Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

141results about How to "Effective tension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

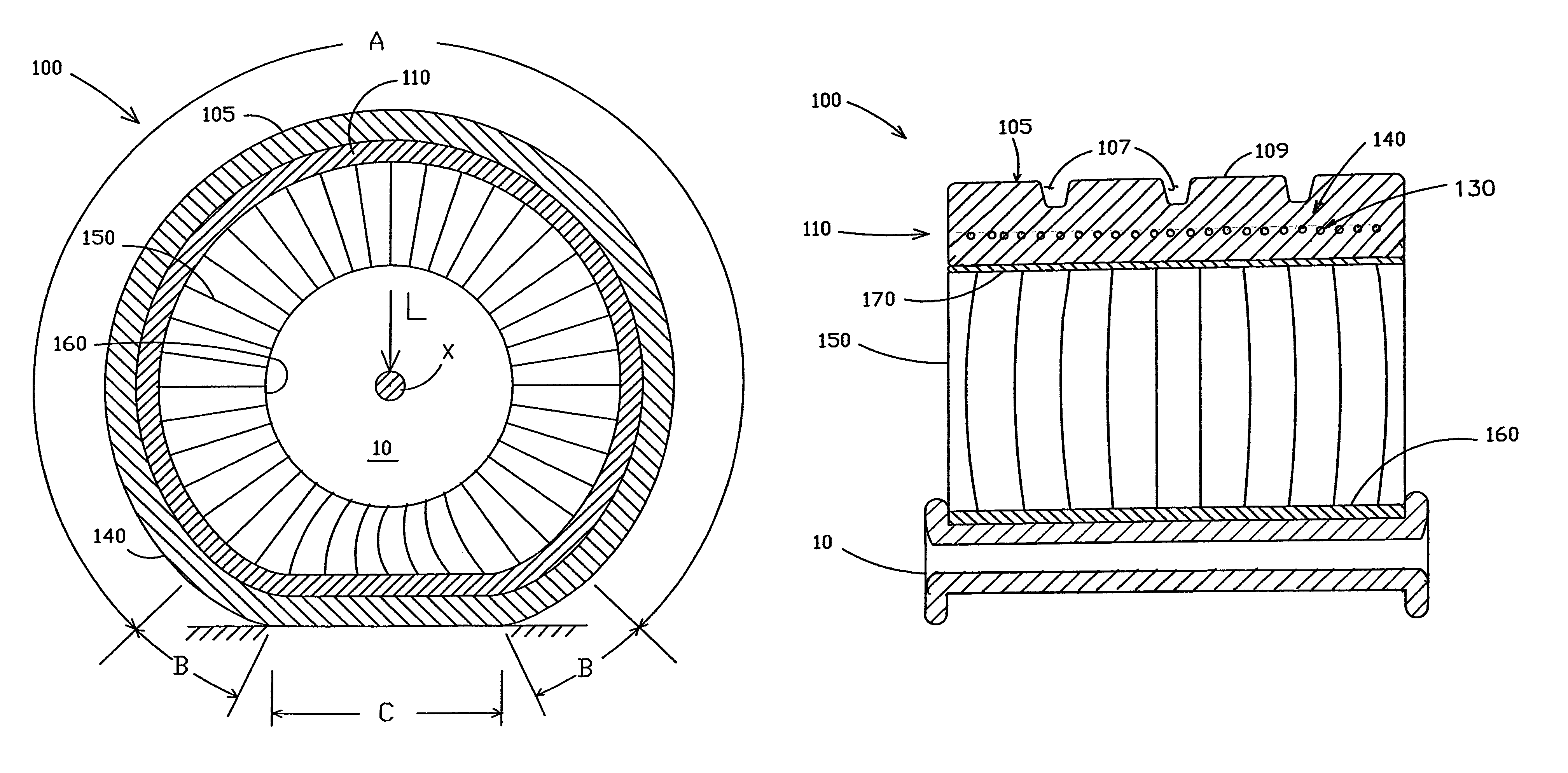

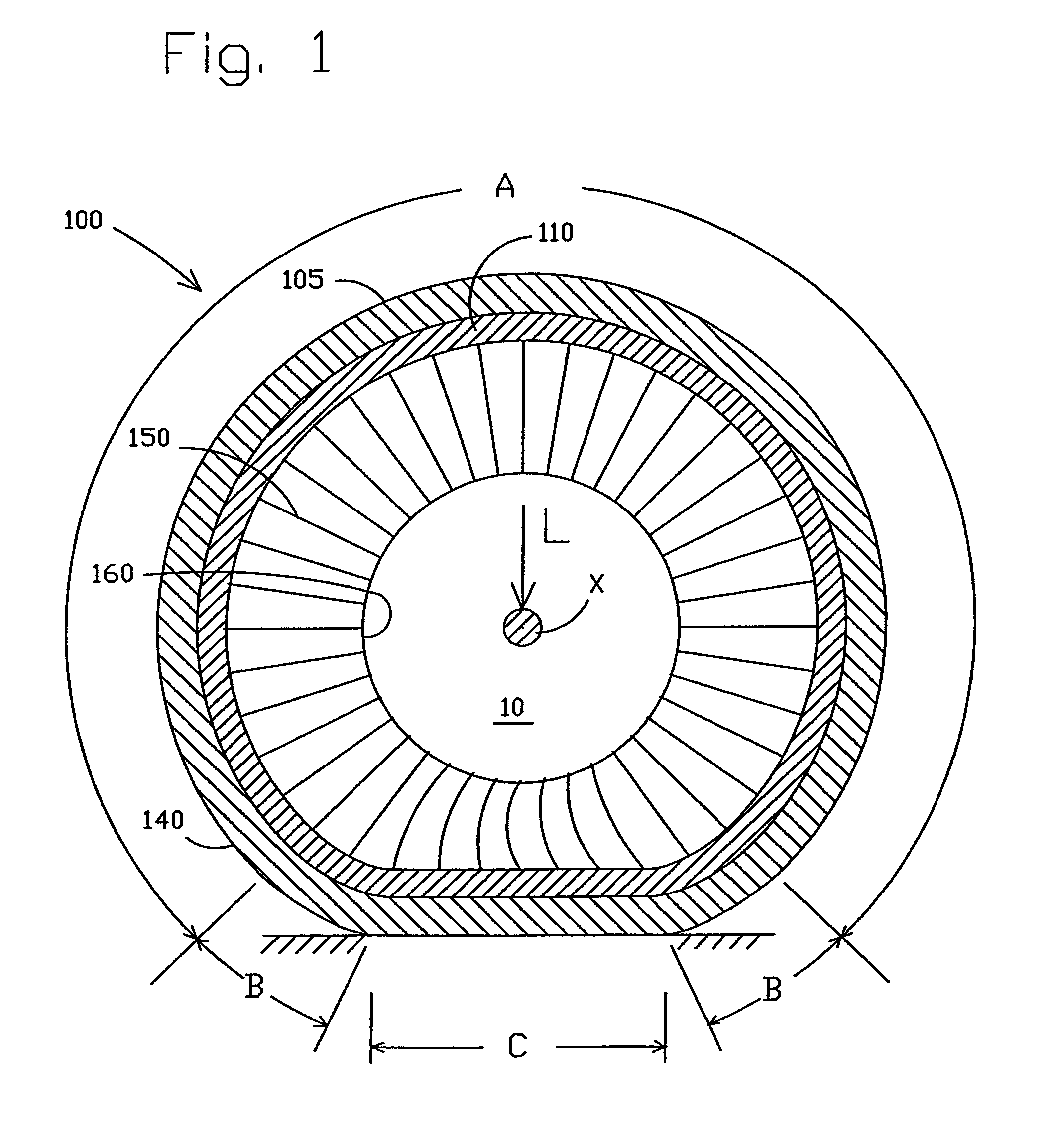

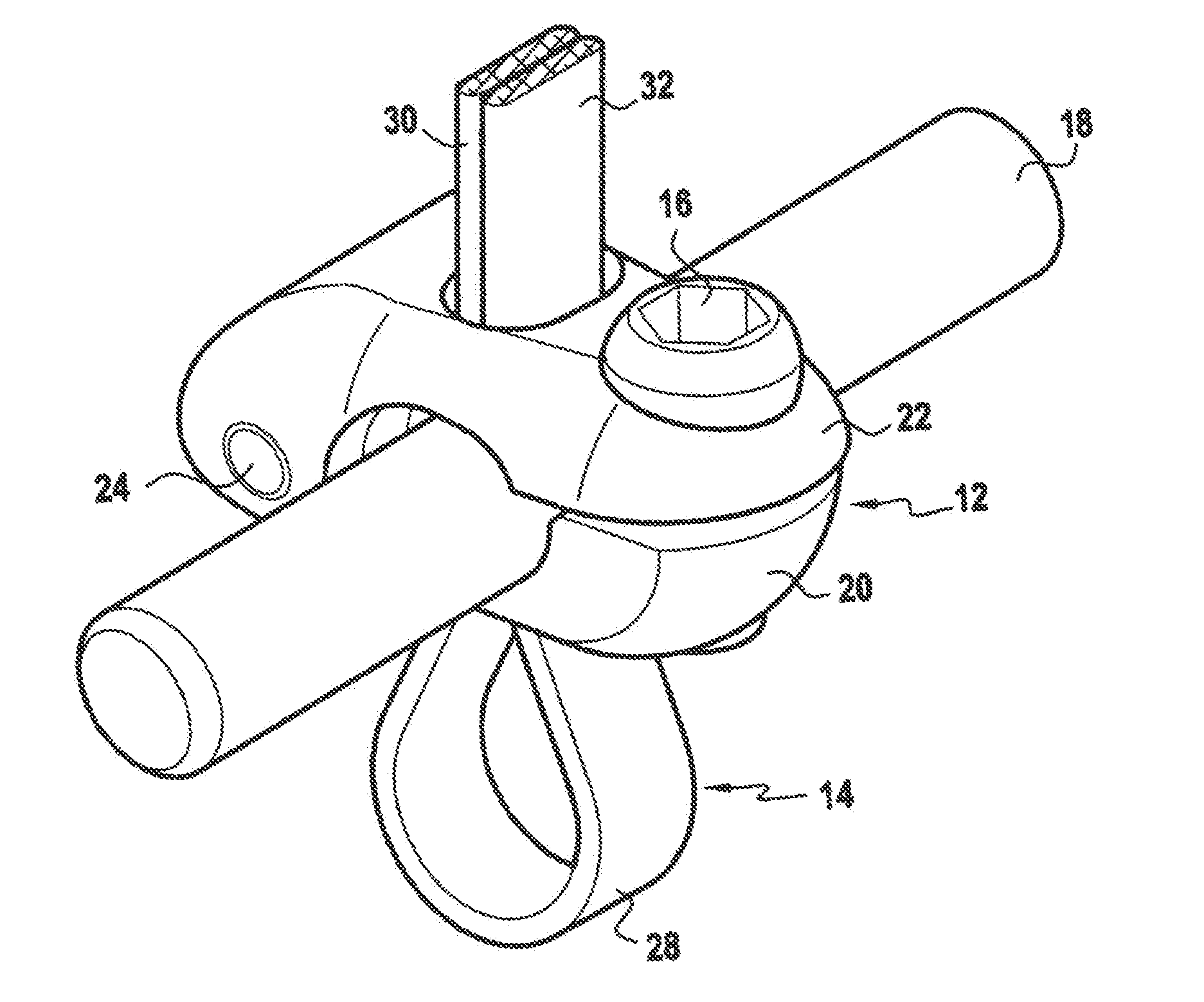

Compliant wheel

InactiveUS7013939B2High effective stiffness in tensionLow effective stiffness in compressionNon-inflatable tyresWheel manufactureBand bendingGround contact

A compliant wheel includes a compliant band and a plurality of web spokes extending transversely across and inward from the reinforced compliant band for attachment to a hub. The compliant band bends to comply with a contact surface and to envelope obstacles. The web spokes transmit load forces between the compliant band and the hub through tension in the web spokes not connected to the ground contacting portion of the wheel. The outer surface of the compliant band may be formed to include a tread, or a separate tread band may be attached.

