Cool skin-friendly PP spun-bonded non-woven fabric and preparation method thereof

A spun-bonded non-woven fabric with cool feeling technology, which is applied in the direction of non-woven fabrics, rayon manufacturing, textiles and paper making, etc. It can solve the problem of low bursting strength and breaking strength, not skin-friendly and hydrophilic, easy to damage and not durable and other problems, to achieve the effect of high bursting strength and breaking strength, uniform distribution of cooling sensation, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] A kind of skin-friendly PP spun-bonded non-woven fabric with cool feeling, the skin-friendly PP spun-bonded non-woven fabric with cool feeling is made of raw materials comprising the following parts by weight:

[0055] 60-70 parts of polypropylene,

[0056] 22-30 parts of polyurethane elastomer,

[0057] 2 to 3 parts of porous diatomaceous earth,

[0058]6-9 parts of sepiolite powder,

[0059] 2-2.5 parts of silicon dioxide porous ceramic powder,

[0060] 3 to 5 parts of nano-titanium dioxide,

[0061] 1.8-2.5 parts of nano-zirconia,

[0062] 8-12 parts of metallocene linear low-density polyethylene,

[0063] 1.5-2.5 parts of maleic anhydride grafted polyethylene.

[0064] In this embodiment, the cool skin-friendly PP spunbonded nonwoven fabric is preferably, but not limited to, made of raw materials including the following parts by weight:

[0065] 65 parts of polypropylene,

[0066] 26 parts of polyurethane elastomer,

[0067] 2.5 parts of porous diatomaceous...

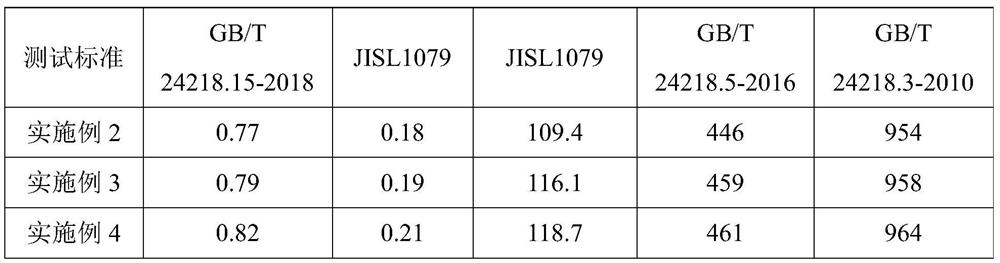

Embodiment 2

[0086] A kind of skin-friendly PP spun-bonded non-woven fabric with cool feeling, the skin-friendly PP spun-bonded non-woven fabric with cool feeling is made of raw materials comprising the following parts by weight:

[0087] 60 parts of polypropylene,

[0088] 22 parts of polyurethane elastomer,

[0089] 2 parts of porous diatomaceous earth,

[0090] 6 parts of meerschaum powder,

[0091] 2 parts of silica porous ceramic powder,

[0092] Nano titanium dioxide 3 parts,

[0093] Nano zirconia 1.8 parts,

[0094] 8 parts of metallocene linear low density polyethylene,

[0095] 1.5 parts of maleic anhydride grafted polyethylene.

[0096] In this embodiment, the polyurethane elastomer is made from poly-1,6-hexanediol adipate diol, polyethylene glycol and hexamethylene diisocyanate, wherein the mass ratio of the three is 100:47.5:2.7.

[0097] In this embodiment, the particle size of the porous diatomite is 2000 mesh.

[0098] In this embodiment, the particle size of the s...

Embodiment 3

[0108] A kind of skin-friendly PP spun-bonded non-woven fabric with cool feeling, the skin-friendly PP spun-bonded non-woven fabric with cool feeling is made of raw materials comprising the following parts by weight:

[0109] 70 parts of polypropylene,

[0110] 30 parts of polyurethane elastomer,

[0111] 3 parts of porous diatomaceous earth,

[0112] 9 parts of meerschaum powder,

[0113] 2.5 parts of silicon dioxide porous ceramic powder,

[0114] Nano titanium dioxide 5 parts,

[0115] Nano zirconia 2.5 parts,

[0116] 12 parts of metallocene linear low density polyethylene,

[0117] 2.5 parts of maleic anhydride grafted polyethylene.

[0118] In this embodiment, the polyurethane elastomer is made from poly-1,6-hexanediol adipate diol, polyethylene glycol and hexamethylene diisocyanate, wherein the mass ratio of the three is 100:50.5:3.

[0119] In this embodiment, the particle size of the porous diatomite is 3000 mesh.

[0120] In this embodiment, the particle siz...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com