Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

39 results about "Serpentine belt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

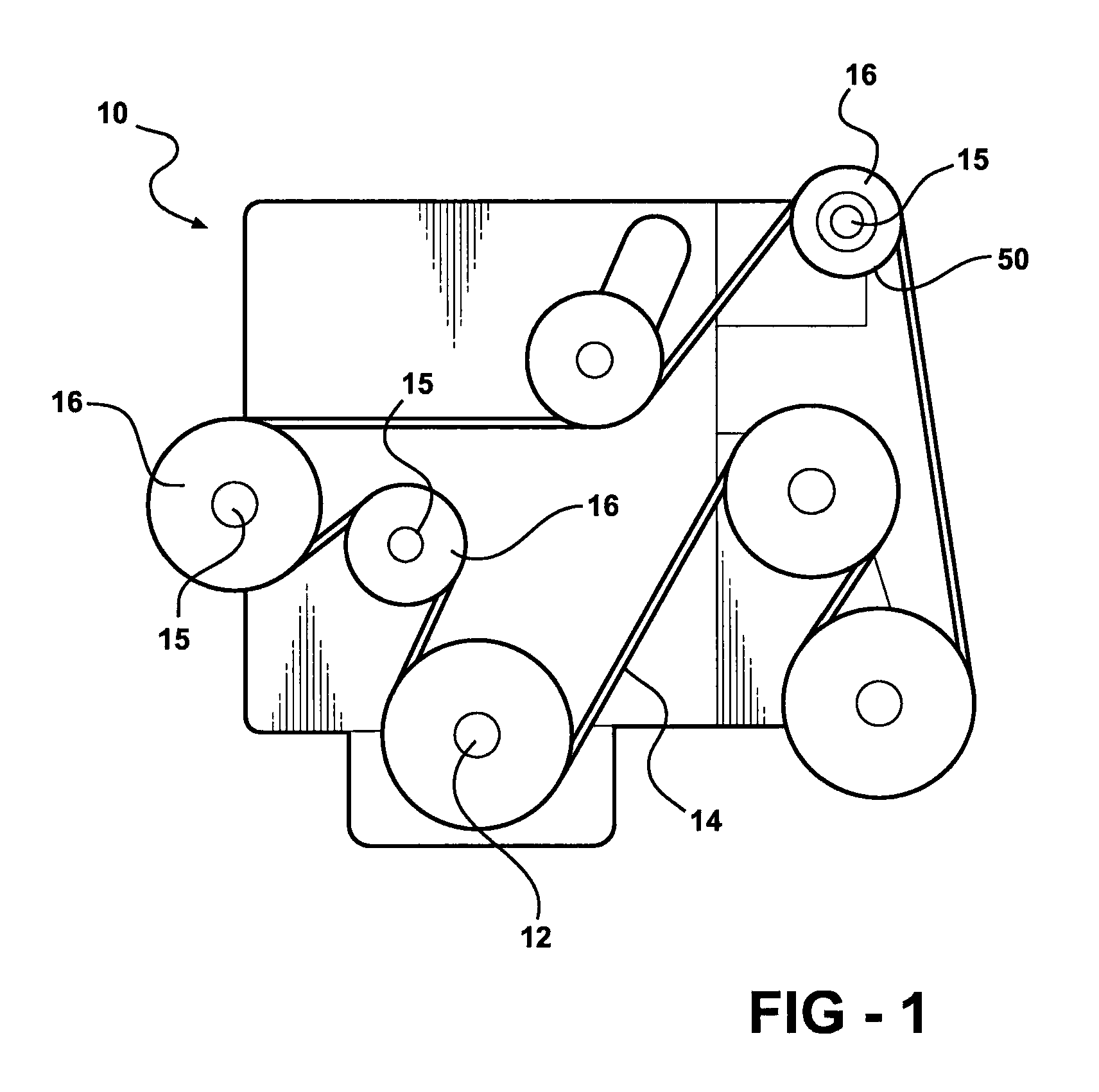

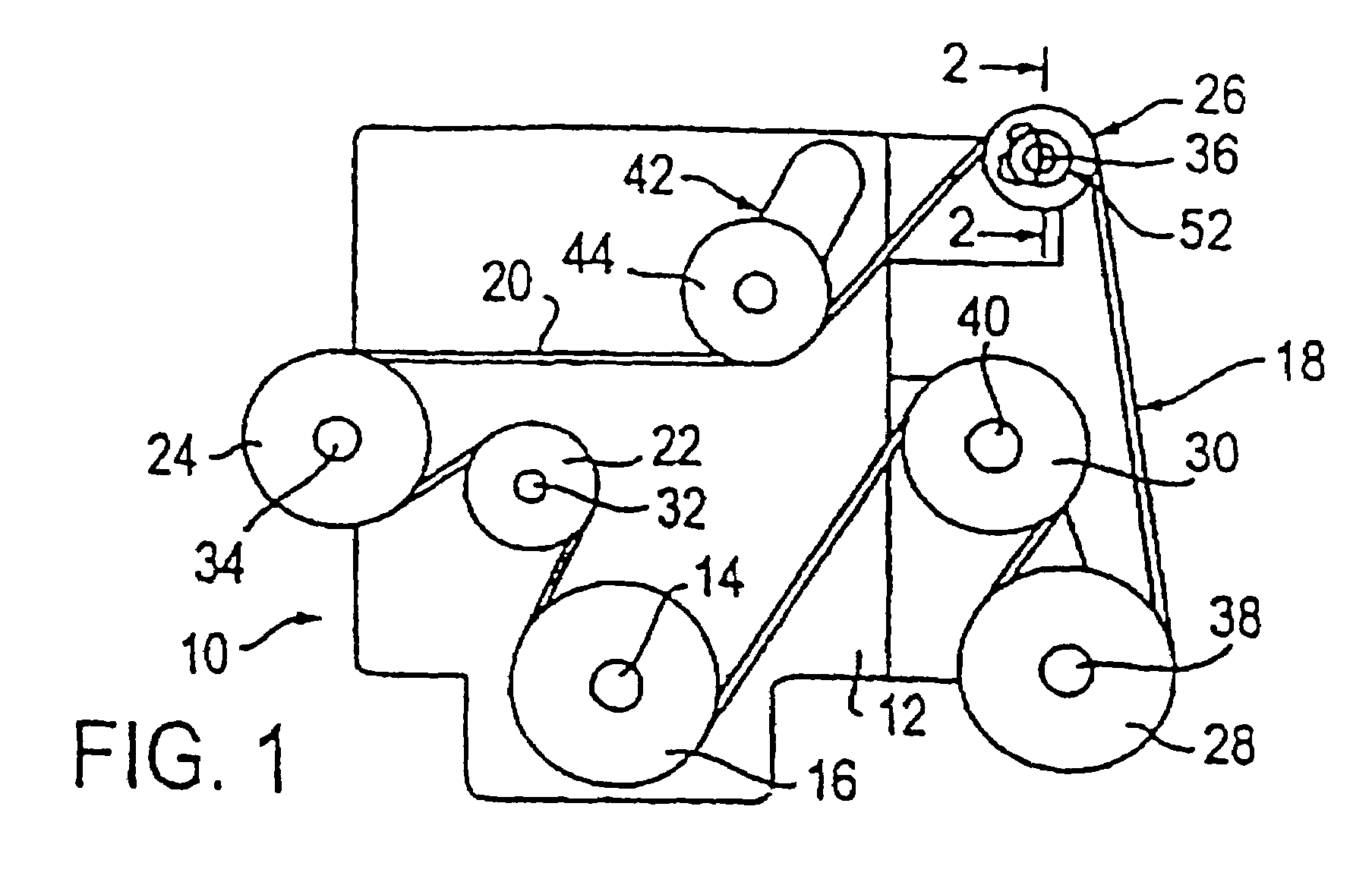

A serpentine belt is a single, continuous belt used to drive multiple peripheral devices in an automotive engine, such as an alternator, power steering pump, water pump, air conditioning compressor, air pump, etc. The belt may also be guided by an idler pulley and/or a belt tensioner (which may be spring-loaded, hydraulic, or manual).

Isolator for alternator pulley

Owner:LITENS AUTOMOTIVE INC

Spring travel limiter for overrunning alternator decoupler

ActiveUS7712592B2Prevent movementPrevent rotationYielding couplingSlip couplingSerpentine beltAlternator