Owner:MICHELIN RECH & TECH SA

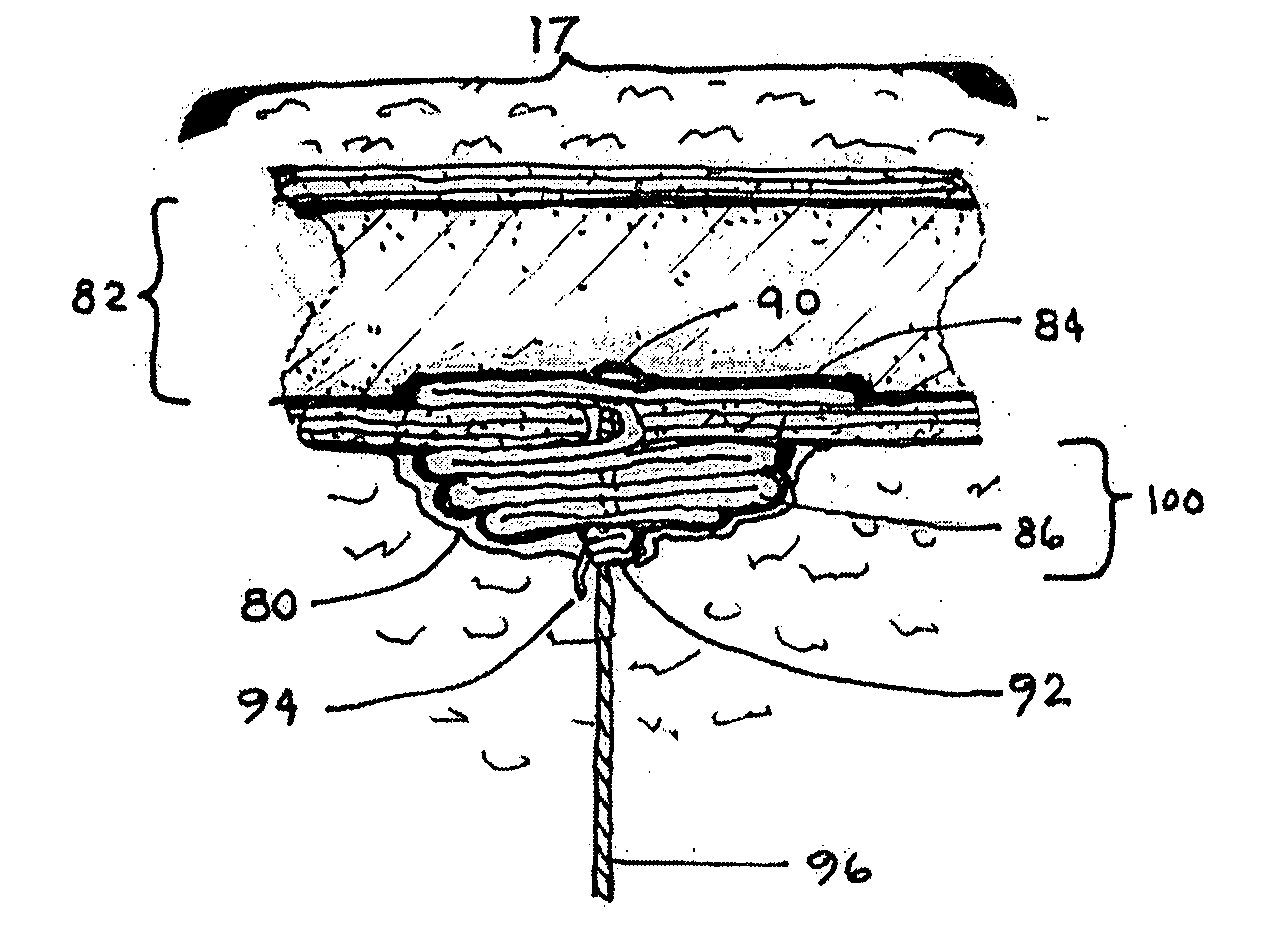

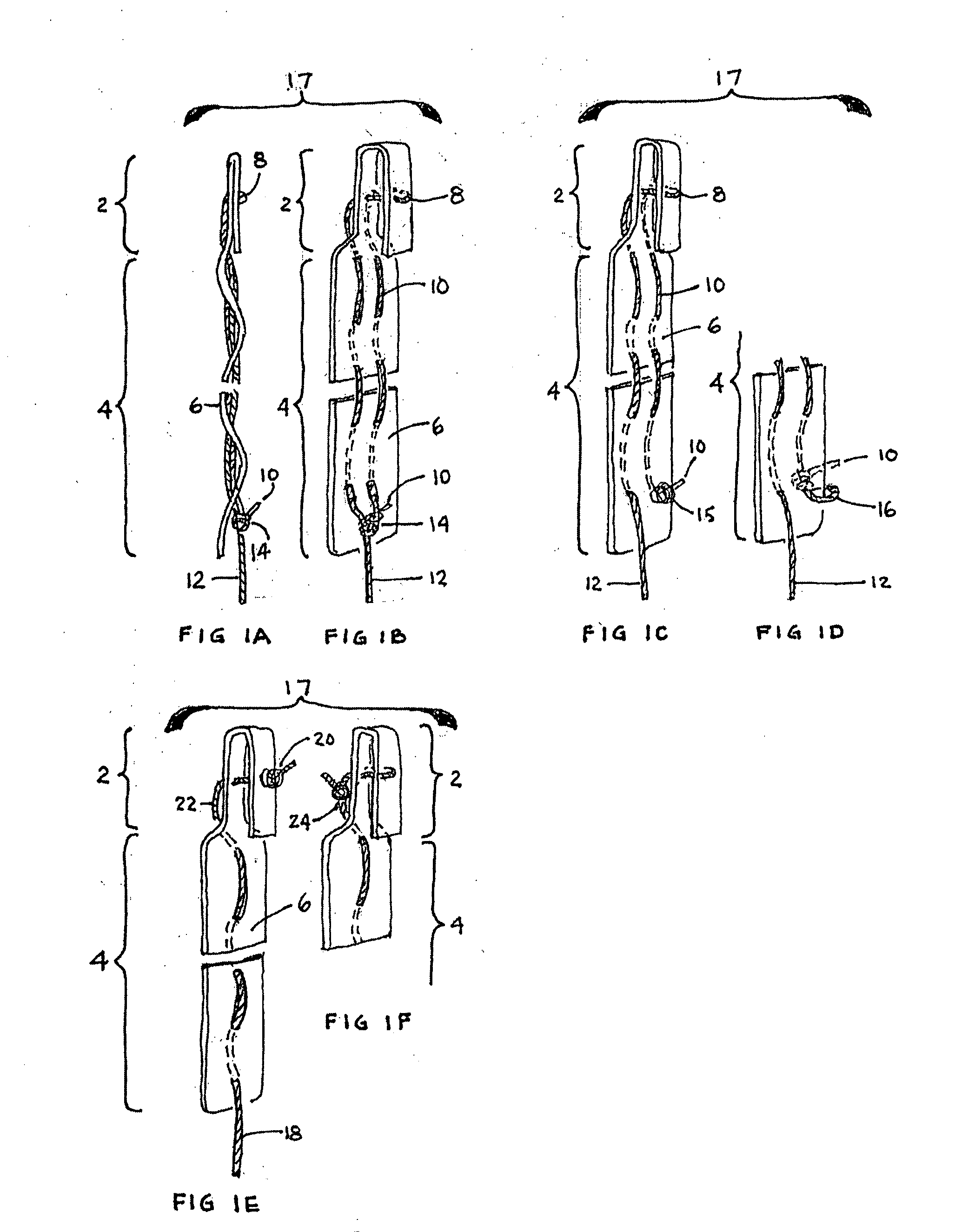

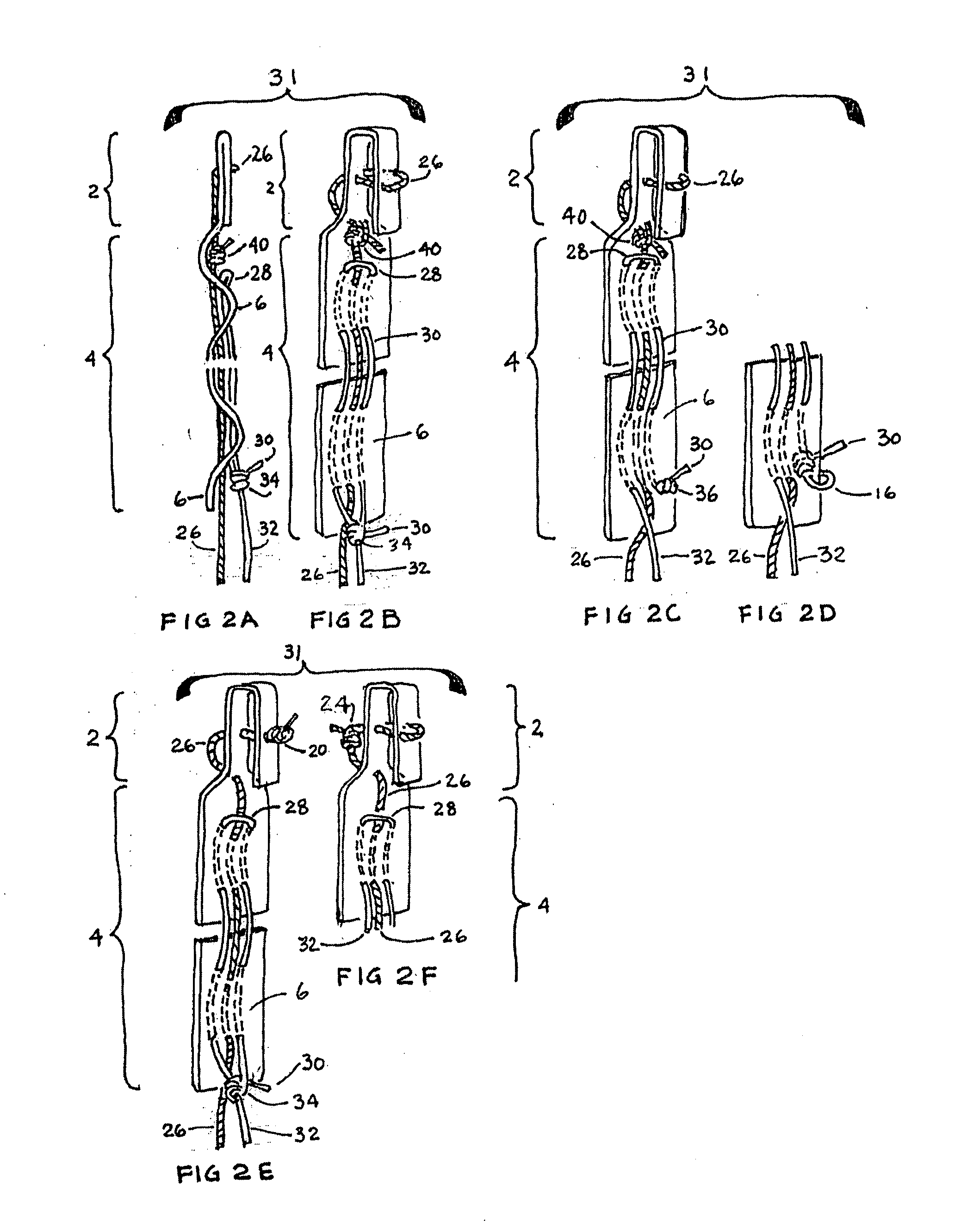

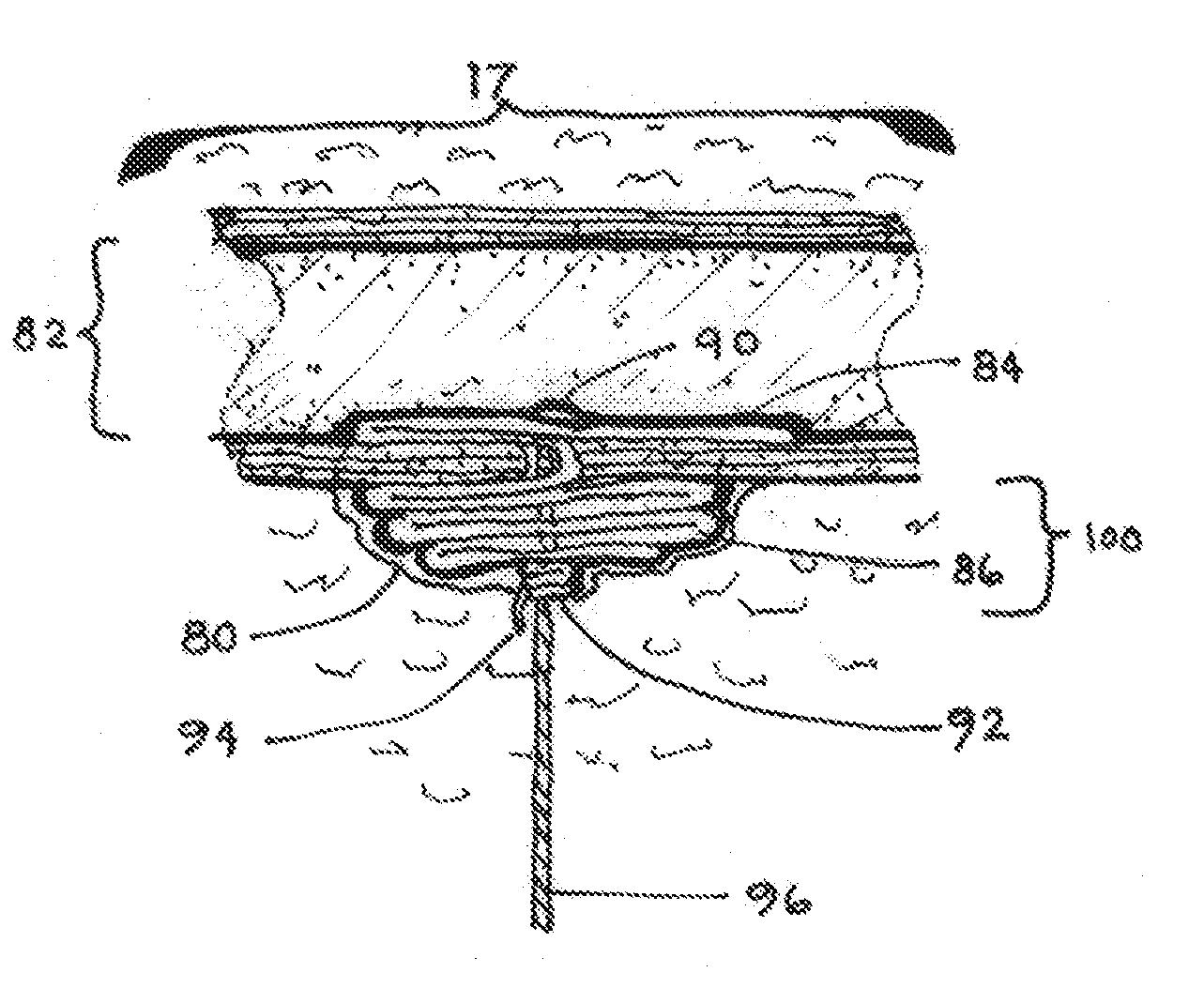

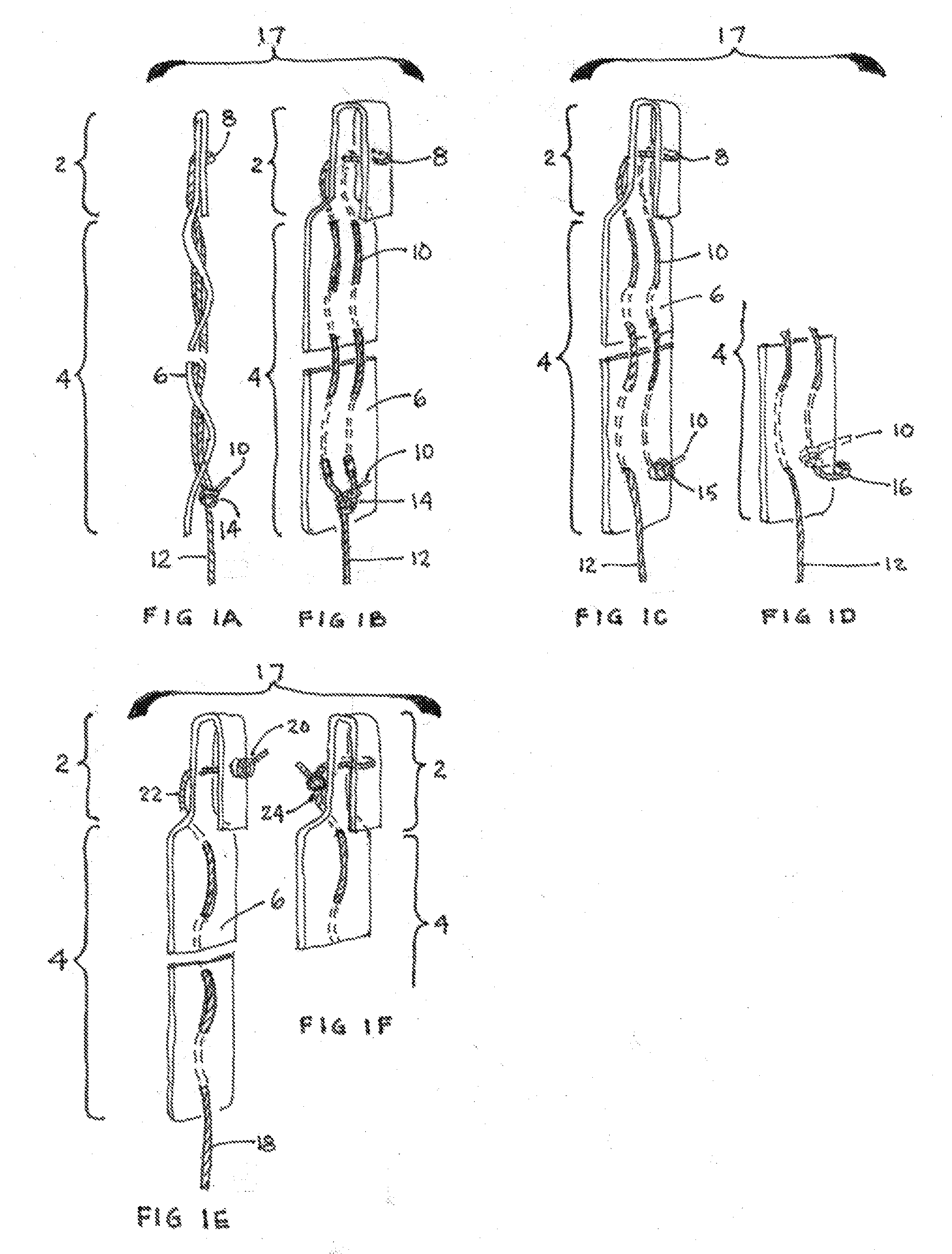

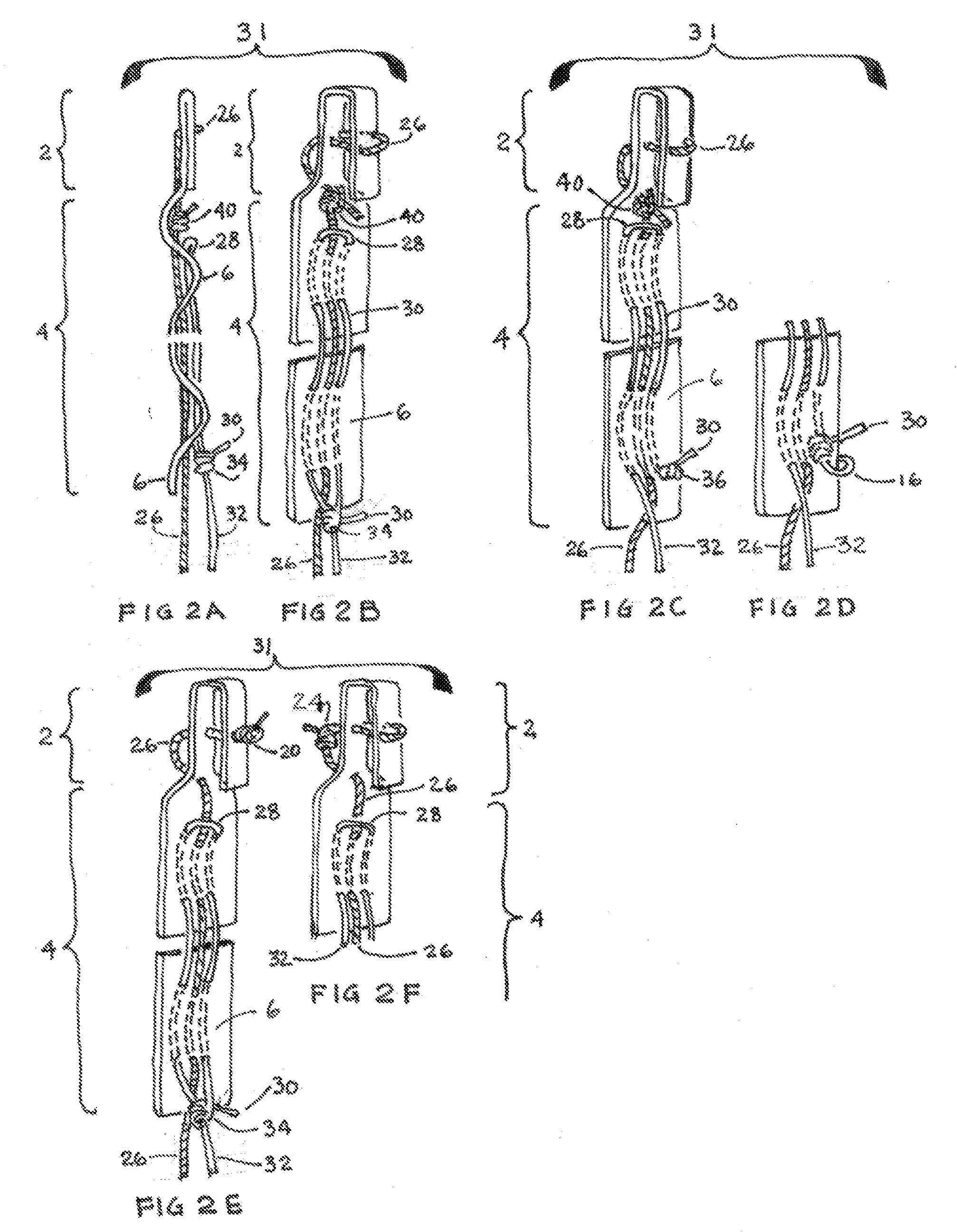

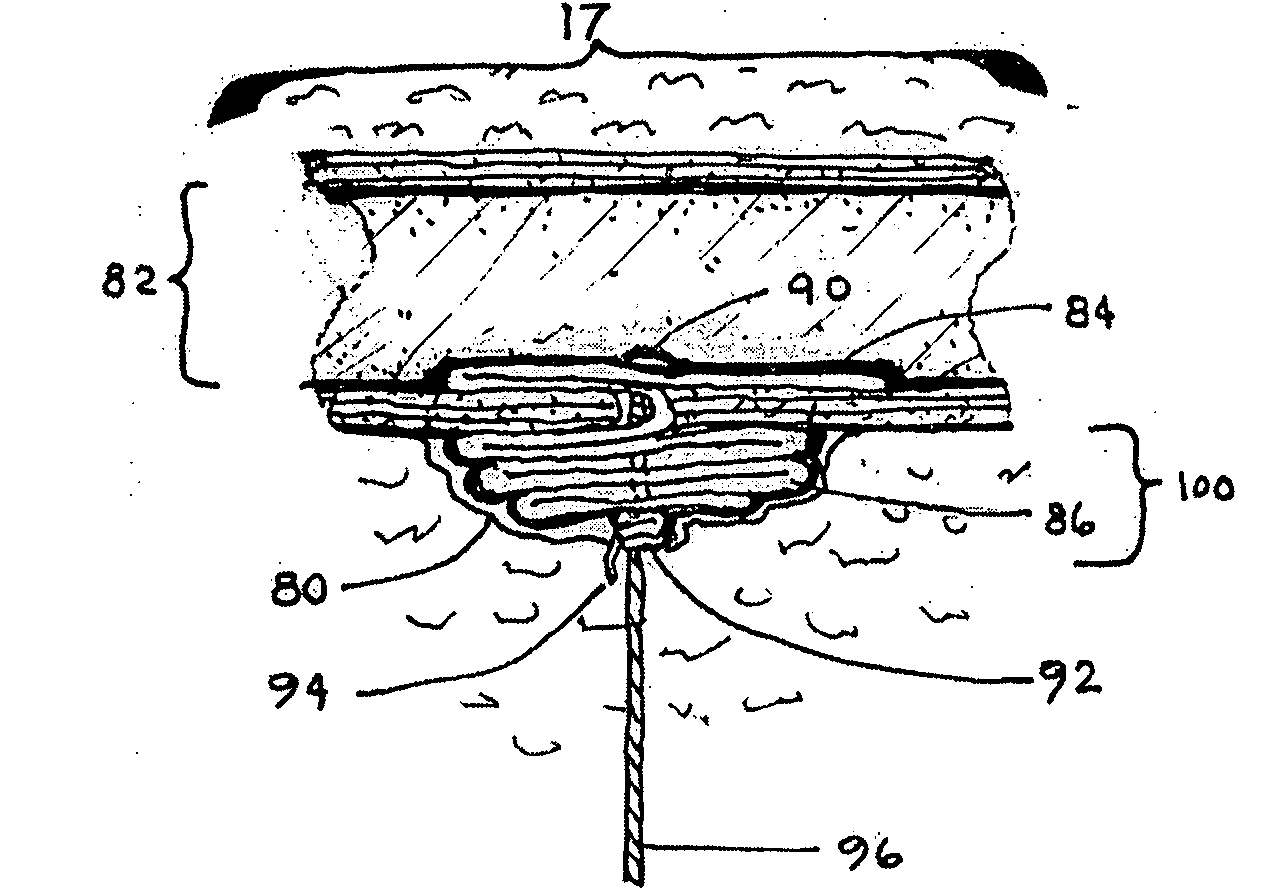

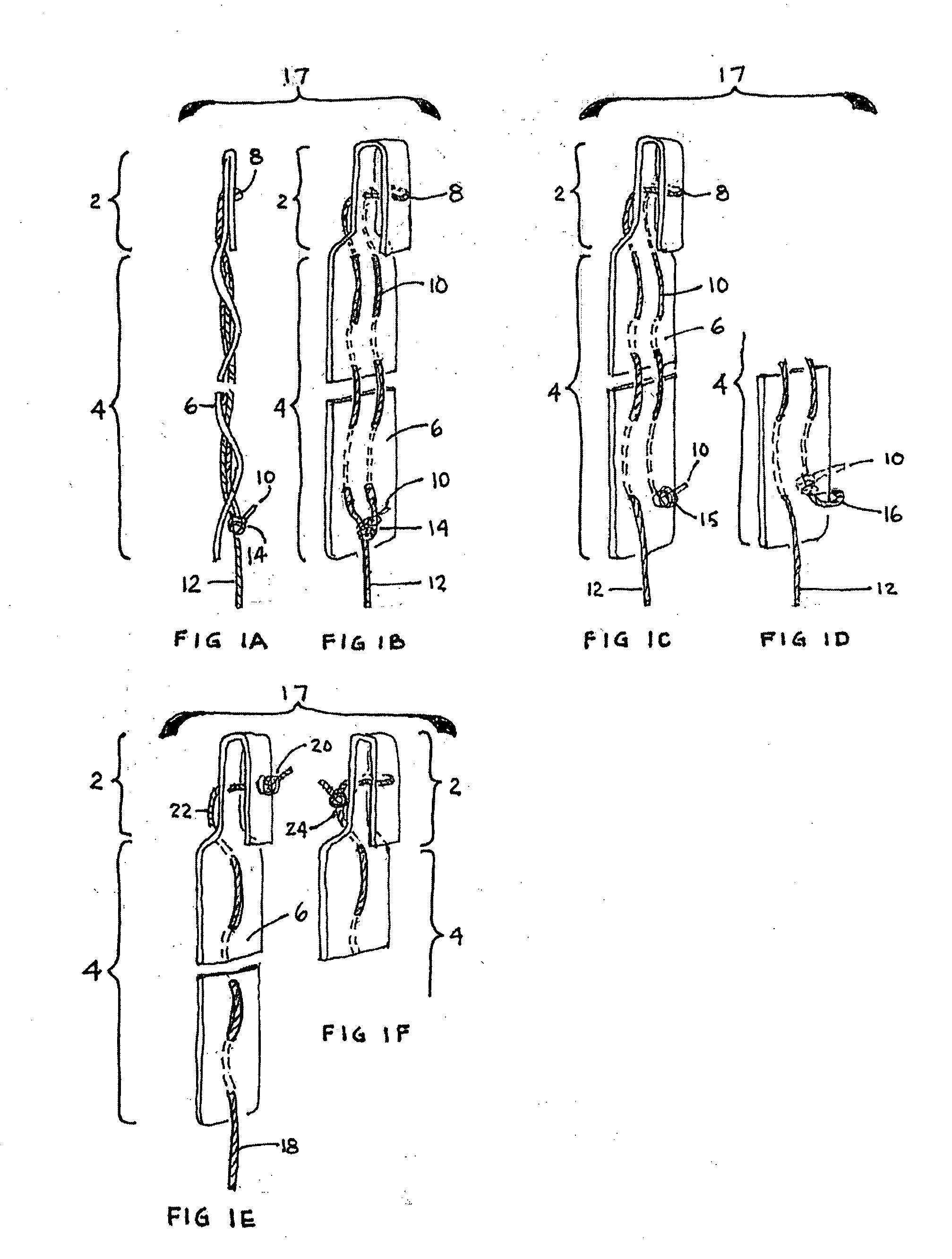

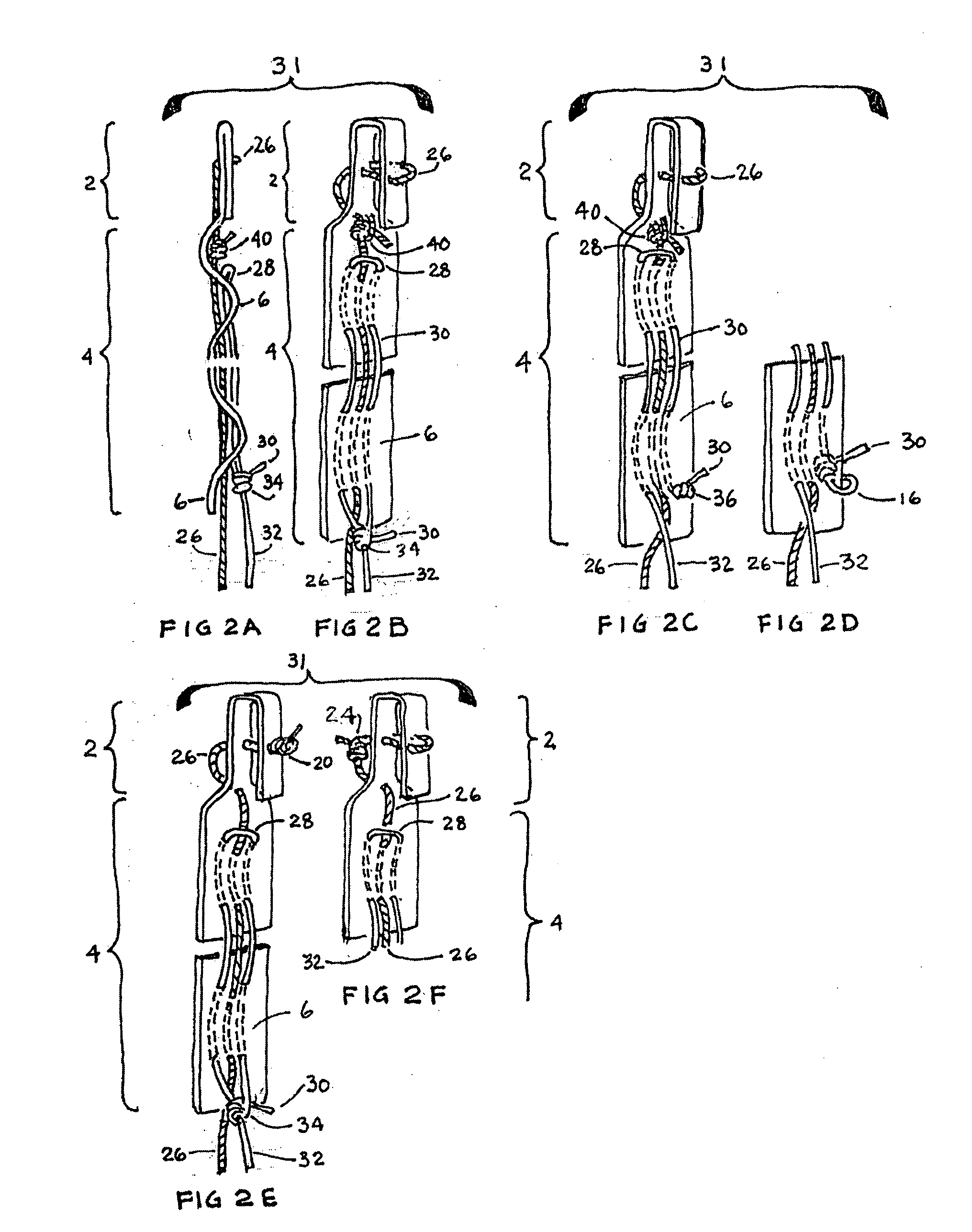

Closure medical device

InactiveUS7731732B2Effective tensionEfficiently pulledSuture equipmentsSurgical veterinaryPuncture WoundMedical device

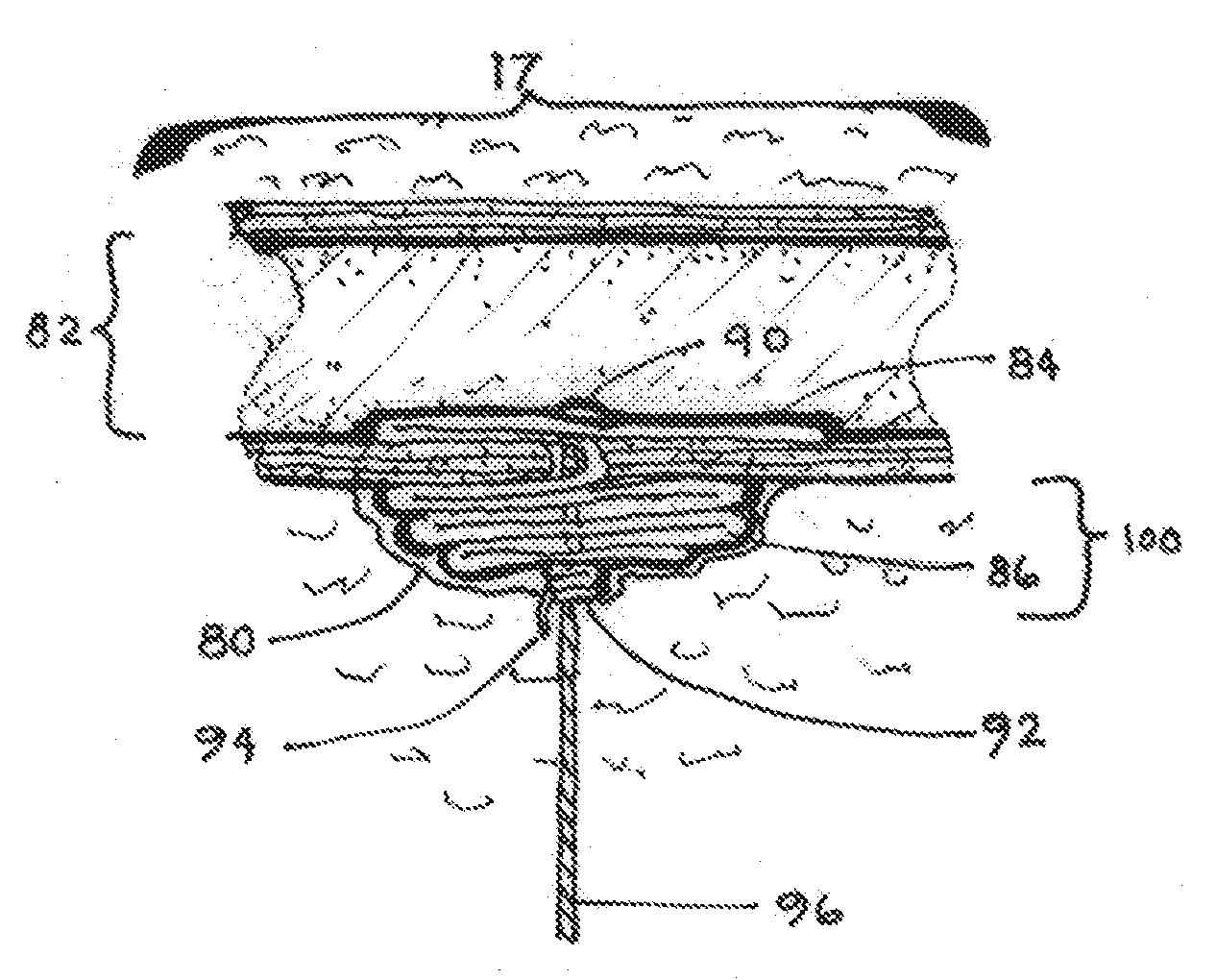

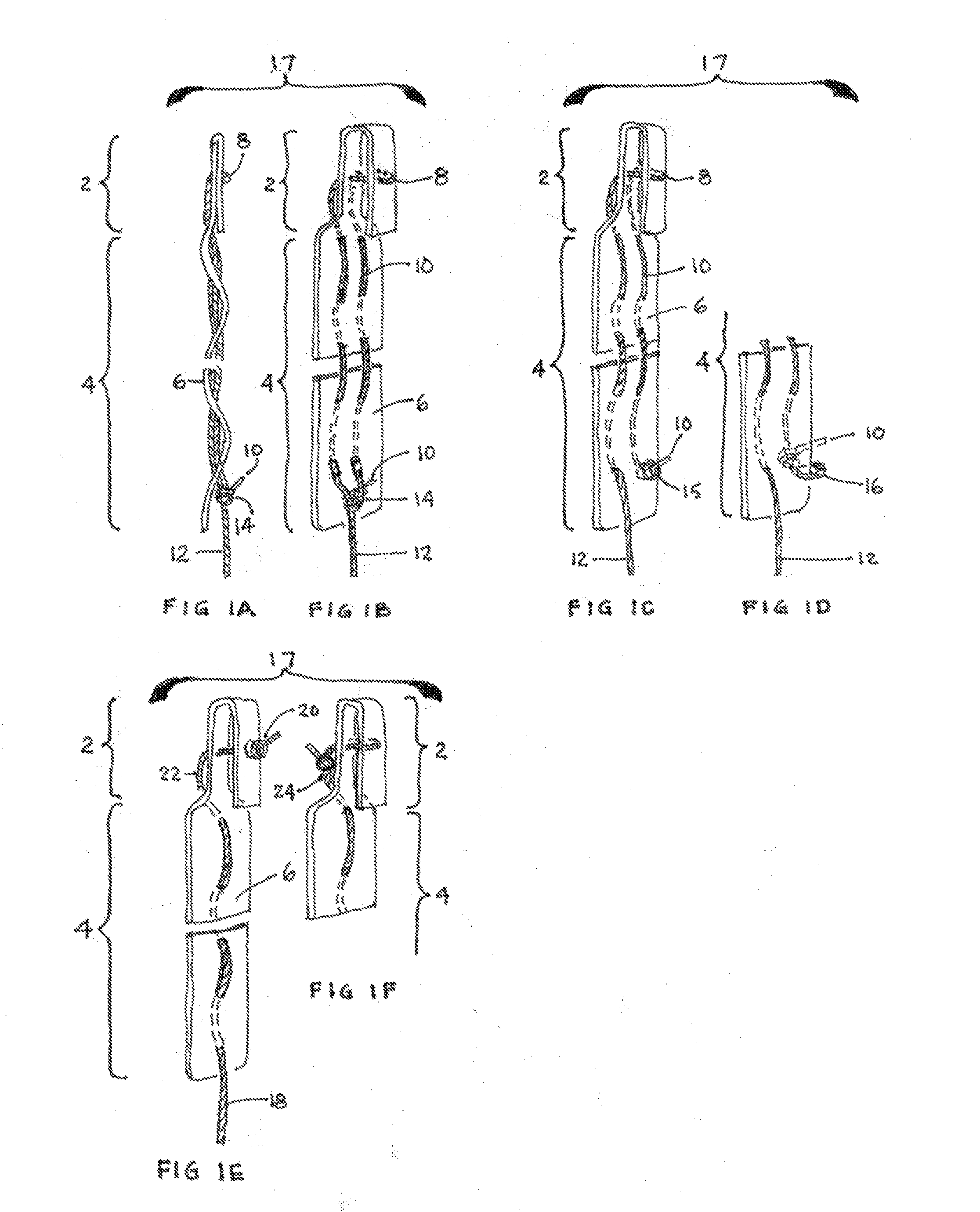

A closure device for closing a puncture wound has a distal section that can be placed against the interior wall of a vessel and a proximal section that bunches in the tissue tract to close the wound. One variation of the device provides for removing the distal section from the vessel so that it resides also in the tissue tract after the proximal section has been securely bunched and lodged within the tissue tract in order to provide unobstructed fluid flow in the vessel.

Owner:KEN CHRISTOPHER G M

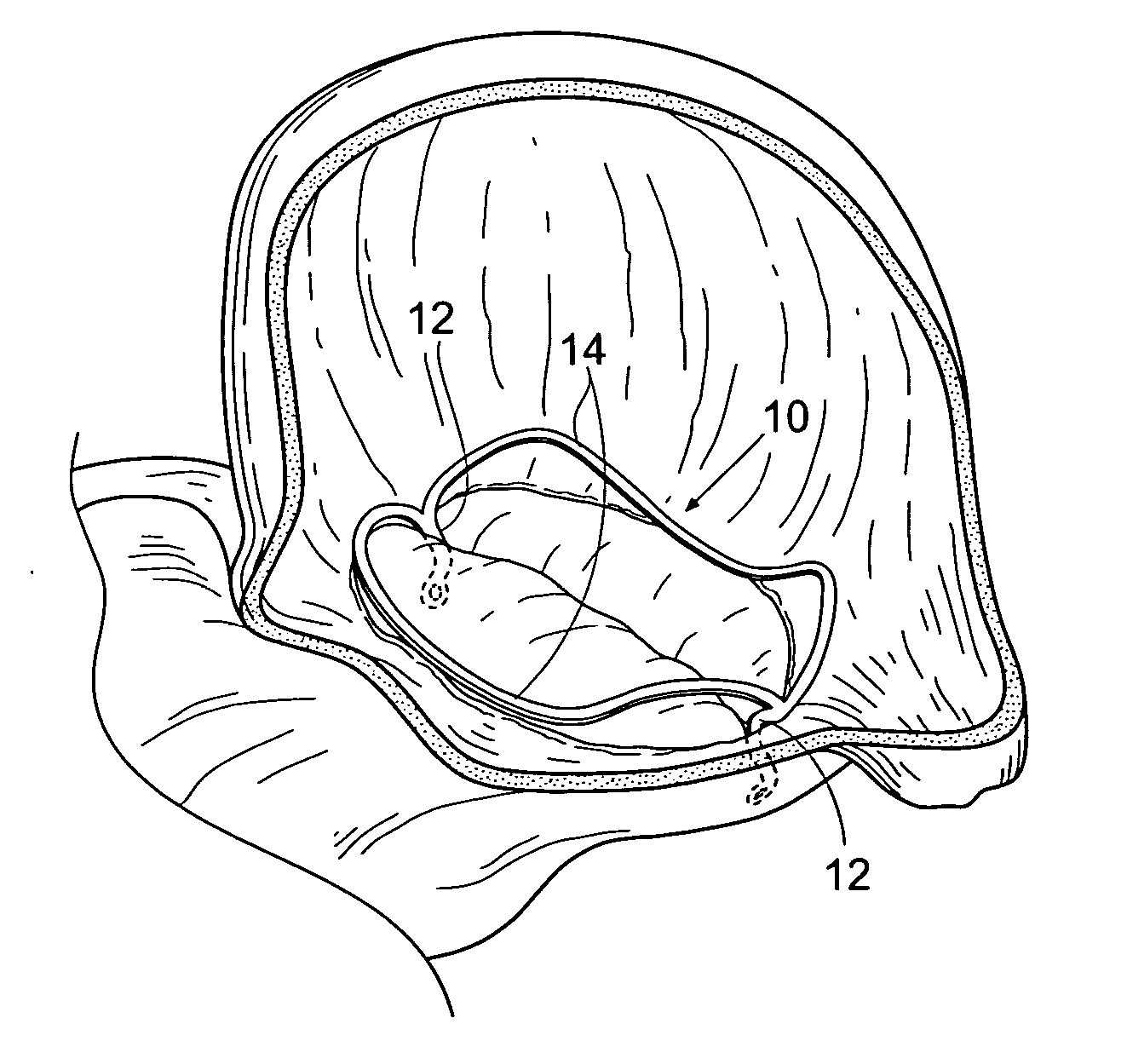

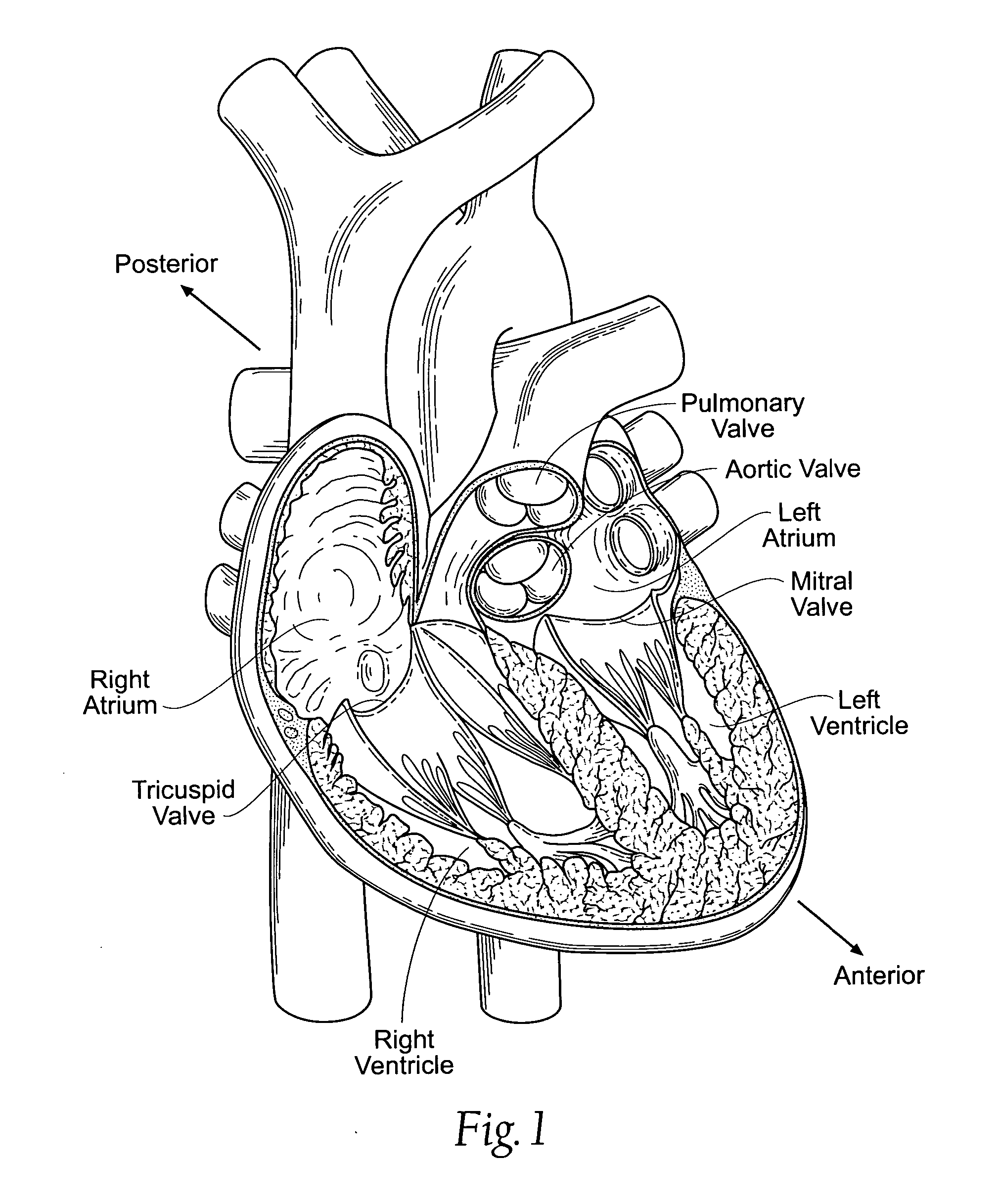

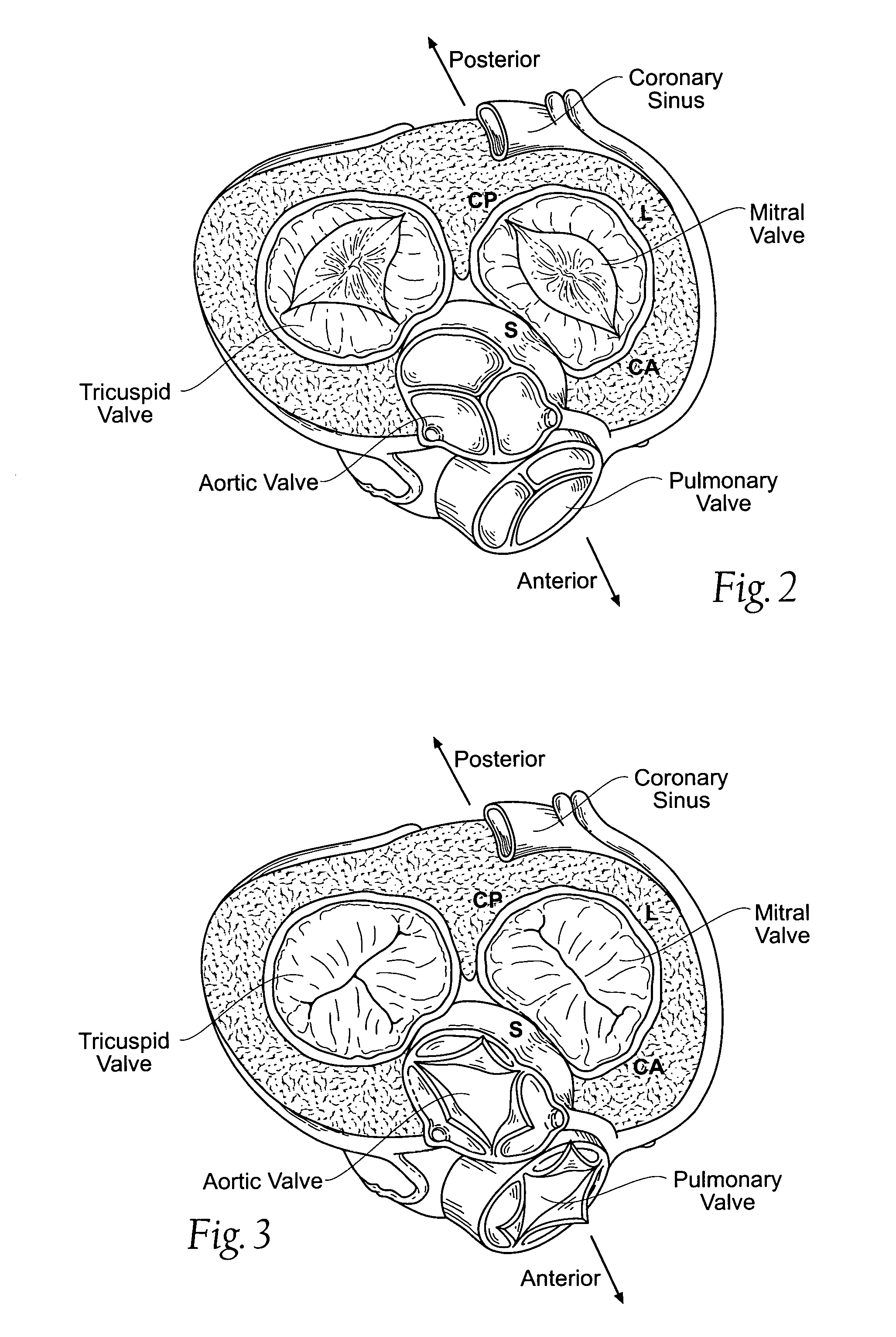

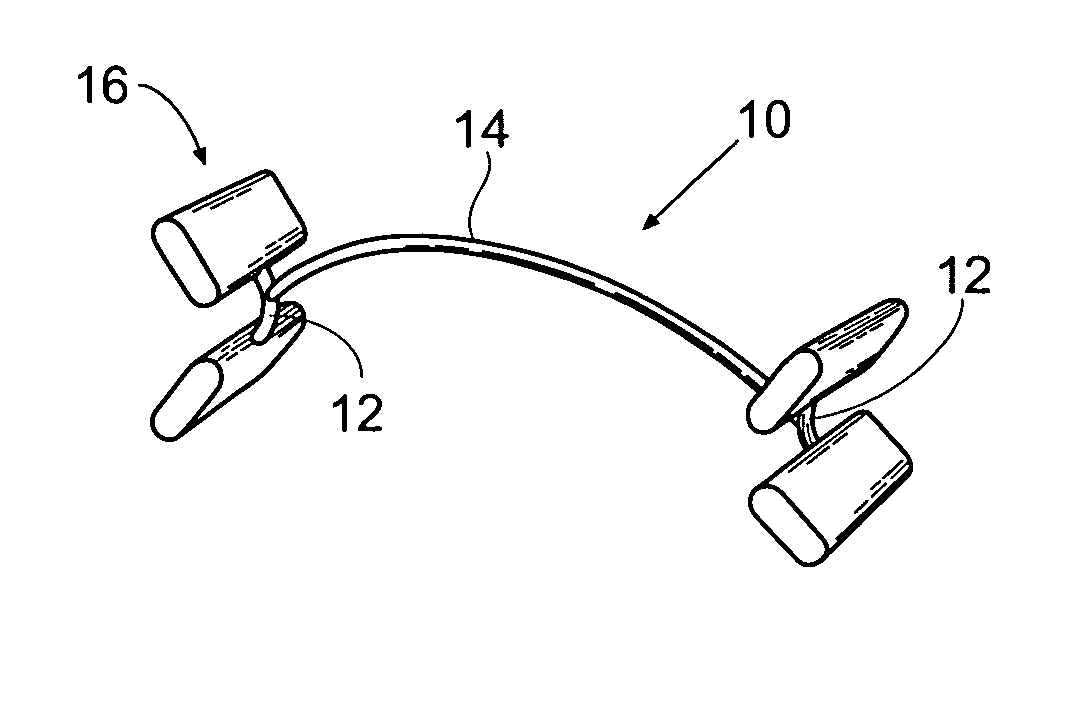

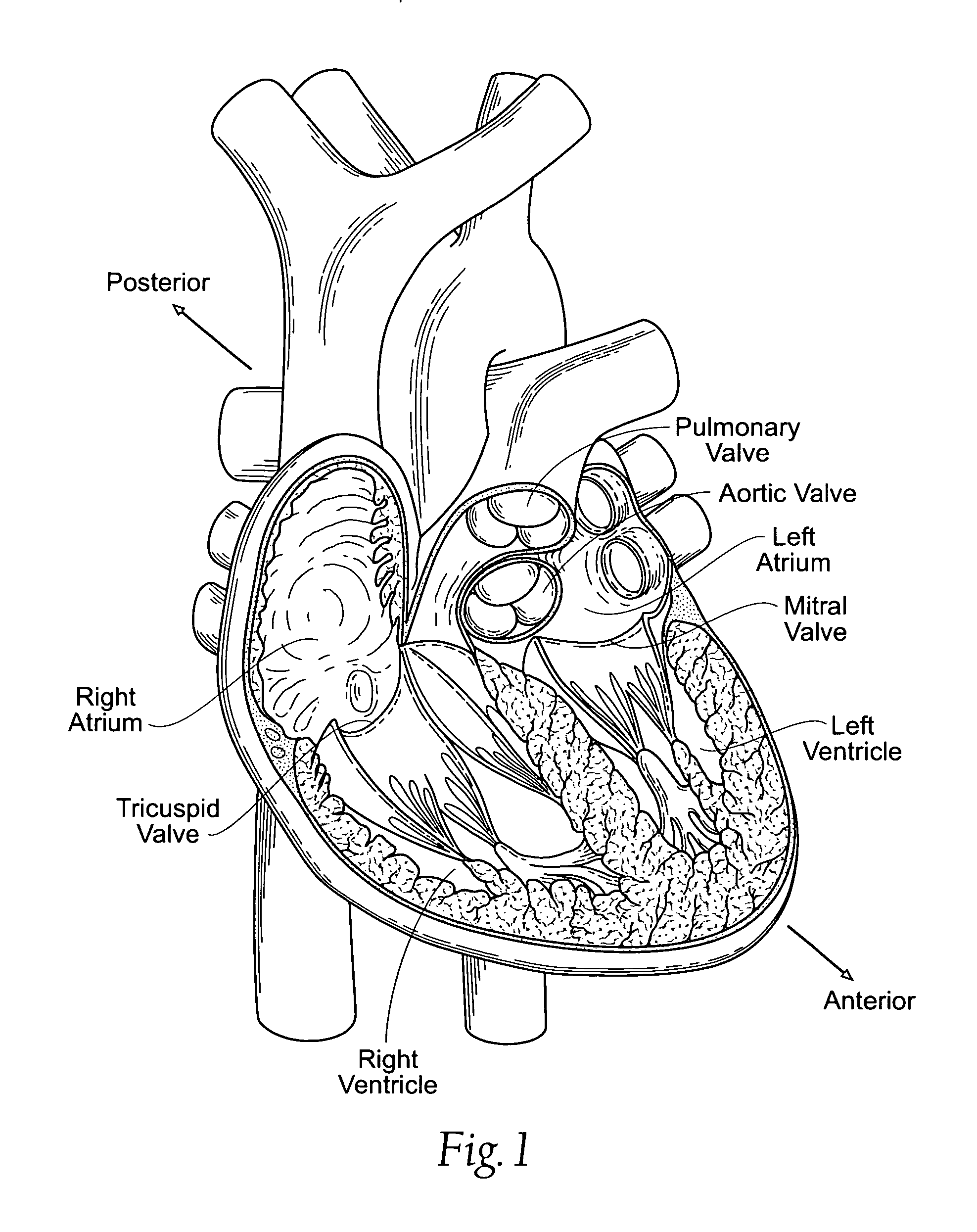

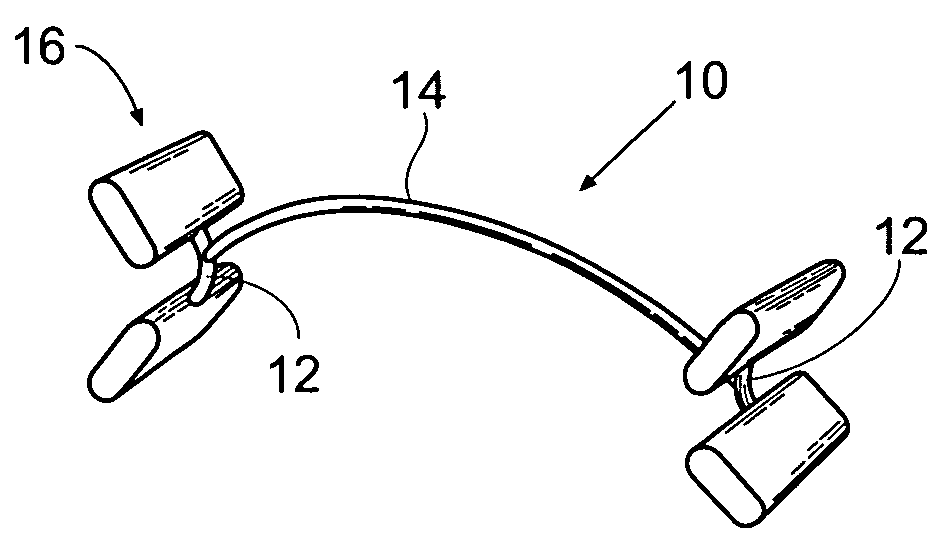

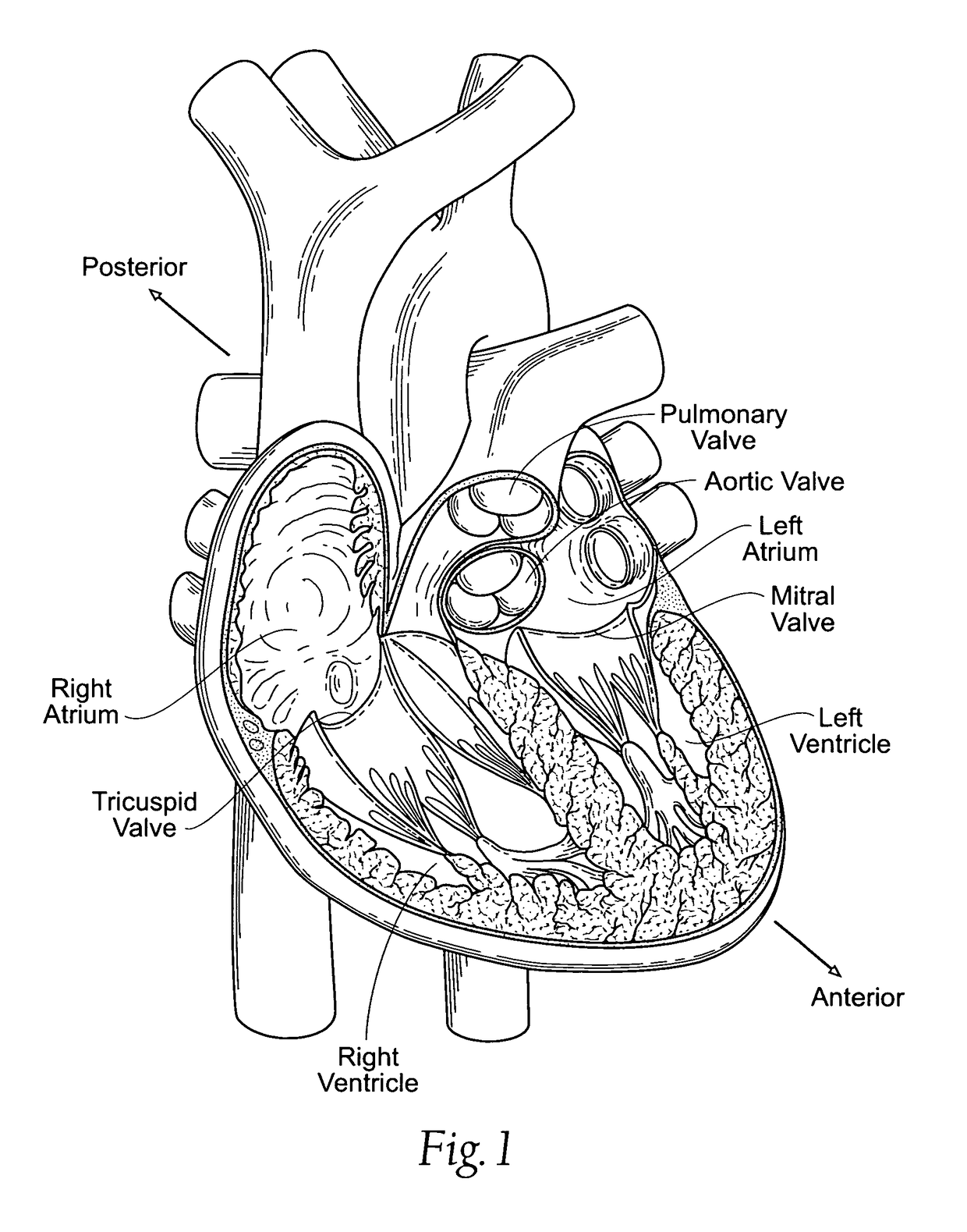

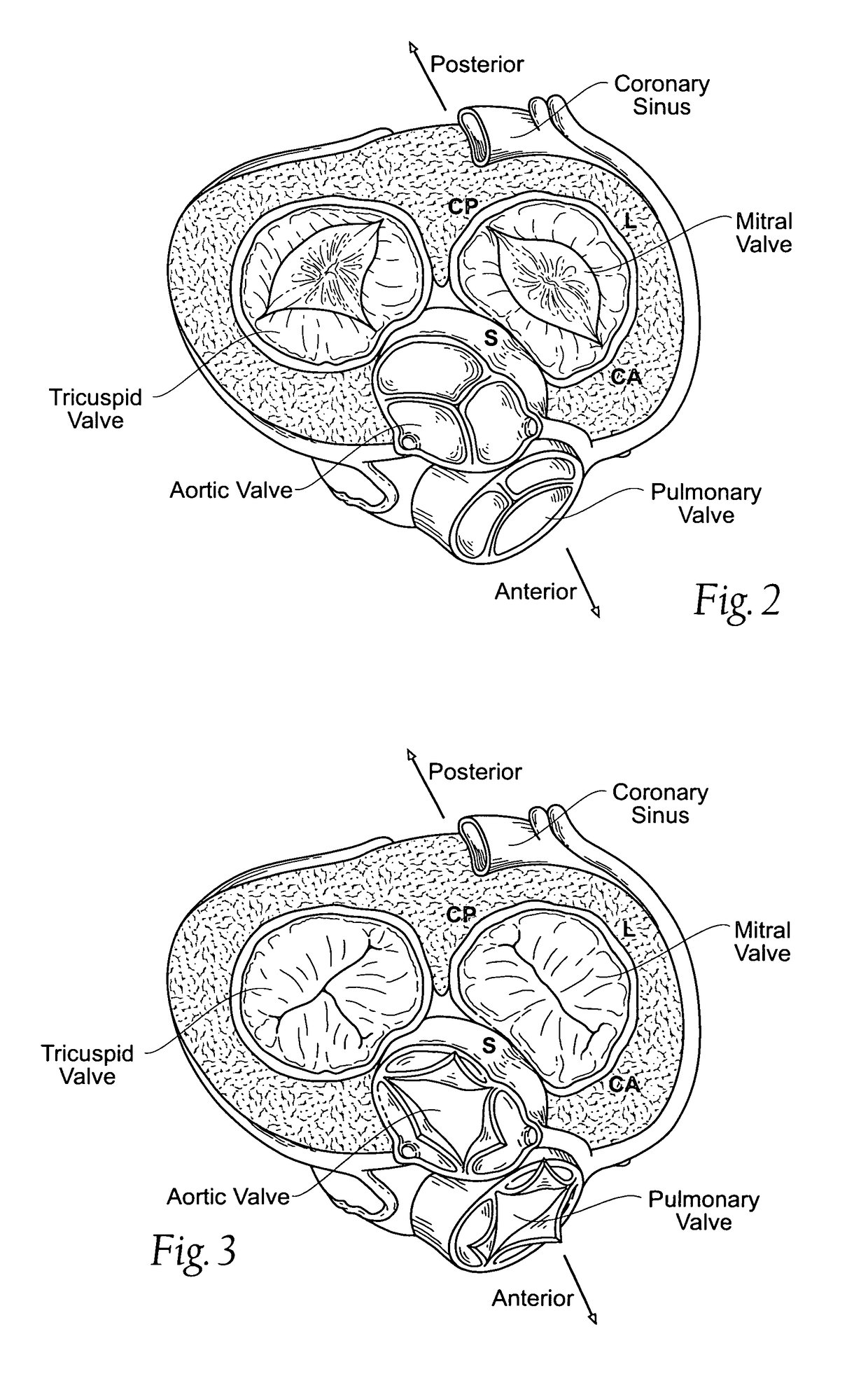

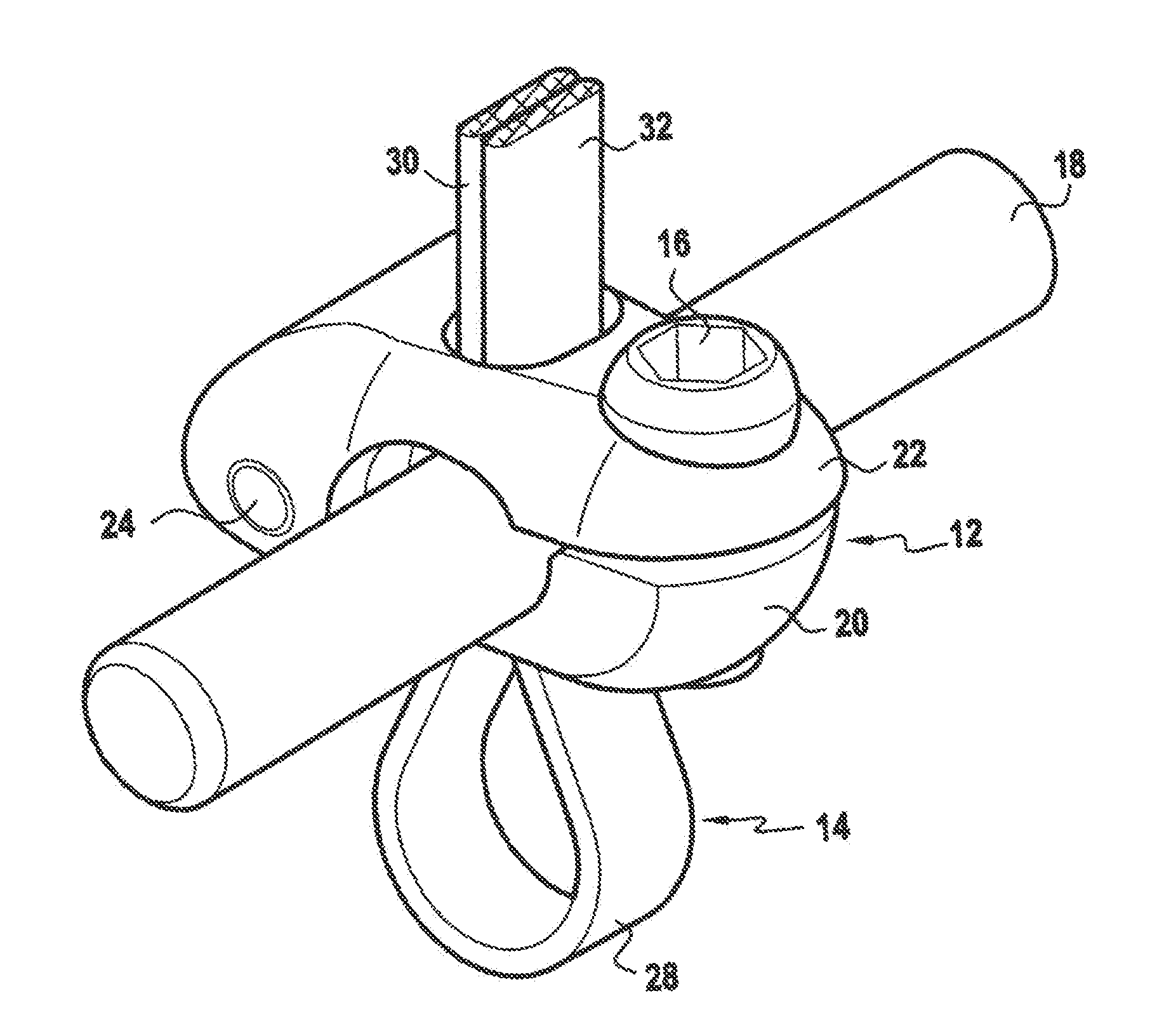

Devices, systems, and methods for reshaping a heart valve annulus

InactiveUS20060106456A9Reduce the amount requiredRecovery functionDiagnosticsAnnuloplasty ringsRetrograde FlowBiomedical engineering

