Surging-prevent compressor volute structure for turbocharger

A turbocharger and compressor technology, which is applied to machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of complex secondary air intake structure, increased compressor cost, and increased assembly steps, etc. Wide and stable working range, reduced assembly steps, and low casting costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

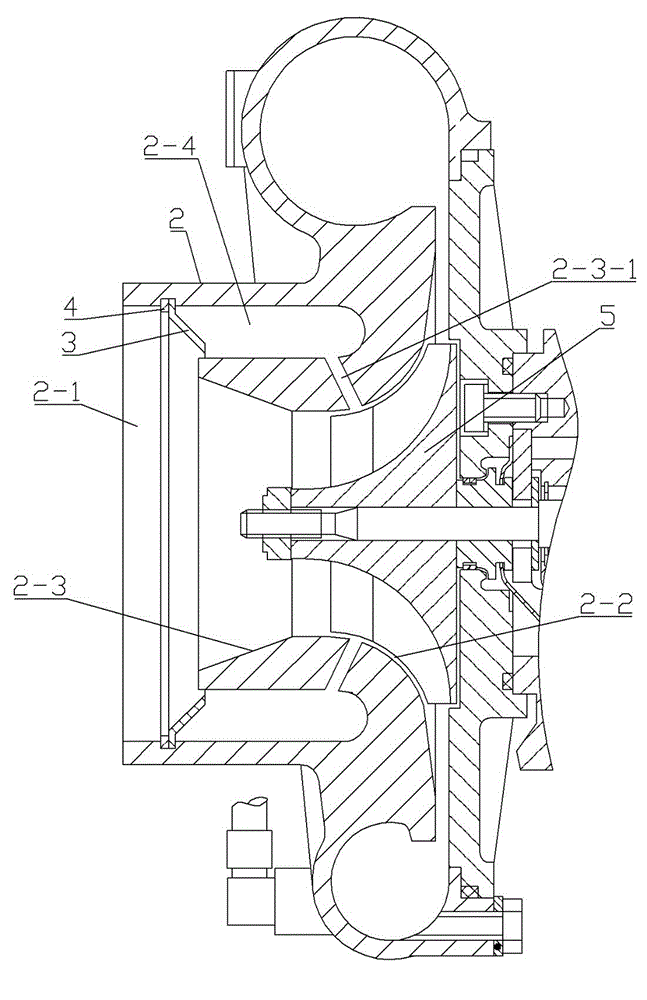

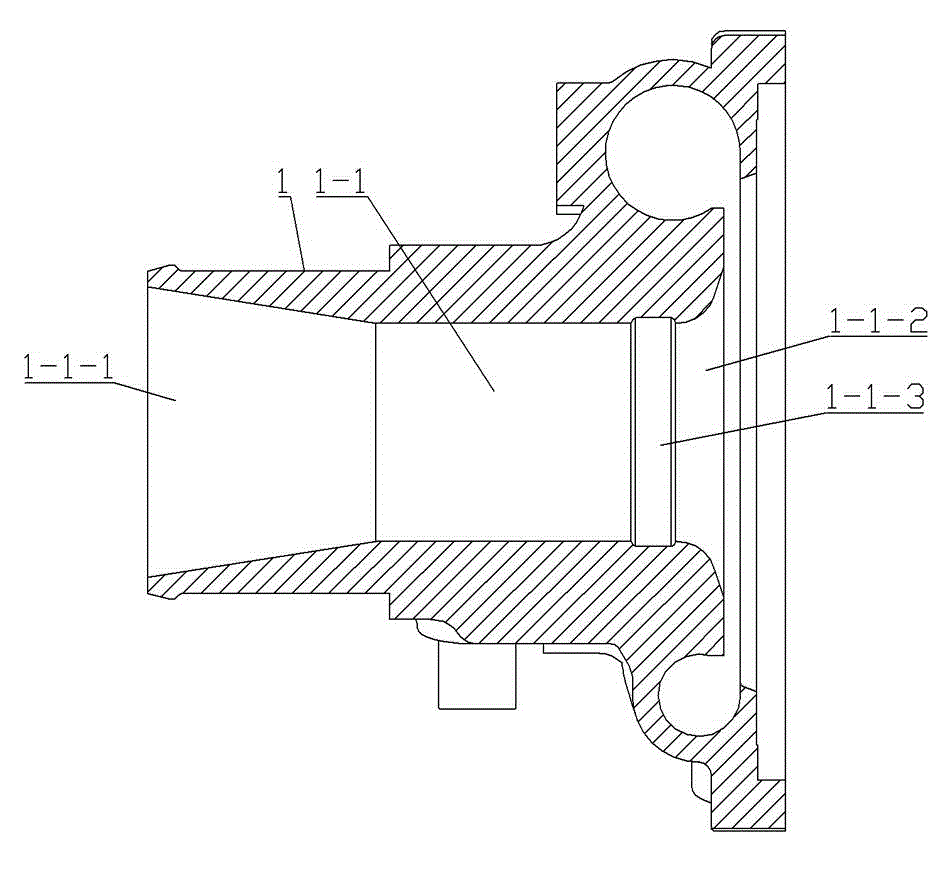

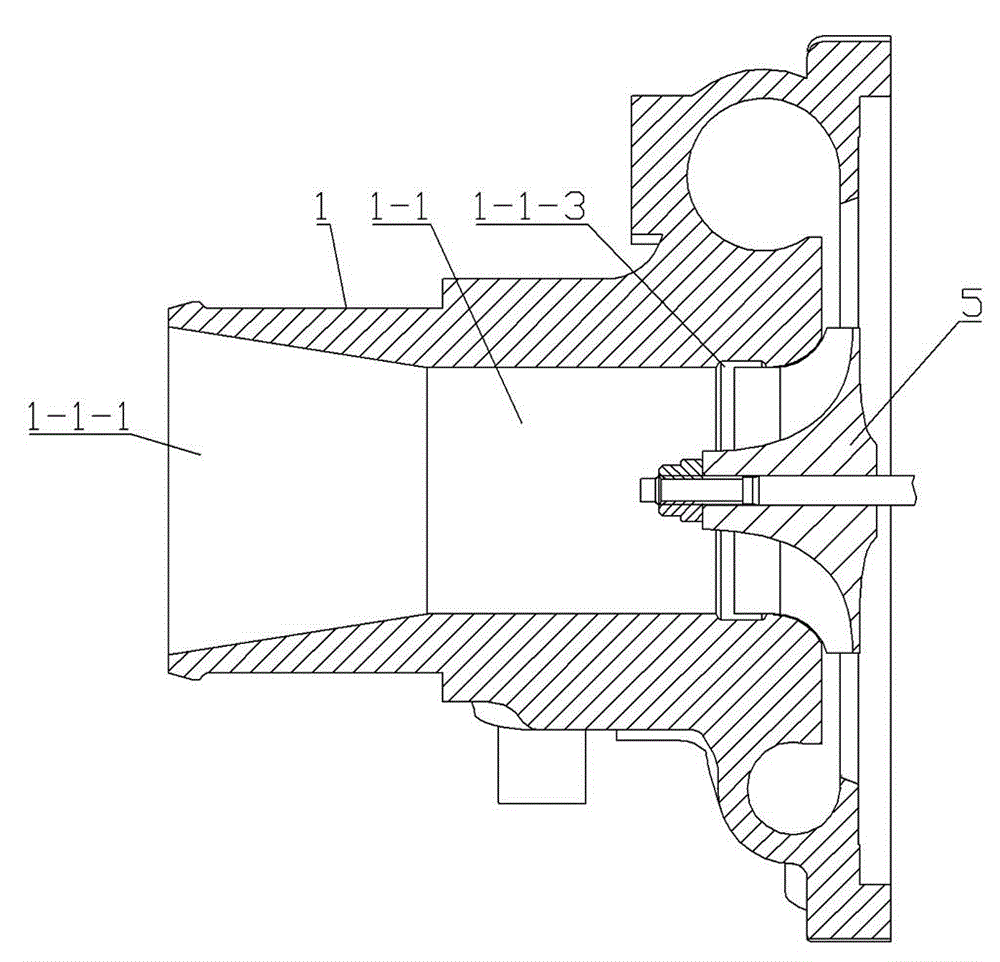

[0017] An anti-surge turbocharger compressor volute structure, comprising a compressor volute 1, one end of the air intake channel 1-1 of the compressor volute 1 is a conical air inlet 1-1-1, and the air intake The other end of the channel 1-1 is an arc-shaped end 1-1-2 matching the outer contour of the impeller 5 arc-shaped blades, and the inner wall at the junction of the inlet channel 1-1 and the arc-shaped end 1-1-2 is provided with The annular diversion cavity 1-1-3, the cross section of the annular diversion cavity 1-1-3 is trapezoidal.

[0018] During use, the impeller 5 is installed at the arc-shaped end 1-1-2 of the compressor volute 1, and the leading edge end of the main blade of the impeller 5 is in the middle of the annular guide cavity 1-1-3. When the airflow disturbance propagates along the hub line of the impeller 5 to the inlet of the impeller 5 and reaches the leading edge of the main blade of the impeller 5, a part of the circumferentially distorted vortex o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com