Method for manufacturing calcined high-temperature and high-pressure resistant mica paper tape

A manufacturing method and high temperature resistant technology, applied in insulators, electrical components, insulators, etc., can solve the problems of easy breakdown and low dielectric strength of mica paper tapes, and achieve improved dielectric strength, expanded applications, and tensile strength. and the effect of improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

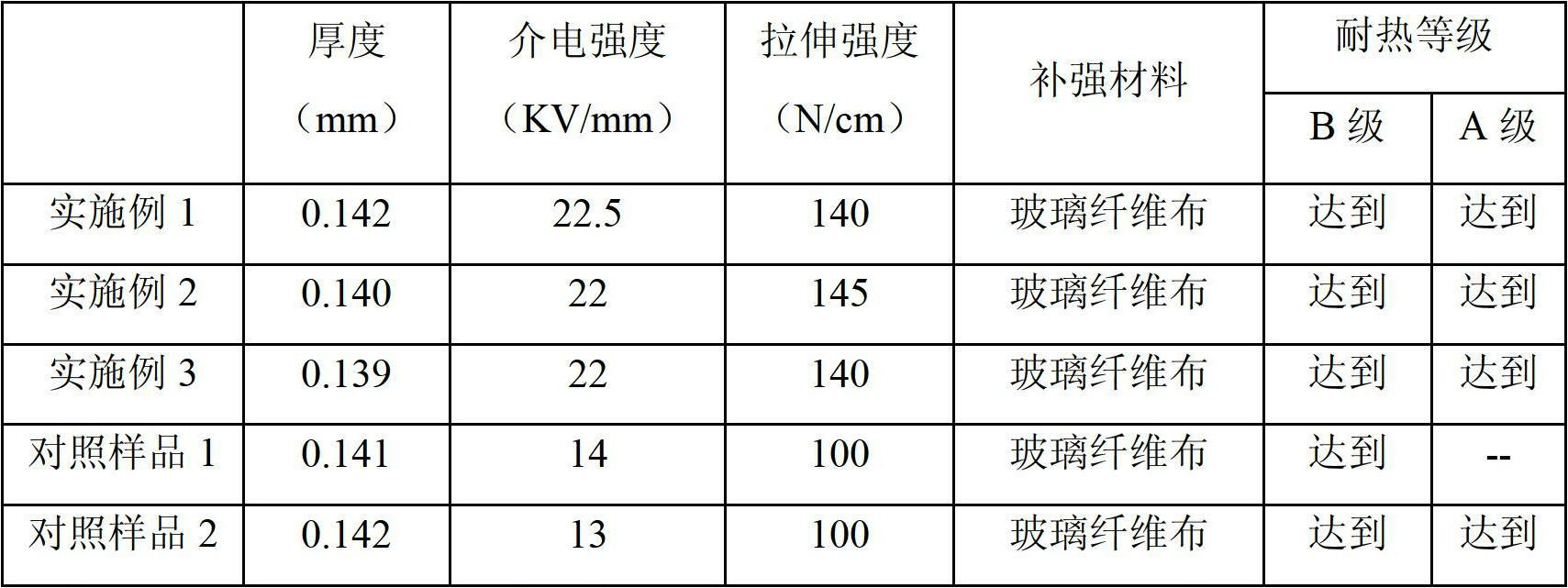

[0039] Embodiment 1 adopts the inventive method to prepare muscovite single-sided paper tape

[0040] Select high-quality muscovite as raw material, with an area of 5cm 2 Around, thickness 1~2mm, and quantitative 15kg / bag. Preheat the calcination furnace (industrial resistance furnace produced by Shanghai Electric Furnace Factory, model: RG2-24-9) to 850°C, open the furnace cover, pour in a pack of 15kg raw materials and close the furnace cover, and calcine in the state of furnace rotation Pour out after 40 minutes. After cooling to normal temperature, the calcined raw materials are screened through a drum sieve to remove the powder.

[0041] After calcination, the raw materials are evenly put into the special hydraulic pulper through the feeder for pulping flotation, and the pressure generated by the high-pressure water pump is 55kg / cm 2 The mica is peeled into fine scales by high-pressure water jet, and dehydrated by 60% through a 120-mesh filter, and then passed throug...

Embodiment 2

[0043] Embodiment 2 adopts the inventive method to prepare muscovite single-sided paper tape

[0044] Select high-quality muscovite as raw material, with an area of 5cm 2 Around, thickness 1~2mm, and quantitative 15kg / bag. Preheat the calcination furnace (industrial resistance furnace produced by Shanghai Electric Furnace Factory, model: RG2-24-9) to 875°C, open the furnace cover, pour in a pack of 15kg raw materials and close the furnace cover, and calcine while the furnace body is rotating Pour out after 50 minutes. After cooling to normal temperature, the calcined raw materials are screened through a drum sieve to remove the powder.

[0045]After calcination, the raw materials are uniformly put into the special hydraulic pulper through the feeder for slurry flotation, and the pressure generated by the high-pressure water pump is 58kg / cm 2 High-pressure water jets peel mica into fine scales, and dehydrate 65% through a 120-mesh filter, and then pass through a cyclone cl...

Embodiment 3

[0047] Embodiment 3 adopts the inventive method to prepare muscovite single-sided paper tape

[0048] Select high-quality muscovite as raw material, with an area of 5cm 2 Around, thickness 1~2mm, and quantitative 15kg / bag. Preheat the calcination furnace (industrial resistance furnace produced by Shanghai Electric Furnace Factory, model: RG2-24-9) to 900°C, open the furnace cover, pour in a pack of 15kg raw materials and close the furnace cover, and calcine while the furnace body is rotating Pour out after 60 minutes. After cooling to normal temperature, the calcined raw materials are screened through a drum sieve to remove the powder.

[0049] After calcination, the raw materials are evenly put into the special hydraulic pulping machine through the feeder for pulping flotation, and the pressure generated by the high-pressure water pump is 60kg / cm 2 High-pressure water jets peel the mica into fine scales, and dehydrate 70% through a 120-mesh filter, and then pass through ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

| dielectric strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com