Devices, systems, and methods employ an implant that is sized and configured to attach to the annulus of a dysfunctional heart valve annulus. In use, the implant extends across the major axis of the annulus above and / or along the valve annulus. The implant reshapes the major axis dimension and / or other surrounding anatomic structures. The implant restores to the heart valve annulus and leaflets a more functional anatomic shape and tension. The more functional anatomic shape and tension are conducive to coaptation of the leaflets, which, in turn, reduces retrograde flow or regurgitation. The implant improves function to the valve, without surgically cinching, resecting, and / or fixing in position large portions of a dilated annulus, or without the surgical fixation of ring-like structures.

Owner:VENTURE LENDING & LEASING IV

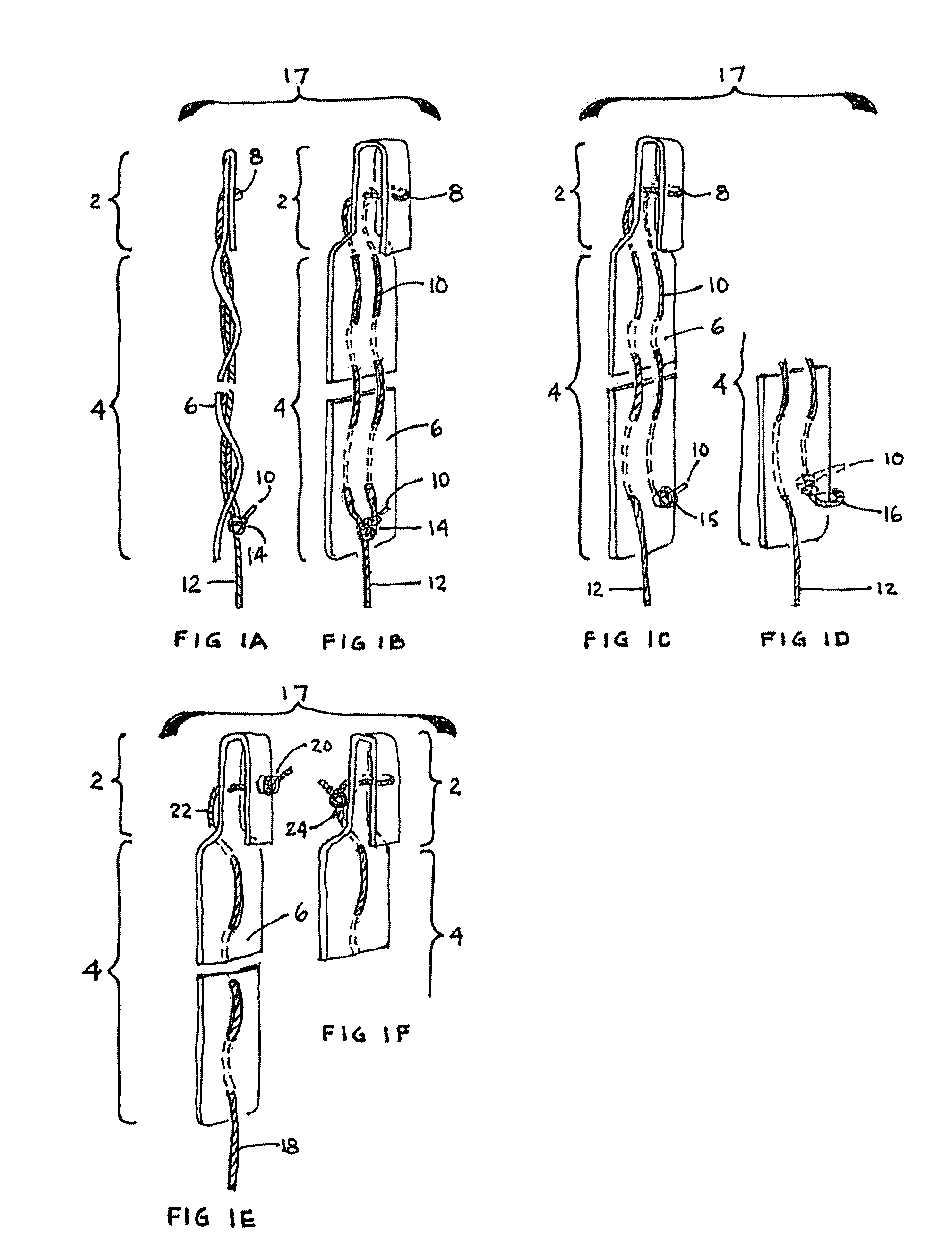

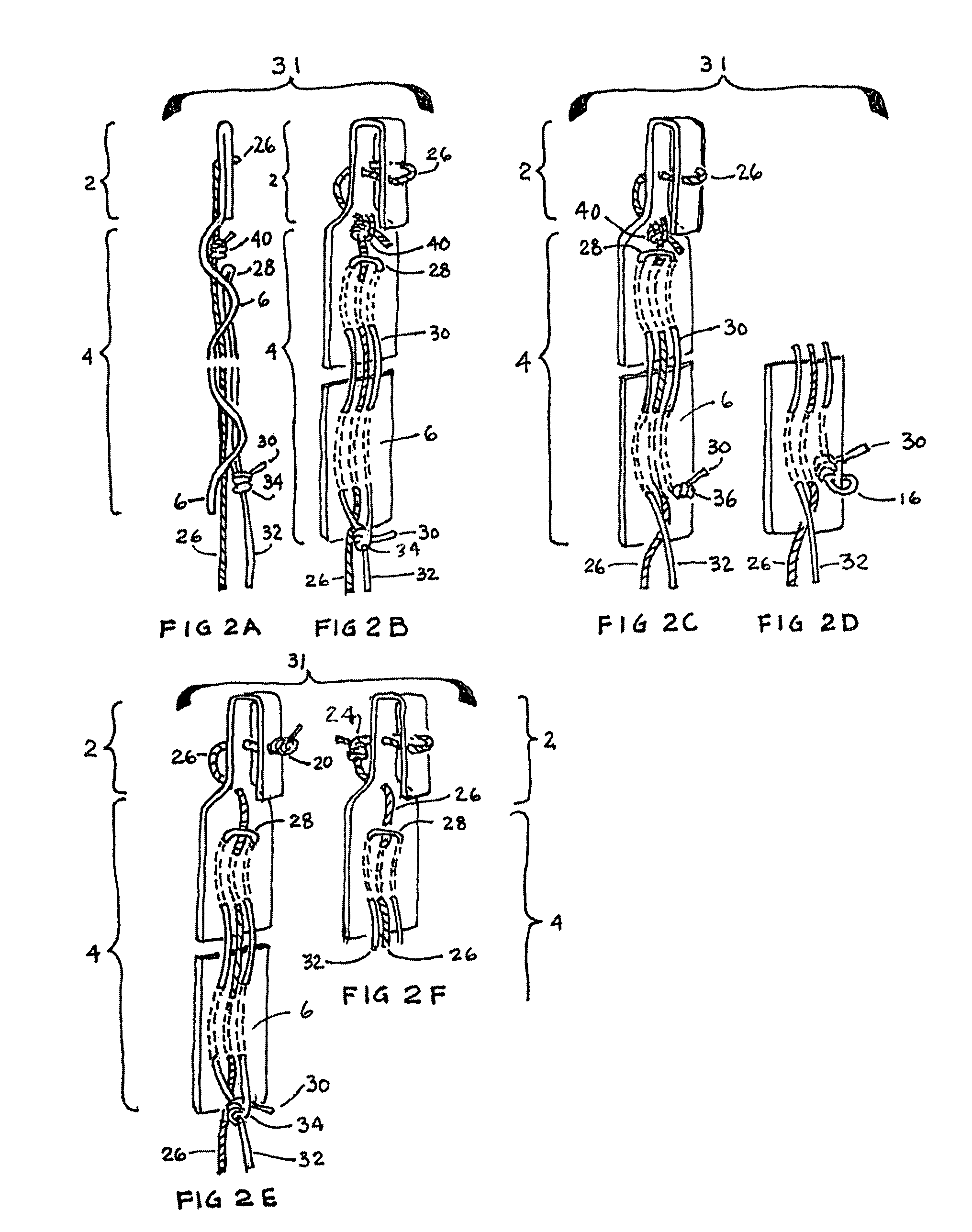

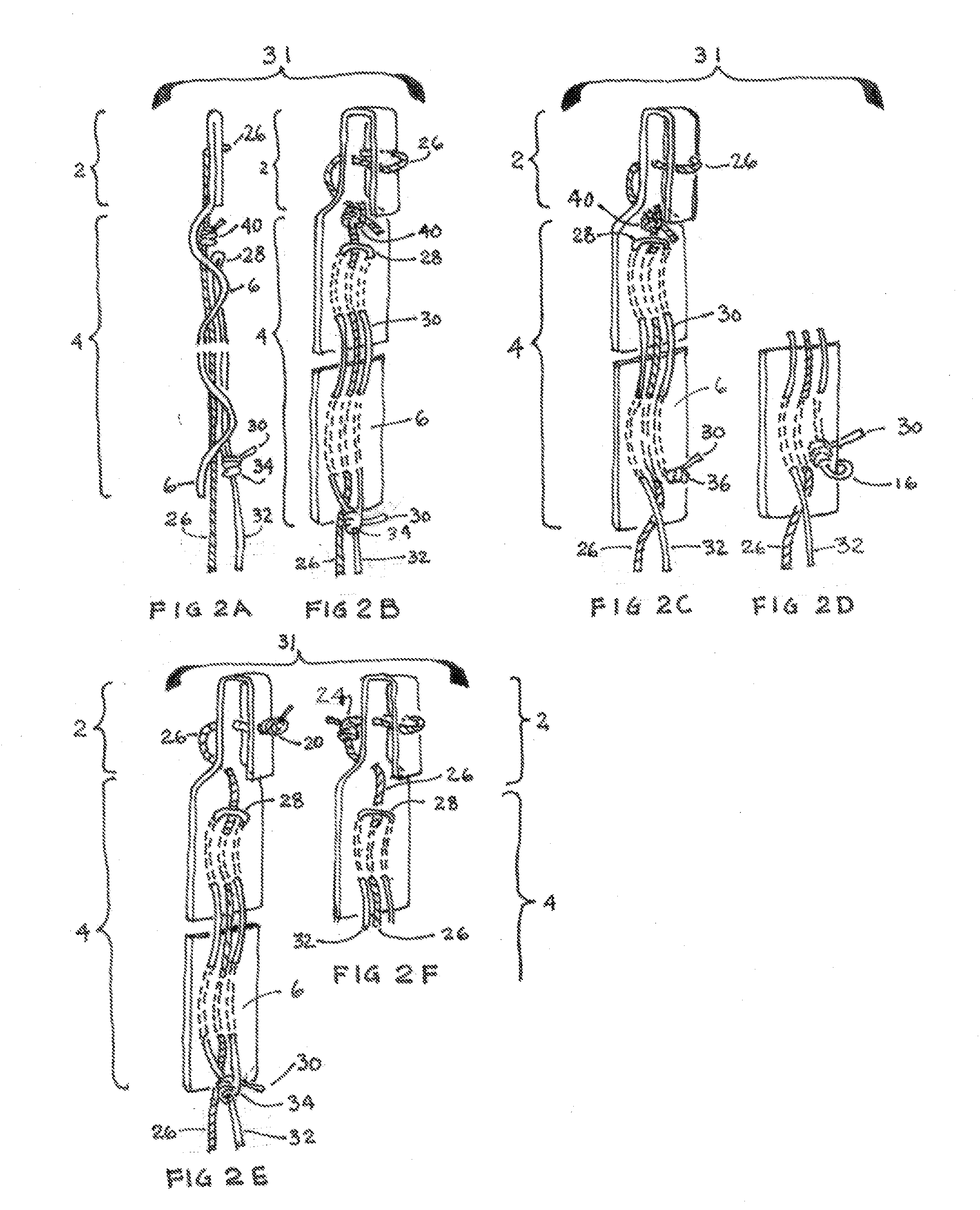

Closure medical device

InactiveUS20090062847A1Effective tensionEfficiently pulledSuture equipmentsSurgical veterinaryPuncture WoundMedical device

A closure device for closing a puncture wound has a distal section that can be placed against the interior wall of a vessel and a proximal section that bunches in the tissue tract to close the wound.

Owner:KEN CHRISTOPHER G M

Closure medical device

ActiveUS20090062850A1Effective tensionEfficiently pulledSuture equipmentsDiagnosticsPuncture WoundMedicine

A closure device for closing a puncture wound has a distal section that can be placed against the interior wall of a vessel and a proximal section that bunches in the tissue tract to close the wound.

Owner:KEN CHRISTOPHER G M

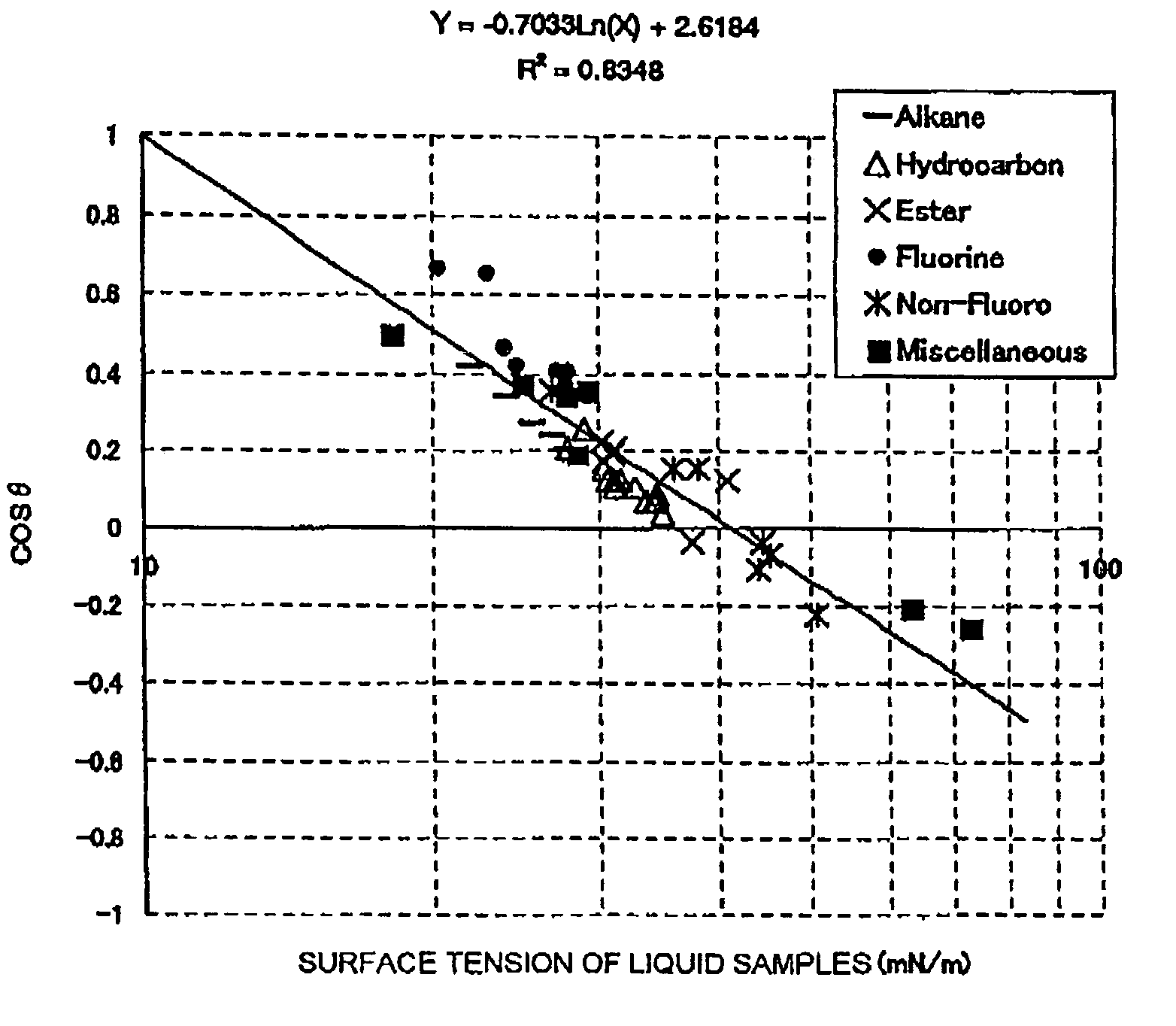

Solid body surface evaluation method, magnetic disk evaluation method, magnetic disk, and manufacturing method thereof

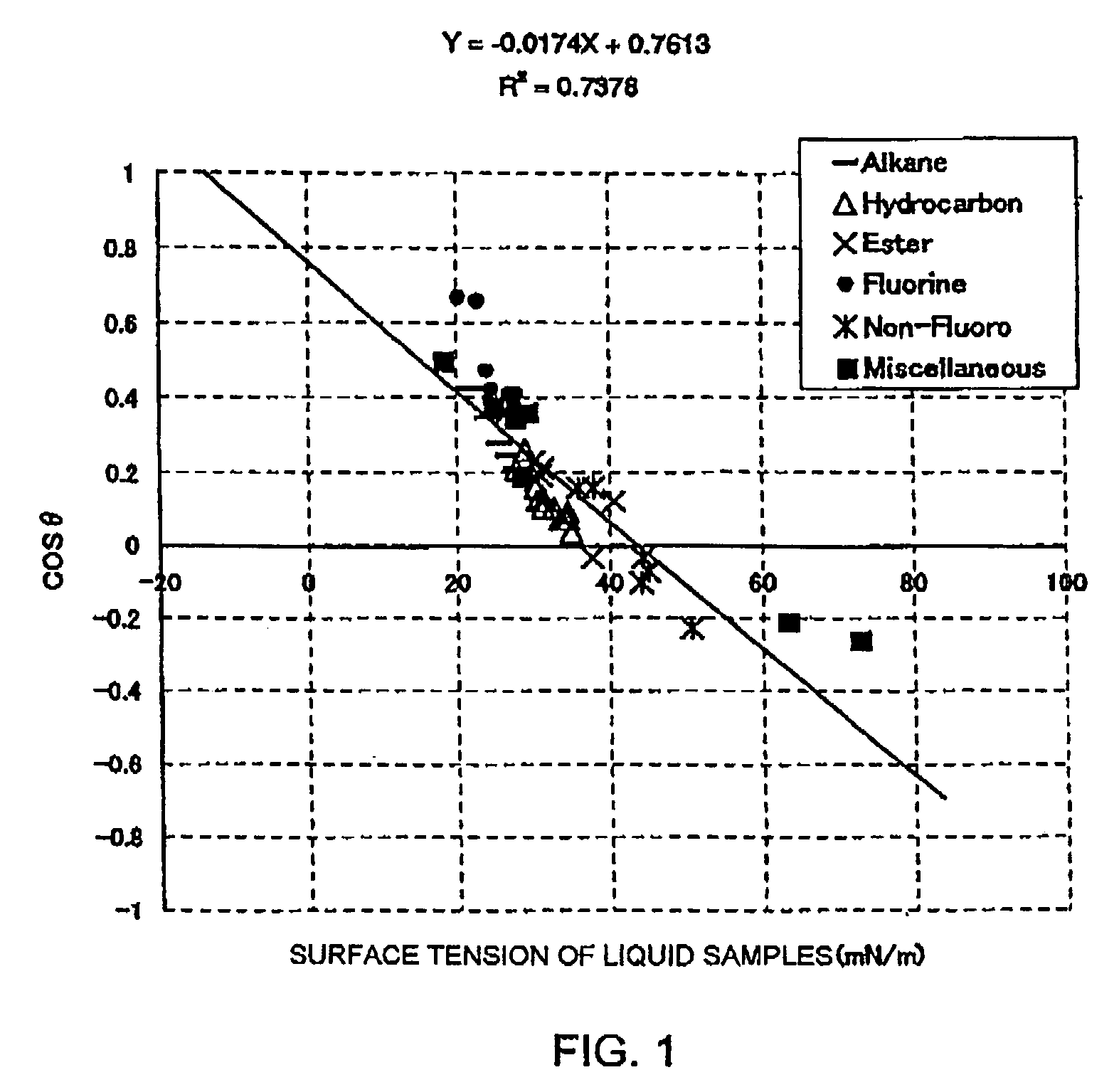

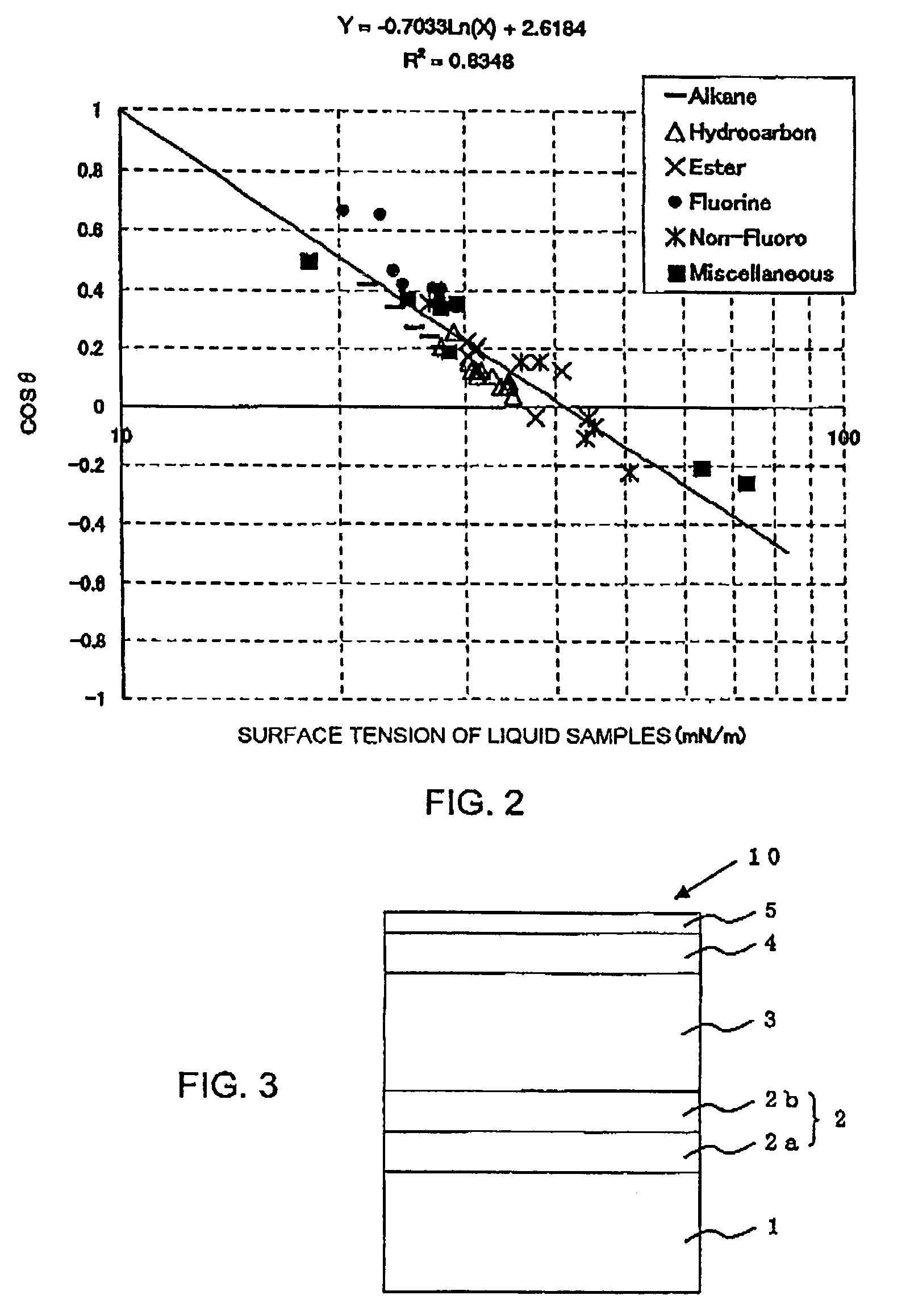

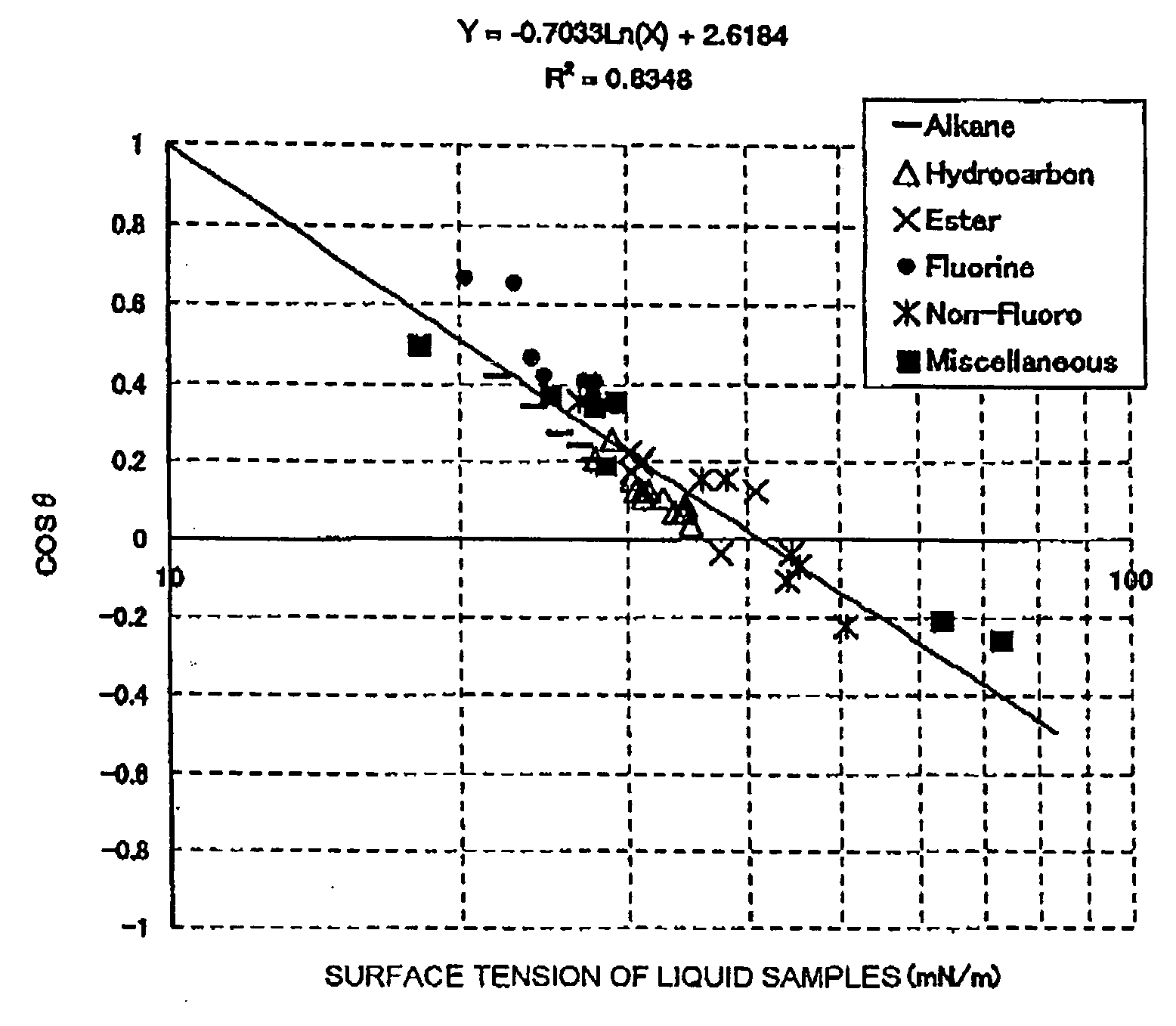

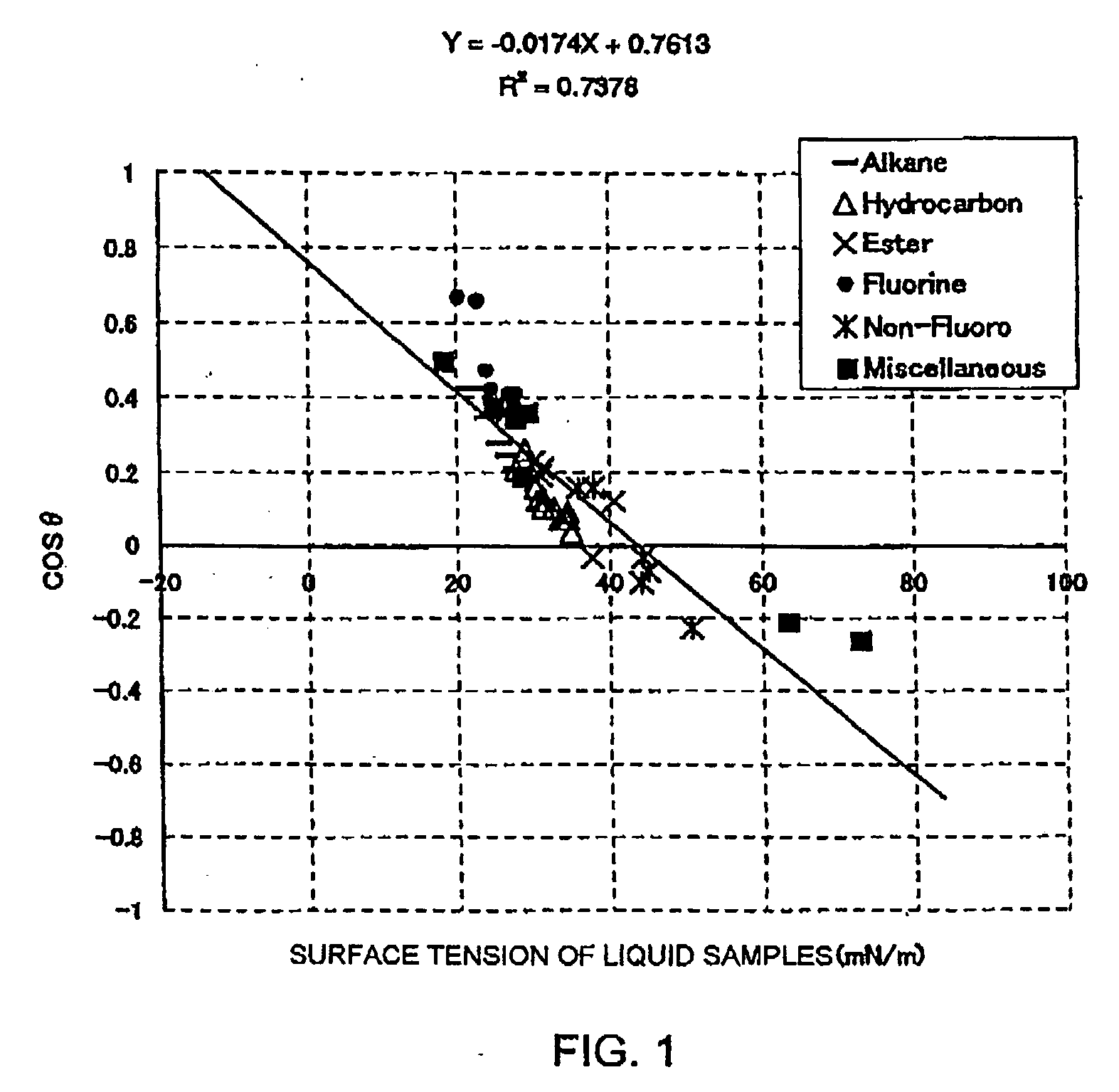

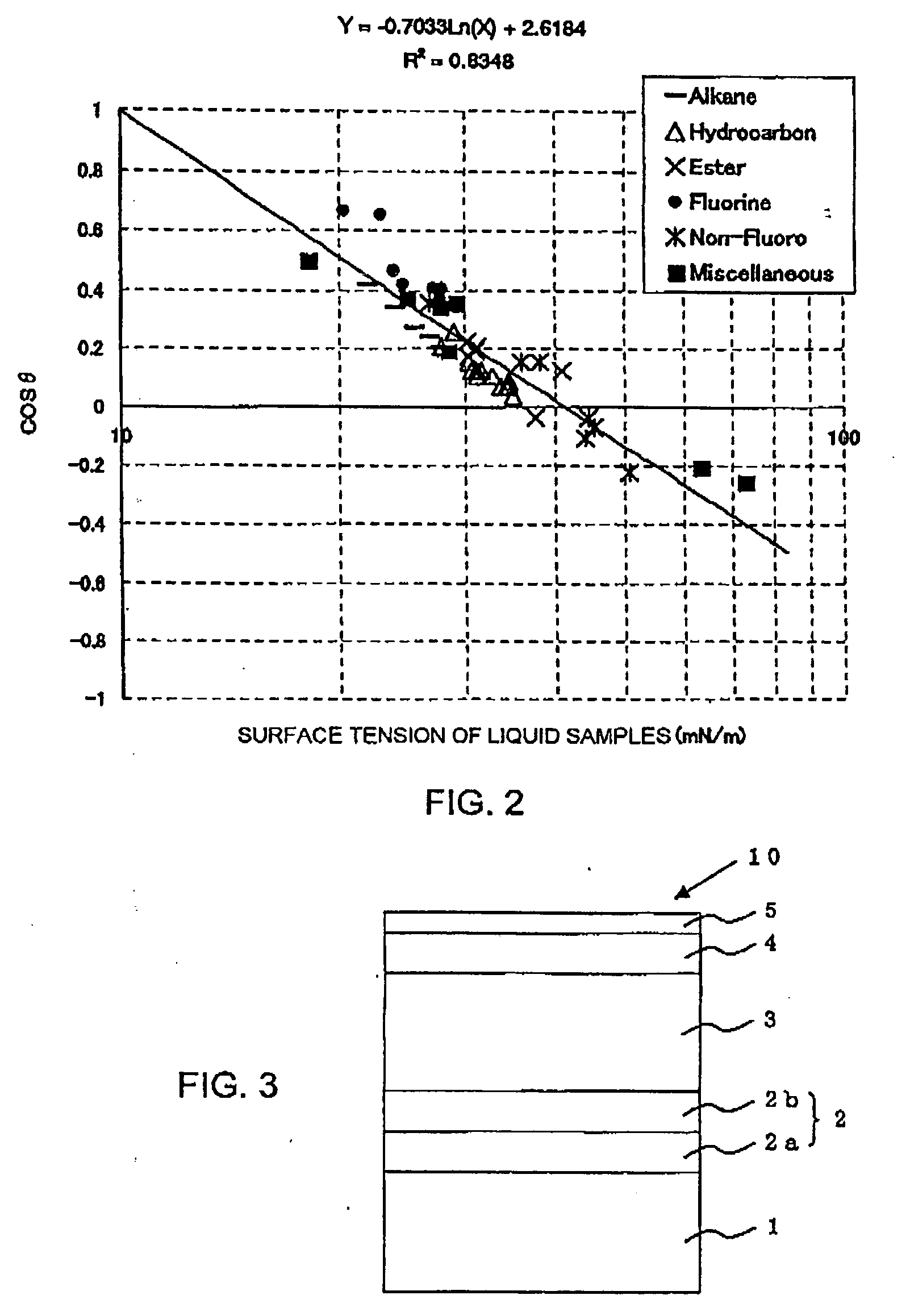

InactiveUS7174775B2Effective tensionSolve the real problemVehicle testingElectronic circuit testingBiomedical engineeringBody surface

In a method of evaluating surface tension of a solid body surface, selection is made of at least three liquid samples having different surface tensions, and contact angles between the respective liquid samples and the solid body surface are measured. Thereby, a correlation between cosines (Y) of the contact angles and surface tensions (X) of the liquid samples is derived as a logarithmic function. Surface tension of the solid body surface is evaluated by the use of a value of X that is calculated by substituting 1 for Y in the correlation. When evaluated by the foregoing evaluation method, a magnetic disk has a surface where the value of X, when 1 is substituted for Y, is greater than 0 and no greater than 17 mN / m.