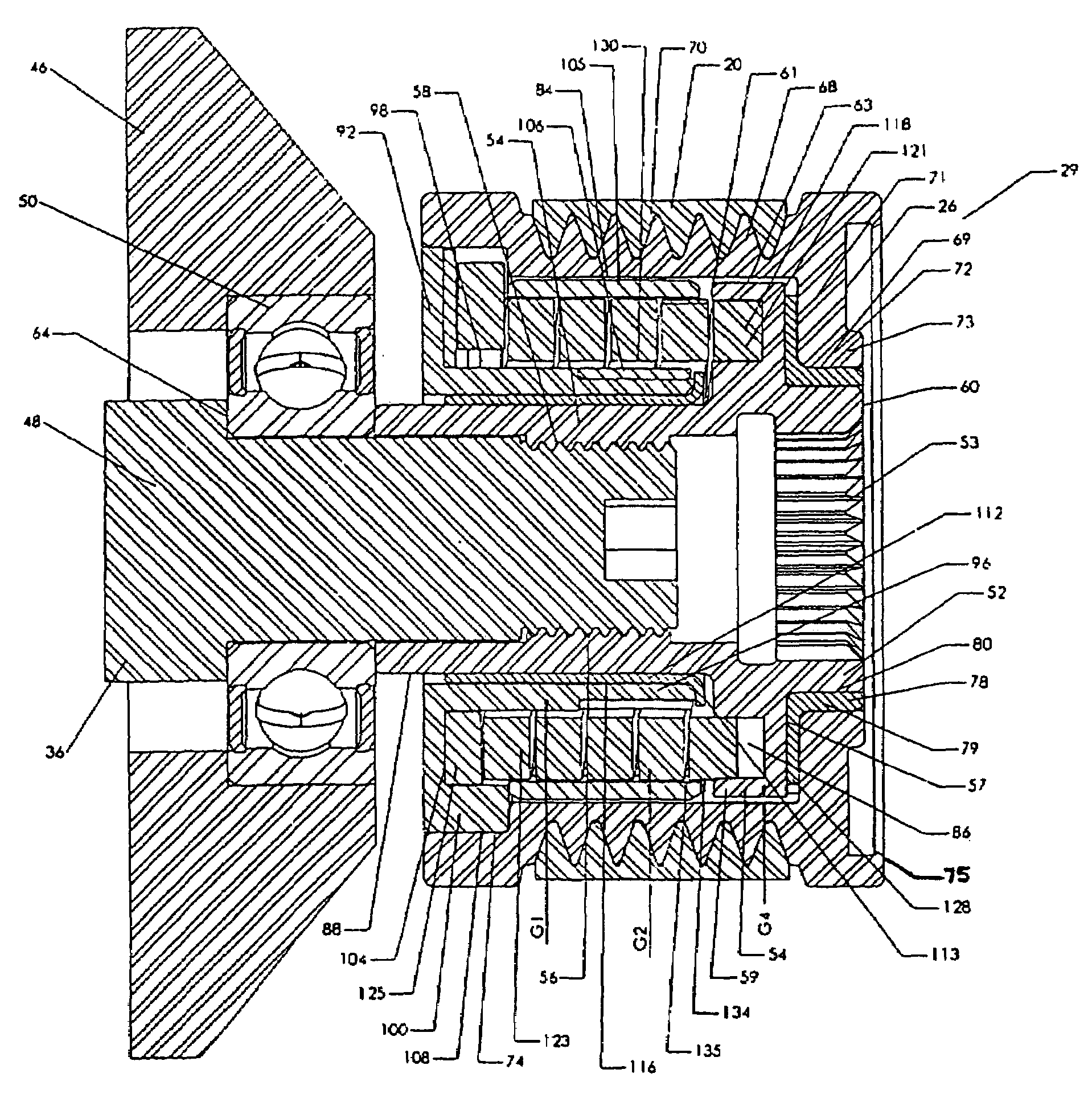

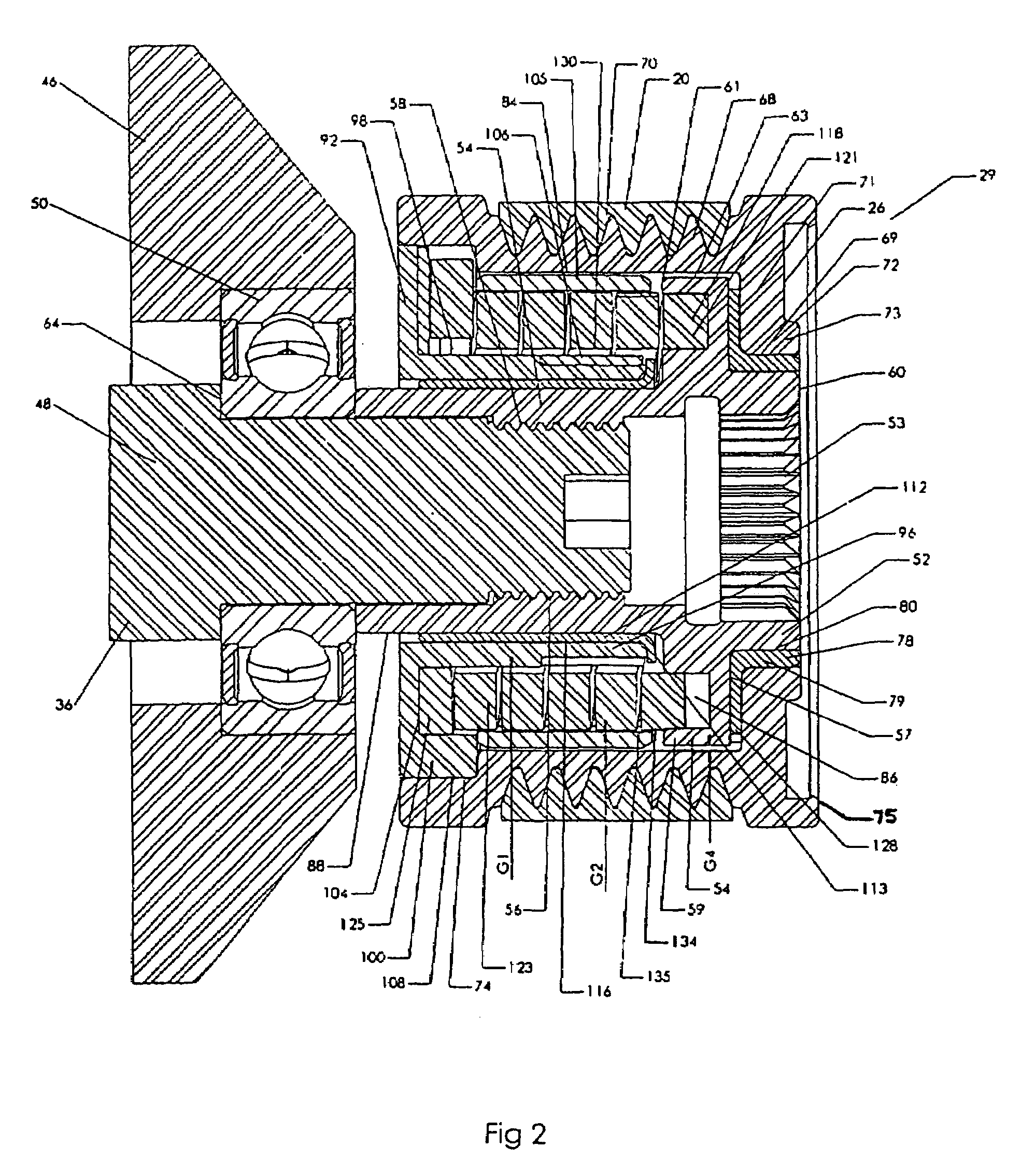

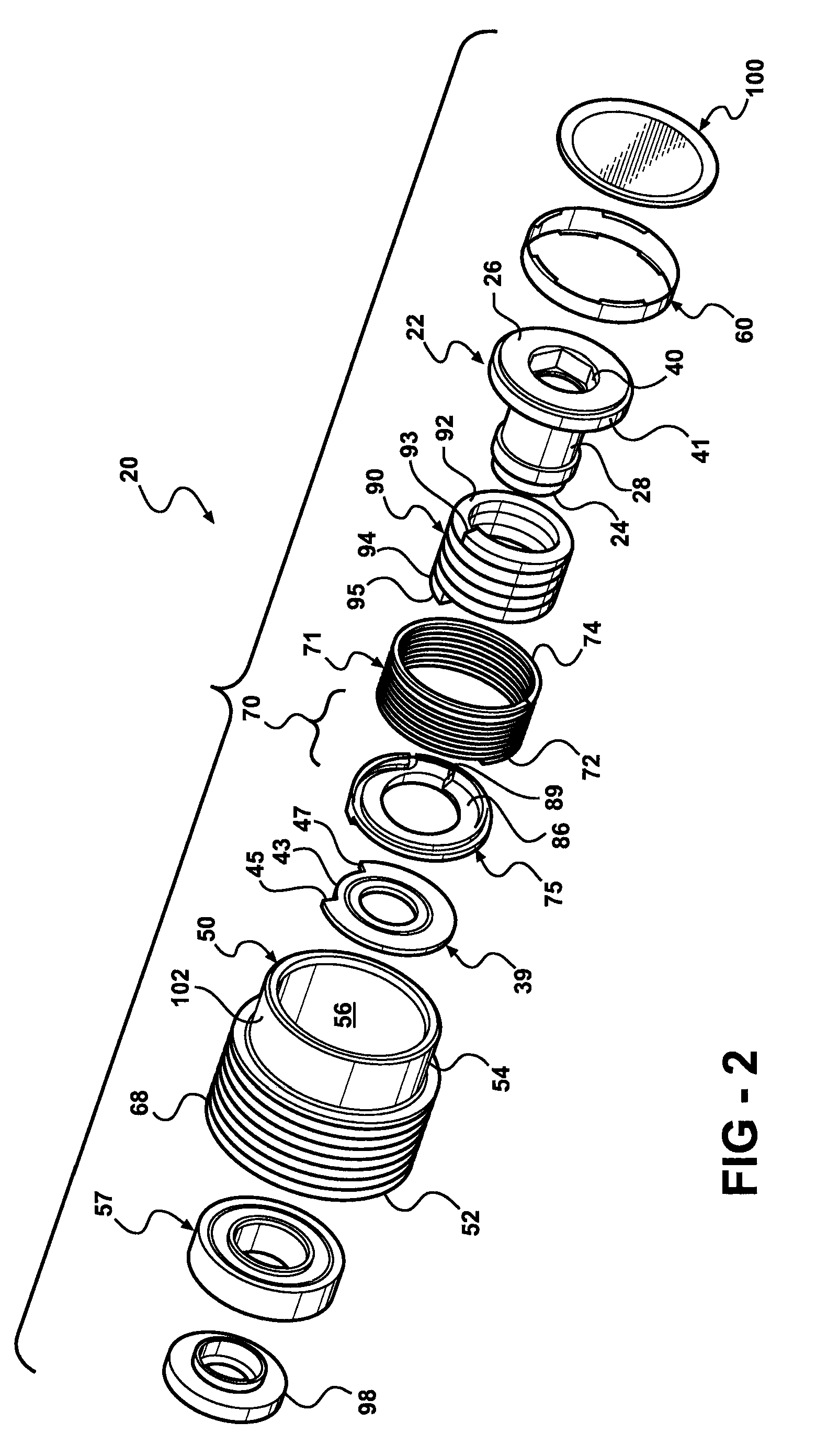

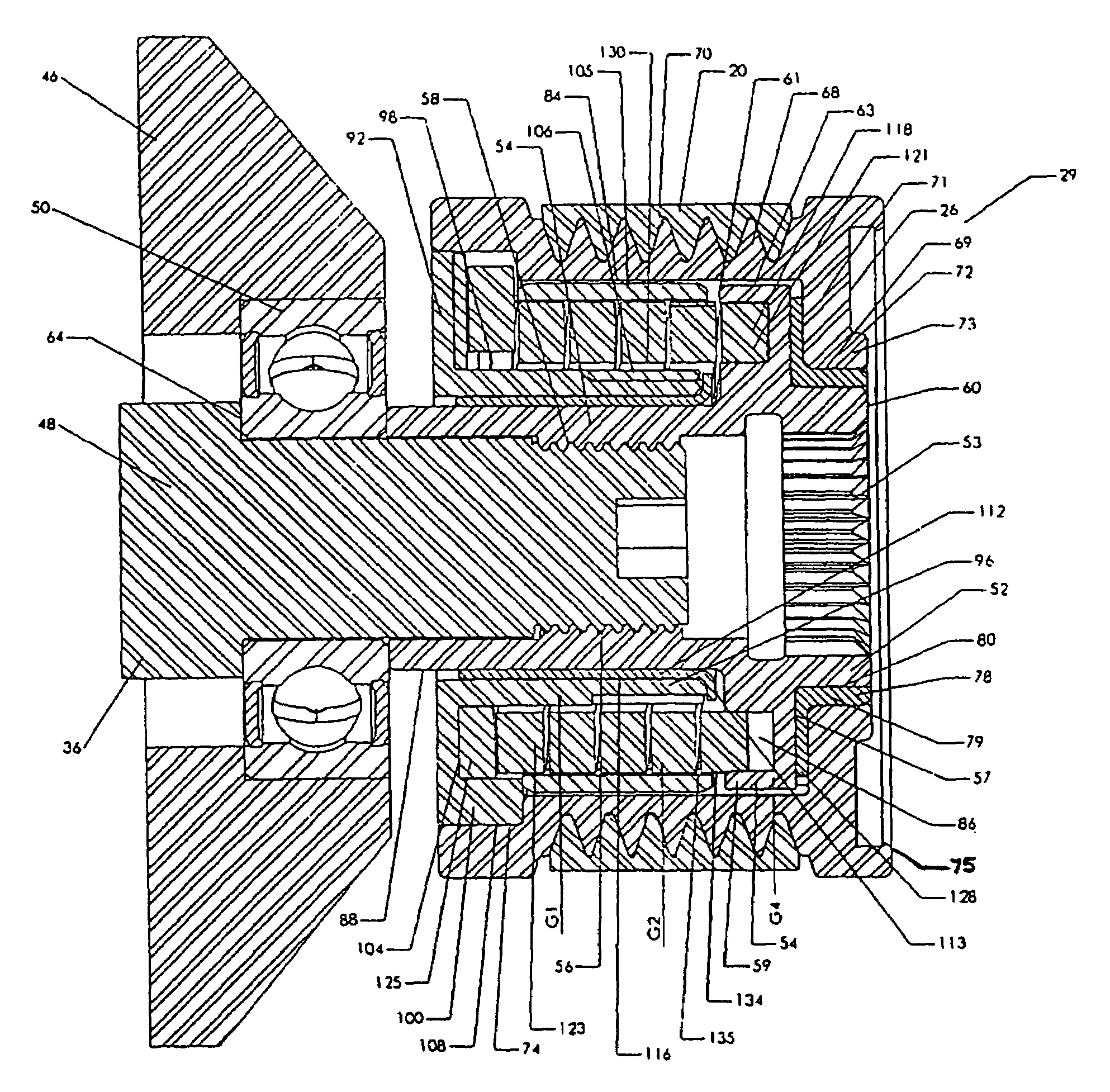

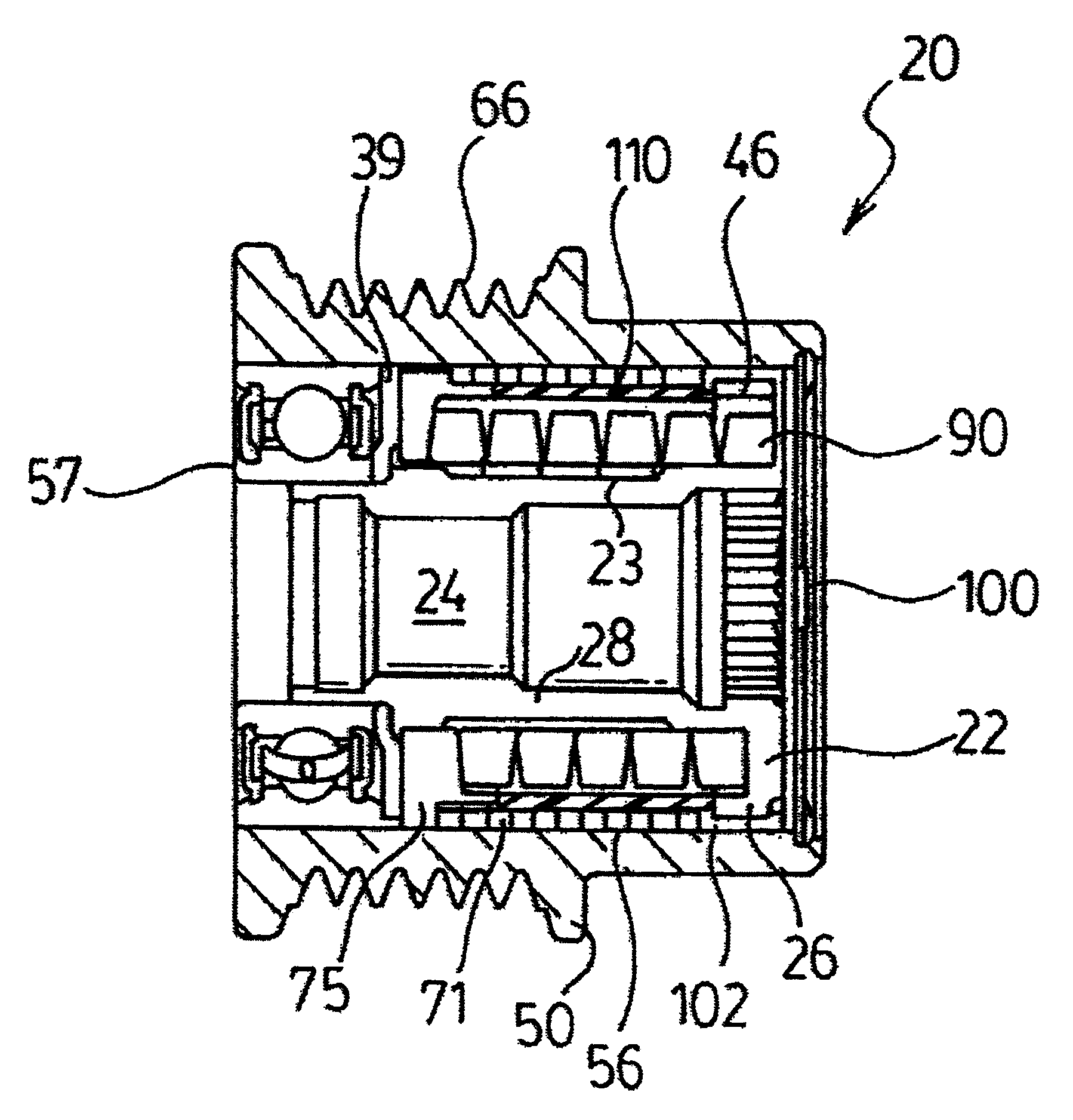

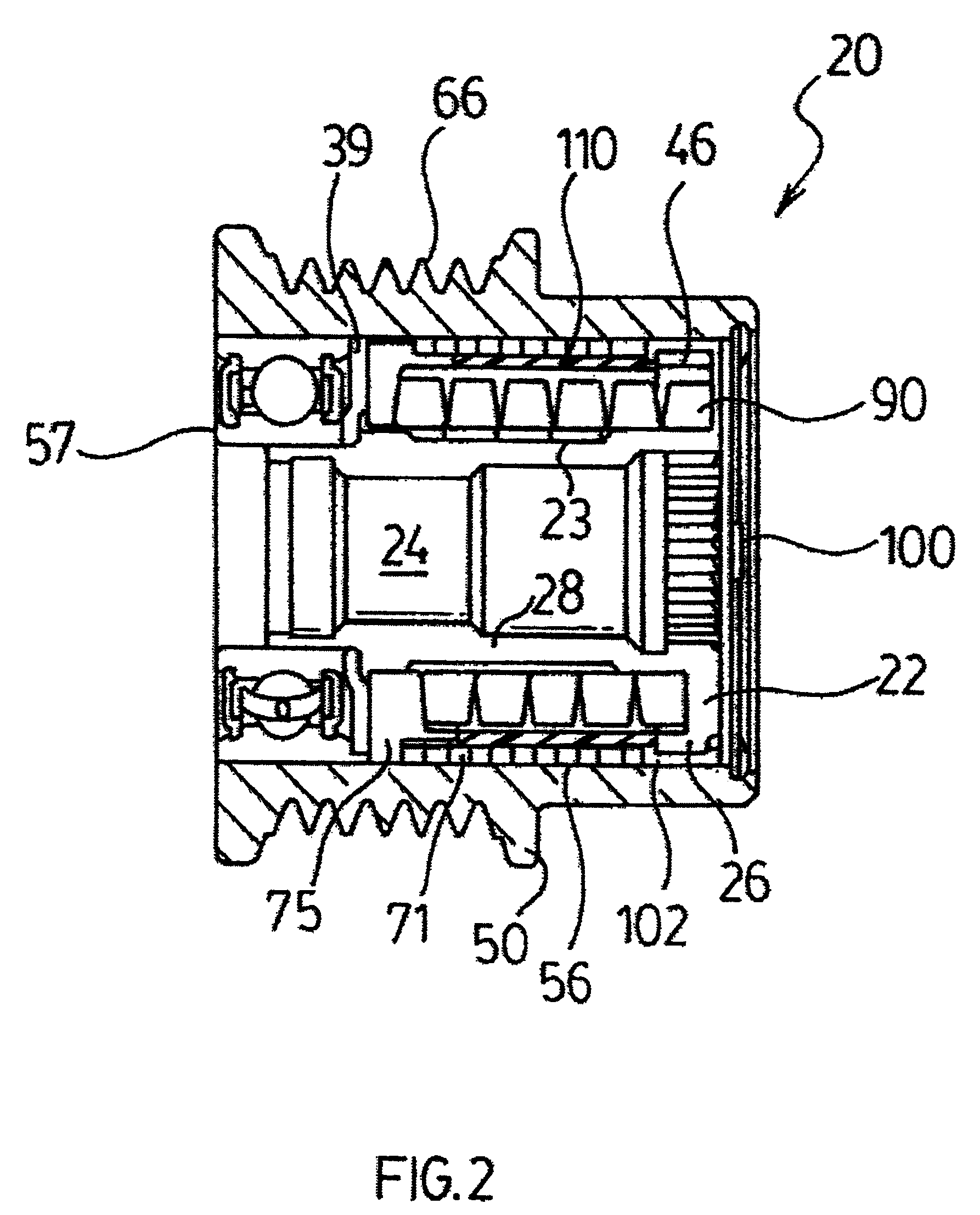

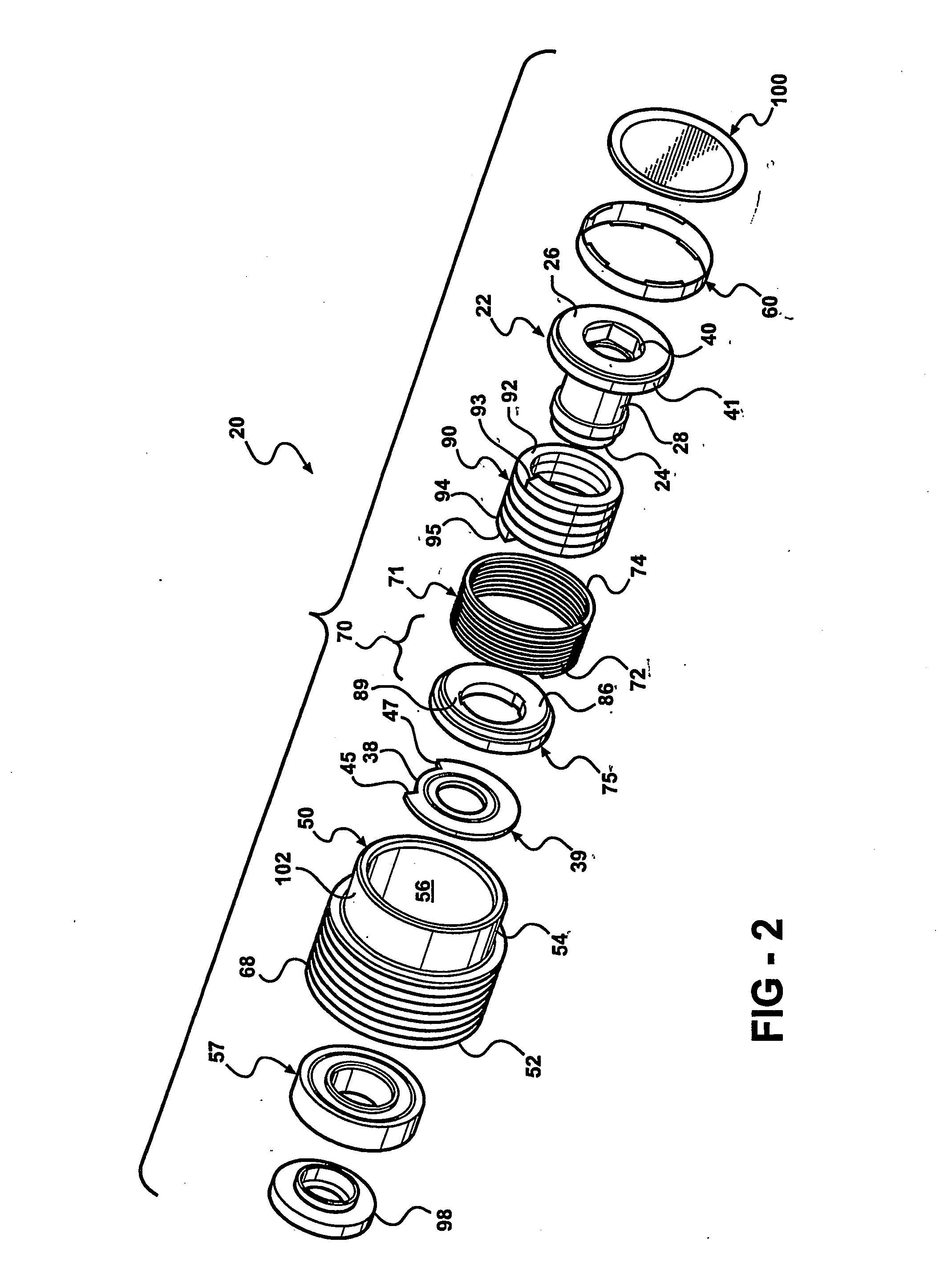

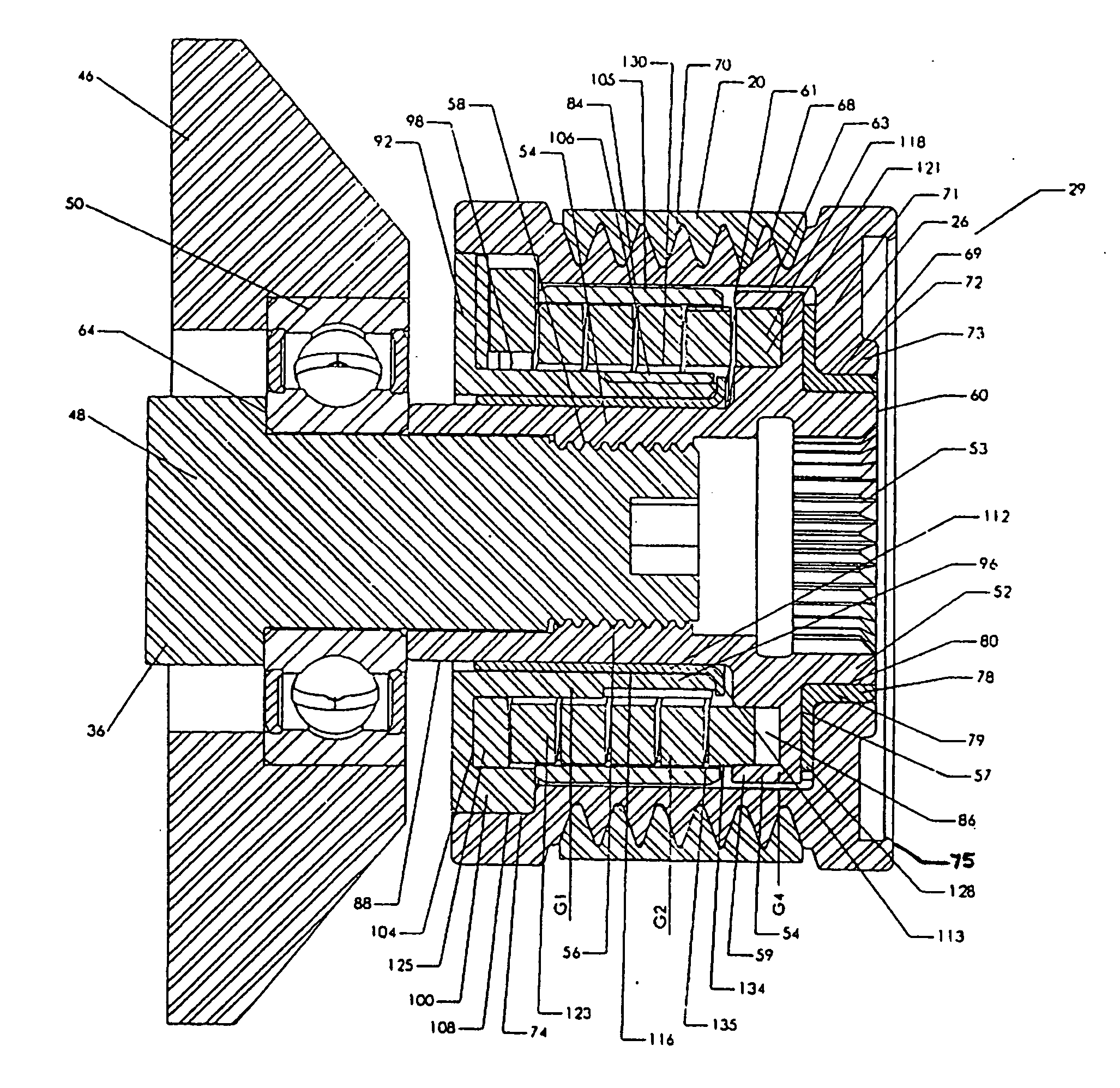

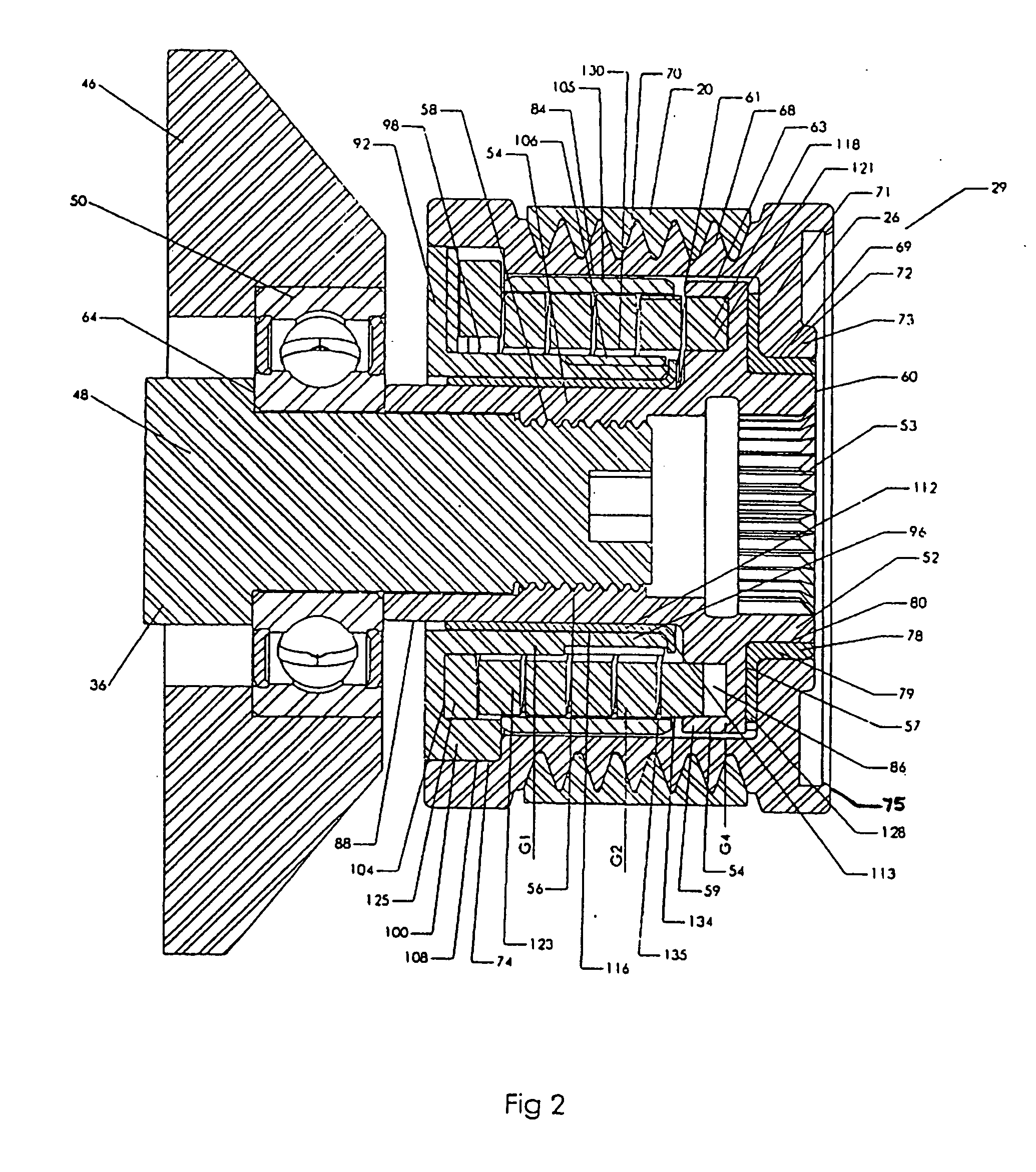

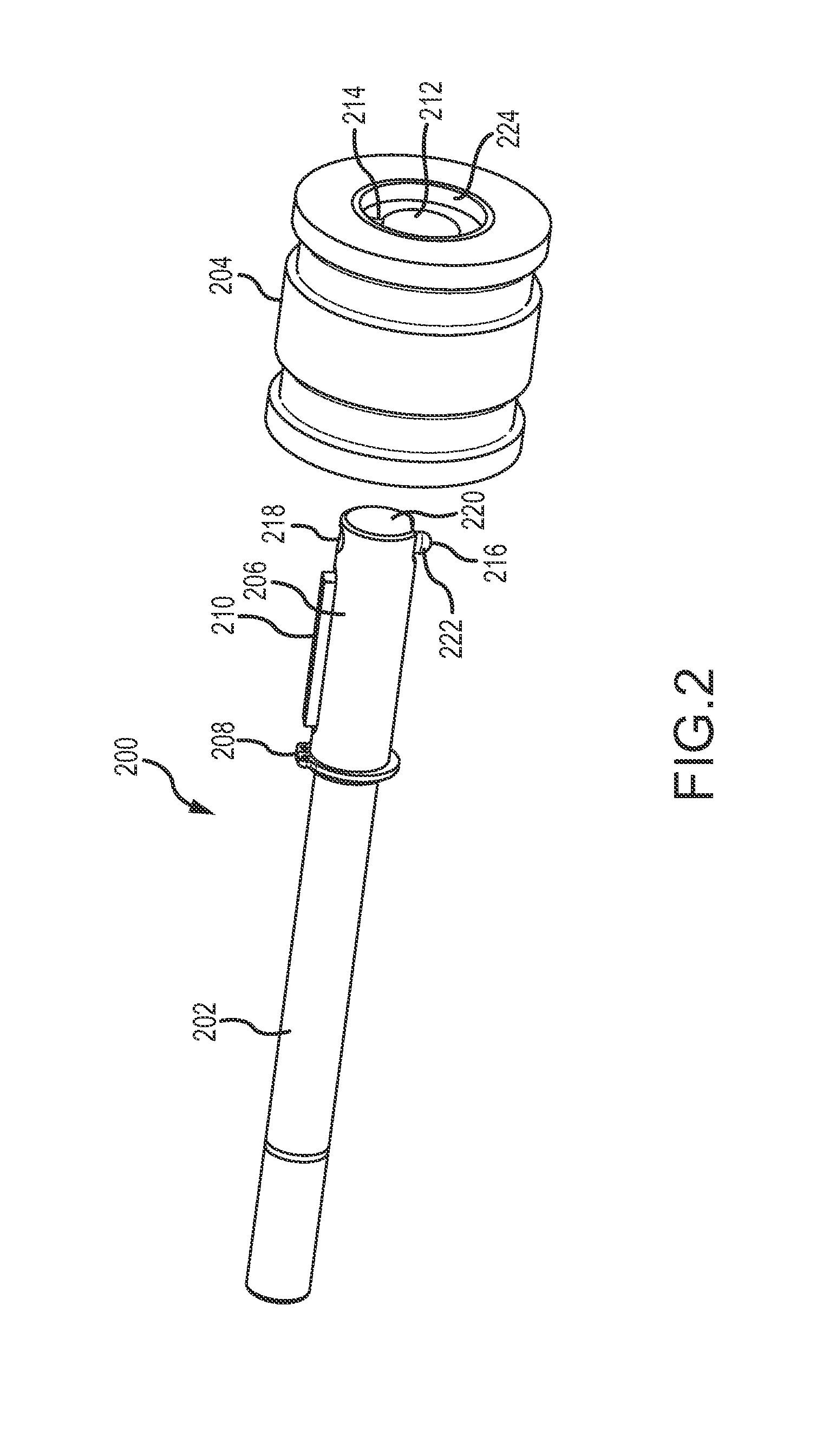

A decoupler assembly for transferring rotary movement between an engine driven shaft and a serpentine belt. The decoupler includes a hub configured to be assembled to the shaft. The hub has a helical first slot formed therein. A pulley is rotatably coupled to the hub. A carrier is mounted on the hub and includes a helical second slot formed therein, as well as an anti-ramp up boss formed thereon. A thrust plate is fixed to the hub and has a slot formed therein. A torsion spring is compressed between a hub end retained in the helical first slot and a carrier end retained in the helical second slot for transferring torque between the hub and carrier. The anti-ramp up boss travels within the slot formed in the thrust plate for limiting rotation between the carrier and thrust plate and preventing rotation of the torsion spring relative to the hub and carrier.

Owner:LITENS AUTOMOTIVE INC

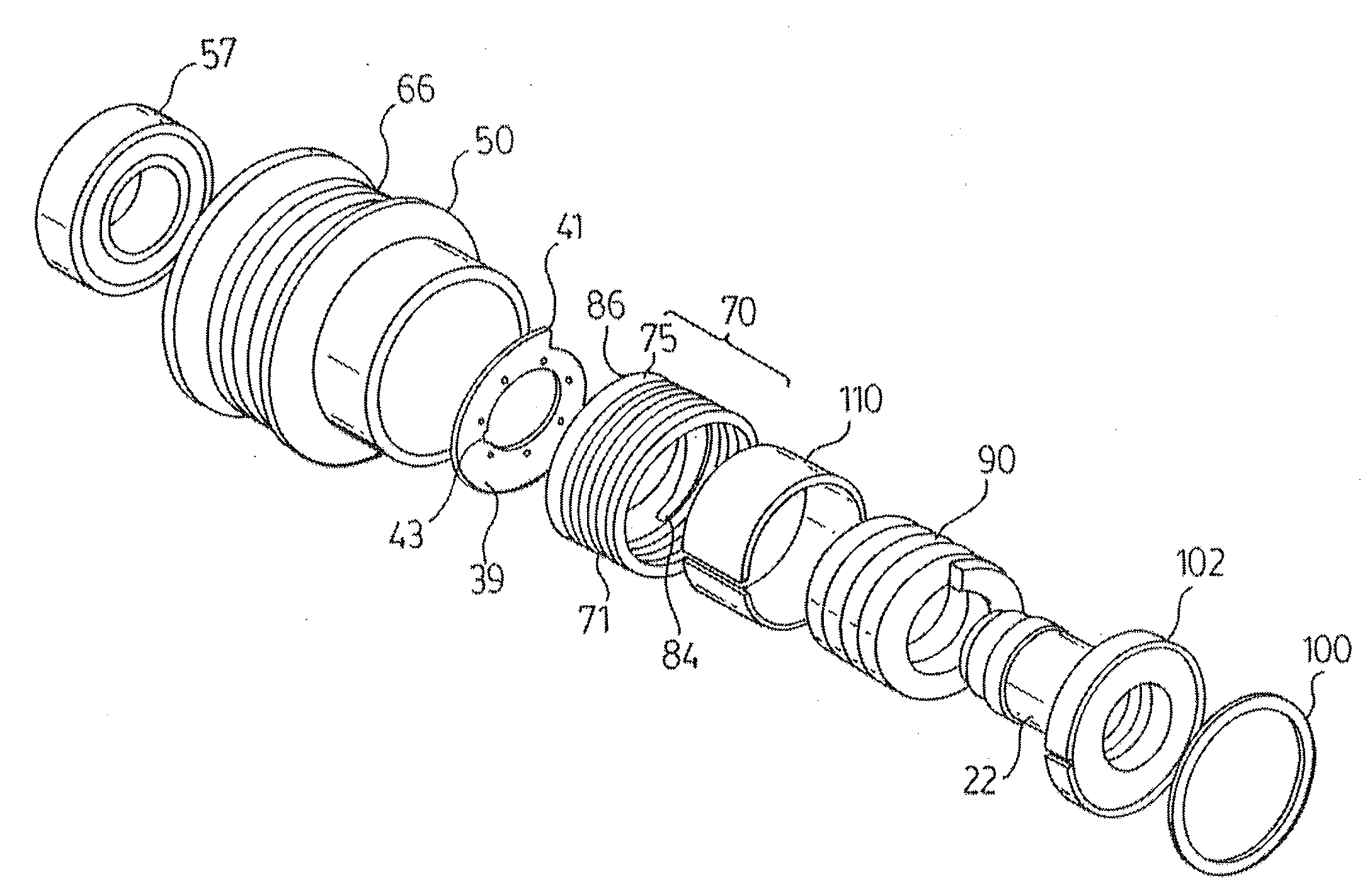

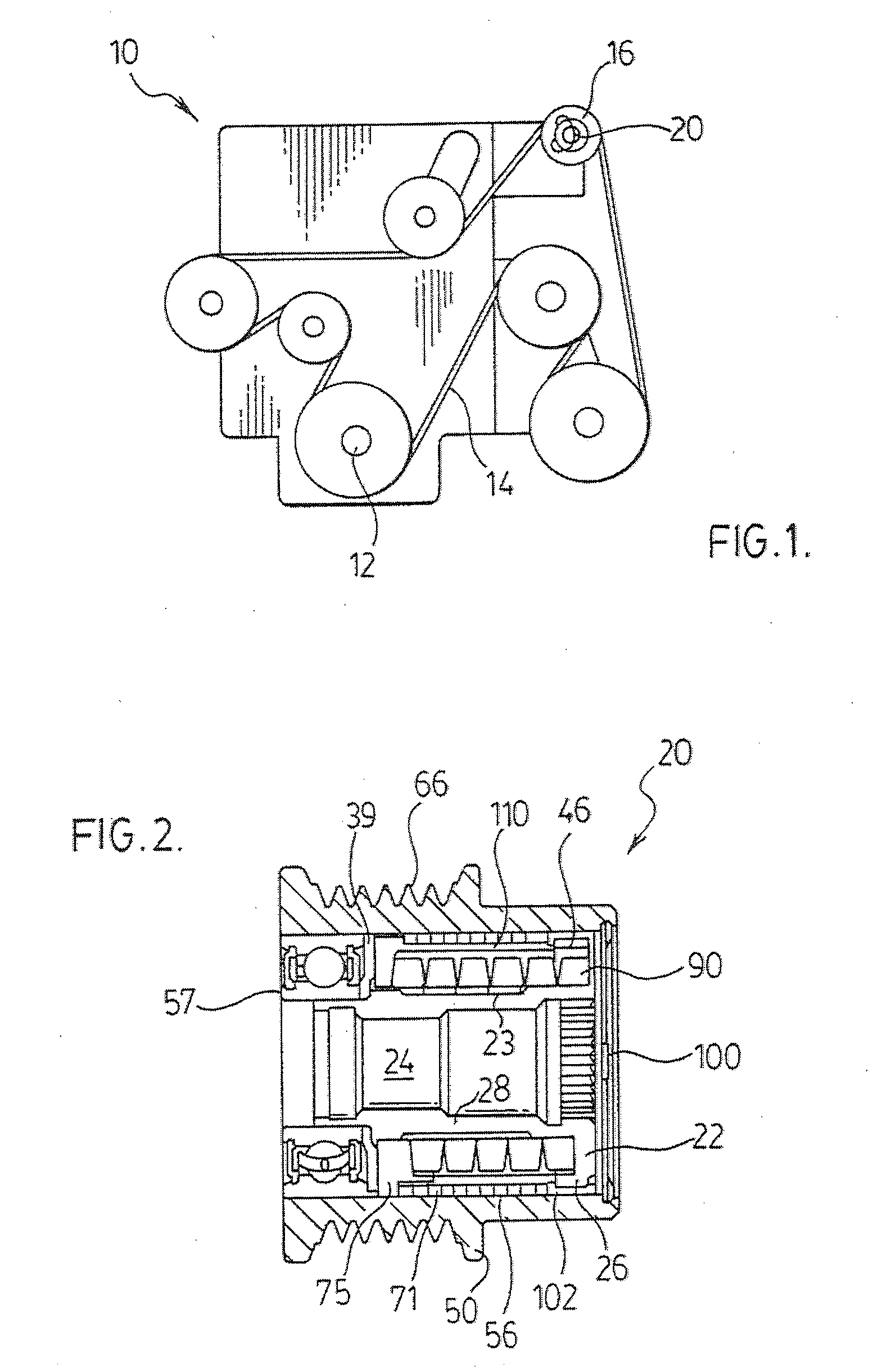

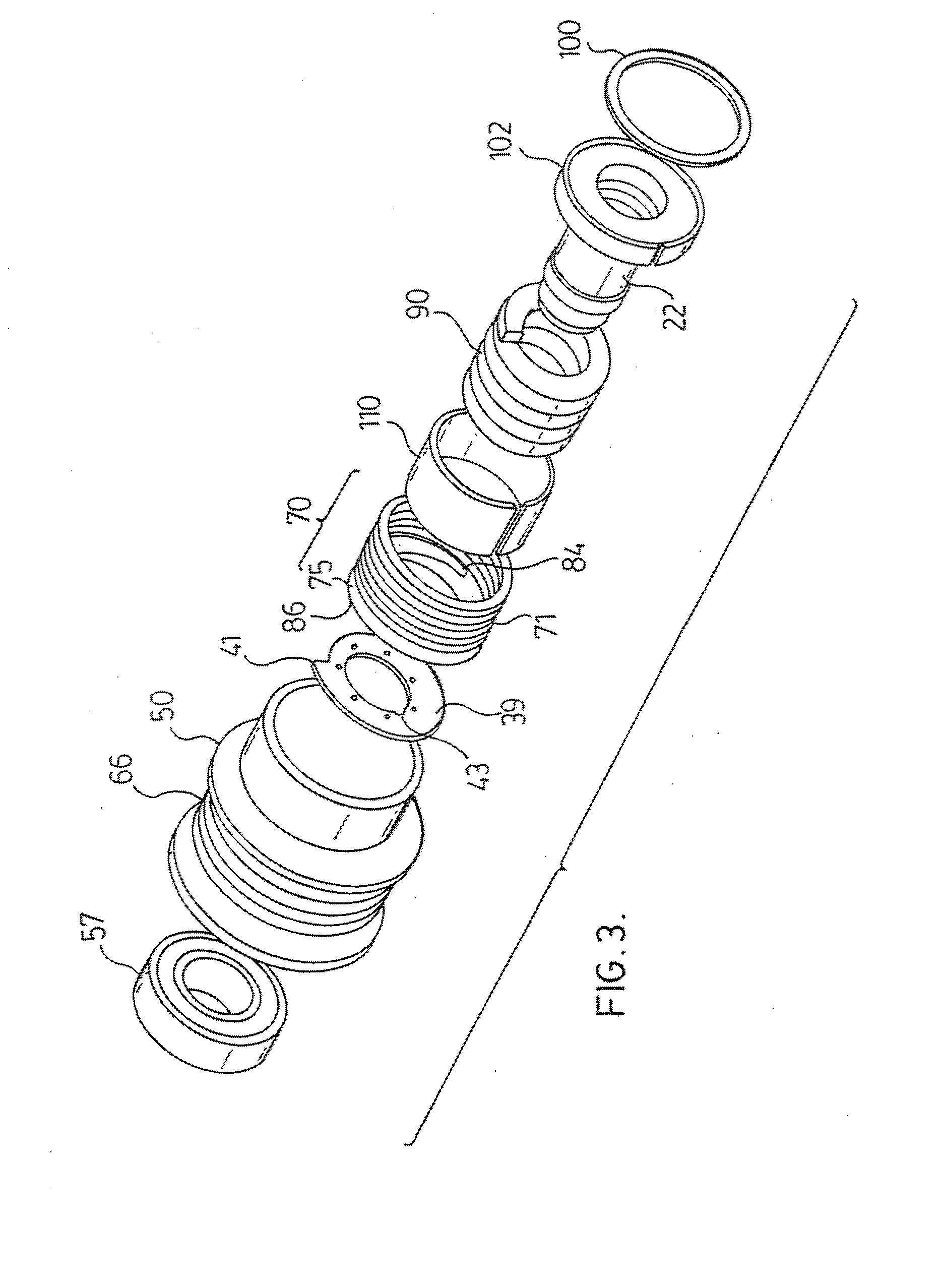

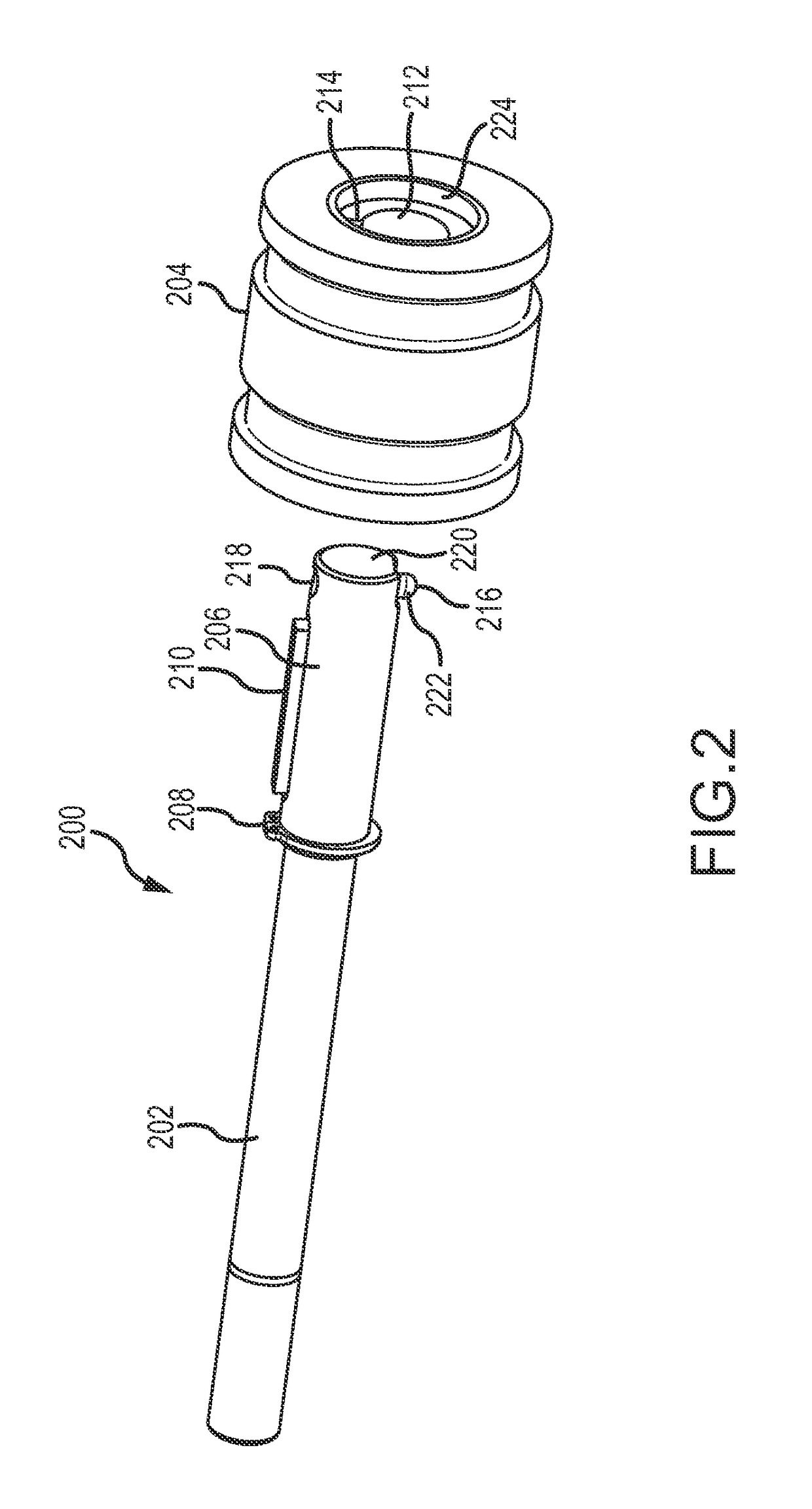

Isolator for alternator pulley

InactiveUS7207910B2Dampen rotational movementIncrease damping forceYielding couplingChain/belt transmissionSerpentine beltAlternator

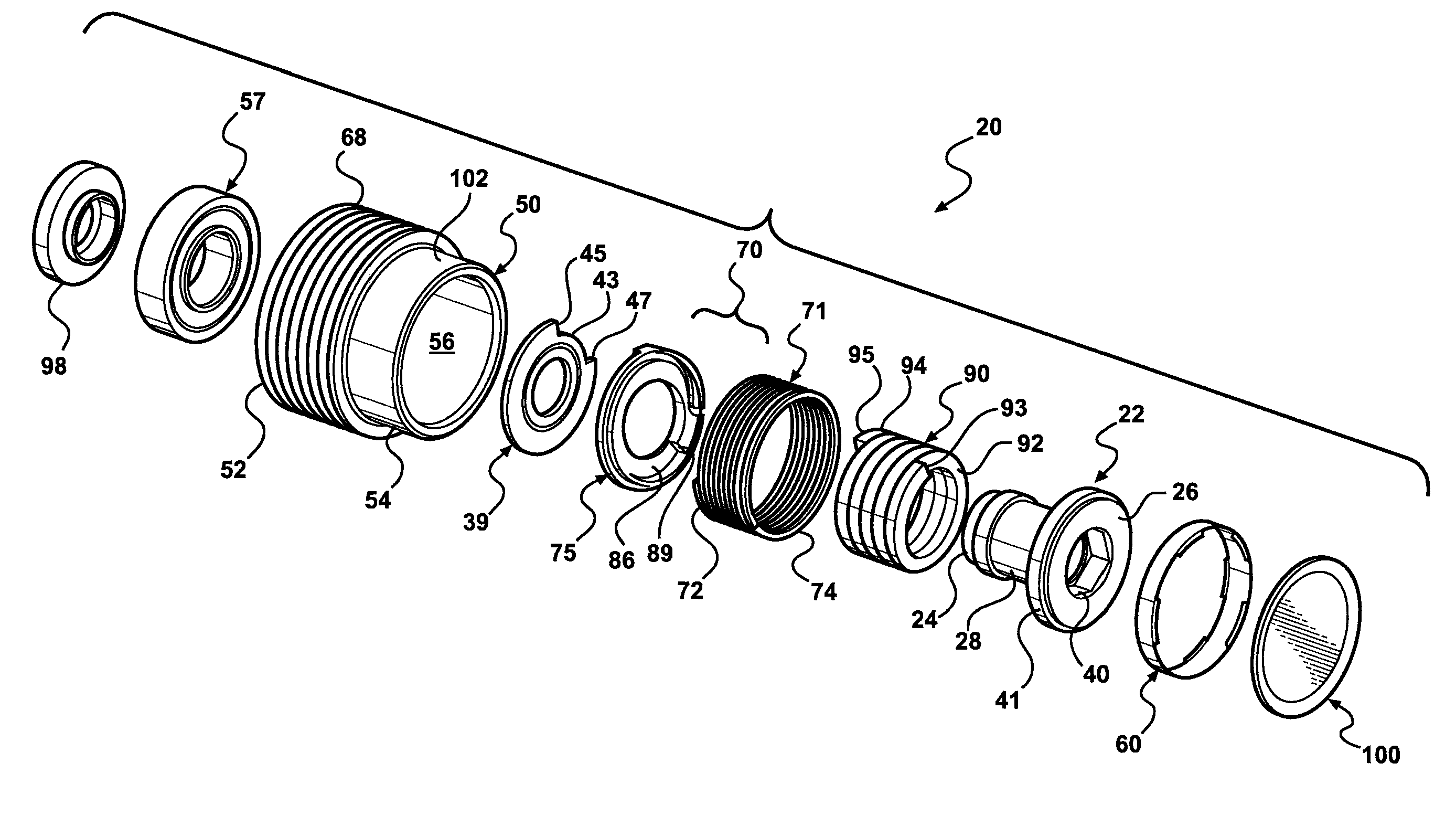

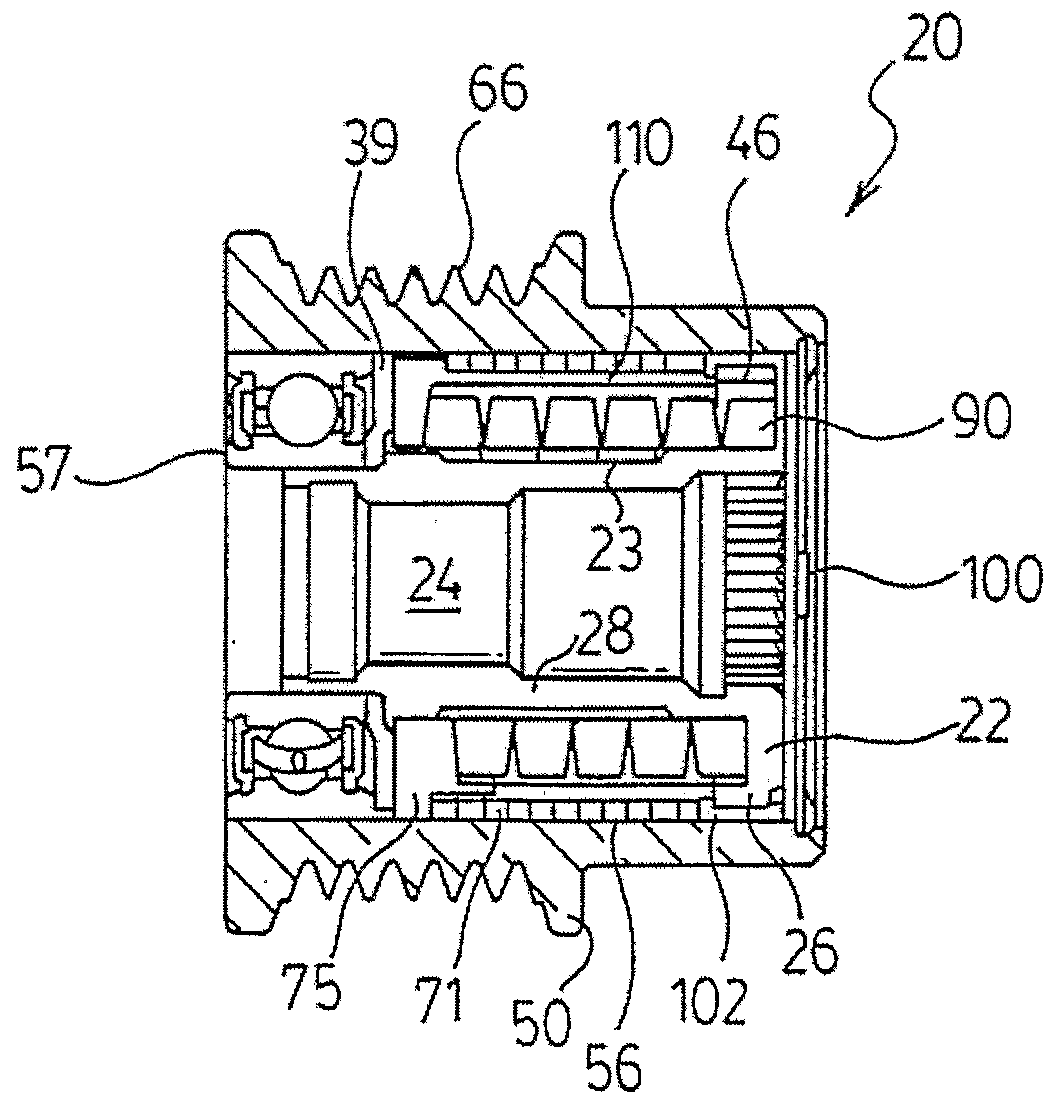

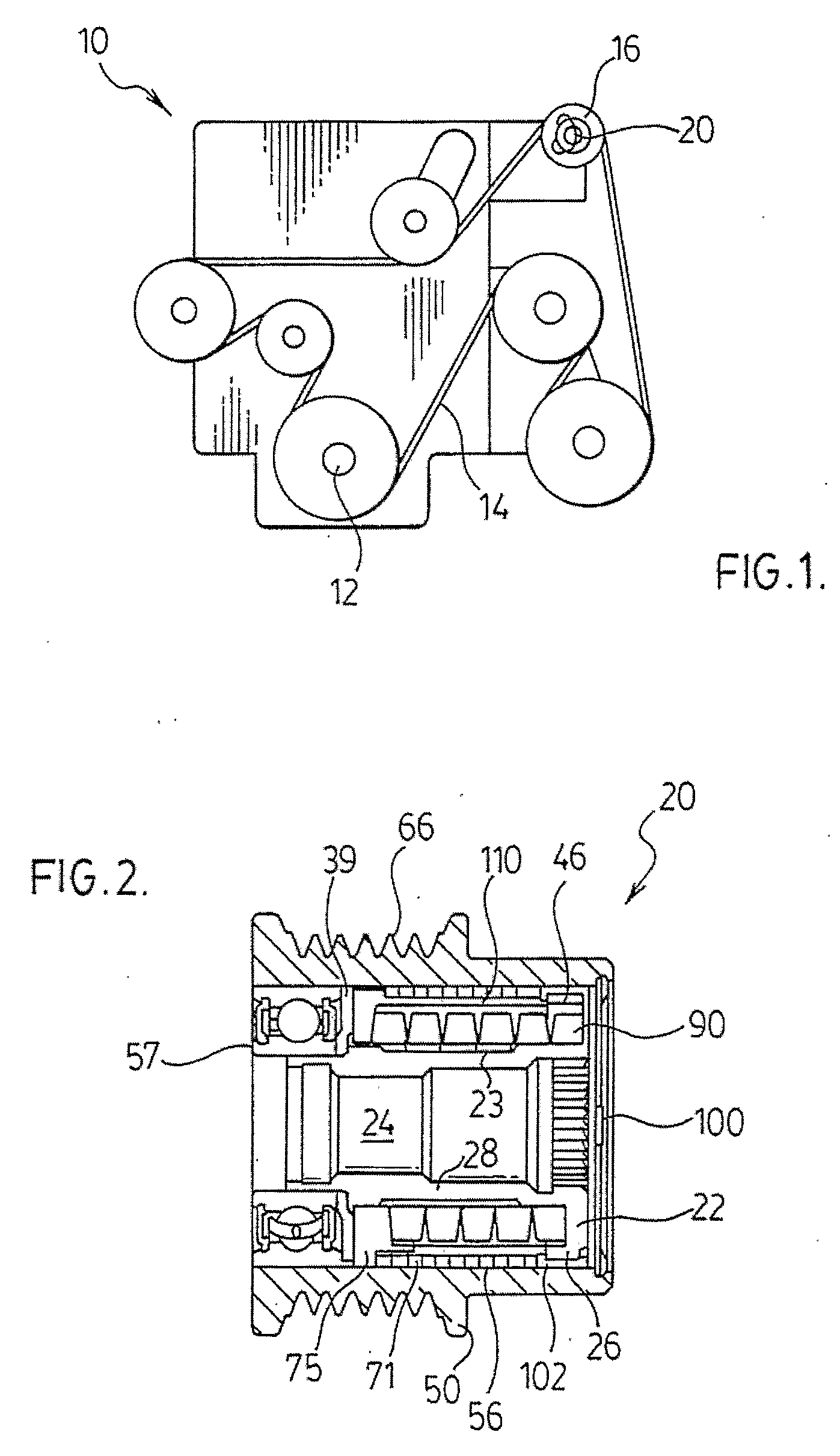

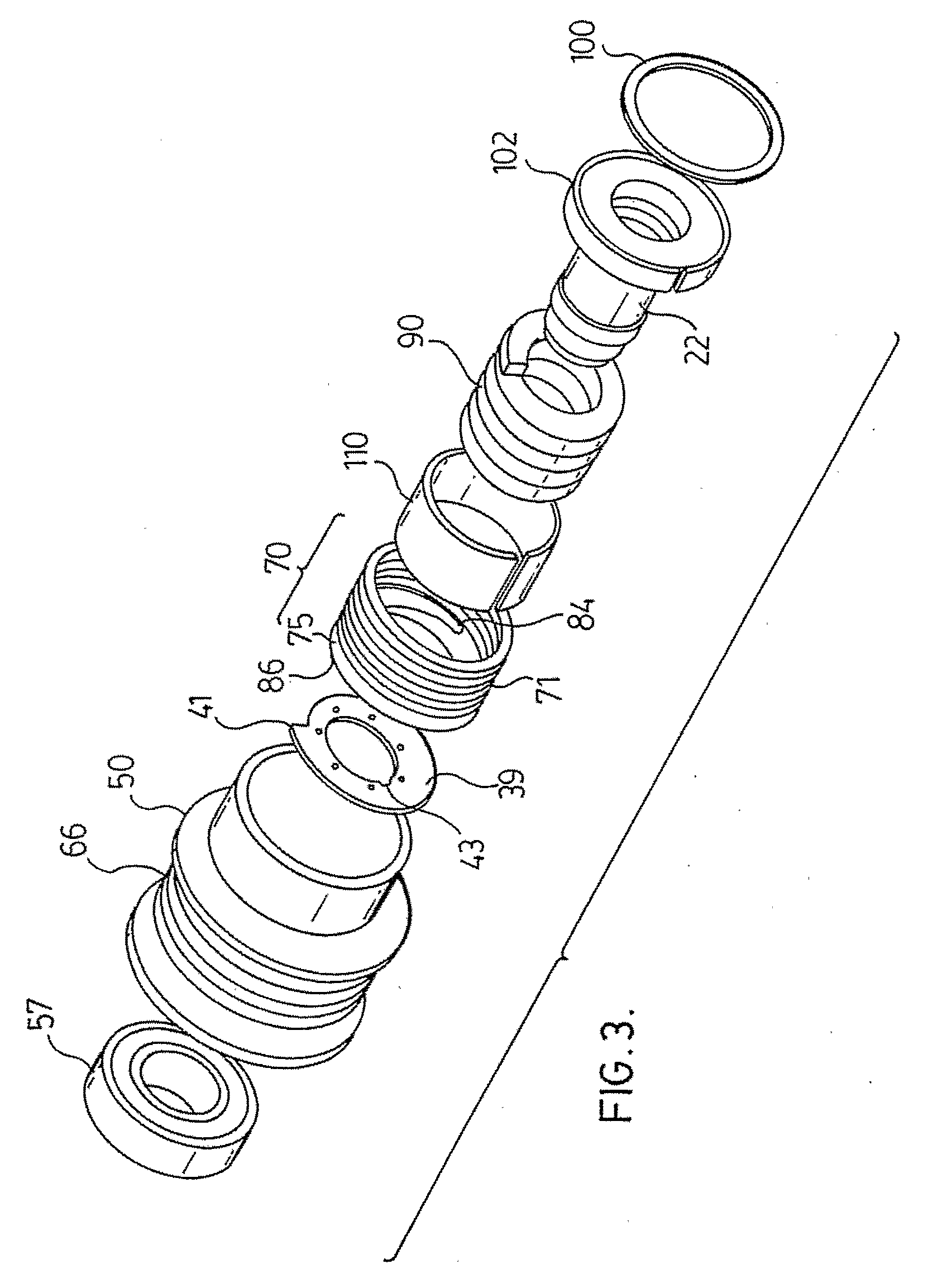

A decoupler for an alternator pulley in a serpentine drive system has a resilient, helical spring member that couples the alternator pulley with a hub structure through a spring retaining member. A bushing is disposed between the spring retaining member and the hub structure to facilitate sliding engagement therebetween. An annular sleeve member is disposed between the spring member and the alternator pulley to facilitate sliding engagement therebetween. The spring member is connected at one end thereof to the hub structure and connected at an opposite end thereof to the spring retaining member. The resilient spring member transmits the driven rotational movements of the alternator pulley by the serpentine belt to the hub structure such that the alternator shaft is rotated in the same direction as the alternator pulley while being capable of instantaneous relative resilient movements in opposite directions with respect to the alternator pulley during the driven rotational movement.

Owner:LITENS AUTOMOTIVE INC

Torque limited decoupler

A decoupler assembly is provided for allowing an alternator to be rotatably driven by a serpentine belt in an engine of an automotive vehicle and for allowing the speed of the belt to oscillate relative to the alternator. A hub is fixedly carried by a drive shaft from the alternator for rotation therewith. A pulley is rotatably journaled to the hub by a ball bearing assembly. A bare, helical clutch spring is operatively coupled between the hub and pulley for transferring rotational movement from the pulley to the hub during acceleration of the pulley relative to the hub by the serpentine belt and for allowing the hub to overrun the pulley during deceleration of the pulley relative to the hub. A torque limiter, preferably a spring or sleeve, is wrapped about the torsion limiting outward expansion of the torsion isolating the torsion spring from torques above a predetermined limit.

Owner:LITENS AUTOMOTIVE INC

Spring Travel Limiter For Overrunning Alternator Decoupler

ActiveUS20080108442A1Prevent movementPrevent rotationYielding couplingSlip couplingSerpentine beltAlternator

A decoupler assembly for transferring rotary movement between an engine driven shaft and a serpentine belt. The decoupler includes a hub configured to be assembled to the shaft. The hub has a helical first slot formed therein. A pulley is rotatably coupled to the hub. A carrier is mounted on the hub and includes a helical second slot formed therein, as well as an anti-ramp up boss formed thereon. A thrust plate is fixed to the hub and has a slot formed therein. A torsion spring is compressed between a hub end retained in the helical first slot and a carrier end retained in the helical second slot for transferring torque between the hub and carrier. The anti-ramp up boss travels within the slot formed in the thrust plate for limiting rotation between the carrier and thrust plate and preventing rotation of the torsion spring relative to the hub and carrier.

