Rotary electric generator

A rotary and generator technology is applied in the field of cooling structures in the form of direct gas cooling of high-power rotary electric generators, and can solve the problems of easy explosion of hydrogen, increased overall cost of electric generator equipment, and inability to reduce unit prices.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

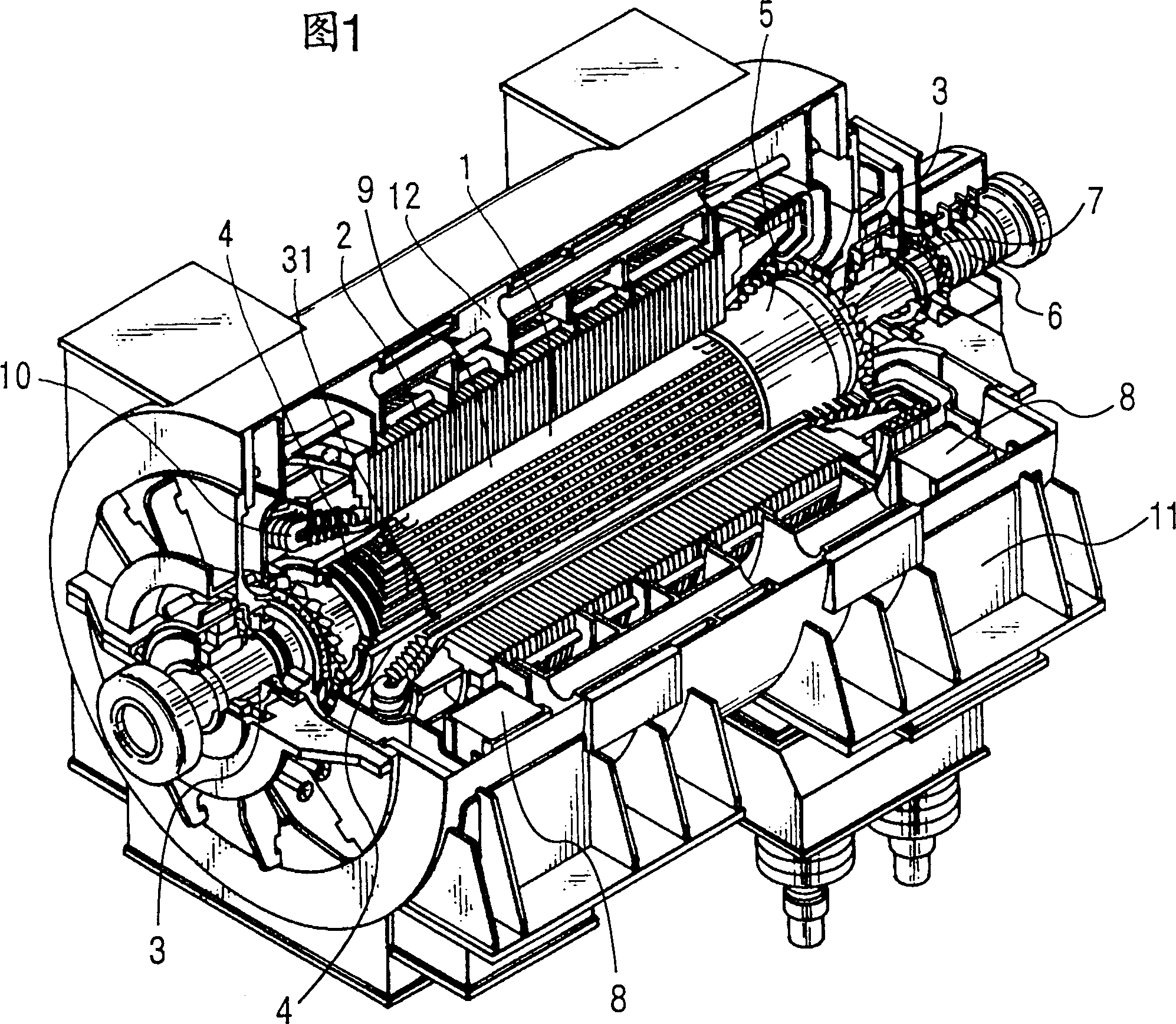

[0032] Before describing the embodiments of the present invention, the schematic structure of the turboelectric generator will be described. Fig. 1 is a schematic configuration diagram of an example of an air-cooled electric power generator using the present invention. However, the basic structure shown here does not depend on the type of cooling fluid.

