A kind of glycerol aqueous solution quenching cooling medium and preparation method thereof

A technology of cooling medium and glycerin, which is applied in the direction of quenching agent, manufacturing tools, heat treatment equipment, etc., can solve the problems of easy aging, high price, and insufficient environmental protection of the working environment, so as to reduce deformation and cracking, and the raw materials are simple and easy to obtain, Inexpensive to prepare

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] According to the volume percentage of 5:95, glycerol (chemically pure) and distilled water are made into glycerin aqueous solution, and the following additives are added (by weight percentage of glycerol aqueous solution): 0.04% anti-aging agent; 0.1% anti-rust agent; 0.01% defoamer; 0.4% cooling rate regulator. Above-mentioned anti-aging agent is salicylic acid; Antirust agent is borax; Defoamer is Polyethylene Glycol (average molecular weight is 400); Cooling rate adjuster is polyvinylpyrrolidone (average molecular weight is 1300000), uniformly mixed by mechanical stirring Prepared as a quenching cooling medium and allowed to stand for 24 hours.

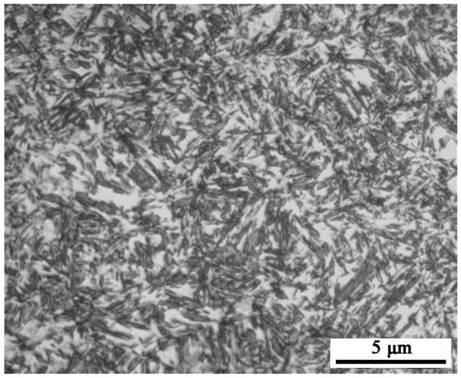

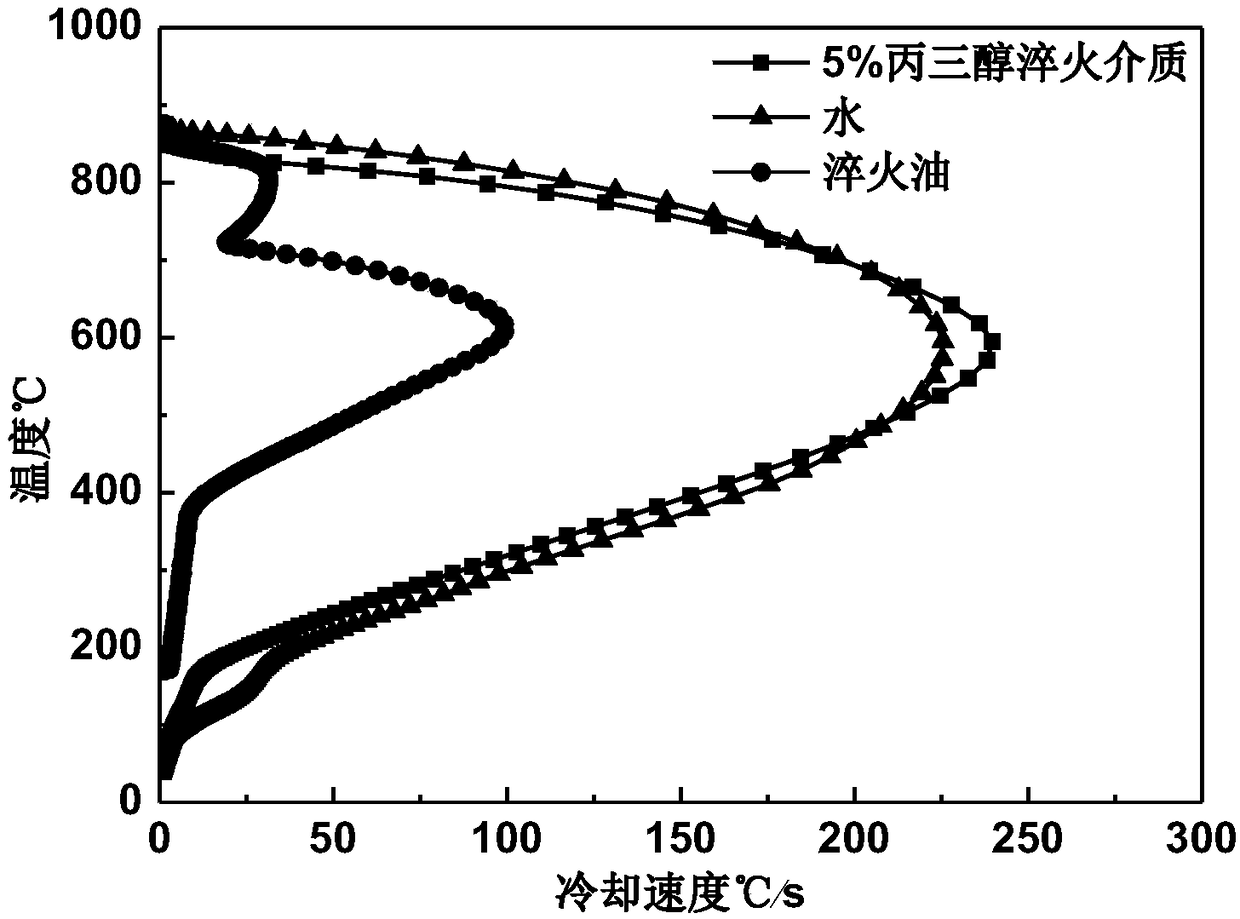

[0021] Three different quenching media were tested with a type quenching cooling rate tester. It was found that in the high temperature zone (pearlite transformation stage), the cooling rate of the 5% glycerol quenching medium was faster than that of quenching oil; in the low temperature zone (martensite) transformation sta...

Embodiment 2

[0024] According to the volume percentage of 3:97, glycerin (chemically pure) and distilled water are made into glycerin aqueous solution, and the following additives are added (by weight percentage of glycerin aqueous solution): 0.04% anti-aging agent; 0.1% anti-rust agent; 0.01% defoamer; 0.4% cooling rate regulator. Above-mentioned anti-aging agent is salicylic acid; Antirust agent is borax; Defoamer is Polyethylene Glycol (average molecular weight is 400); Cooling rate adjuster is polyvinylpyrrolidone (average molecular weight is 1300000), uniformly mixed by mechanical stirring Prepared as a quenching cooling medium and allowed to stand for 24 hours.

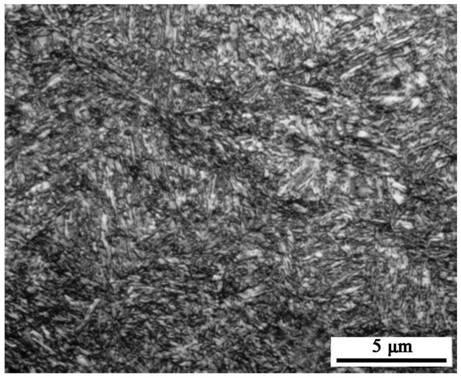

[0025] Three different quenching media were tested with a type quenching cooling rate tester. It was found that in the high temperature zone (pearlite transformation stage), the cooling rate of the 3% glycerin quenching medium was faster than that of quenching oil; in the low temperature zone (martensite) transformation sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com