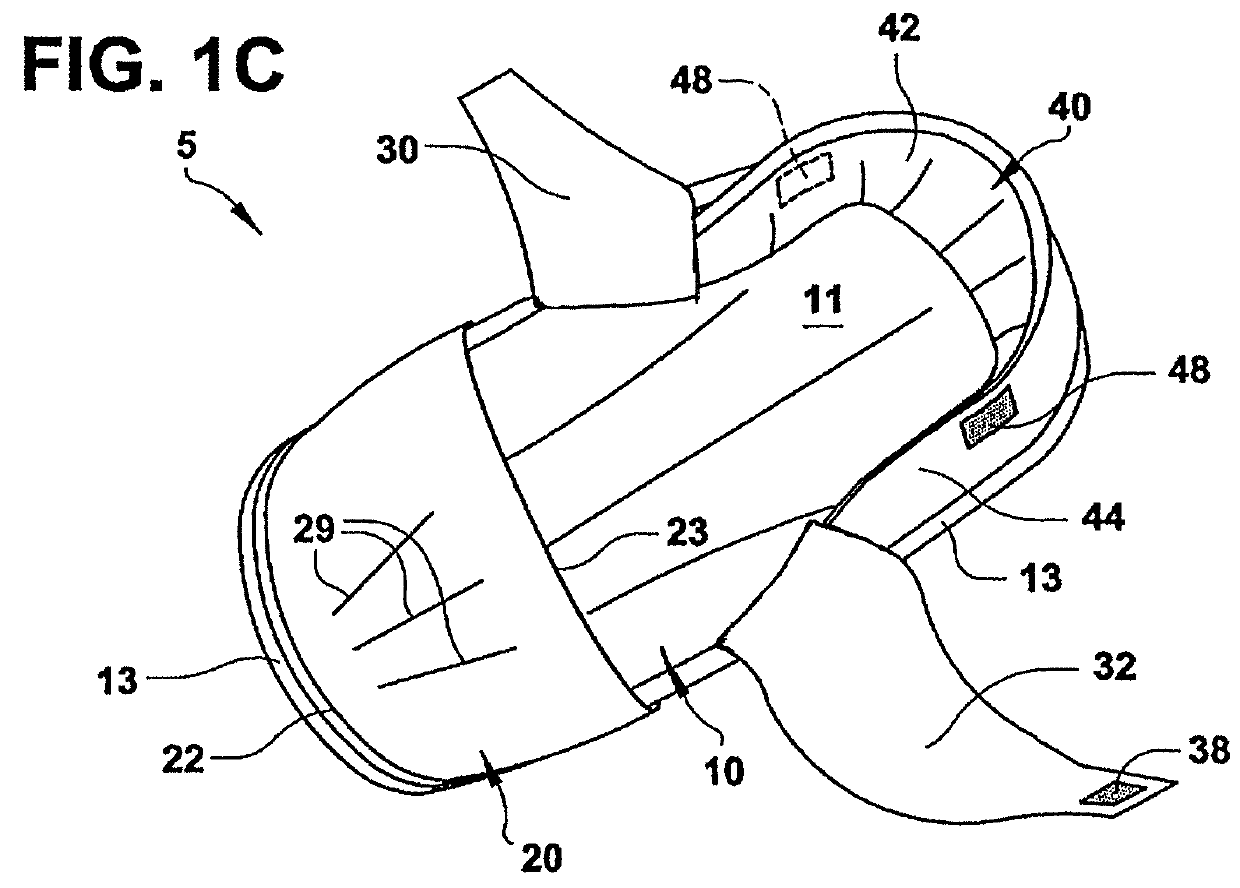

Multipurpose positioning device for infants

ActiveUS9332791B1Flexible positioningImprove comfortDressing tableBaby-incubatorsSide lyingEngineering

A multipurpose infant positioning device that includes a lower pad with front and back surfaces, wings attached to lateral sides of the lower pad and a bottom flap attached to the bottom portion of the lower pad. At least one of the wings and bottom flap have fastening segments attached thereto for adjustably attaching these components to portions of the lower pad. The fastened wing and bottom flap are made of a material having sufficient resiliency to maintain and bring an infant back to flexed midline position within the infant positioning device. These infant positioning devices may further include a headpiece, brim, pocket at the back surface of the lower pad and a detachable readjustable multipurpose pillow for positioning the infant from and between supine, prone and side-lying positions, all while maintaining and reinforcing the flexed midline position of the infant for normal development.

