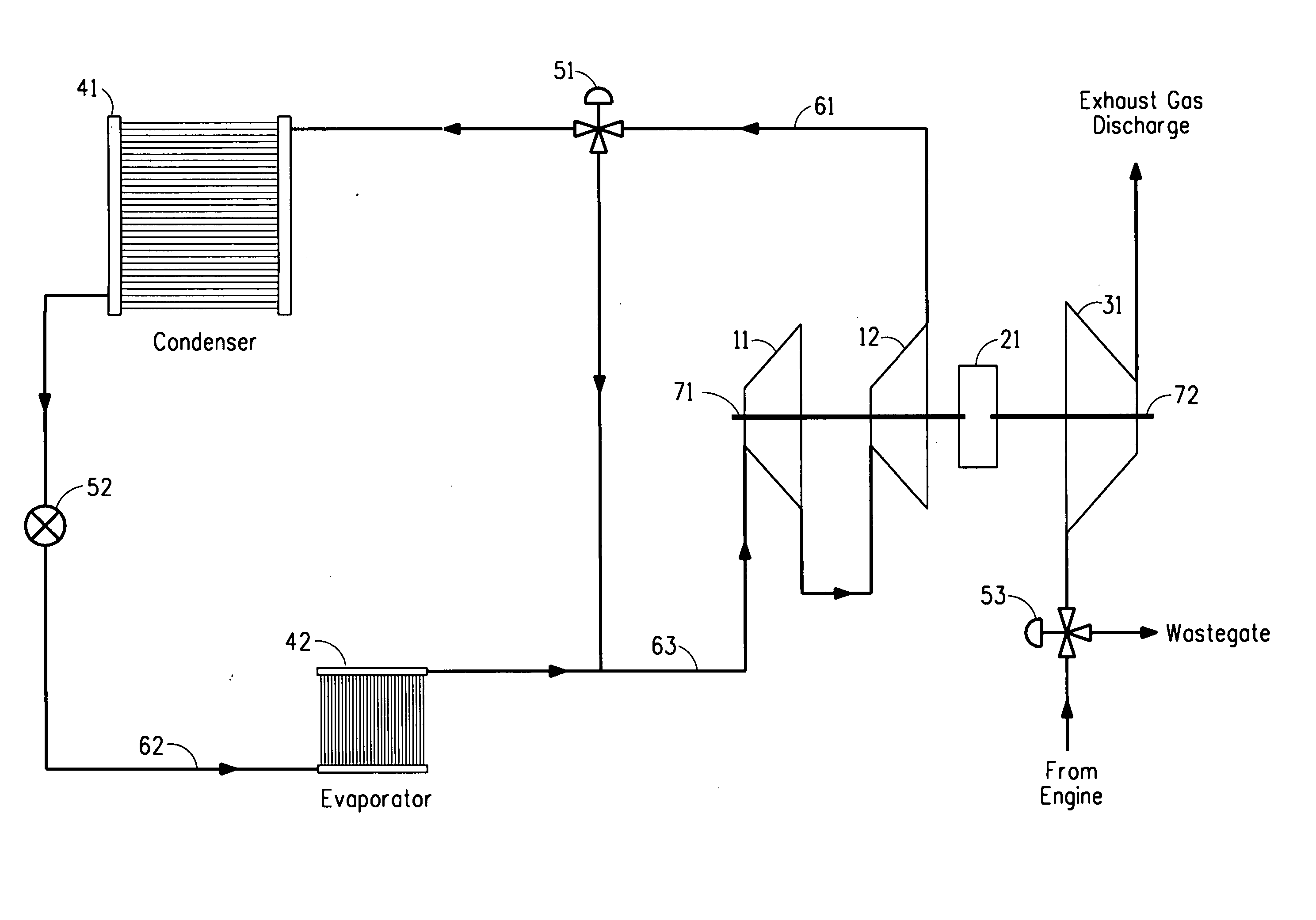

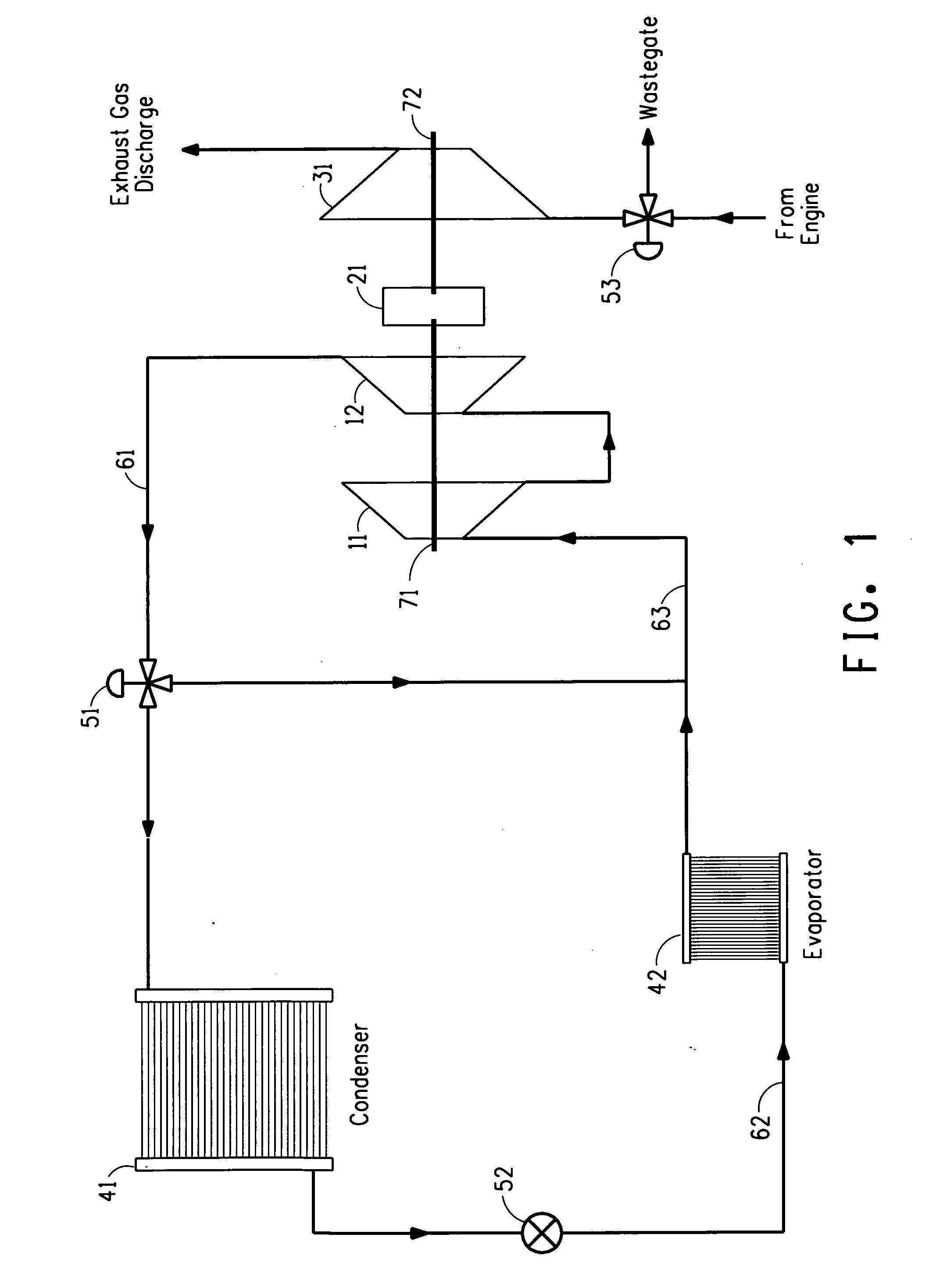

Refrigeration/air-conditioning apparatus powered by an engine exhaust gas driven turbine

a technology of exhaust gas and refrigeration equipment, which is applied in the direction of light and heating equipment, transportation and packaging, and the operation mode of machines, etc., can solve the problem that the power requirements for adequate cooling cannot be m

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

[0077] In this Example, a refrigeration apparatus using PEIK (perfluoroethylisopropylketone) as refrigerant to produce cooling capacity of approximately 1.5 tons at an impeller speed of 40,000 rpm is illustrated. The conditions assumed for this example are:

Evaporator temperature 40.0° F. (4.4° C.)Condenser temperature110.0° F. (43.3° C.)Liquid subcool temperature 10.0° F. (5.5° C.)Return gas temperature 75.0° F. (23.8° C.)Compressor efficiency is 80%

[0078] These are typical conditions under which a mini centrifugal compressor performs. Table 1 below shows the enthalpy of the refrigerant gas as it leaves the evaporator, (H Evaporator Out), the enthalpy of the refrigerant gas as in enters condenser (H Condenser In), the change in enthalpy between the evaporator and compressor, (Delta Hi), and the change in enthalpy between the evaporator and compressor multiplied by 0.8). The table below also shows theoretical tip speed and impeller diameter for a refrigeration apparatus.

TABLE 1HH...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com