Graphene lyogel thin-film preparation method

A technology of graphene gel and graphene hydrogel, which is applied in the manufacture of hybrid/electric double layer capacitors, etc., can solve the problems of low energy density of supercapacitors, collapse of three-dimensional pore networks, and no significant improvement, and achieve easy Large-scale production preparation, simple preparation method, and the effect of reducing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

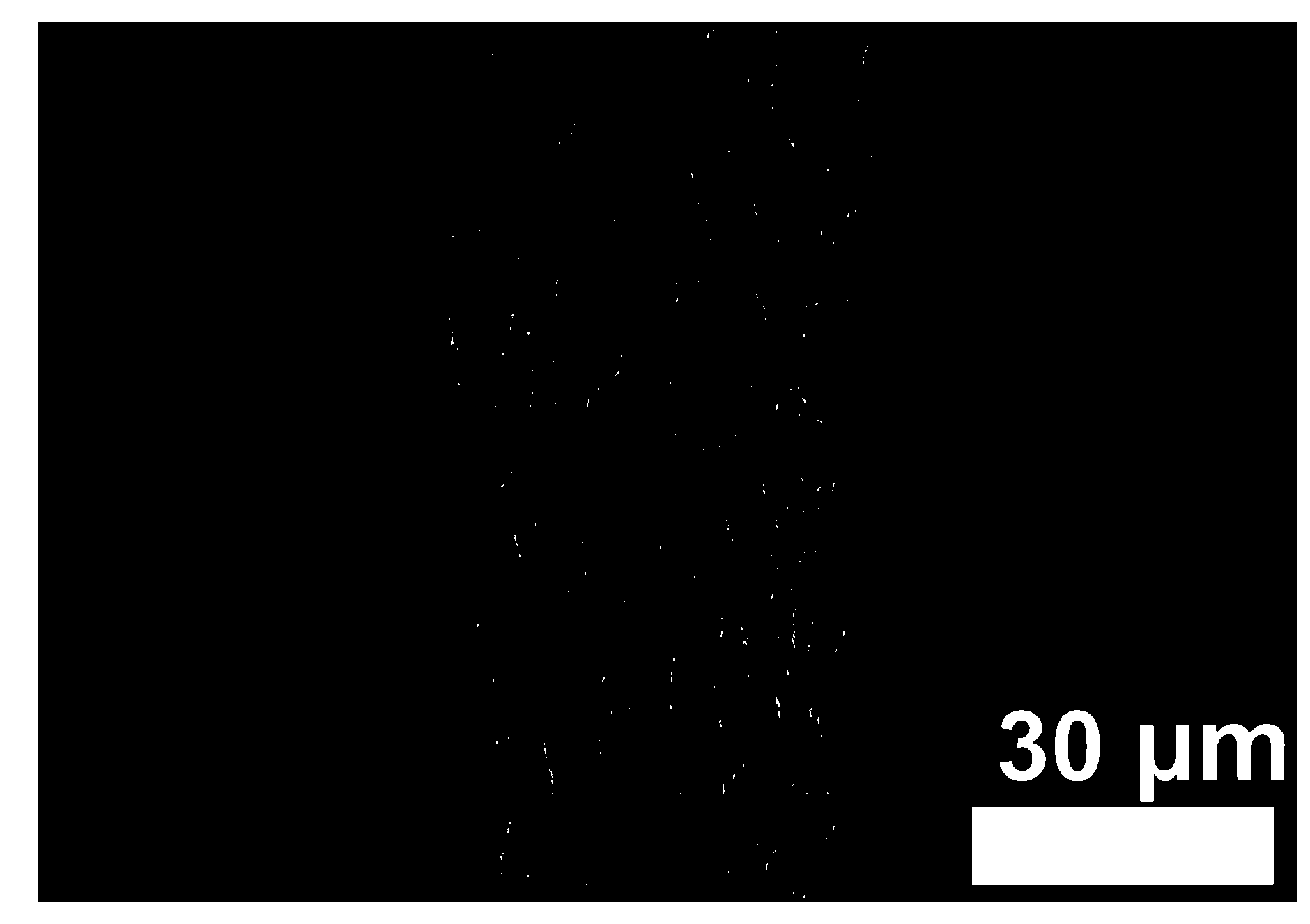

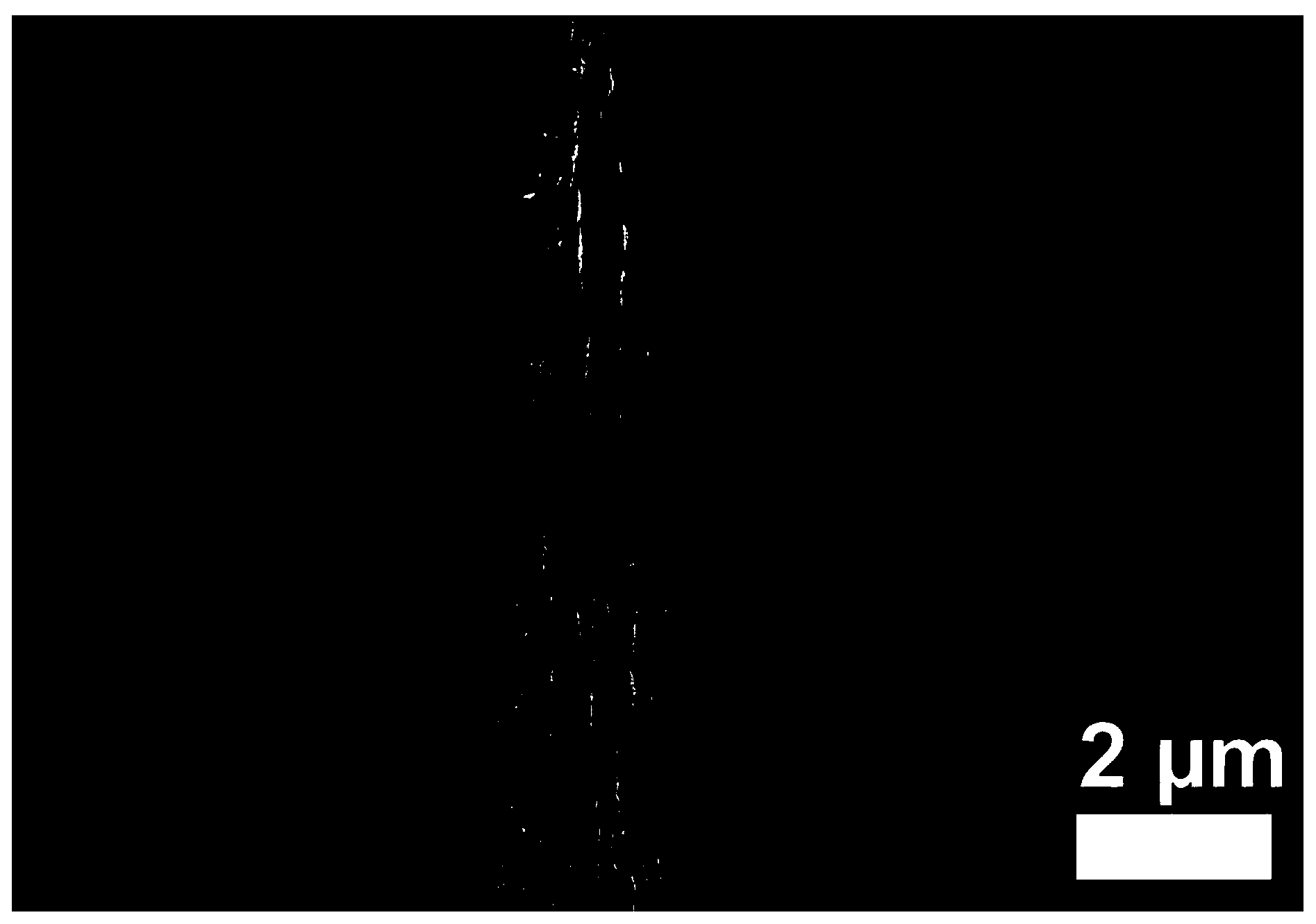

[0026] Add 100 mg of graphene microflakes into a beaker filled with 200 ml of deionized water, then place the ultrasonic breaker inside the beaker, and perform ultrasonic treatment with a power of 200W for 2 hours. After the treatment, the graphene microchips are dispersed in deionized water to become a colloidal dispersion of graphene microchips. A mixed cellulose ester filter membrane with a filter pore size of 0.05 μm was placed on a glass suction filter flask with a 80 mm diameter frit funnel. Take 100ml of the prepared dispersion and carry out suction filtration. During the process of suction filtration, a layer of black film will be formed on the filter membrane, such as figure 1 shown. When the liquid on the membrane has just been pumped out, immediately turn off the vacuum pump of the suction filter. At this time, what is obtained on the filter membrane is a graphene hydrogel film, such as figure 1 , 2 shown. Carefully remove the membrane from the filter. Prepar...

Embodiment 2