Owner:TARRY MEDICAL PROD

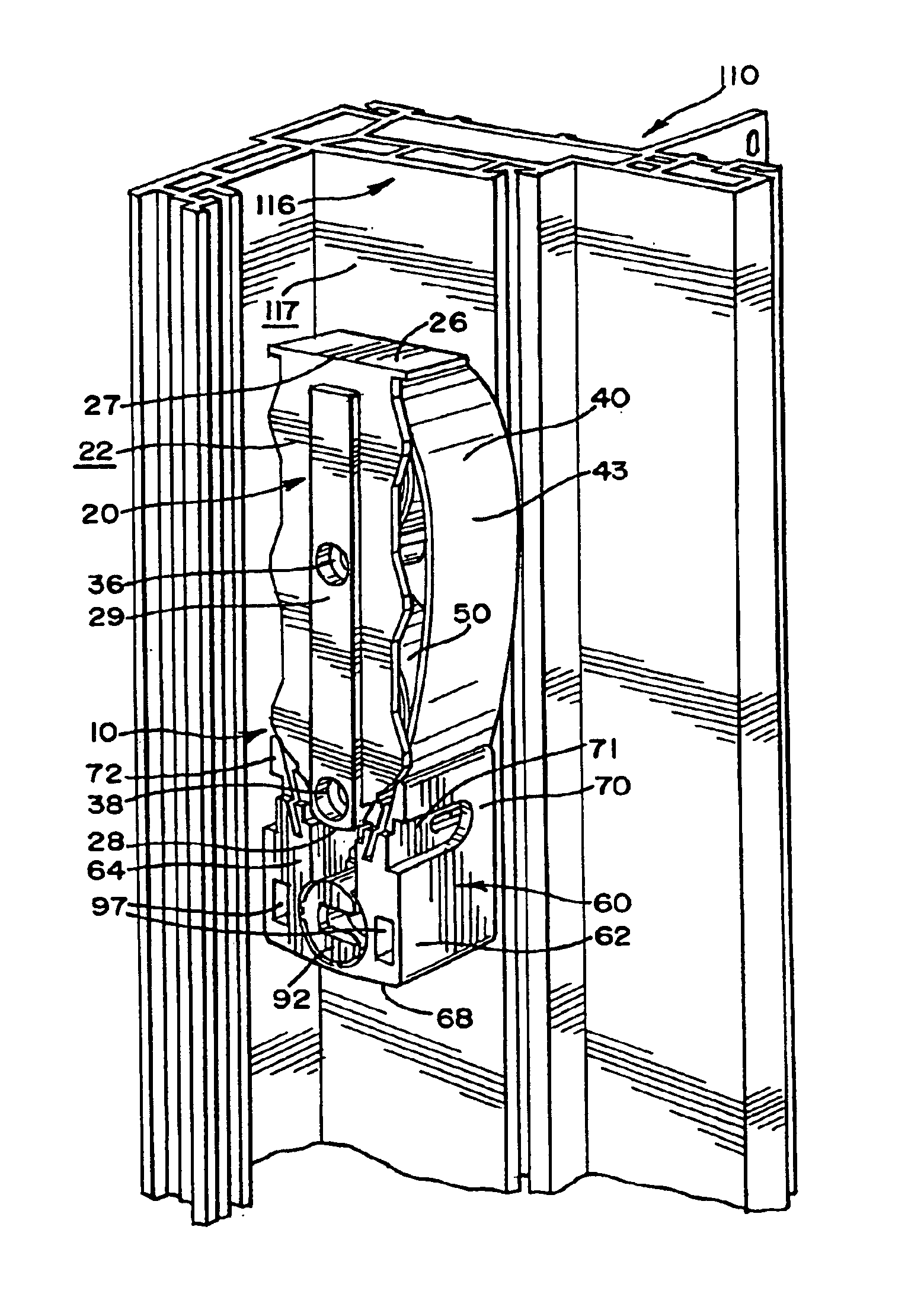

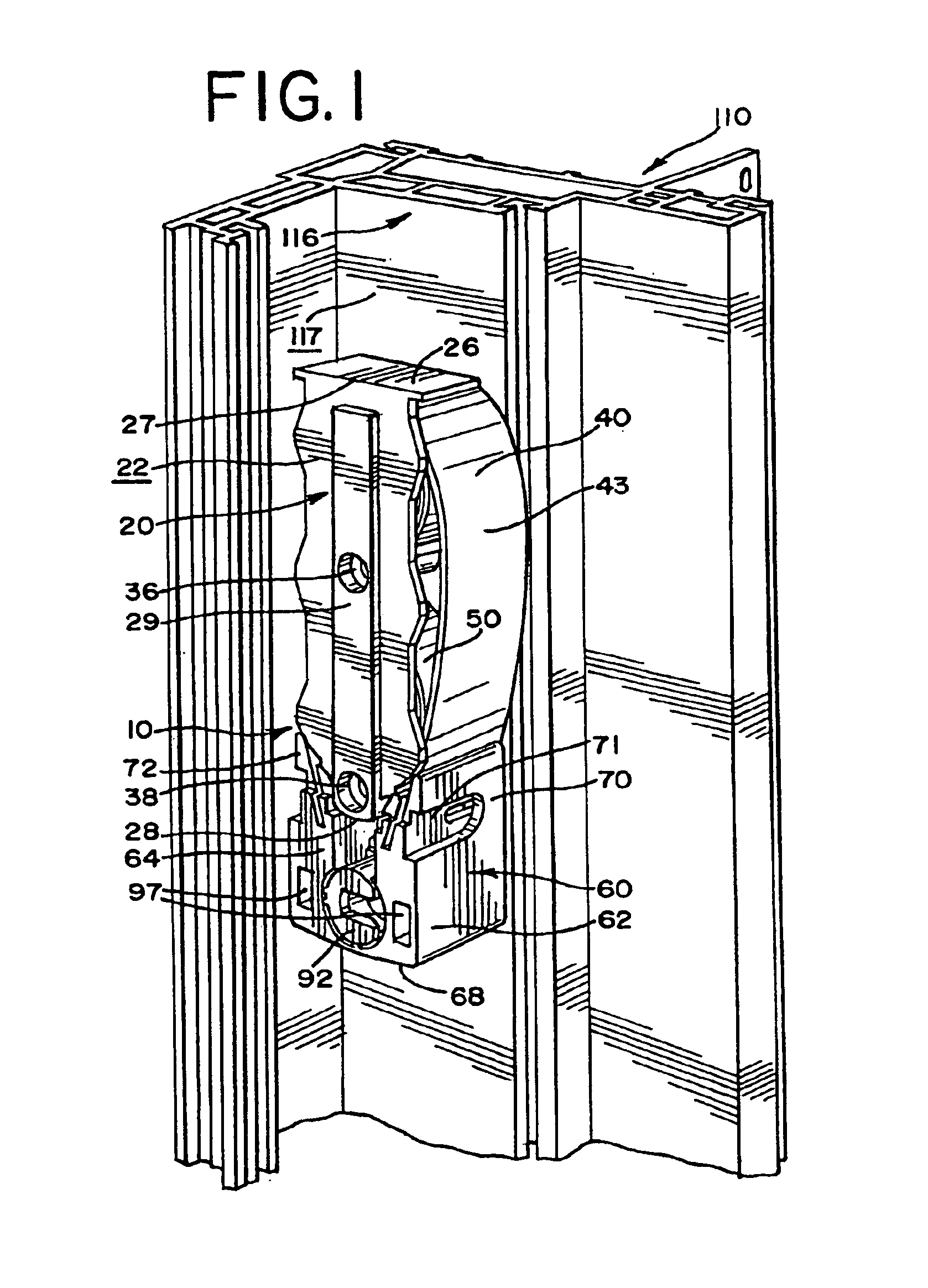

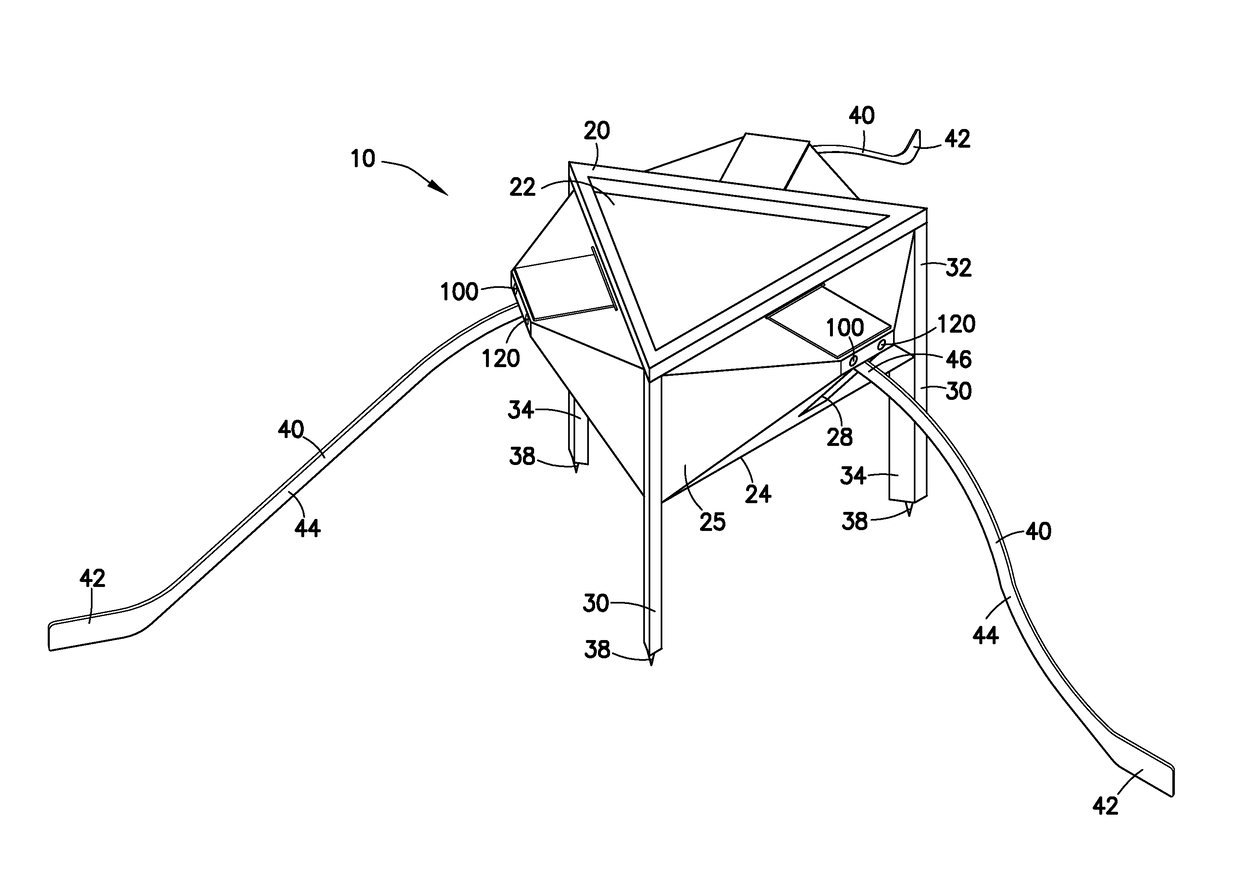

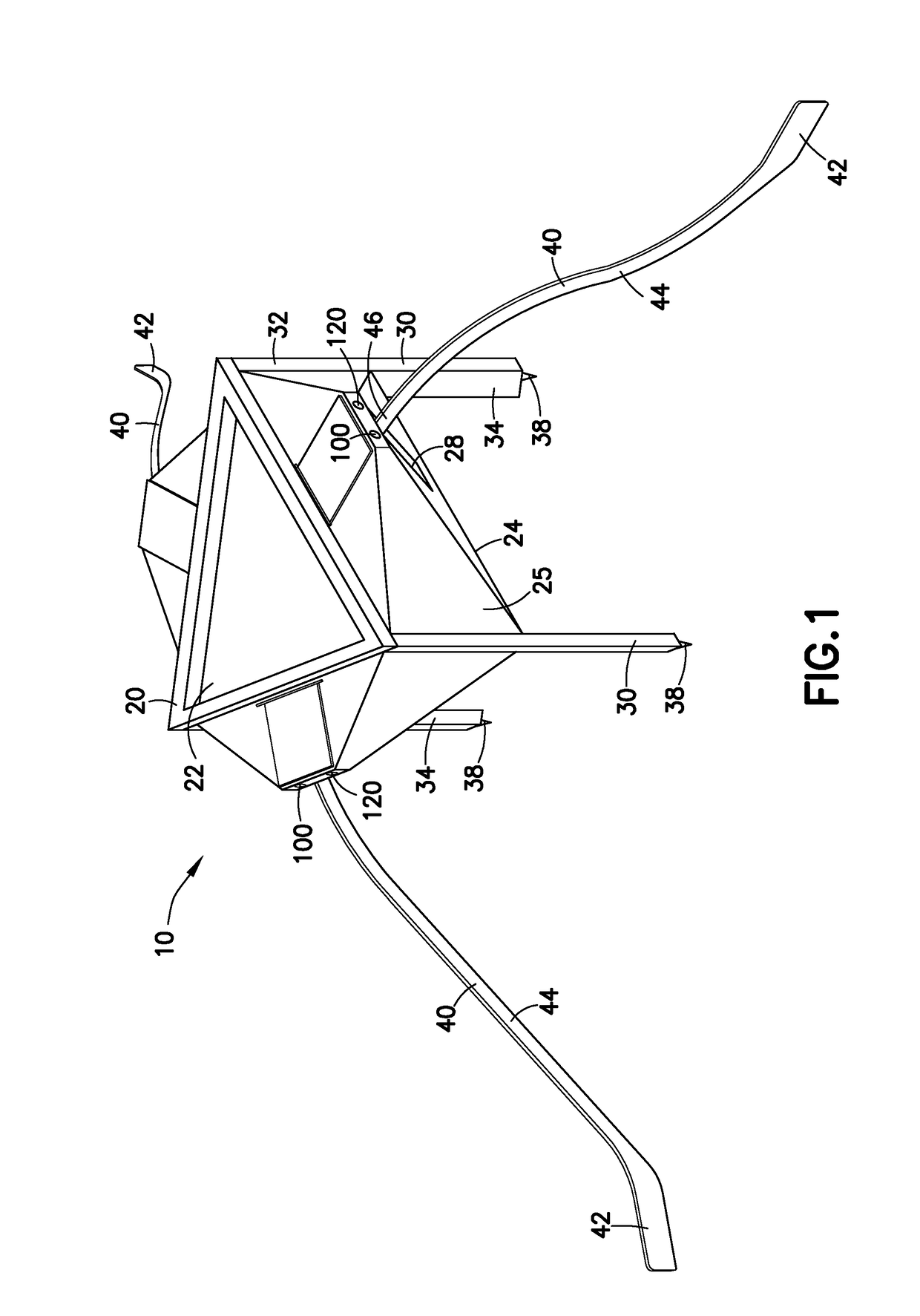

Spring balance assembly

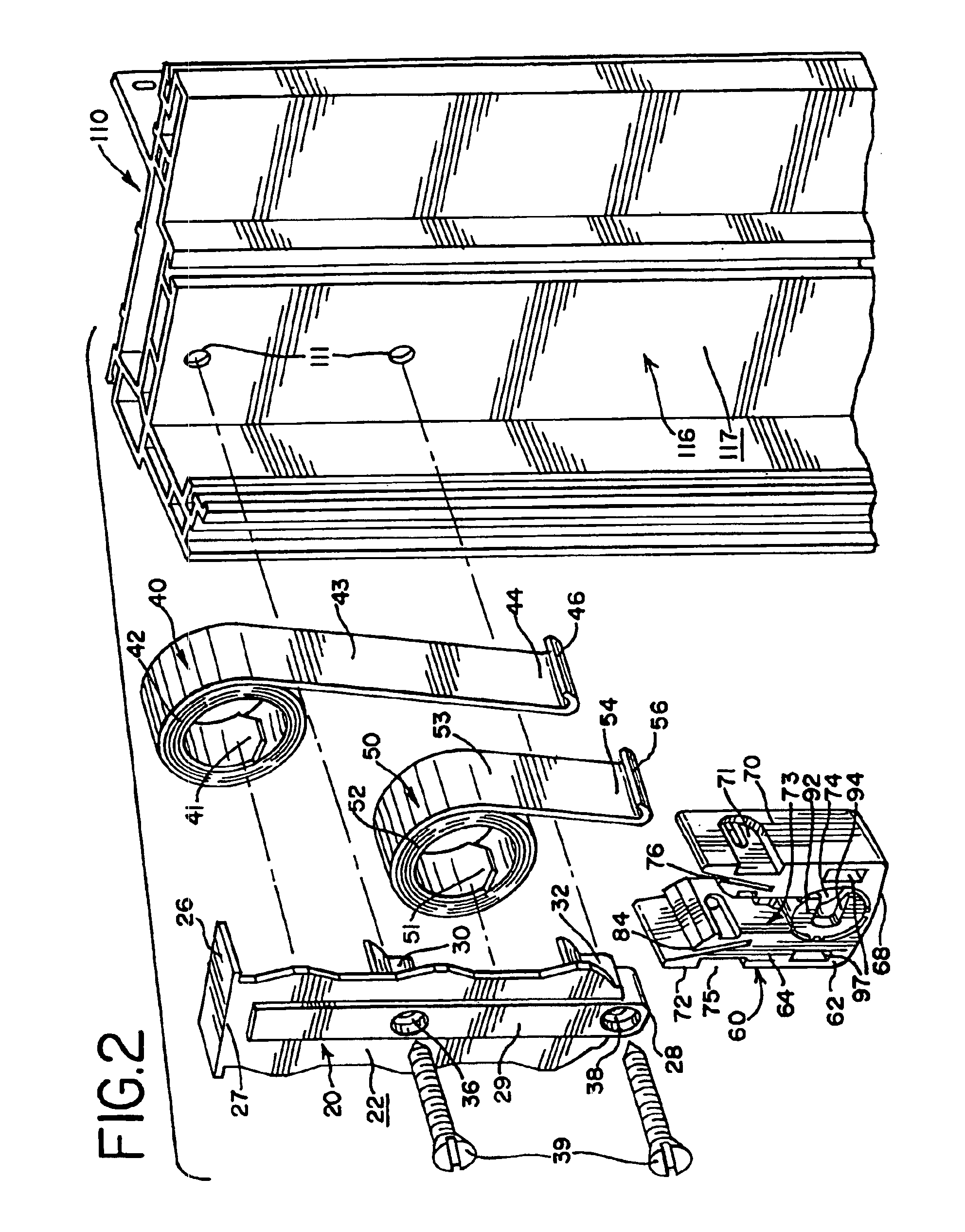

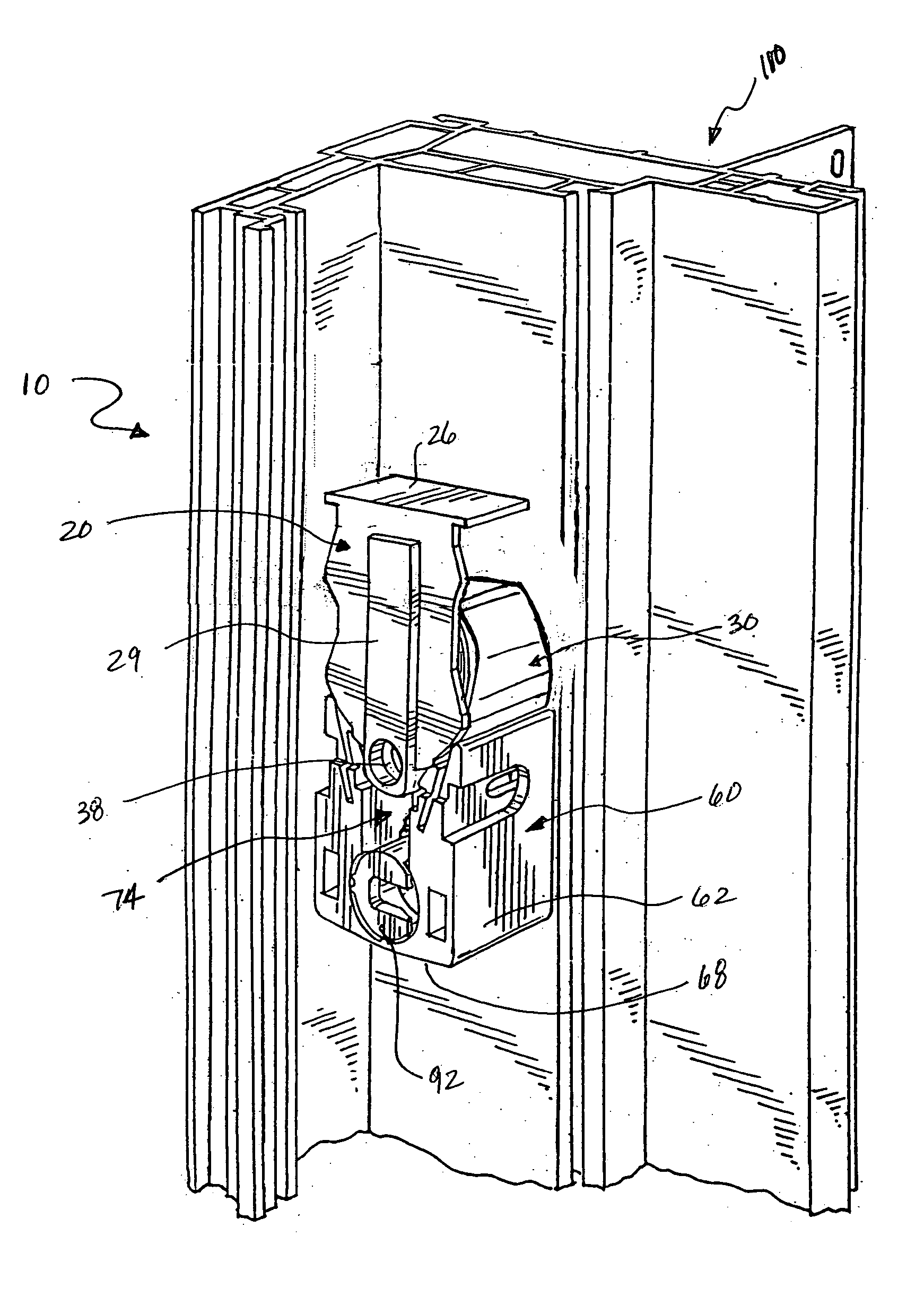

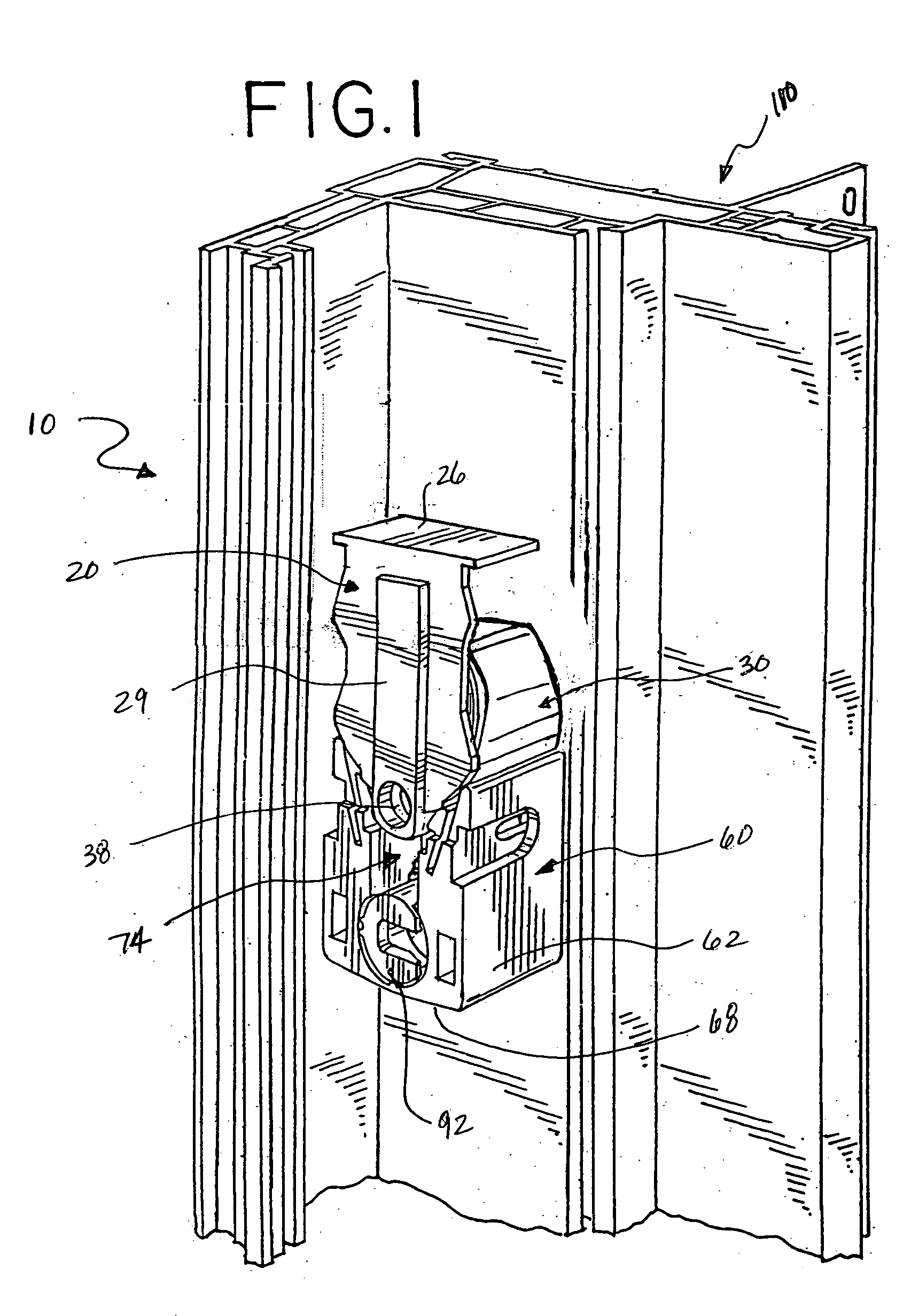

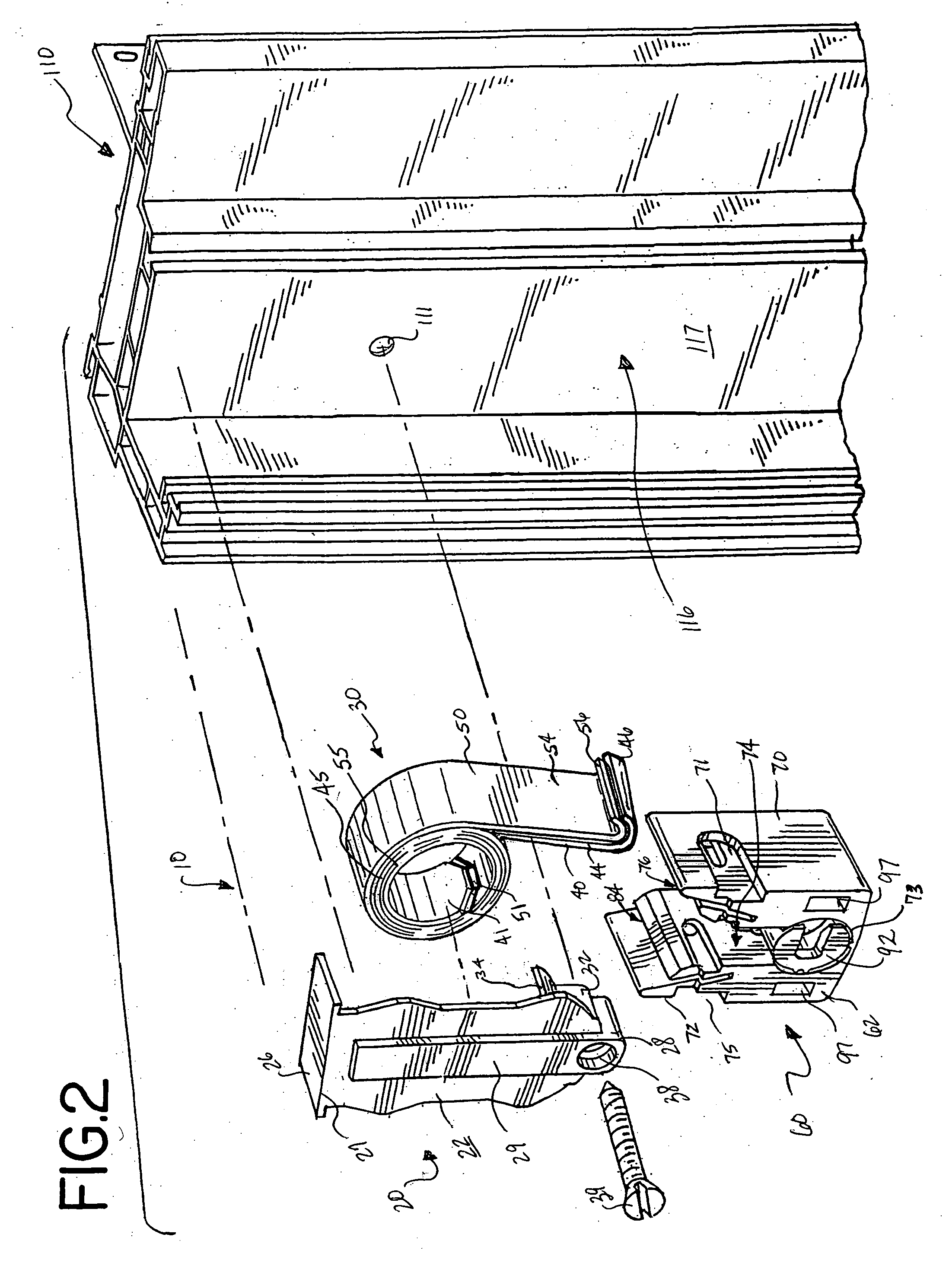

InactiveUS6983513B2Easy to assembleWith balanceBuilding braking devicesWing openersSash windowMechanical engineering

The present invention provides a balance assembly (10) for use with a sash window assembly (104) slidable within a master frame (110). The balance assembly (10) generally includes a plate (20), at least one coil (40), and a shoe or pivot brake assembly (60). The plate (20) is adapted to be attached to the master frame (110). The spring (40) has a coiled portion (42), an intermediate portion (43), and a free portion (44). The coiled portion (42) of the spring (40) is rotatably supported by a support member (30) extending from the plate (20). The free portion (44) of the spring (40) has a curved configuration with a curved end (46). The pivot brake assembly (60) has at least one slot (76) adapted to receive and retain the free portion (44) of the spring (40). The slot (76) defines a protrusion (83) that engages the free portion (44).

Owner:ASHLAND HARDWARE LLC

Spring balance assembly

InactiveUS20050198775A1Reduced dimensionExpand exportsBuilding braking devicesWing openersSash windowEngineering

The present invention provides a balance assembly for use with a sash window assembly slidable within a master frame. The balance assembly generally includes a plate, a spring assembly, and a brake shoe or pivot brake assembly. The plate is removably connected to the master frame. The spring assembly includes a first spring that is inter-wound or nested within a second spring. Each spring has a coiled portion, an intermediate portion, and a free portion. The coiled portions of the springs are rotatably supported by the support member that extends from the plate. The free portions of the springs have a curved configuration and are received by a slot in the brake shoe, which is operably coupled to the sash window. The inter-wound springs exert a balancing force on the sash window during movement of the window.

