Engine coupling analytical method

A coupling analysis and engine technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as imperfect evaluation standards, high cost, and insufficient systematization, and achieve saving test costs, shortening development cycles, The effect of improving development efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

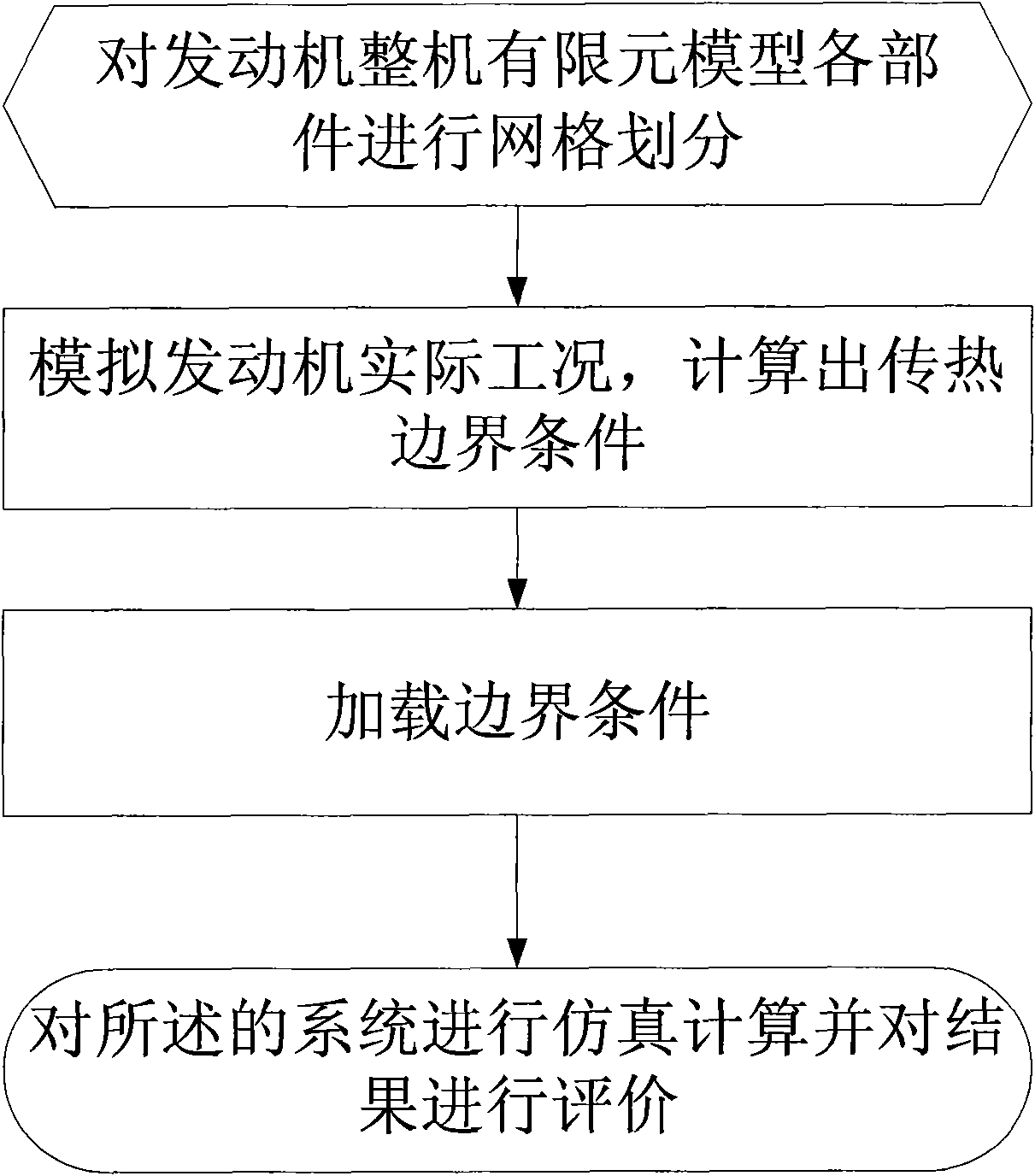

[0018] Example 1, such as figure 1 Shown: the present invention utilizes computer simulation to realize engine development, and the coupling analysis of the whole machine is mainly aimed at engine under cold state and hot state environment, several extreme working conditions are investigated its temperature, strength, deformation and fatigue performance and comprise the following steps:

[0019] Step A: Carry out mesh division for each part of the finite element model of the whole engine;

[0020] In this embodiment, meshing is performed on the components included in the analysis such as the cylinder block, cylinder head, frame, valve, valve guide rod, valve seat ring, cylinder gasket, spark plug, and cylinder head bolts. Use DS6 type unit (second-order 6-node 2D heat transfer unit), DC3D10 type unit (second-order 10-node 3D heat transfer unit), and C3D10M type unit (modified second-order 10-node 3D unit) as the basic unit of the grid, In the parts prone to stress concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com