Design and manufacturing method for hexagonal honeycomb aluminum platform

A manufacturing method and regular hexagon technology, applied in design optimization/simulation, calculation, special data processing applications, etc., can solve problems such as high R&D cost and difficult quantification, improve reliability, reduce production cost, and optimize platform performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Now in conjunction with the accompanying drawings, the preferred embodiments of the present invention will be described in detail.

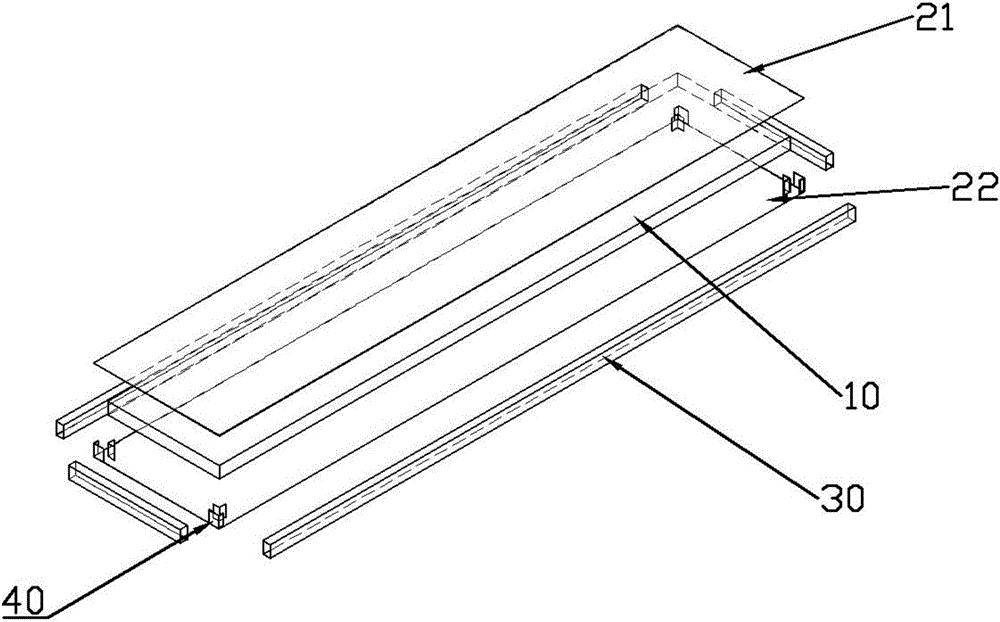

[0029] A design and manufacturing method of a regular hexagonal honeycomb aluminum platform, the regular hexagonal honeycomb aluminum platform includes a honeycomb aluminum core and an external frame, the design design and manufacturing method includes steps:

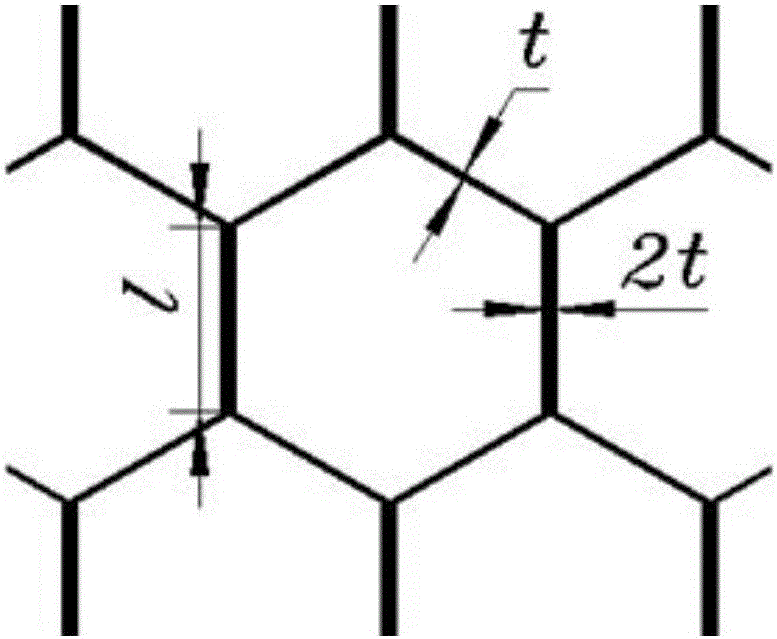

[0030] S01. Equivalent the honeycomb aluminum core into an orthotropic uniform continuous solid structure, and calculate the engineering parameters of the uniform continuous solid structure, the engineering parameters at least include elastic modulus, shear modulus, Poisson's ratio and density;

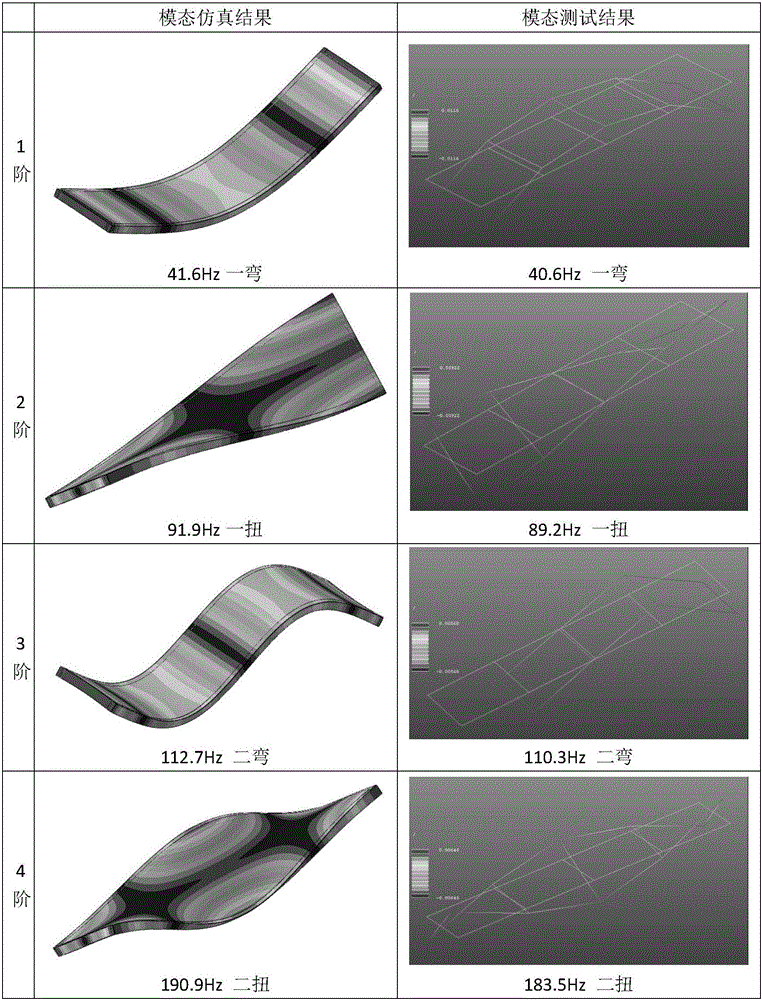

[0031] S02. Establish an overall simulation model combining a uniform continuous solid structure with an external frame, and analyze the performance of the overall simulation model through finite element technology, wherein, establish a uniform continuous solid structure simulation model ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com