Owner:LITENS AUTOMOTIVE INC

Isolator for alternator pulley

InactiveUS20060264280A1Dampen rotational movementIncrease damping forceYielding couplingChain/belt transmissionSerpentine beltAlternator

A decoupler for an alternator pulley in a serpentine drive system has a resilient, helical spring member that couples the alternator pulley with a hub structure through a spring retaining member. A bushing is disposed between the spring retaining member and the hub structure to facilitate sliding engagement therebetween. An annular sleeve member is disposed between the spring member and the alternator pulley to facilitate sliding engagement therebetween. The spring member is connected at one end thereof to the hub structure and connected at an opposite end thereof to the spring retaining member. The resilient spring member transmits the driven rotational movements of the alternator pulley by the serpentine belt to the hub structure such that the alternator shaft is rotated in the same direction as the alternator pulley while being capable of instantaneous relative resilient movements in opposite directions with respect to the alternator pulley during the driven rotational movement.

Owner:LITENS AUTOMOTIVE INC

Torque Limited Decoupler

A decoupler assembly is provided for allowing an alternator to be rotatably driven by a serpentine belt in an engine of an automotive vehicle and for allowing the speed of the belt to oscillate relative to the alternator. A hub is fixedly carried by a drive shaft from the alternator for rotation therewith. A pulley is rotatably journaled to the hub by a ball bearing assembly. A bare, helical clutch spring is operatively coupled between the hub and pulley for transferring rotational movement from the pulley to the hub during acceleration of the pulley relative to the hub by the serpentine belt and for allowing the hub to overrun the pulley during deceleration of the pulley relative to the hub. A torque limiter, preferably a spring or sleeve, is wrapped about the torsion limiting outward expansion of the torsion isolating the torsion spring from torques above a predetermined limit.

Owner:LITENS AUTOMOTIVE INC

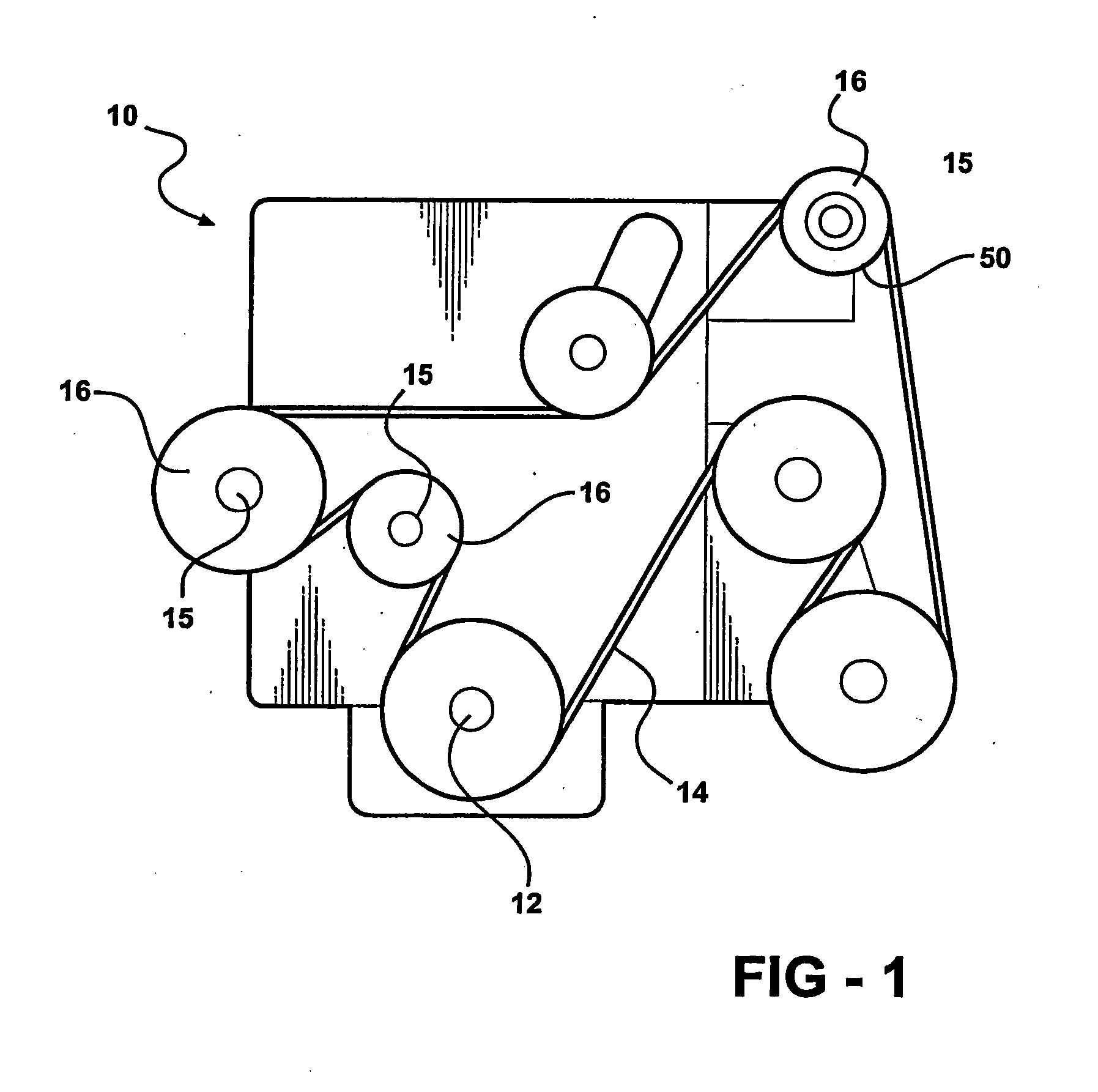

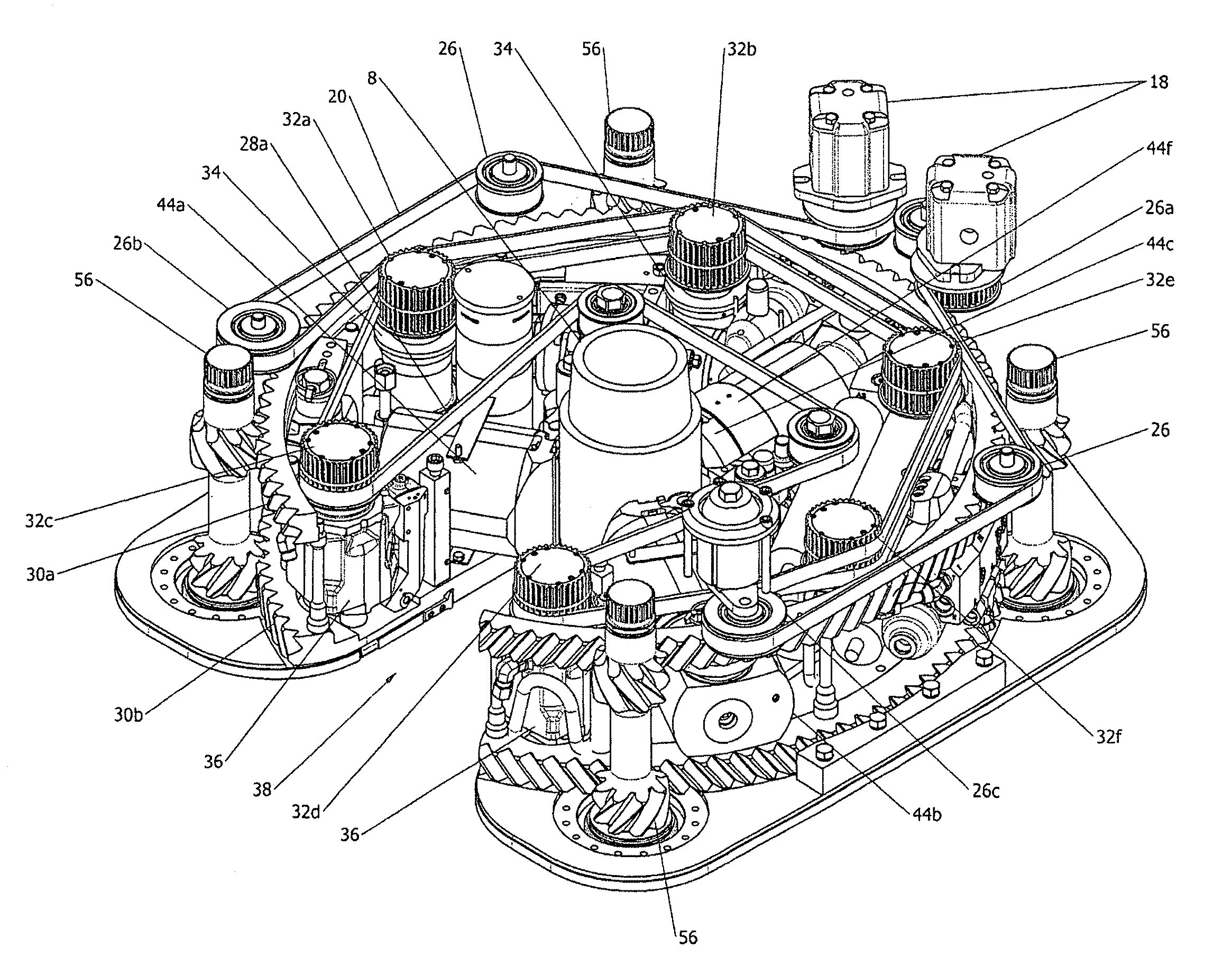

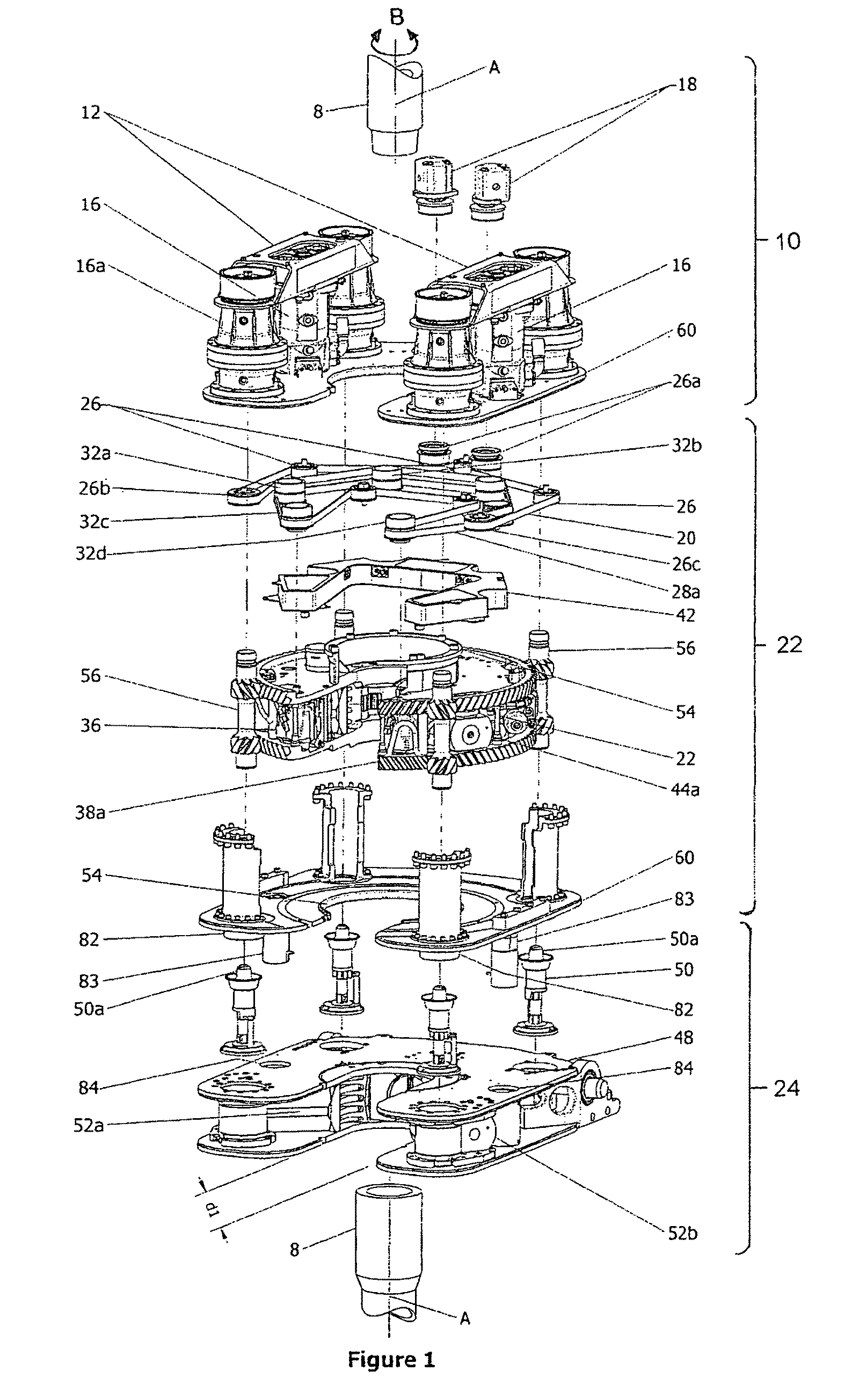

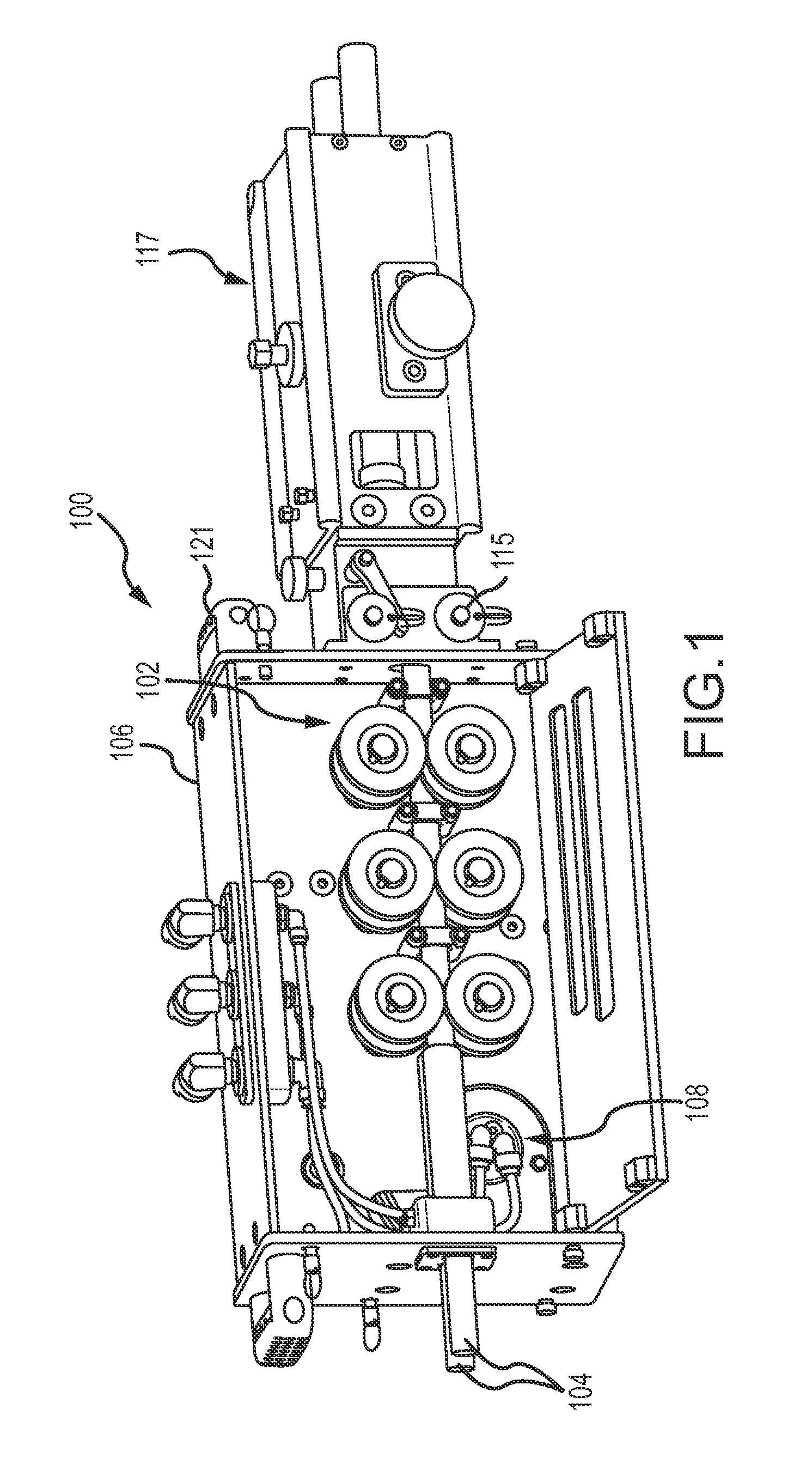

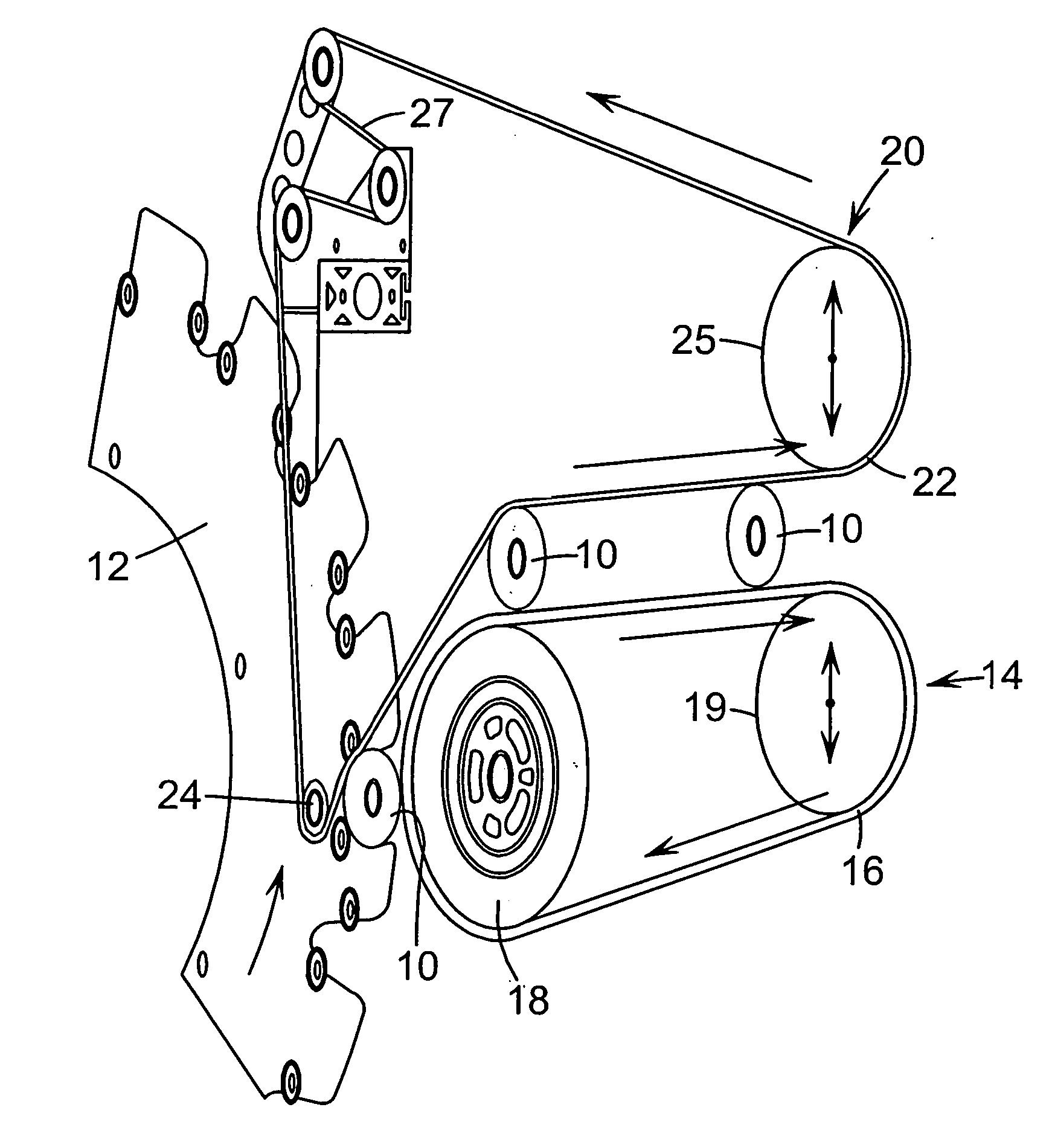

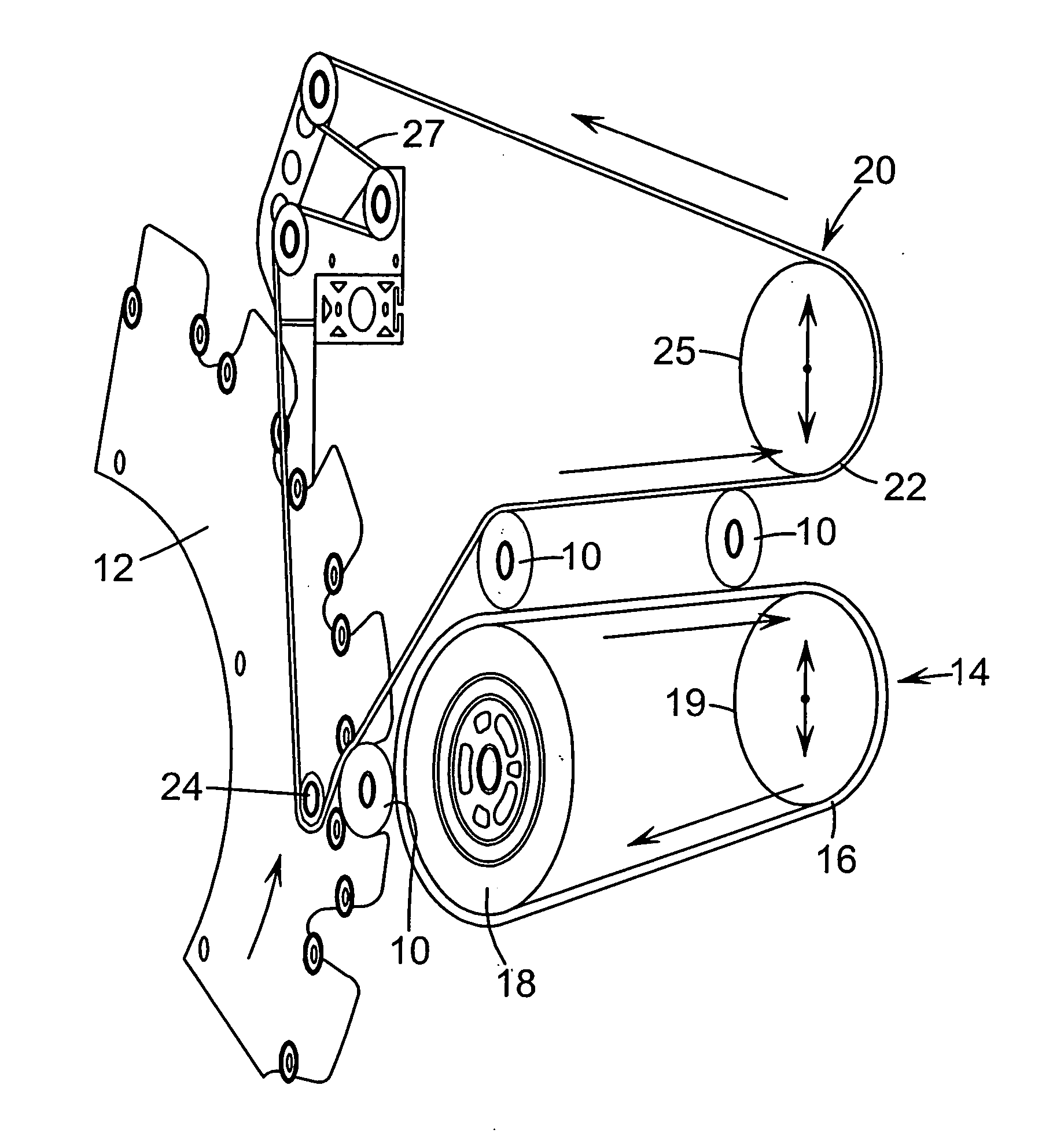

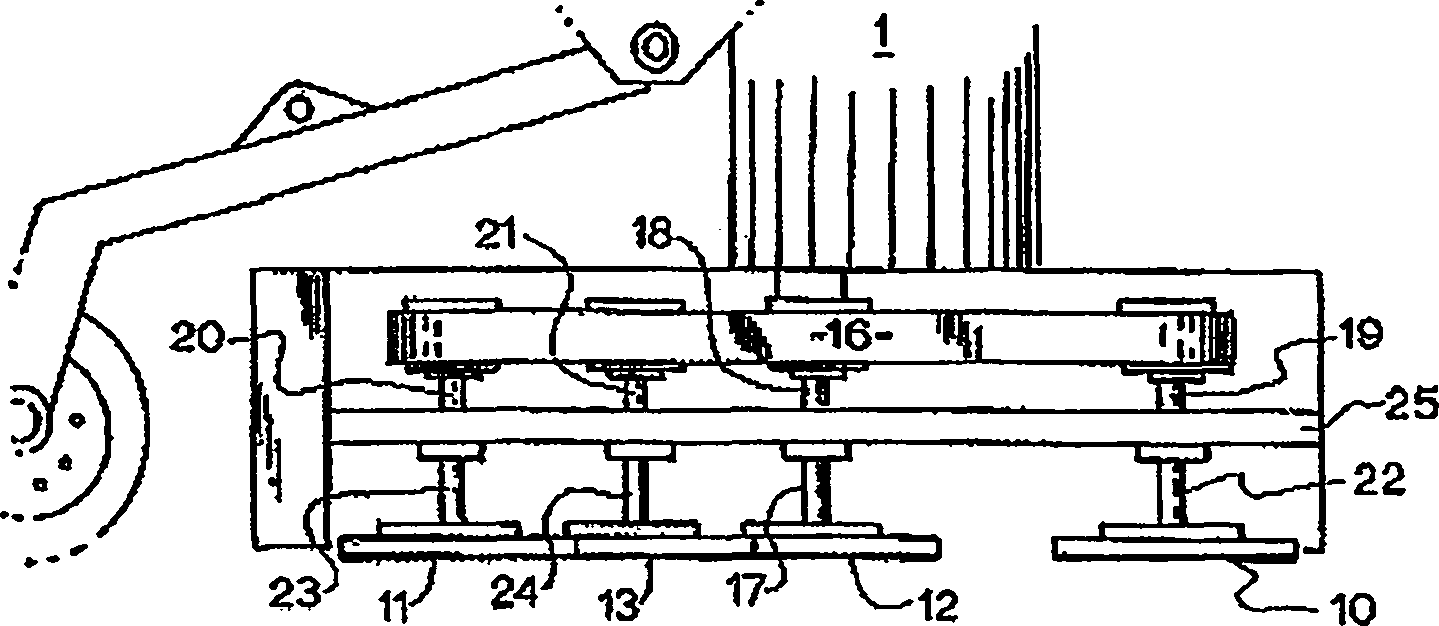

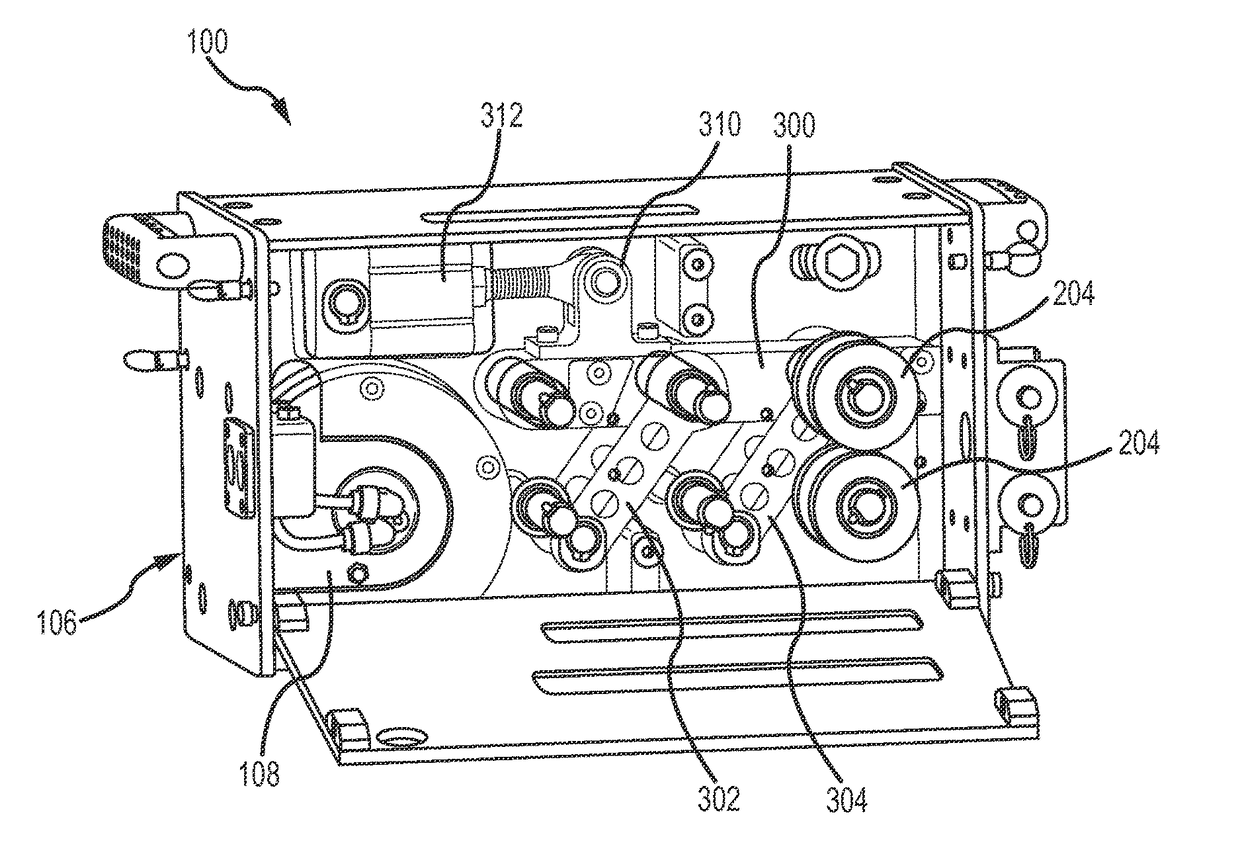

Power tong

A power tong continuously rotates tubulars for spinning and torquing threaded connections. Continuous rotation is achieved through a rotating jaw having grippers that grip the tubular and continuously rotate with it. Hydraulic and electrical power necessary for actuating the grippers is generated on board. A serpentine belt system turns the motors of the on-board hydraulic power unit and electric generators to supply the grippers with hydraulic and electrical power. The serpentine belt system is driven by a secondary drive mounted on a fixed frame. The rotating jaw is rotatably mounted to the fixed frame and driven during continuous three hundred and sixty degrees of rotation by a primary drive, mounted on the fixed frame. A fixed jaw is also mounted to the frame. Tubular grippers on the fixed jaw grip a first side of a tubular joint. The grippers on the rotating jaw grip the opposite second side of the tubular joint. High torque low-rotational speed applied to the rotating jaw torques the joint. Low torque high-rotational speed applied to the rotating jaw spins the joint.

