Wheel hub heat treatment speed-up technology

A heat treatment method and wheel hub technology, applied in heat treatment furnaces, heat treatment equipment, manufacturing tools, etc., can solve the problems of unsuitability for large-scale industrial production, slow heating of heat treatment solid solution furnaces, low heat treatment production efficiency, etc., to achieve good cooling characteristics, Reduced energy consumption and high cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

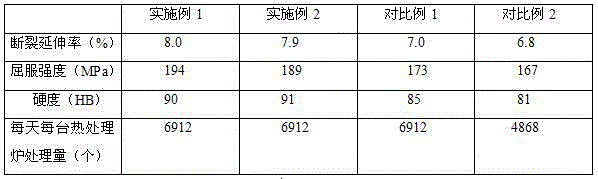

Examples

Embodiment 1

[0015] The aluminum wheel hub first passes through the camera system. The camera system takes pictures of the shape of the wheel rim and then transmits it to the X-ray machine control system. The X-ray machine retrieves the corresponding program and uses X-rays to irradiate different parts of the wheel rim to find defects inside the aluminum wheel hub. ; The X-ray machine judges that it is OK to continue to stay, and it is NG to discard it. The aluminum wheel hub passes through the X-ray machine, then the riser machine and then reaches the heat treatment. The heat treatment is divided into solid solution, quenching and aging; the temperature of the solid solution stage is set at 544°C, the heating time is 25 minutes, the holding time is 110 minutes, and then the wheel hub is maintained at 544 The temperature of ℃ enters the quenching, the time is 20S, and soaks in the quenching medium of 85 ℃ for 5 minutes. The quenching medium is 15 parts of potassium nitrate, 20 parts of sod...

Embodiment 2

[0020] The aluminum wheel hub first passes through the camera system. The camera system takes pictures of the shape of the wheel rim and then transmits it to the X-ray machine control system. The X-ray machine retrieves the corresponding program and uses X-rays to irradiate different parts of the wheel rim to find defects inside the aluminum wheel hub. ; The X-ray machine judges that it is OK to continue to stay, and it is NG to discard it. The aluminum wheel hub passes through the X-ray machine, then the riser machine and then reaches the heat treatment. The heat treatment is divided into solid solution, quenching and aging; the temperature of the solid solution stage is set at 540°C, the heating time is 28 minutes, the holding time is 115 minutes, and then the wheel hub is kept at 540°C. The temperature of ℃ enters quenching, the time is 19S, and soaks in the medium of 80 ℃ for 5 minutes. The quenching medium is 18 parts of potassium nitrate, 23 parts of sodium chloride, 25 ...

Embodiment 3

[0025] The aluminum wheel hub first passes through the camera system. The camera system takes pictures of the shape of the wheel rim and then transmits it to the X-ray machine control system. The X-ray machine retrieves the corresponding program and uses X-rays to irradiate different parts of the wheel rim to find defects inside the aluminum wheel hub. ; The X-ray machine judges that it is OK to continue to stay, and it is NG to discard it. The aluminum wheel hub passes through the X-ray machine, then the riser machine and then reaches the heat treatment. The heat treatment is divided into solid solution, quenching and aging; the temperature of the solid solution stage is set at 550°C, the heating time is 26 minutes, the holding time is 113 minutes, and then the wheel hub is kept at 550°C. The temperature of ℃ enters quenching, the time is 18S, and soaks in the medium of 90 ℃ for 5 minutes. The quenching medium is 16 parts of potassium nitrate, 22 parts of sodium chloride, 27 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com