Owner:WD MEDIA SINGAPORE PTE

Closure medical device

InactiveUS20090062846A1Effective tensionEfficiently pulledSuture equipmentsSurgical veterinaryPuncture WoundMedicine

A closure device for closing a puncture wound has a distal section that can be placed against the interior wall of a vessel and a proximal section that bunches in the tissue tract to close the wound.

Owner:KEN CHRISTOPHER G M

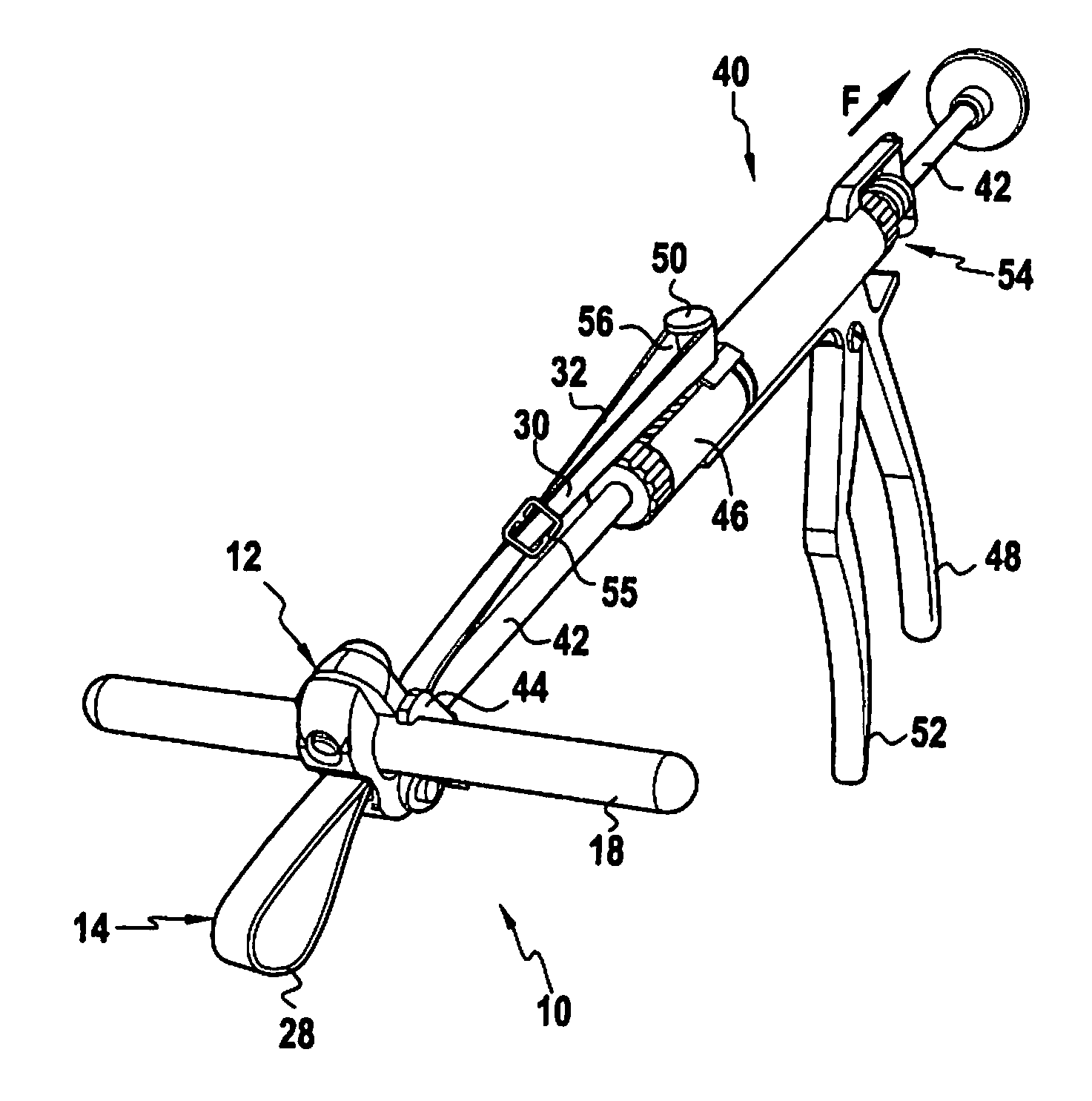

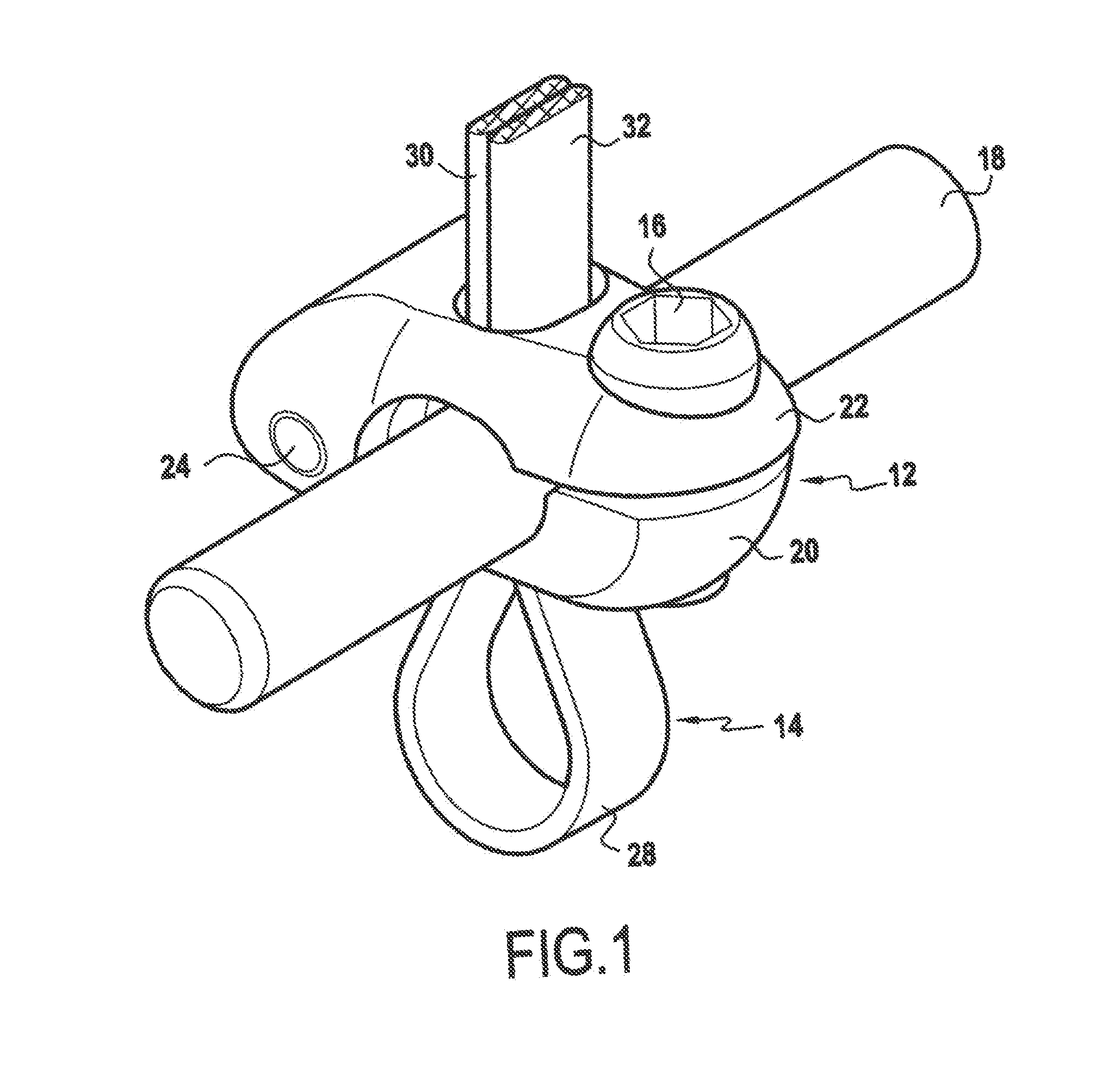

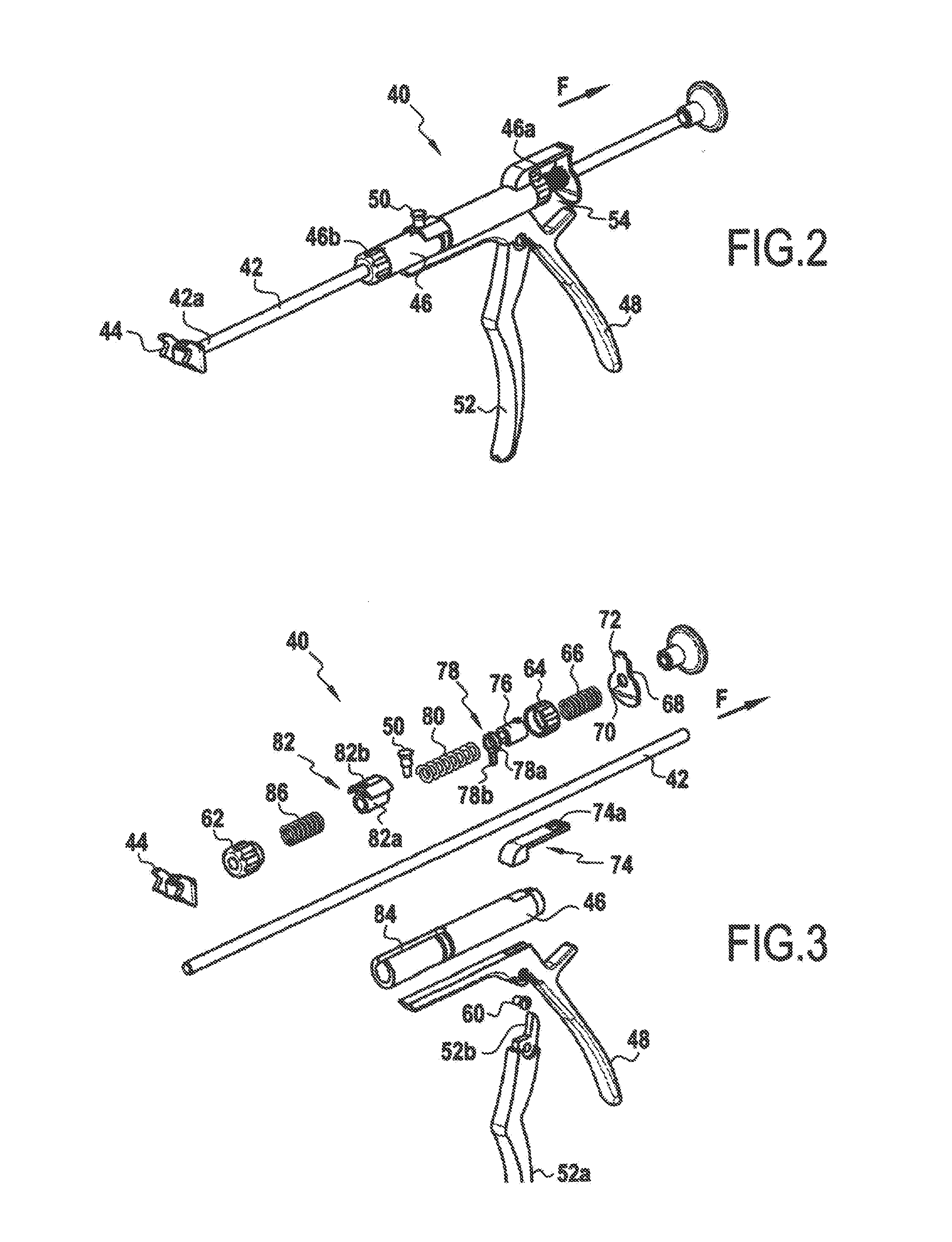

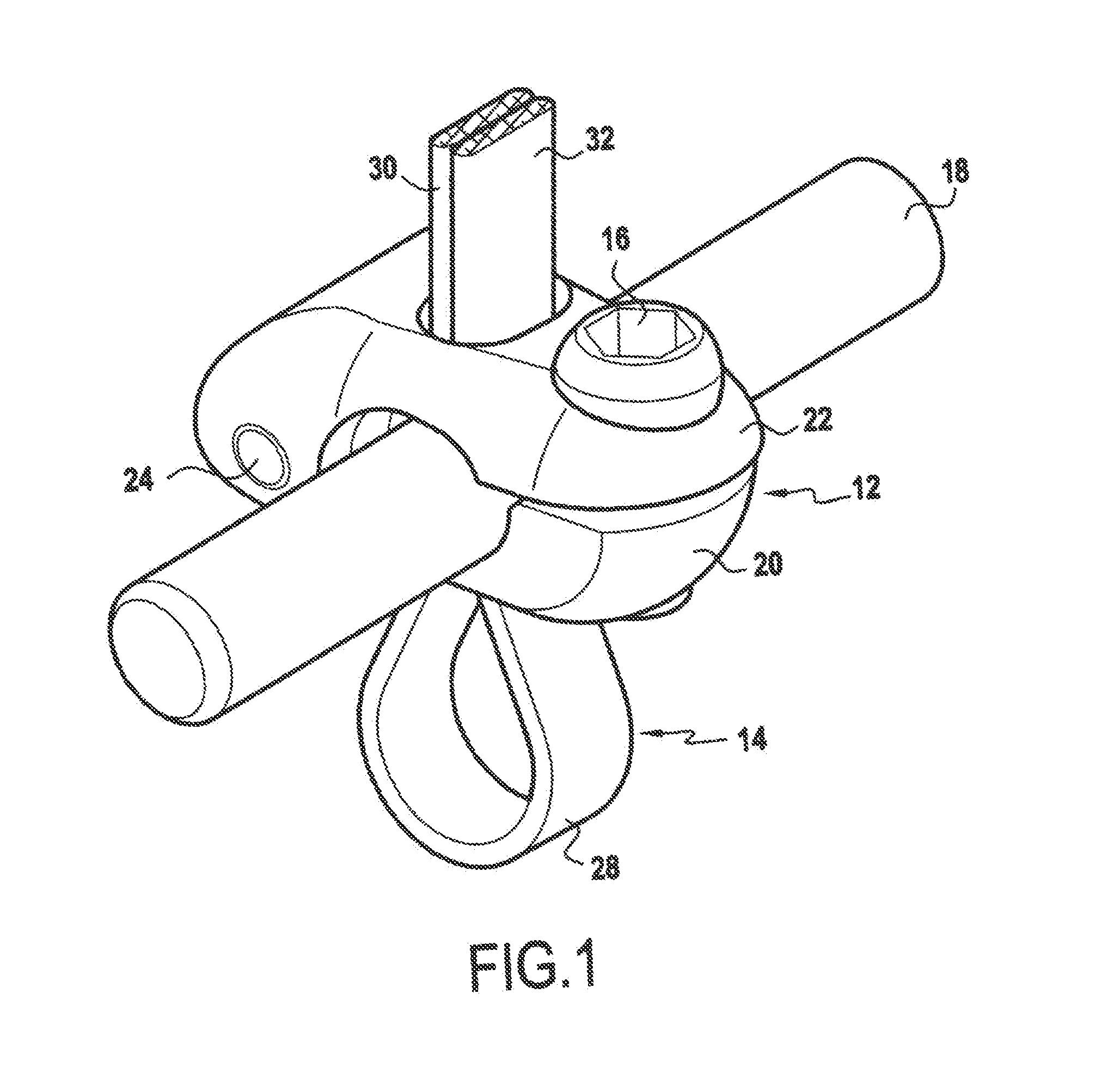

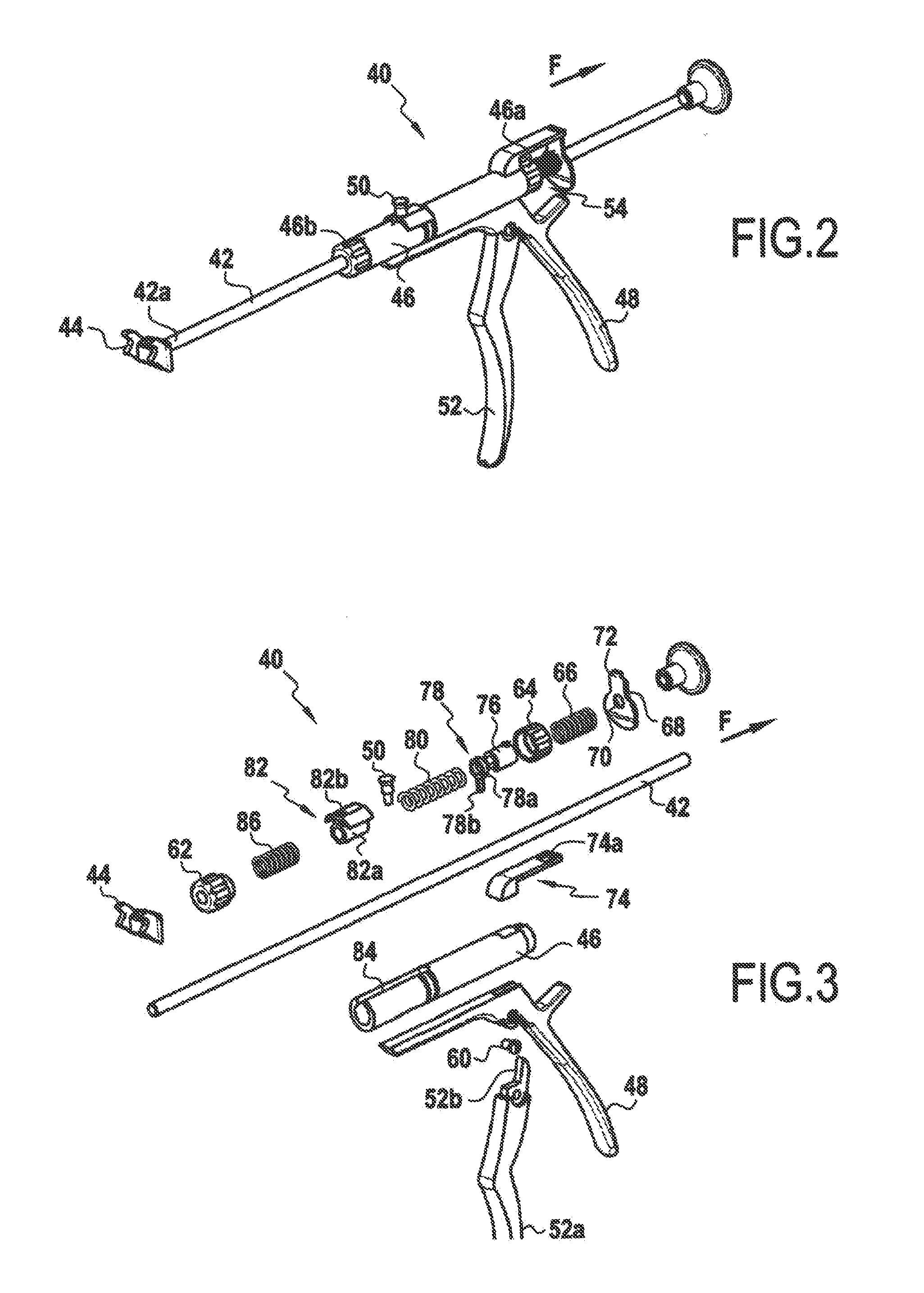

Instrument for tensioning a flexible tie

ActiveUS8162946B2Reduce riskAvoid displacementInternal osteosythesisJoint implantsEngineeringBiomedical engineering

A surgical system for stabilizing at least a portion of a spine is provided. In at least one embodiment, the system comprises a spinal rod, an implant, and an instrument. The instrument comprises a shaft, a moving part, and a holder. The implant comprises a flexible tie and may further comprise a bearing for bearing against the rod. The tie has at least one end that projects out from the implant. The shaft comprises a distal end configured to bear against the implant. The moving part is configured to move in translation with respect to the shaft and comprises an anti-return system. The holder is configured to hold an end of the tie and is connected to the moving part. The anti-return system engages the shaft for temporarily preventing the moving part from moving in translation relative to the shaft.