Owner:NEWELL OPERATING COMPANY

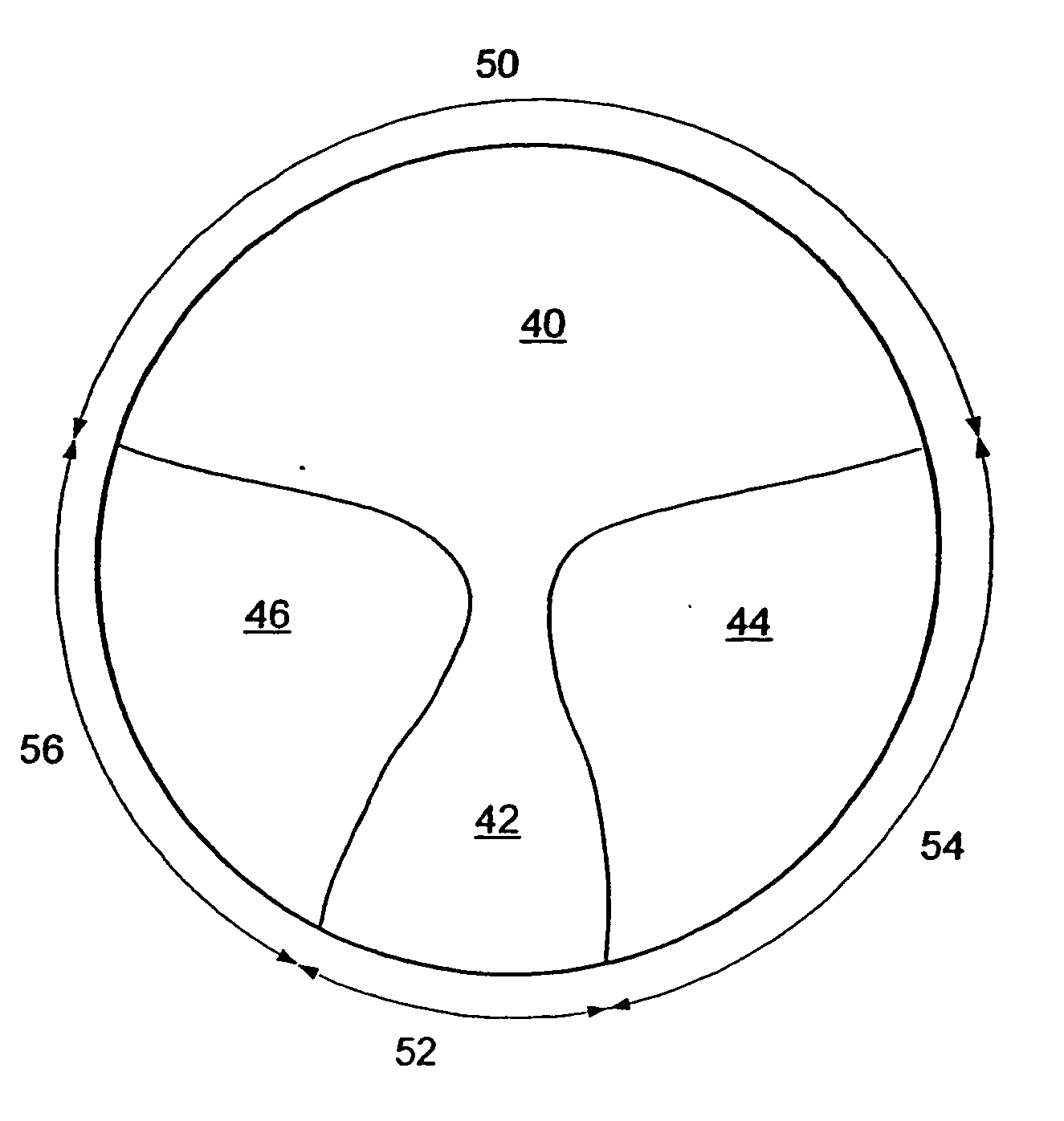

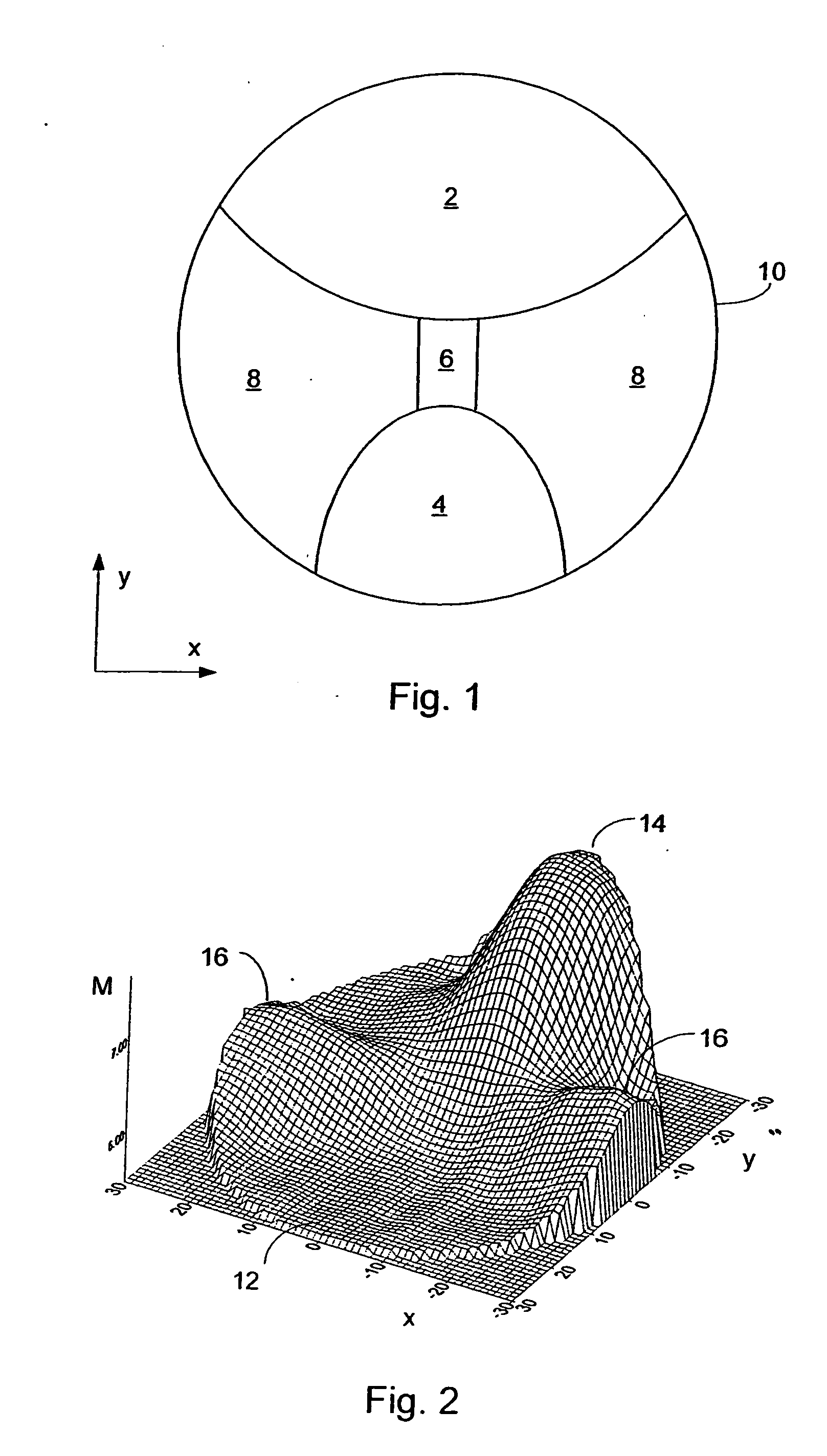

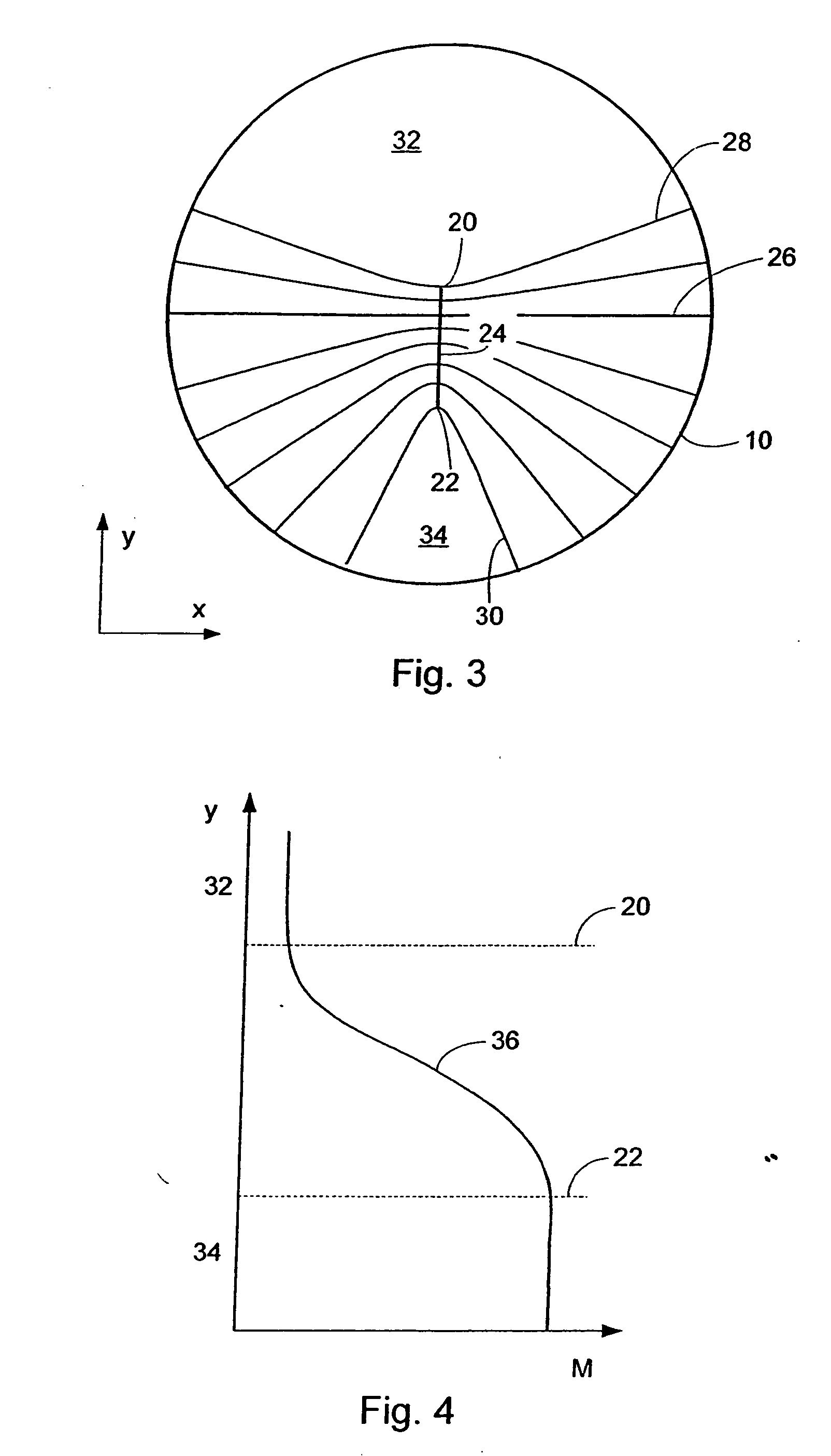

Progressive addition power lens

InactiveUS20050012895A1Effective areaReduces peak of astigmatismOptical partsSuccessive over-relaxationRelaxation equation

A system and method for designing a progressive lens are provided. Mean power is specified at points distributed over the entire surface of the lens and lens height is specified around the edge of the lens. Lens height is determined at the points consistent with the specified mean power and the lens edge height in part by solving a partial differential equation of the elliptic type subject to the lens edge height as a boundary condition. A successive over-relaxation technique may be employed to converge on the solution to the partial differential equation, and an over-relaxation factor may be determined to most efficiently relax the equation.

Owner:CROSSBOWS OPTICAL

Multi-eye image pickup apparatus and adjusting method

InactiveUS7956886B2With balanceImprove the level ofTelevision system detailsColor signal processing circuitsStereo cameraPhotoelectric conversion

A stereoscopic camera includes a master camera for photoelectric conversion of object light to generate a first image signal with three color components G, R and B. A slave camera generates a second image signal. In an adjusting method, a first gain Dmr, Dmg and Dmb of the color components is determined according to the first image signal to correct a brightness level and white balance of the master camera, to adjust the first image signal by use thereof. A second gain Dsr, Dsg and Dsb of the color components is determined according to the first gain and color calibration information predetermined according to color sensitivity of the master and slave cameras in relation to the color components. The second image signal is adjusted by use thereof, for color matching between the first and second image signals to set equal the brightness level and the white balance.

