Cotton core bar forming machine

A molding machine and cotton core technology, applied in textiles and papermaking, metal processing, non-woven fabrics, etc., can solve the problems of low cost and complete sets of production equipment without cotton core rods, so as to reduce labor costs and realize production automation. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

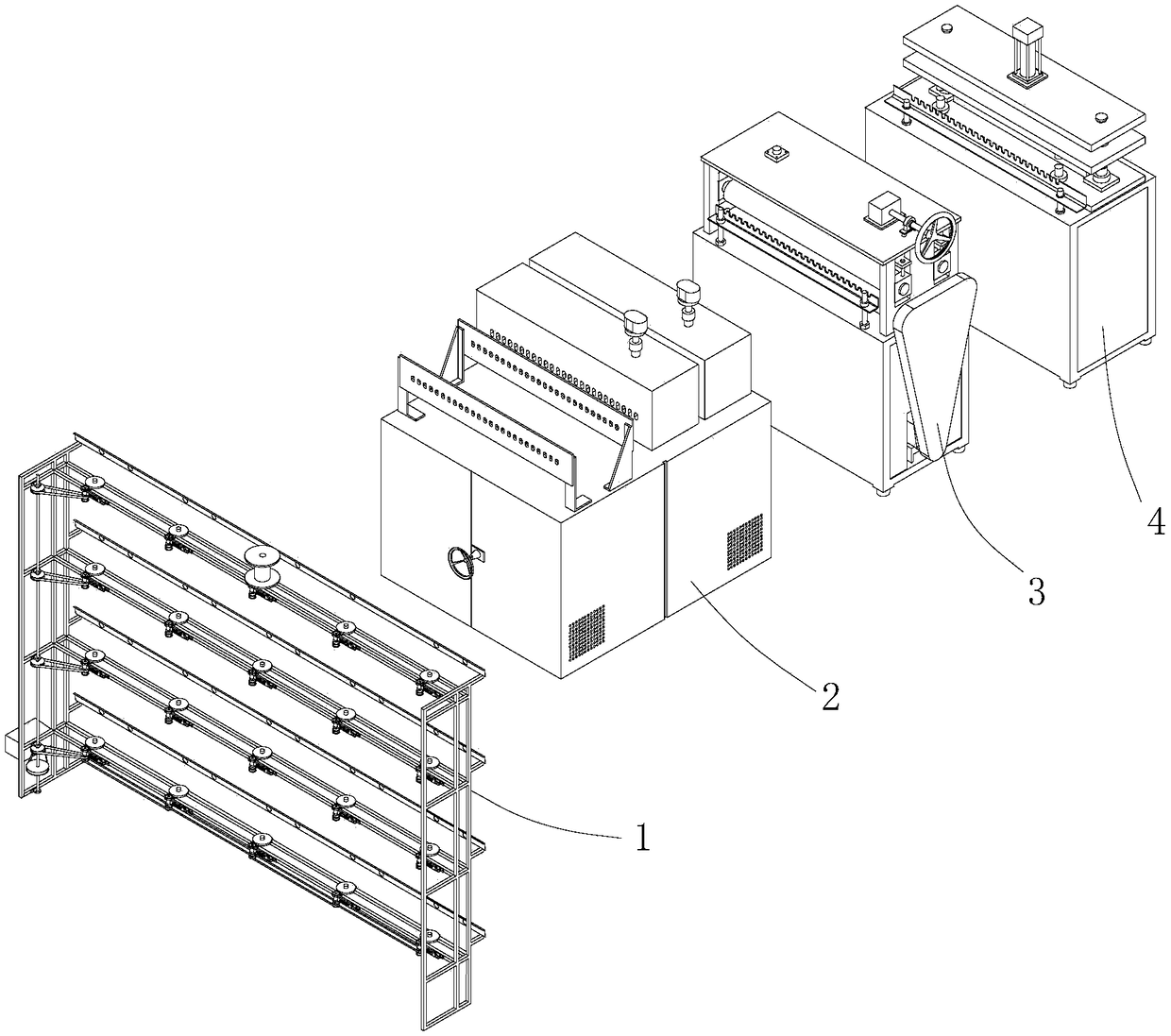

[0036] Please refer to figure 1 As shown, a cotton plug forming machine includes a feeding part 1, a forming part 2, a pulling part 3 and a cutting part 4 arranged in sequence along the direction of material travel.

