Finishing machine

A polishing machine and head technology, which is applied in the field of grinding machines, can solve the problems of difficulty in moving, time-consuming replacement of worn belts, and low working efficiency of dust collection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

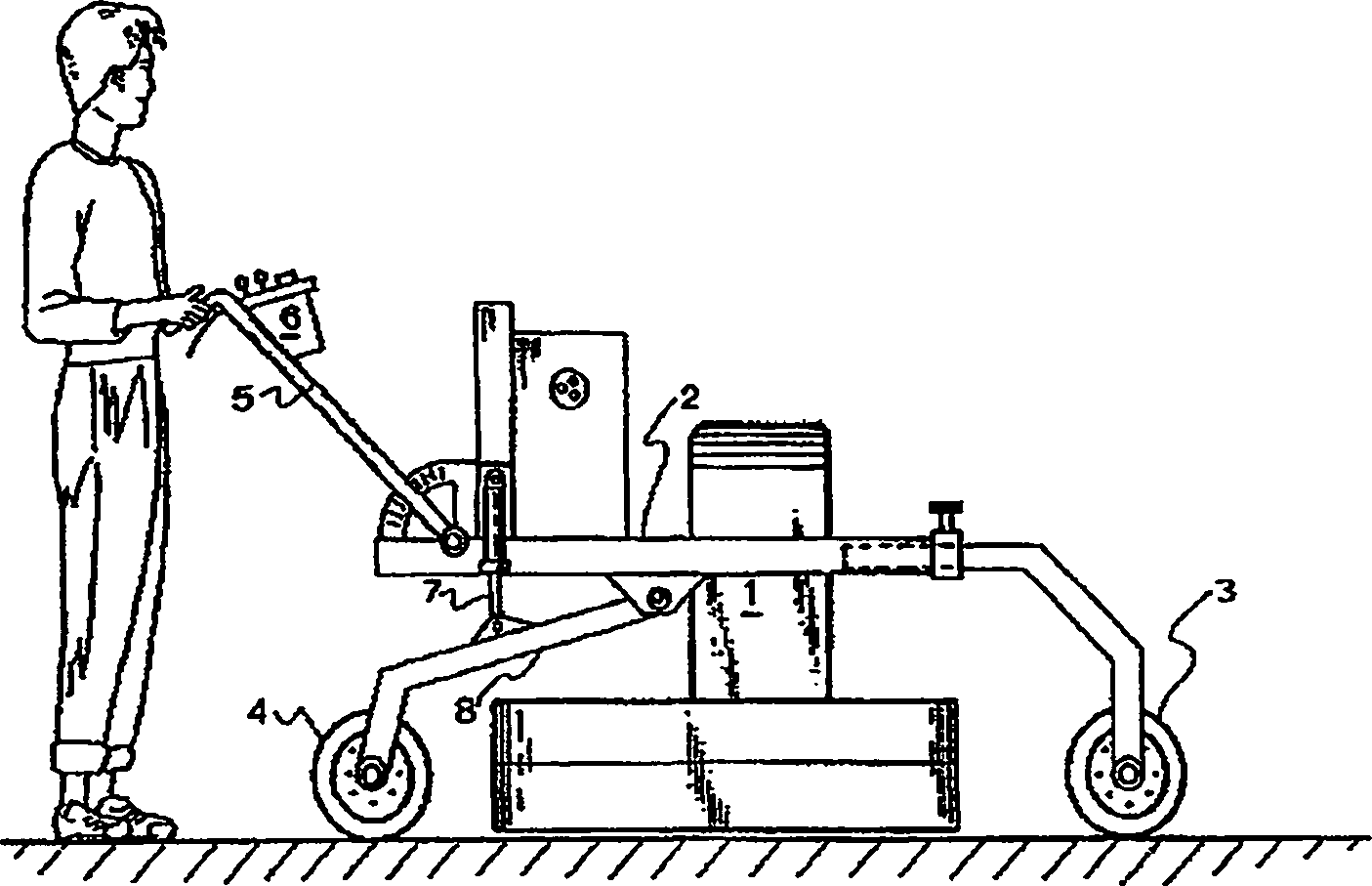

[0017] figure 1 An operator is shown using a polishing machine with a motor 1 mounted on a frame 2 with removable front wheels 3 and adjustable rear wheels 4 . A control box 6 within reach of the operator is installed on the handle 5 . As the machine is turned on and off, the control box 6 controls the height adjustment by operating the hydraulic cylinder 7 to turn the rear wheel strut 8 up or down. Thus, when not in use, the strut 8 is lowered and the machine can be easily pushed to another location.