Owner:FUJIFILM CORP

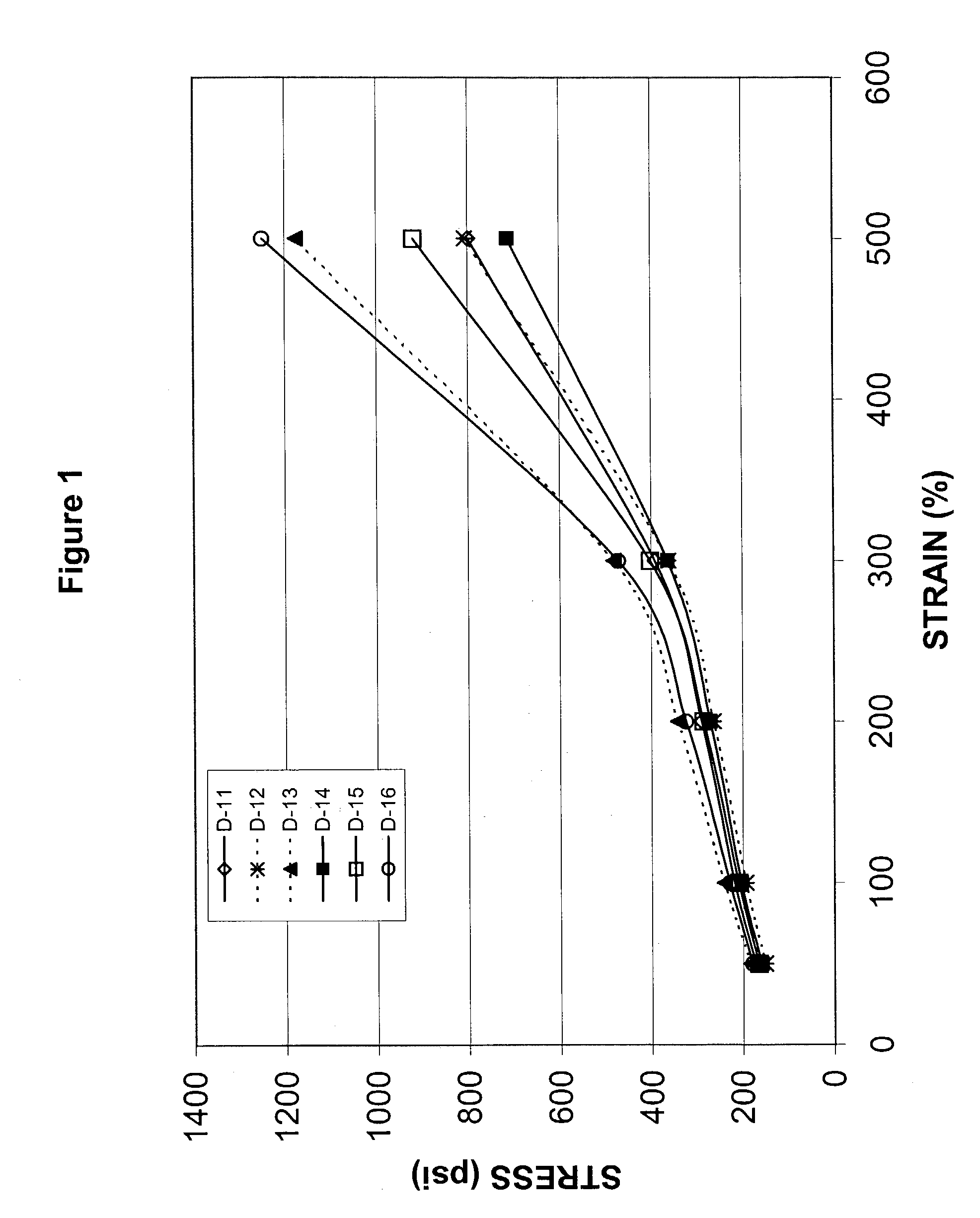

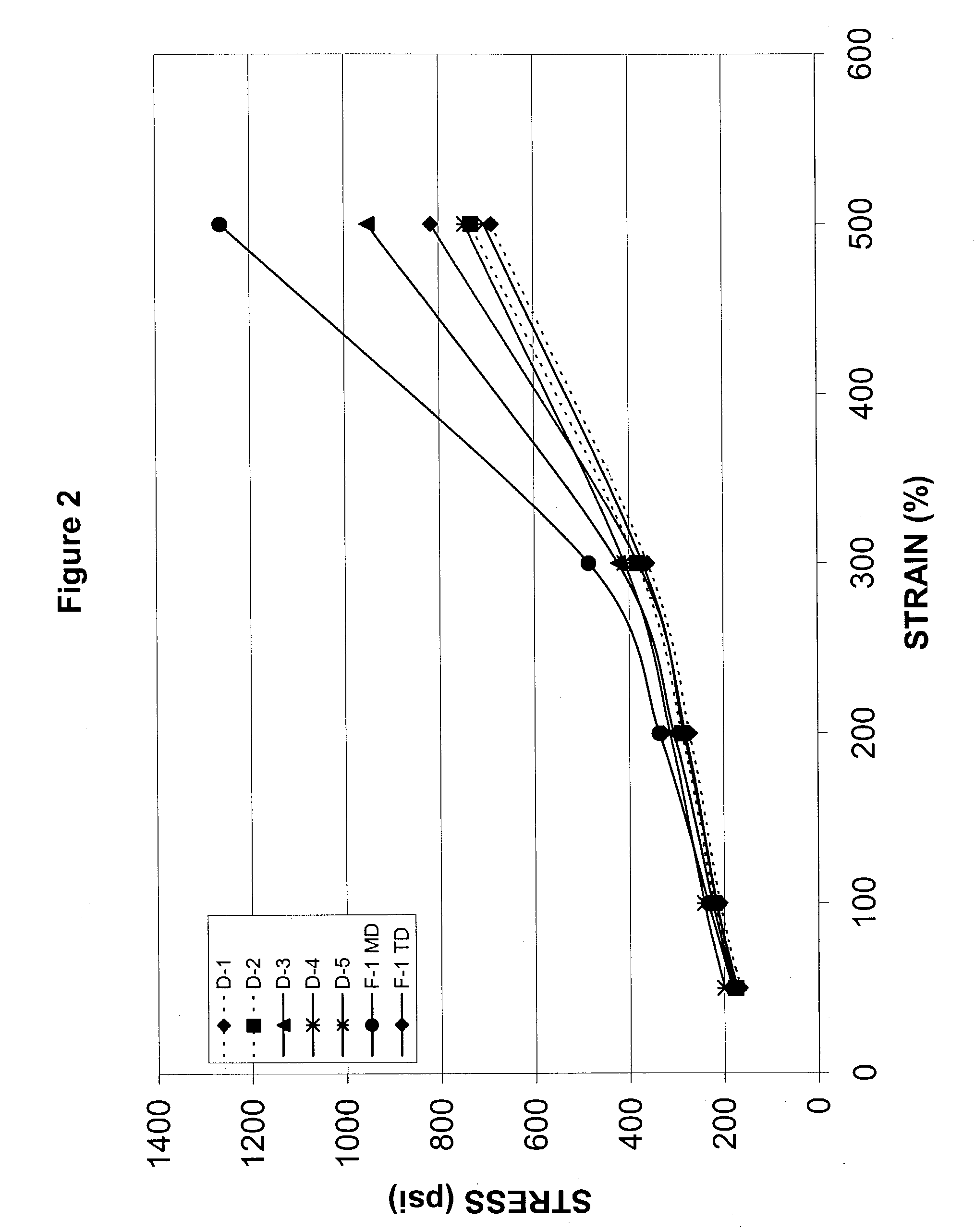

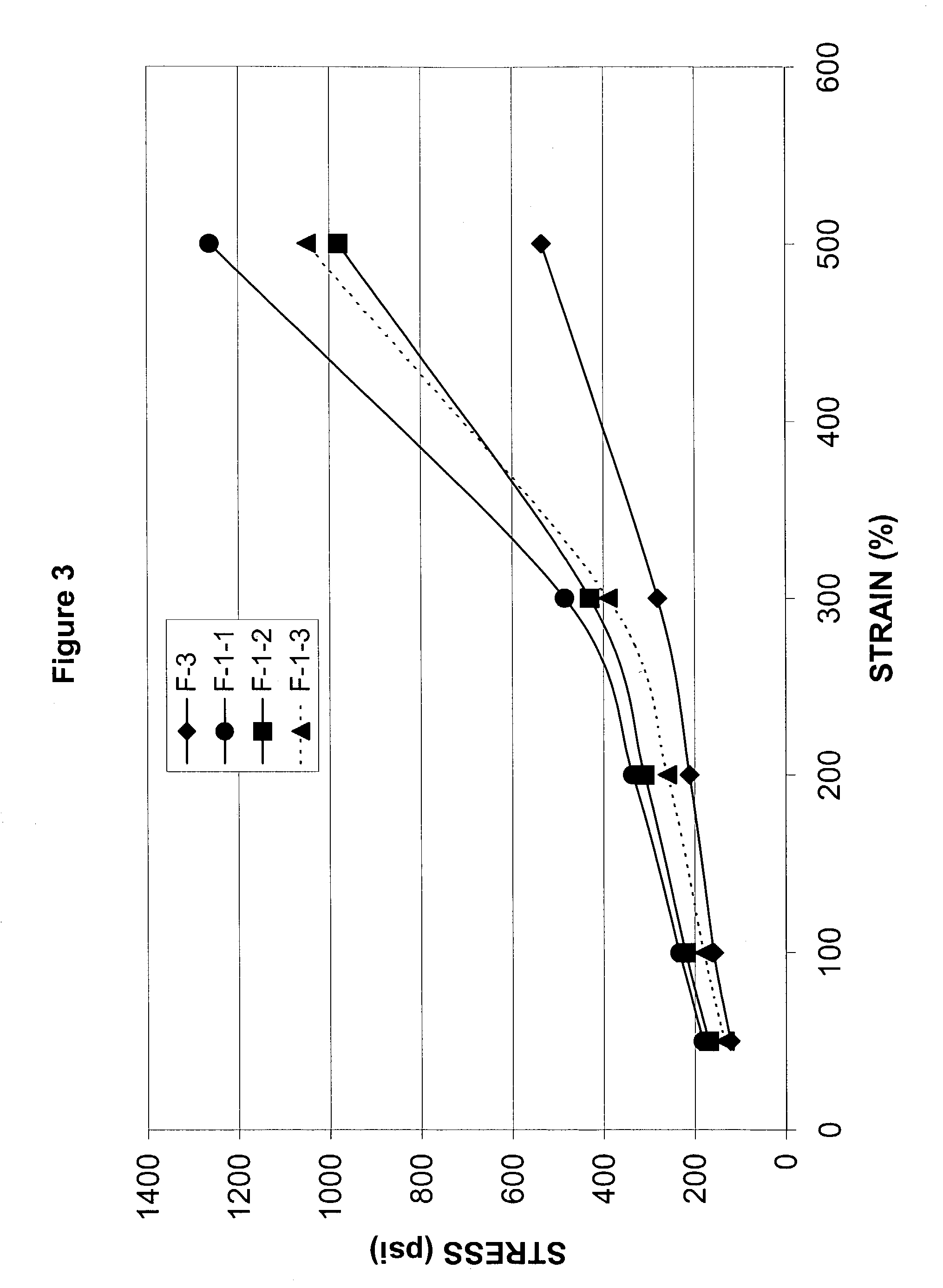

Tetrablock copolymer and compositions containing same

Disclosed is a novel tetrablock copolymer having the general configuration of A1-B1-A2-B2, where the A1 and A2 blocks are mono alkenyl arene and the B1 and B2 blocks are blocks of hydrogenated butadiene, having a 1,2-vinyl content of between 25% and 60%. The blocks have well defined molecular weight ranges, resulting in a polymer having a unique set of property advantages. Also disclosed are elastomeric compositions containing the linear hydrogenated block copolymer, a styrene polymer, an ethylene polymer and a tackifying resin. These elastomeric compositions have particular utility in injection molded parts and in extruded parts such as extruded films and fibers.

Owner:KRATON POLYMERS US LLC

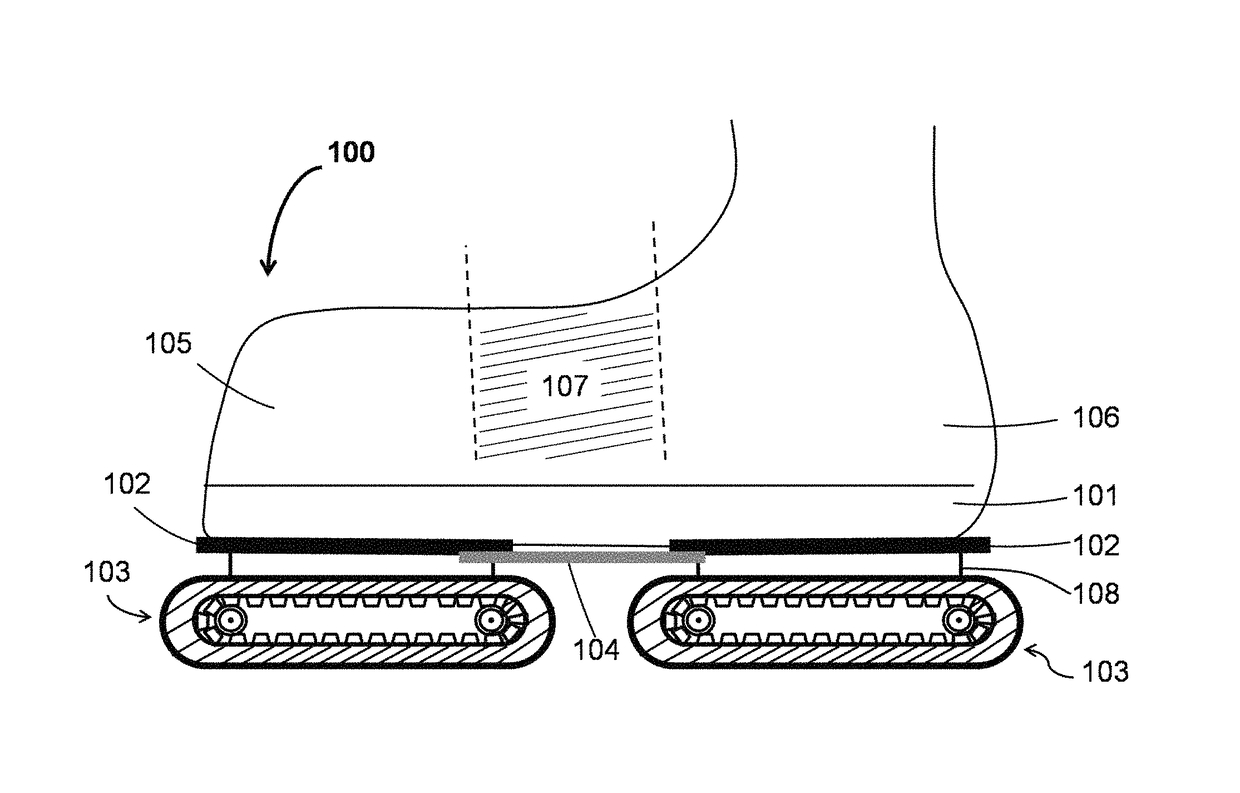

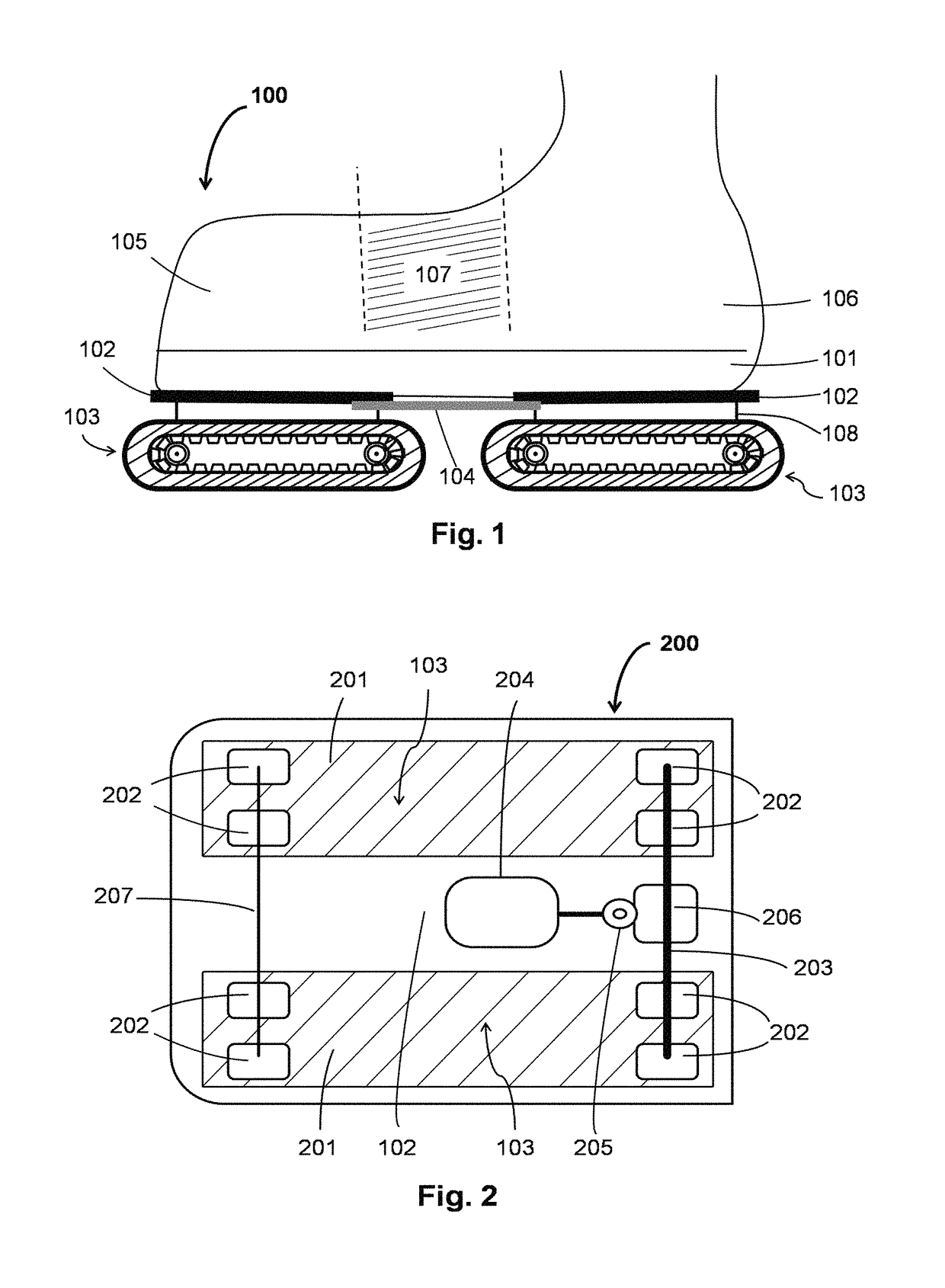

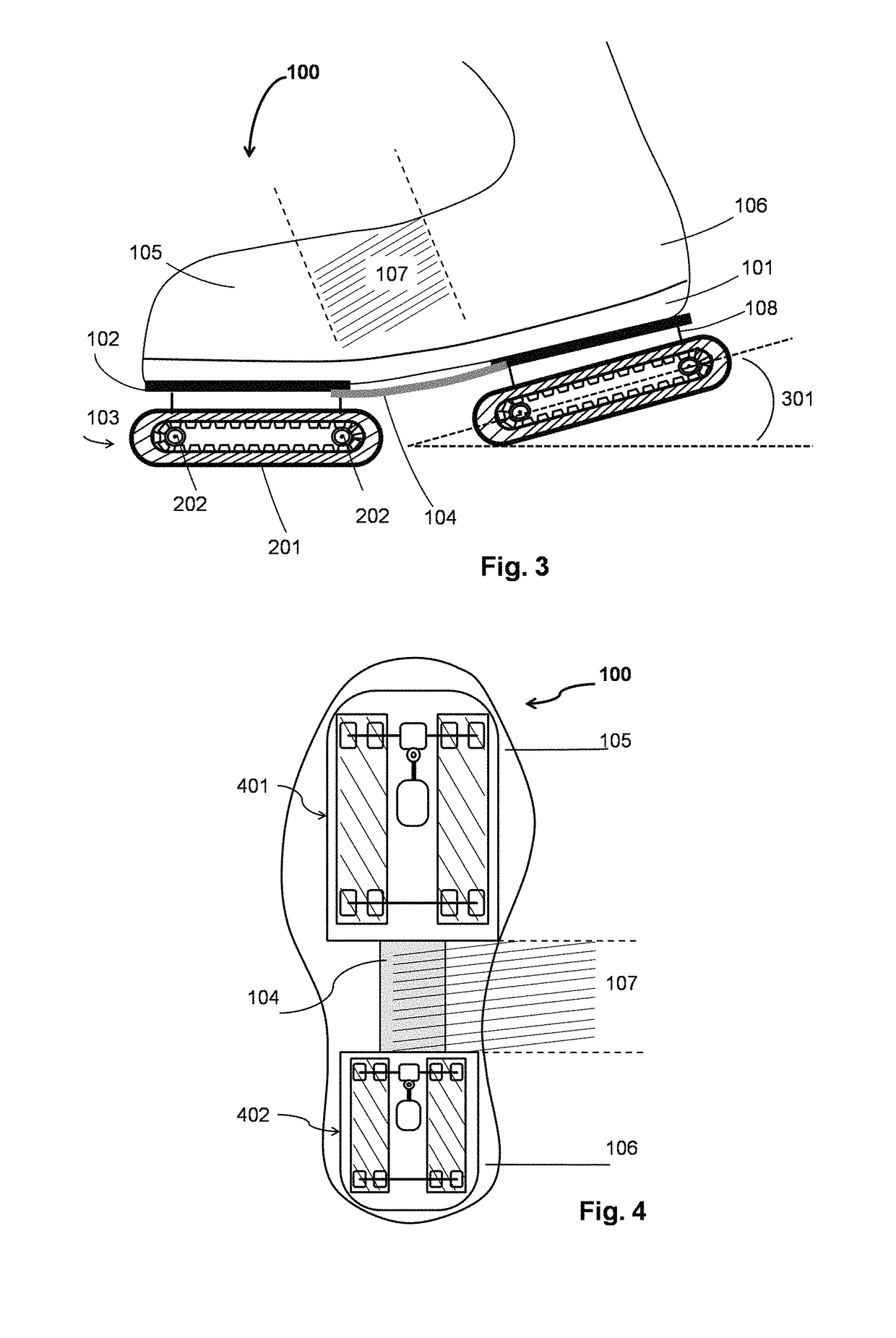

Motorized walking shoes

ActiveUS9925453B1Maintaining normal walking movementMaintain balanceSolesFasteningsEngineeringWalking balance

A motorized personal transportation article is provided to transport a person by wearing a pair of power-assisted motorized shoes, used in a normal forward walking action that provides a supplementary walking speed adjusted based on a user intended walking speed, even the intended speed changes during a mid-step. The sole of each of the shoes houses a relatively stiff plate coupled with conveyor assemblies in the toe and heel sections, respectively, which are connected by a relatively flexible portion. The assembly is designed to neutralize forces acting to disrupt its operation during walking while the flexible portion assists in bending the shoe naturally to maintain the natural walking balance and movement. Further, the flexible portion may equip with ribs or hinges for easier bending than twisting. The front and rear relatively stiff plates may make of twistable and bendable materials but to a lesser extent than the flexible portion.