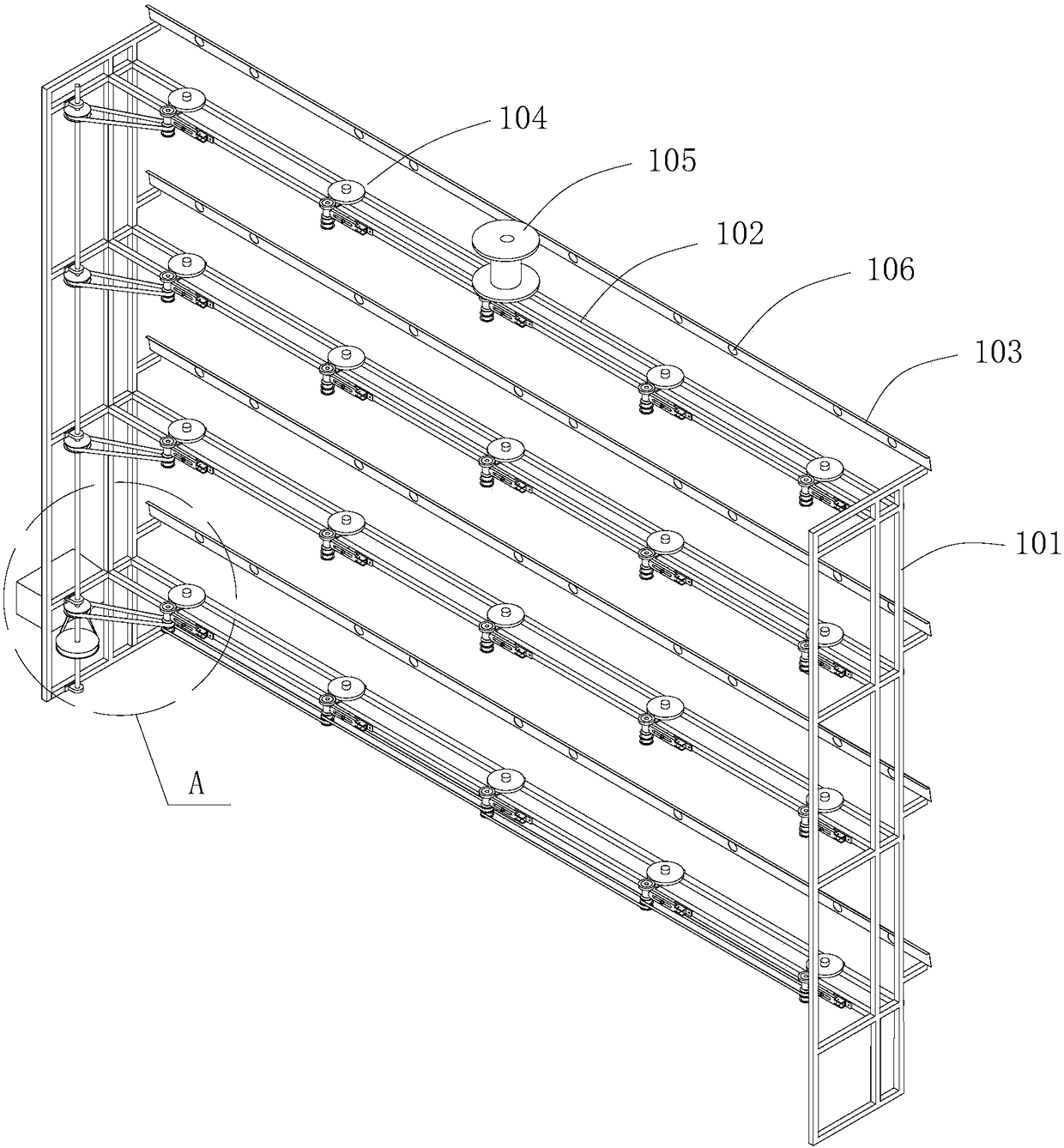

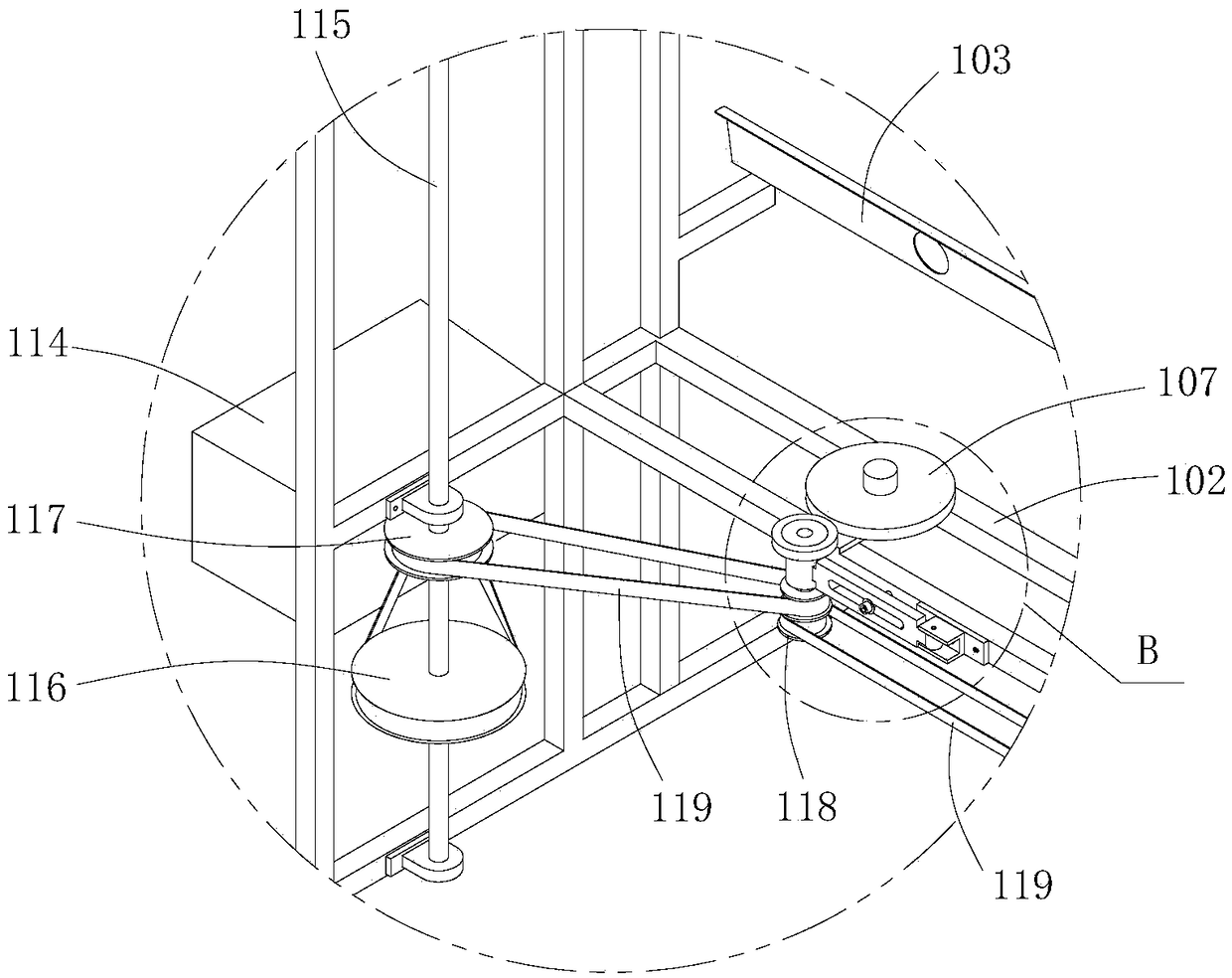

[0037] Please refer to figure 2 As shown, the feeding part 1 is used to transport the fiber threads to the forming part 2 in groups, and its main body is a bracket 101 welded by square tubes. According to the design requirements, a plurality of brackets 101 are welded side by side to form a larger shelf. Along the height direction of the support 101, there are 4 layers of matching yarn tray support frames 102 and yarn support frames 103, and each layer of yarn tray support frames 103 is distributed with 5 yarn tray rotating mechanisms 104 along the horizontal direction, a total of 20. Used to drive the yarn disc 105 to rotate, the yarn support frame 103 is located at the front top of the yarn disc support frame 102, and two yarn positioning holes 106 are opene...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com