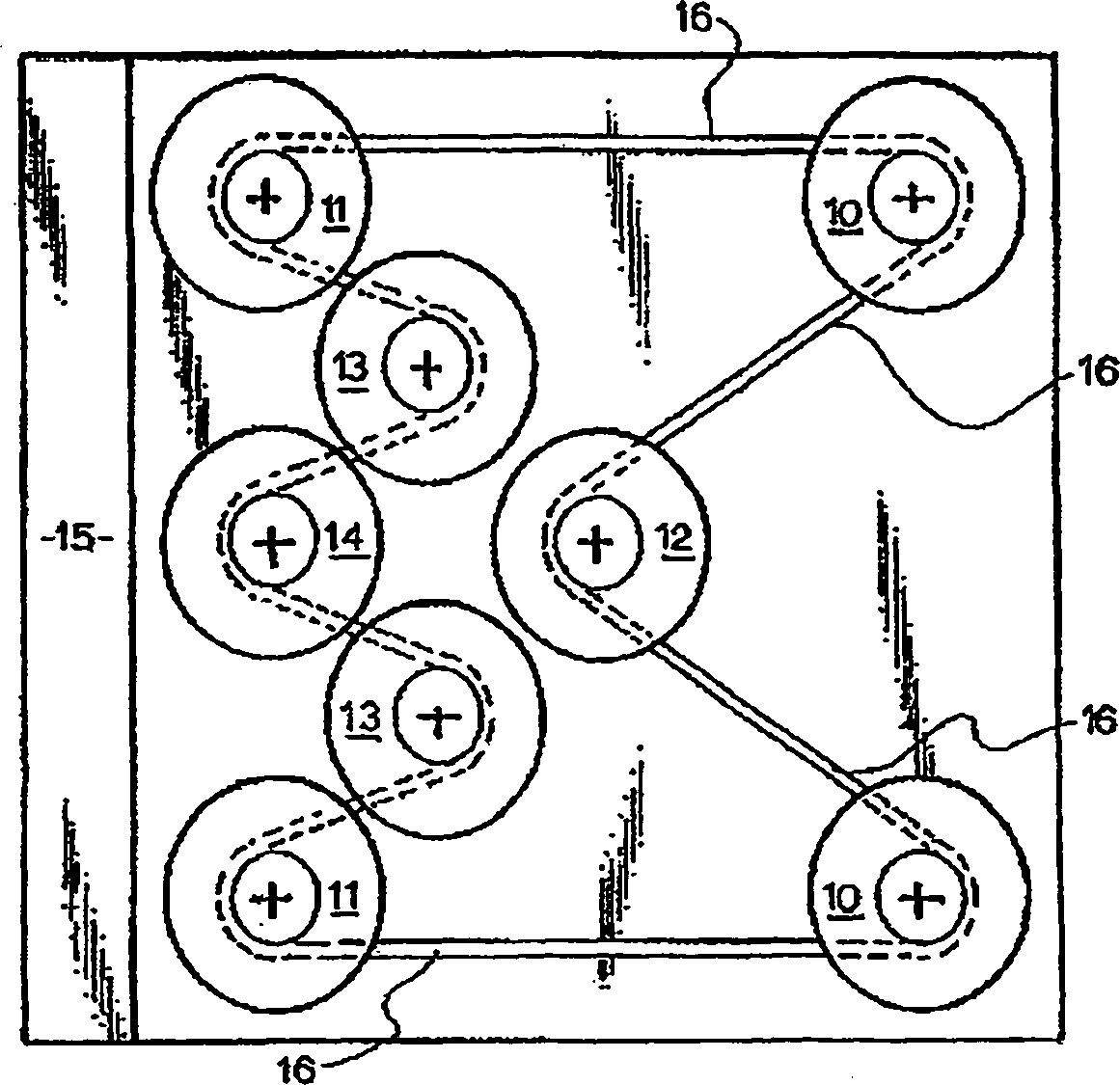

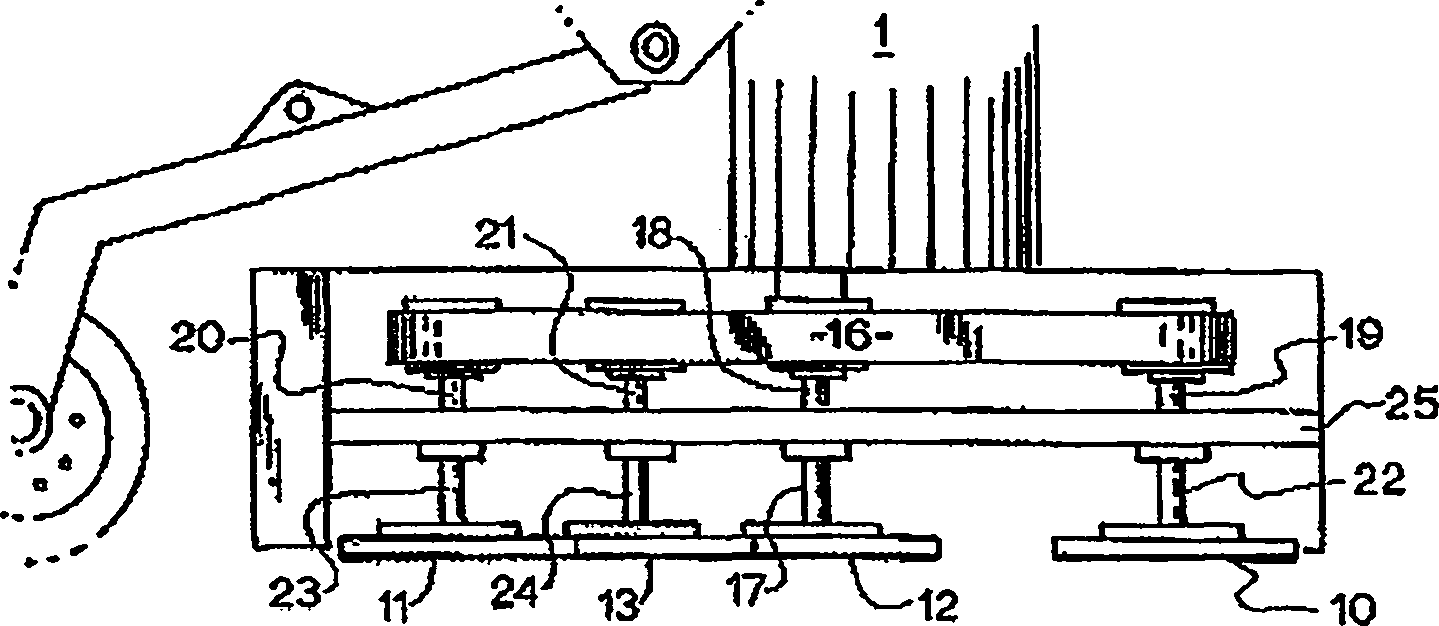

[0018] figure 2 The structure of the grinding head assembly is shown with a pair of assemblies 10 at the front corners, a pair of assemblies 11 at the rear corners, a single assembly 12 in the center, and a pair of assemblies 13 between the center and rear corners. The assembly 14 in the middle of the rear corner does not have a grinding head, but has a fan that pushes the dust into a vacuum manifold 15 located at the rear of the assembly.

[0019] Motor 1 drives assembly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com