Owner:TULI RAJA SINGH

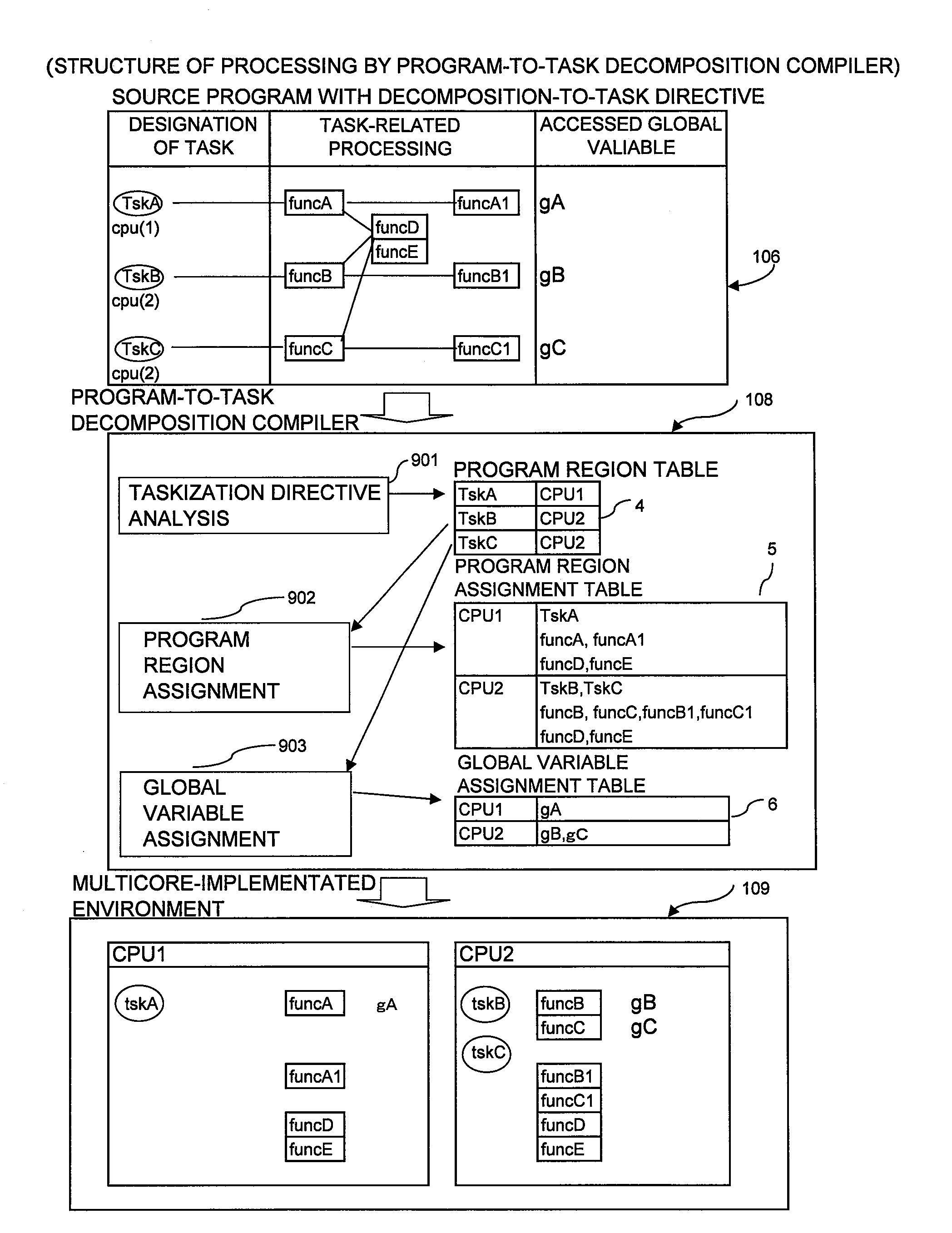

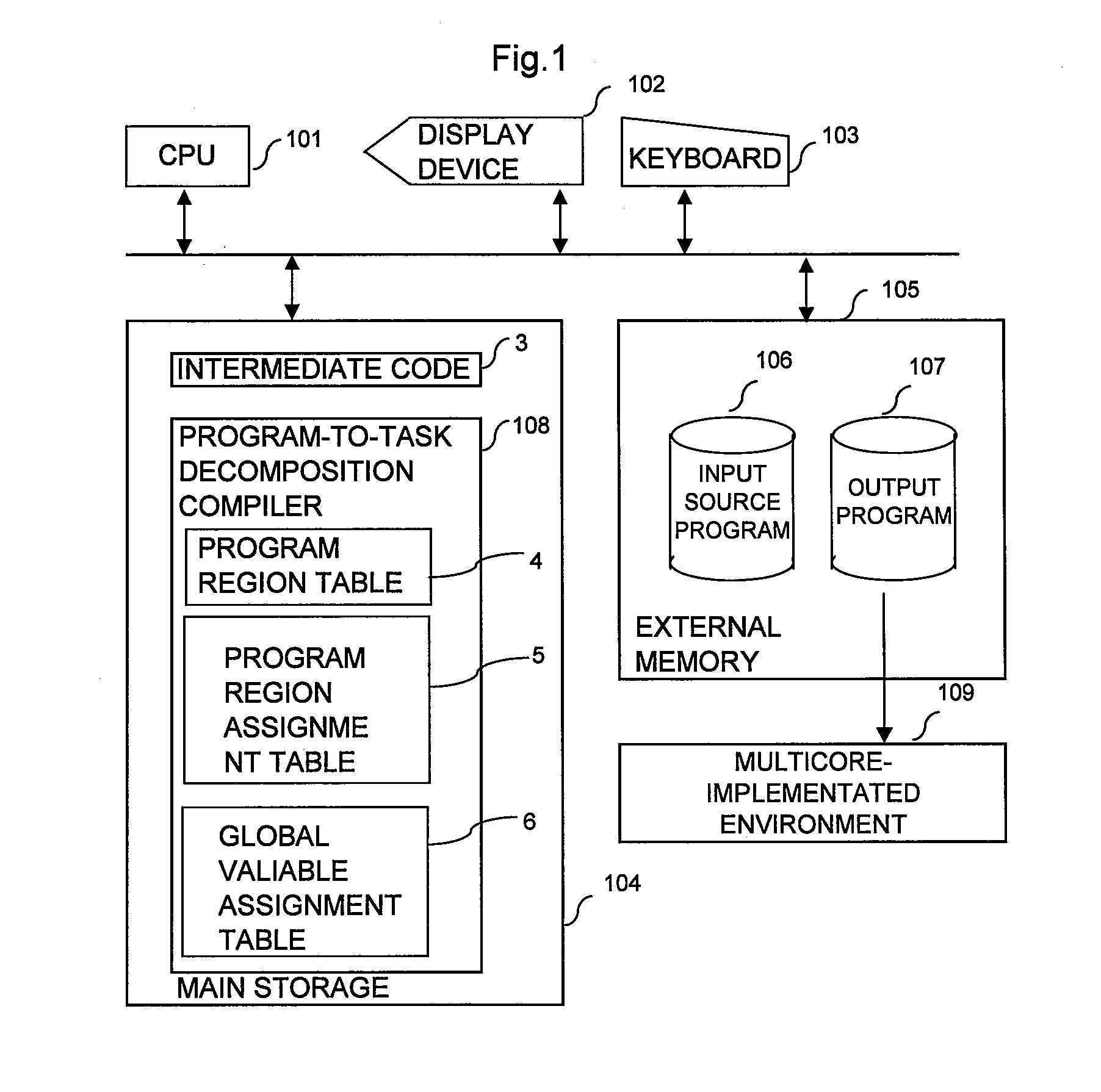

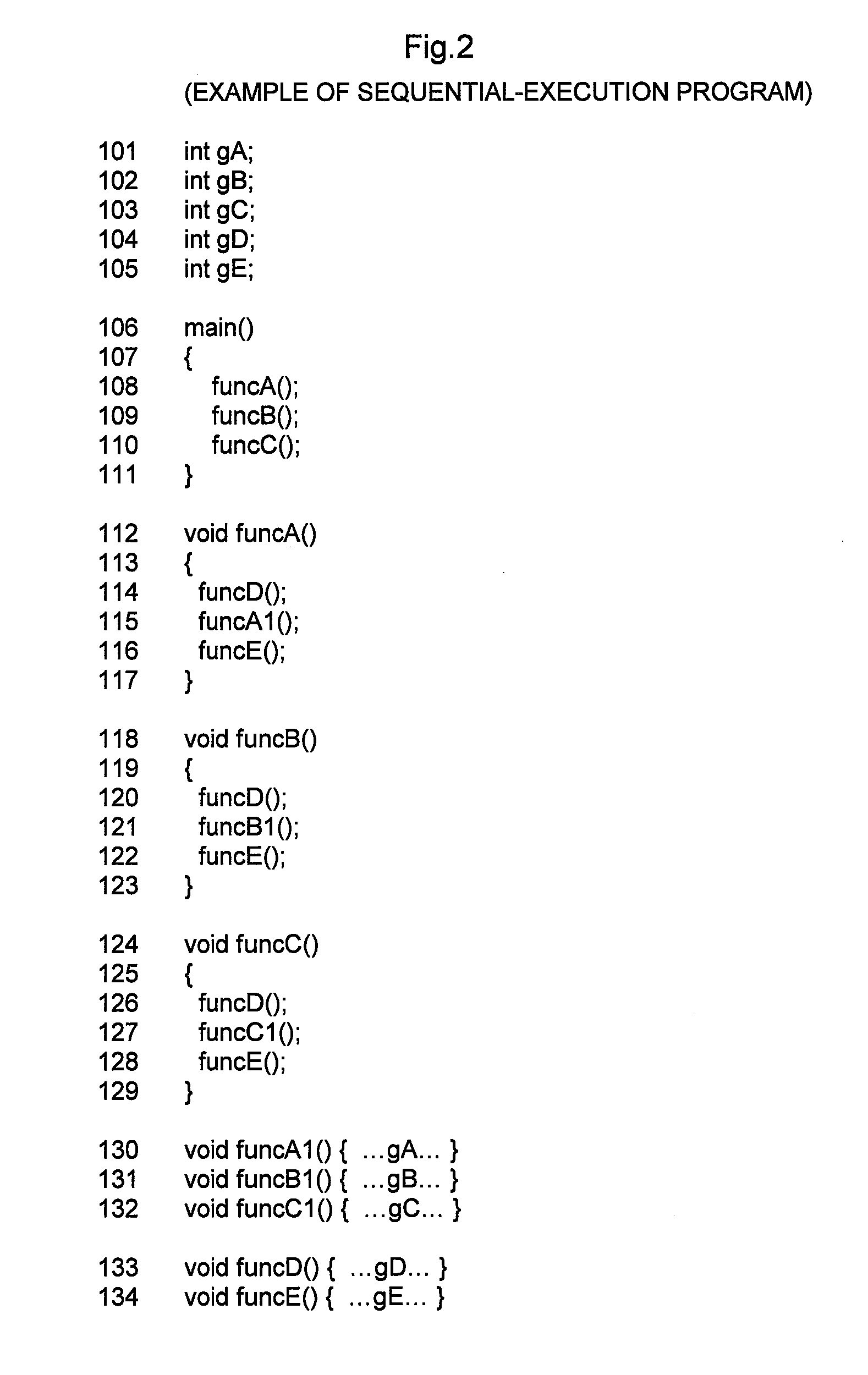

Compile method and compiler

InactiveUS20100229161A1Efficient executionEffective distributionSoftware engineeringProgram controlQR decompositionCompiler

A compile technique is provided for multicore allocation, by which a desired running performance can be achieved. The steps of analyzing a taskization directive, taskizing a specified part, and assigning a specified CPU the task are adopted for the compile technique. According to the program-to-tasks-decomposition compile technique, the multicore decomposition is performed by allocating tasks to CPUs individually while following a task decomposition directive of a main part designated by a user. When no direction is issued concerning a CPU to be allocated, the relation with a principal task is judged from the relation of invocation and the dependency, and CPU to be allocated, and then the CPU to be allocated is determined. In allocation to the CPU, an efficient multicore-task decomposition is achieved in consideration of copy and assignment of one processing to more than one CPU while figuring in the balance between processing speed and resources.