Owner:WARRIOR RIG TECH LTD

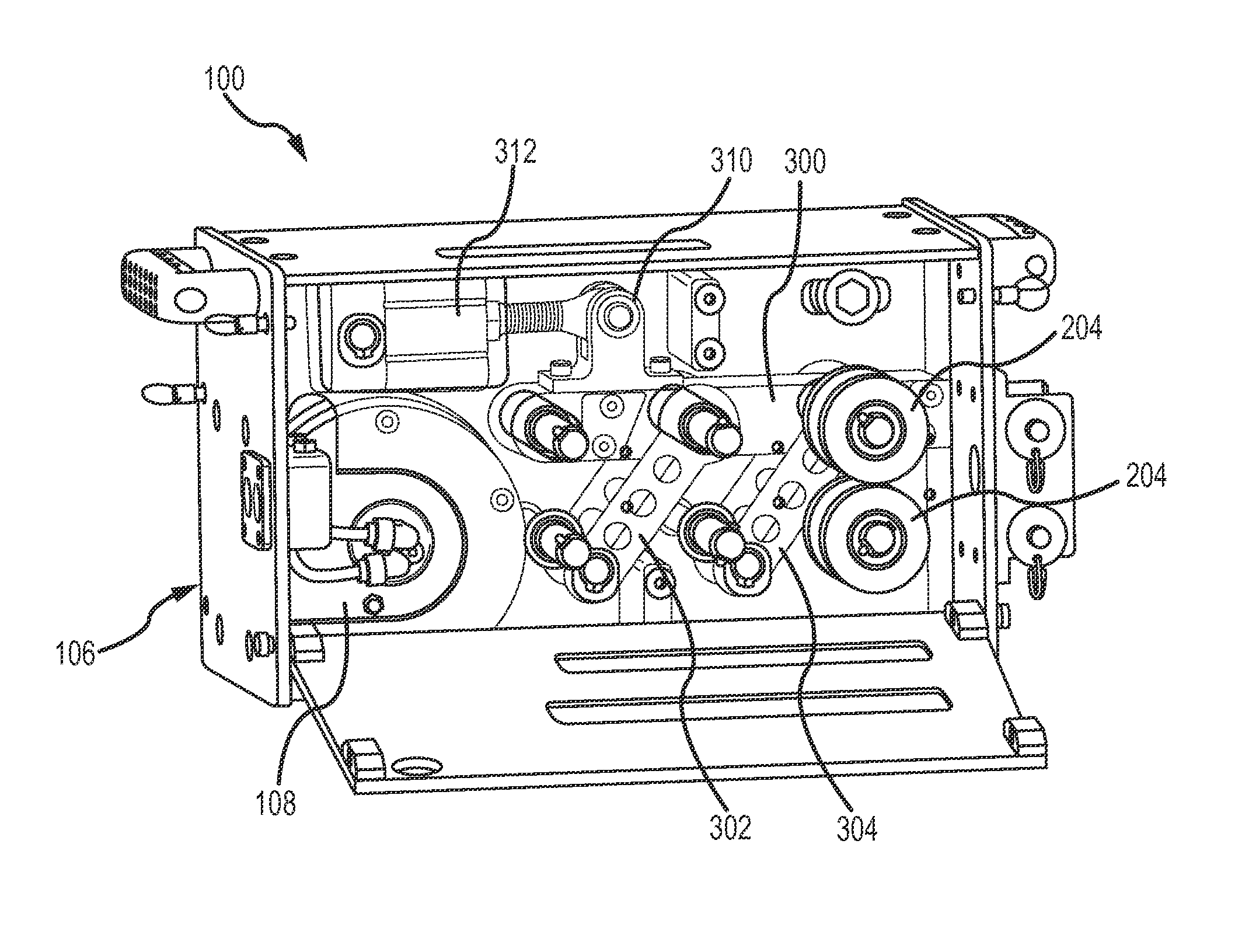

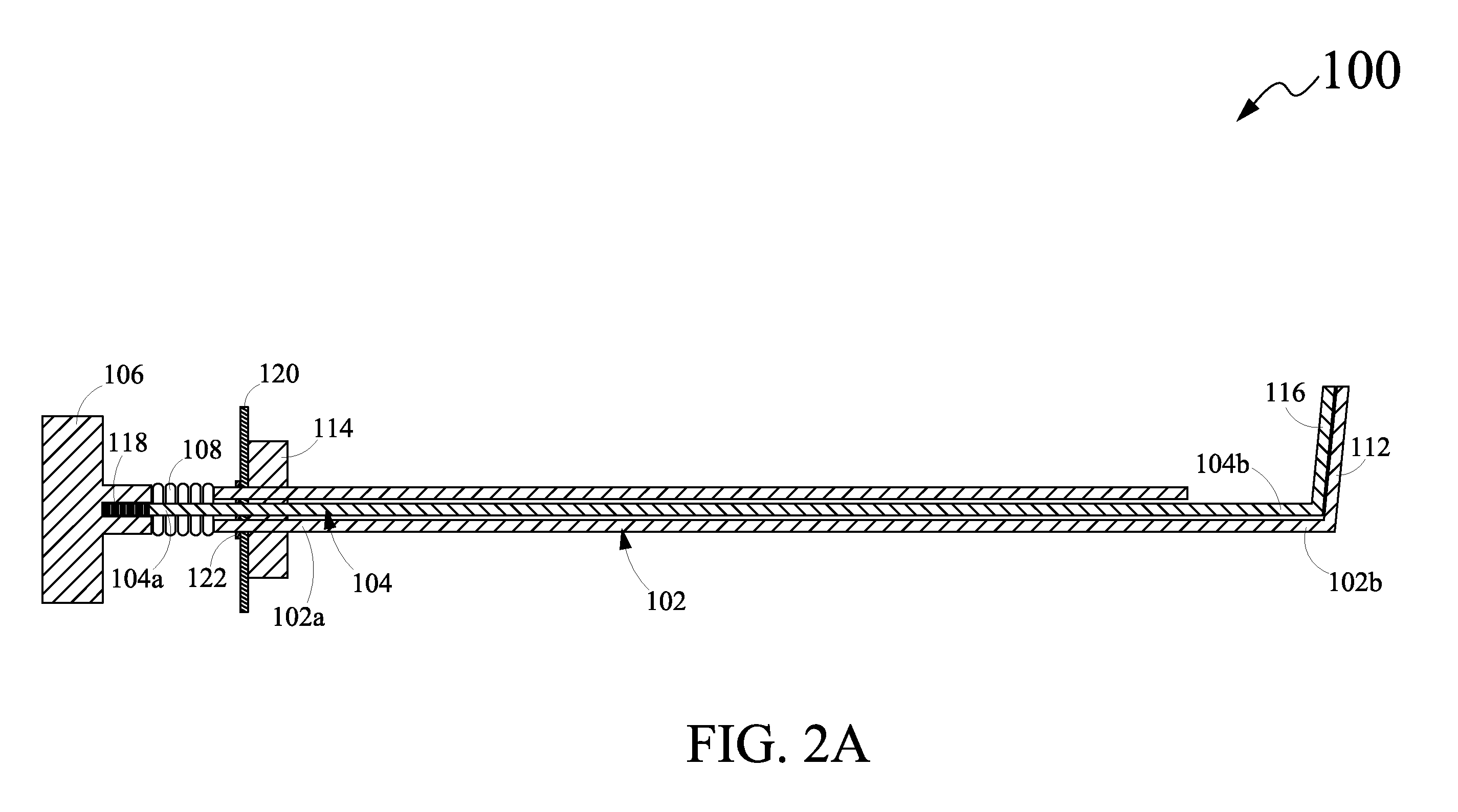

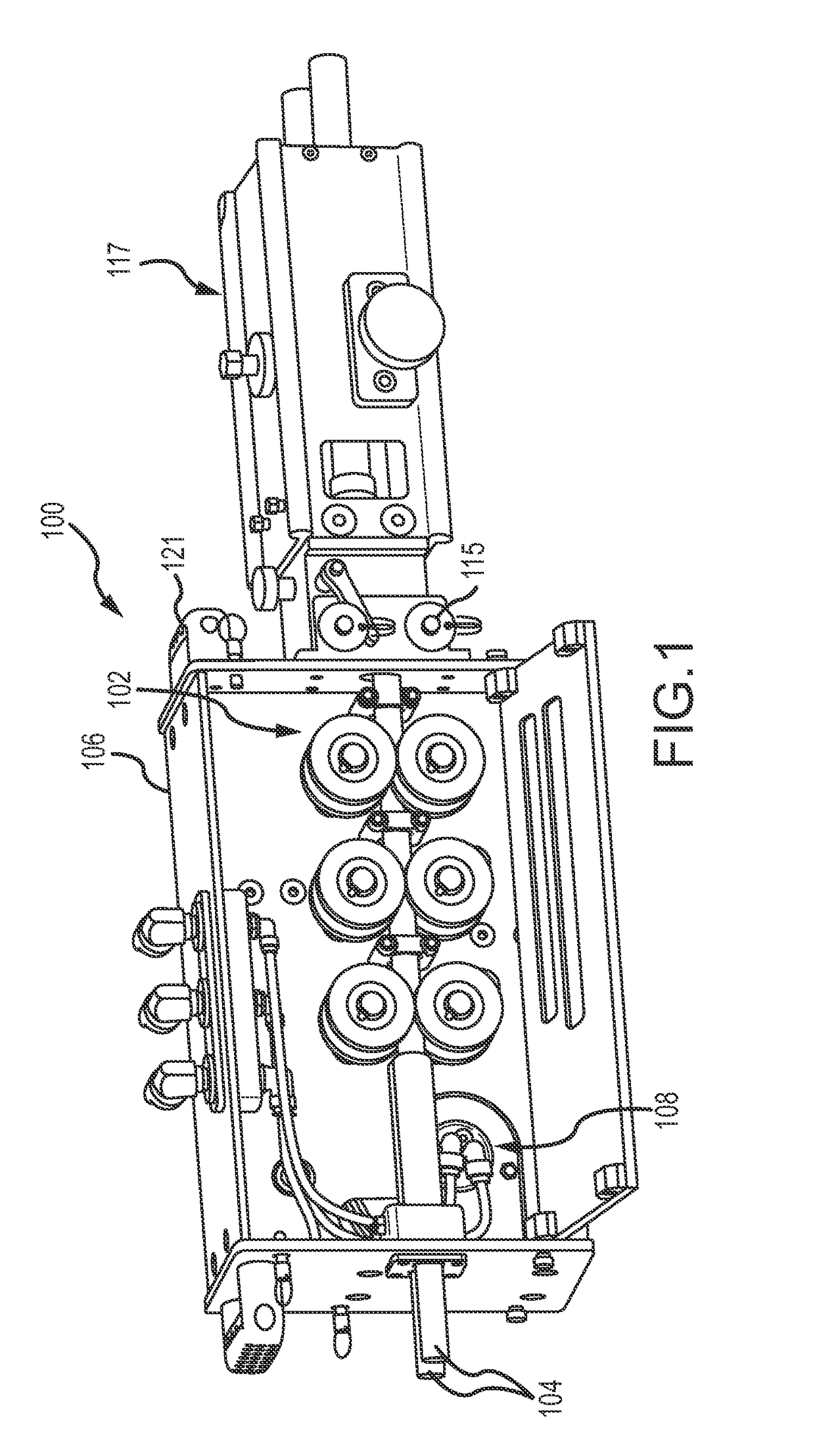

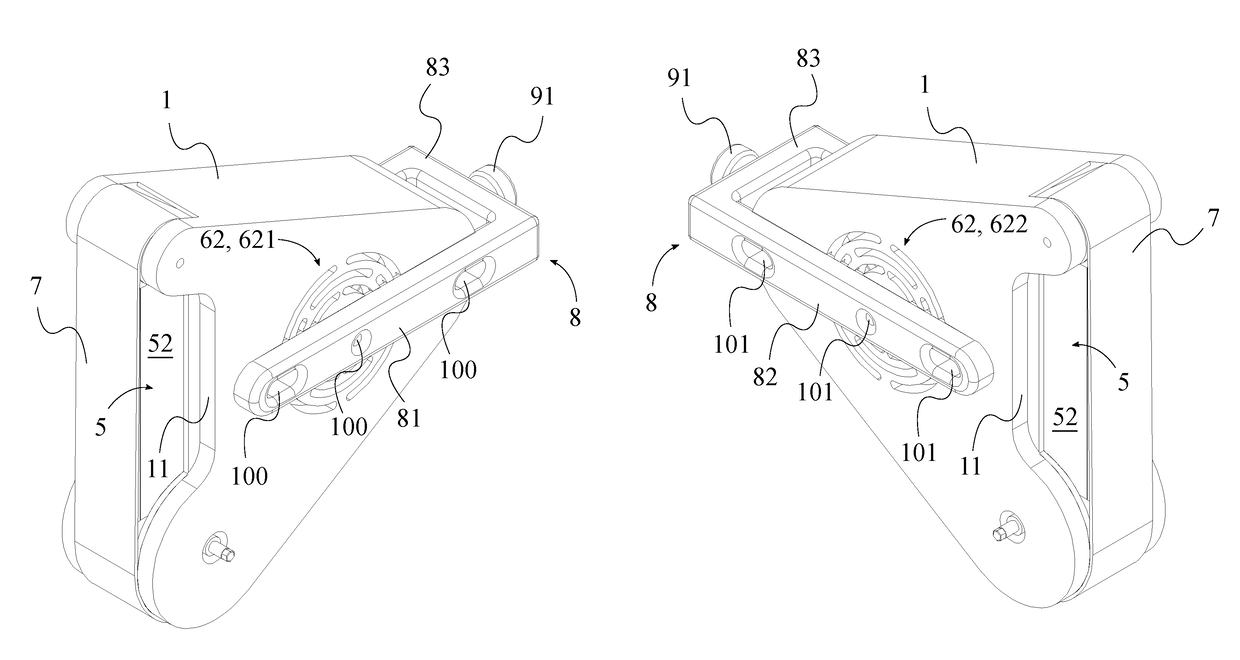

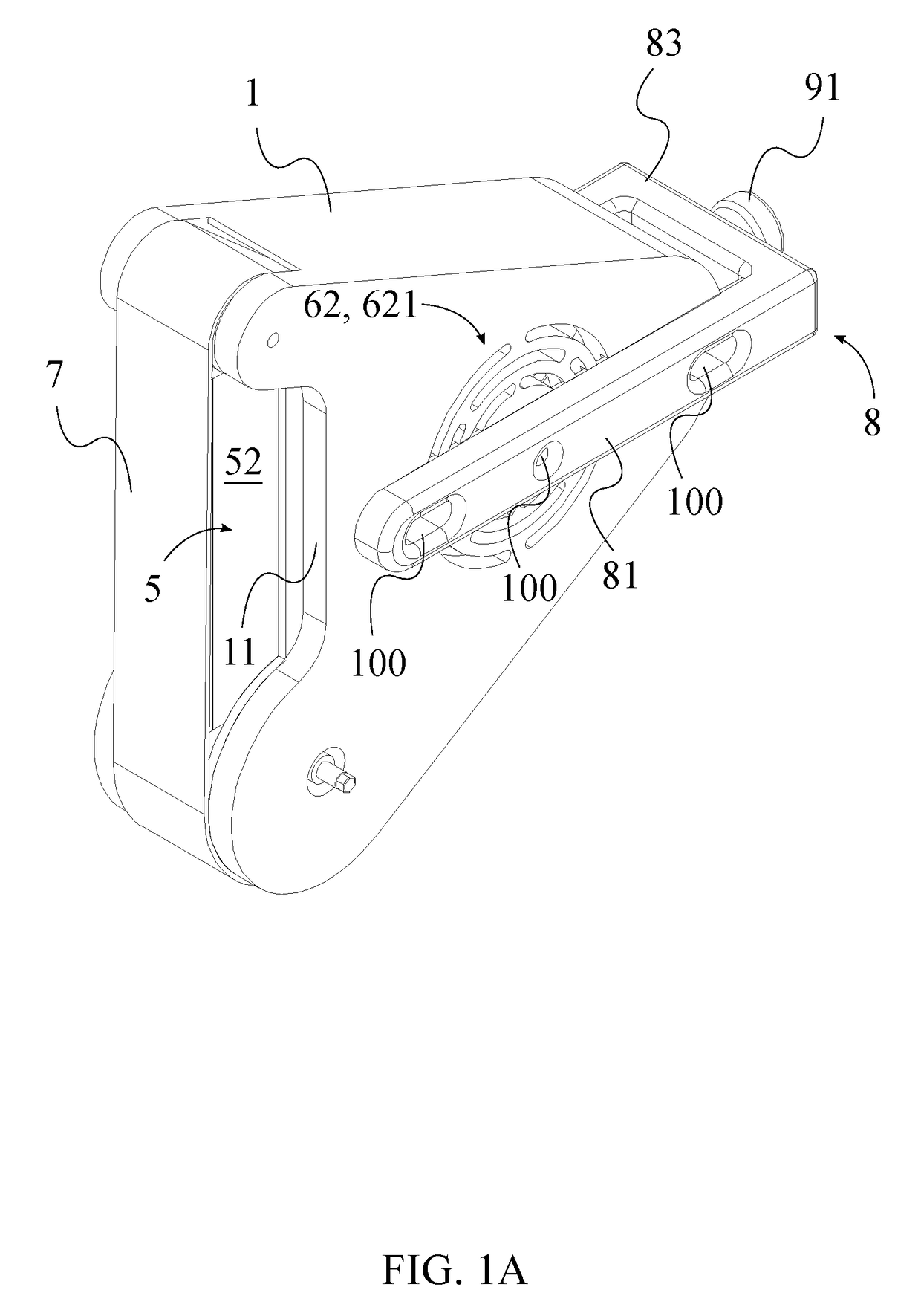

Flexible tube cleaning lance drive apparatus

ActiveUS20160023264A1Promote withdrawalPrevent removalMetal-working feeding devicesHollow article cleaningSerpentine beltSprocket

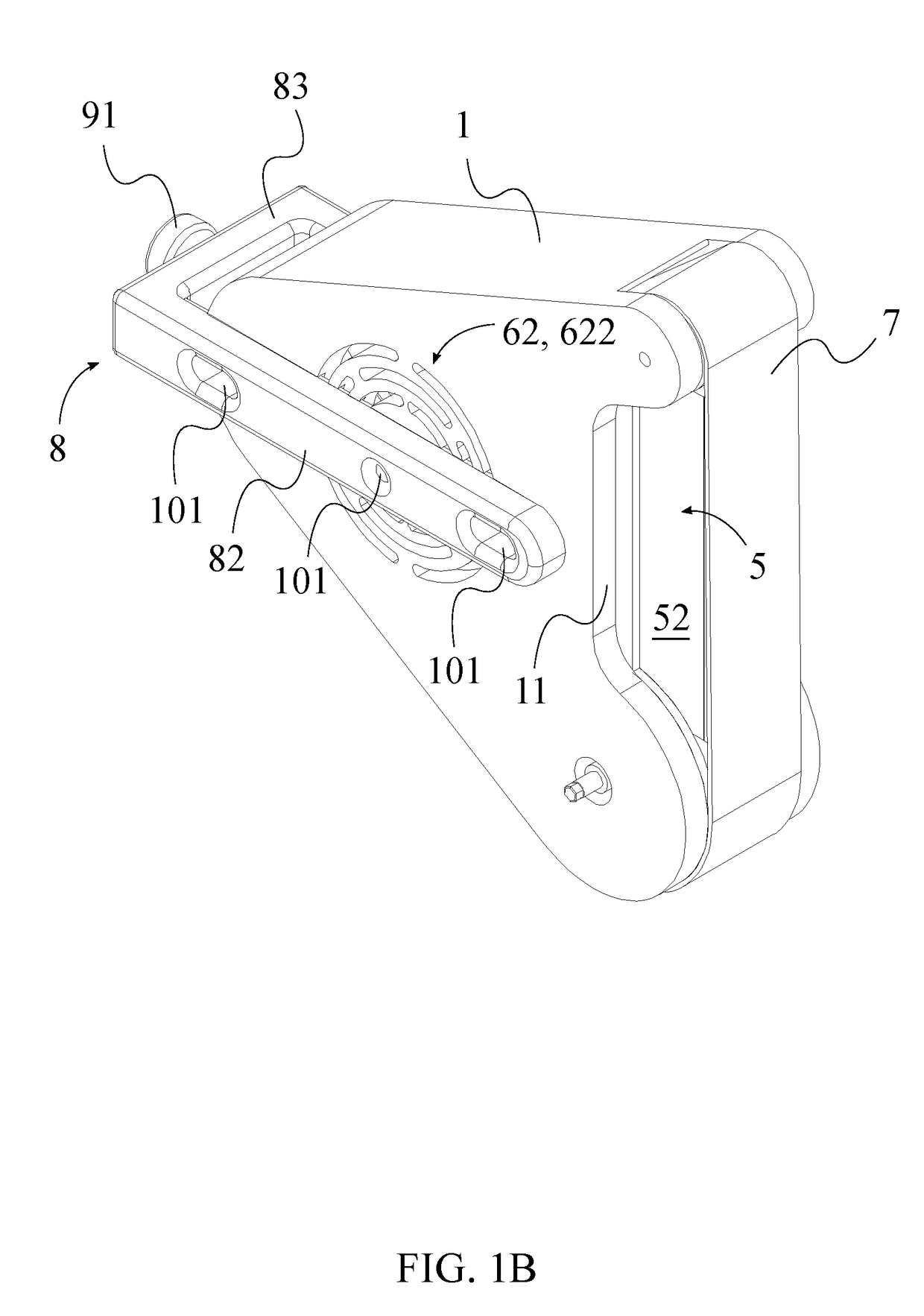

A flexible lance drive device is disclosed that has, in a compact housing, a drive motor between an inner and an outer wall, a linear array of pairs of driven upper and lower drive rollers outside the outer wall coupled to the drive motor via shafts extending through both of the inner and outer walls. Each driven roller is fastened to its shaft via a quick release device. A drive sprocket is fastened to each shaft outside the inner wall. The drive motor is coupled to each of the drive sprockets via a serpentine belt carried outside the inner wall. The lower driven rollers are rotatably carried by the inner and outer walls. The upper driven rollers are rotatably carried by a block positioned between the inner and outer walls and coupled to the lower driven rollers by a pair of parallel links releasably biased by a piston driven linkage.

