Method for optimizing metal accurate forging process conditions based on finite element technology and operation drawing technology

A process condition and finite element technology, which is applied in the field of optimizing metal precise forging process conditions based on finite element technology and machining drawing technology, and achieves the effect of optimizing process conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

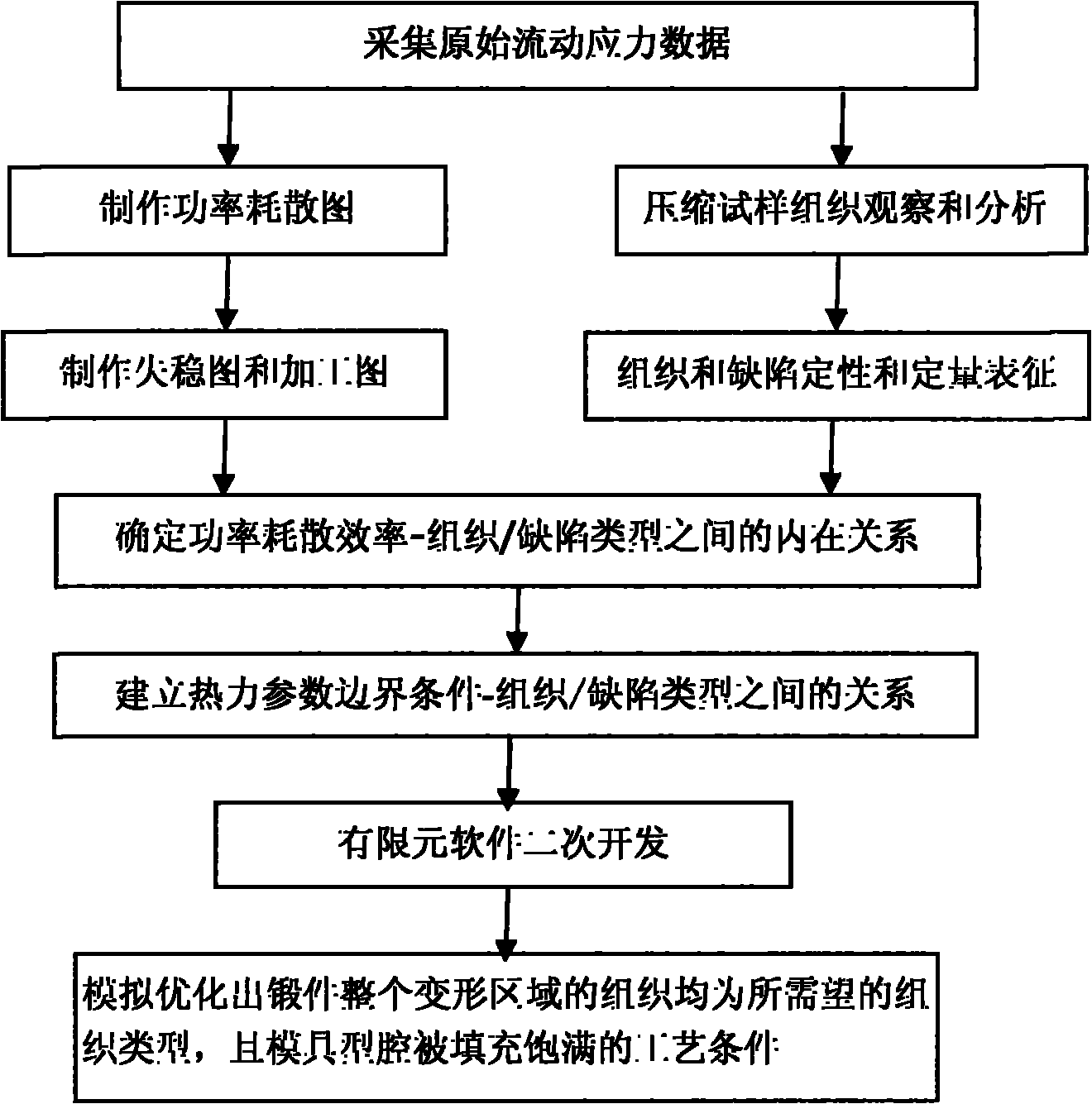

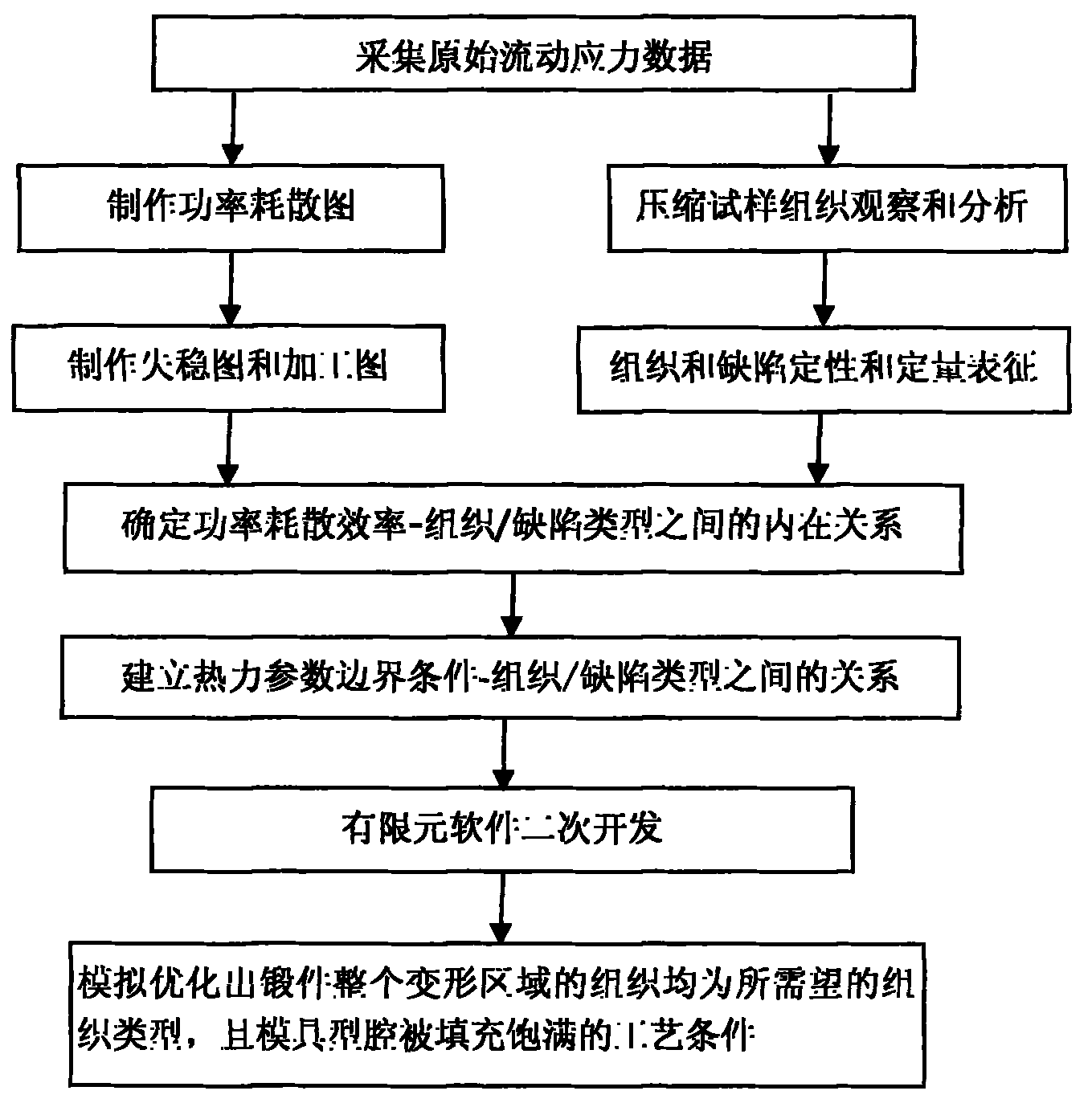

[0023] Such as figure 1 As shown, the original flow stress data is collected first, and the power dissipation diagram, instability diagram and processing diagram are made according to the data to determine the heat of the rheological instability region, stable processing region, optimal processing region and optimal processing region of the metal. parameter boundary conditions and their corresponding organizational types, and then carry out secondary development of commercialized finite element software, introduce various thermal parameter boundary conditions into the finite element model, use "thermal parameters" as the connecting bridge, and simulate the finite element The thermal parameter field variables in the deformation body of each deformation step are compared with the thermal parameter boundary conditions, and the final optimization is achieved by repeatedly adjusting the forging process conditions (ie, externally applied forging temperature, deformation speed, blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com