Owner:RENESAS ELECTRONICS CORP

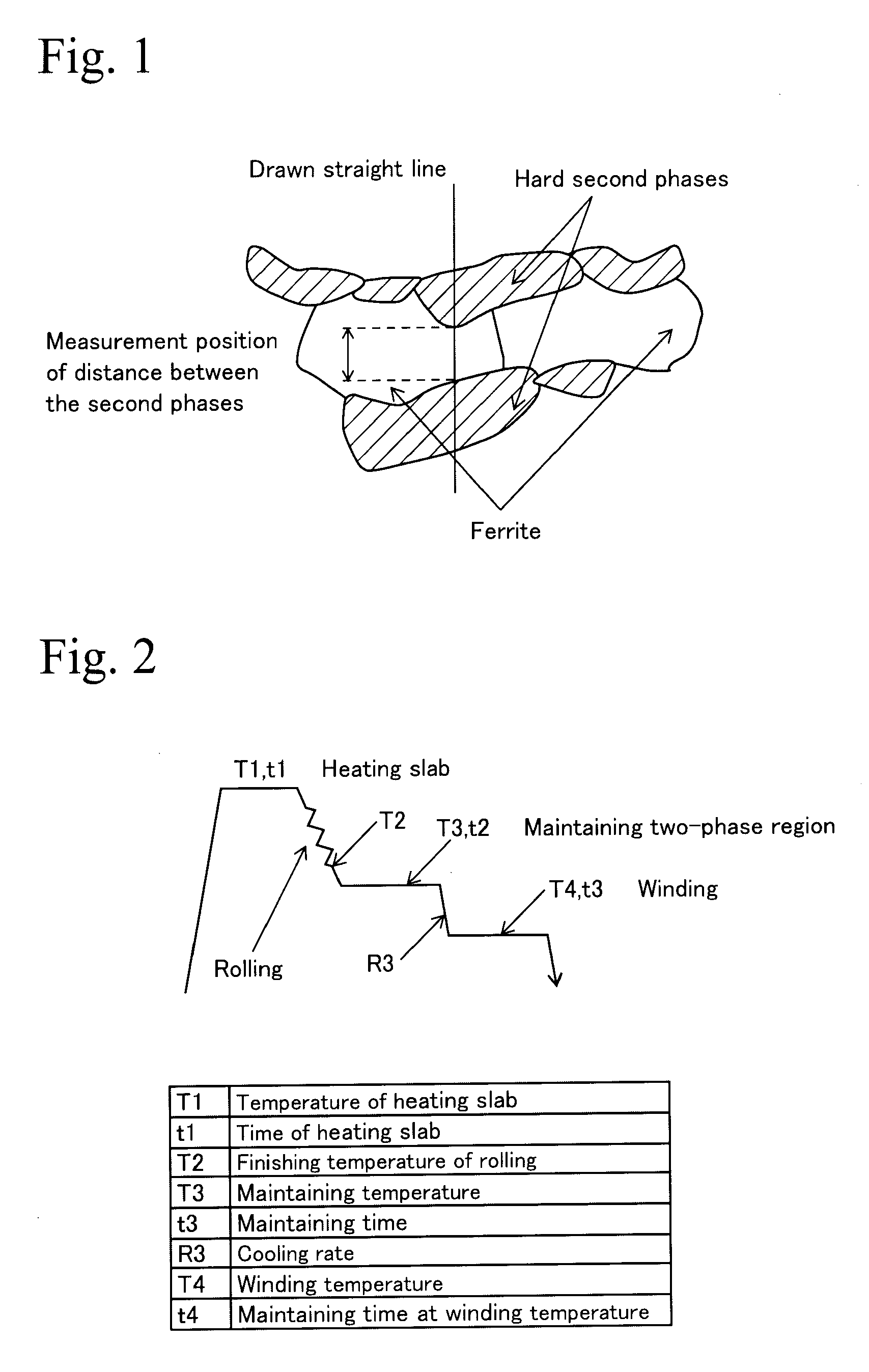

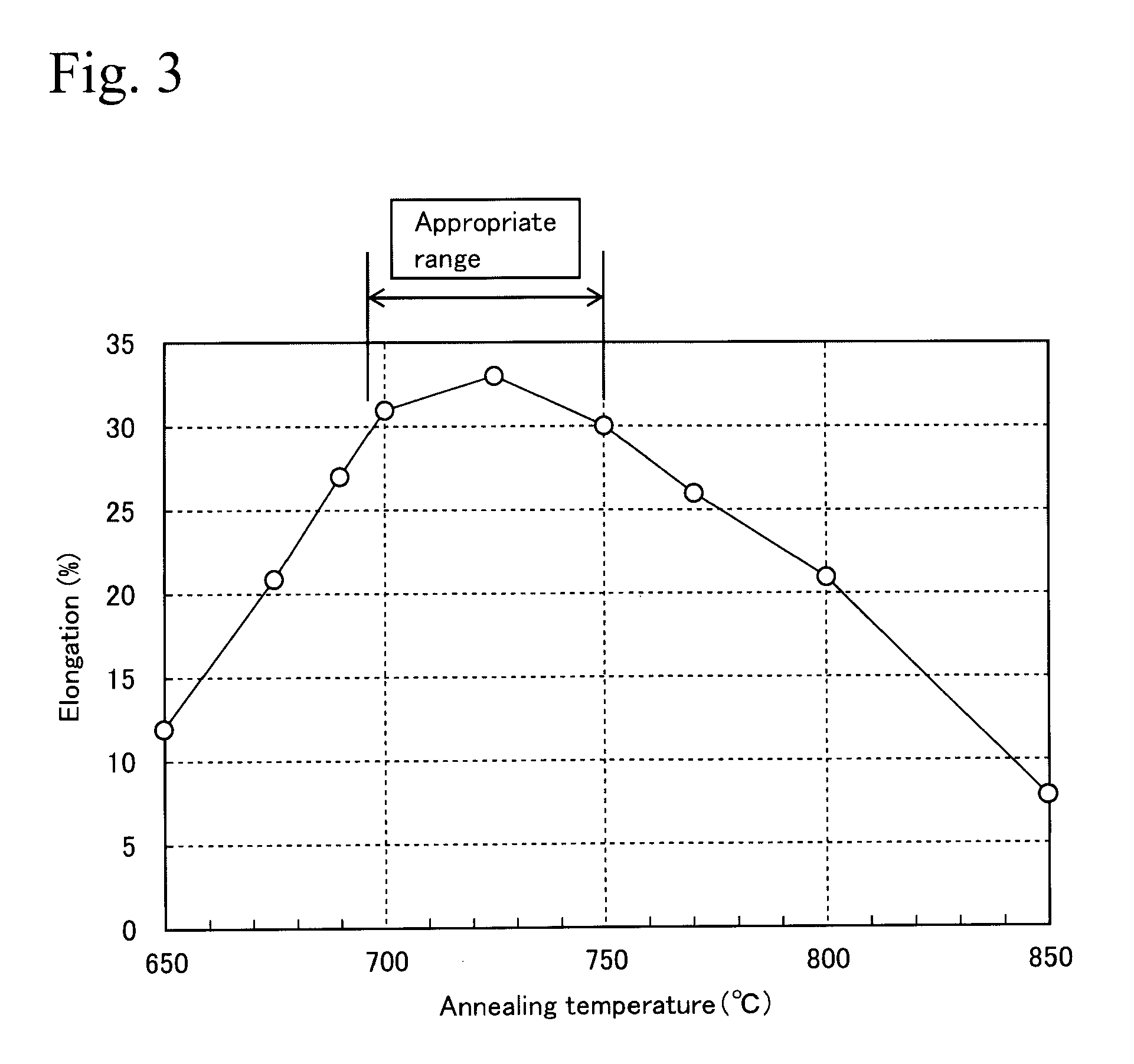

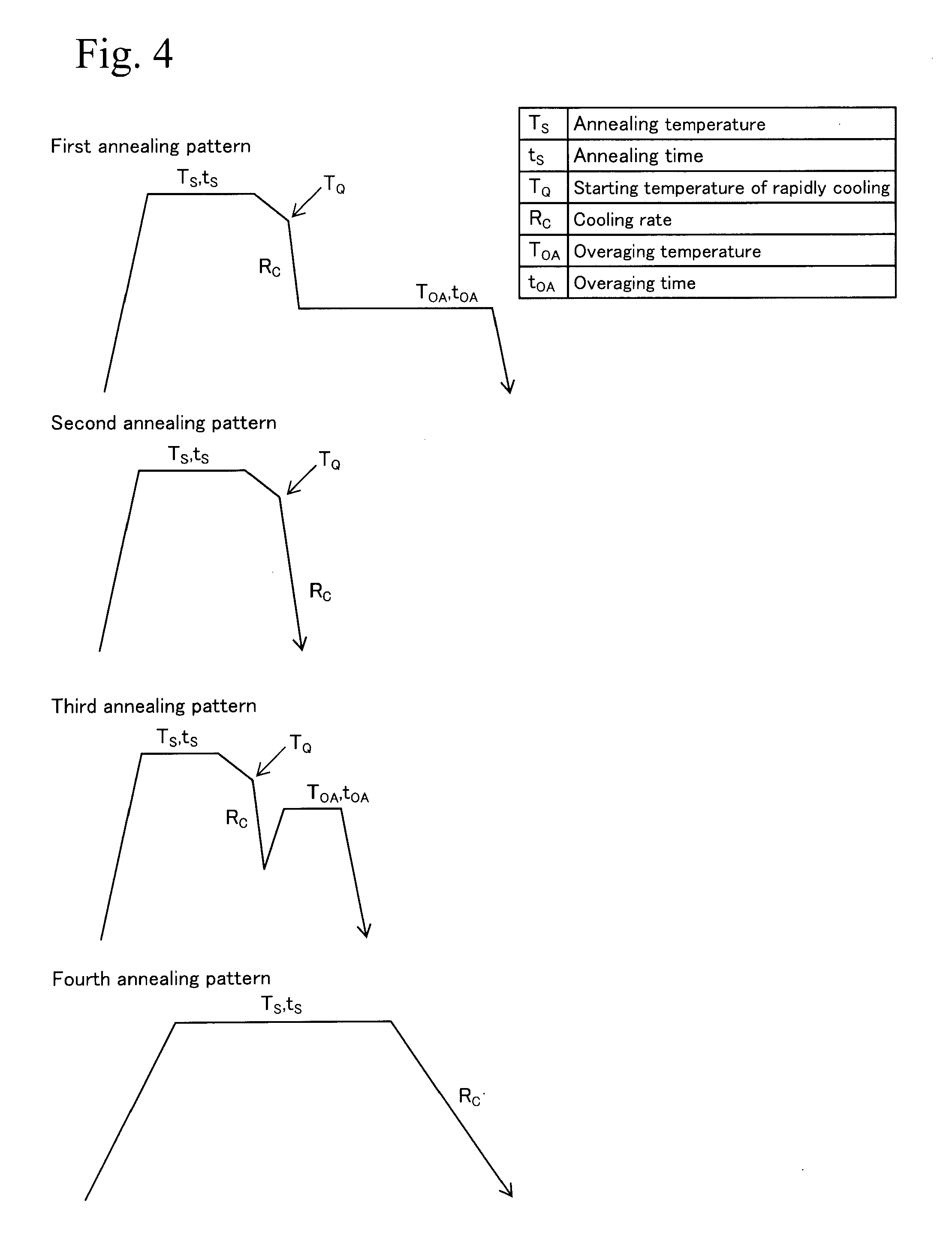

High-strength steel sheet and process for producing the same

InactiveUS20090188589A1High strengthImprove ductilityFurnace typesHeat treatment process controlHigh intensityArea ratio

A high-strength steel sheet comprises a metallic structure consisting of a ferrite phase and a hard second phase dispersed in the ferrite phase, the hard second phase in the metallic structure having an area ratio of 30 to 70%, and the ferrite of which grain sizes are not more than 1.2 μm having an area ratio of 15 to 90% in the ferrite phase. The term ds is an average grain size of the ferrite of which grain sizes are not more than 1.2 μm, the term dL is an average grain size of ferrite of which grain sizes are more than 1.2 μm, and the ds and the dL satisfy the following equation (1):dL / ds≧3 (1).