Owner:STONEAGE

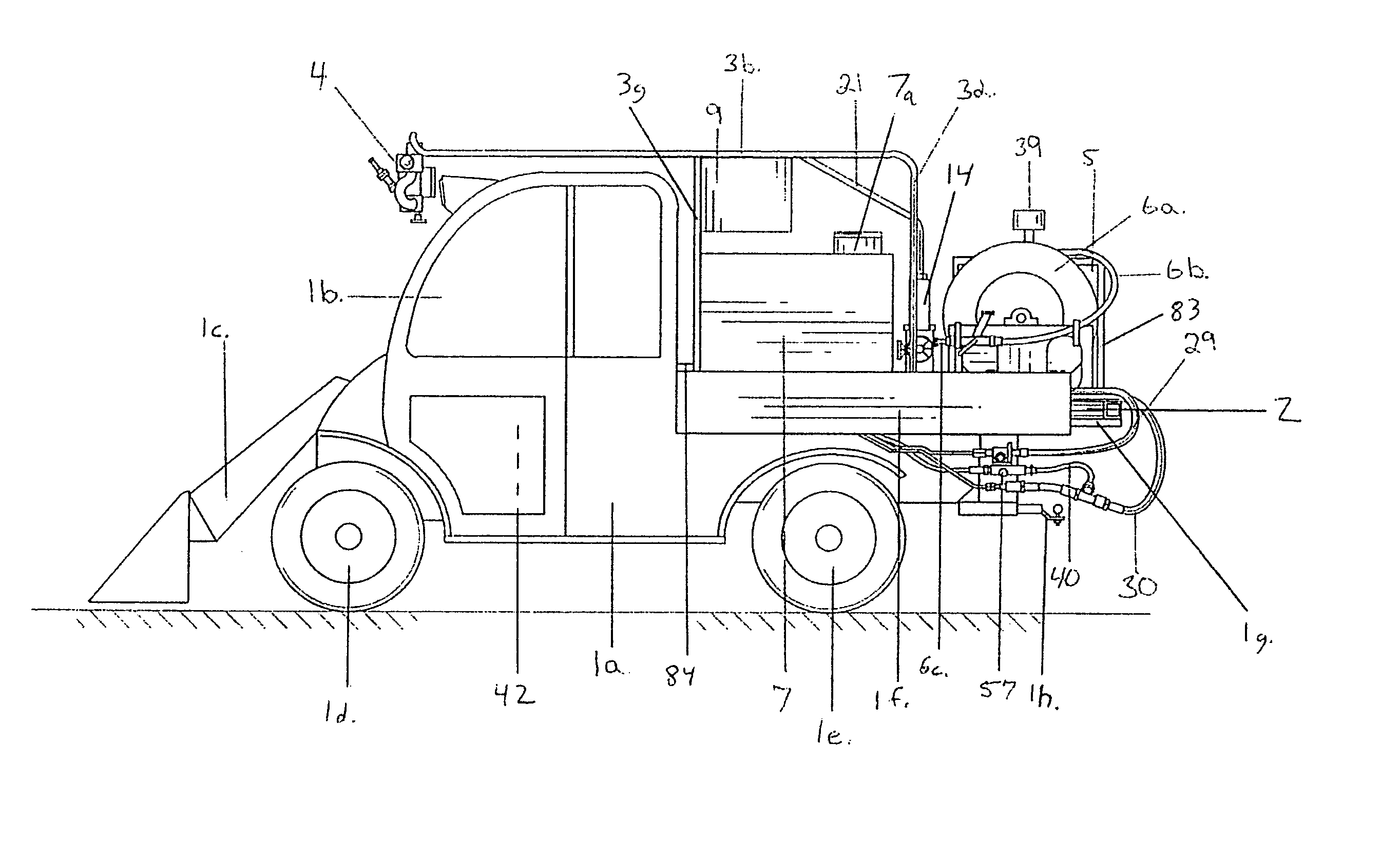

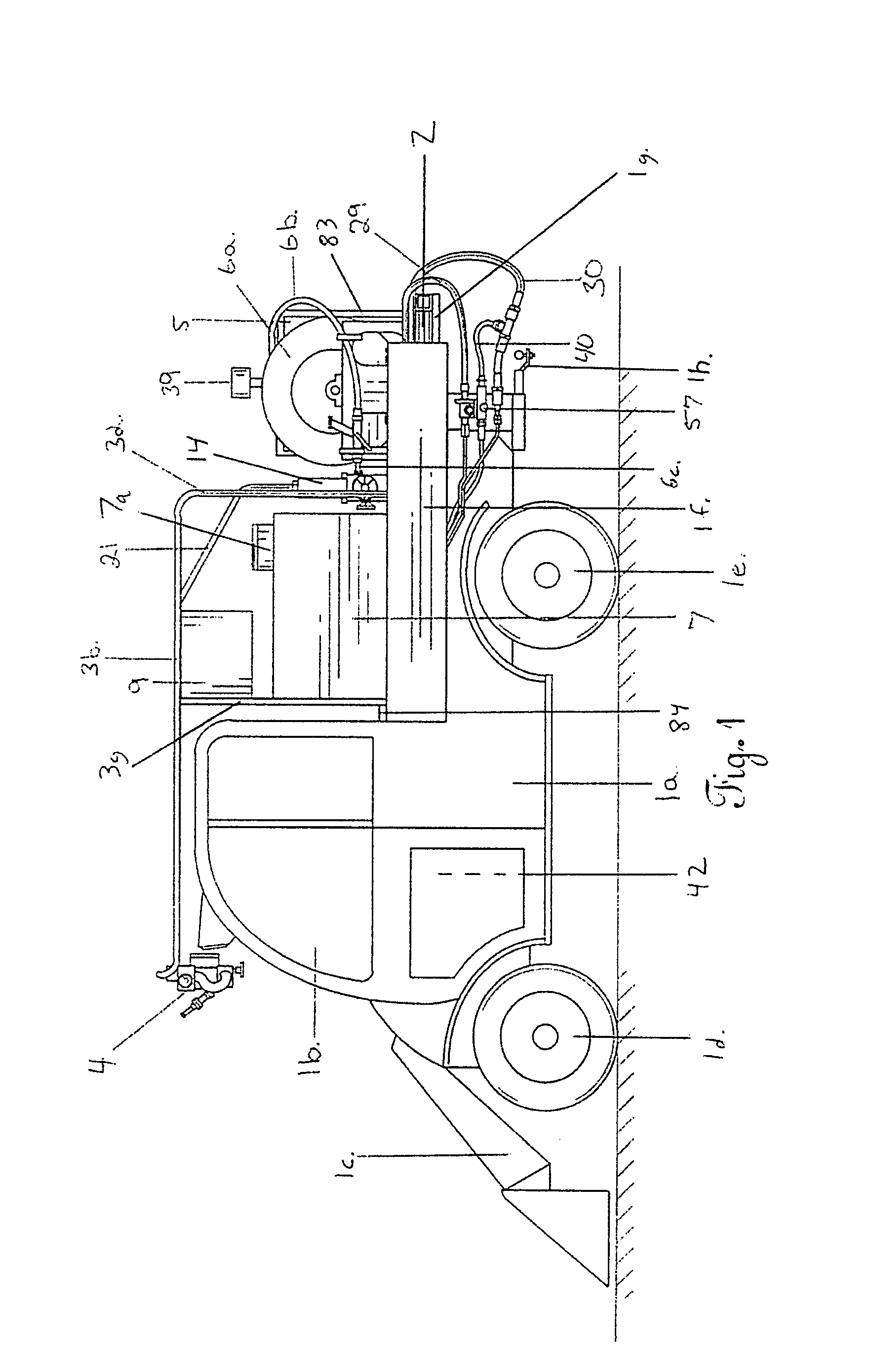

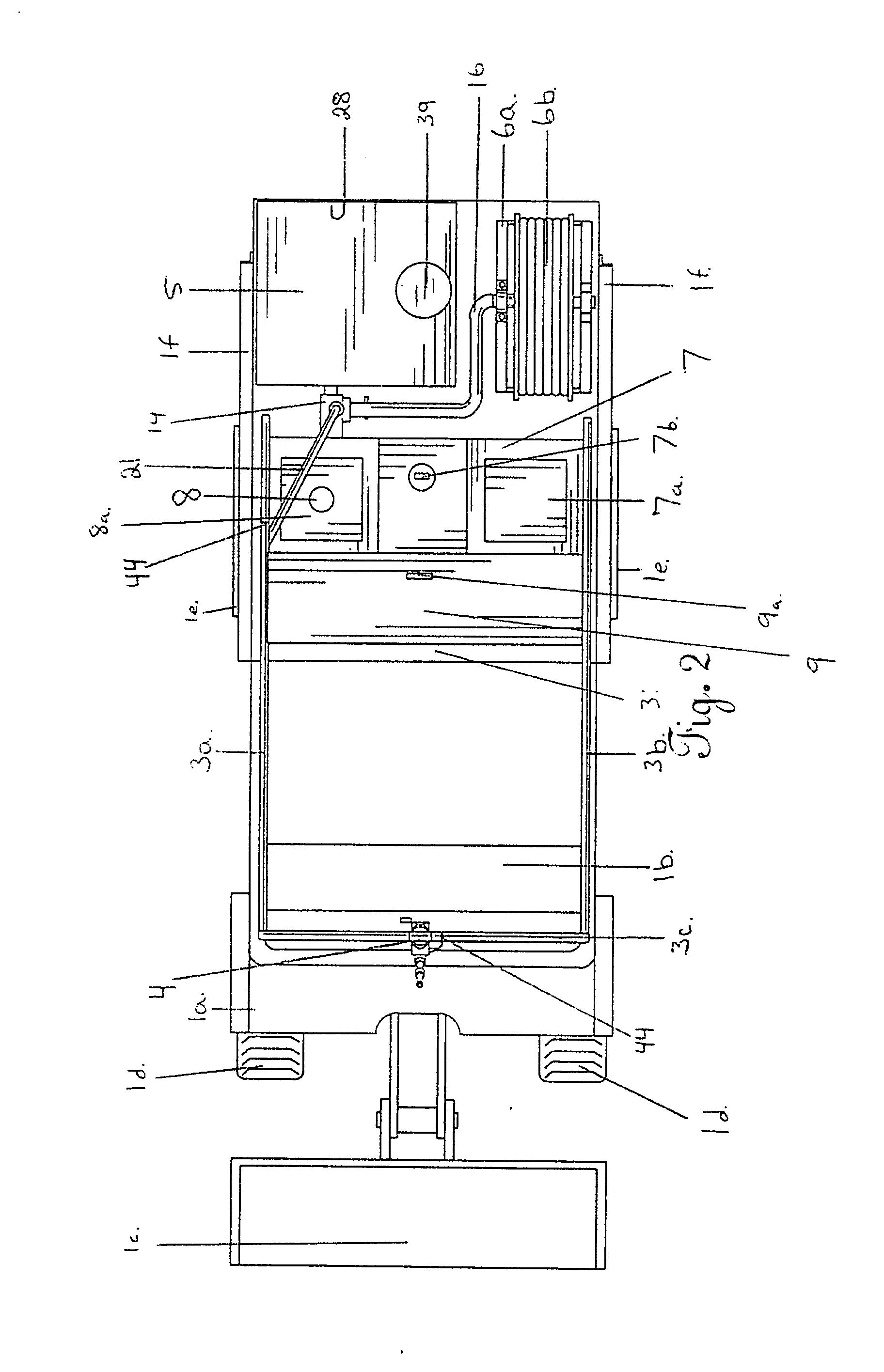

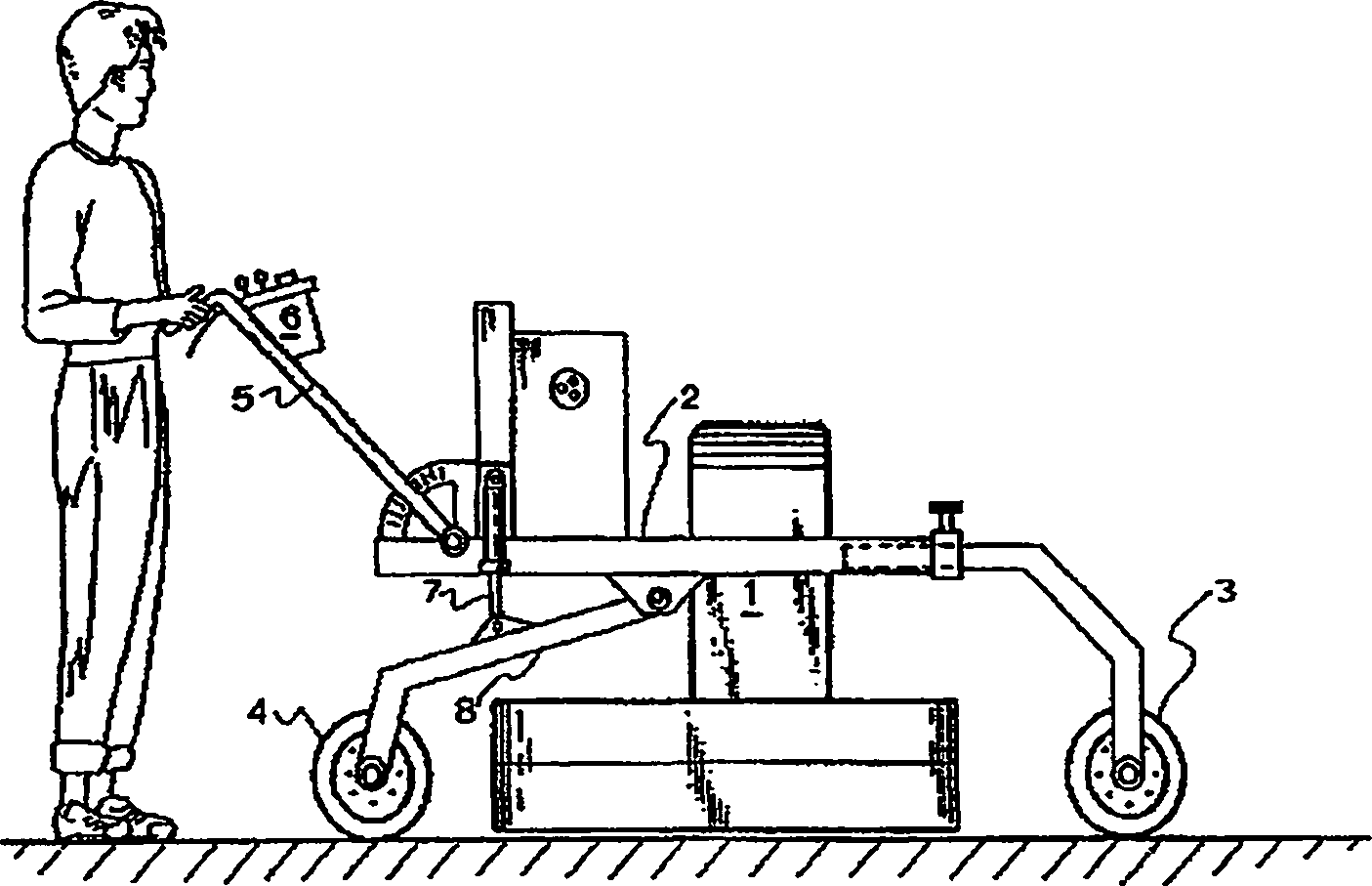

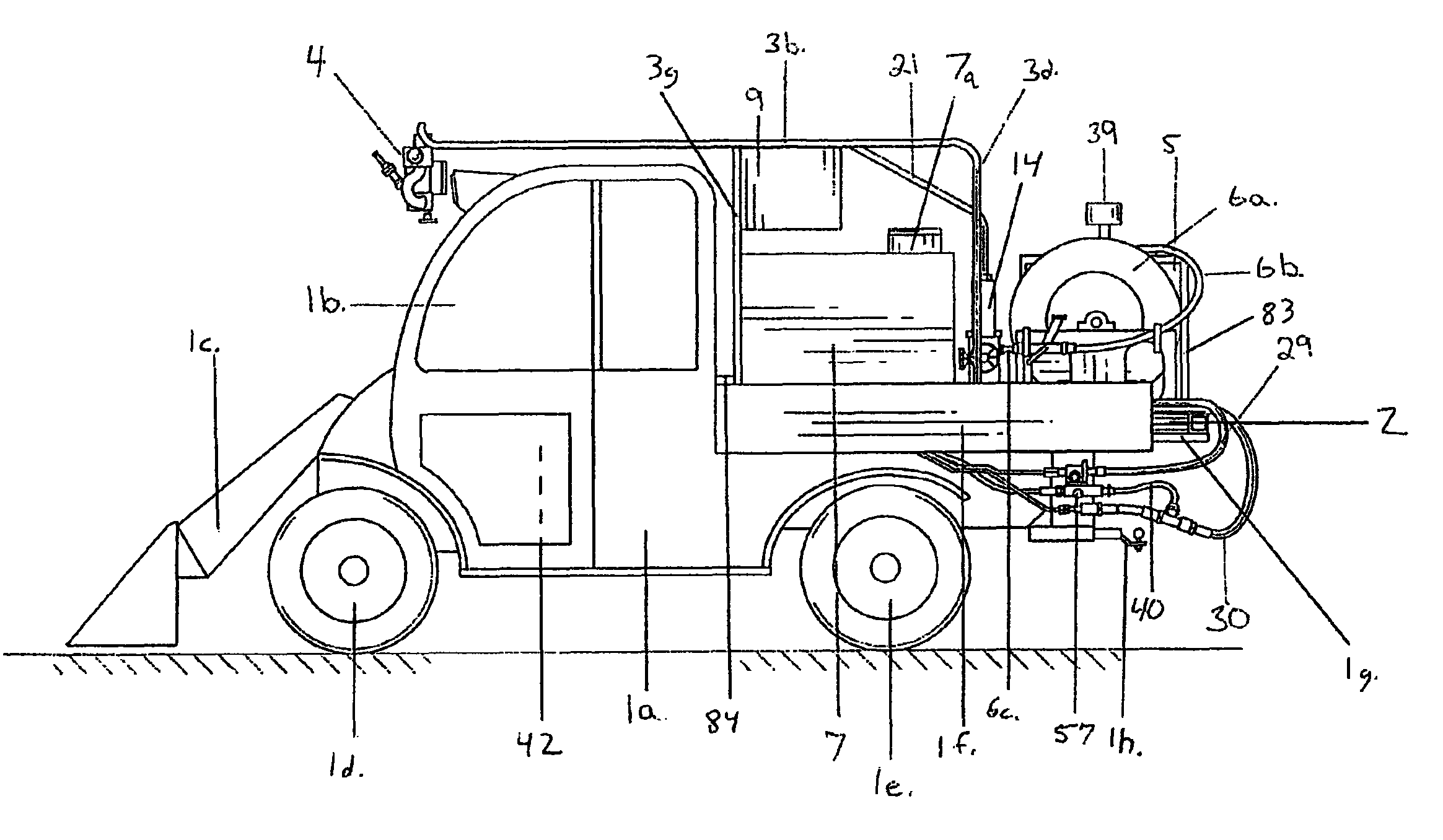

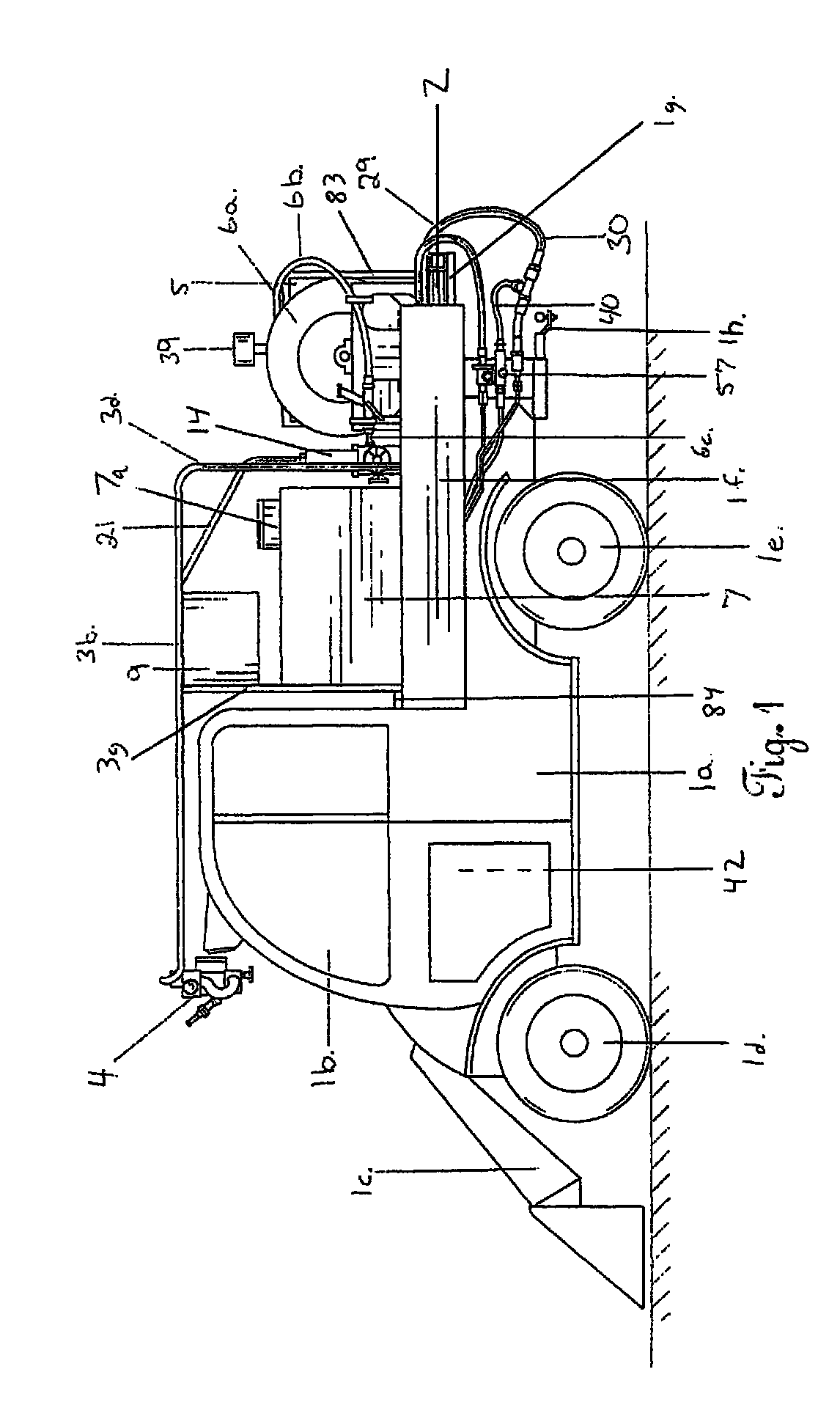

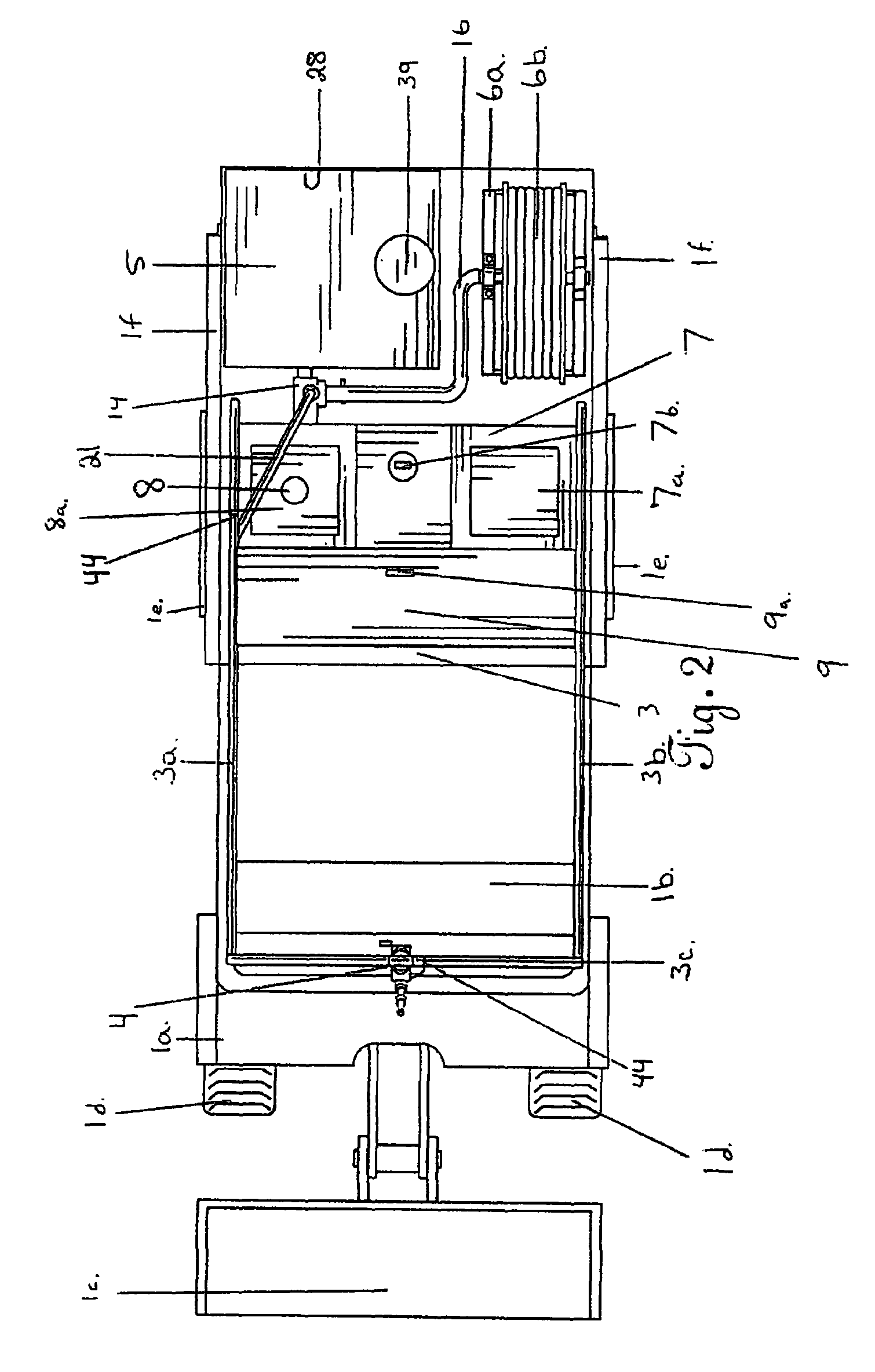

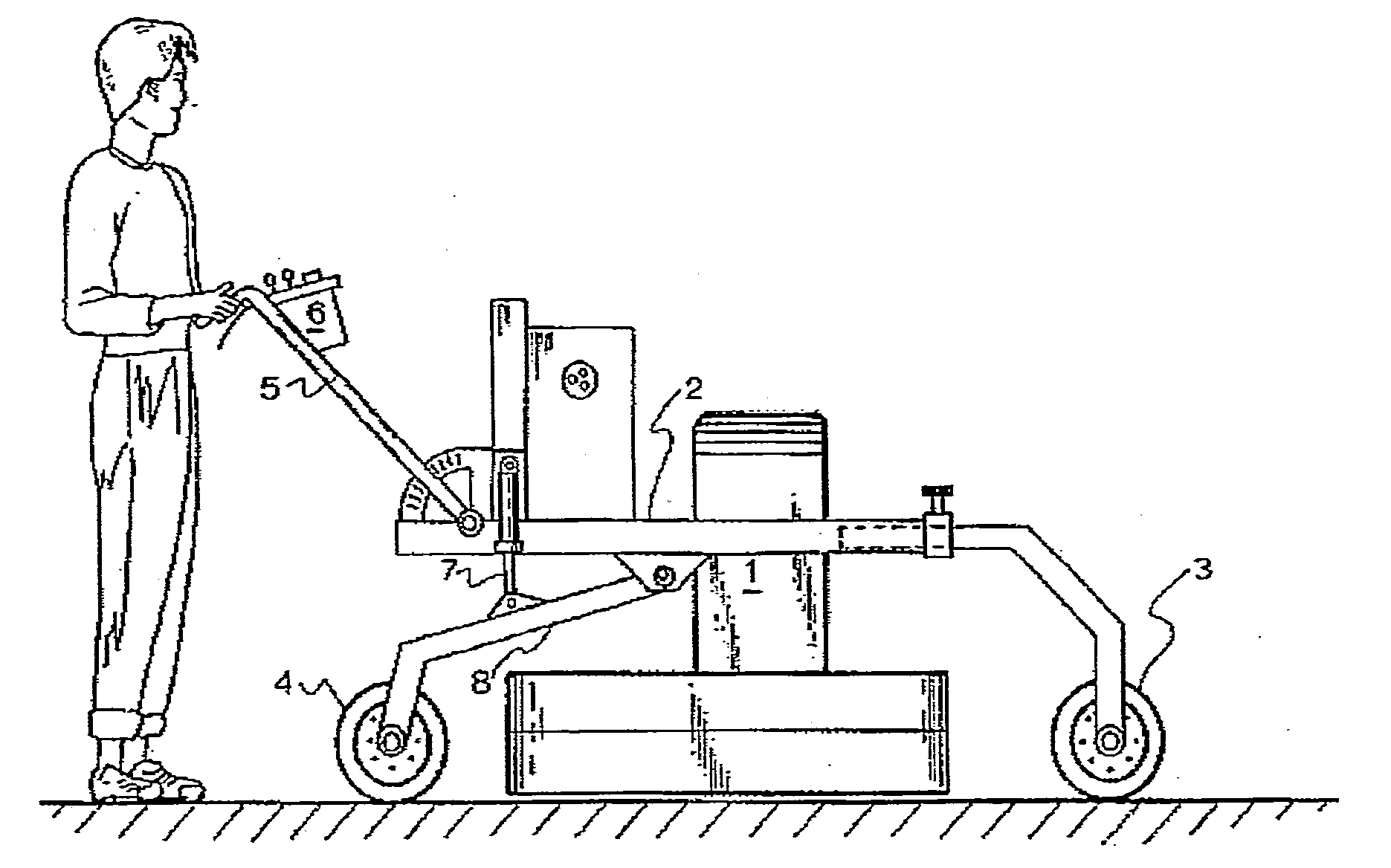

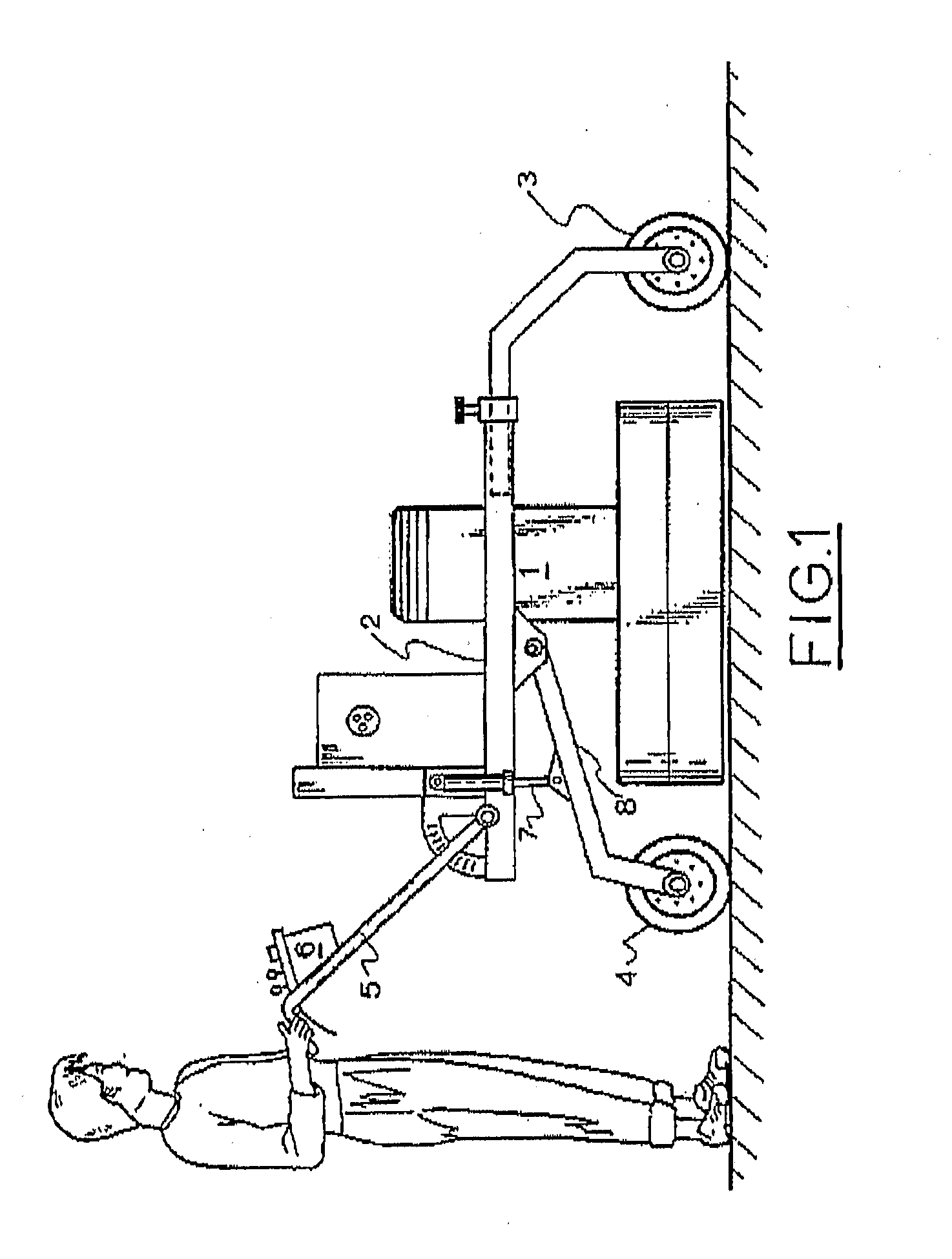

Compact self contained removable firefighting unit

InactiveUS20090014186A1Eliminate needSafe and efficient firefightingFire rescueSerpentine beltCompressed air foam system

A system which is sufficiently compact and portable to be moved via skid support platform to a multi-wheel diesel-powered host containing active pump and roll capability with front and rear active hydraulics, such as a Bobcat Toolcat Turbo 5600. The system contains a water tank, generally 150 gallons, as well as built in foam tank. The system is wholly powered by the hydraulic system of the host vehicle powering a hydraulic motor on the system. The system hydraulic motor turns a serpentine belt at sufficient RPM's to power a water pump, air compressor and the compressed air foam system (CAFS) module. Using solely the power provided by the hydraulic motor, water is drawn from the tank, either used alone or mixed with foam at the percentage inputted by the user. Compressed air is added and the air alone, water alone or water / foam mixture is routed via adjustable valve to either the 1 inch firefighters hose or the rigid waterway ending in an adjustable, movable nozzle attached to the cab roof of the host.

Owner:COLLINS JEFF

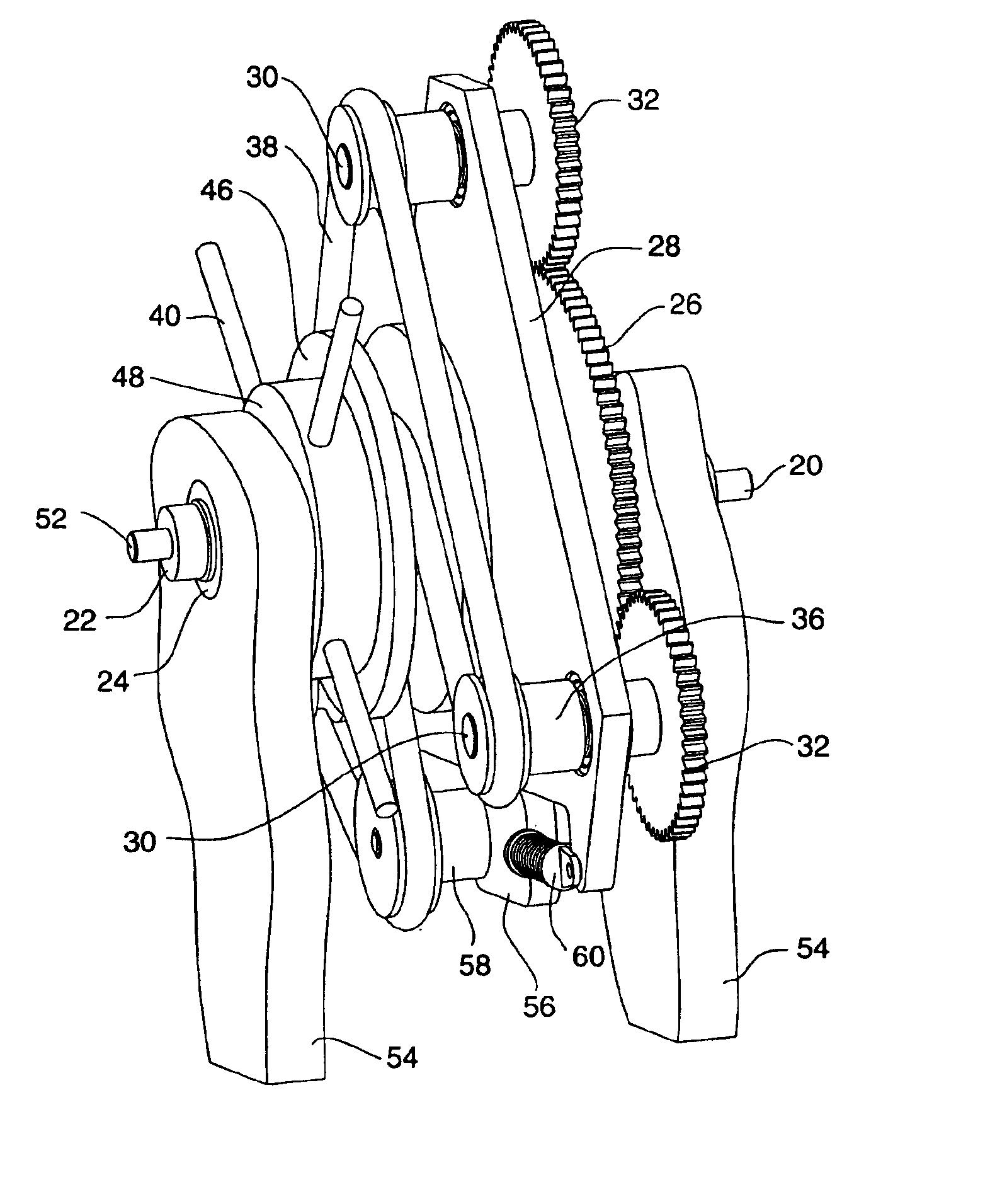

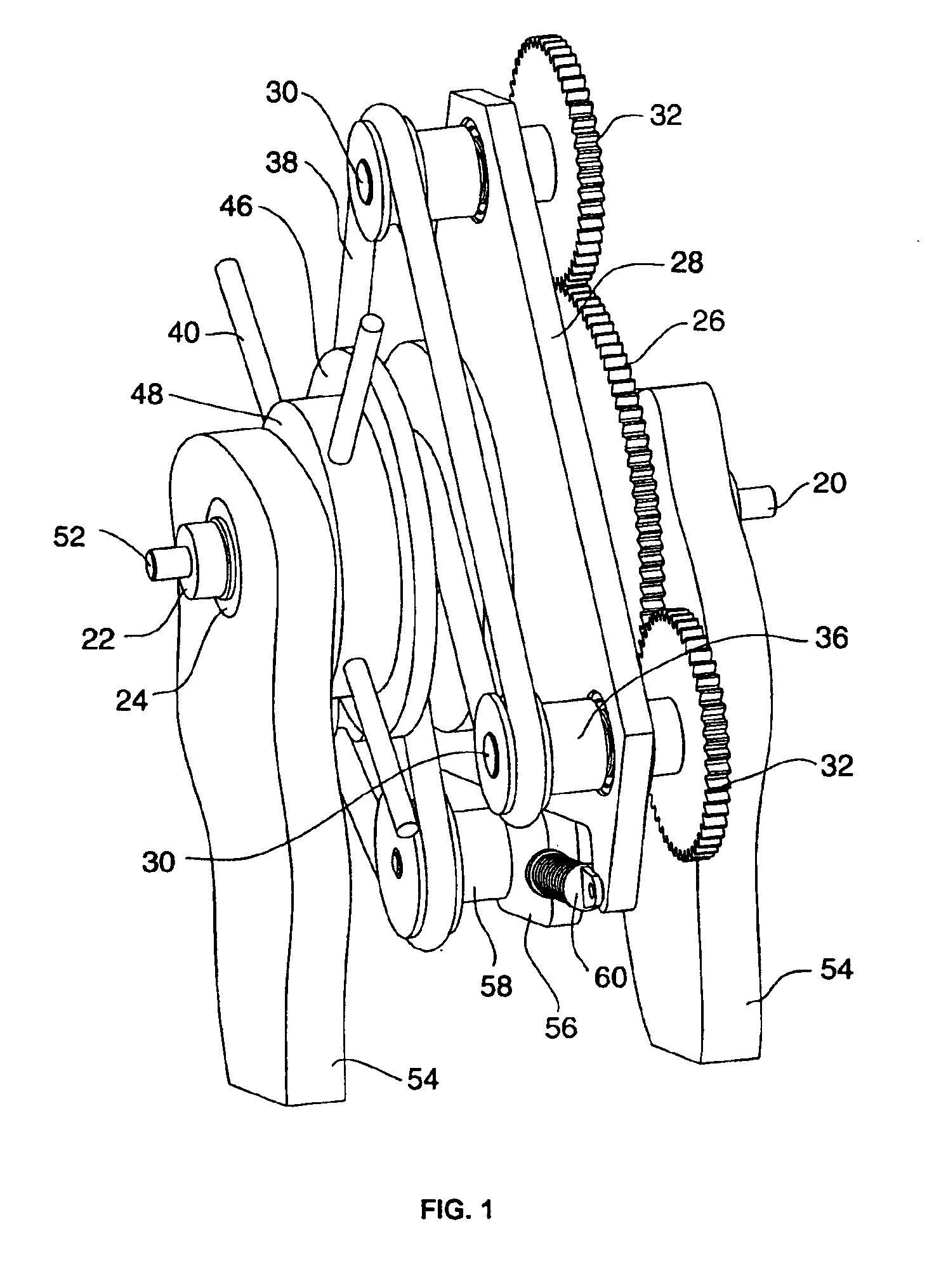

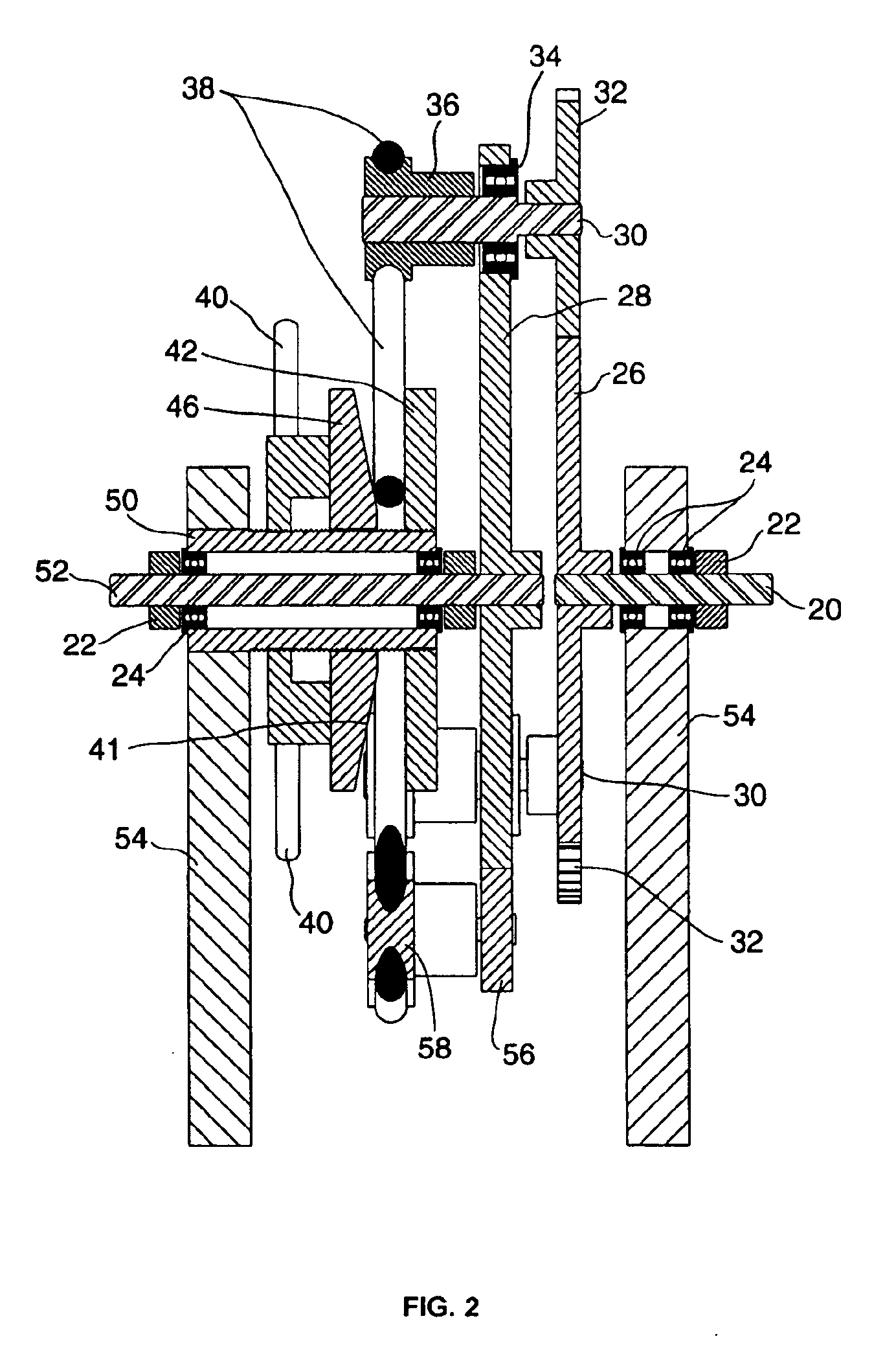

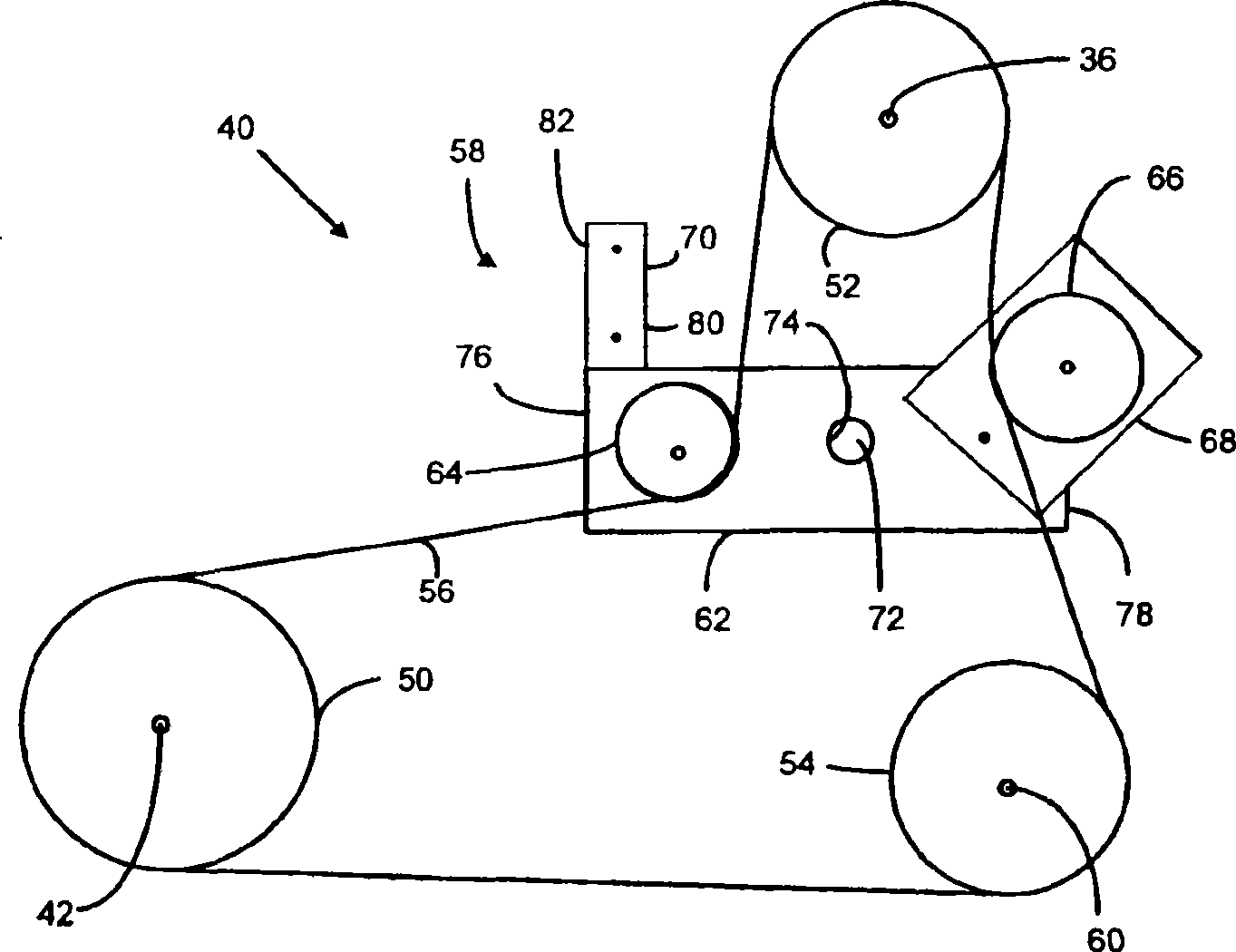

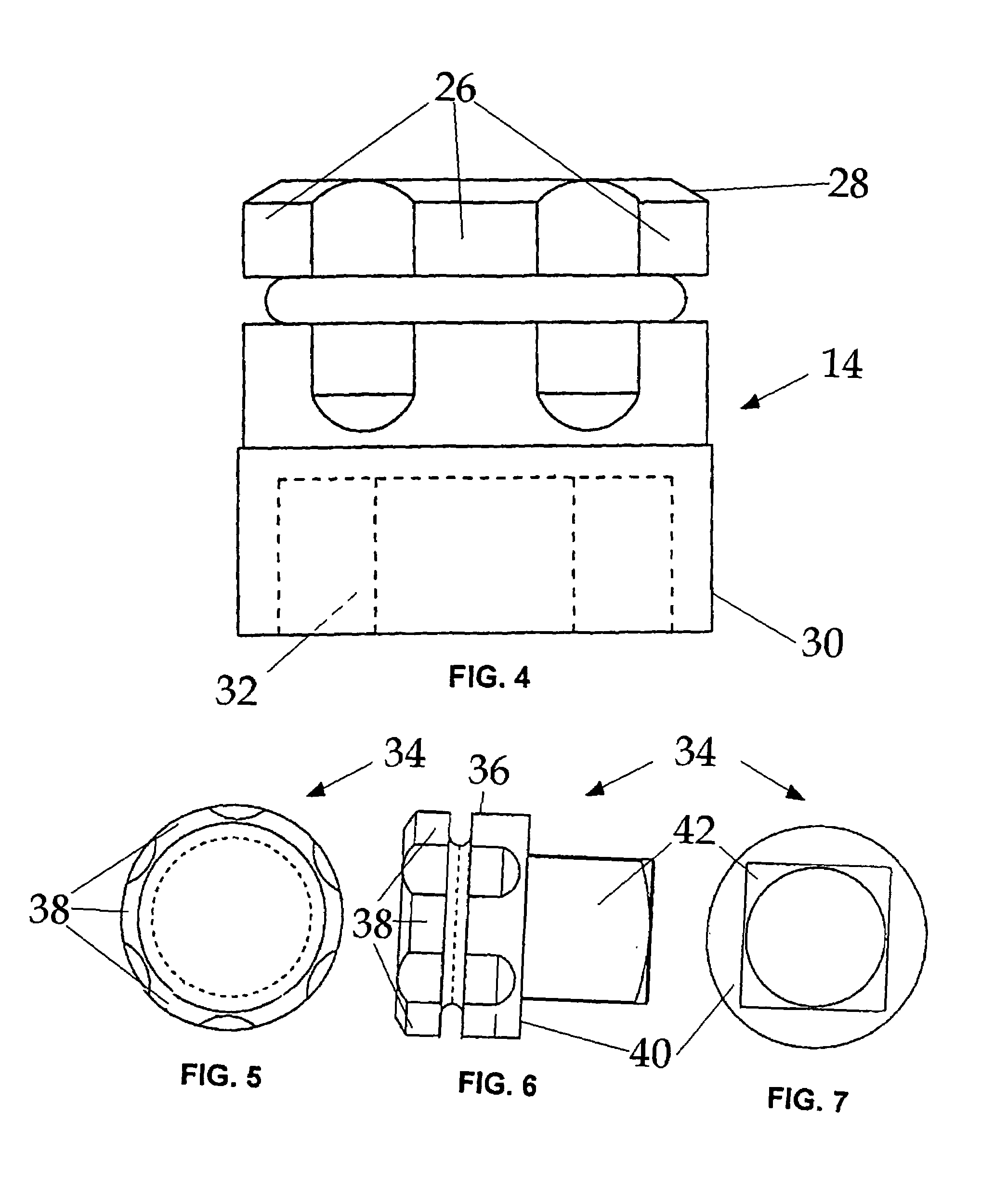

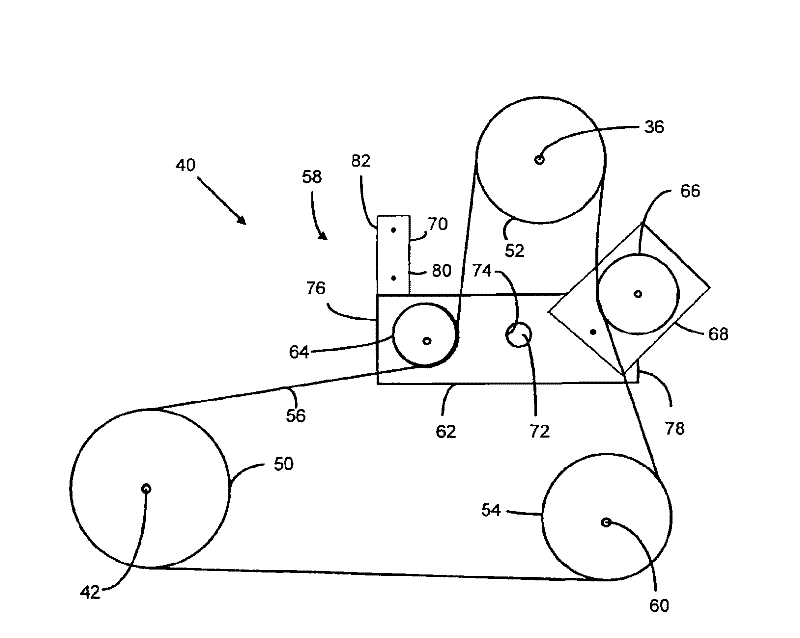

Infinitely variable epicyclic transmissions

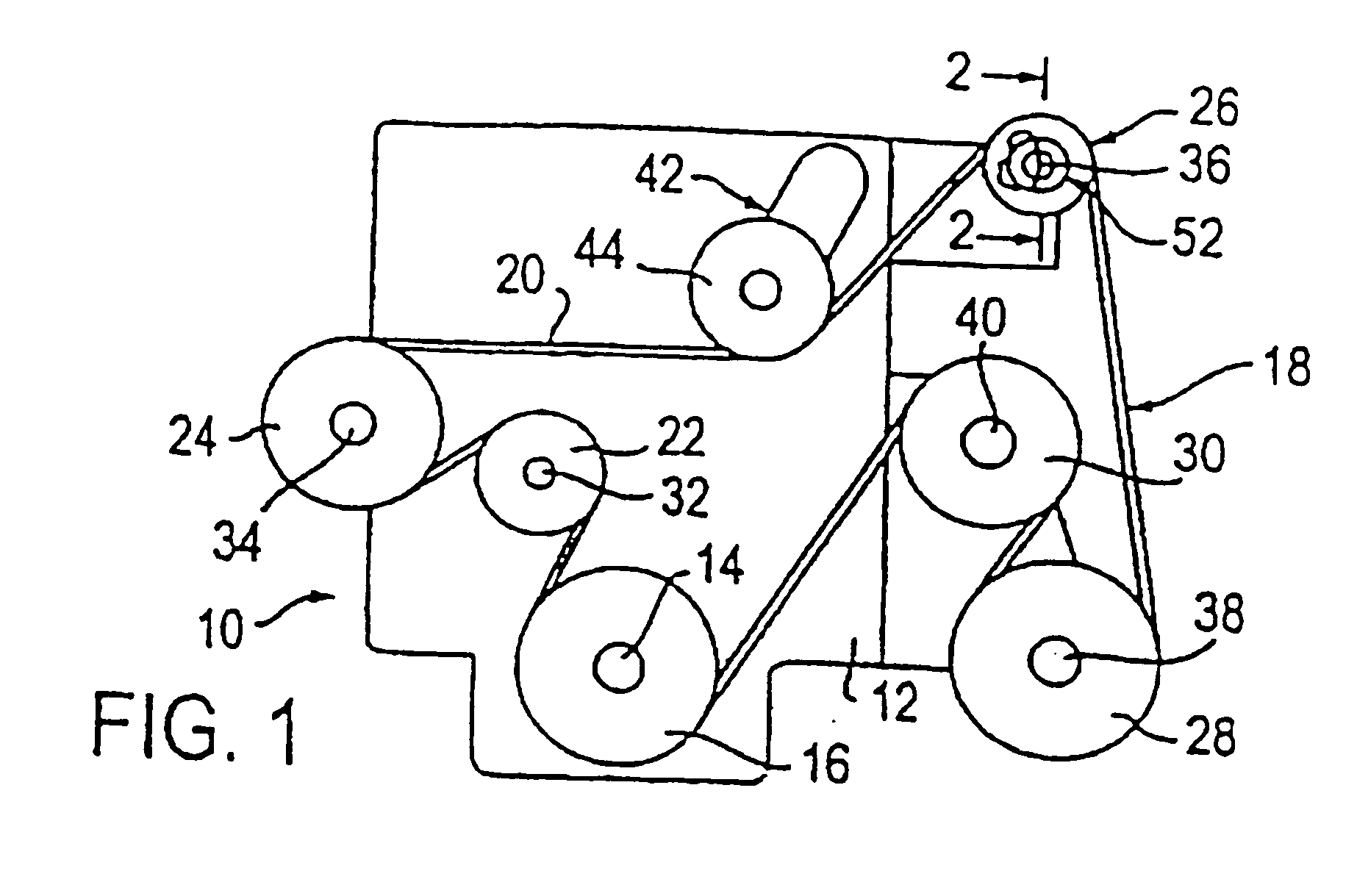

InactiveUSRE38887E1Reliable and inexpensive to manufactureContinuous changePortable liftingToothed gearingsSerpentine beltPulley

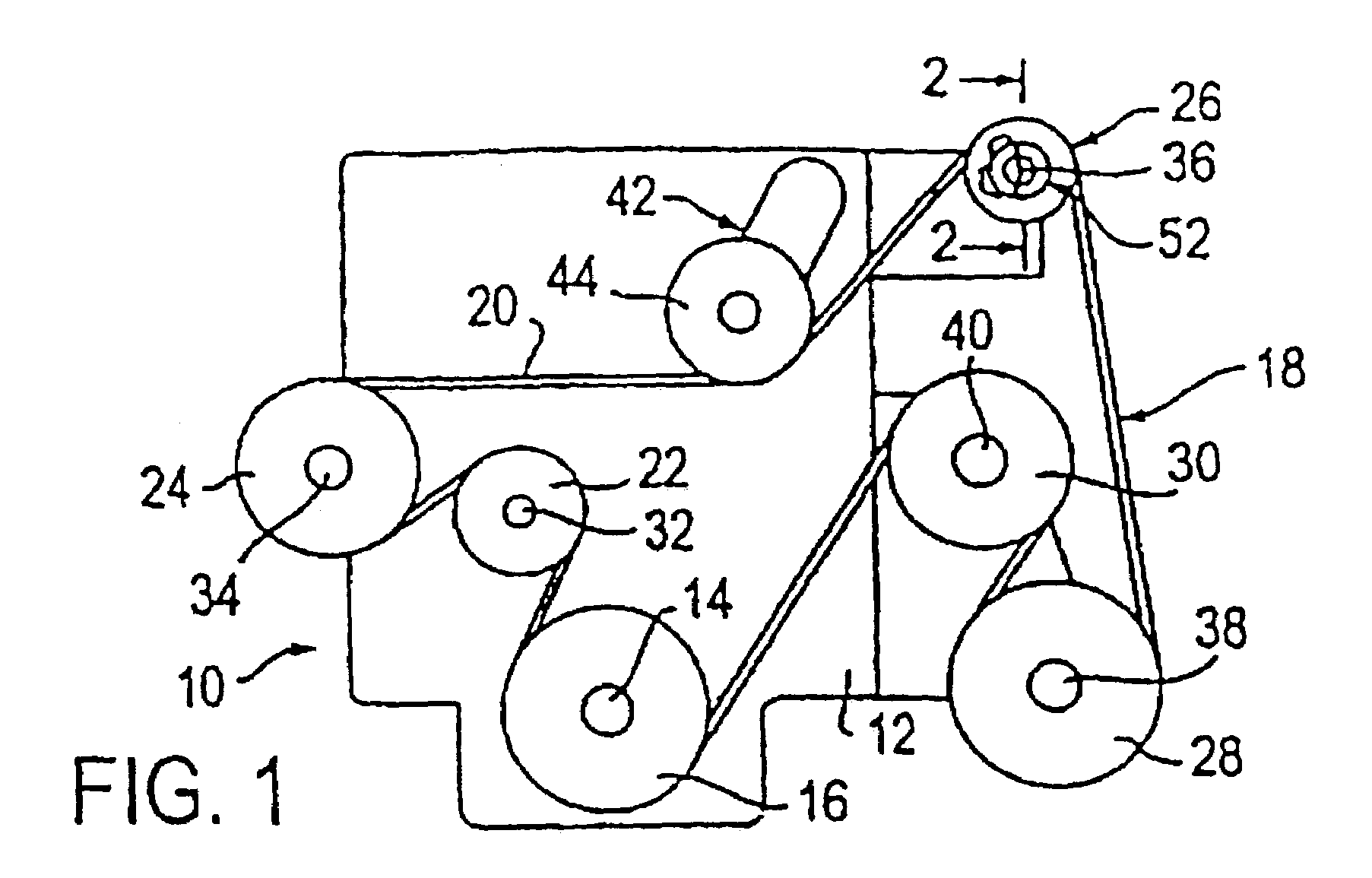

An infinite variable transmission with input shaft (52), planetary carrier (28), planetary pulleys (36) and planetary gears (32) with planetary axles (30) equiangularly disposed on the carrier (28). Variable pitch pulley (41) adjust a serpentine belt (38) which adjust the rotation of the planetary gears (32) to adjust the output shaft (20).

Owner:VERITRAN

Outfeed mechanism for starwheel type glass inspection machine

InactiveUS20070068774A1Improve stabilityImprove reliabilityConveyorsConveyor partsSerpentine beltBottle

A bottle inspection machine is disclosed which has a starwheel feeder and an outfeed mechanism for receiving bottles from the starwheel feeder. The outfeed mechanism has an inner belt conveyor which has a pickoff wheel adjacent the starwheel feeder and a second wheel. At least one drive belt is supported by the pickoff and second wheels for defining a linear outfeed belt portion. The outfeed mechanism also has an outer serpentine belt conveyor which has an idler wheel located radially inwardly from the pick off wheel which defines an opening for receiving a bottle displaced by the starwheel feeder and a third wheel. At least one flexible serpentine belt is supported by the idler and third wheels which are located to define a location where a bottle will be discharged from the outfeed mechanism. The serpentine belt is sufficiently flexible so that a bottle displaced into the opening between the pickoff and idler wheels will be conveyed by the serpentine and inner belts with the serpentine belt changing its configuration as the bottle is conveyed to the discharge location.