[0028] Add 100 mg of graphene microflakes into a beaker filled with 500 ml of N-methylpyrrolidone, then place a sonicator inside the beaker, and perform ultrasonic treatment at a power of 200W for 3 hours. After the treatment, the graphene microplates are dispersed in N-methylpyrrolidone to become a colloidal dispersion of graphene microplatelets. A polypropylene filter membrane with a filter pore size of 0.1 μm was placed on a glass suction filter flask with a 40 mm diameter fritted funnel. Take 200ml of the prepared dispersion and carry out suction filtration. During the suction filtration, a black film will form on the filter membrane. When the liquid on the membrane has just been pumped out, immediately turn off the vacuum pump of the suction filter. At this time, what is obtained on the filter membrane is a graphene gel film. Carefully remove the film from the filter, completely soak it in a beaker filled with 500 ml of deionized water, and continuously stir it mechani...

Embodiment 3

[0030]Add 100 mg of graphene microflakes into a beaker filled with 100 ml of N-methylpyrrolidone, then place the sonicator inside the beaker, and perform ultrasonic treatment at a power of 200W for 3 hours. After the treatment, the graphene microplates are dispersed in N-methylpyrrolidone to become a colloidal dispersion of graphene microplatelets. A polypropylene filter membrane with a filter pore size of 0.1 μm was placed on a glass suction filter flask with a 40 mm diameter fritted funnel. Take 200ml of the prepared dispersion and carry out suction filtration. During the suction filtration, a black film will form on the filter membrane. When the liquid on the membrane has just been pumped out, immediately turn off the vacuum pump of the suction filter. At this time, what is obtained on the filter membrane is a graphene gel film. Carefully remove the film from the filter, completely soak it in a beaker filled with 500 ml of deionized water, and continuously stir it mechan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com