Owner:HONDA MOTOR CO LTD

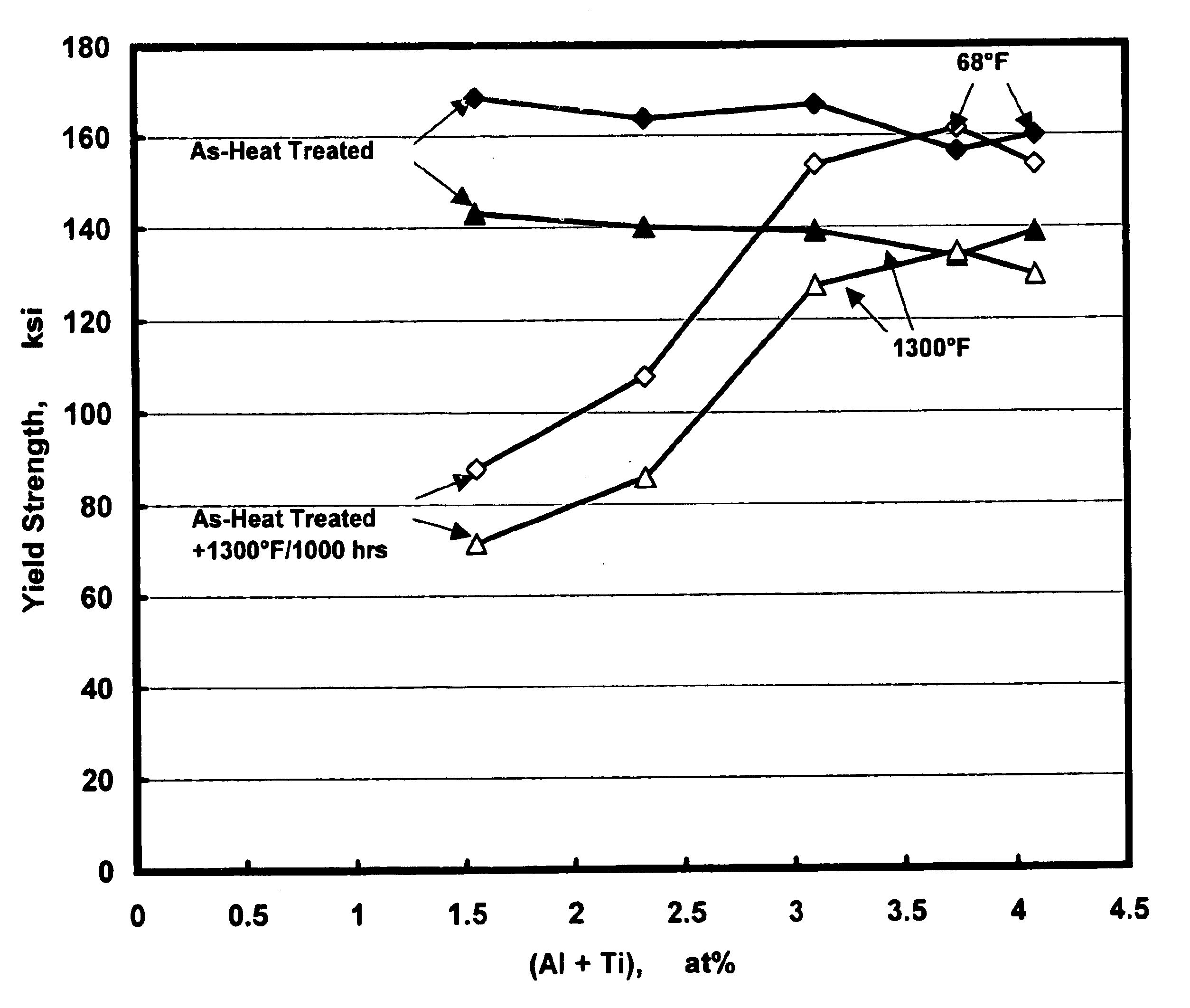

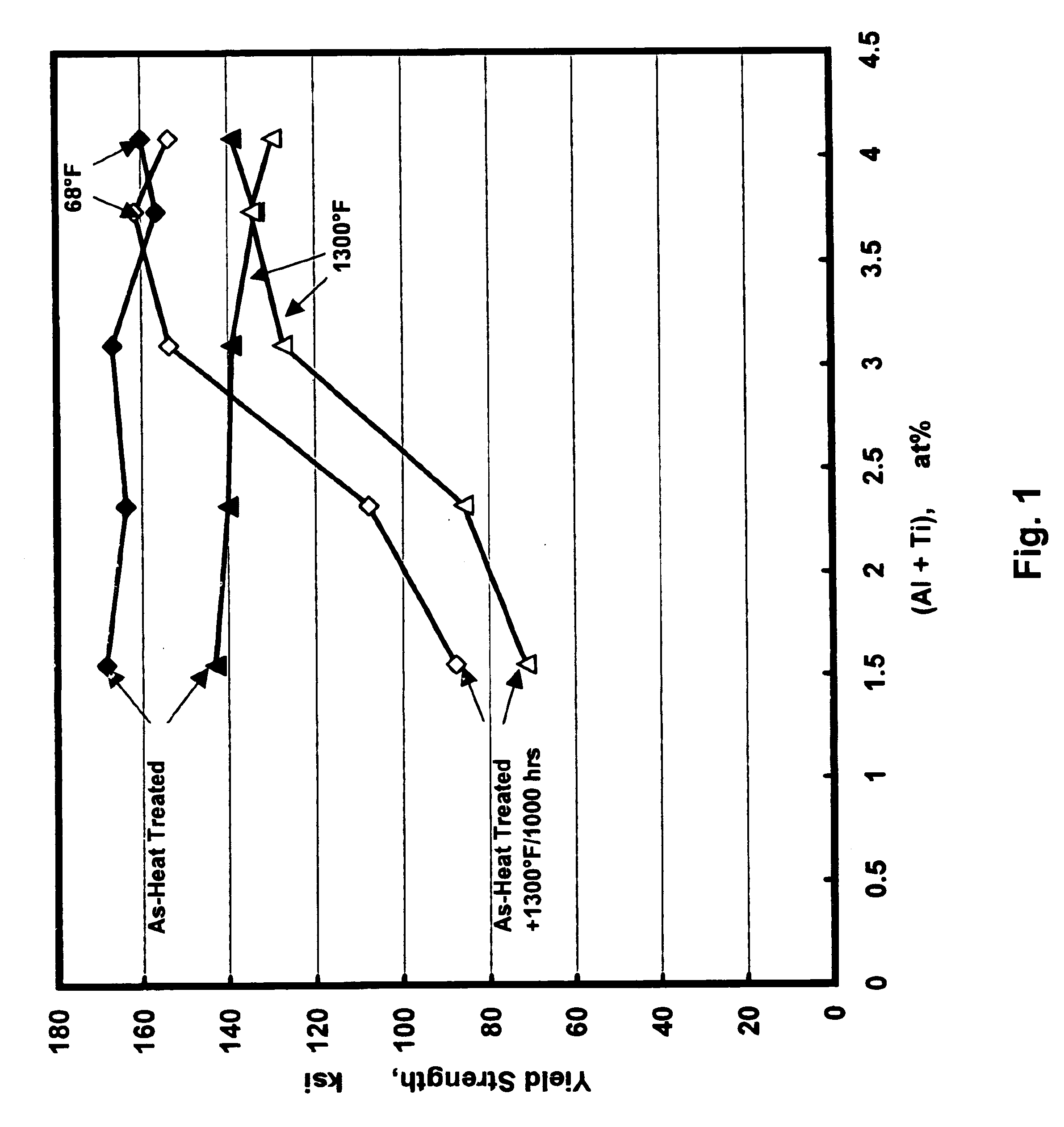

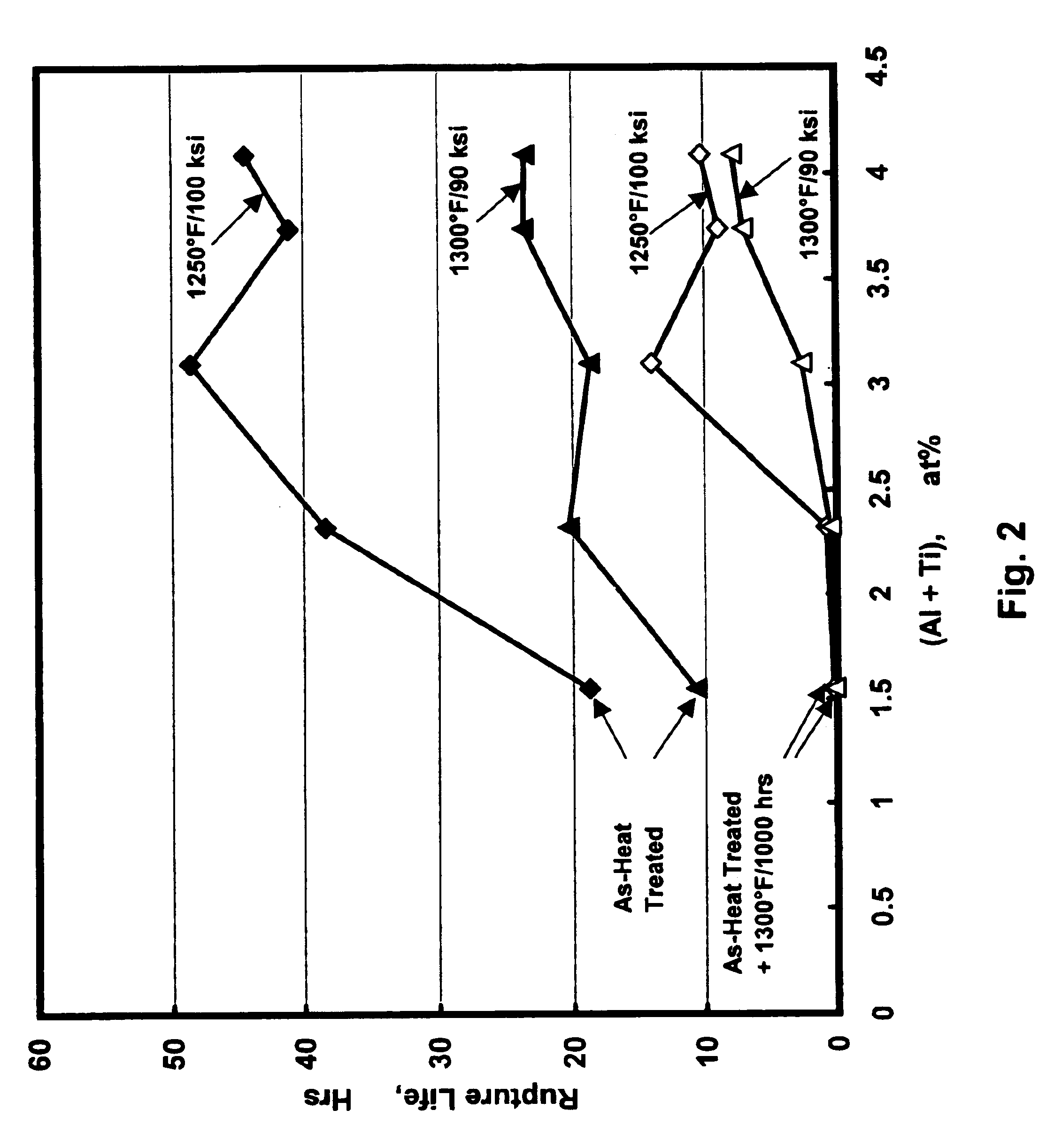

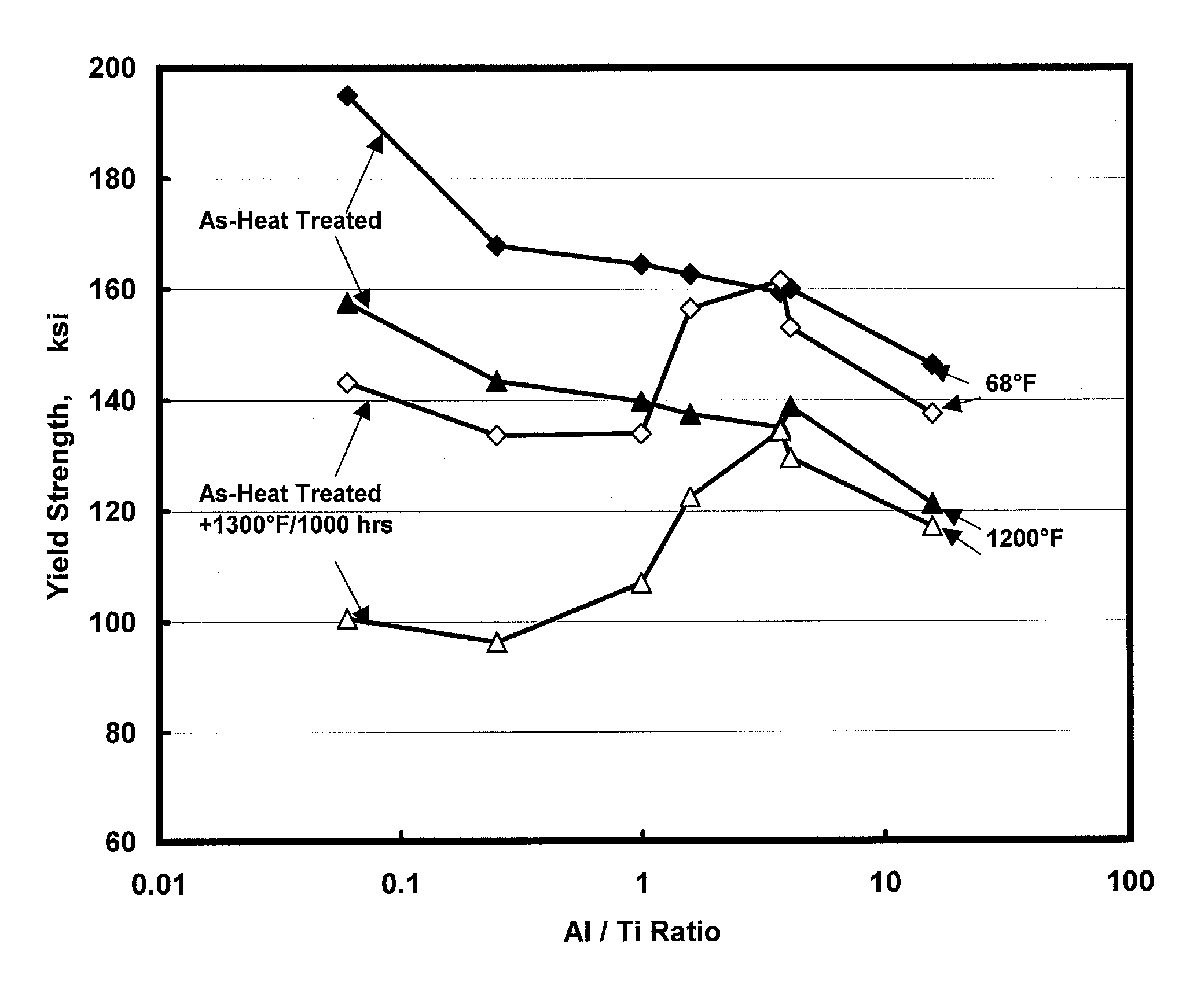

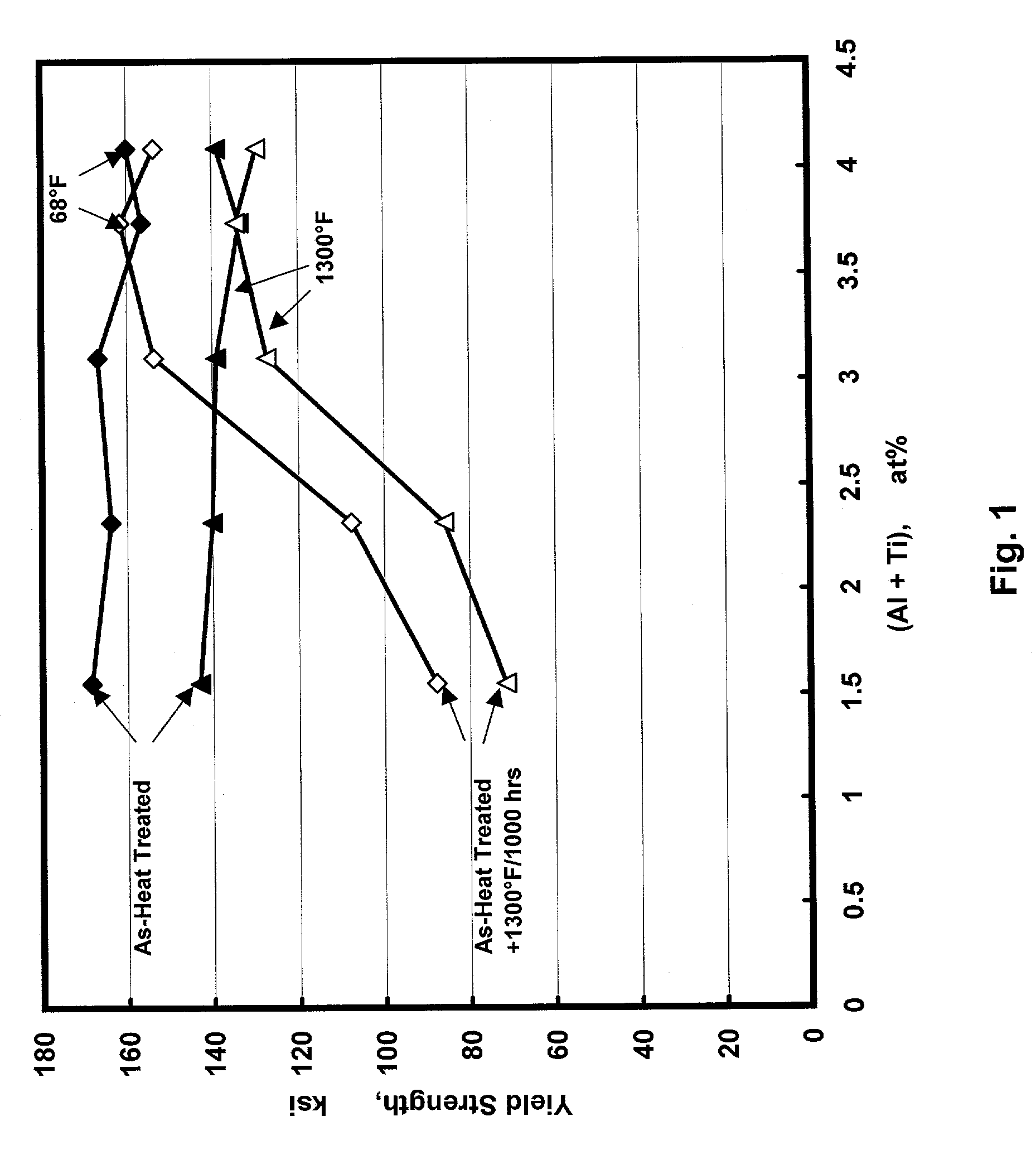

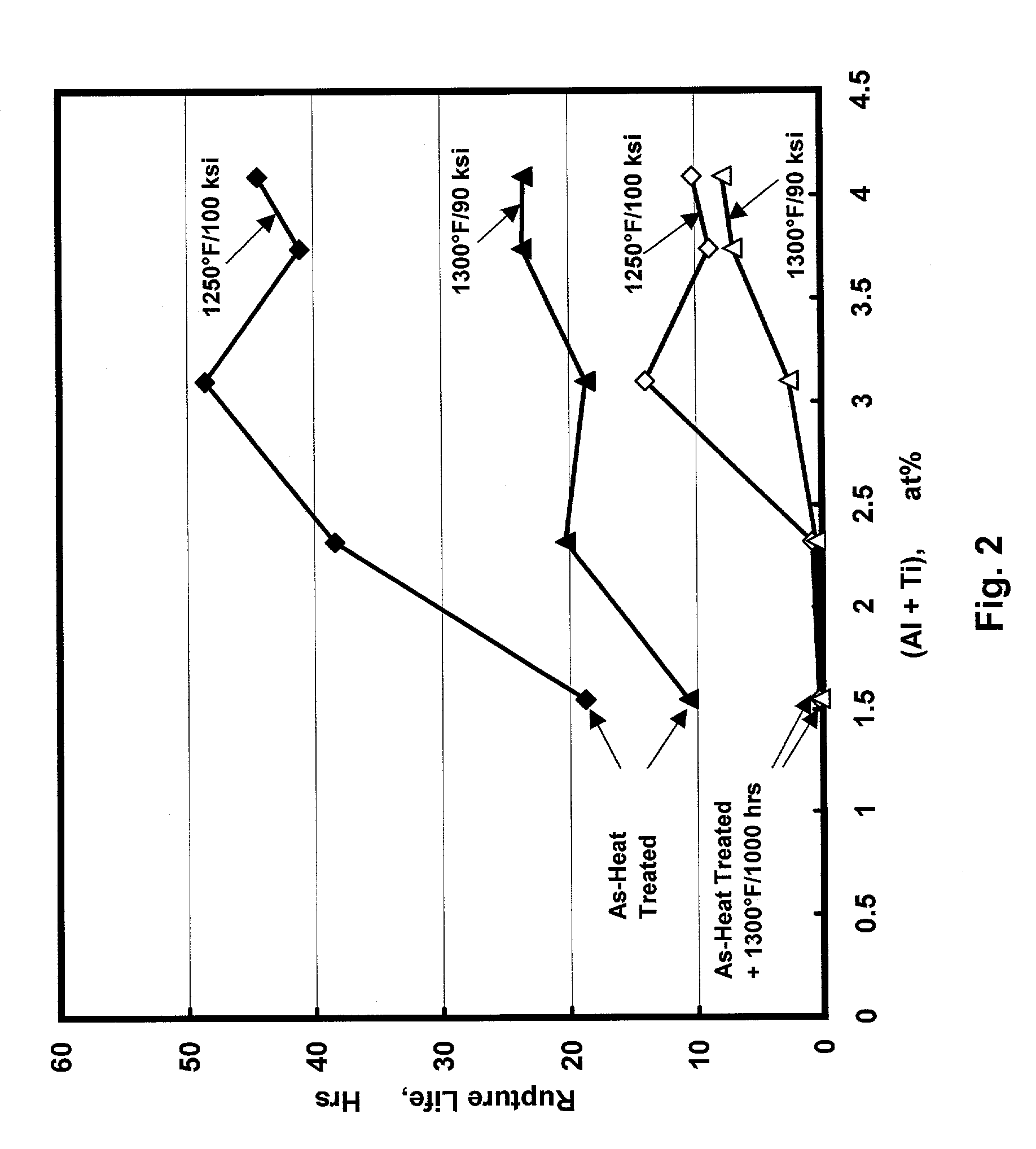

Nickel-base alloy

A nickel-base alloy includes, in weight percent, up to about 0.10 percent carbon; about 12 up to about 20 percent chromium; up to about 4 percent molybdenum; up to about 6 percent tungsten, wherein the sum of molybdenum and tungsten is at least about 2 percent and not more than about 8 percent; about 5 up to about 12 percent cobalt; up to about 14 percent iron; about 4 percent up to about 8 percent niobium; about 0.6 percent up to about 2.6 percent aluminum; about 0.4 percent up to about 1.4 percent titanium; about 0.003 percent up to about 0.03 percent phosphorous; about 0.003 percent up to about 0.015 percent boron; nickel; and incidental impurities. The sum of atomic percent aluminum and atomic percent titanium is from about 2 to about 6 percent, the ratio of atomic percent aluminum to atomic percent titanium is at least about 1.5, and the atomic percent of aluminum plus titanium divided by the atomic percent of niobium equals about 0.8 to about 1.3. The nickel-base alloy may be provided in the form of an article of manufacture, such as, for example, a disk, a blade, a fastener, a case, or a shaft. A method for making a nickel-base alloy also is disclosed. It is emphasized that this abstract is provided to comply with the rules requiring an abstract that will allow a searcher or other reader to quickly ascertain the subject matter of the technical disclosure. It is submitted with the understanding that it will not be used to interpret or limit the scope or meaning of the claims.

Owner:ATI PROPERTIES

Automated stirring and mixing apparatus for cooking

InactiveUS20140069282A1Effective and uniform stirringEffective and uniform and mixingKitchen equipmentBaking plantsAdditive ingredientKinematic pair

The present application discloses an automated cooking apparatus that includes a holder configured to hold a container of food or food ingredients, one or more first kinematic pairs, each comprising a first mating part and a second mating part, wherein the first mating part is connected to the holder; a transport mechanisms that can move the second mating parts of the one or more kinematic pairs; and a driver or controller configured to drive or control the transport mechanism to produce a movement of properly fast speed so that a center point on the internal surface of the container is displaced by properly small distance. The first kinematic pairs and the transport mechanisms in combination can move the holder and the cooking pan to produce fast enough acceleration in the container.

Owner:HE ZHENGXU

Track having rotatable bushing and link for the same

In a track with a rotatable bushing which is brought into engagement with a sprocket of a track-type vehicle, it is intended that strength is enhanced rationally by link functionality sharing and by combination of such assigned functional tasks for achieving further improvements in rotatable bushing function. To this end, a track link comprises a combination of an external link and an internal link; a coupler pin hole is provided through the external link; a bushing hole is provided through the internal link, and the thickness dimension of a bushing hole formation part of the internal link is made greater than that of a coupler pin formation part of the external link.

Owner:KOMATSU LTD

Spread-compensated anisotropic texture sampling

ActiveUS7271810B1Increase or decrease the numberBalance performanceCathode-ray tube indicators3D-image renderingPattern recognitionGraphics

Systems and methods for determining the number of texture samples used to produce an anisotropically filtered texture mapped pixel may improve texture mapping performance or image quality. The number of texture samples may be increased or decreased based on texture state variables that may be specific to each texture map. Furthermore, the texture samples may be positioned along an axis of anisotropy to approximate an elliptical footprint, ensuring that the texture samples span the entire axis of anisotropy. A graphics driver may load the texture state variables and configure a system to modify the number of texture samples and / or position the texture samples used to produce the anisotropically filtered texture mapped pixel.

Owner:NVIDIA CORP

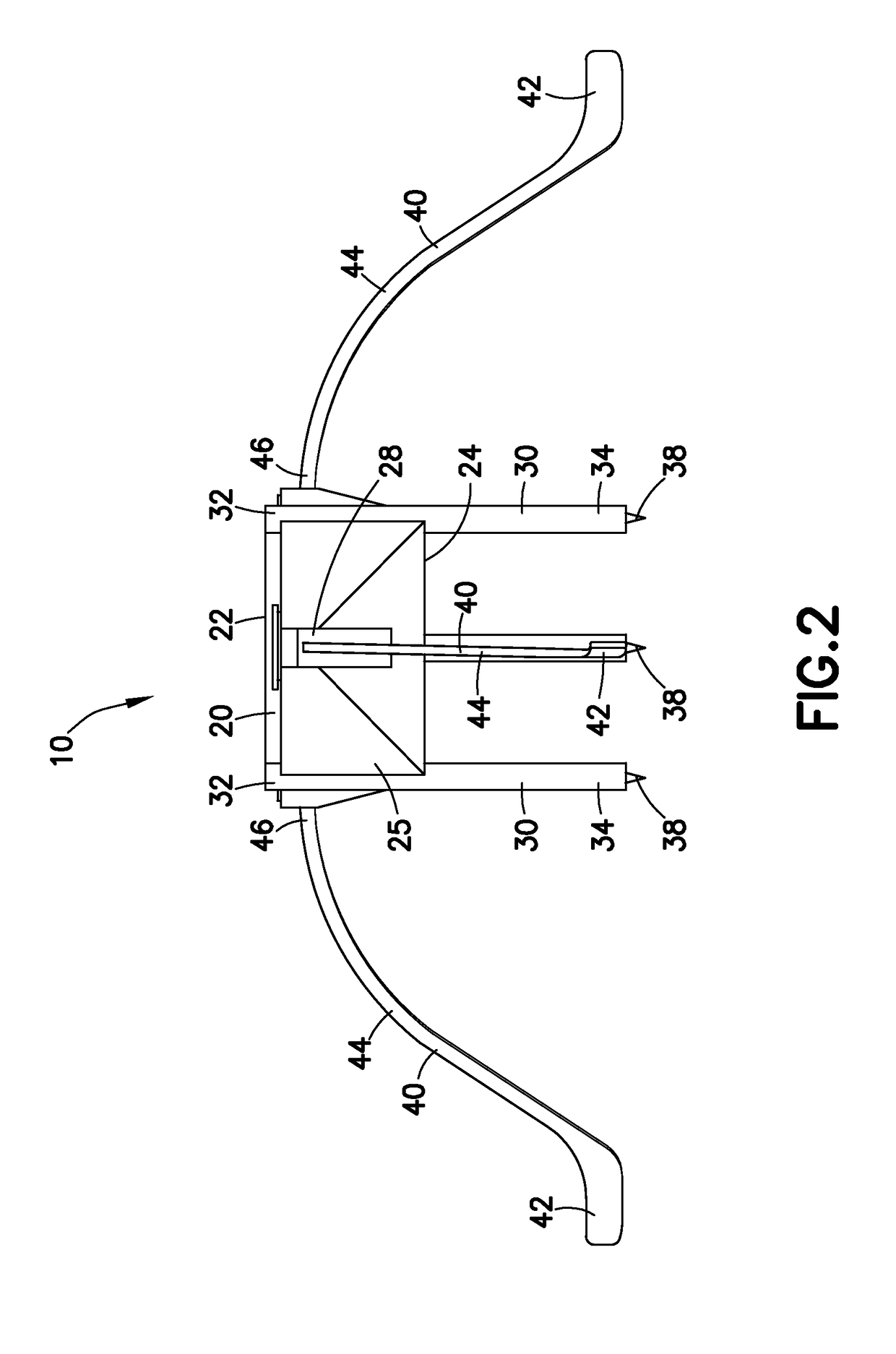

Hockey training system

InactiveUS20170095717A1AccuracyWith balanceGymnastic exercisingSpace saving gamesEngineeringMechanical engineering

A system and device that includes a base, supported by supports adapted to stand or slide on ice, and at least two hockey sticks movably attached to the base, where the base houses at least one mechanism for actuating the hockey sticks and preferably houses one individual mechanism for each hockey stick, so that the hockey sticks, which are preferably movable left to right and up and down, are actuated individually.