Owner:EMHART GLASS SA

Finishing machine

Owner:艾伦·托马斯·皮克

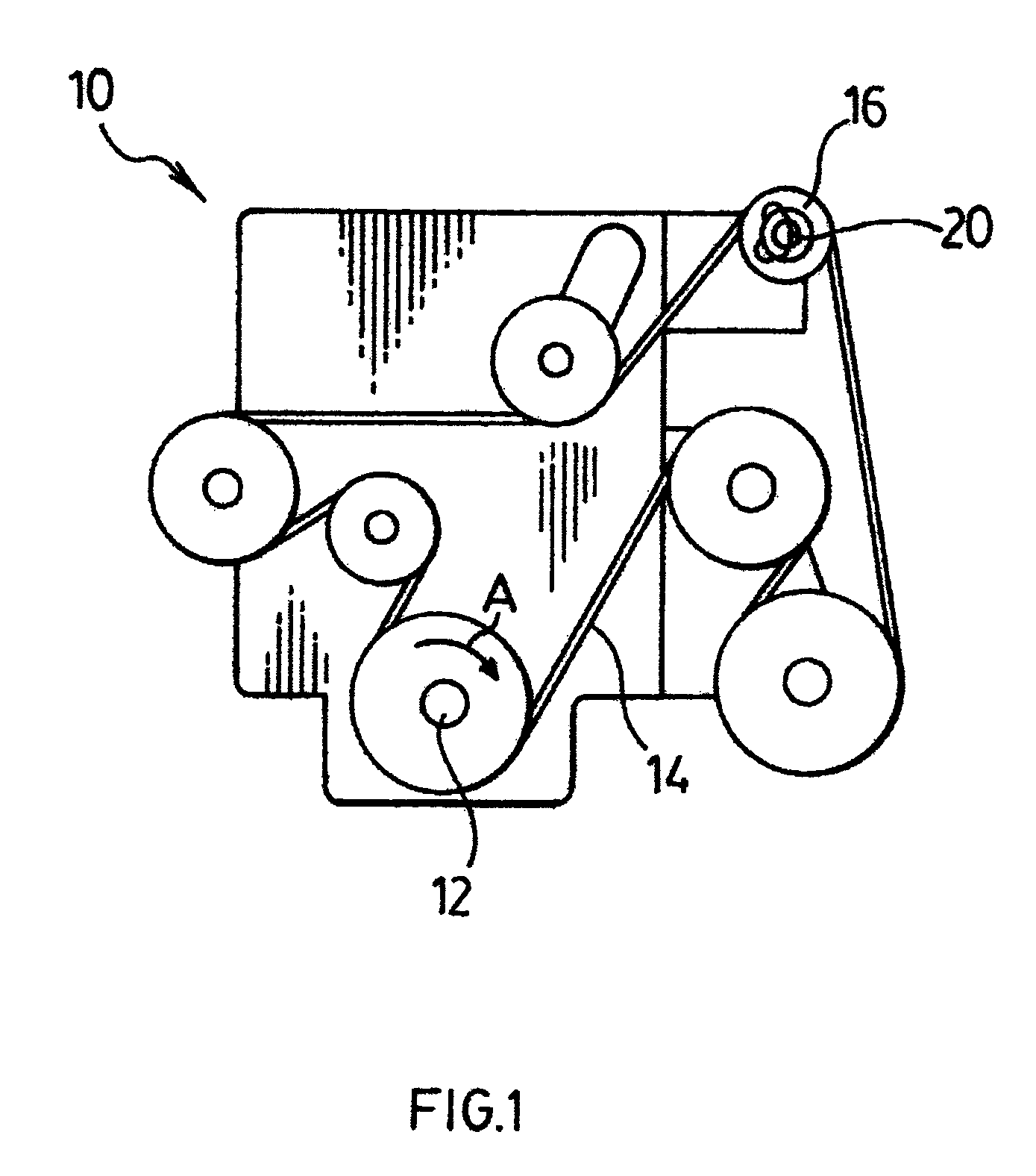

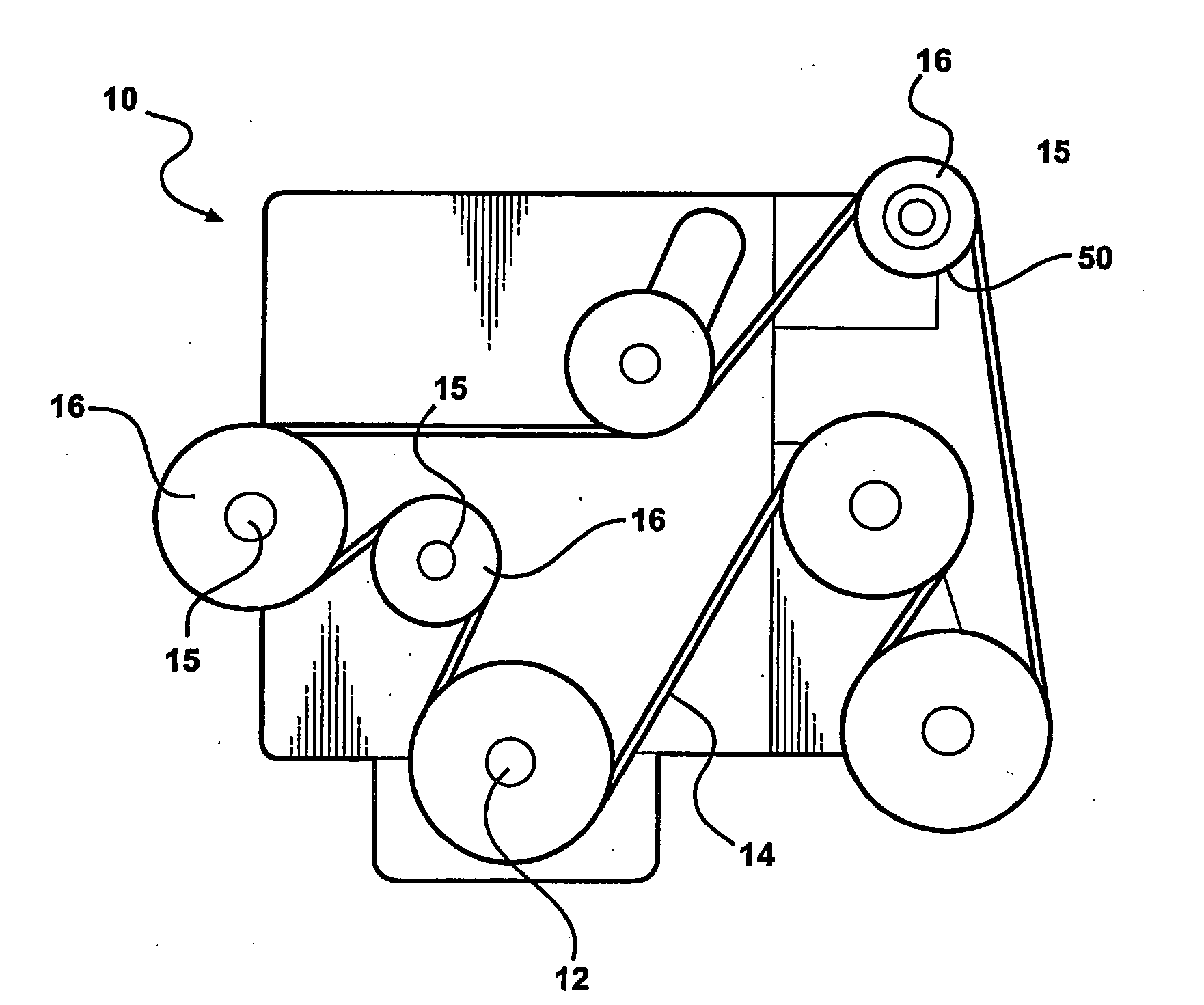

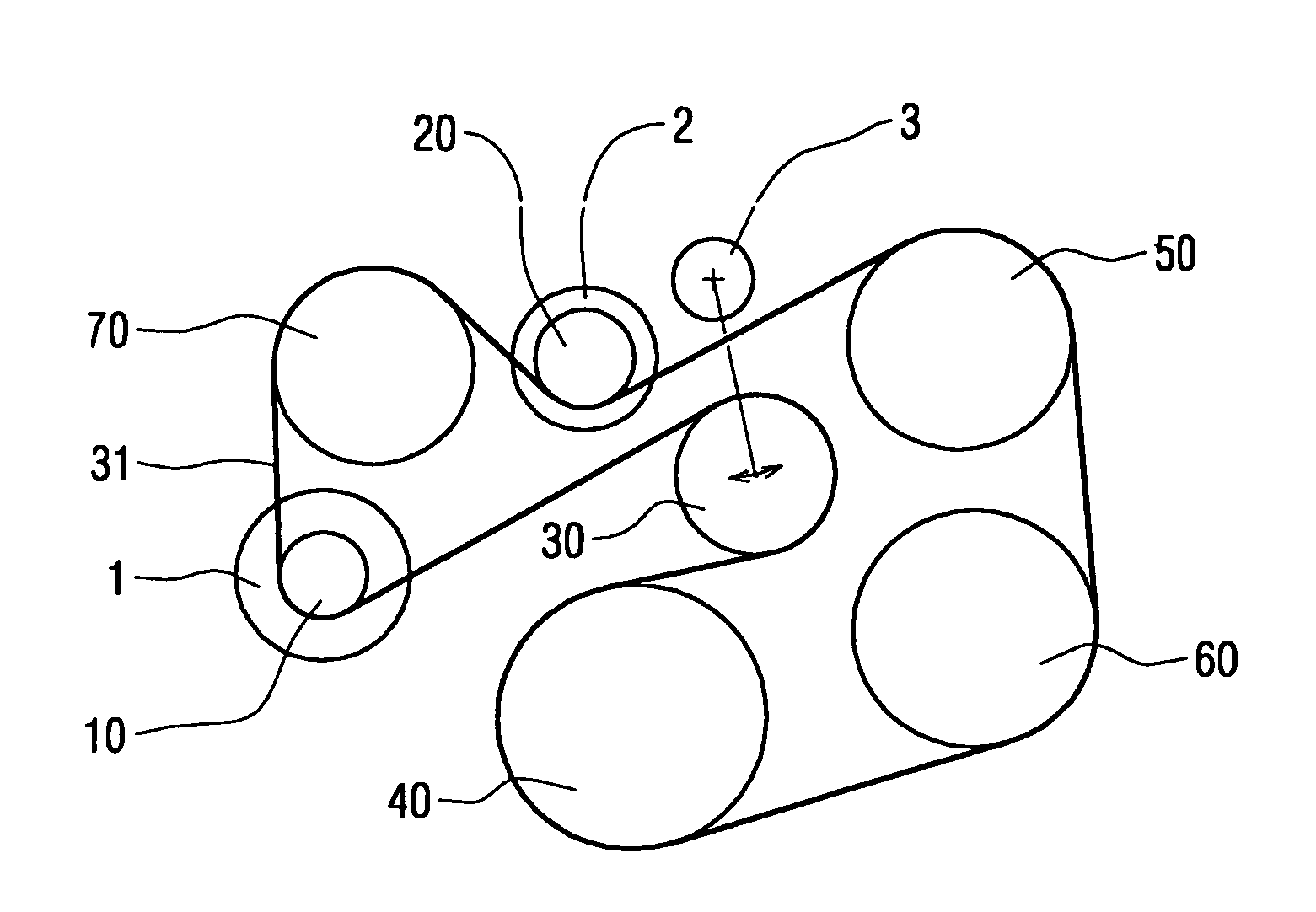

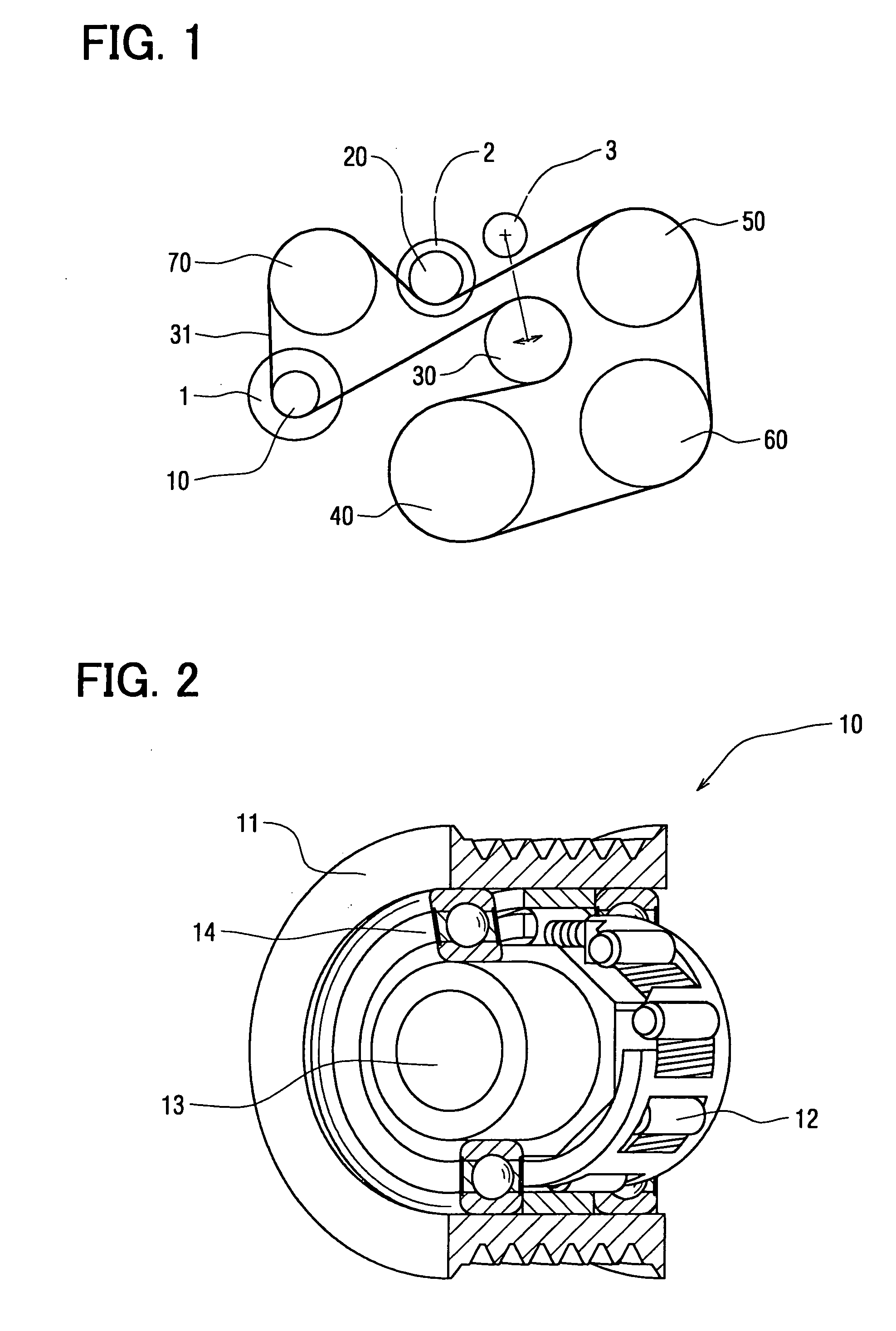

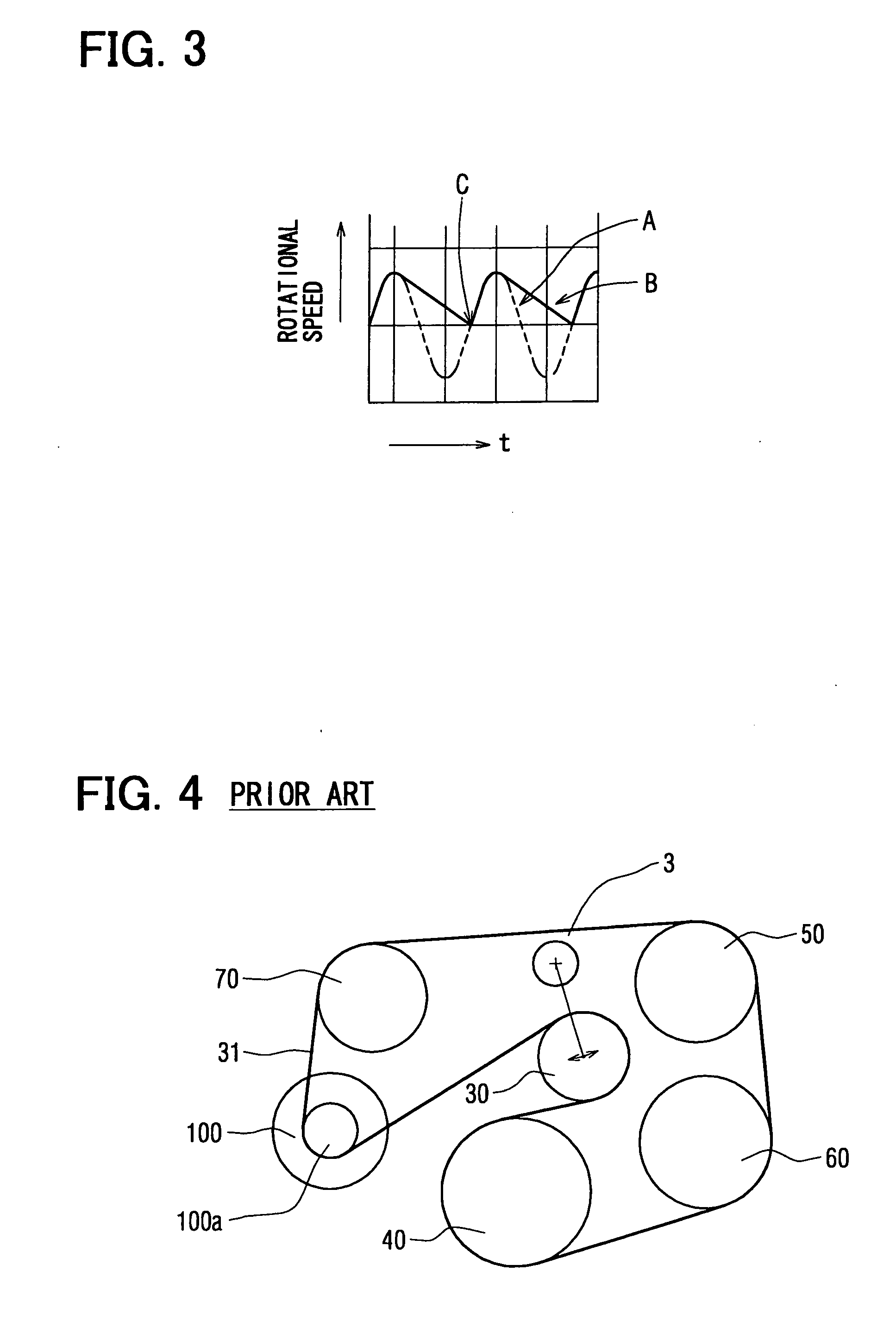

Belt-drive system driven by internal combustion engine mounted on automotive vehicle

InactiveUS7182707B2SpeedEasy to installGearingPortable liftingSerpentine beltExternal combustion engine

Plural auxiliary devices such as a water pump and a generator coupled to a serpentine belt-drive system are driven by an internal combustion engine mounted on an automobile vehicle. The generator is divided into a first generator having a pulley in which a one-way clutch is installed and a second generator having a usual solid pulley. Fluctuations in the belt tension caused by changes in instantaneous rotational speed of the internal combustion engine are suppressed or reduced by the one-way clutch installed in the pulley of the first generator. An inertia torque of a rotor of the first generator may be made higher than that of the second generator because effects of the inertia torque on the belt tension fluctuations are alleviated by the one-way clutch.

Owner:DENSO CORP

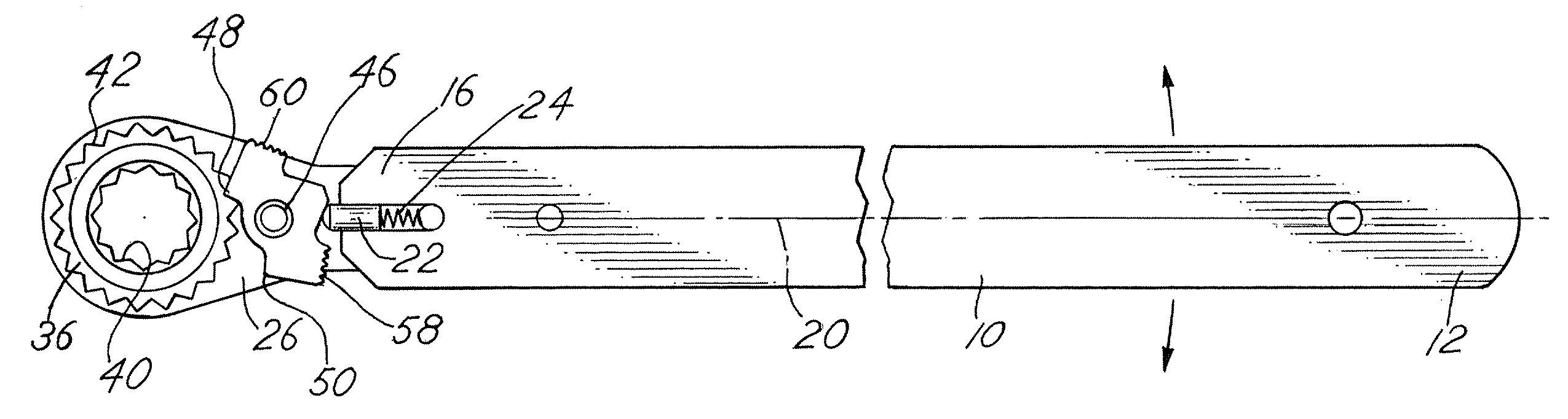

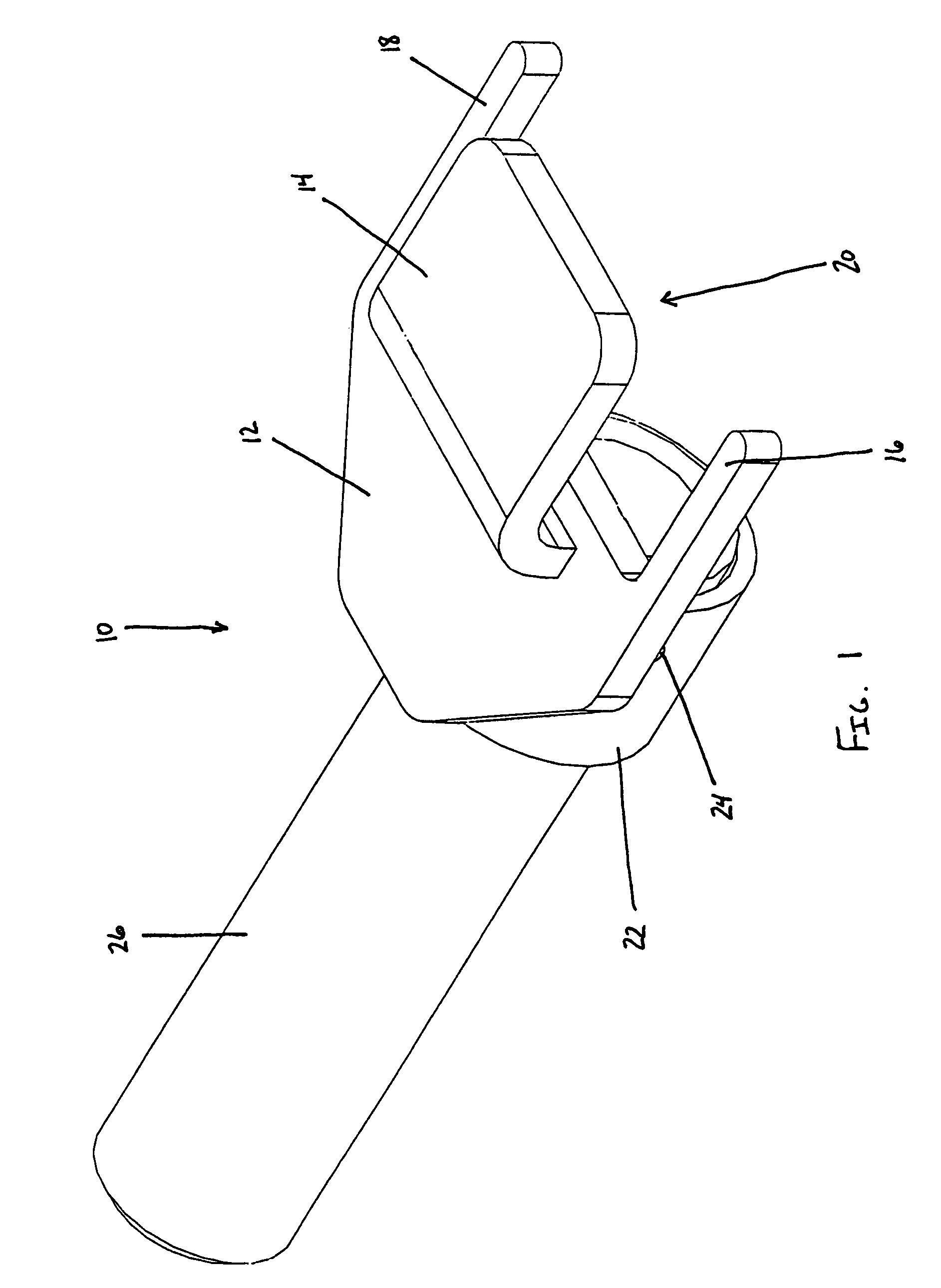

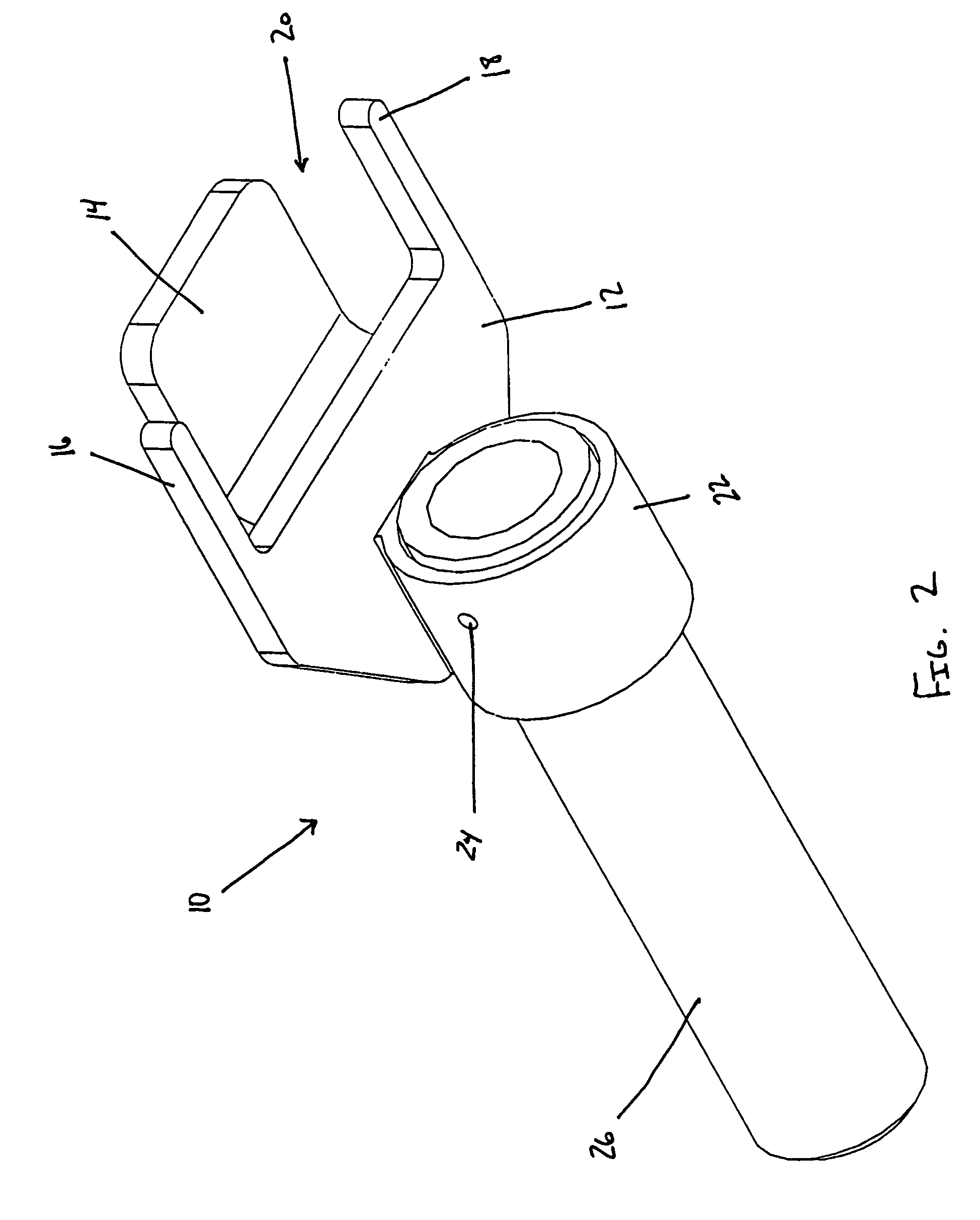

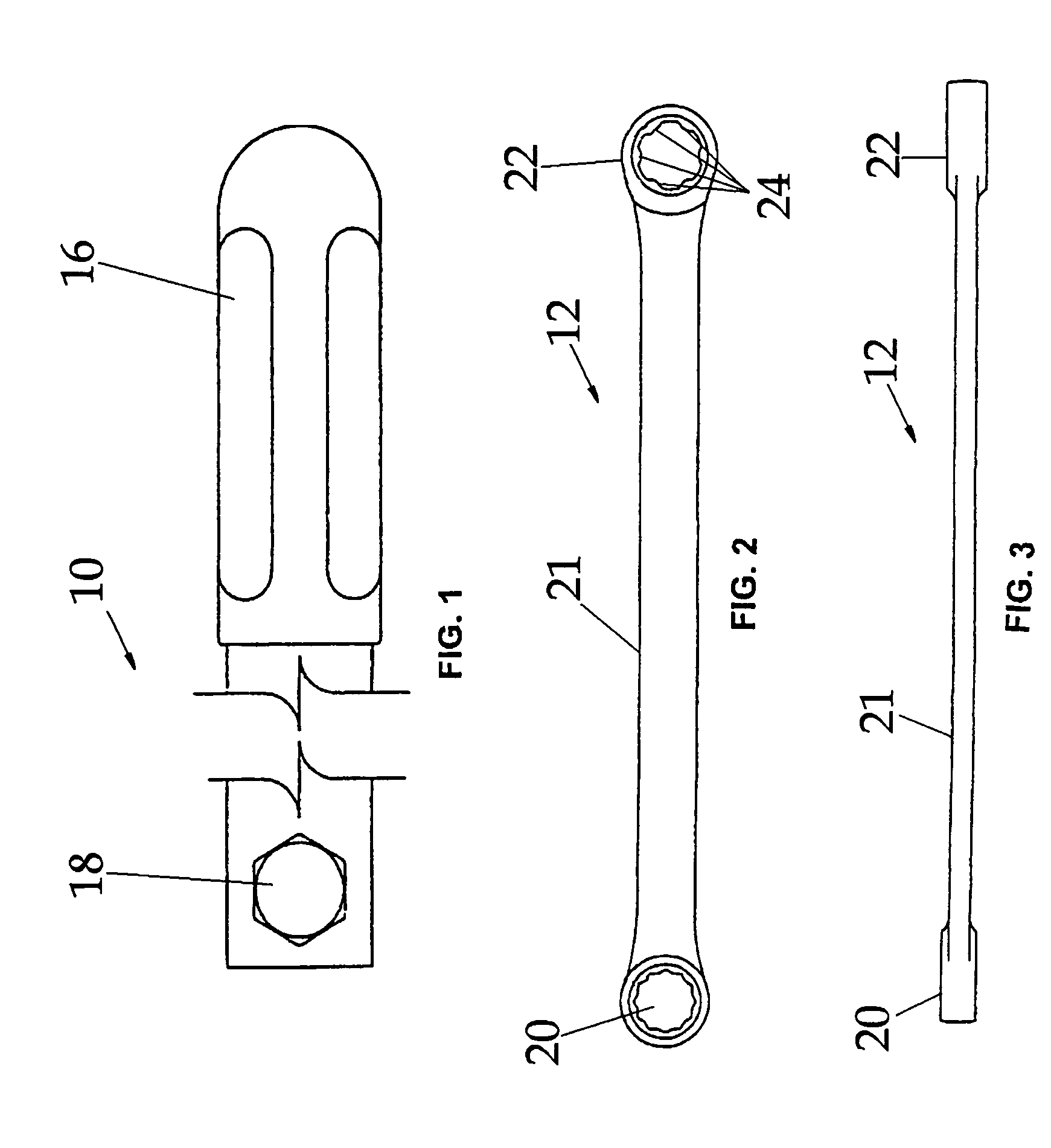

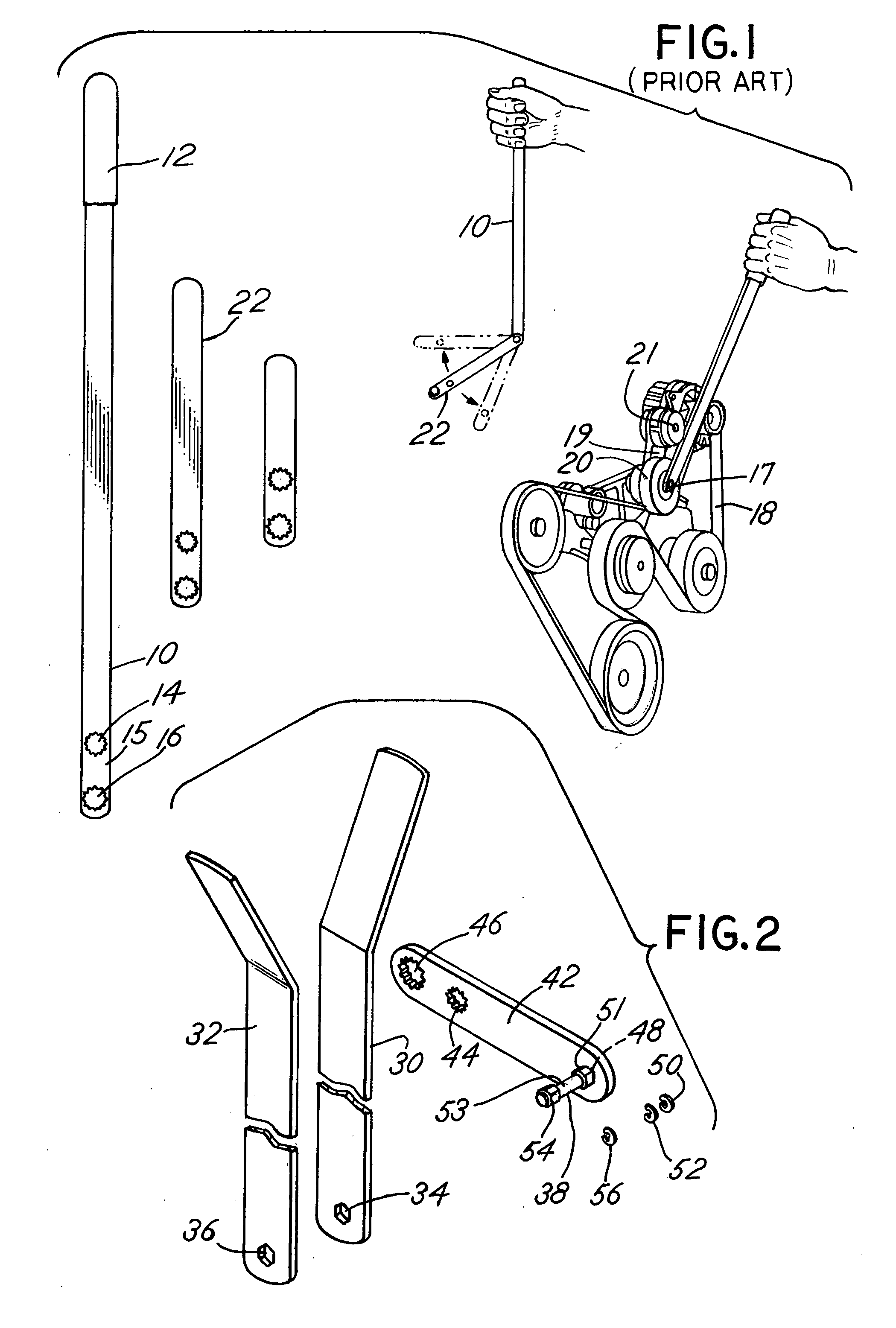

Ratcheting serpentine belt tool

InactiveUS20090107299A1Efficient positioning orientationEasy to useSpannersWrenchesSerpentine beltIdler-wheel

A serpentine belt tool for releasing tension on a serpentine belt biased by an idler pulley includes an elongate handle which is connected to a ratchet mechanism. The pawl associated with the ratchet mechanism has three positions including a neutral position which facilitates placement of the tool on an idler pulley.

Owner:LISLE CORPORATION

Compact self contained removable firefighting unit

InactiveUS7836963B2Safe and efficient firefightingEasy accessFire rescueHydraulic motorSerpentine belt

A system which is sufficiently compact and portable to be moved via skid support platform to a multi-wheel diesel-powered host containing active pump and roll capability with front and rear active hydraulics, such as a Bobcat Toolcat Turbo 5600. The system contains a water tank, generally 150 gallons, as well as built in foam tank. The system is wholly powered by the hydraulic system of the host vehicle powering a hydraulic motor on the system. The system hydraulic motor turns a serpentine belt at sufficient RPM's to power a water pump, air compressor and the compressed air foam system (CAFS) module. Using solely the power provided by the hydraulic motor, water is drawn from the tank, either used alone or mixed with foam at the percentage inputted by the user. Compressed air is added and the air alone, water alone or water / foam mixture is routed via adjustable valve to either the 1 inch firefighters hose or the rigid waterway ending in an adjustable, movable nozzle attached to the cab roof of the host.