Owner:ZIMMER SPINE SAS

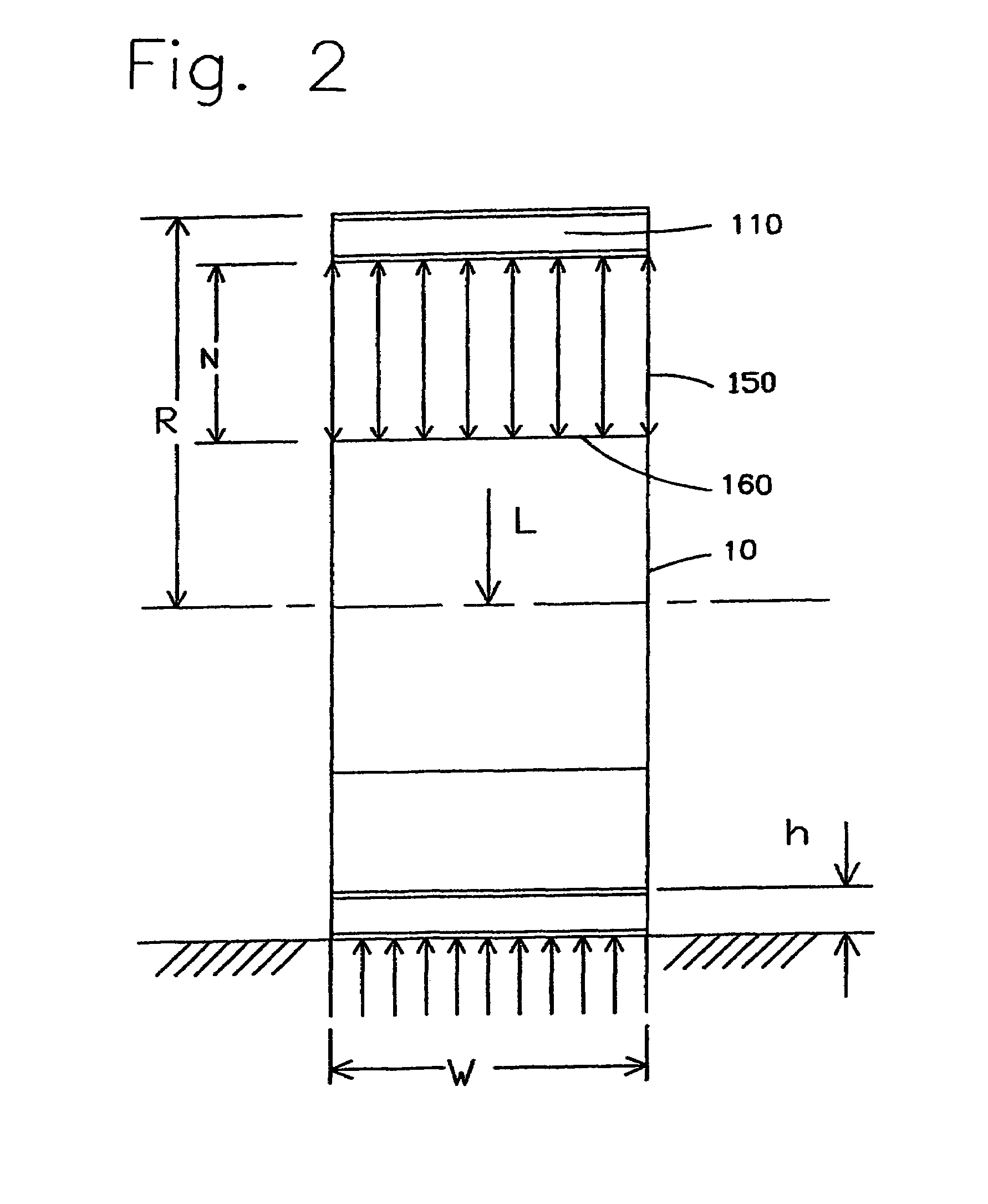

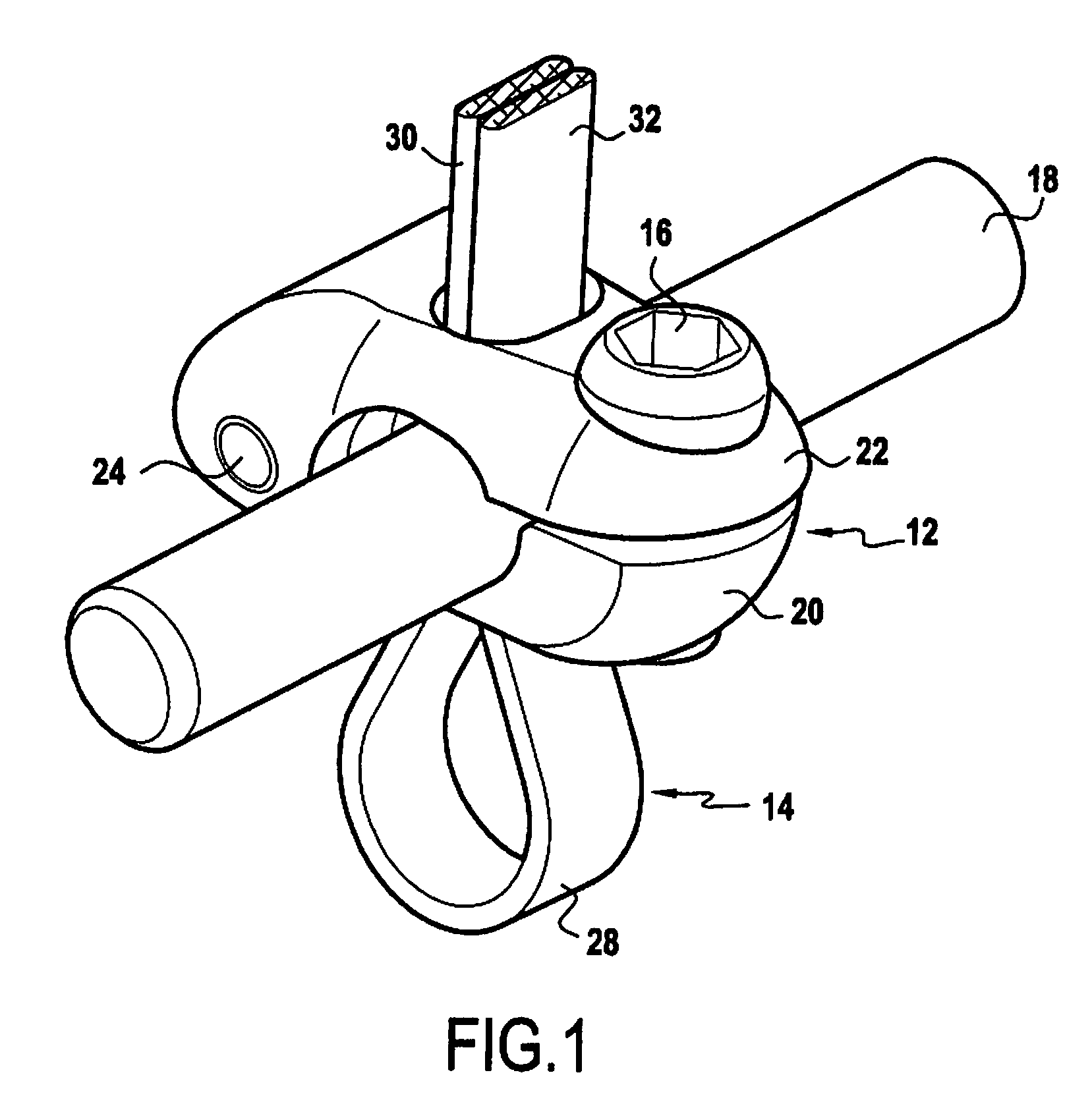

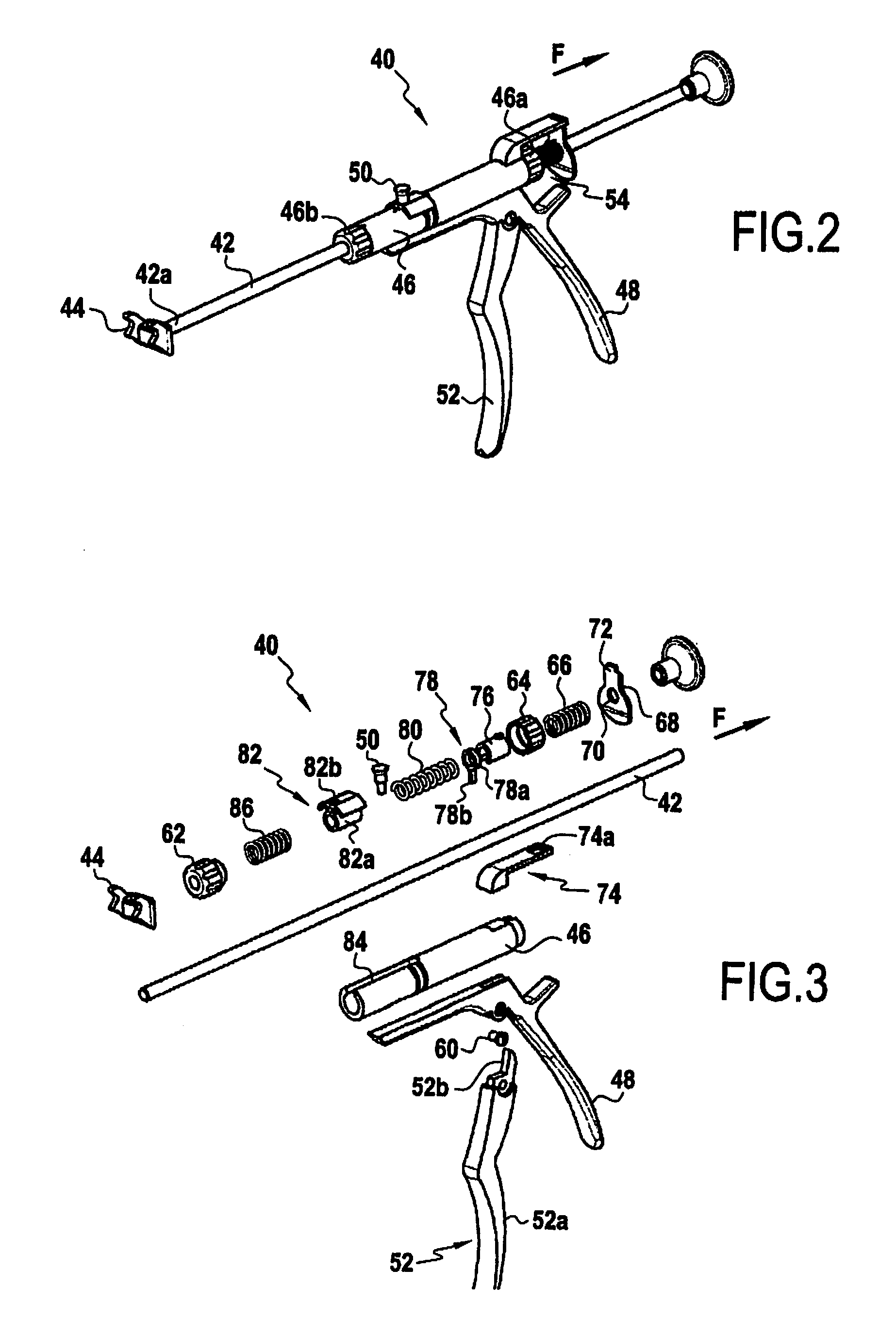

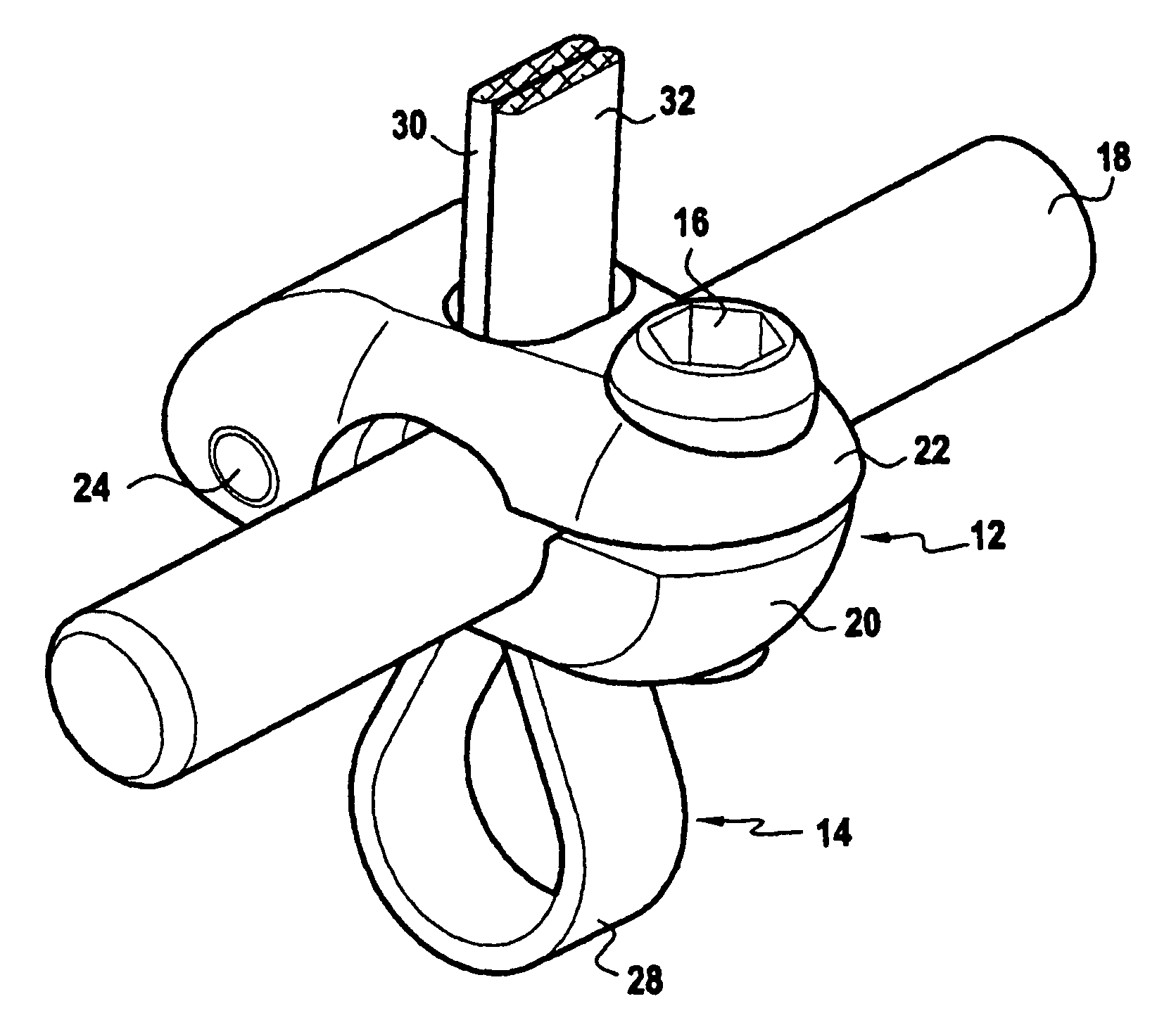

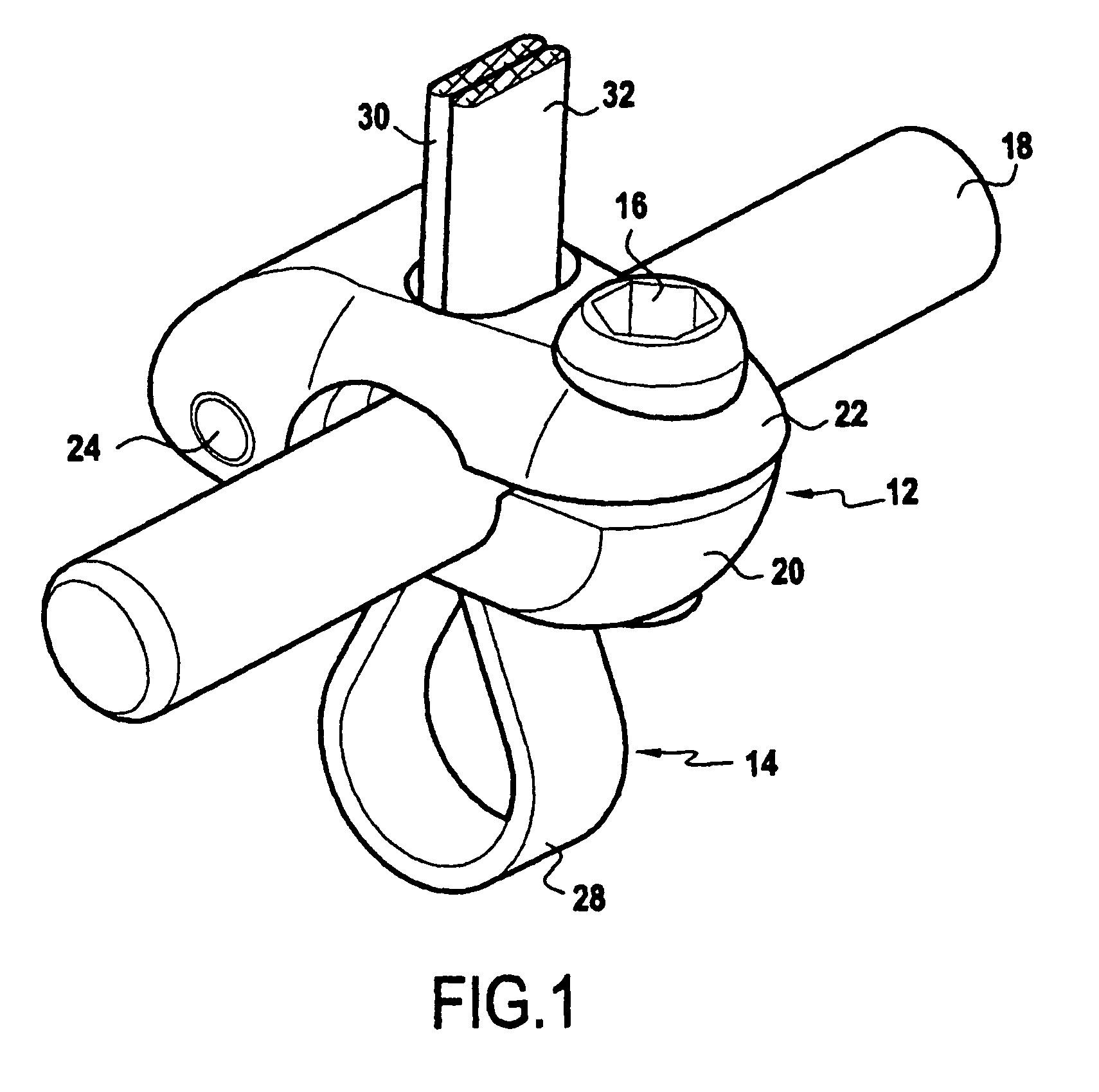

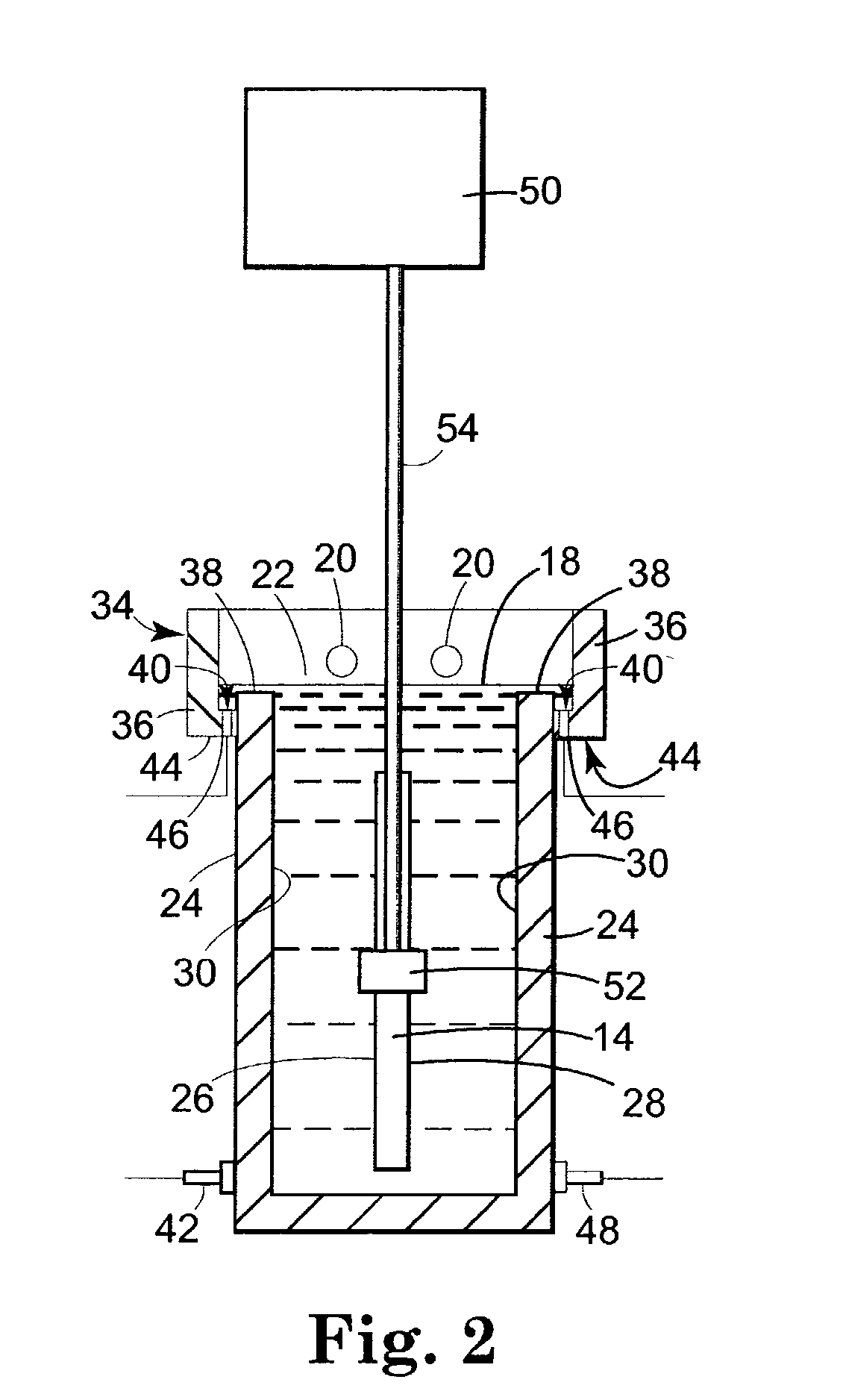

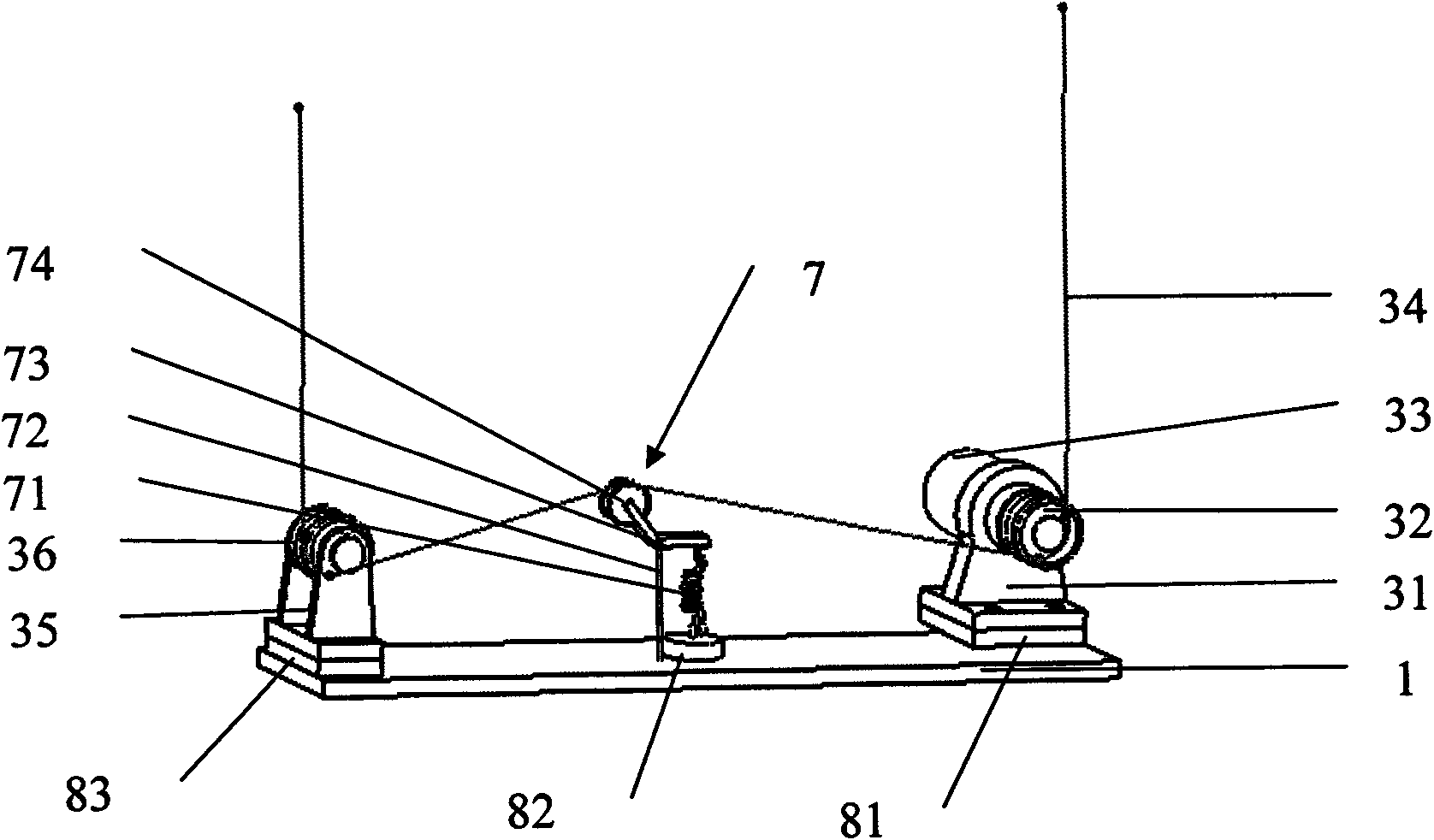

Flexible tie fastening system

InactiveUS8323318B2Reduce riskAvoid displacementInternal osteosythesisJoint implantsImplant fixationMoving parts

The present invention relates to an instrument for tensioning a flexible tie (14) used for fastening an implant on a bony element of a patient by forming a first loop around the bony element. Said instrument comprises:a rod (42) having a first end provided with bearing means (44) for bearing against said implant;a moving part (46) that is movable in translation and that surrounds said rod (42) over a fraction of its length, said moving part including holder means (50) for holding the end of said tie; andcontrol means (52) mounted on said moving part (46) to cause the moving part to move relative to said rod, thereby tending to move the first end (42a) of the rod away from said moving part, thereby exerting tension on said tie relative to said implant.

Owner:LDR MEDICAL SAS

Devices, systems, and methods for reshaping a heat valve annulus

ActiveUS20090306622A1Recovery functionReshape the heart valve annulusDiagnosticsAnnuloplasty ringsSystoleSurgical department

Devices, systems, and methods employ an implant that is sized and configured to attach to the annulus of a dysfunctional heart valve annulus. In use, the implant extends across the major axis of the annulus above and / or along the valve annulus. The implant reshapes the major axis dimension and / or other surrounding anatomic structures. The implant restores to the heart valve annulus and leaflets a more functional anatomic shape and tension. The more functional anatomic shape and tension are conducive to coaptation of the leaflets during systole, which, in turn, reduces regurgitation. The implant improves function to the valve, without surgically cinching, resecting, and / or fixing in position large portions of a dilated annulus, or without the surgical fixation of ring-like structures.

Owner:MVRX INC +1

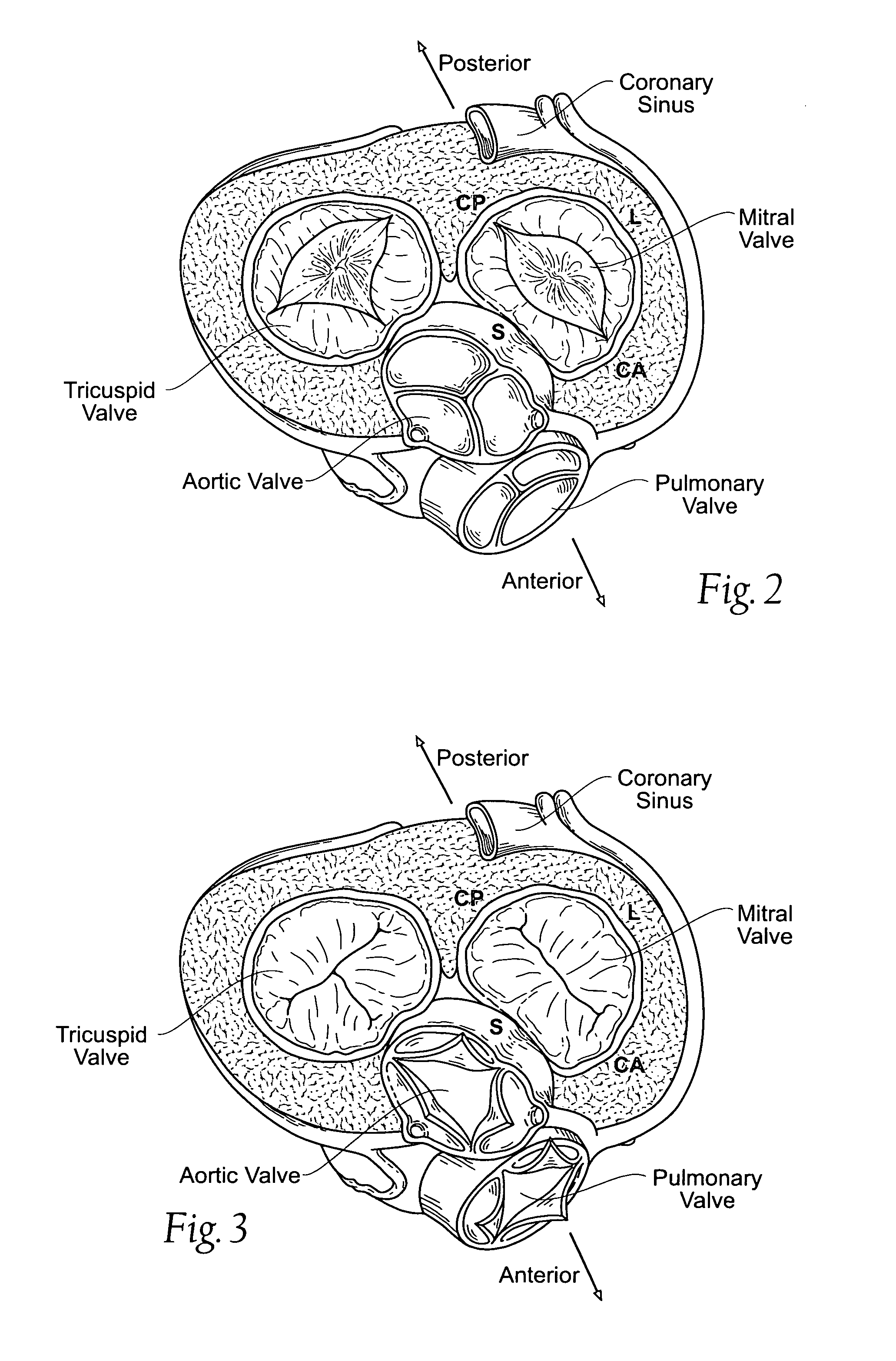

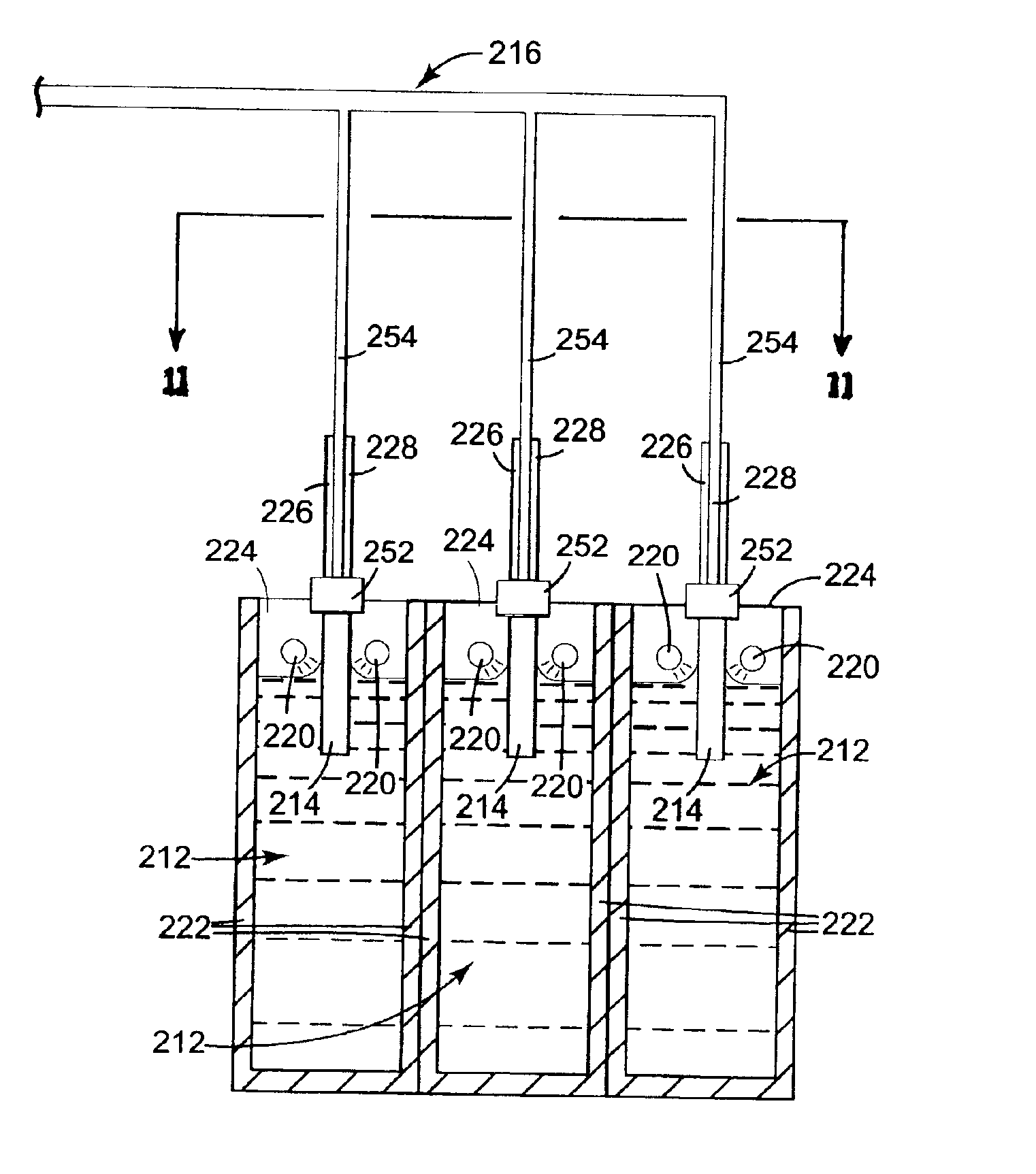

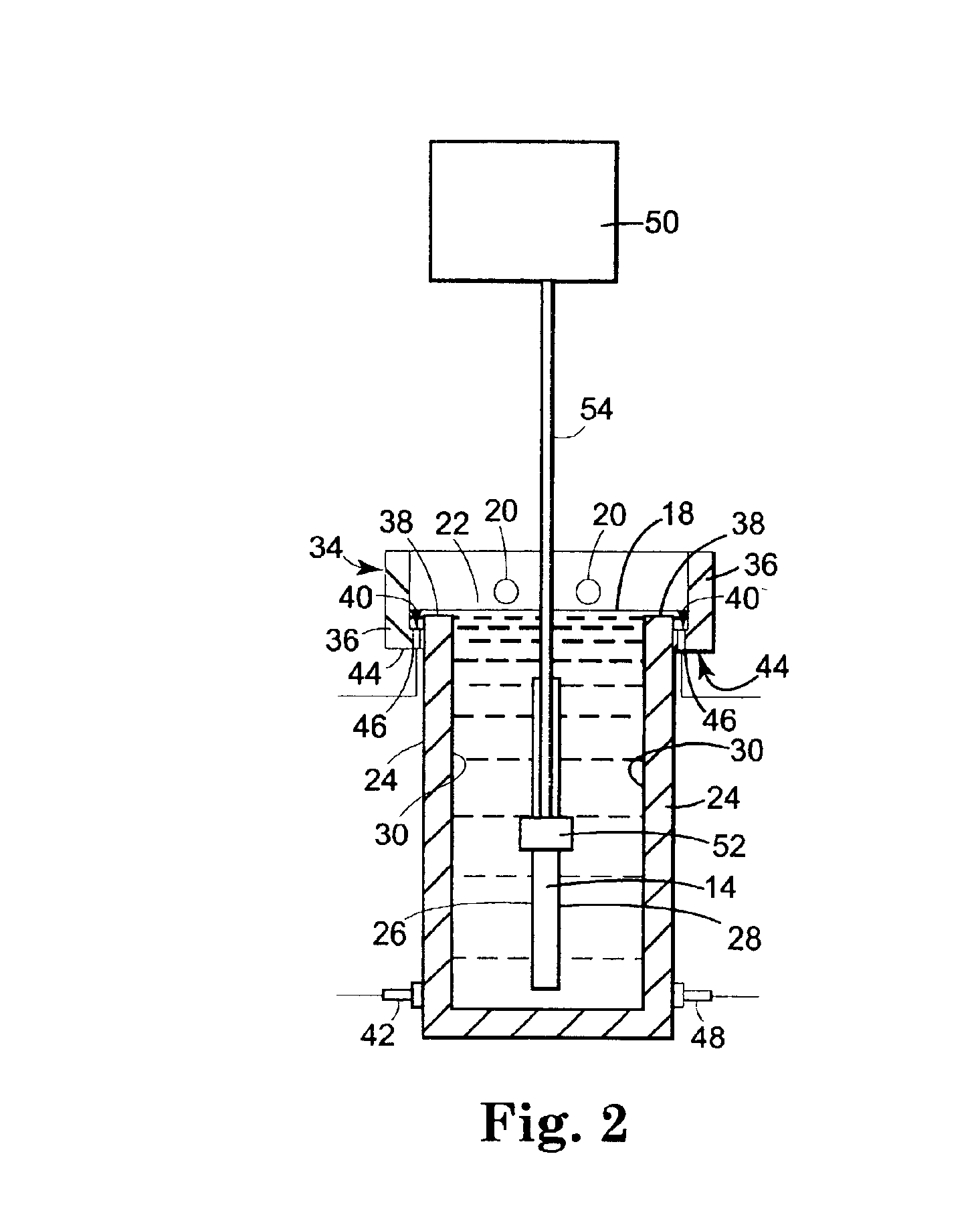

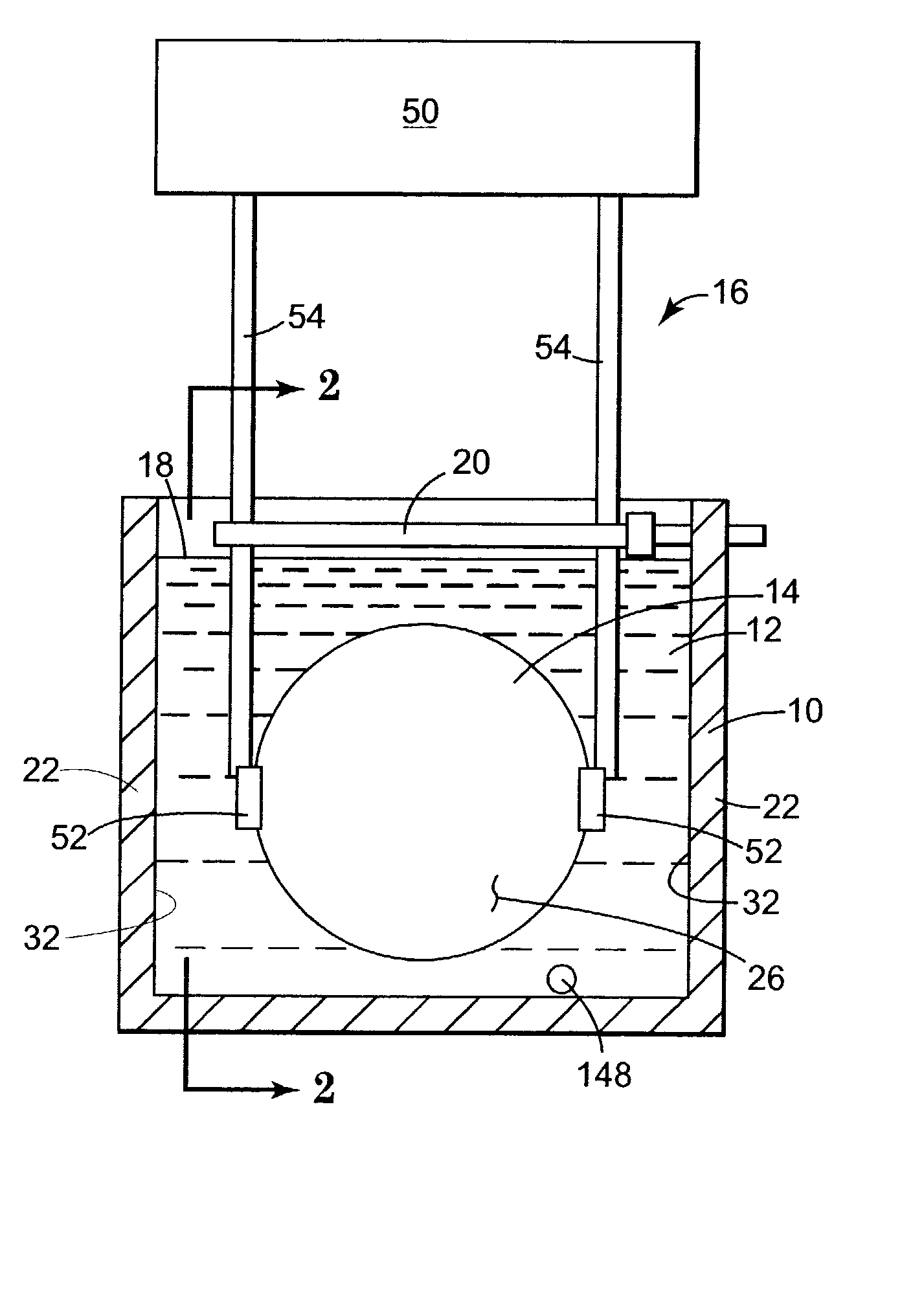

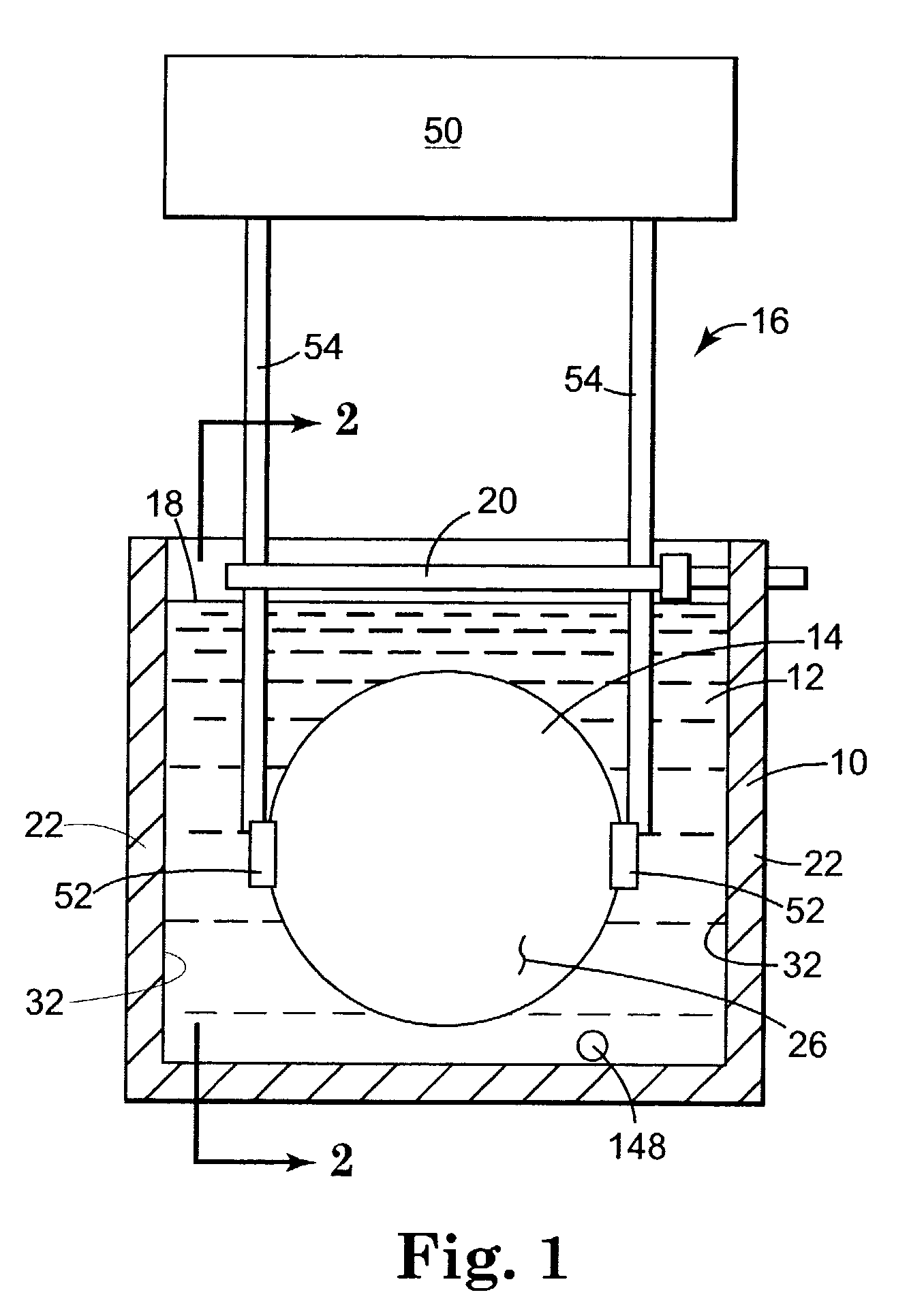

Semiconductor wafer cleaning systems and methods

InactiveUS6875289B2Improve efficiencySubstance may accumulateDrying solid materials with heatReconditioning/cleaning record carriersEngineeringDelivery system

An immersion processing system is provided for cleaning wafers with an increased efficiency of chemical use. Such a system advantageously uses less cleaning enhancement substance that may be provided as gas, vapor or liquid directly to a meniscus or wafer / liquid / gas bath interface so as to effectively modify surface tensions at the meniscus with minimized chemical usage. Such a delivery system design may be applied for single wafer processing or for processing multiple wafers together within a single liquid bath vessel. For single wafer processing, in particular, cleaning enhancement substance can be delivered along one or both major sides of the wafer, preferably at the meniscus that is formed as the wafer and liquid are relatively moved, while a processing vessel usable for such single wafer processing may itself be designed with a minimized size to accommodate a single wafer. By reducing the vessel volume, chemical usage for any processing chemicals that are to be provided within a liquid bath may also be advantageously reduced.

Owner:TEL EPION

Semiconductor wafer cleaning systems and methods

InactiveUS20040050405A1Improve efficiencyMinimized chemical usageDrying solid materials with heatReconditioning/cleaning record carriersEngineeringDelivery system

An immersion processing system is provided for cleaning wafers with an increased efficiency of chemical use. Such a system advantageously uses less cleaning enhancement substance that may be provided as gas, vapor or liquid directly to a meniscus or wafer / liquid / gas bath interface so as to effectively modify surface tensions at the meniscus with minimized chemical usage. Such a delivery system design may be applied for single wafer processing or for processing multiple wafers together within a single liquid bath vessel. For single wafer processing, in particular, cleaning enhancement substance can be delivered along one or both major sides of the wafer, preferably at the meniscus that is formed as the wafer and liquid are relatively moved, while a processing vessel usable for such single wafer processing may itself be designed with a minimized size to accommodate a single wafer. By reducing the vessel volume, chemical usage for any processing chemicals that are to be provided within a liquid bath may also be advantageously reduced.

Owner:TEL EPION

Spinal implant with flexible tie

ActiveUS20110238118A1Avoid breakageReduce riskInternal osteosythesisJoint implantsSpinal implantFixed position

A spinal implant can be fastened on a bony element of a patient via a flexible tie. In some embodiments, the spinal implant has two jaws, each having a recess and an opening. The recess is configured to receive a portion of a rod. A portion of the flexible tie is passed through the opening and between a wall of the recess and a surface of the rod to form a loop that can be placed around the bony element. The two jaws are hinged at one end and engaged at the opposite end via a locking member. The locking member can be adjusted to simultaneously hold the jaws together in a fixed position relative to the rod and lock the flexible tie, which has been properly tensioned, in translation relative to the spinal implant.

Owner:ZIMMER SPINE SAS

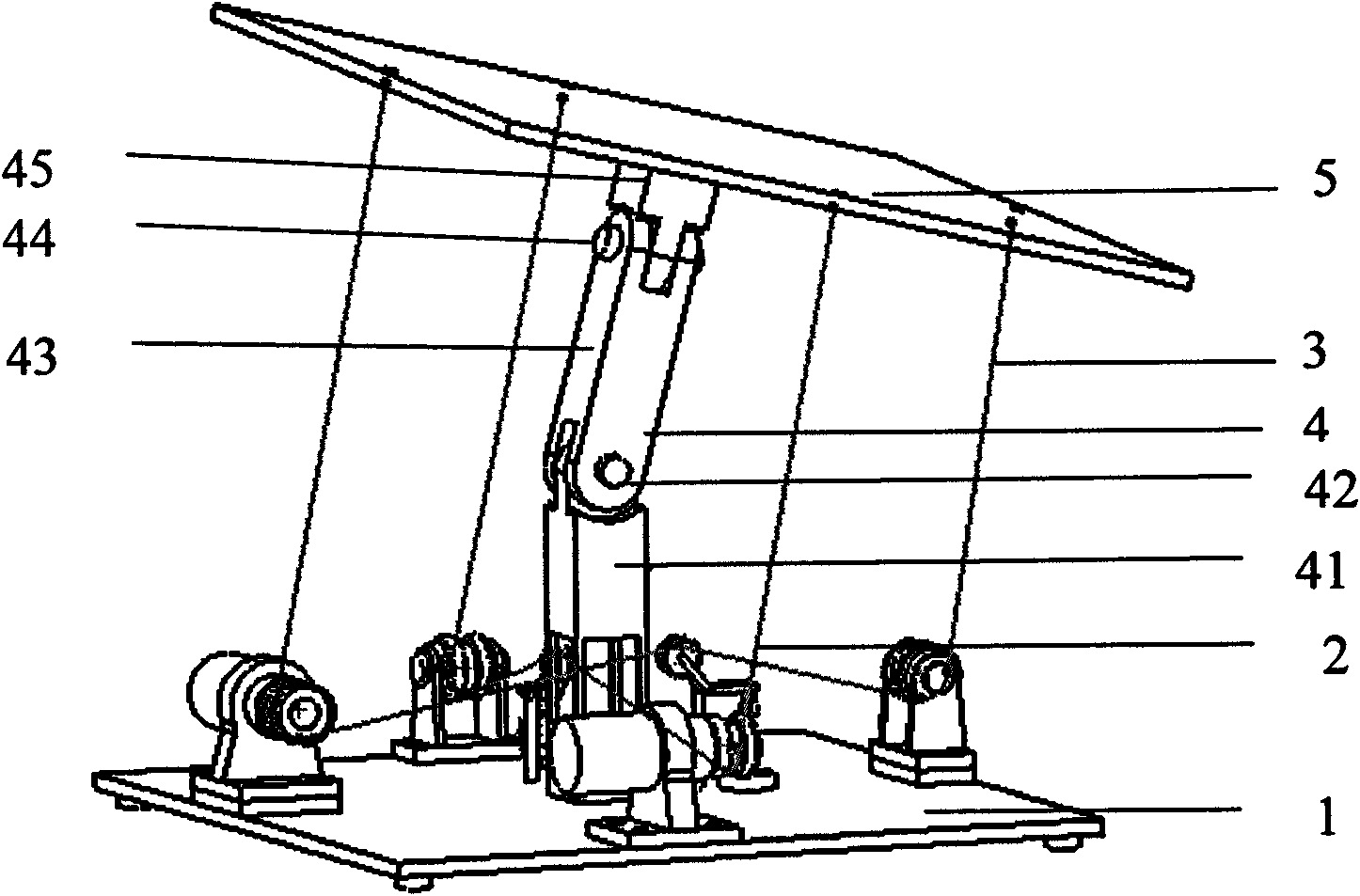

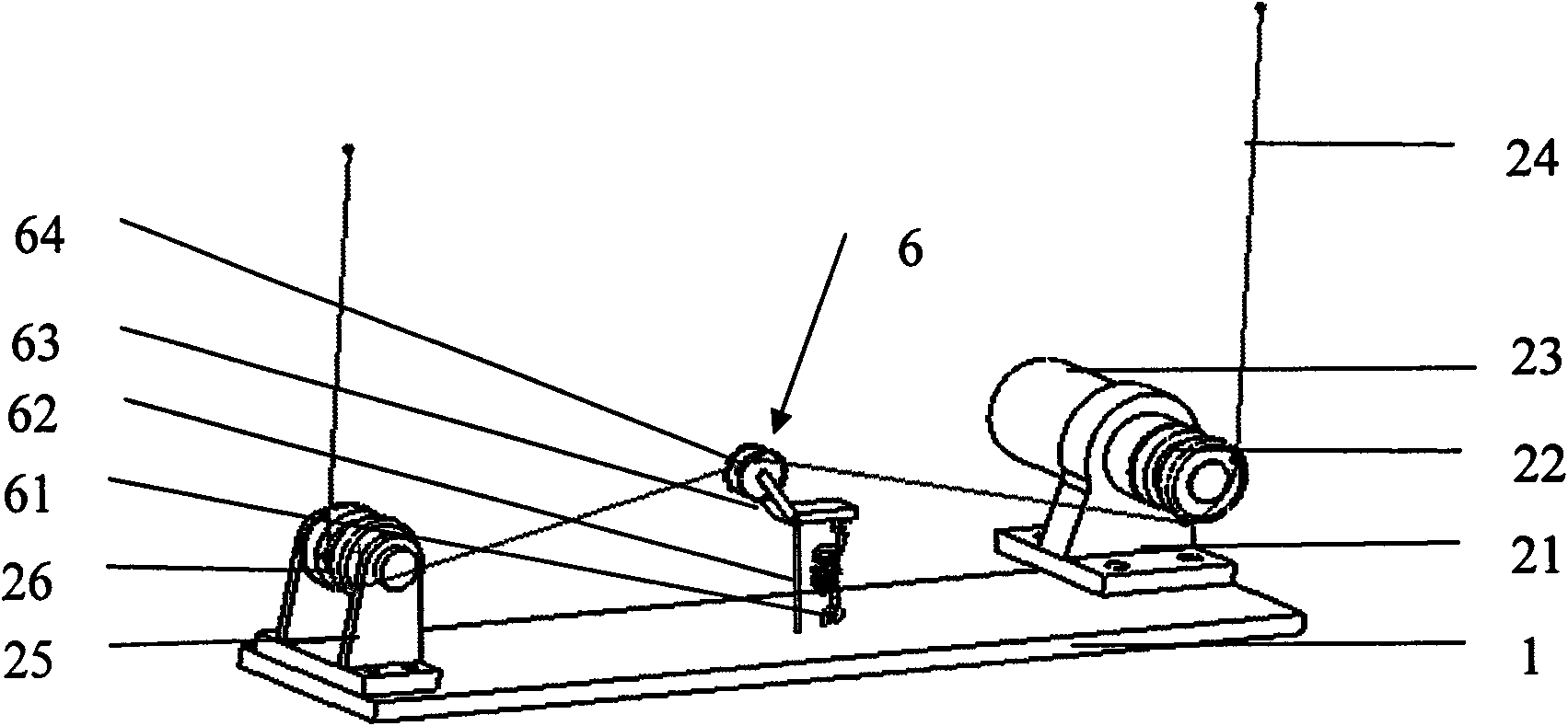

Two-degree freedom rope traction and parallel-connection mechanism

InactiveCN101664924AEffective tensionAvoid redundant drivesProgramme-controlled manipulatorMotor driveEngineering

The invention relates to a two-degree freedom rope traction and parallel-connection mechanism which comprises a rack and a dynamic platform. The mechanism is characterized by also comprising an intermediate branched chain and two groups of rope traction branched chains, the intermediate branched chain is formed by hinging two rotational joints which are vertical mutually and is installed at the center position between the rack and the dynamic platform; the two groups of rope traction branched chains have the same structures and are installed between the rack and the dynamic platform in a crossway by taking the intermediate branched chain as a center, and each group of rope traction branched chains is driven by a motor fixed on the rack, and the motor drives a rope to drive the dynamic platform through a tension mechanism and a pulley mechanism to rotate around the intermediate branched chain, thereby realizing that the dynamic platform can rotate in two mutually vertical directions. The invention is a non-redundant drive and has simple mechanism and can be controlled easily.