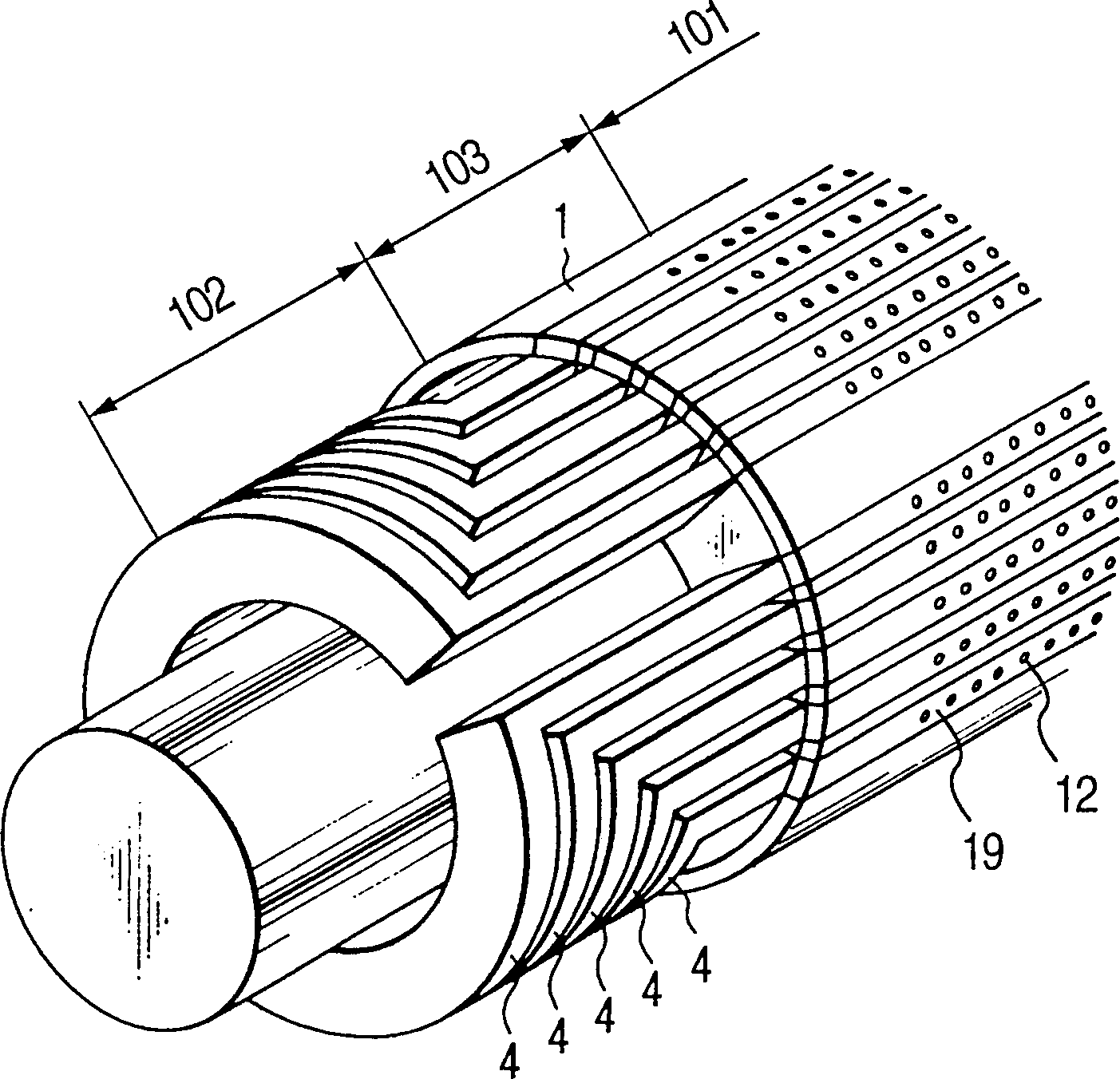

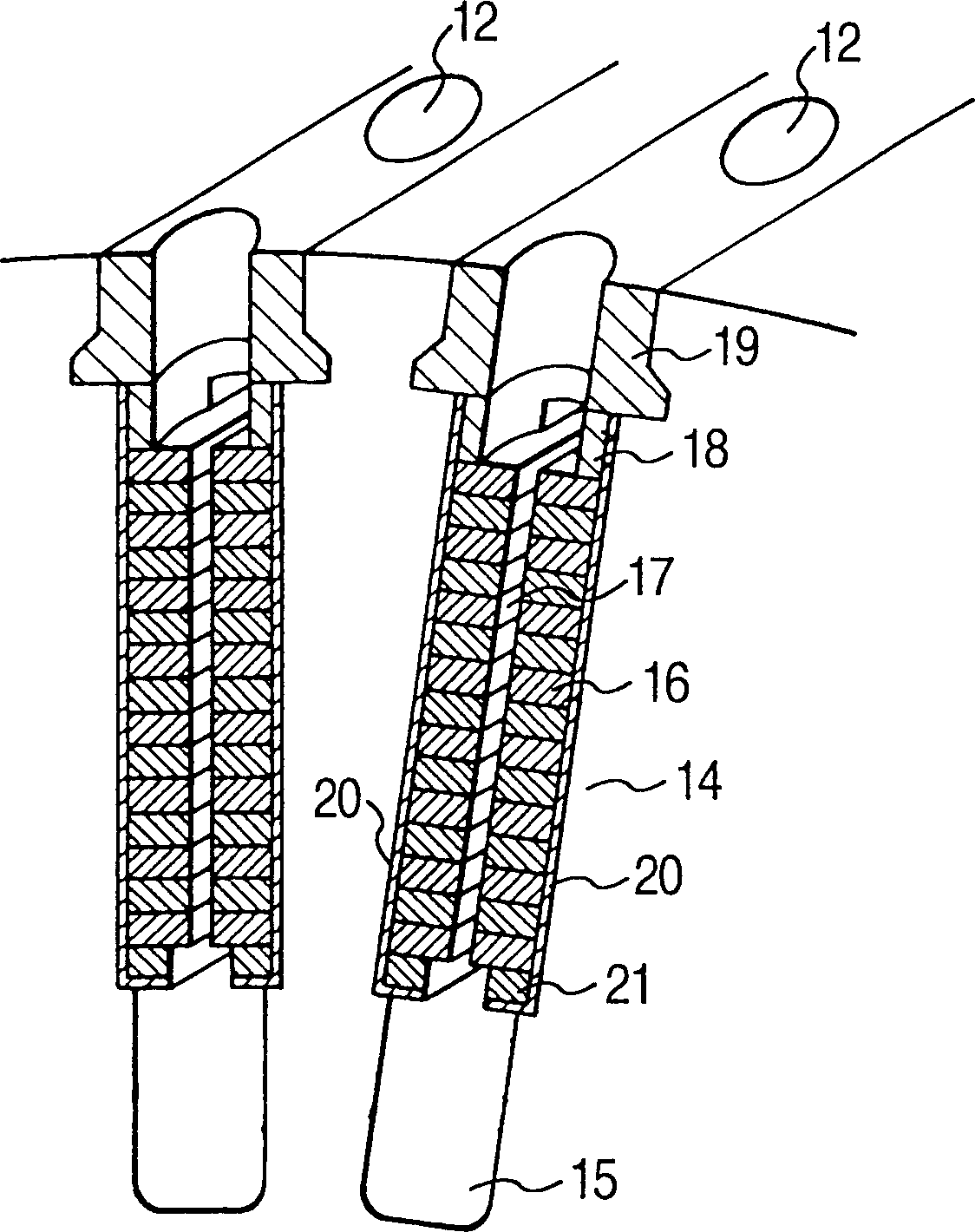

[0033] In FIG. 1 , a rotor 1 is rotatably supported by a bearing 3 inside a stator 2 . In the rotor 1, a plurality of rotor windings 4 constituting the same magnetic pole are coaxially arranged around the magnetic pole, and are fixed. The centrifugal force exerted on the rotor winding 4 is supported at winding slots formed at intervals on the rotor circumferential surface with respect to the axial part, and is firmly supported at the guard ring 5 by the rotor end peripheral portion.

[0034] In the figure, although only one side of the slip ring 6 supplying current to the rotor is shown for convenience of explanation, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com