Owner:COLLINS JEFF

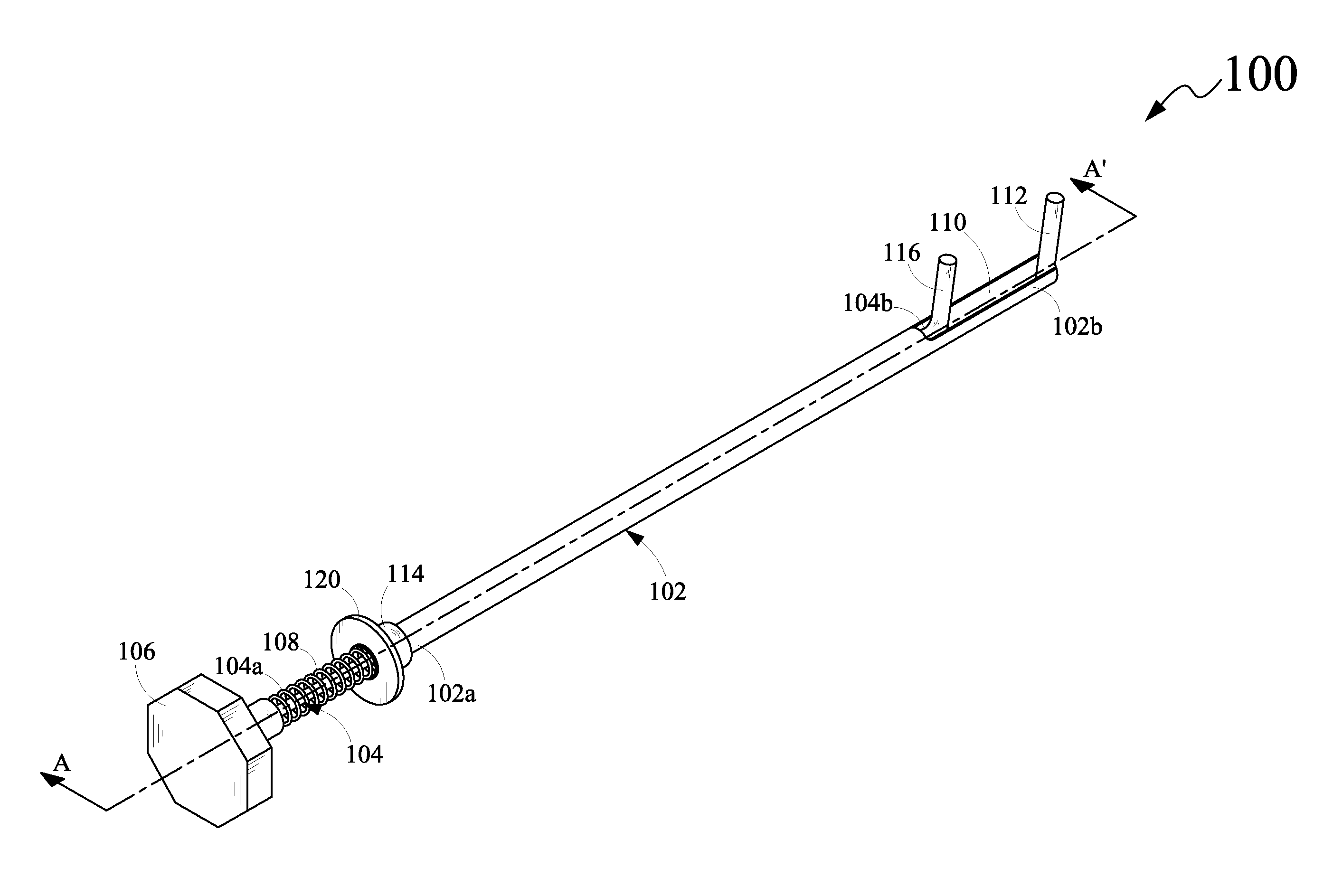

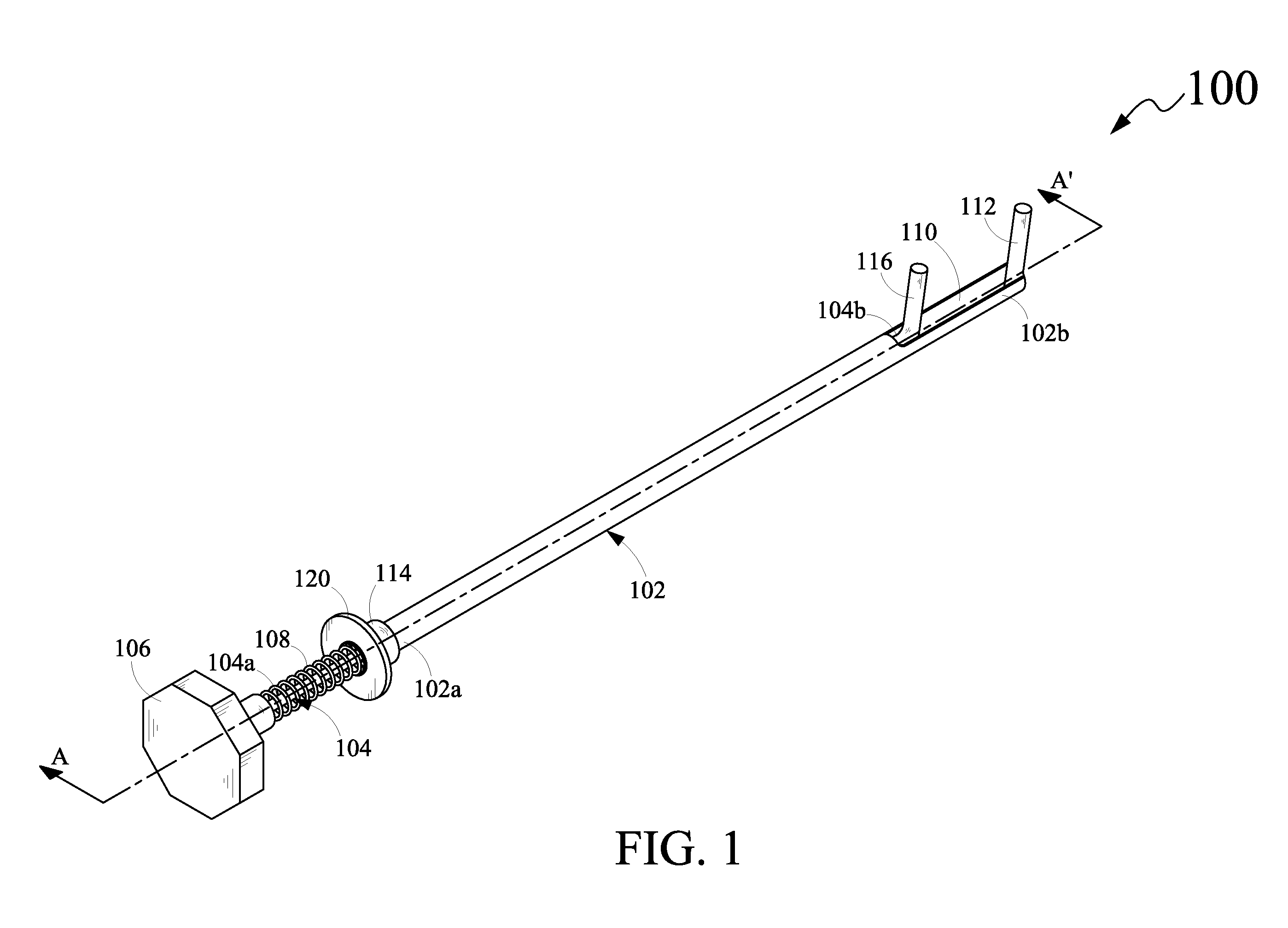

Tool for handling serpentine belt

Owner:CONNEELY PETER

Torque Limited Decoupler

A decoupler assembly is provided for allowing an alternator to be rotatably driven by a serpentine belt in an engine of an automotive vehicle and for allowing the speed of the belt to oscillate relative to the alternator. A hub is fixedly carried by a drive shaft from the alternator for rotation therewith. A pulley is rotatably journaled to the hub by a ball bearing assembly. A bare, helical clutch spring is operatively coupled between the hub and pulley for transferring rotational movement from the pulley to the hub during acceleration of the pulley relative to the hub by the serpentine belt and for allowing the hub to overrun the pulley during deceleration of the pulley relative to the hub. A torque limiter, preferably a spring or sleeve, is wrapped about the torsion limiting outward expansion of the torsion isolating the torsion spring from torques above a predetermined limit.

Owner:LITENS AUTOMOTIVE INC

Flexible tube cleaning lance drive apparatus

ActiveUS9630801B2Promote withdrawalPrevent removalFilament handlingHollow article cleaningSerpentine beltDrive motor

A flexible lance drive device is disclosed that has, in a compact housing, a drive motor between an inner and an outer wall, a linear array of pairs of driven upper and lower drive rollers outside the outer wall coupled to the drive motor via shafts extending through both of the inner and outer walls. Each driven roller is fastened to its shaft via a quick release device. A drive sprocket is fastened to each shaft outside the inner wall. The drive motor is coupled to each of the drive sprockets via a serpentine belt carried outside the inner wall. The lower driven rollers are rotatably carried by the inner and outer walls. The upper driven rollers are rotatably carried by a block positioned between the inner and outer walls and coupled to the lower driven rollers by a pair of parallel links releasably biased by a piston driven linkage.

Owner:STONEAGE

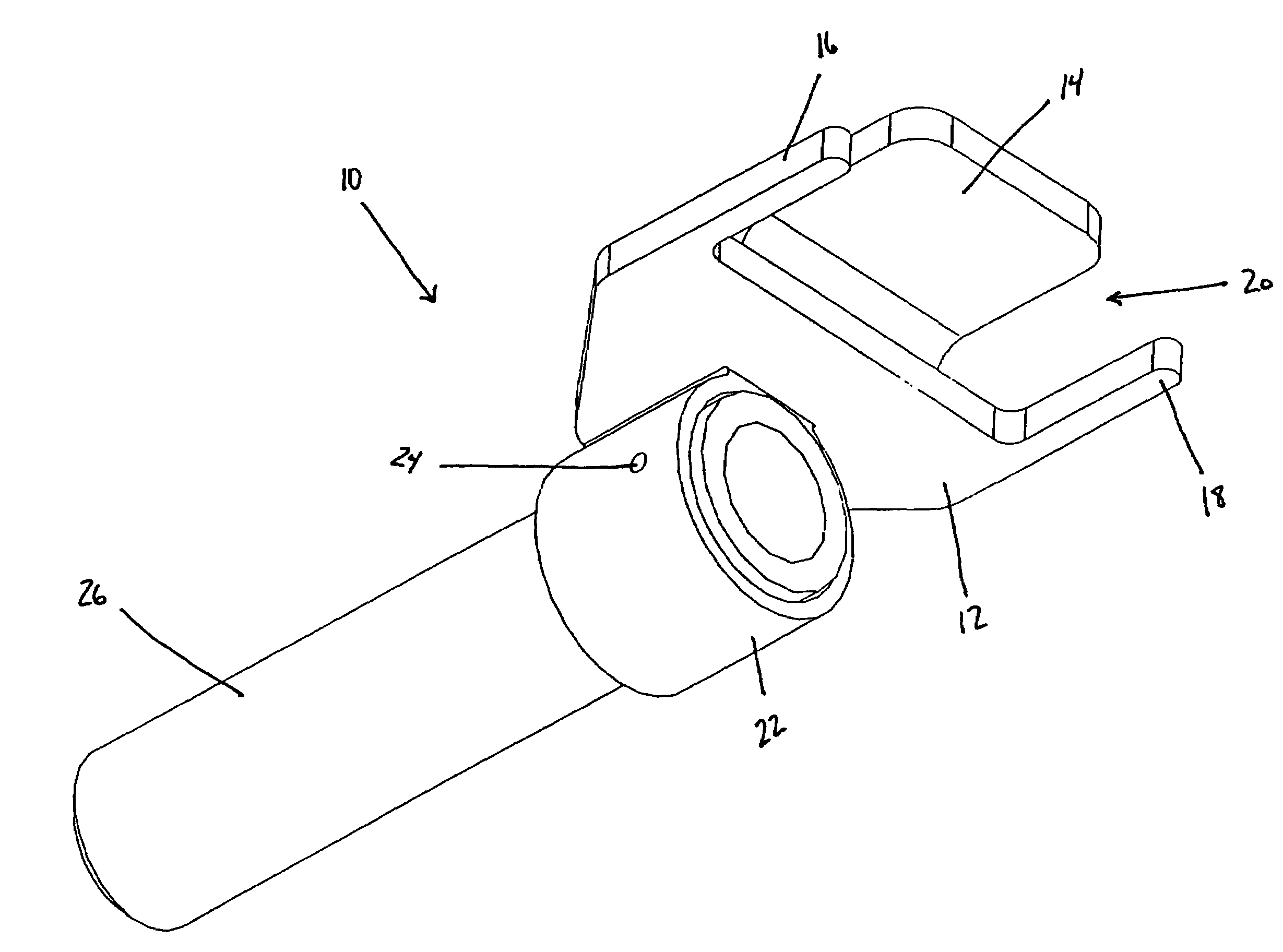

Belt inspection tool

A tool for inspecting serpentine belts of vehicles includes a main body, an upper tang, a right tang, a left tang, a holder and a handle. The tangs define a window therebetween. The window is adapted to receive a belt to be inspected. The handle may be a flashlight used to illuminate the belt to be inspected. When in use, the window shows a portion of the belt to be inspected. A technician can inspect the portion of the belt shown for cracks and recommend replacing the belt.

Owner:JS PRODS

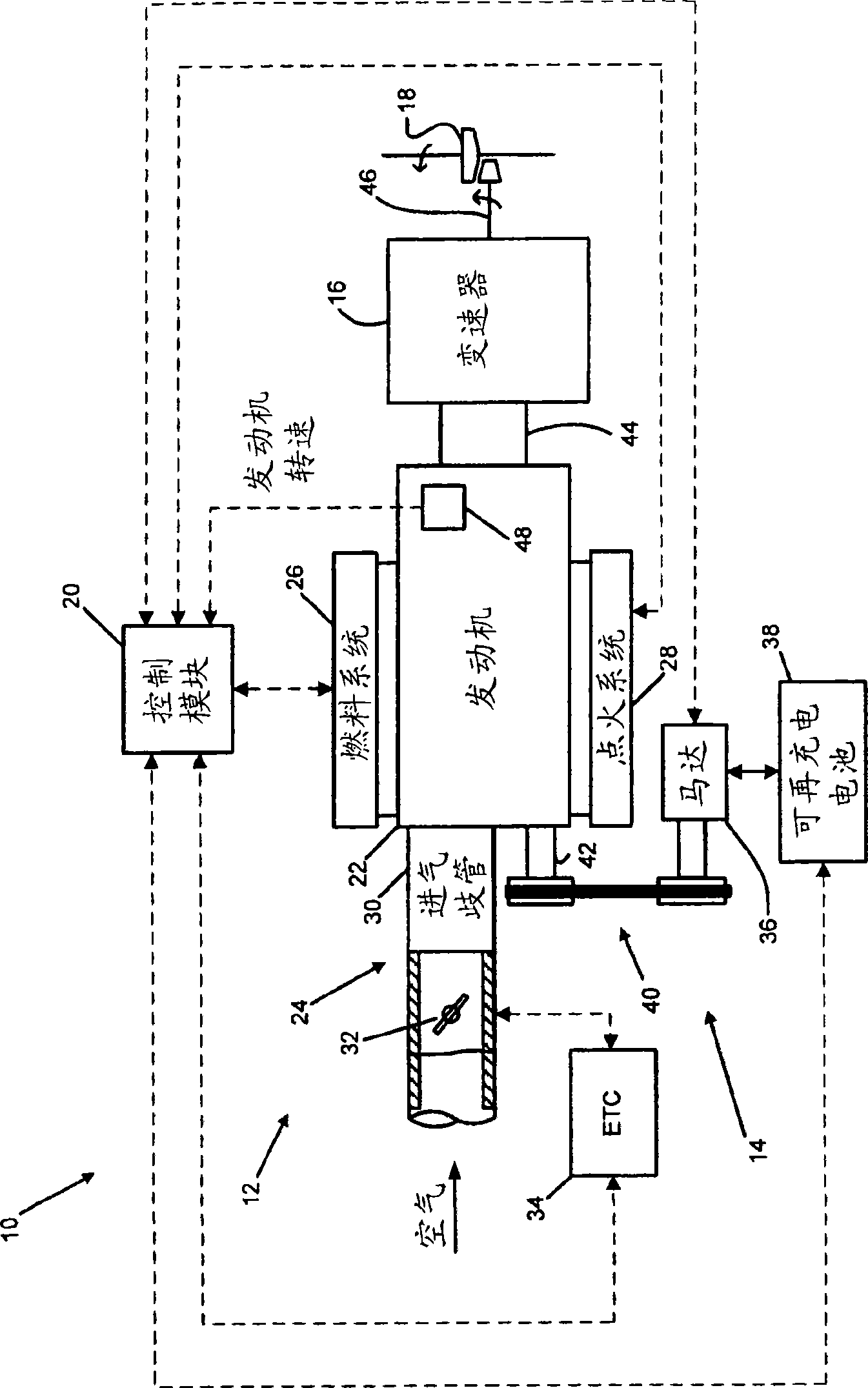

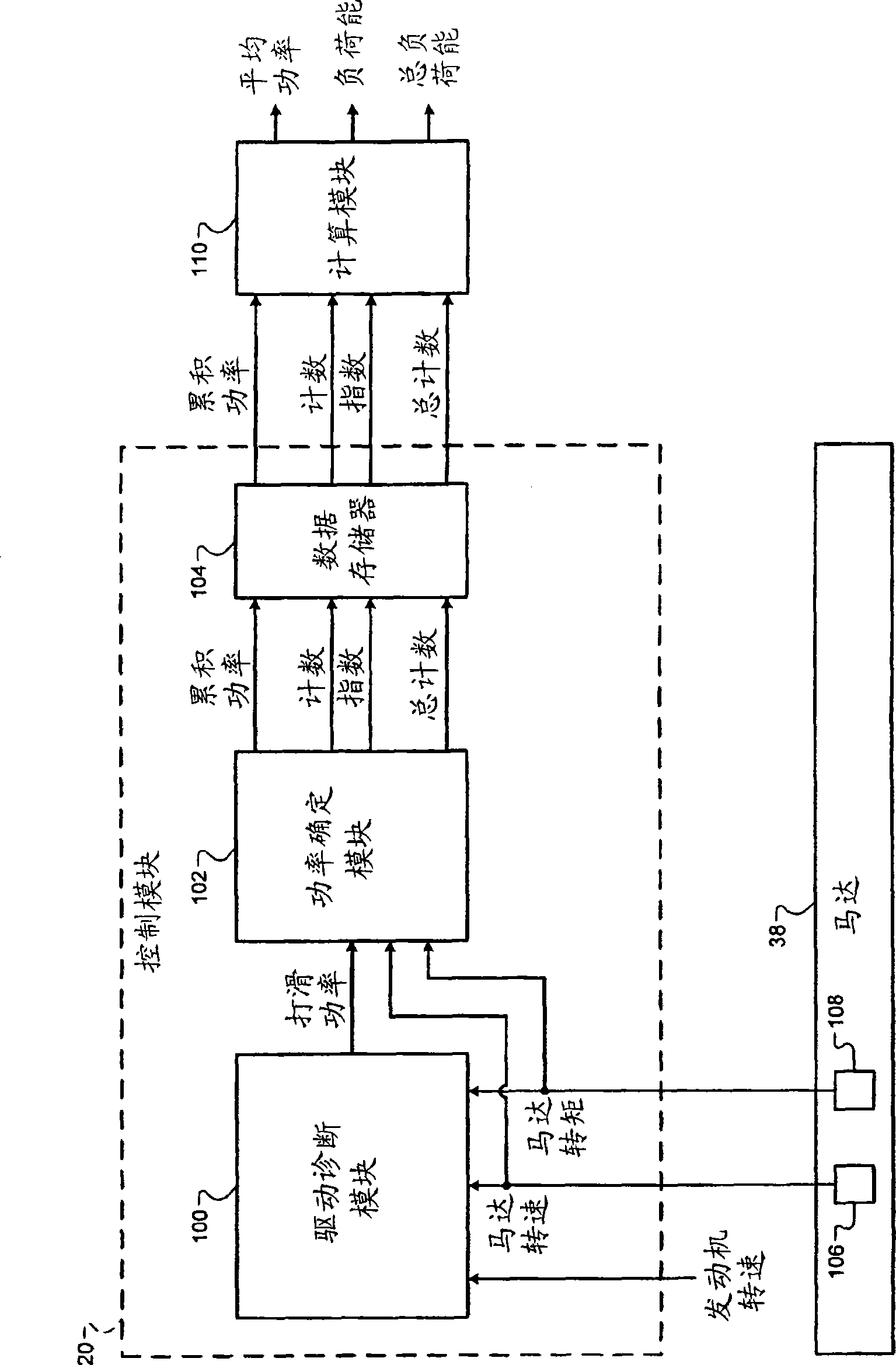

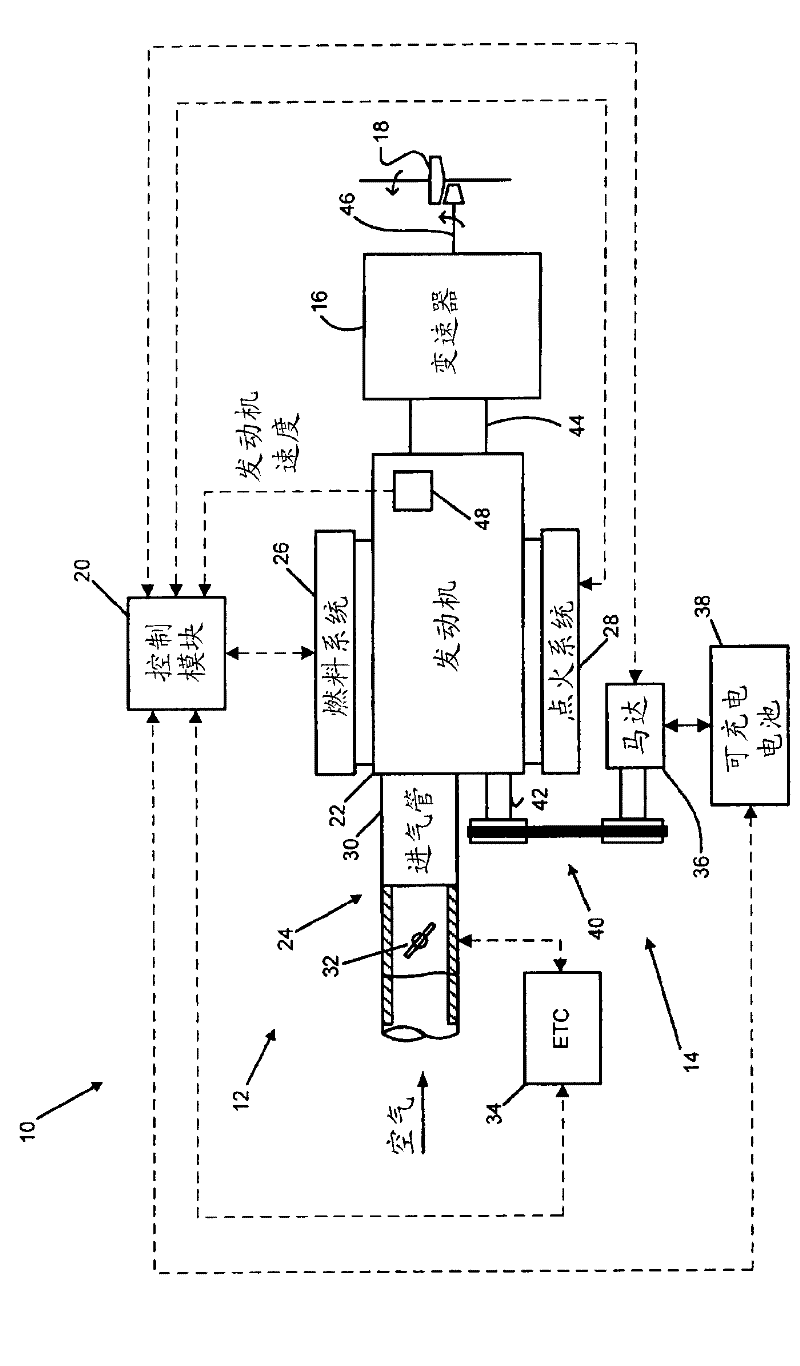

Serpentine belt useful life monitor

The invention relates to a snake belt effective service life monitor. A control module of a vehicle comprises a drive diagnostic module and a power determination module. The drive diagnostic module determines a slip power of a belt based on engine speed, motor speed, and motor torque. The power determination module determines an accumulated power of the belt based on the slip power, the motor speed, and the motor torque. The control module diagnoses a condition of the belt based on the accumulated power.

Owner:GM GLOBAL TECH OPERATIONS LLC

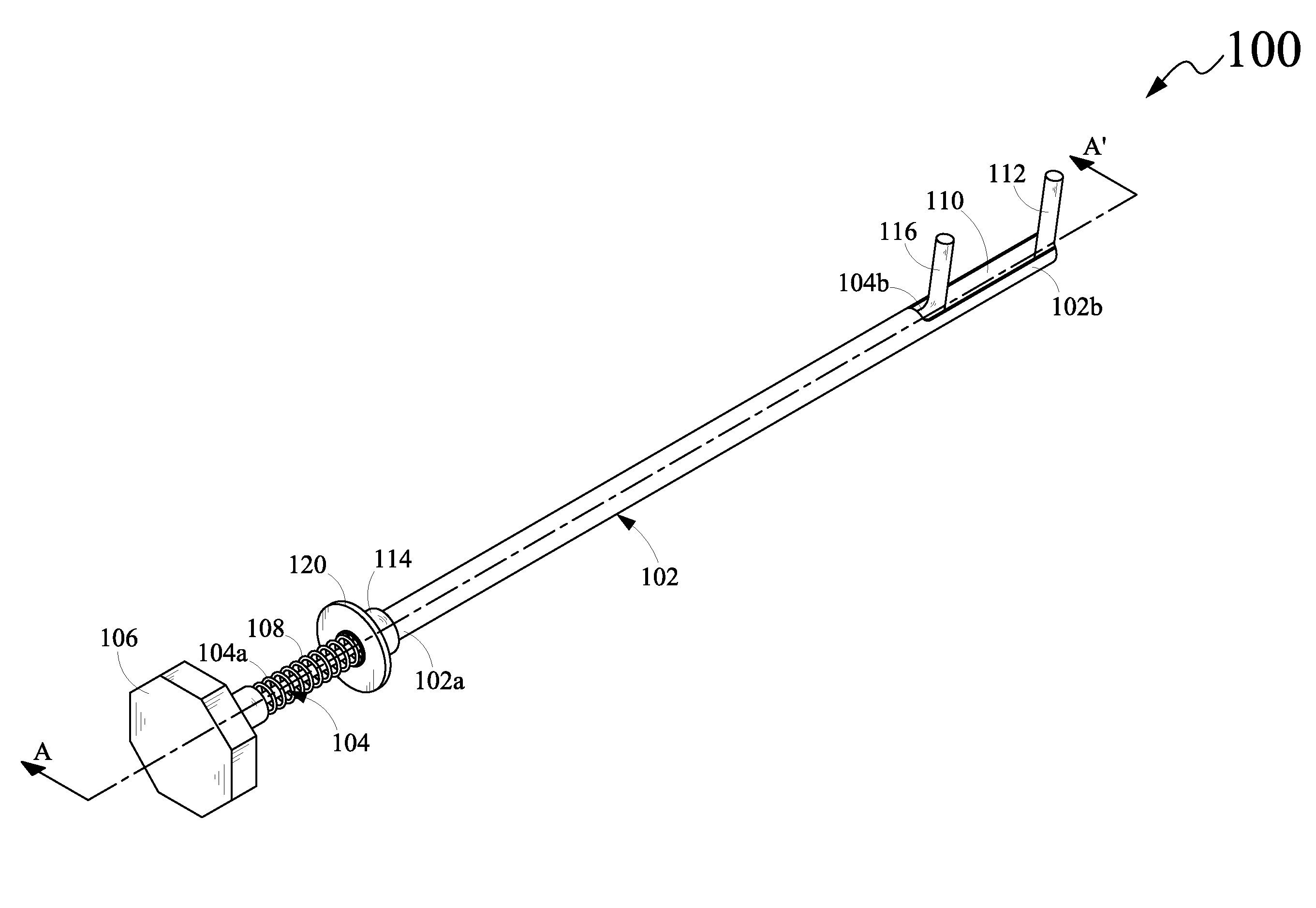

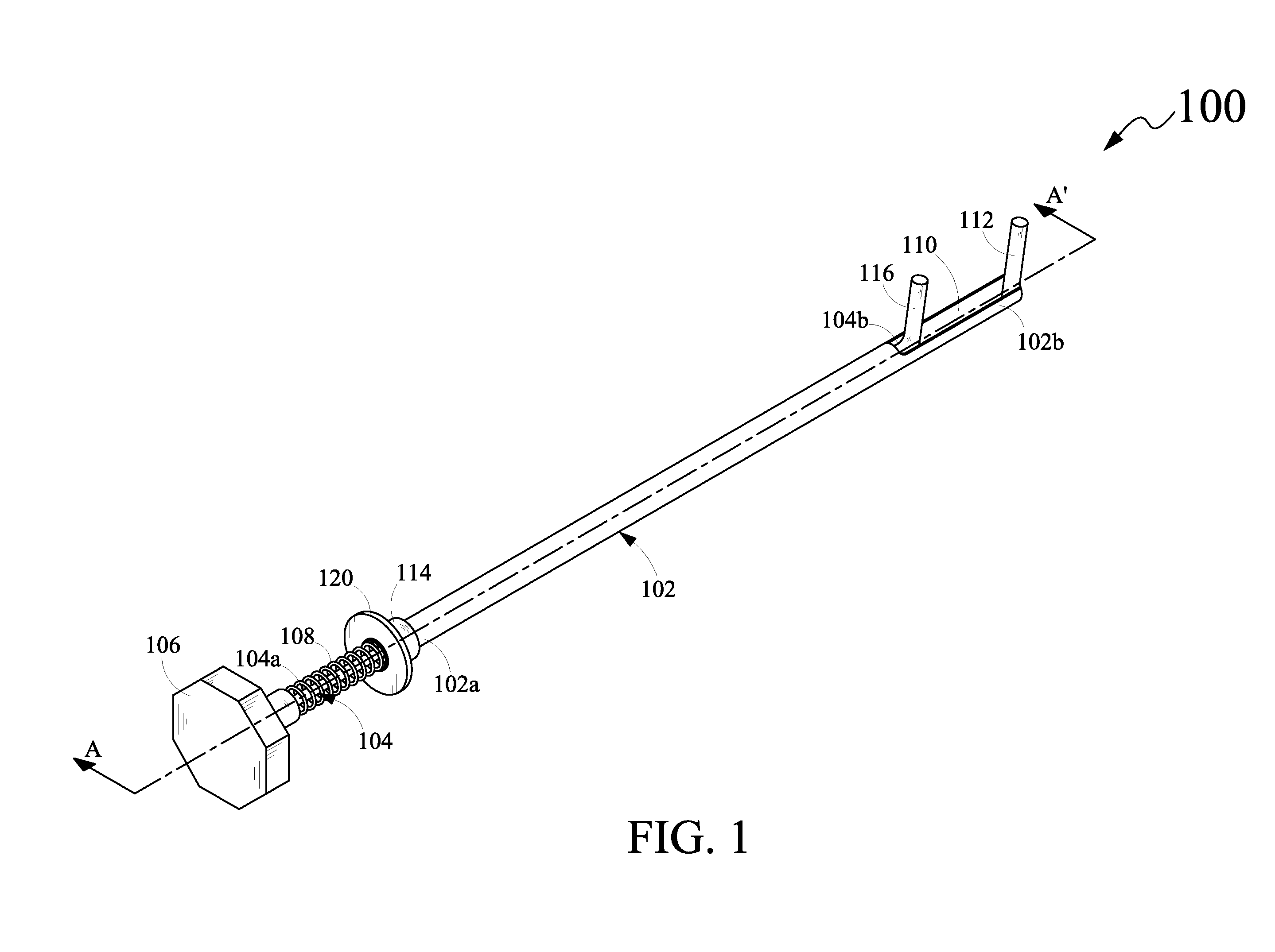

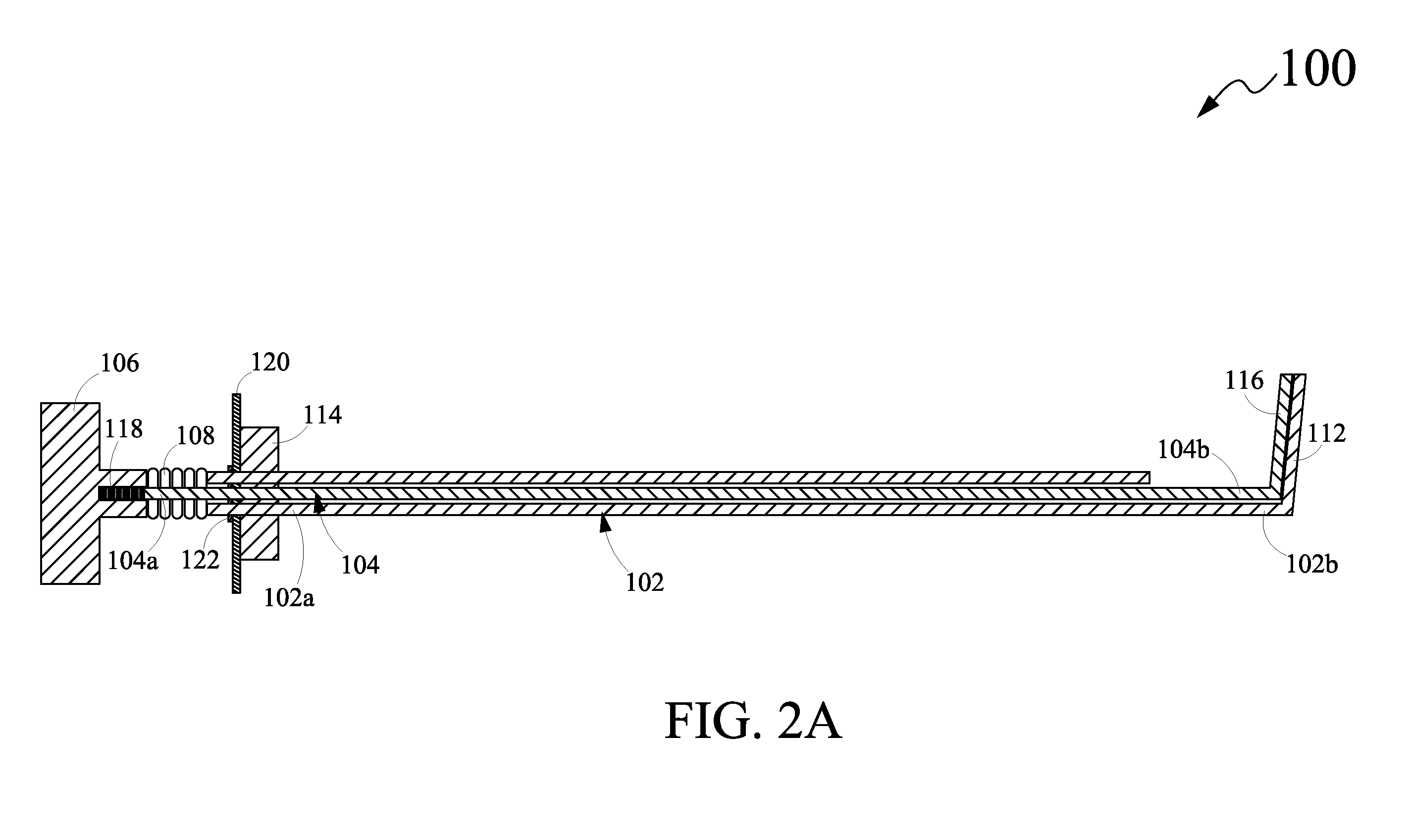

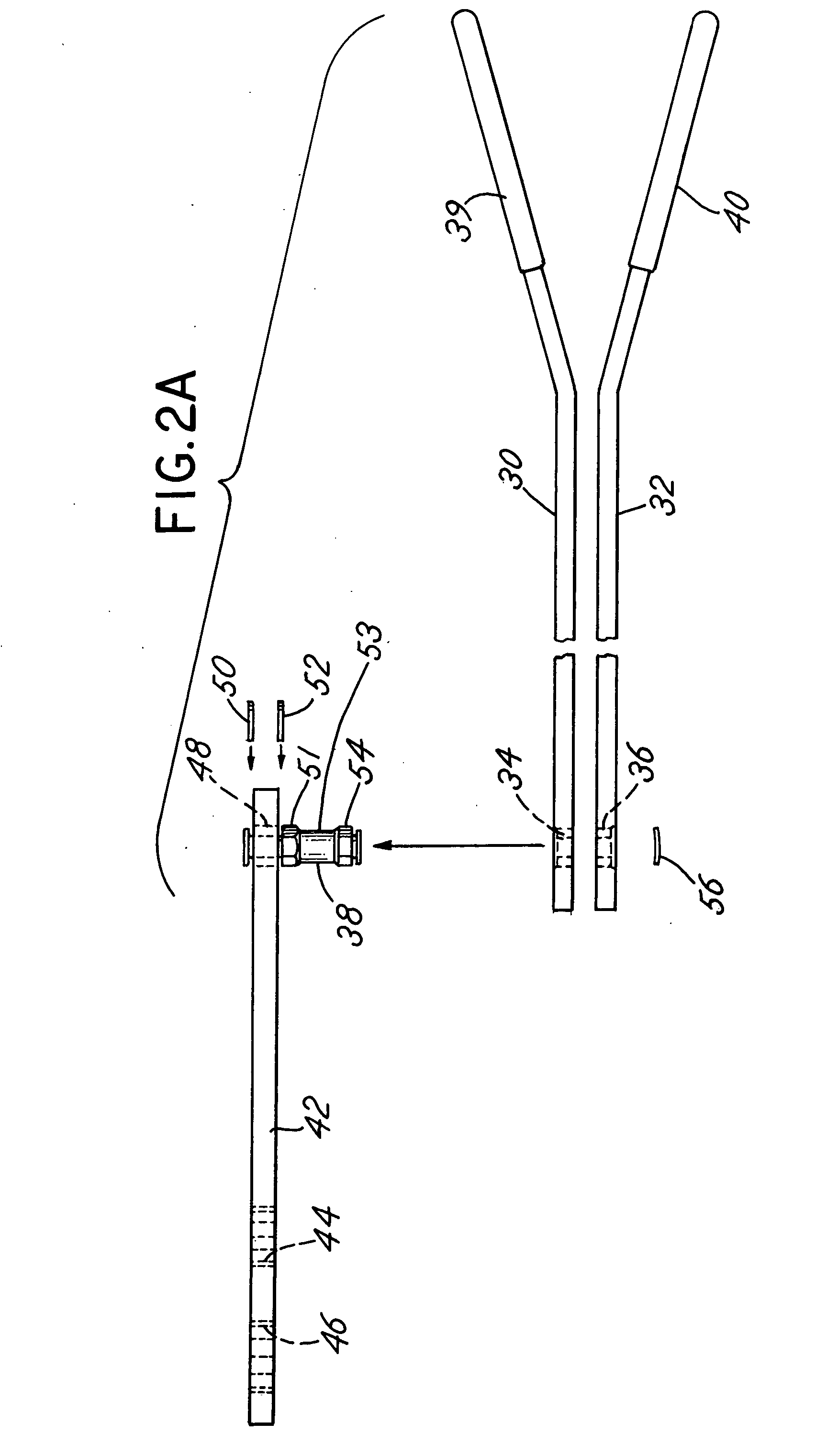

Tool for handling serpentine belt

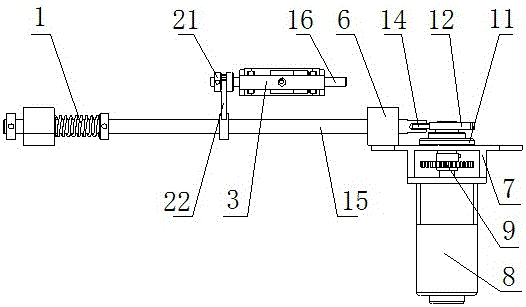

One embodiment of a tool for handling a serpentine belt may include a hollow pipe that may have a longitudinal opening configured at a distal end portion thereof. Further, the hollow pipe may include a first griping member and a sleeve member. The first gripping member may be configured at the distal end portion of the hollow pipe and may be projected outwards from the longitudinal opening. Moreover, the sleeve member may be configured at a proximal end portion of the hollow pipe. The tool may also have a rod that may be partially enclosed and slidably engaged with the hollow pipe. Further, the rod may include a second gripping member that may be configured at a distal end portion thereof in a parallel relationship with the first gripping member. The second gripping member may project outwards from the longitudinal opening. The tool may also have a handle member that may be configured at a proximal end portion of the rod. Further, the tool may have a spring member that may be disposed between the sleeve member and the handle member. The spring member may be capable of being compressed upon directing the handle member toward the sleeve member, and retracted upon releasing the handle member. Furthermore, upon directing the handle member toward the sleeve member, the second gripping member may move toward the first gripping member to hold the serpentine belt therebetween for handling the serpentine belt.