Owner:天津捷力安建筑机械有限公司

Devices, systems, and methods for reshaping a heart valve annulus

ActiveUS9861475B2Recovery functionReshape the heart valve annulusDiagnosticsAnnuloplasty ringsSystoleHeart valve

Devices, systems, and methods employ an implant that is sized and configured to attach to the annulus of a dysfunctional heart valve annulus. In use, the implant extends across the major axis of the annulus above and / or along the valve annulus. The implant reshapes the major axis dimension and / or other surrounding anatomic structures. The implant restores to the heart valve annulus and leaflets a more functional anatomic shape and tension. The more functional anatomic shape and tension are conducive to coaptation of the leaflets during systole, which, in turn, reduces regurgitation. The implant improves function to the valve, without surgically cinching, resecting, and / or fixing in position large portions of a dilated annulus, or without the surgical fixation of ring-like structures.

Owner:MVRX INC +1

Closure medical device

InactiveUS20090062848A1Effective tensionEfficiently pulledSuture equipmentsSurgical veterinaryPuncture WoundMedical device

A closure device for closing a puncture wound has a distal section that can be placed against the interior wall of a vessel and a proximal section that bunches in the tissue tract to close the wound. One variation of the device provides for removing the distal section from the vessel so that it resides also in the tissue tract after the proximal section has been securely bunched and lodged within the tissue tract in order to provide unobstructed fluid flow in the vessel.

Owner:KEN CHRISTOPHER G M

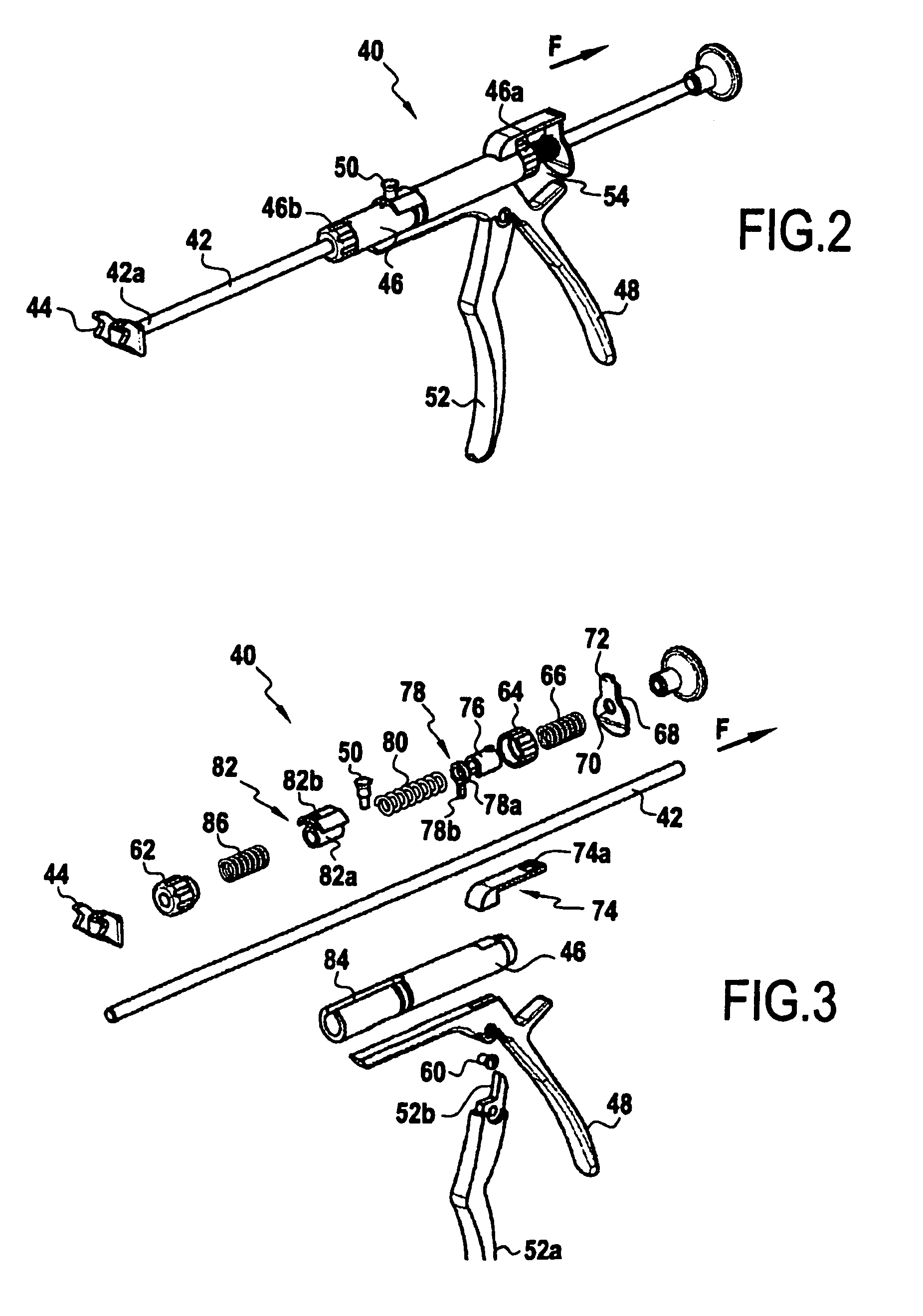

Method and instrument for tensioning a flexible tie

A method and instrument for tensioning a flexible tie used for fastening an implant on a bony element by forming a first loop around it. In some embodiments, the instrument comprises a shaft having a distal end configured for contact with a rod, a moving part slidably engaged with the shaft, a holder connected to the moving part and configured to hold an end of the flexible tie, and a tension control member comprising a trigger that pivots relative to the moving part. In some embodiments, the method comprises coupling the end of the flexible tie to the instrument and squeezing the trigger to shorten the first loop of the flexible tie around the bony element, causing the moving part and the holder holding the end of the flexible tie to move in translation away from the distal end of the shaft, thereby exerting tension on the flexible tie.

Owner:ZIMMER SPINE SAS

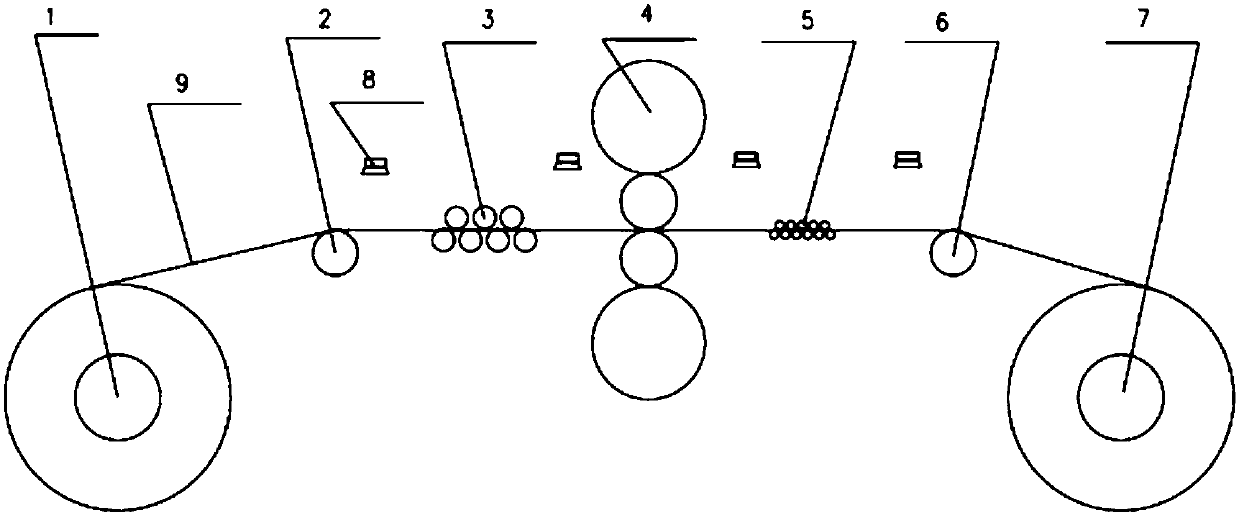

High-strength strip steel straightening, flattening and straightening process

ActiveCN107838199AReduce loadEasy to shapeProfile control deviceMetal rolling arrangementsStrip steelResidual stress

The invention discloses a high-strength strip steel straightening, flattening and straightening process. The high-strength strip steel straightening, flattening and straightening process is characterized in that a hot rolling high-strength steel plate or strip steel sequentially passes through an inlet straightening machine, a temper mill and an outlet straightening machine, and by means of the combined working procedures of straightening, flattening and straightening, the adjustment of the plate shape, the surface quality, the mechanical performance and the residual stress of the strip steelis completed; the inlet straightening machine is used for conducting rough straightening on the strip steel, on the one hand, the plate shape of the supplied material is improved, and on the other hand, the scale on the surface of the strip steel is reduced; the temper mill is used for conducting flattening on the strip steel, the plate shape of the strip steel is improved, the mechanical performance of the strip steel is adjusted, and the surface quality of the strip steel is improved; and the outlet straightening machine is used for conducting precise straightening on the strip steel, the unquenched plate shape problems and newly-generated plate shape problems in the flattening process are solved, and the unquenched residual stress and newly-generated residual stress in the flattening process are eliminated.

Owner:WISDRI ENG & RES INC LTD

Solid body surface evaluation method, magnetic disk evaluation method, magnetic disk, and manufacturing method thereof

InactiveUS20050217353A1Effective tensionSolve the real problemVehicle testingElectronic circuit testingBiomedical engineeringBody surface

In a method of evaluating surface tension of a solid body surface, selection is made of at least three liquid samples having different surface tensions, and contact angles between the respective liquid samples and the solid body surface are measured. Thereby, a correlation between cosines (Y) of the contact angles and surface tensions (X) of the liquid samples is derived as a logarithmic function. Surface tension of the solid body surface is evaluated by the use of a value of X that is calculated by substituting 1 for Y in the correlation. When evaluated by the foregoing evaluation method, a magnetic disk has a surface where the value of X, when 1 is substituted for Y, is greater than 0 and no greater than 17 mN / m.

Owner:WD MEDIA SINGAPORE PTE

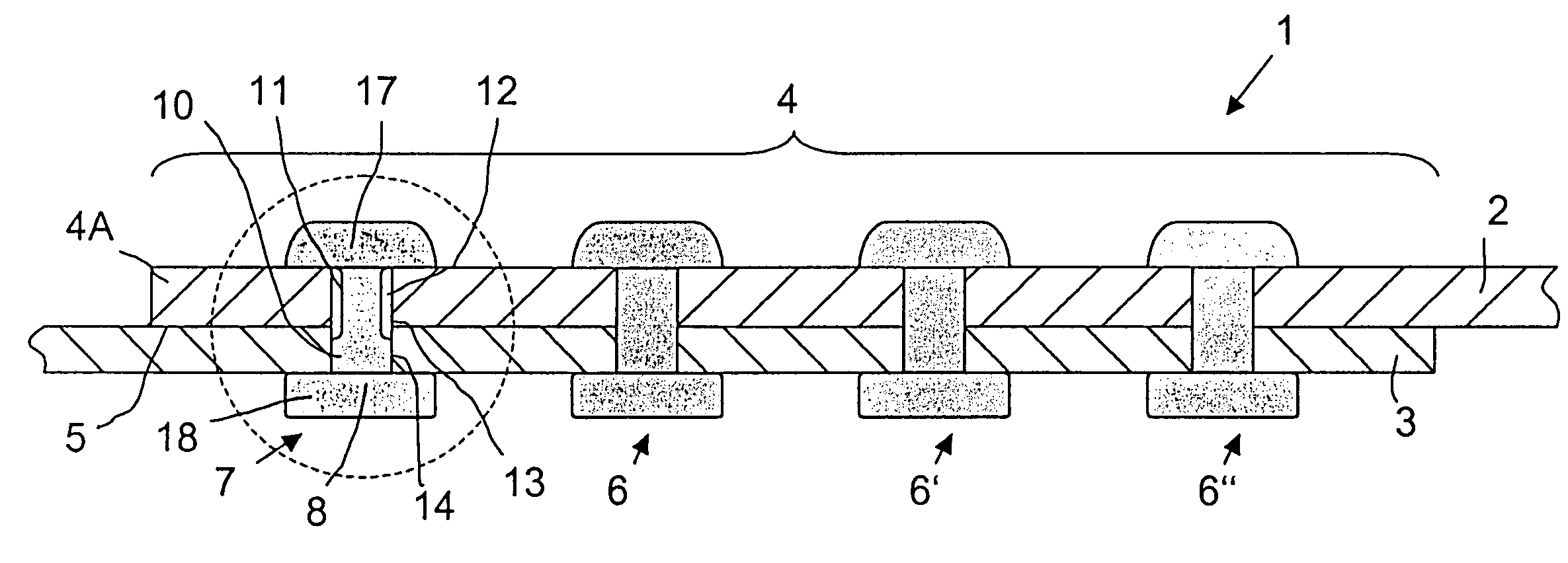

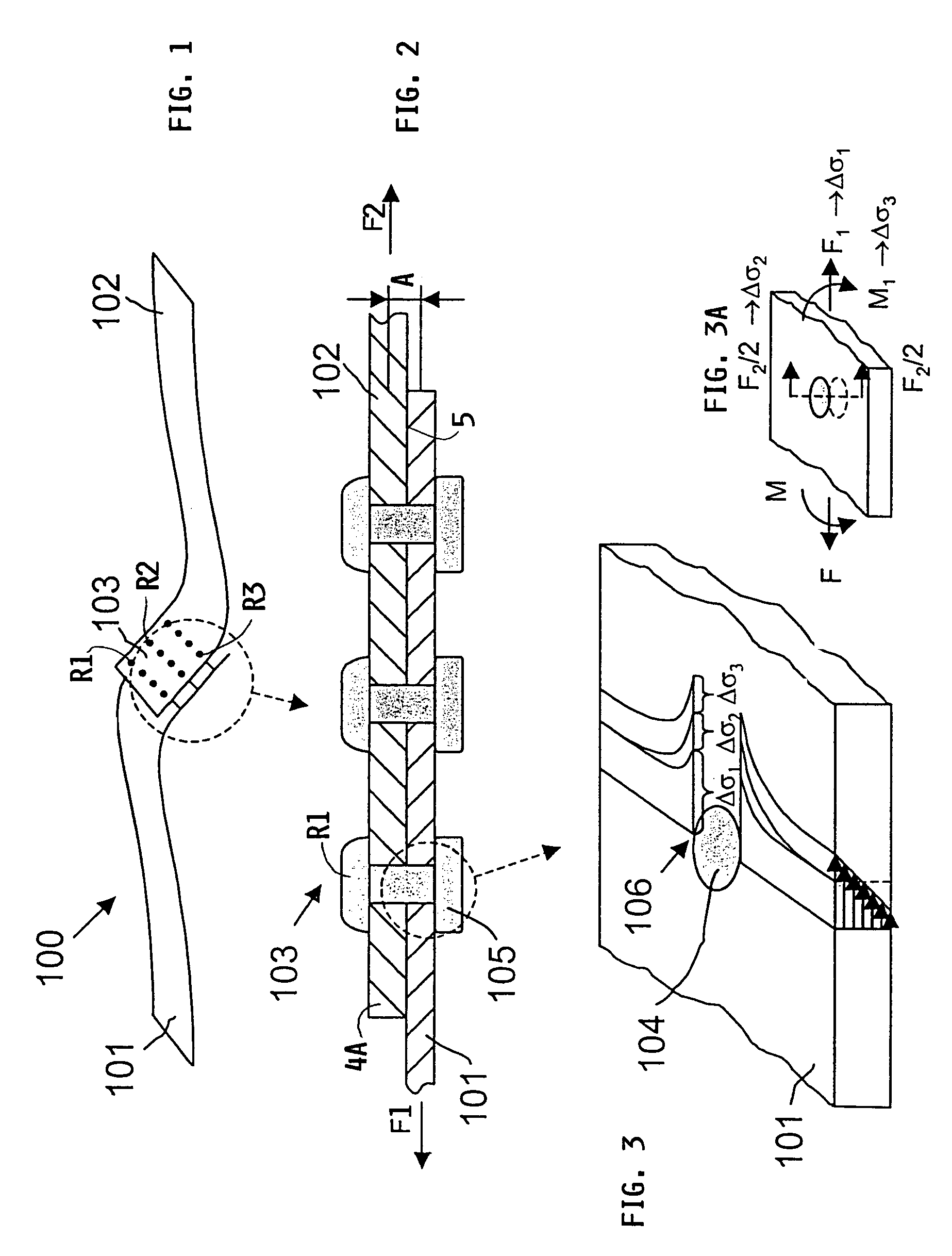

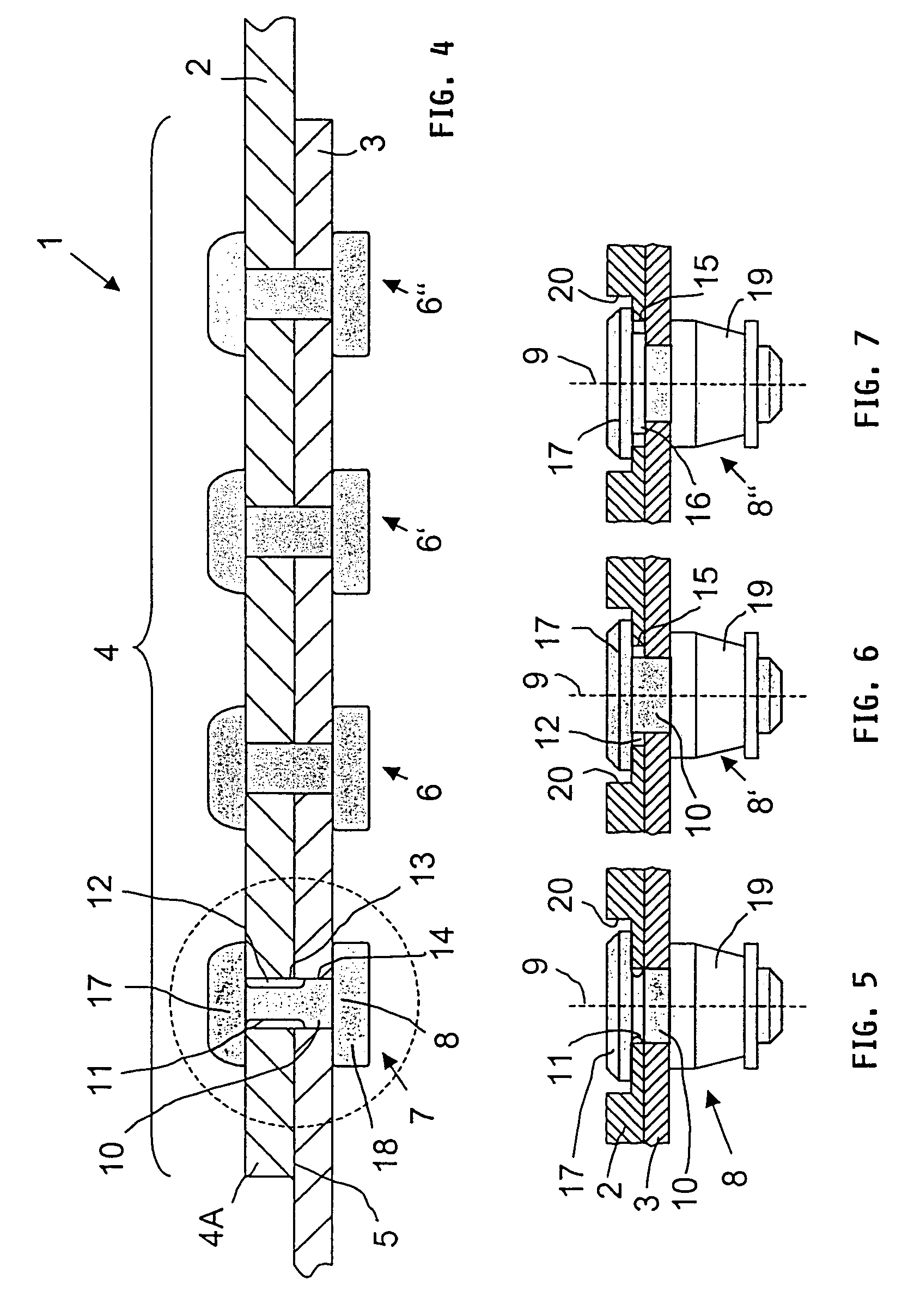

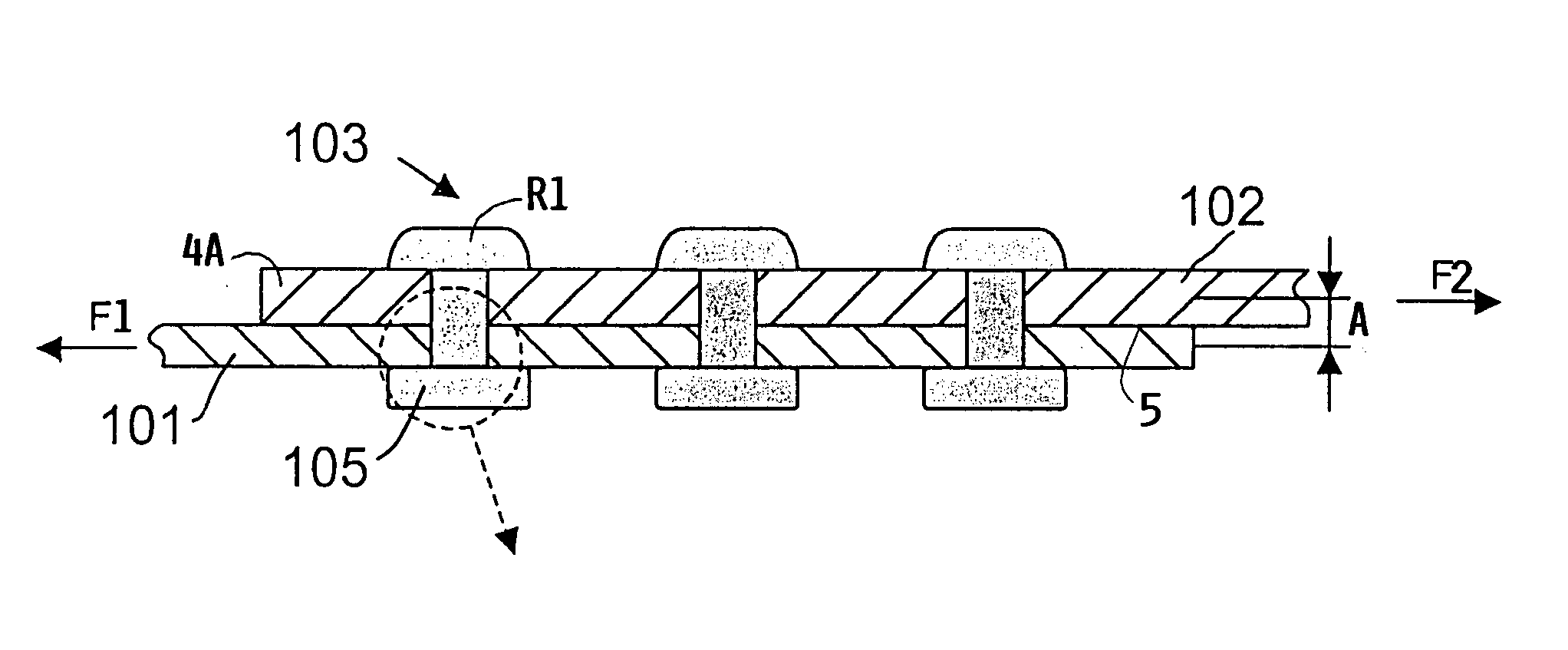

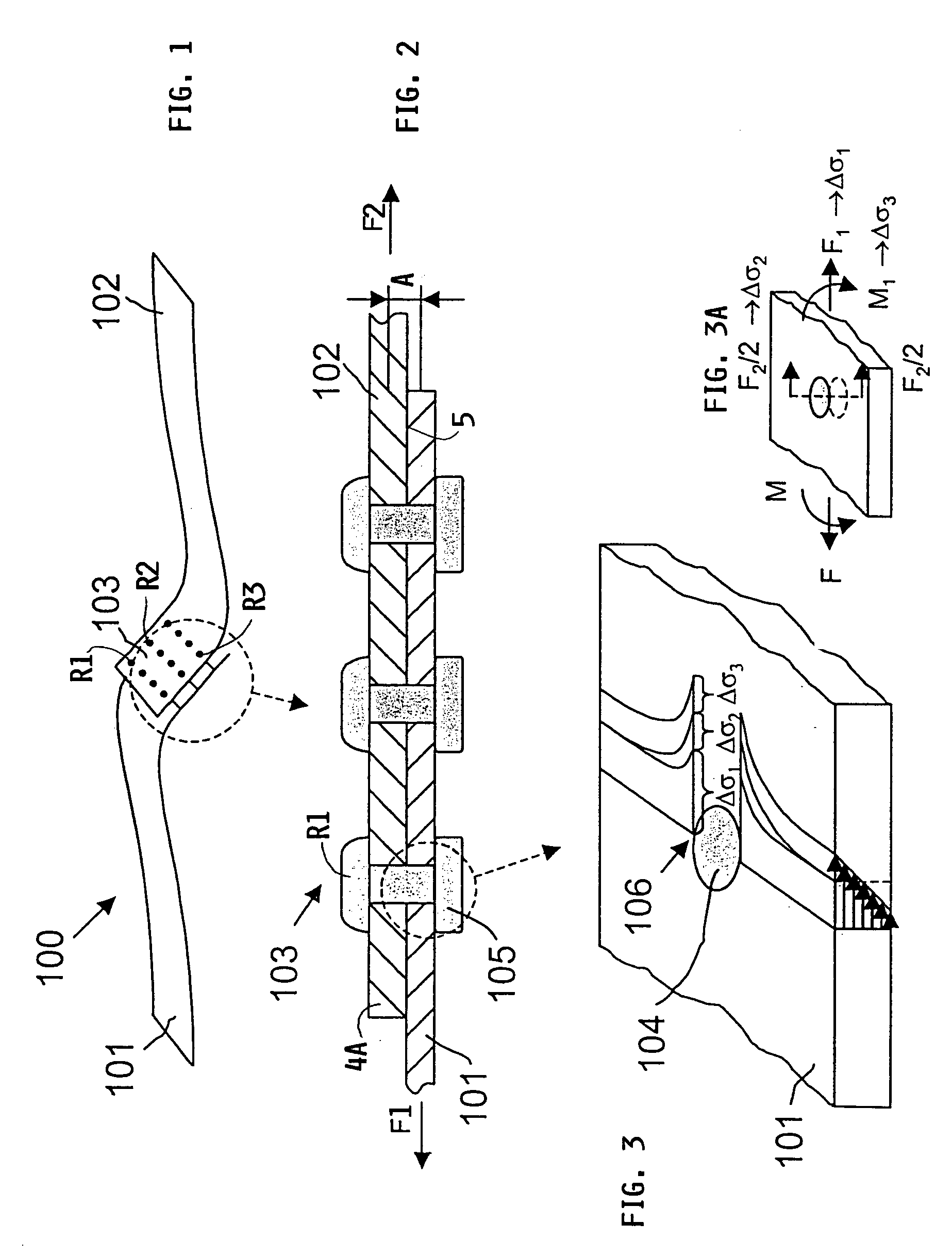

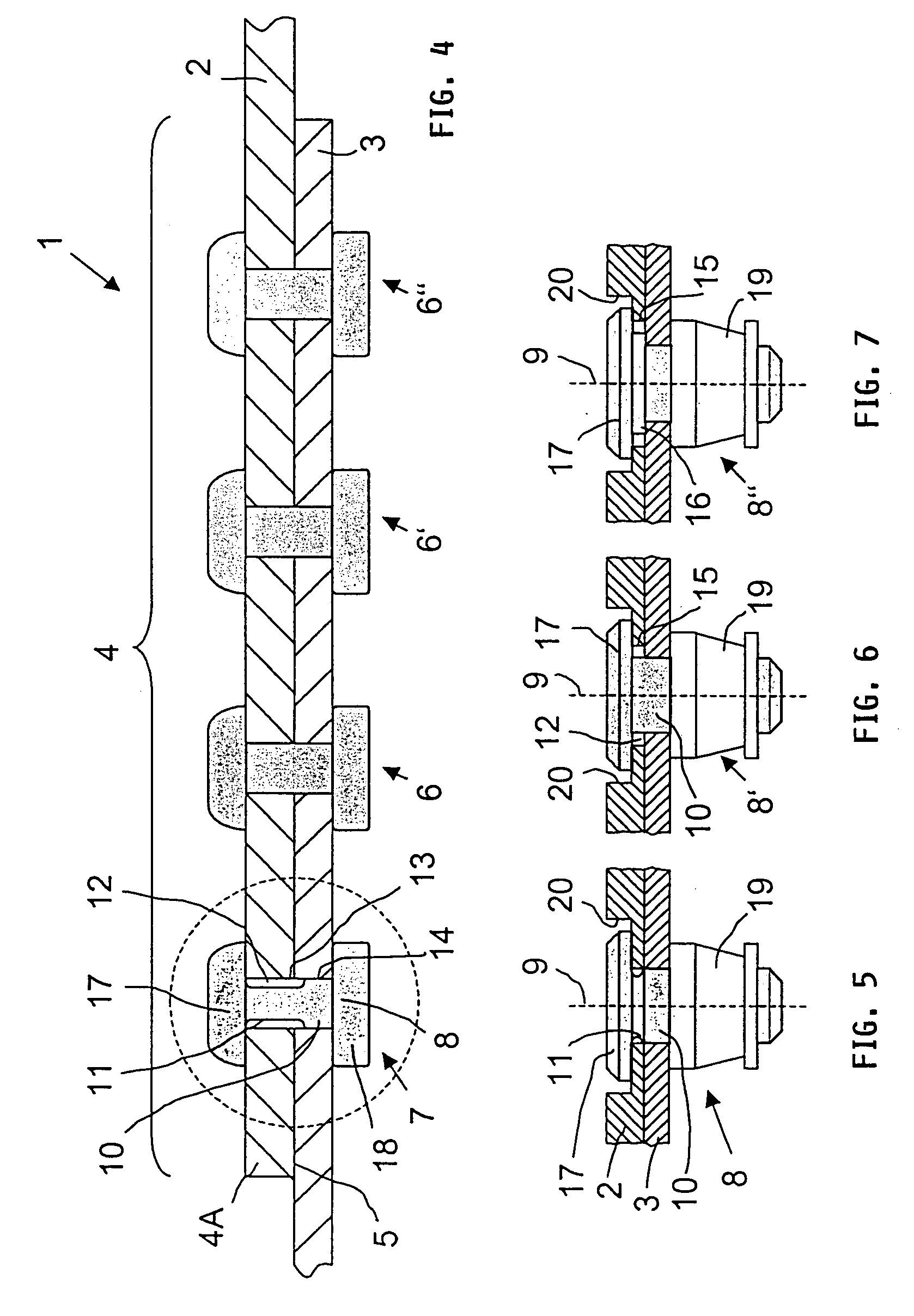

Splicing for interconnected thin-walled metal structures

A rivet splice that holds an upper and a lower sheet metal end portion together includes at least one row (6) of rivets that is subject to dynamic loads and a further row (7) of rivets that holds the sheet metal end portions together so that a limited sliding motion between the sheet metal end portions is possible. The further row (7) of rivets is positioned between an end edge (4A) of an upper sheet metal end portion and the at least one row (6) of rivets. The limited sliding motion provides a load relief of the at least one row of rivets thereby reducing the starting of cracks at the walls of the rivet holes and impeding the spreading of cracks.

Owner:AIRBUS OPERATIONS GMBH

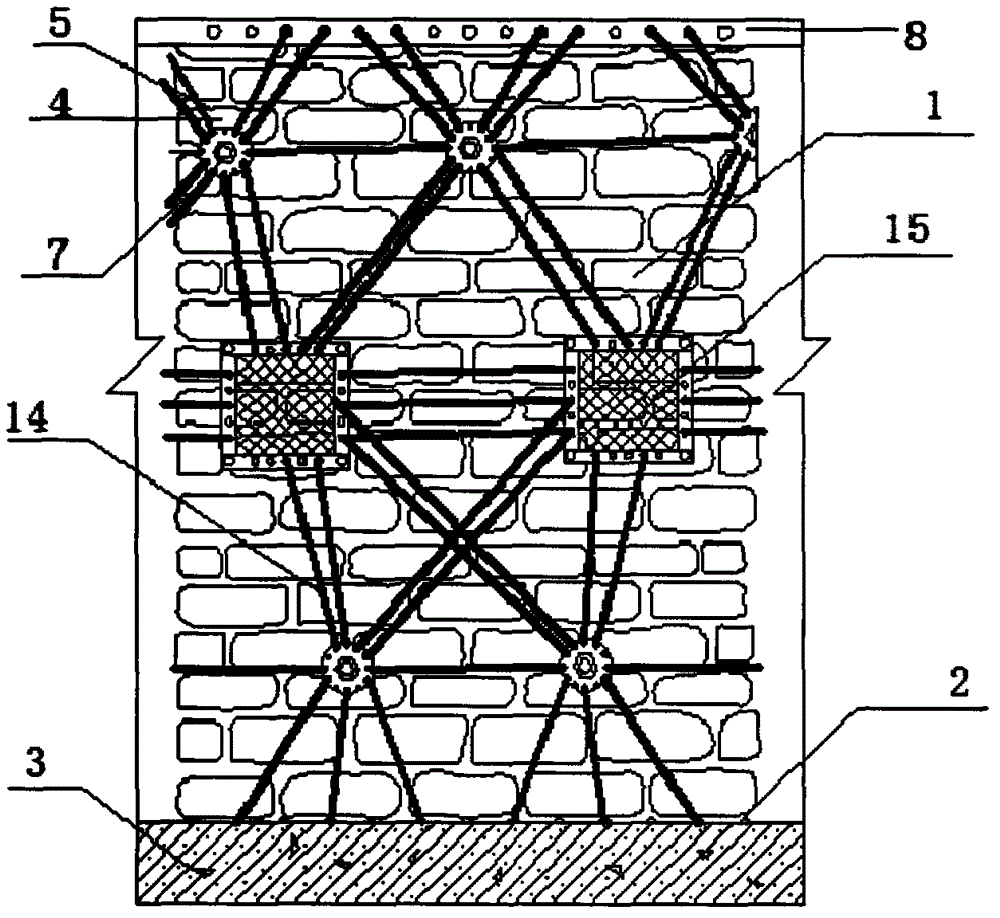

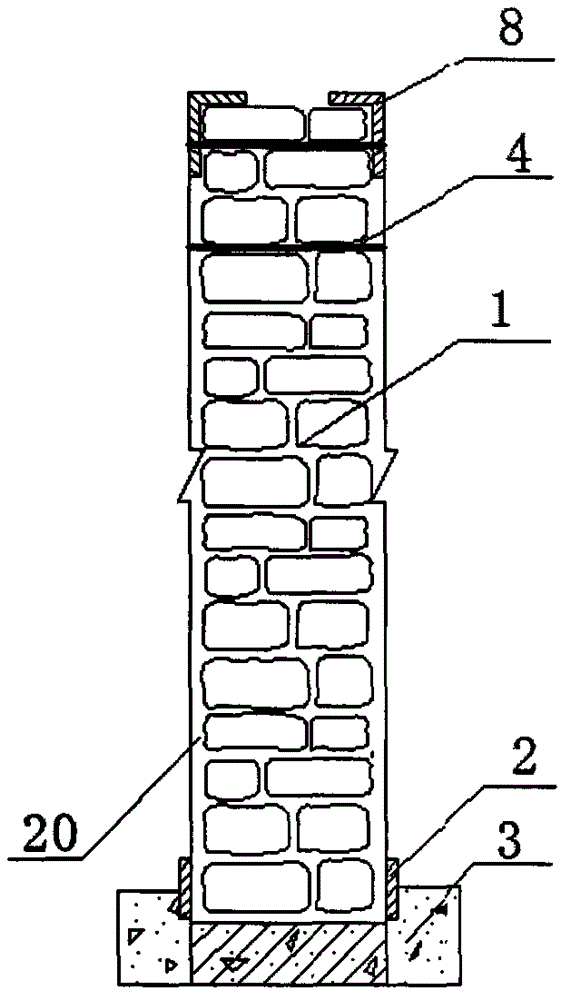

Strengthening method for stone wall body

The invention discloses a strengthening method for a stone wall body. The strengthening method including preparing pre-buried hook members (2), screws (4), flange plates (5), nuts (7), steel angles (8, 11), expansion bolts (12), zinc-coated wires (14), assembling units of steel plates and meshes (15), structural adhesive and concrete material; then excavating foundation pits on two sides of the stone wall body, pouring a concrete foundation (3) and inserting the pre-buried hook members (2); punching through holes in the stone wall body (1), blowing off dust, allowing the screws (4) to penetrate through the through holes, fixing two ends of each screw (4) by the nuts (7); arranging the assembling units of steel plates and meshes (15) on the stone wall body (1) and fixing by the expansion bolts (12); connecting flange plate holes (16), the hook members (2), binding holes (19) and eyelets (18) by binding through the zinc-coated wires (14), to form a criss-cross zinc-coated wires (14) net; the strengthening of the stone wall body (1) is achieved by jetting fine aggregate concrete (20).

Owner:SOUTHWEAT UNIV OF SCI & TECH

Splicing for interconnected thin-walled metal structures

InactiveUS20040052581A1Improve fatigue strengthComponent with highFuselage framesFuselage bulkheadsMetalRivet

A rivet splice that holds an upper and a lower sheet metal end portion together includes at least one row (6) of rivets that is subject to dynamic loads and a further row (7) of rivets that holds the sheet metal end portions together so that a limited sliding motion between the sheet metal end portions is possible. The further row (7) of rivets is positioned between an end edge (4A) of an upper sheet metal end portion and the at least one row (6) of rivets. The limited sliding motion provides a load relief of the at least one row of rivets thereby reducing the starting of cracks at the walls of the rivet holes and impeding the spreading of cracks.