Owner:SIMONOV SERGEY

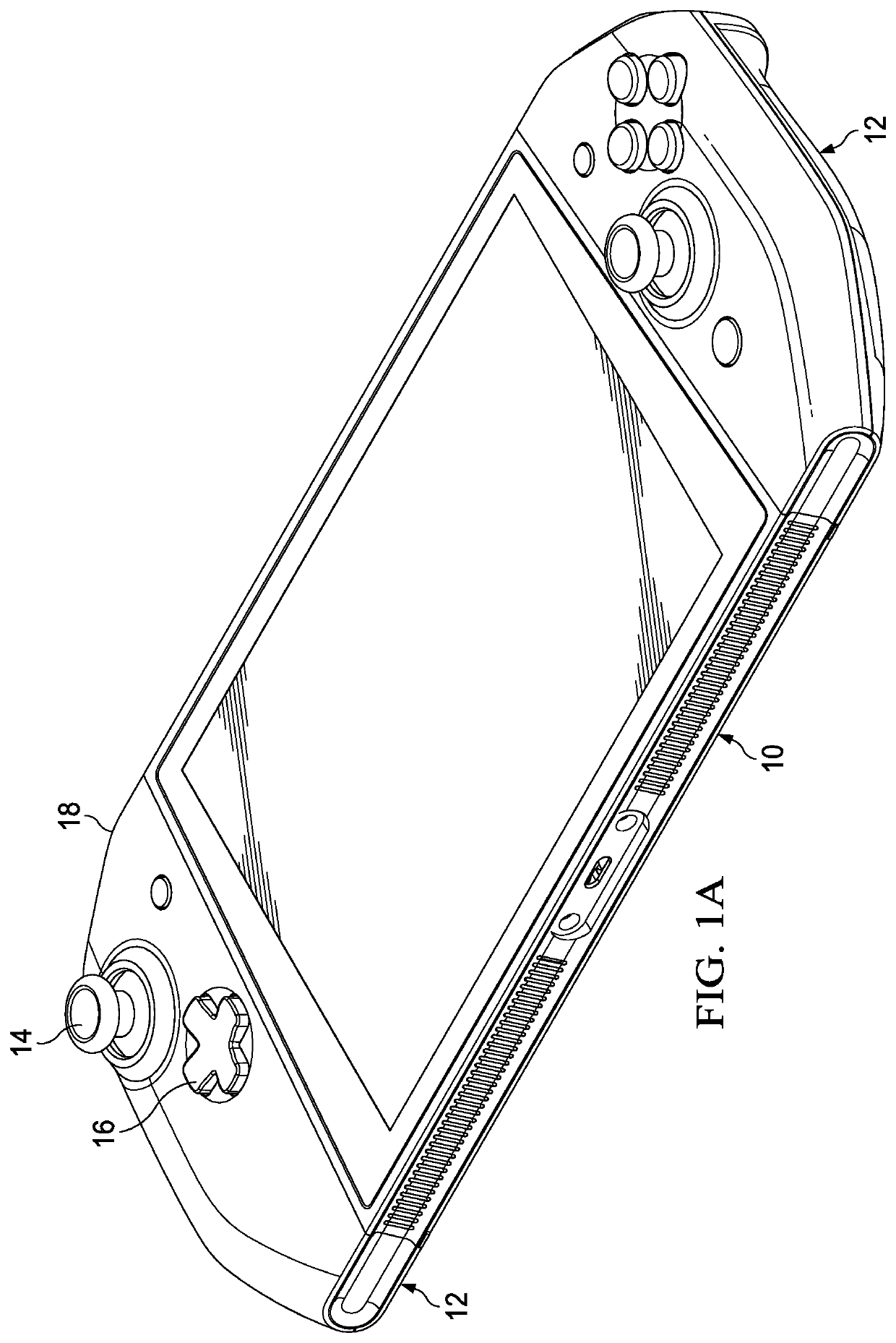

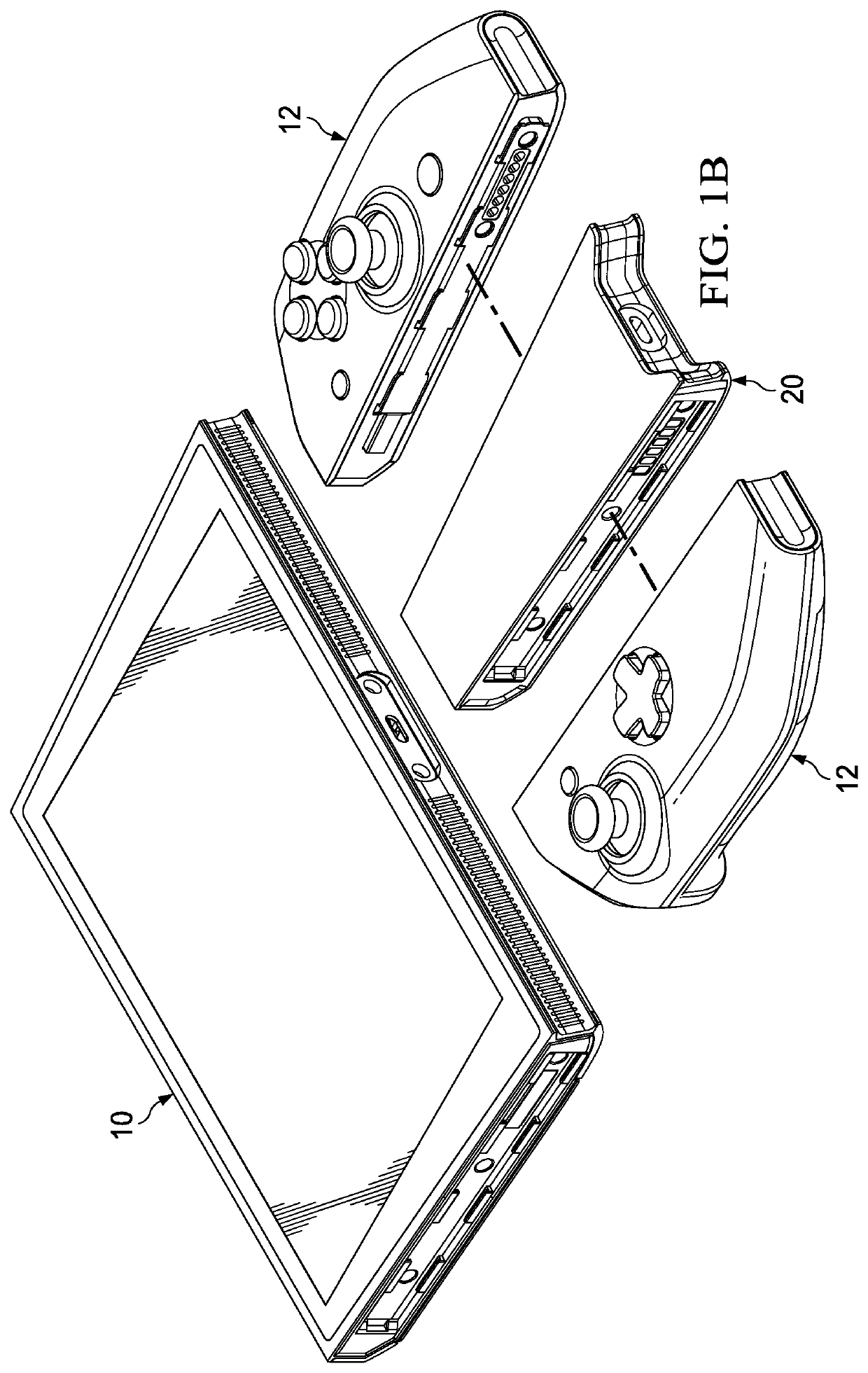

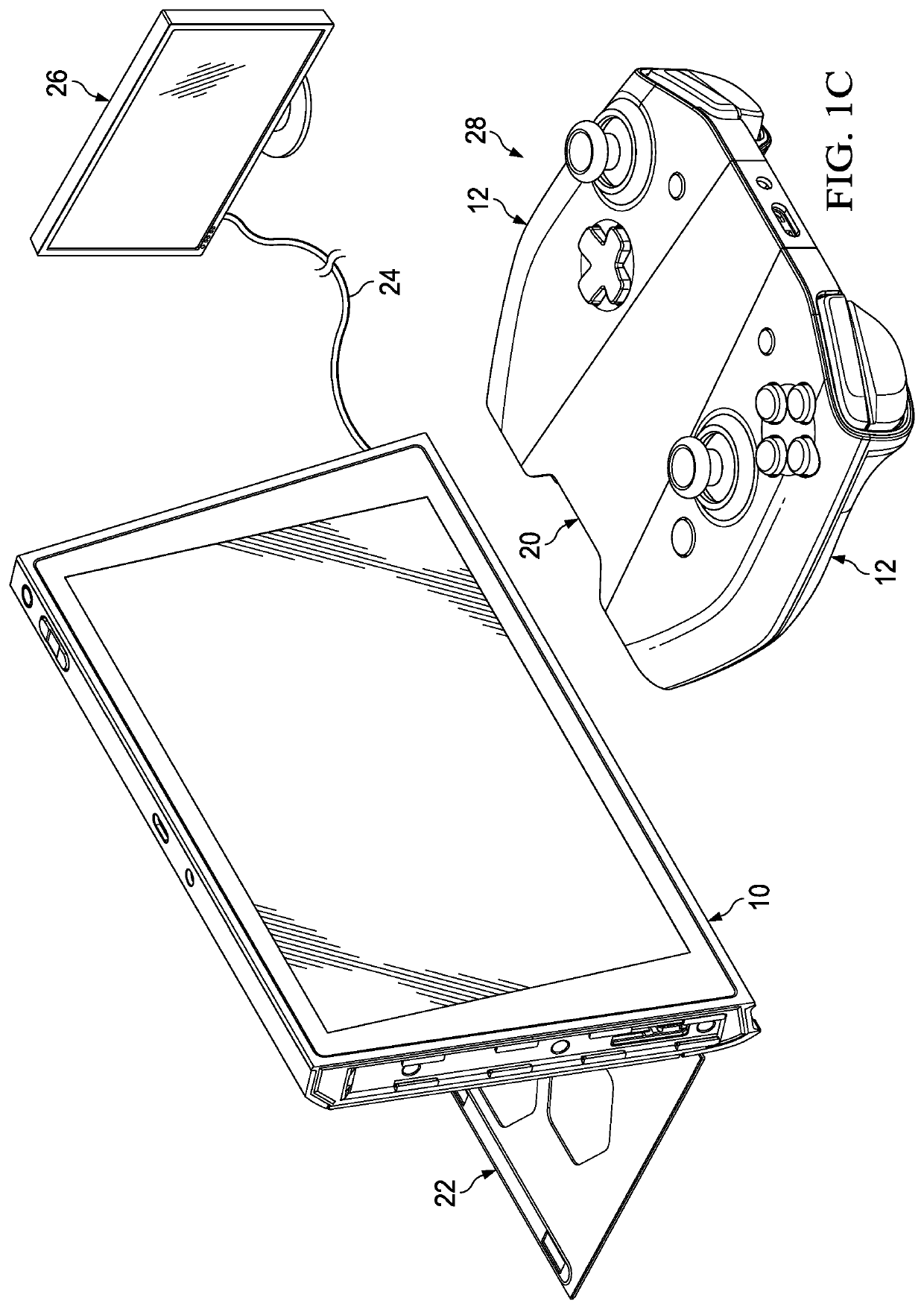

Information handling system controller scalable interface

A portable information handling system interacts with a game controller through either a direct connection at a wired interface at the sides of opposing controller housings and the information handling system housing or through a bridge having a bridge housing that directly couples to the controller housing as a bridge to the information handling system, such as with a wireless interface. During a sliding coupling motion, pins of the controller housing wired interface move across pins of the bridge or information handling system wired interface. Analysis of the interface signals through a sliding coupling motion identifies the type of controller housing, such as a controller housing with game input devices or with extra functions like speaker audio and supplemental battery power.

Owner:DELL PROD LP

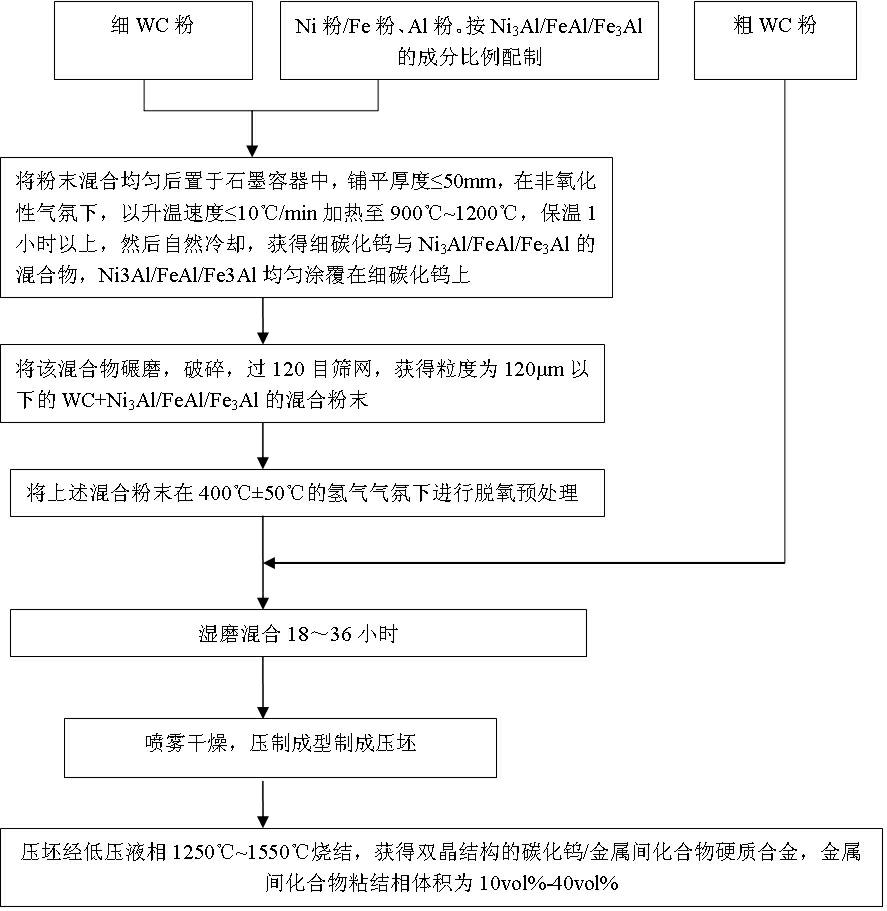

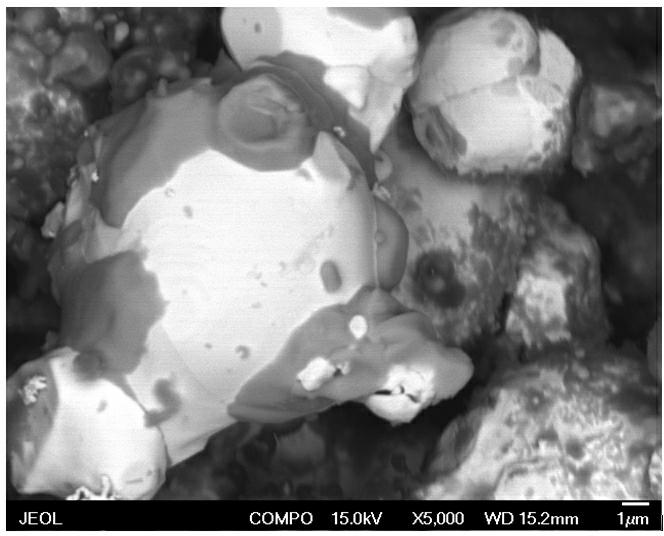

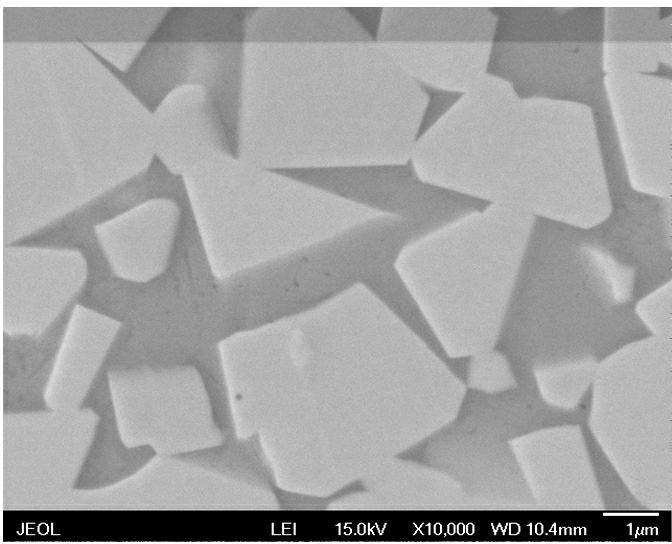

Tungsten carbide-intermetallic compound hard alloy of twin structure and preparation method thereof

The invention provides a tungsten carbide-intermetallic compound hard alloy of a twin structure. The alloy comprises a hard phase WC and an adhesive phase Ni3Al or FeAl or Fe3Al, wherein the adhesive phase is 10 to 40 volume percent. A manufacturing method for the alloy sequentially comprises the following steps of: mixing Ni powder or Fe powder, Al powder and fine WC powder uniformly according to the component proportion of the Ni3Al or the FeAl or the Fe3Al; spreading the mixed powder in a graphite container, heating the mixed powder to the temperature of between 900 and 1,200 DEG C under a non-oxidizing atmosphere, preserving the heat for over 1 hour, naturally cooling the heated powder, and coating the adhesive phase to the surface of the fine WC; grinding, crushing and screening the mixture of the fine WC and the adhesive phase; performing deoxidation pretreatment at the temperature of 400+ / -50 DEG C under the hydrogen atmosphere; performing pre-wet milling on 52.31 to 75.97 weight percent or 55.79 to 76.97 weight percent or 53.66 to 76.37 weight percent of crude granular WC powder and the balance of mixed powder to obtain a wet milled mixture; performing spray drying and pressure molding; and performing low-pressure liquid phase sintering at the temperature of between 1,250 and 1,550 DEG C, and thus obtaining the tungsten carbide-intermetallic compound hard alloy of the twin structure. The crude crystal WC and the fine crystal WC are matched uniformly, so the alloy has high densification, high strength, good abrasion resistance and excellent high-temperature oxidation resistance and corrosion resistance; and the preparation method is simple and low in cost.

Owner:ZHUZHOU HARD ALLOY GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com