Owner:CONNEELY PETER

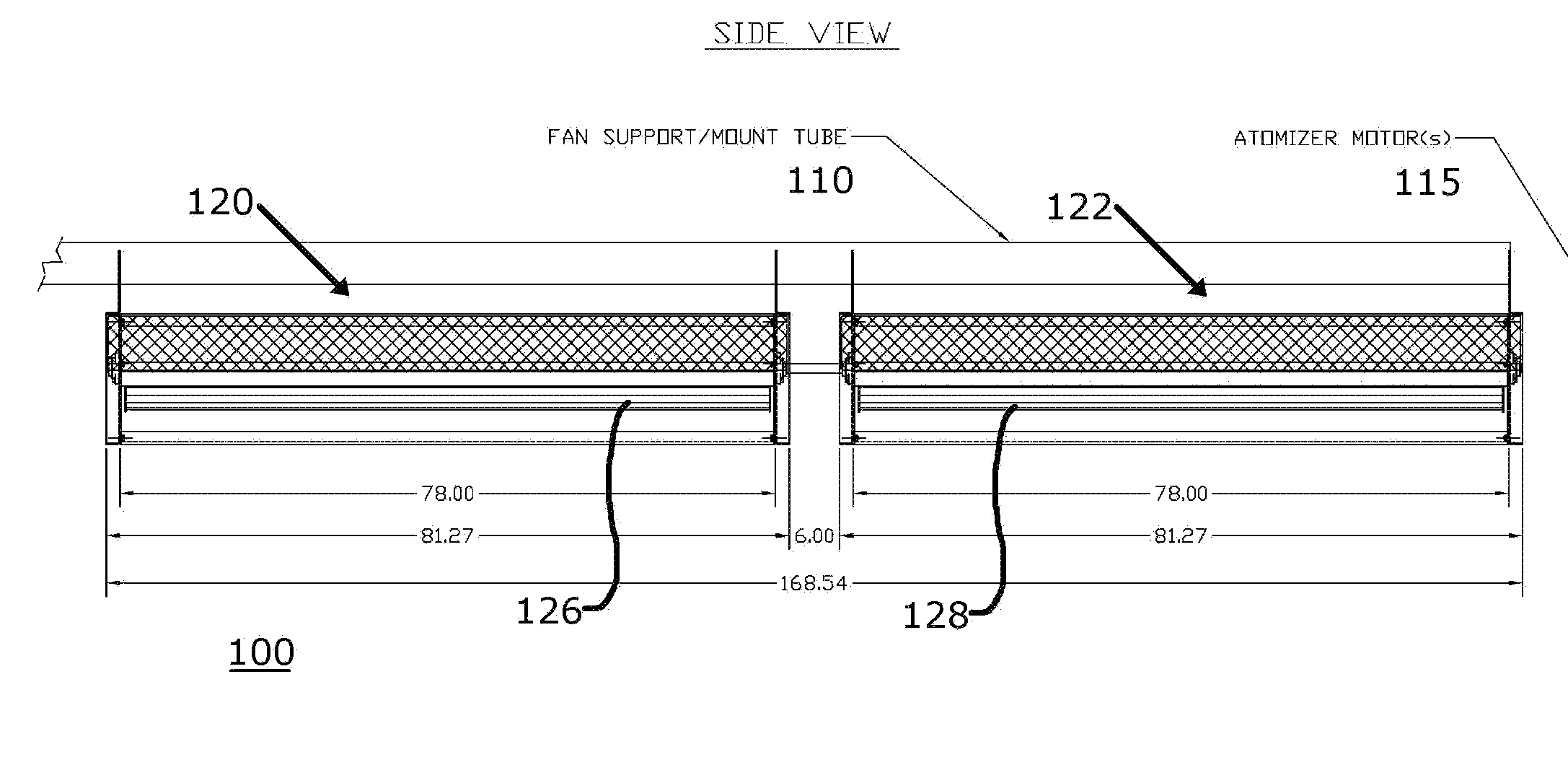

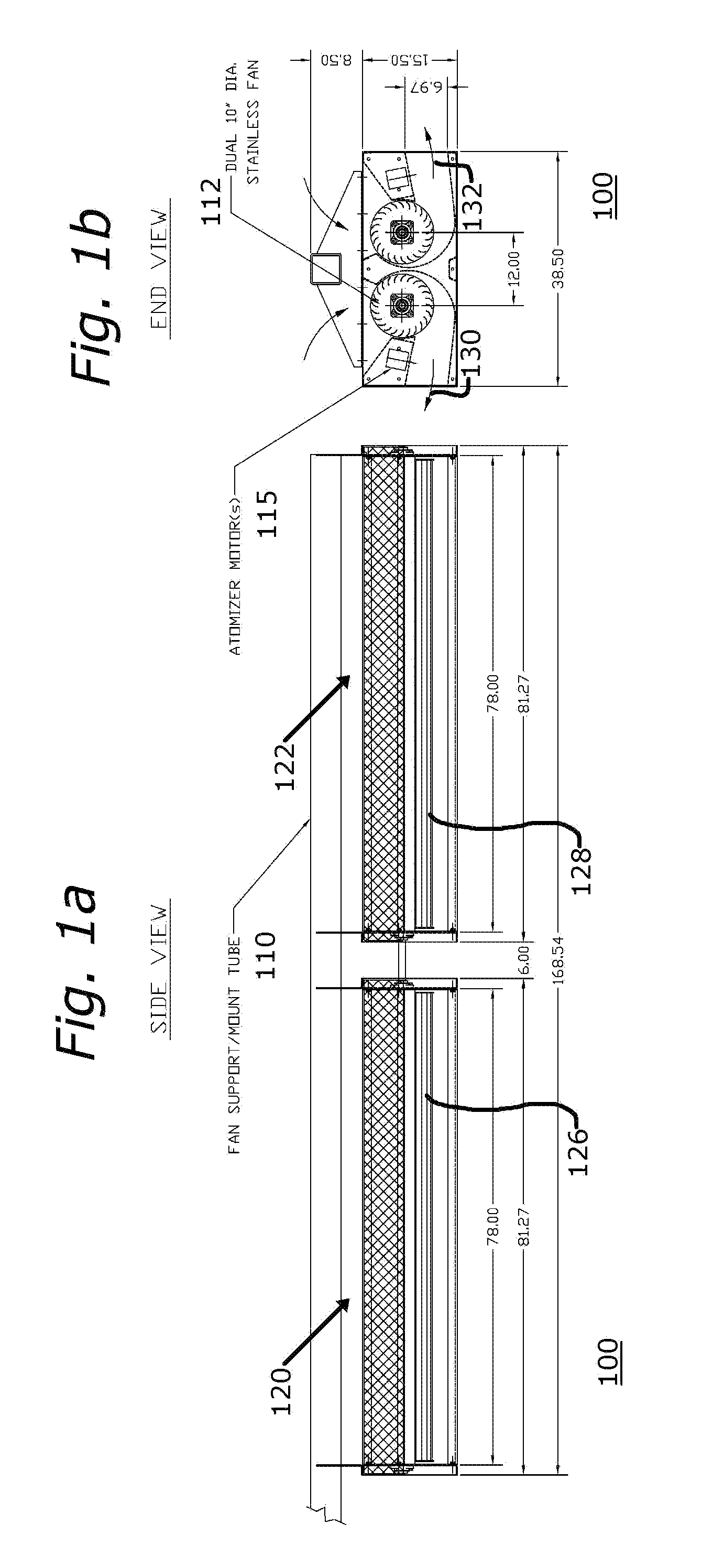

Dual Fan Sprayer

A spray unit and process for controlled droplet atomization for use particularly in an orchard, wherein air is urged under pressure in substantially opposite directions in response to the actuation of dual, counter-rotating fans. The fans are, in one embodiment, driven by a motor that is coupled to the fans by a serpentine belt. The flowing air receives droplets of material to be substantially atomized from one or more motor-powered atomizers. The spray unit is easily retrofitted to be installed on a convention sprayer cart or tractor-pulled trailer.

Owner:VANDIKE MARIO

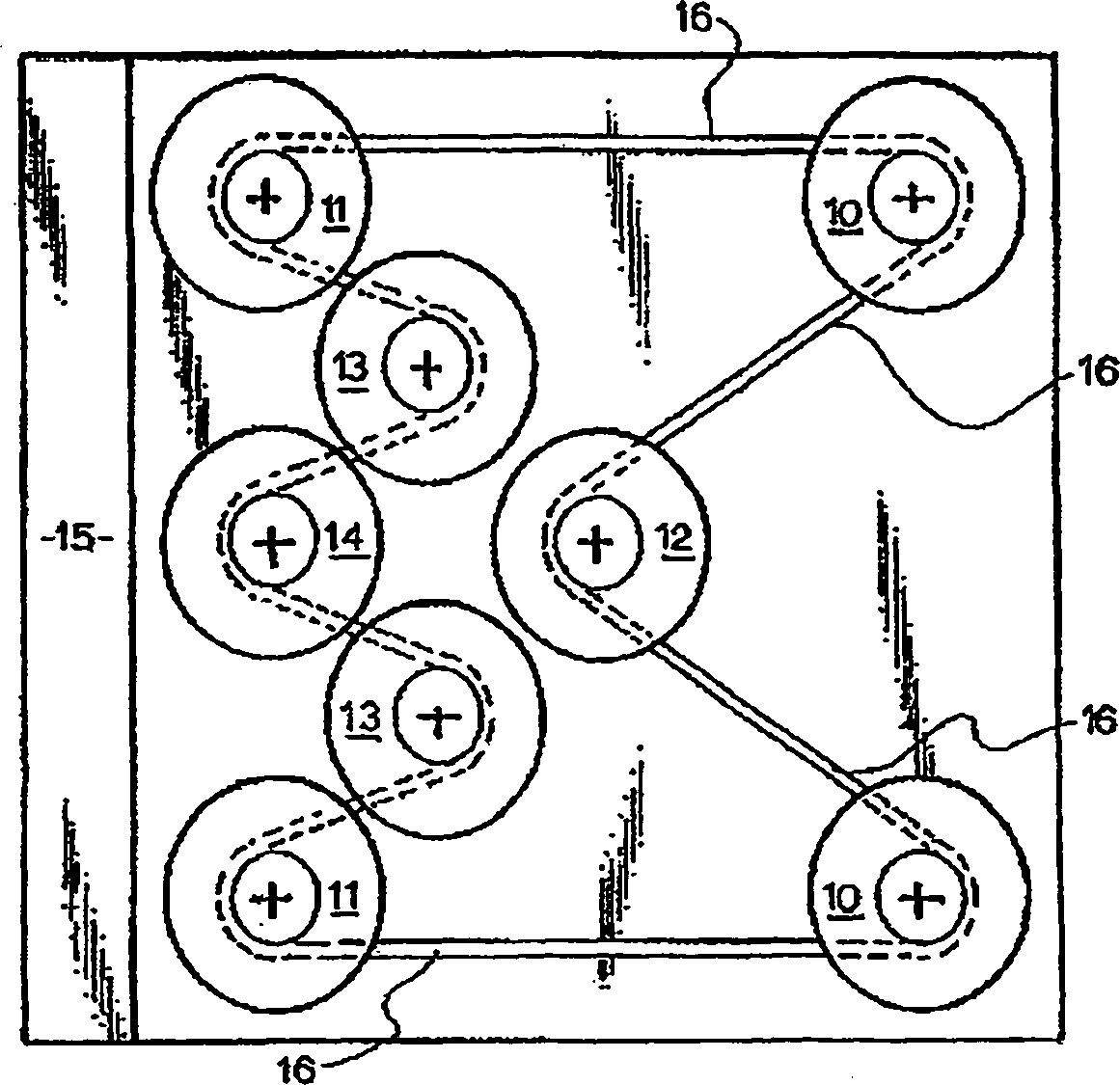

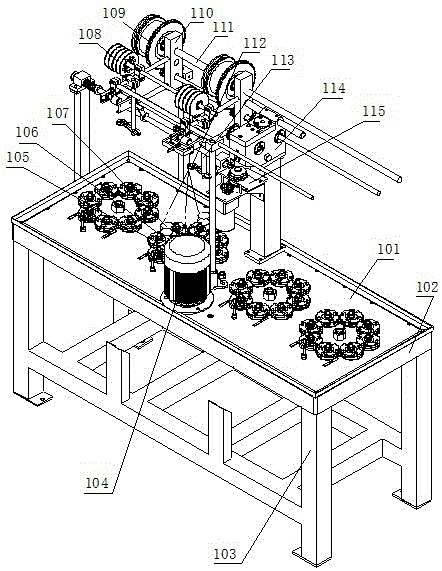

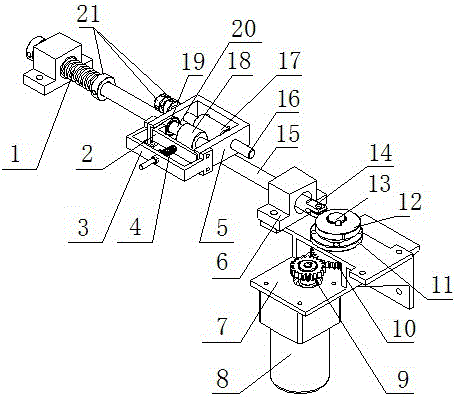

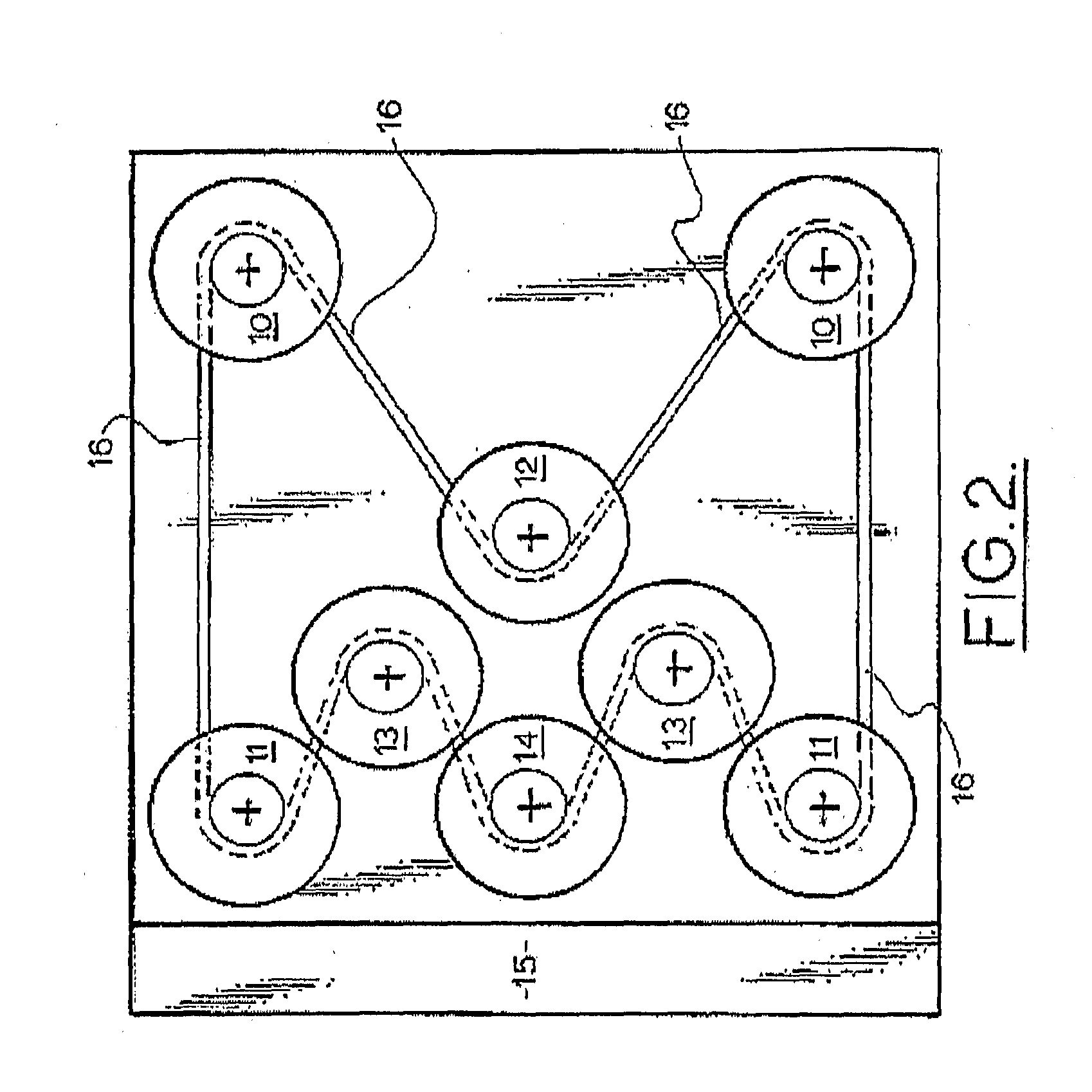

Serpentine belt braiding machine

A serpentine belt braiding machine is a braiding machine and comprises an upper disc, a lower disc, a frame, a main motor, a spindle drive device, a winding device, a serpentine transmission device and a support pillar; the upper disc and the lower disc are connected in succession on the frame, the spindle drive device, the main motor and the support pillar are connected to the upper disc, the winding device and the serpentine transmission device are connected to the support pillar, and the winding device is located above the serpentine transmission device; the serpentine transmission device comprises a roller moving mechanism and a drive mechanism; the roller mechanism and the drive mechanism are in rolling connection through their cams and rollers. The problem that a serpentine form made by the prior art is non-uniform in variation pitch, unstable in diameter deviation and low in yield is solved; this machine has the advantages that manual operation is replaced, serpentine pitch is uniform, time and labor are saved, product quality and yield are increased and materials are saved.

Owner:XUZHOU HENGHUI BRAIDING MACHINE

Finishing machine

A finishing machine comprises a motor mounted on a support frame and connected to a drive shaft and two or more finishing heads and an impeller fan driven by the drive shaft via a serpentine belt drive which rotates the finishing heads in opposite directions. The impeller fan impels dust from the grinding heads into a rear vacuum manifold and the support frame has rear wheels the height of which is adjustable by means of an hydraulic cylinder.

Owner:PEAKE ALAN THOMAS

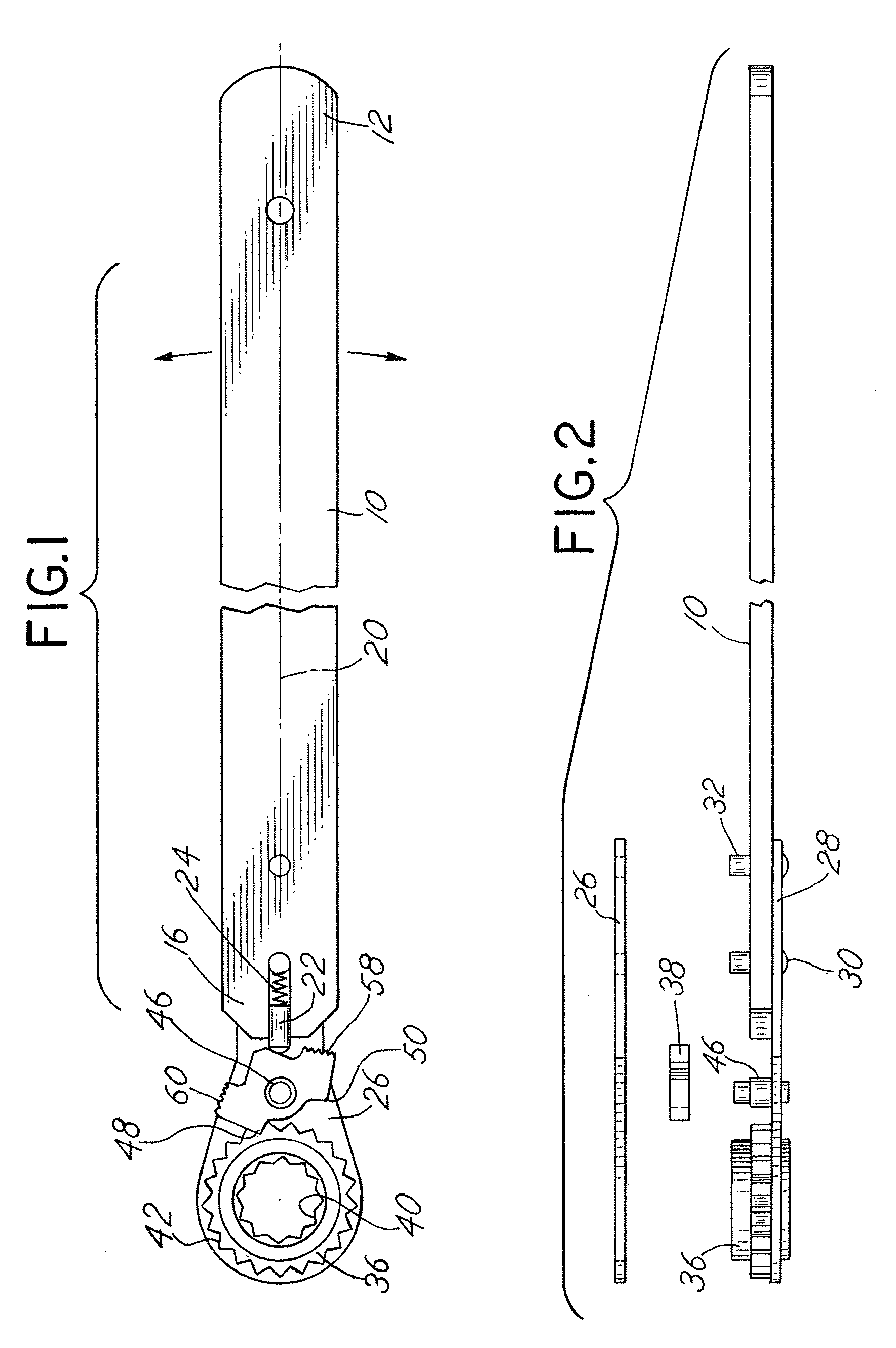

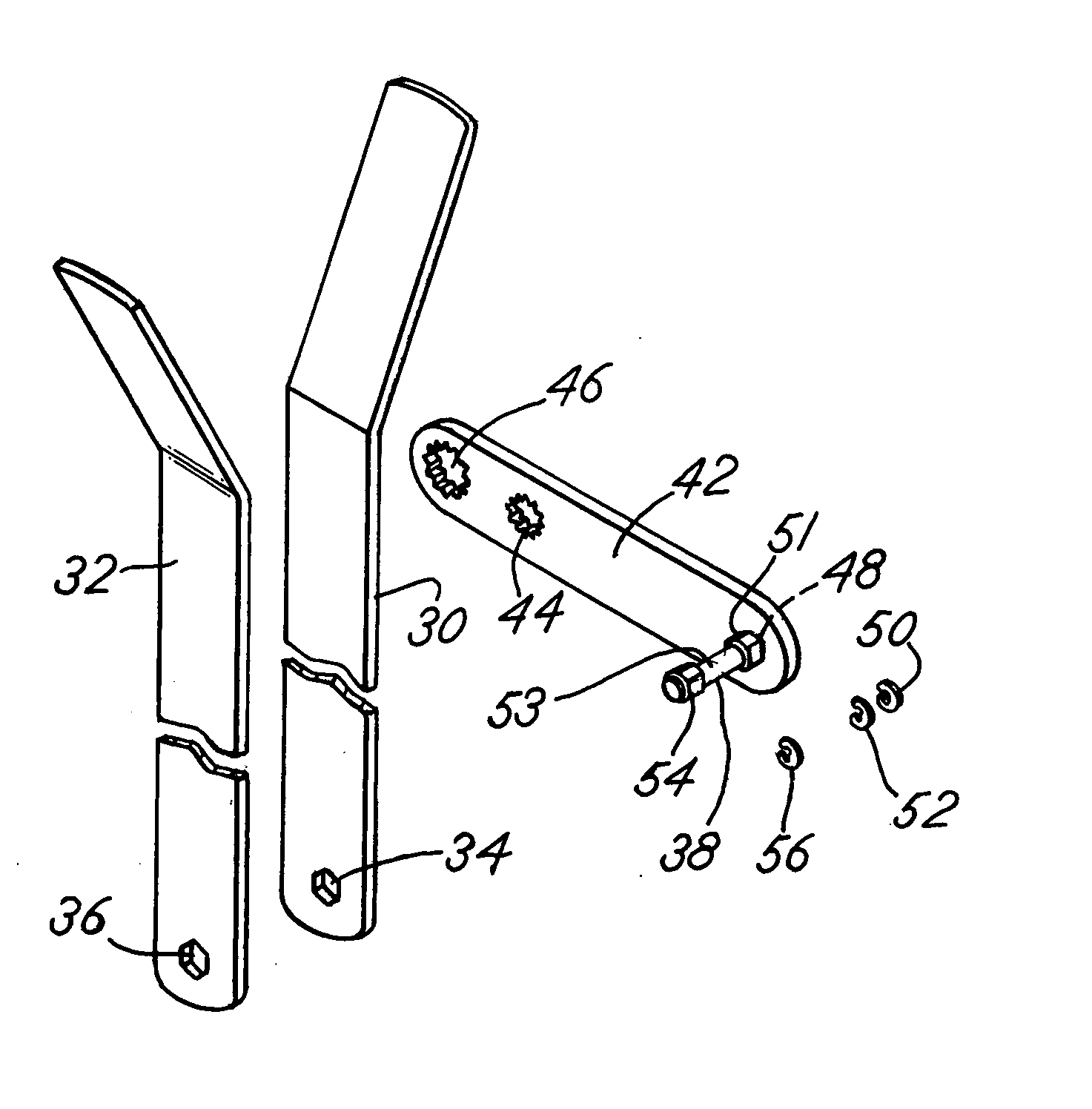

Geared serpentine belt tool

A tool for removing and installing serpentine belts in vehicles has a drive bar, a double box end wrench and a socket. The drive bar has a handle at a first end and a fitting at an opposite second end that is used to connect to the double box end wrench. The double box end wrench has a first end defining a polygonally shaped opening and an opposite second end that defines a ratcheting wrench having a first plurality of teeth on an inner circumference thereof. The socket defines a second plurality of teeth on an outer circumference thereof that are adapted to be received by the ratcheting wrench first plurality of teeth. The socket also defines one of a polygonally shaped opening and a polygonally shaped tang that is received by a work piece of an vehicle idler pulley.

Owner:APEX BRANDS

Abrasive Belt Grip

InactiveUS20180311780A1Belt grinding machinesOther manufacturing equipments/toolsSerpentine beltCarbide

An abrasive belt grip is an apparatus that is used to apply a finish to a knife blade. The apparatus includes a casing, a carbide plate, a drive roller, an idle roller, a heat-sinking saddle, a cooling system, and a serpentine belt. The casing is used as a structural base to mount all of the aforementioned components. The conveying movement of the serpentine belt allows the apparatus to apply a finish onto the knife blade. The conveying movement of the serpentine belt is driven by the rotation of the drive roller and is stabilized by the rotation of the idle roller. The carbide plate provides a flat backing for the serpentine belt as a knife blade is pressed against the serpentine belt. The heat-sinking saddle draws heat away from the serpentine belt and the carbide plate, while the cooling system exhausts that heat out of the casing.

Owner:MOEN JERRY MICHEAL

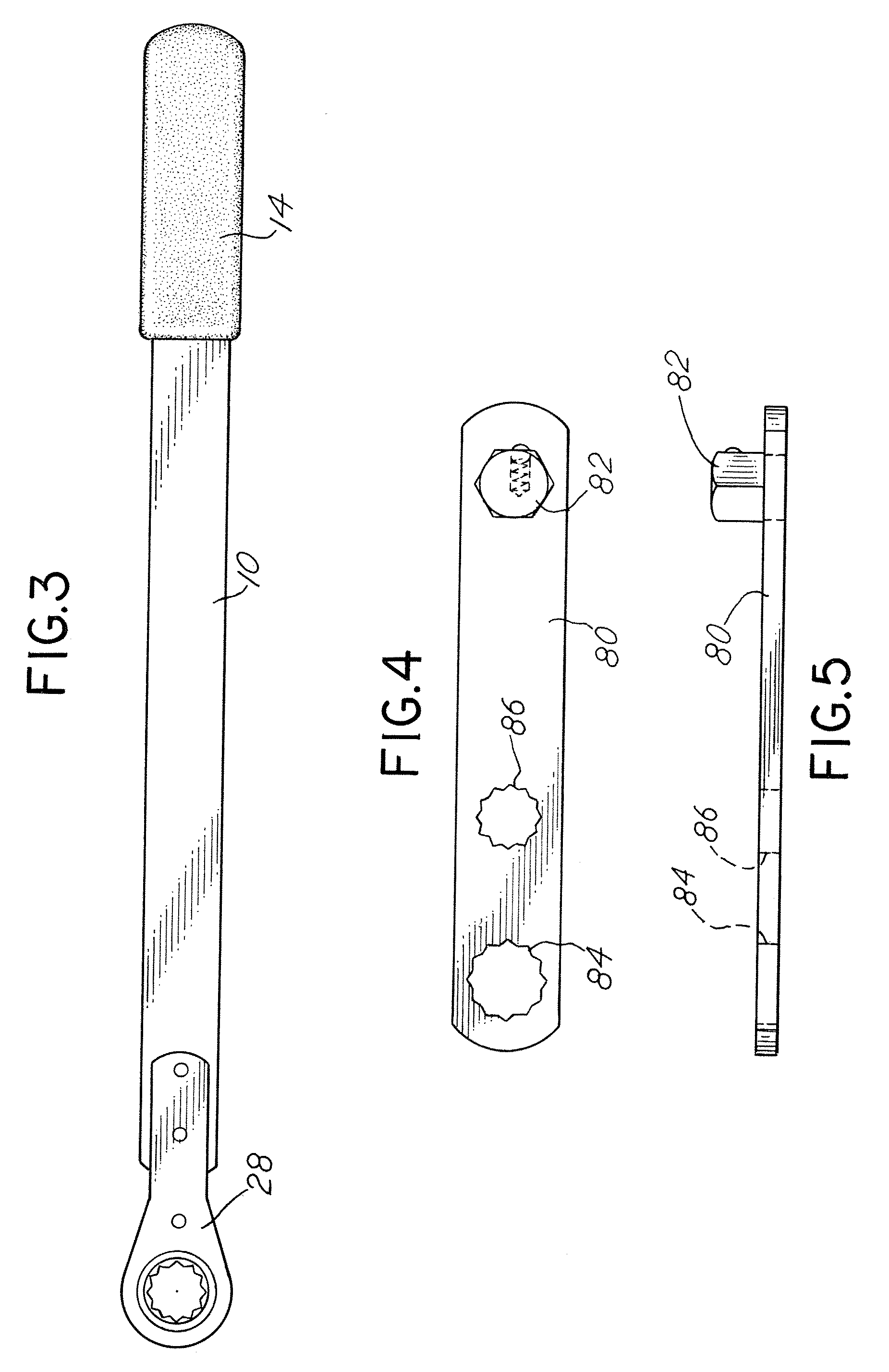

Serpentine belt tool

A serpentine belt tool for release of tension on a serpentine belt tensioned by a biased idler pulley mounted on a spring loaded arm includes first and second manually operable handles which may alternately be engaged with an extension bar keyed to the center spindle of the idler pulley to thereby provide ratchet like action and movement of the extension bar releasing the tension of the idler pulley on the belt.

Owner:LISLE CORPORATION

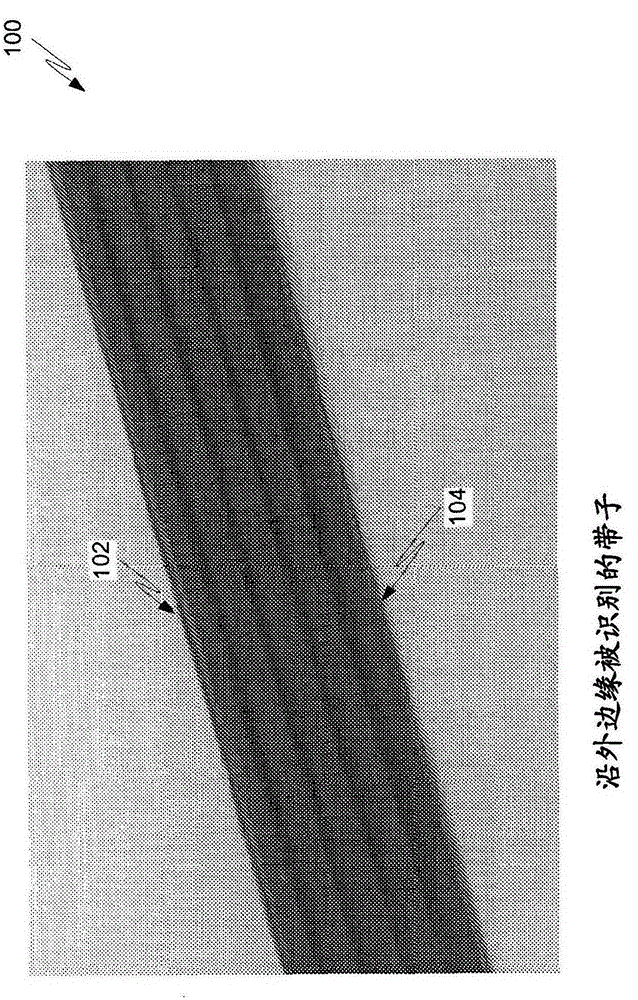

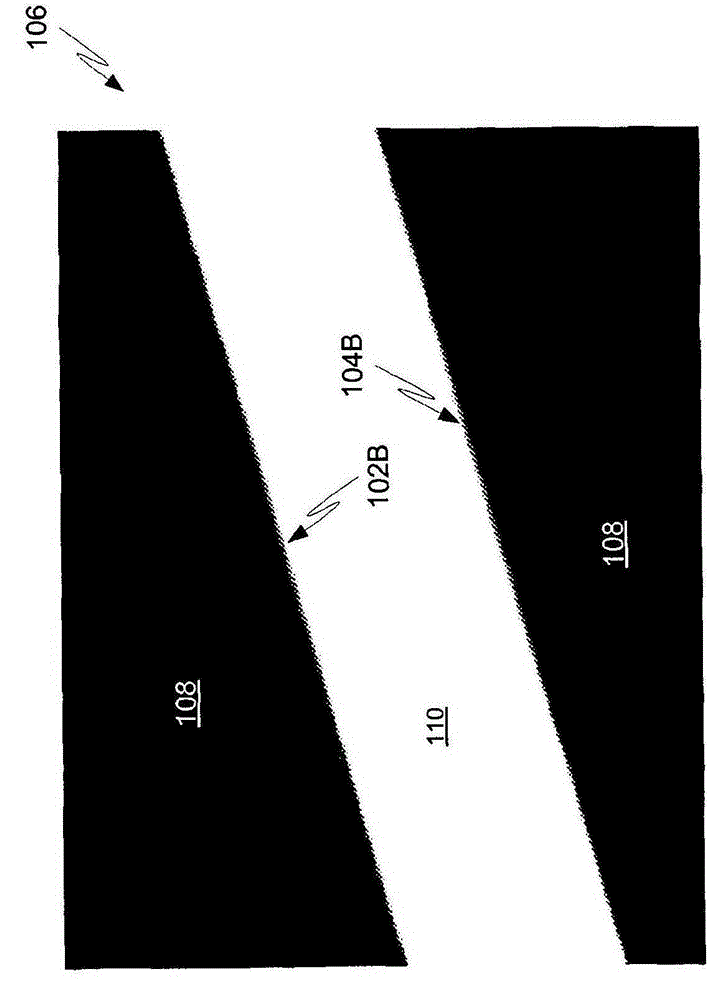

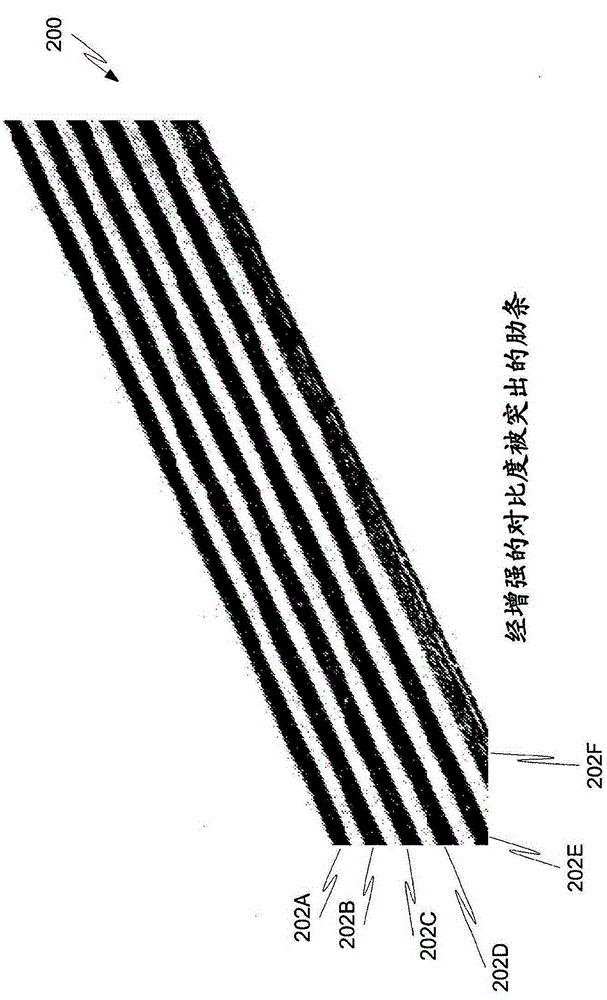

Enhanced analysis for image-based serpentine belt wear evaluation

ActiveCN105229665AHigh speedImprove accuracyMachine part testingImage enhancementSerpentine beltEvaluation system

Systems and methods are provided for the improvement of an image of a device under test, such as a belt. The image of device under test is made more optimal by determining if the object is rotated away from a preferred axis of the image frame. If so, the image is rotated an opposing angle such that the object is parallel to the preferred axis of the image frame. The rotated image is then made available for analysis of the object. Rib width analysis is performed along the entire length of the detected rib by either de-rotating the image or not.

Owner:THE GATES CORP

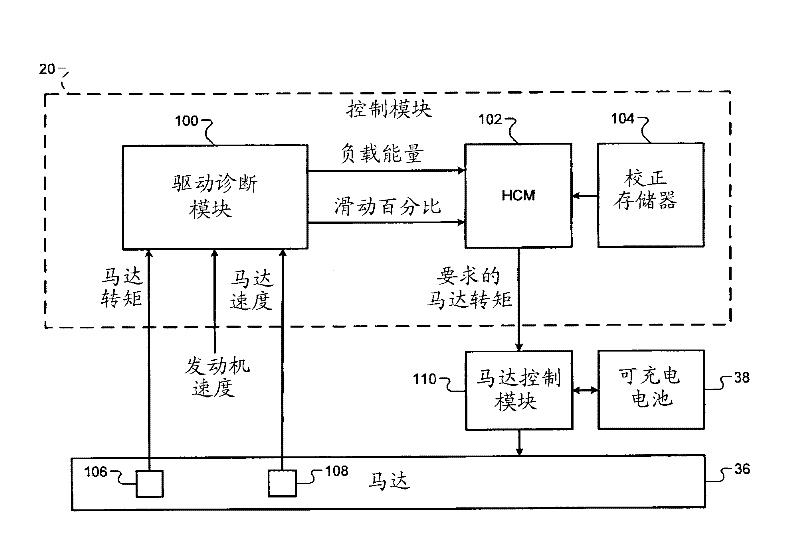

Virtual tensioner travel sensor for a serpentine belt tensioner assembly

The present invention relates to a virtual tensioner travel sensor for a serpentine blet tentioner assembly, wherein, a control module of a vehicle comprises a drive diagnostic module and a hybrid control module. The drive diagnostic module determines a load energy of an accessory drive system of the vehicle and determines a slip percentage of a belt of the accessory drive system based on an engine speed and a motor speed. The hybrid control module determines a requested motor torque based on at least one of the load energy and the slip percentage. The control module controls a motor of the vehicle based on the requested motor torque.

Owner:GM GLOBAL TECH OPERATIONS LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com