Owner:AIRBUS OPERATIONS GMBH

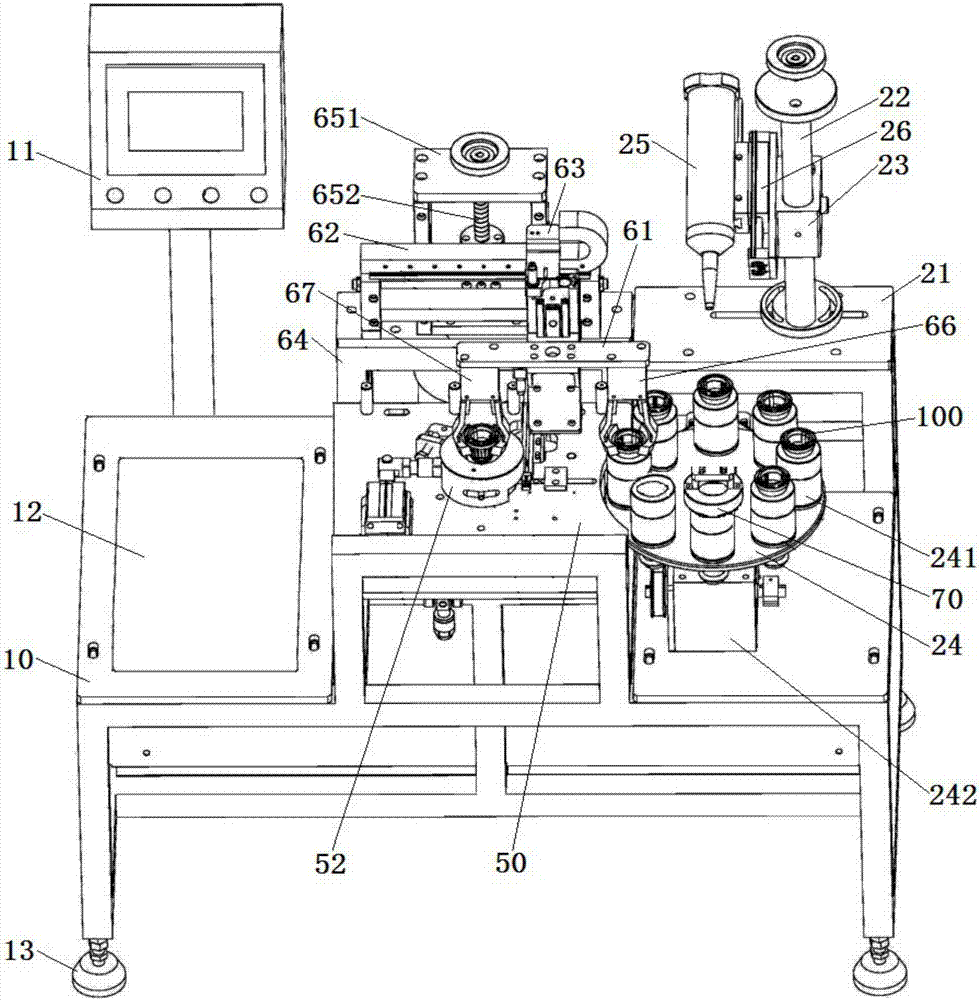

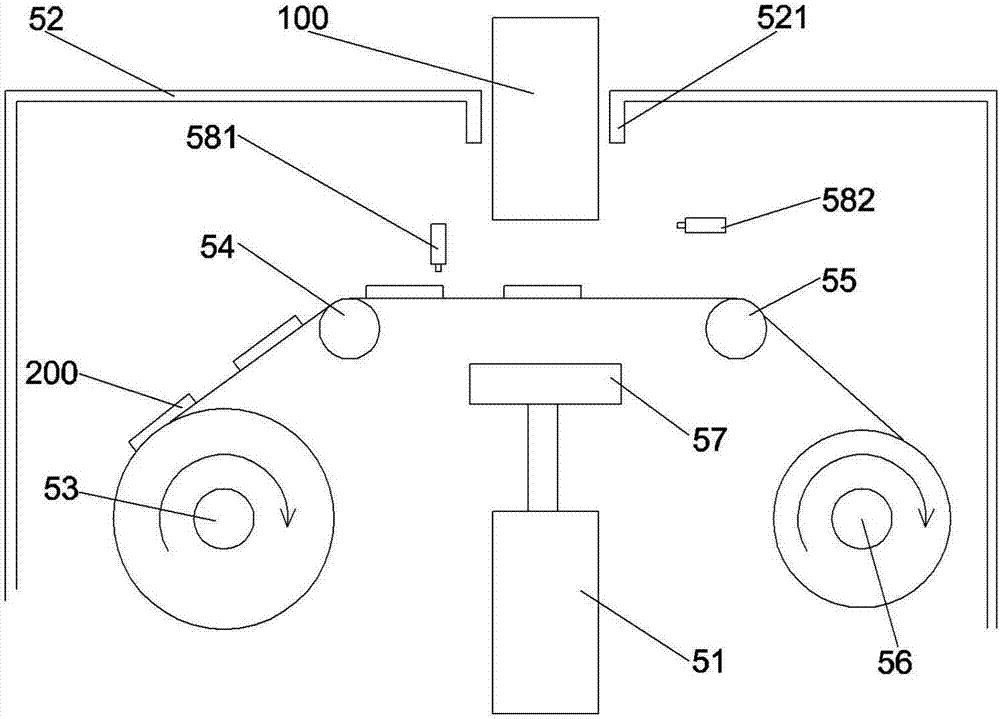

Automated loading and labeling device

ActiveCN107264905AAvoid sliding left and rightEffective squeezeLabelling machinesTransfer mechanismManipulator

The invention discloses an automated loading and labeling device. The automated loading and labeling device comprises a working table, a control mechanism, a loading mechanism, a first labeling mechanism, a second labeling mechanism and a transferring mechanism, wherein the loading mechanism comprises a loading rack, a loading stand column, a mounting sliding block, a loading rotary table and a loading head; the second labeling mechanism comprises a feeding and conveying belt, a driving labeling rotary table, a driven labeling rotary table, a second discharging roll, a second paper collecting roll, shifting rods, an unloading plate, a first guiding plate, a second guiding plate, a U-shaped connecting piece and a pushing cylinder; the first labeling mechanism comprises a label pressing cylinder, a feeding roll, a first guiding roll, a second guiding roll, a paper collecting roll and a paper collecting motor; and the transferring mechanism comprises a transferring arm, a transverse guide track, a lead screw assembly, a sliding table, a transferring rack, a first manipulator and a second manipulator. The automated loading and labeling device is compact in structure; automatic loading, side labeling and bottom labeling of packing boxes can be finished on the device; and the automated loading and labeling device is high in degree of automation and quite convenient to use.

Owner:嘉兴普艾仕自动化科技有限公司

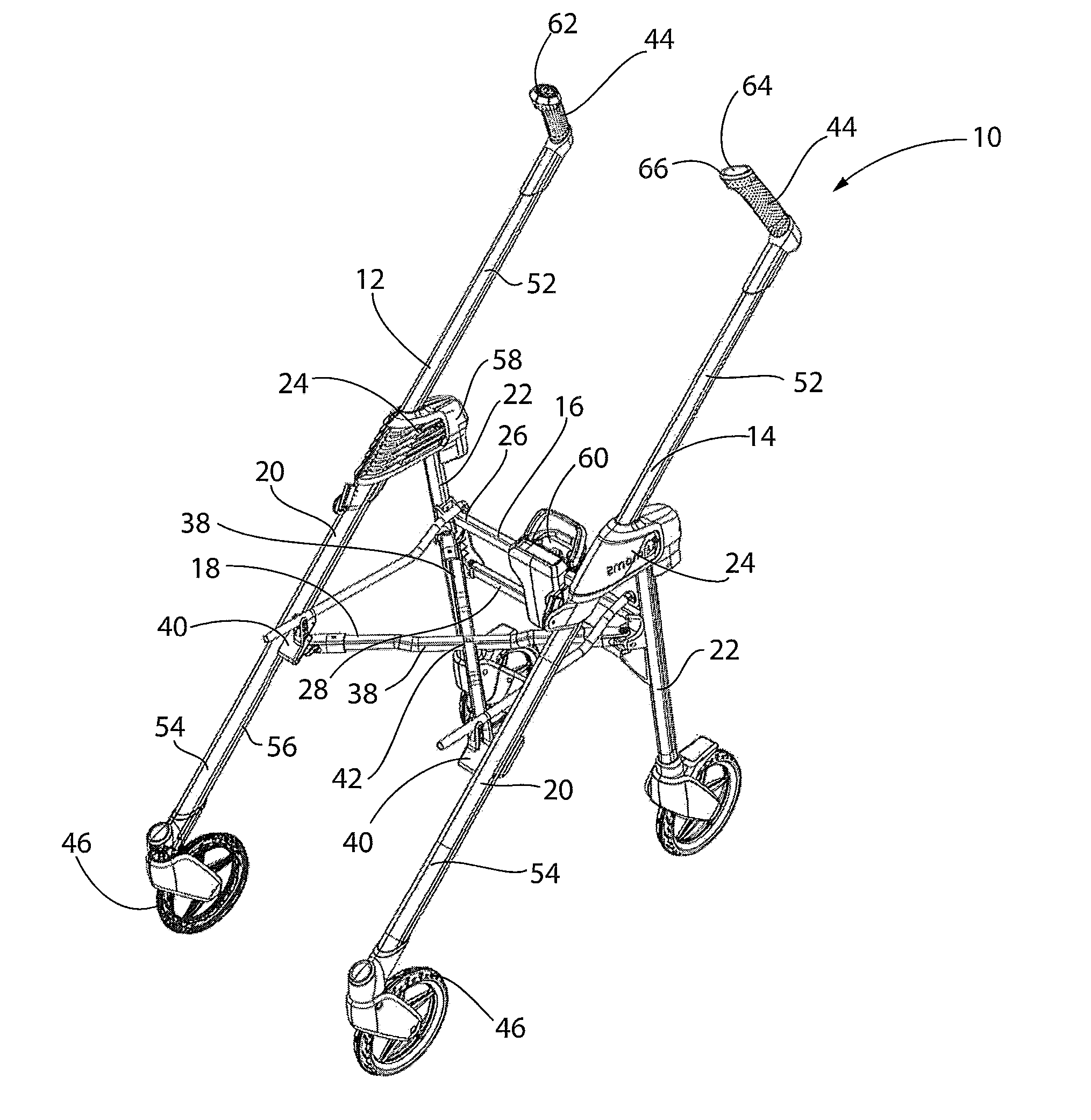

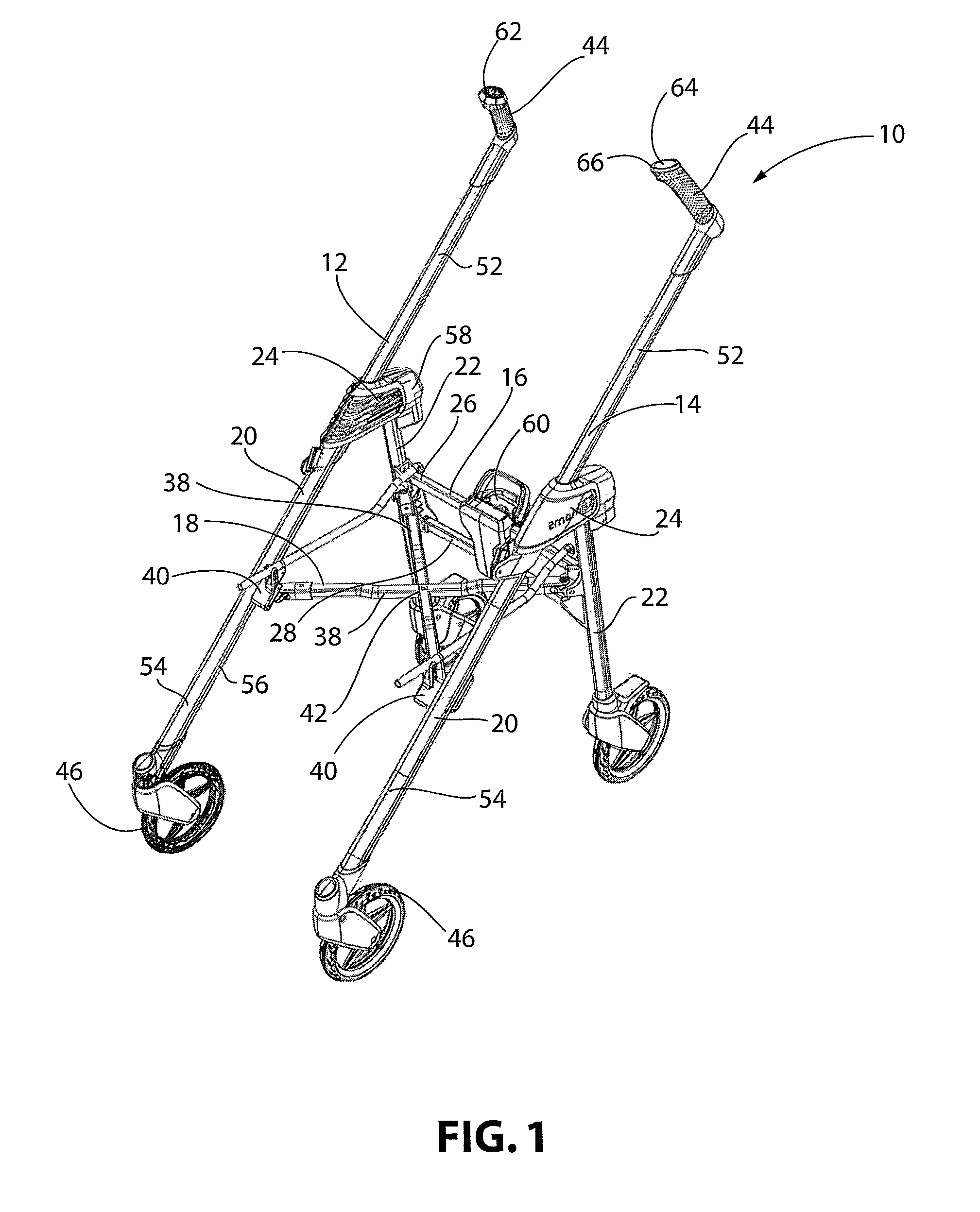

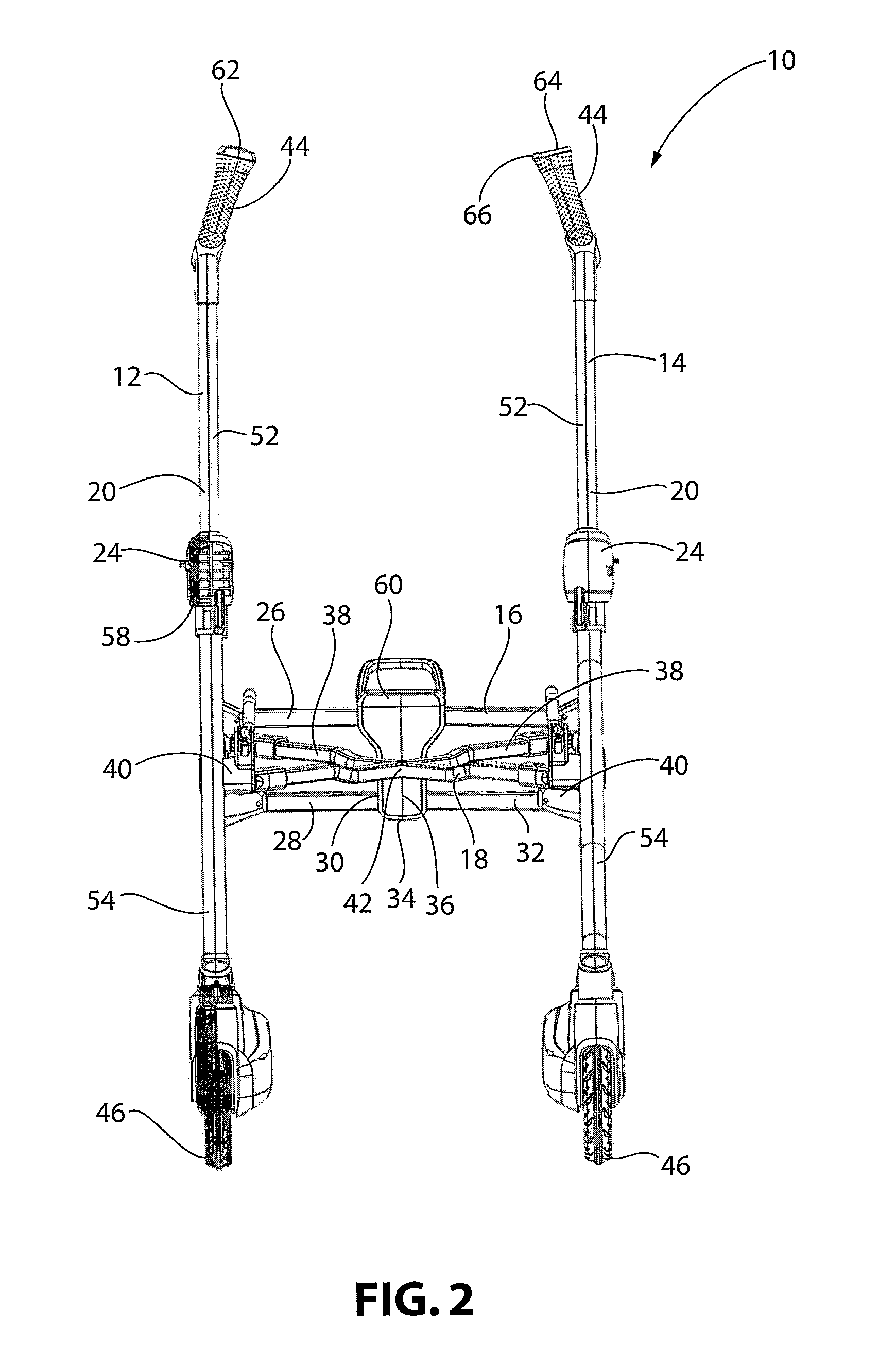

Lightweight Collapsible Stroller

ActiveUS20140035261A1Quick and easy transitionEffective tensionCarriage/perambulator accessoriesCarriage/perambulator with multiple axesEngineeringMechanical engineering

Provided herein is a lightweight stroller that can be transitioned between a closed position and an open position. The stroller includes a seating portion and at least one frame supporting the seating portion and transitionable from an open position to a closed position. The frame includes at least a front support rotatably connected to rear support. The stroller also includes a cinching strap connected between the front support and the rear support. The cinching strap is configured such that, as the frame transitions from the open position to the closed position, the cinching strap pulls the rear support toward the front support or the front support toward the front support. The cinching strap may at least partially maintain the front support and the rear support in the closed position. The cinching strap may include a flexible portion formed from a string, cable, polymer sheet, braided webbing, or any combination thereof.

Owner:THORLEY INDS

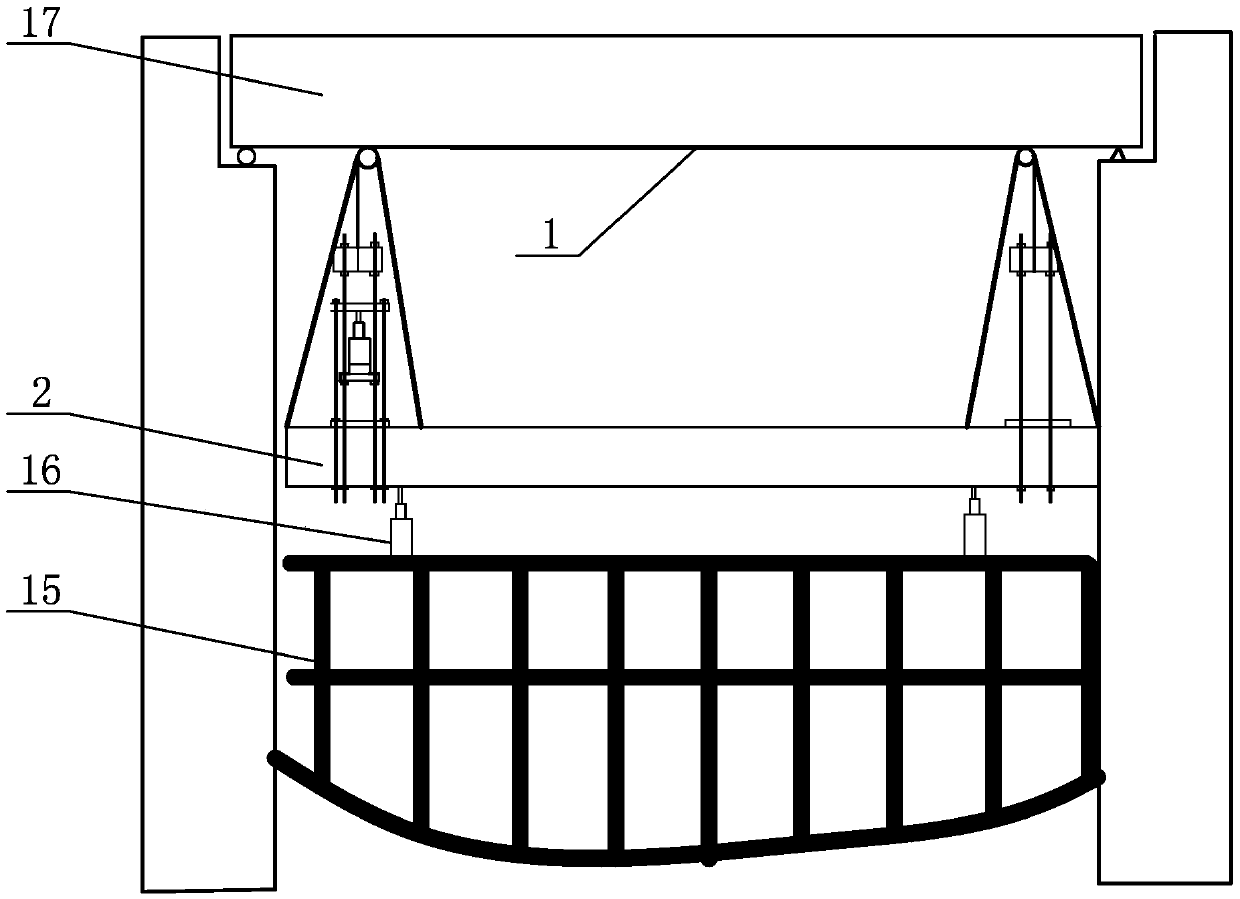

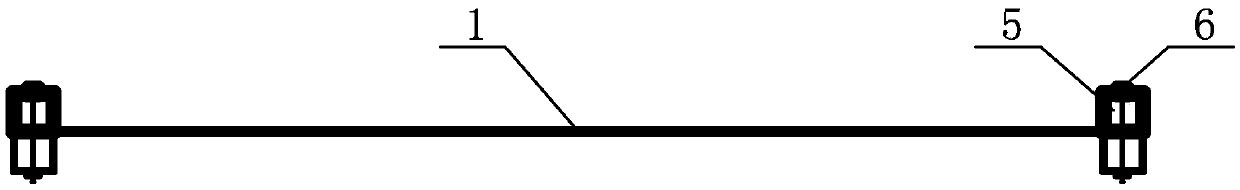

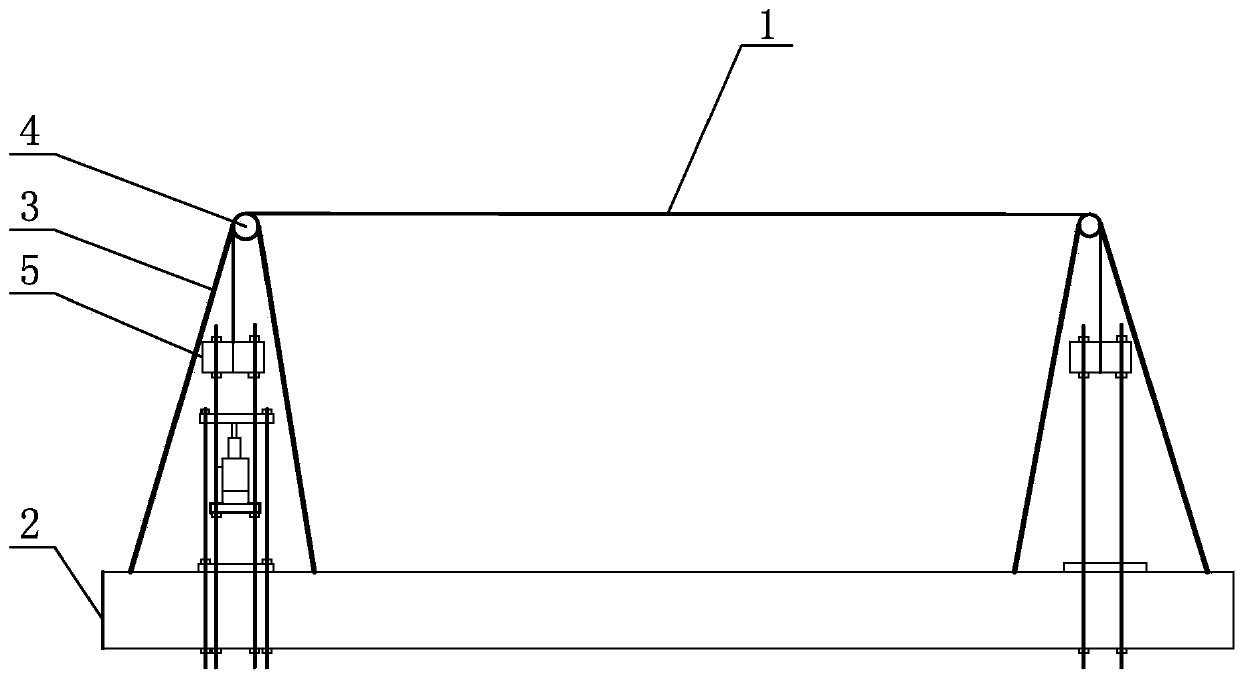

Tensioning and anchoring device for reinforcing reinforced concrete bridge through prestress FRP(fiber reinforced plastic) cloth and reinforcing method

ActiveCN105507169AHigh strengthImprove the effect of bridge reinforcementBridge erection/assemblyBridge strengtheningRebarStress level

The invention relates to a tensioning and anchoring device and a reinforcing method, in particular to a tensioning and anchoring device for reinforcing a reinforced concrete bridge through prestress FRP(fiber reinforced plastic) cloth and a reinforcing method. The device aims to solve the problems that due to an existing method of reinforcing the bridge by pasting the FRP cloth, the stress level of the FRP cloth is reduced, the advantage of high strength can not be given into full play effectively, and the reinforcing effect of the bridge is poor. The device comprises the FRP cloth, a prestress tensioning pedestal, two tensioning assemblies, two triangular supports, two anchoring assemblies and two steel rollers. The two triangular supports are arranged on the upper surface of the prestress tensioning pedestal side by side. One steel roller is installed at the upper end of each triangular support. One tensioning assembly is arranged at the lower end of each triangular support. The two ends of the FRP cloth are connected with the two anchoring assemblies respectively. Each anchoring assembly is wound around one steel roller and connected with one corresponding tensioning assembly. The device belongs to the field of bridge building.

Owner:黑龙江省工研院资产经营管理有限公司

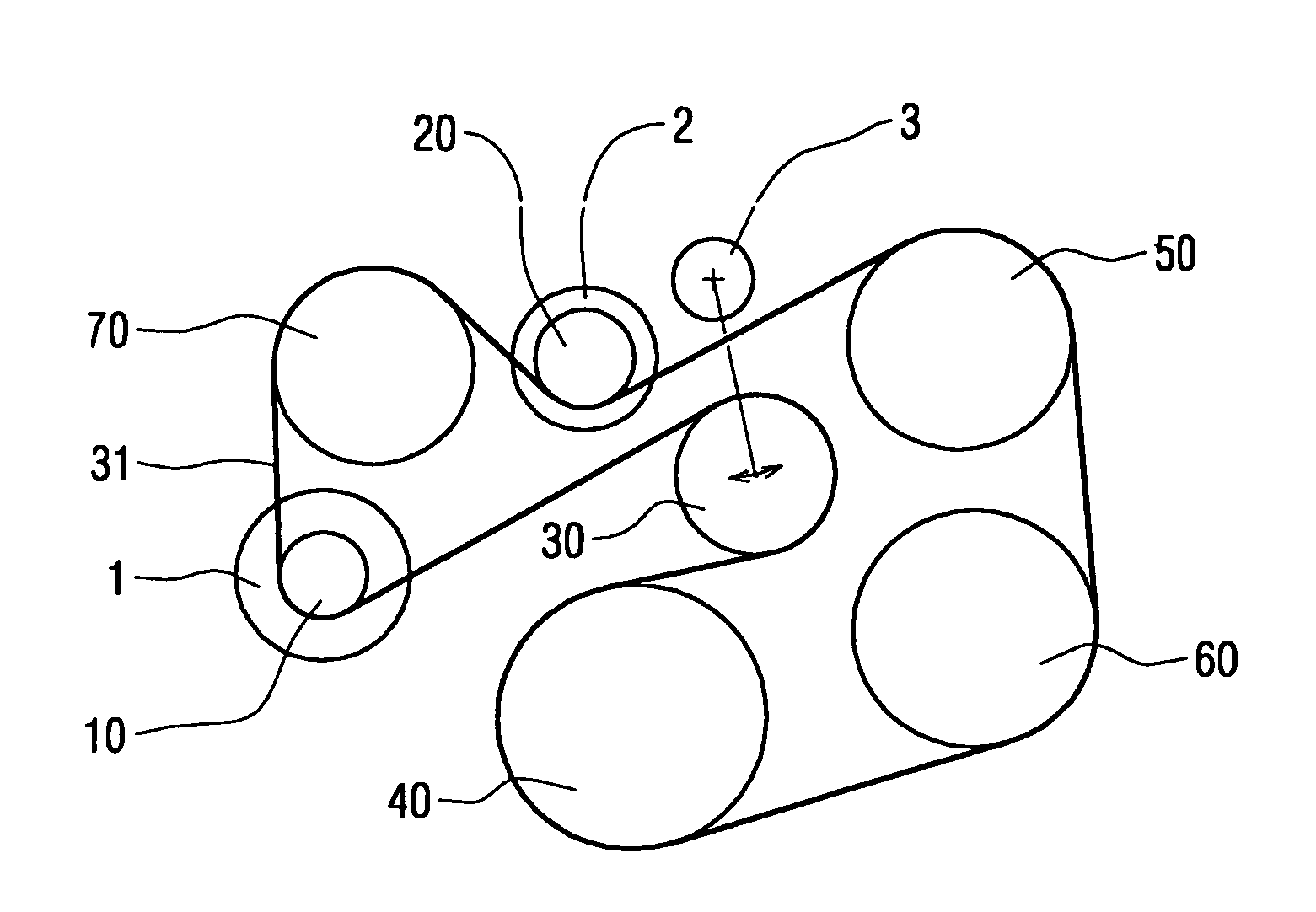

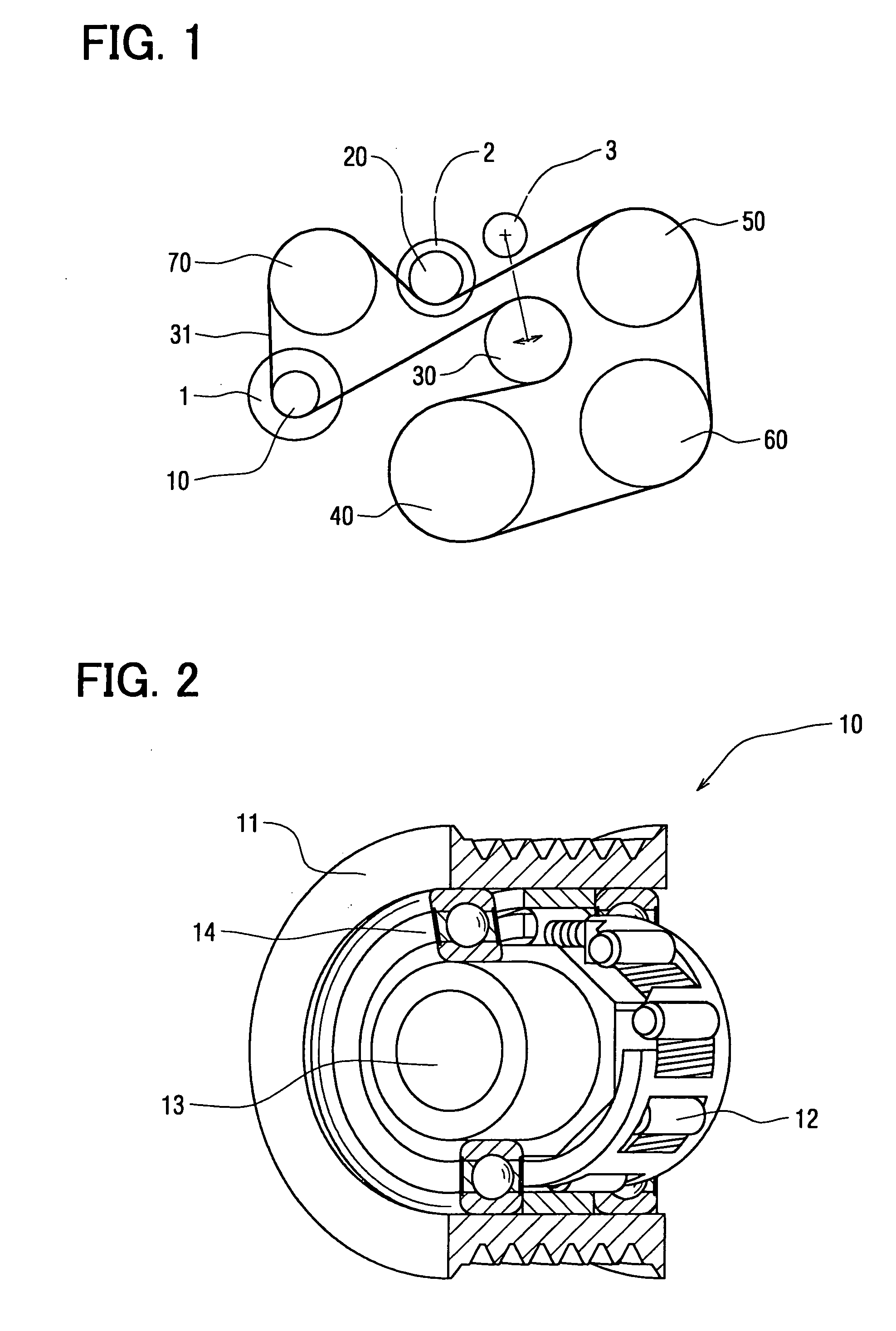

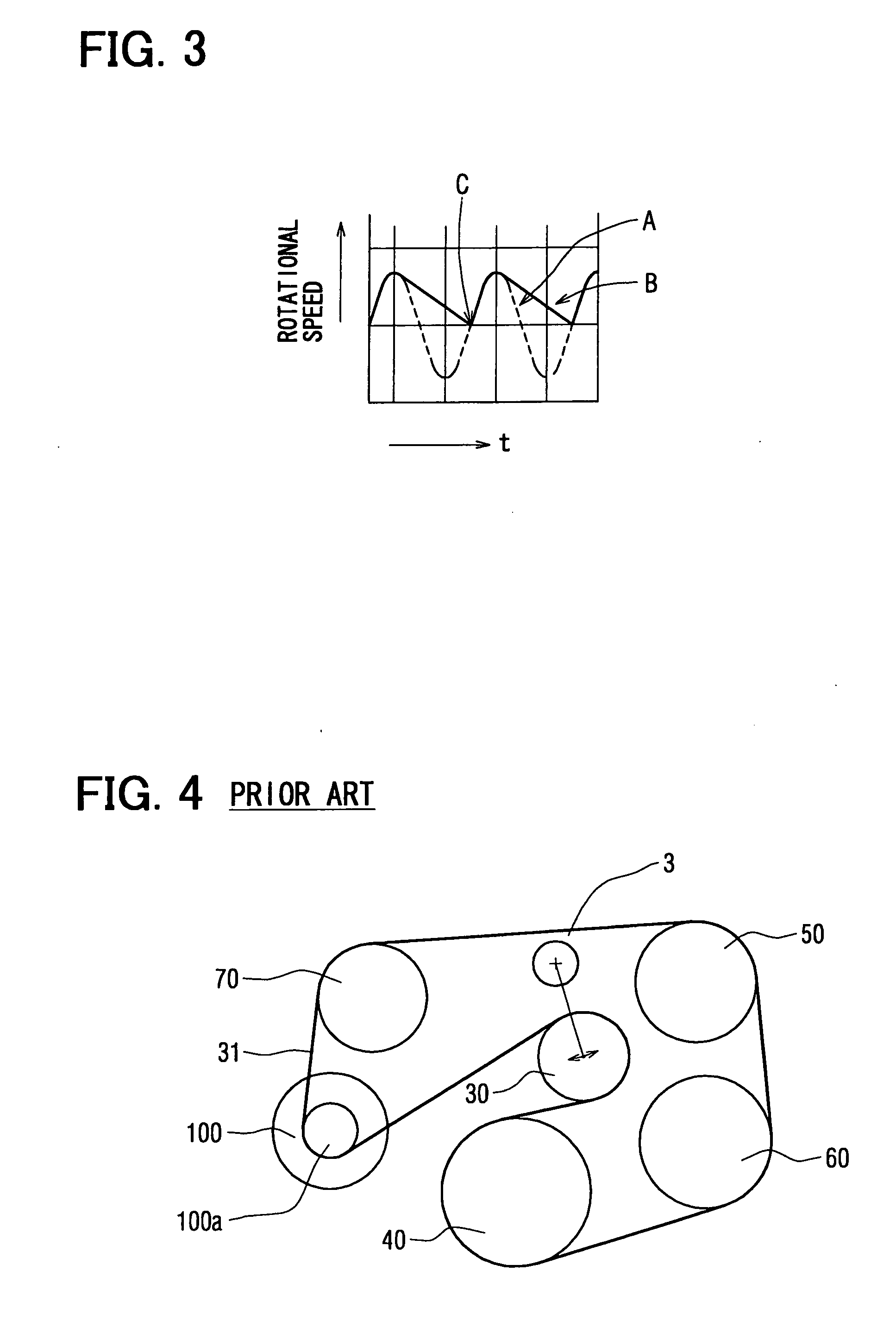

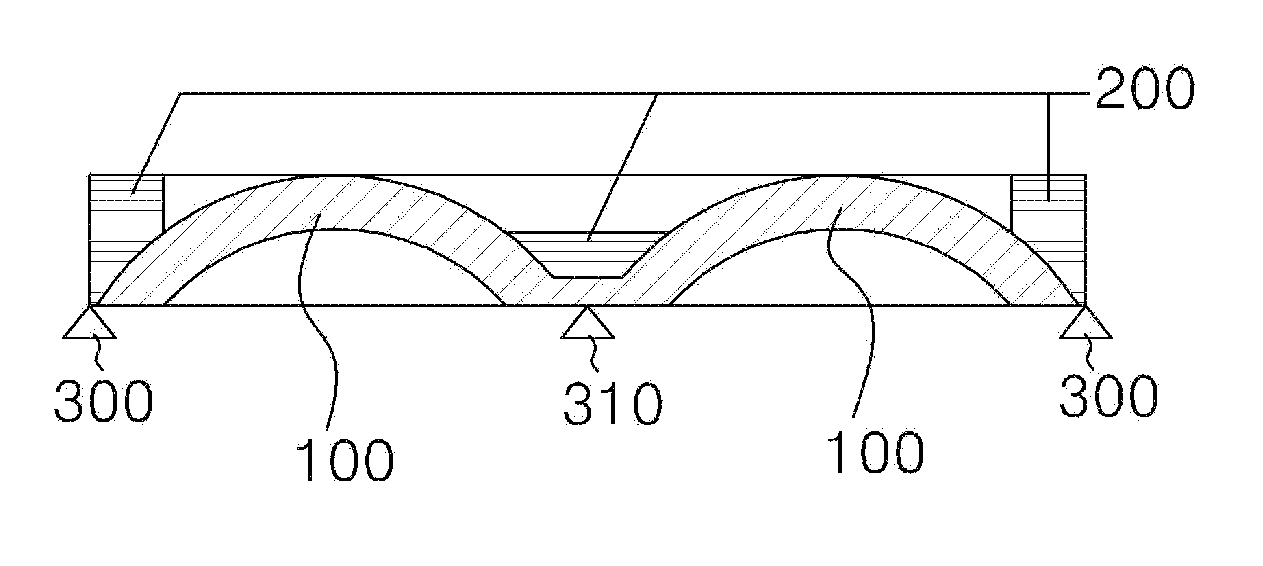

Belt-drive system driven by internal combustion engine mounted on automotive vehicle

InactiveUS7182707B2SpeedEasy to installGearingPortable liftingSerpentine beltExternal combustion engine

Plural auxiliary devices such as a water pump and a generator coupled to a serpentine belt-drive system are driven by an internal combustion engine mounted on an automobile vehicle. The generator is divided into a first generator having a pulley in which a one-way clutch is installed and a second generator having a usual solid pulley. Fluctuations in the belt tension caused by changes in instantaneous rotational speed of the internal combustion engine are suppressed or reduced by the one-way clutch installed in the pulley of the first generator. An inertia torque of a rotor of the first generator may be made higher than that of the second generator because effects of the inertia torque on the belt tension fluctuations are alleviated by the one-way clutch.

