Load testing-analyzing method of rotor compressor for refrigeration plant

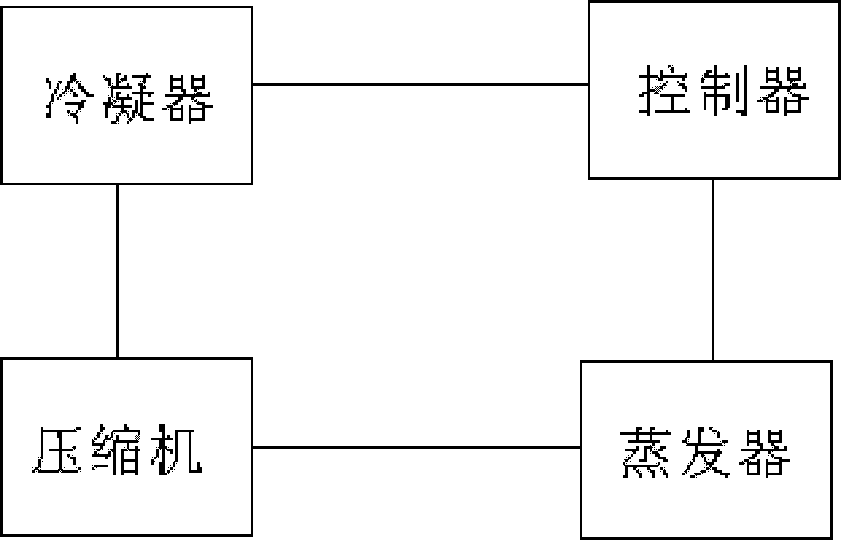

A technology of rotary compressors and refrigeration equipment, which is applied in pump testing, mechanical equipment, machines/engines, etc., and can solve problems such as lack of theoretical basis, test inconsistency, and influence on the reference value of analysis results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

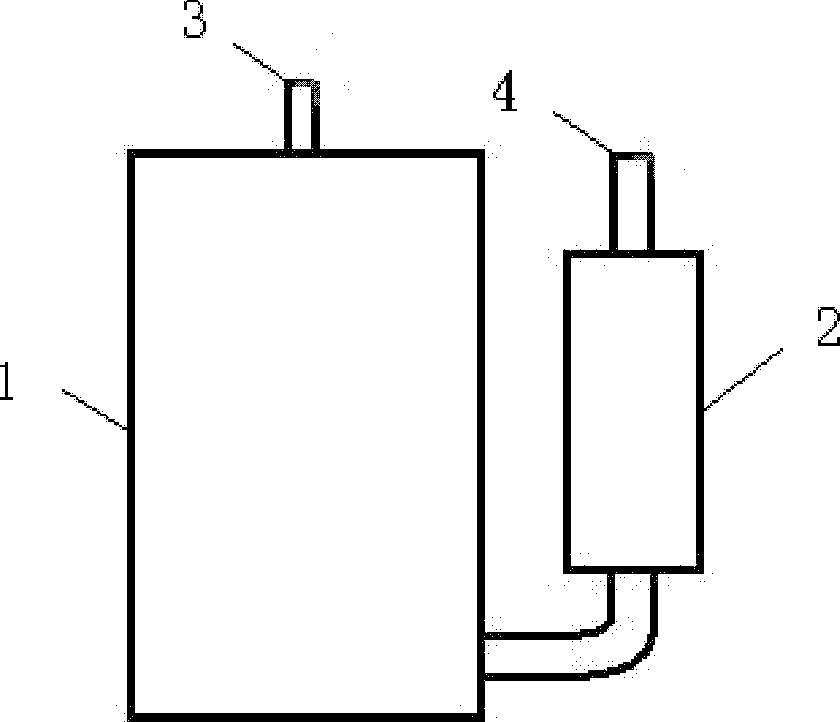

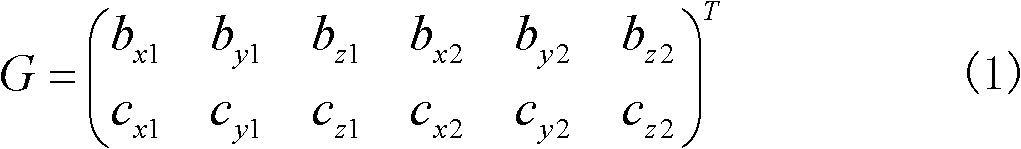

[0027] The vibration response of the piping structure of refrigeration equipment is determined by the load applied to the piping by the compressor. Therefore, accurate identification of the load of the compressor is a prerequisite for predicting and evaluating the vibration response of the piping structure and evaluating its reliability. However, the rotary compressor used in refrigeration equipment is usually a hermetic compressor, and its load is not easy to be directly measured by conventional testing methods. In order to solve this problem and meet the needs of the vibration response of the piping structure, this embodiment proposes a compressor load test and analysis method for refrigeration equipment. Through the vibration test and analysis of the single compressor, the compressor load can be determined more conveniently. It can be used for the vibration response of the piping structure of refrigeration equipment. In this embodiment, the method for testing and analyzing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com