Owner:DENSO CORP

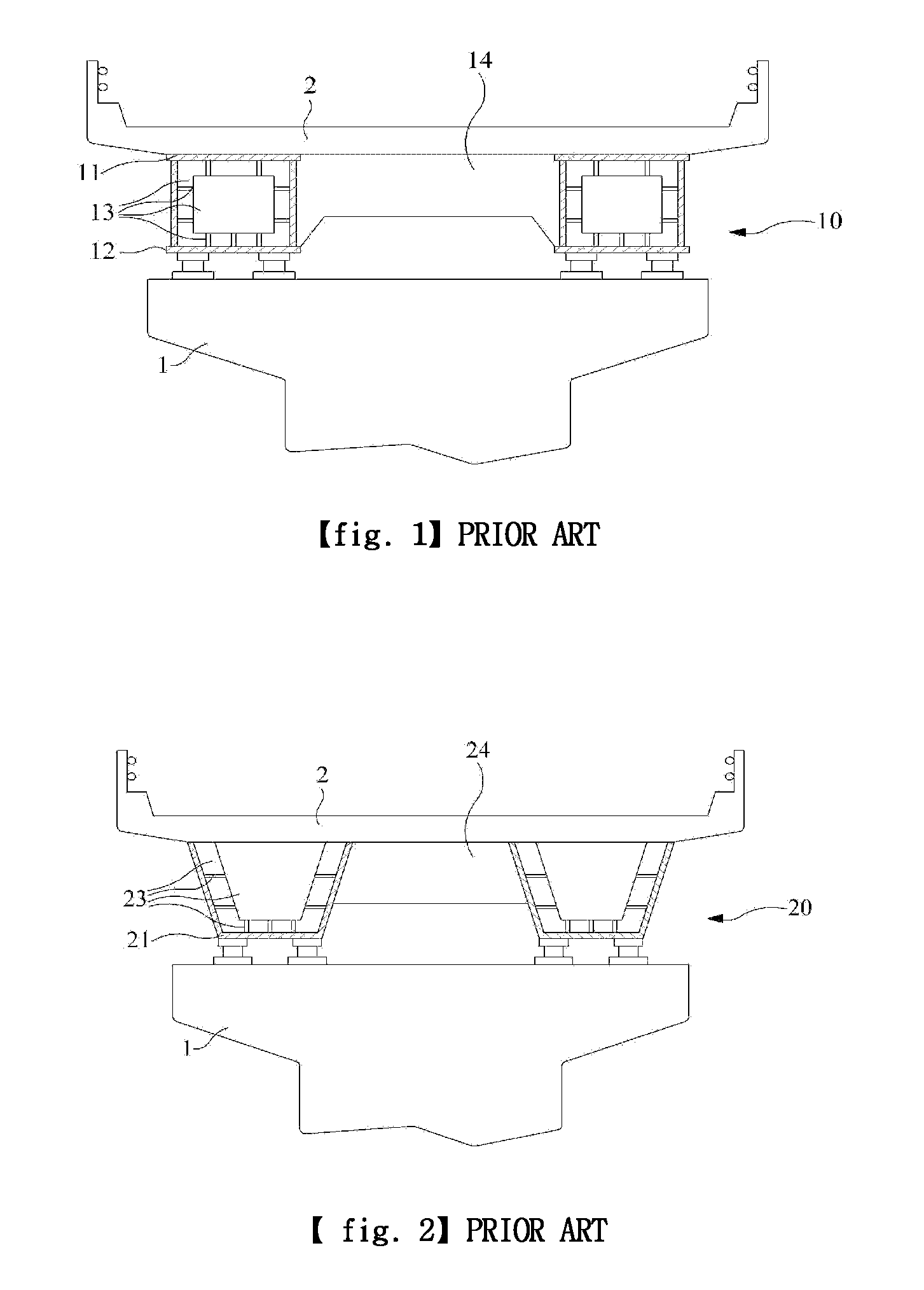

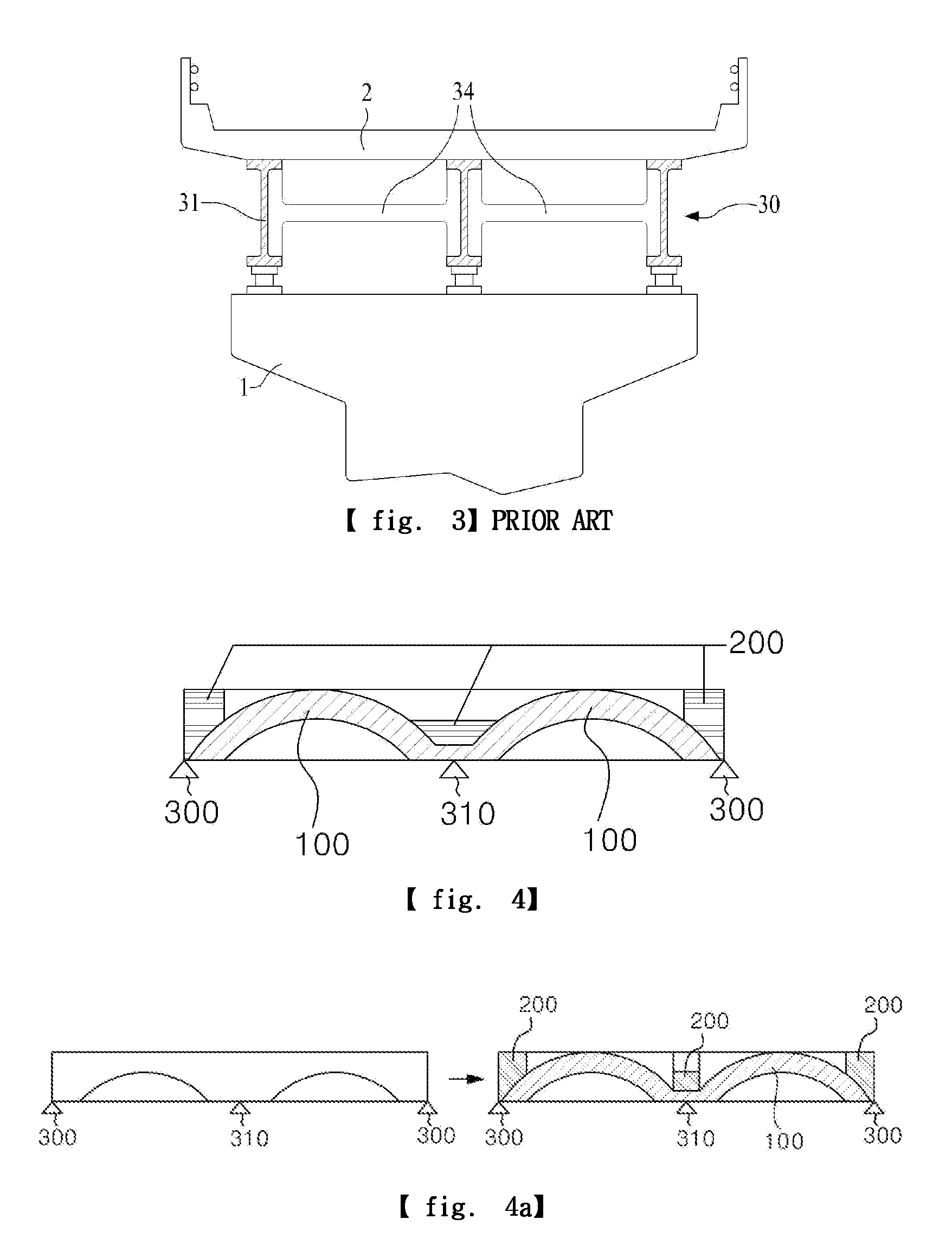

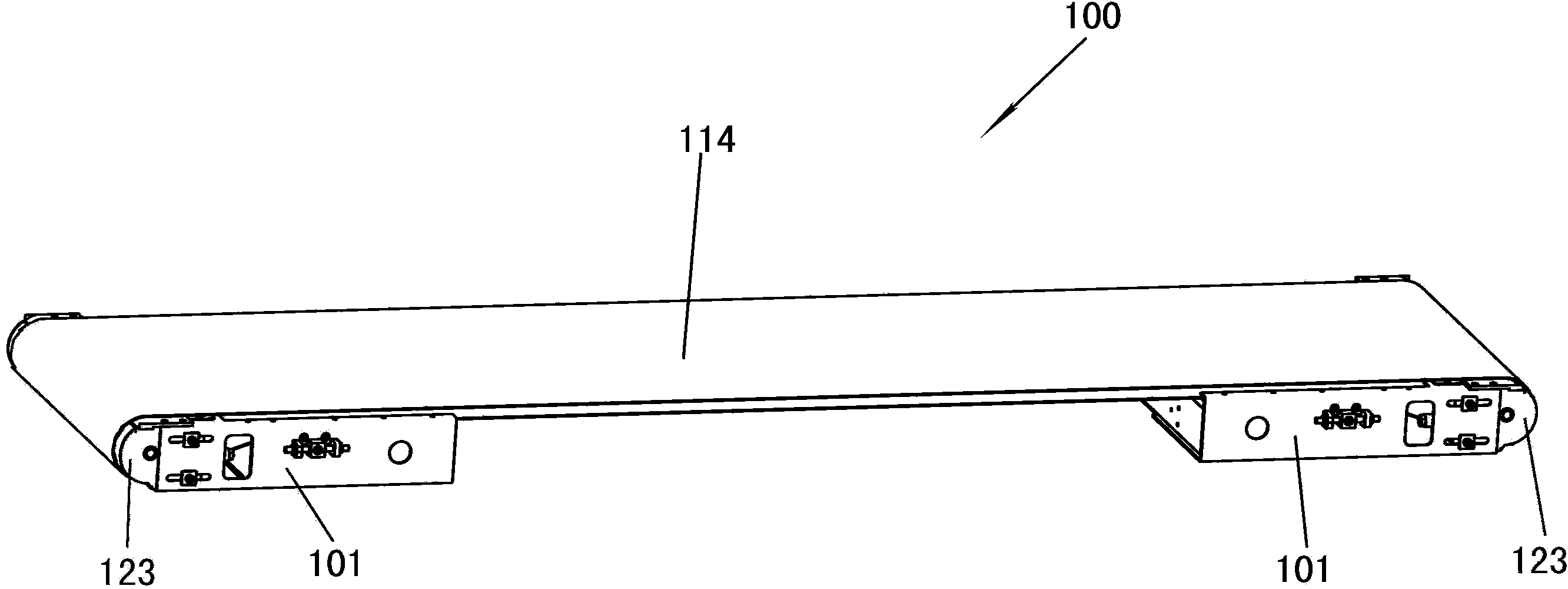

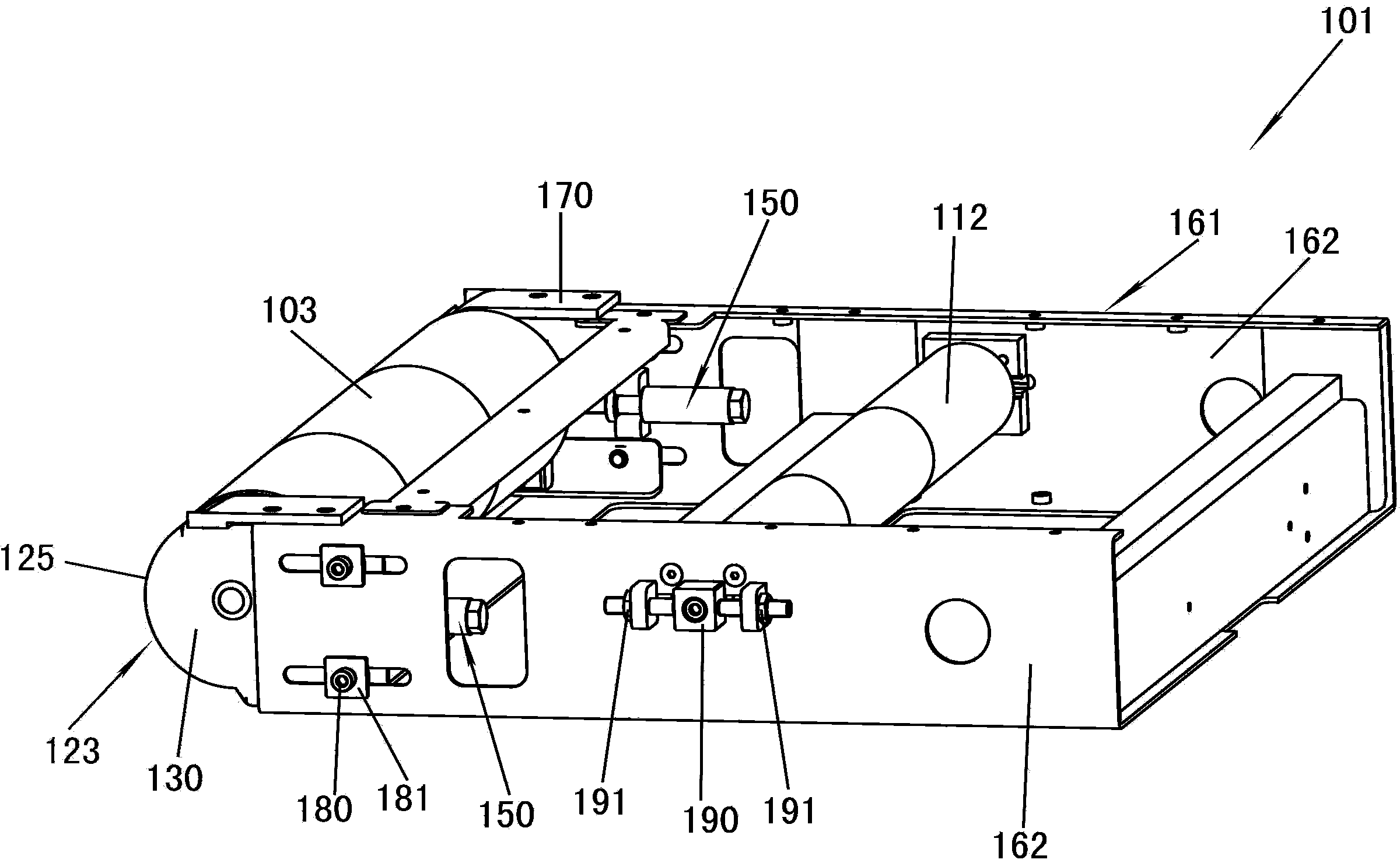

Composite girder for bridge construction

ActiveUS20130104320A1Efficiently tension stressReduce manufacturing costBuilding roofsArched girdersManufacturing cost reductionLong span

The present invention pertains to a composite girder for bridge construction. More preferably, a girder is formed in a rectangular shape that is horizontally long and opened at the top portion thereof, wherein the girder is convexly curved in the center so as to be formed in the shape of an arch. The girder has a compression section, a web and a tension section, which are integrally composed together; and is filled with concrete inside the girder so as to increase the sectional strength of the girder. Therefore, it is possible to reinforce a support that receives a great shearing stress even without the use of any rebar. Simultaneously, a stopper is formed on the inside surface of the compression section to prevent the separation of the steel materials and the concrete. Therefore, compared with the existing girders, the composite girder of the present invention may be mounted over a noticeably long span. In addition, it is possible to reduce manufacturing costs by minimizing the use of expensive steel reinforcement materials, exhibiting sufficient strength characteristics in spite of a small dead load.

Owner:SB ENG CO LTD

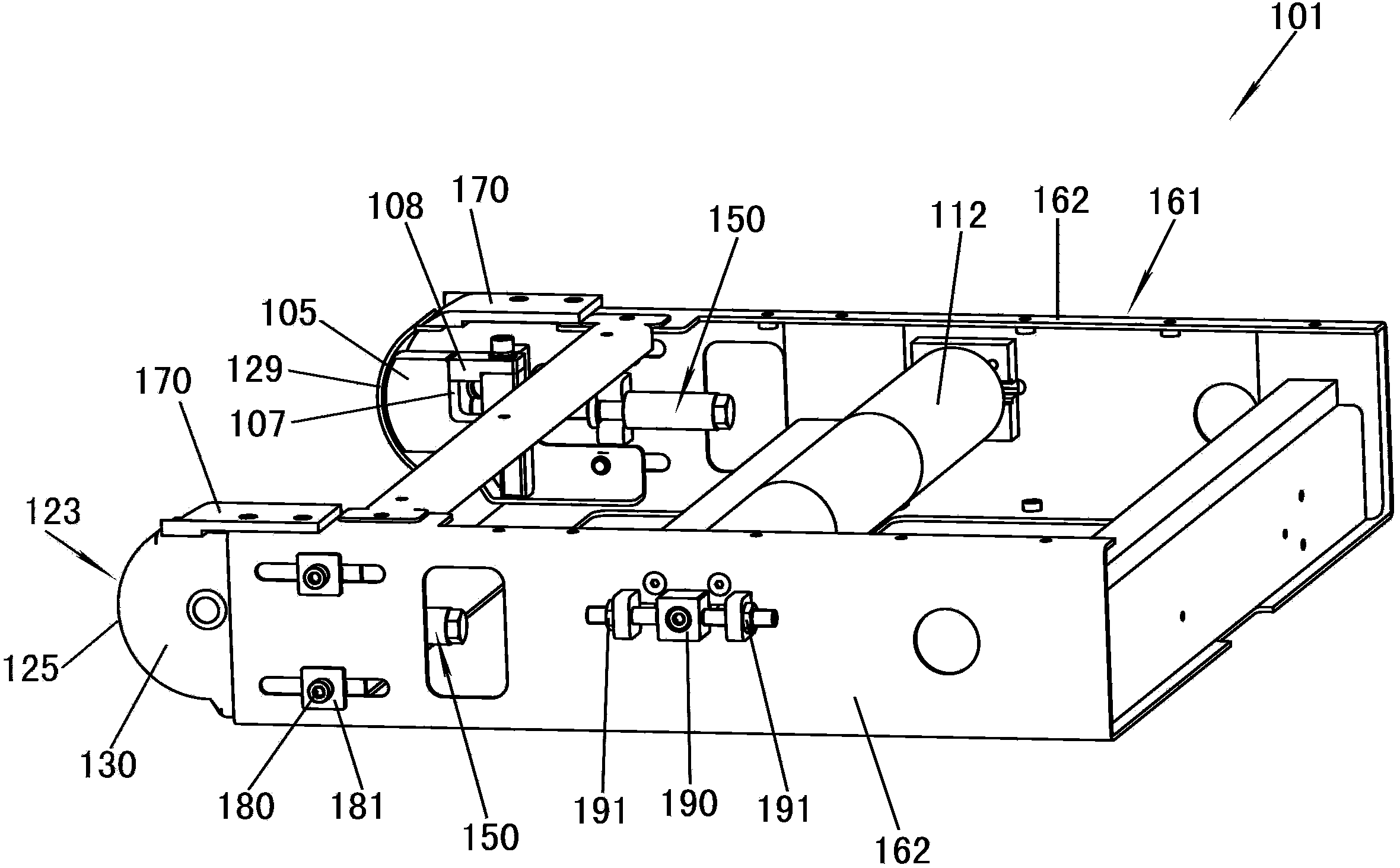

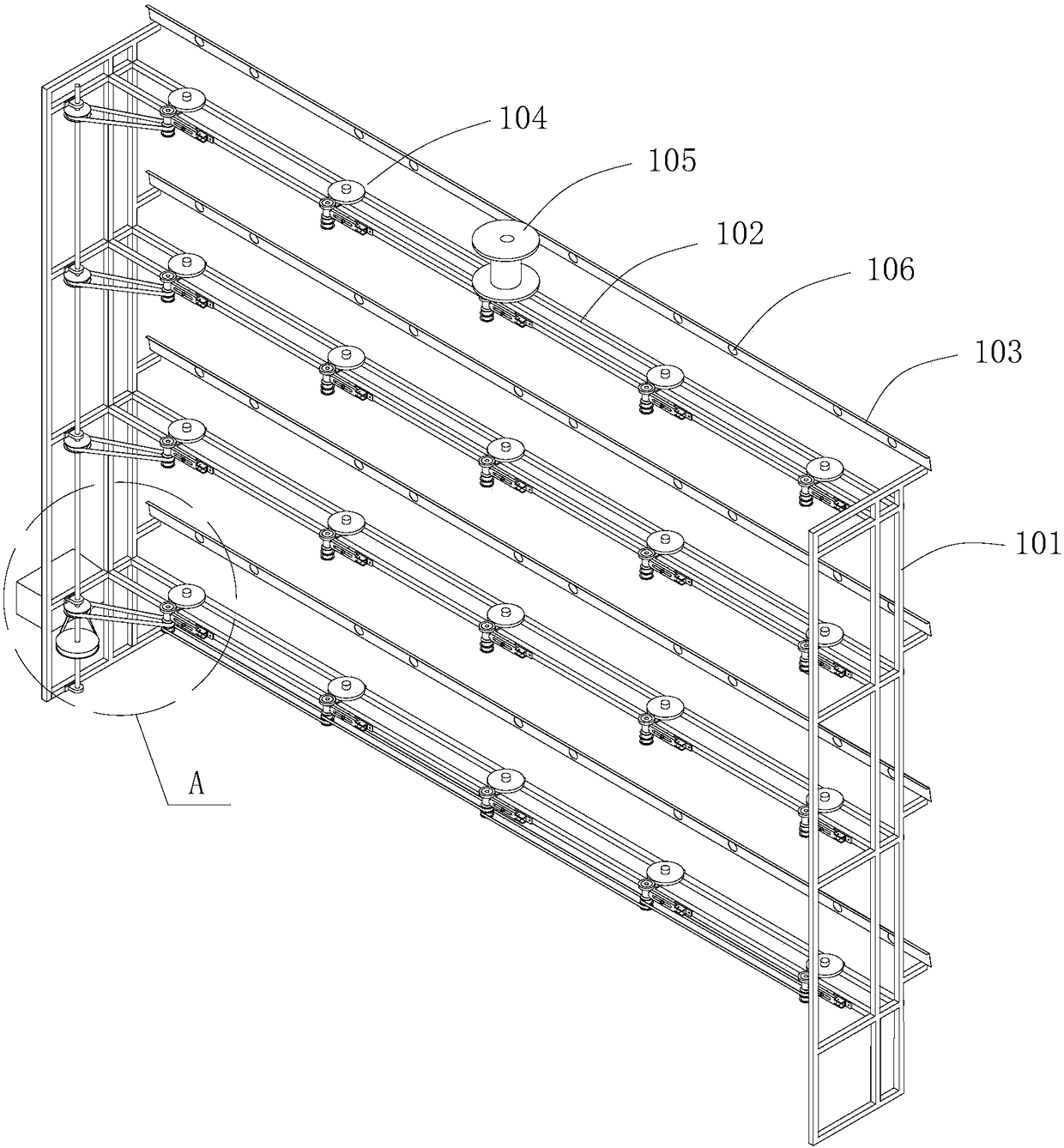

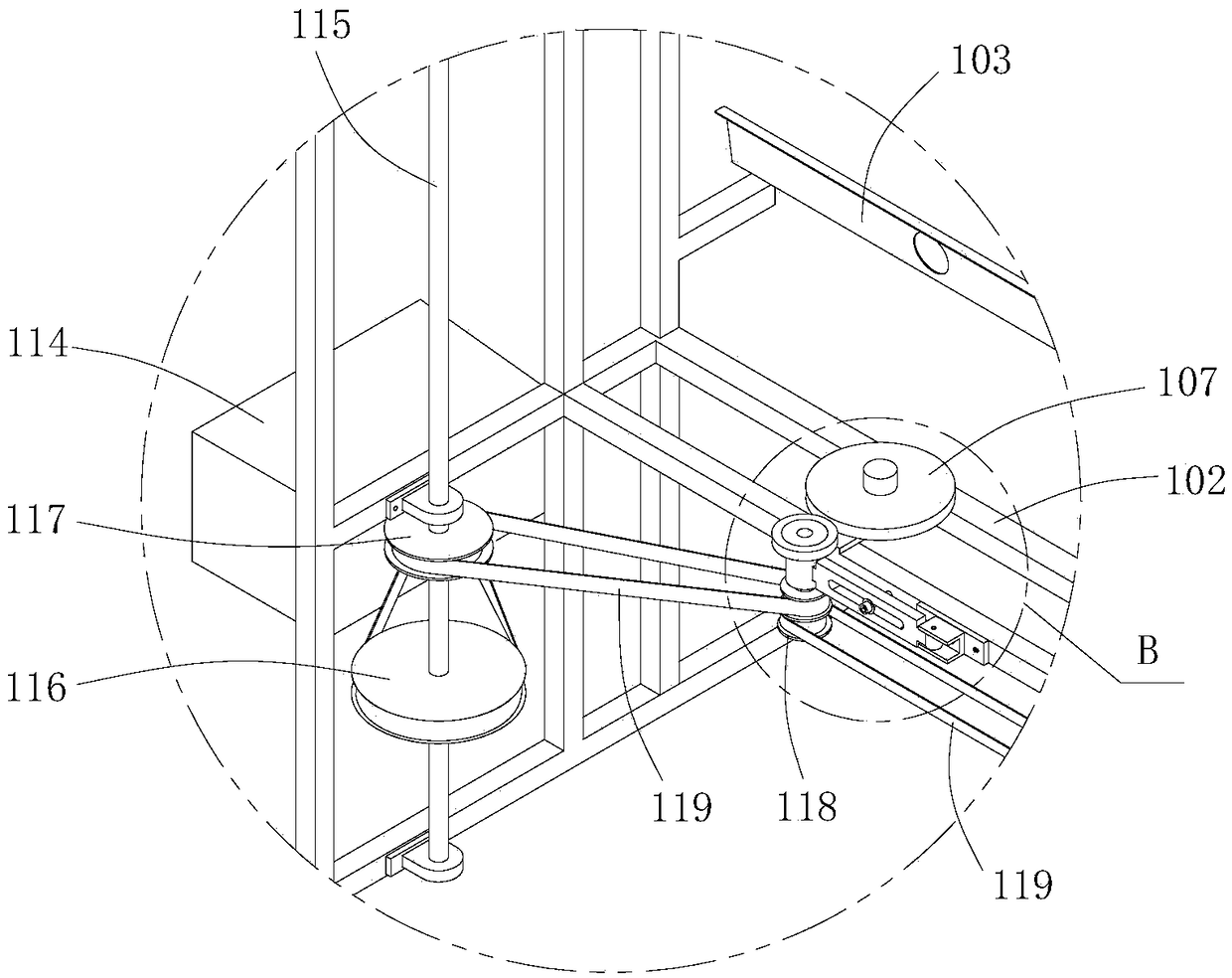

Belt conveyer and roller supporting assembly for same

The invention discloses a belt conveyer and a roller supporting assembly for the belt conveyer. The roller supporting assembly for the belt conveyer comprises two installation bases where the two ends of a shaft of a roller are installed. One installation base is provided with a groove for containing the corresponding end of the shaft of the roller, wherein an upward opening is formed in the groove. According to the technical scheme, the roller can be disassembled conveniently, and the edge of a conveying belt can be effectively tensioned.

Owner:NUCTECH BEIJING CO LTD +1

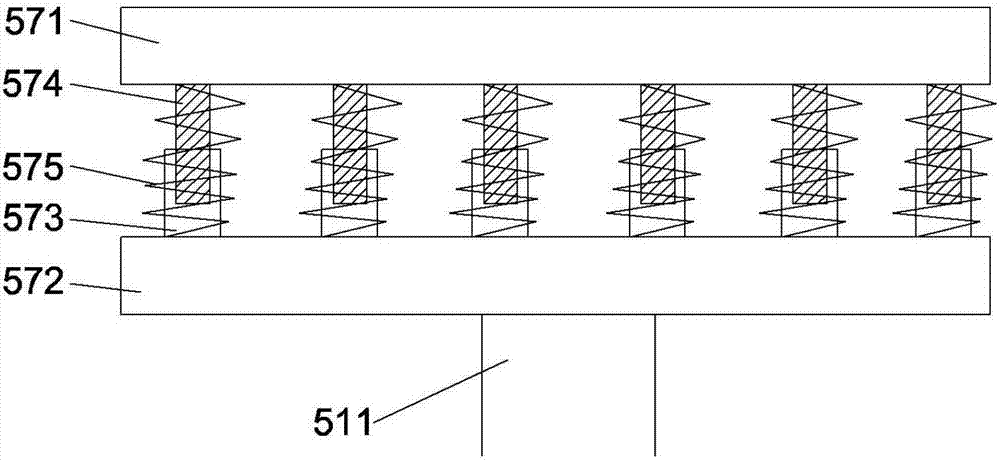

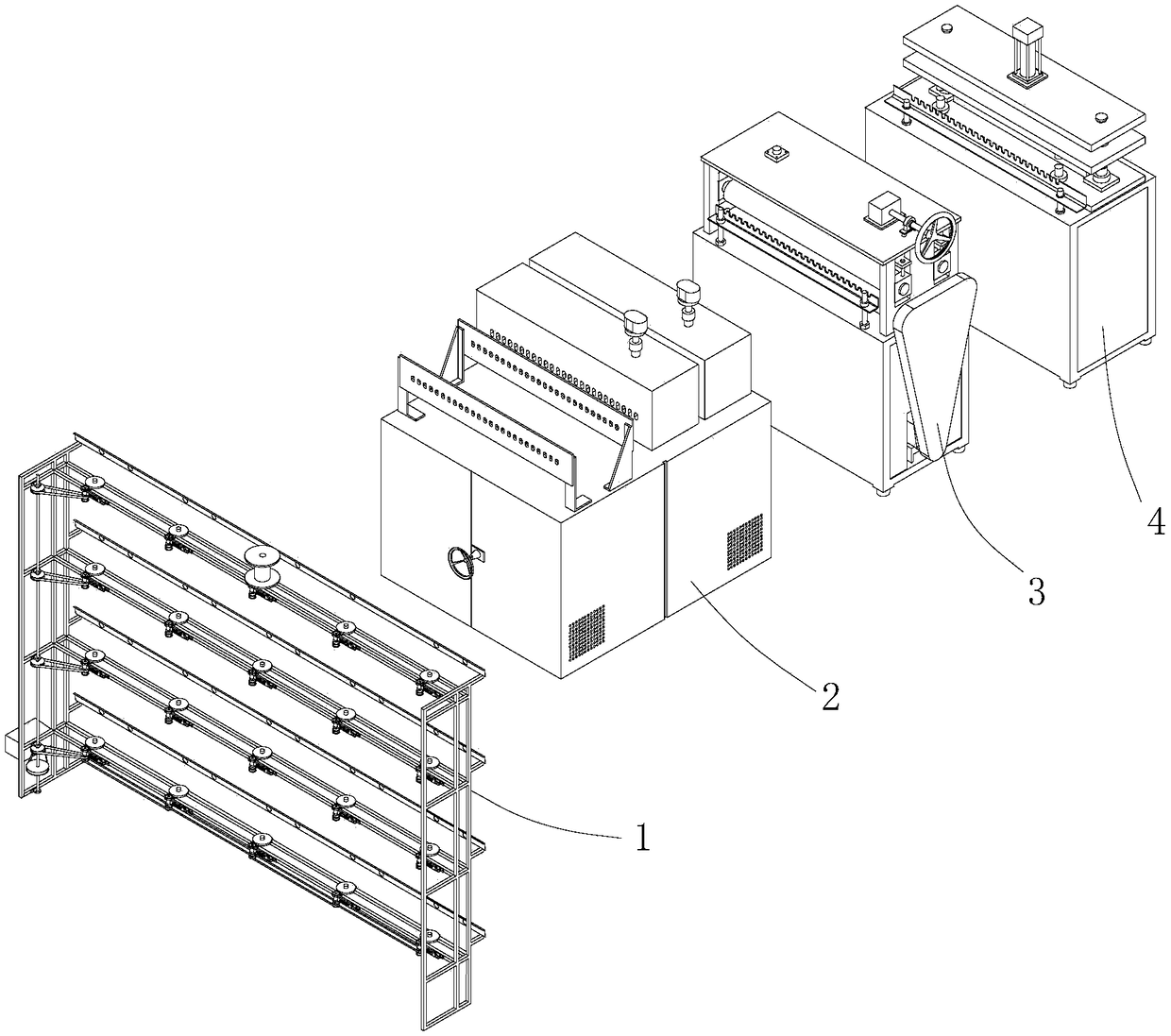

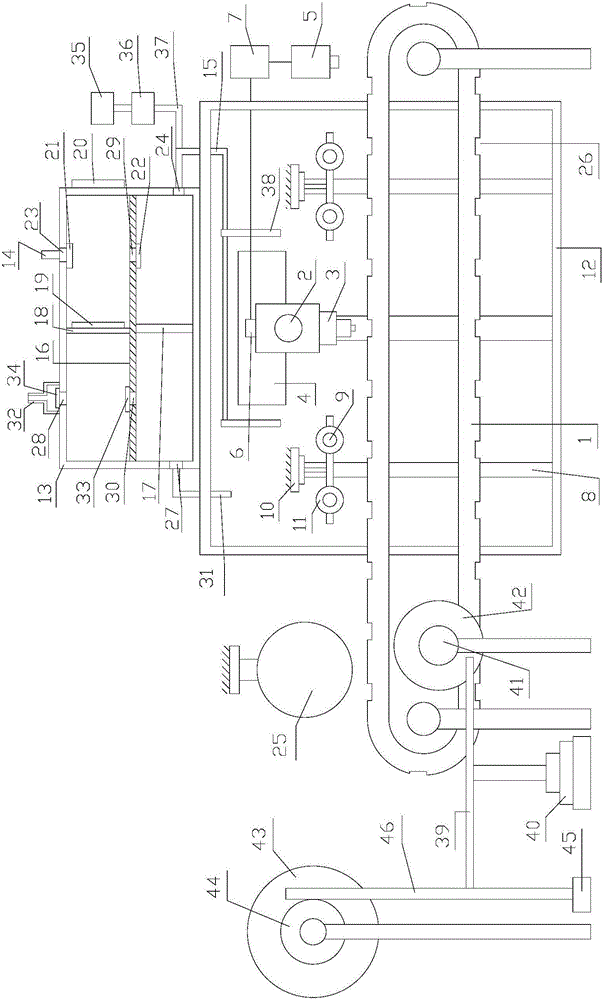

Cotton core bar forming machine

PendingCN108396465AIncrease productivityRealize production automationSevering textilesNon-woven fabricsYarnFiber

The invention discloses a cotton core bar forming machine. The cotton core bar forming machine comprises a feeding part, a forming part, a traction part and a cutting part which are arranged in the material travel direction in sequence. The forming part comprises heating furnaces, a row of hot melting channels which are horizontally distributed are formed in each heating furnace; the feeding partis used for conveying fiber silk yarn into the holt melting channels of the first heating furnace in groups, each group of fiber silk yarn is composed of multiple pieces of fiber silk yarn, and all groups of fiber silk yarn are heated through the holt melting channels to be bonded into a cotton core bar; the traction part comprises opposite rolling shafts driven by a motor, the opposite rolling shafts comprise the first rolling shaft and the second rolling shaft which are horizontally arranged, the rotating direction of the first rolling shaft is opposite to that of the second rolling shaft, and backward tractive force is provided through rubbing between the opposite rolling shafts and the cotton core bar; the cutting part is used for cutting the cotton core bar off according to a set length. By means of the cotton core bar forming machine, cotton core bar production automation is achieved, and the labor cost is reduced.

Owner:广东鑫球新材料科技有限公司

Metal plate cutting device for elevator production and processing

ActiveCN105945442AImprove cutting accuracyImprove cutting efficiencyWelding/cutting auxillary devicesAuxillary welding devicesUnit/actuationDistance sensors

The invention discloses a metal plate cutting device for elevator production and processing. The metal plate cutting device comprises a transmission part, a cutting part and a hold-down part, wherein the transmission part comprises a power mechanism and a conveyor belt; the power mechanism is used for driving the conveyor belt to rotate; the cutting part comprises N cutting mechanisms, wherein N is an integer; the N cutting mechanisms are sequentially distributed in a conveying direction of the conveyor belt; each cutting mechanism comprises a sliding rod, a welding gun assembly, a first drive unit, a positioning plate, a speed sensor, a distance sensor and a controller; each sliding rod is arranged above the conveyor belt, and is horizontally arranged; the length direction of the sliding rod is perpendicular to the conveying direction of the conveyor belt; each welding gun assembly can be movably mounted on each sliding rod; the gun head of each welding gun assembly is downwards arranged; each welding gun assembly and each first drive unit are in communication connection with each controller; each first drive unit drives each welding gun assembly to move in a length direction of each sliding rod; and each positioning plate is arranged at one side of the conveyor belt. The metal plate cutting device is good in metal plate cutting effect, is high in cutting precision and is convenient to use.

Owner:安徽省恒胜机电工程股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com