Method for counting early-stage macroscopic elasticity modulus of cement paste under axle center stress state

A technology of cement slurry and stress state, applied in the direction of measuring devices, strength characteristics, instruments, etc., can solve the problem of less application of finite element theory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

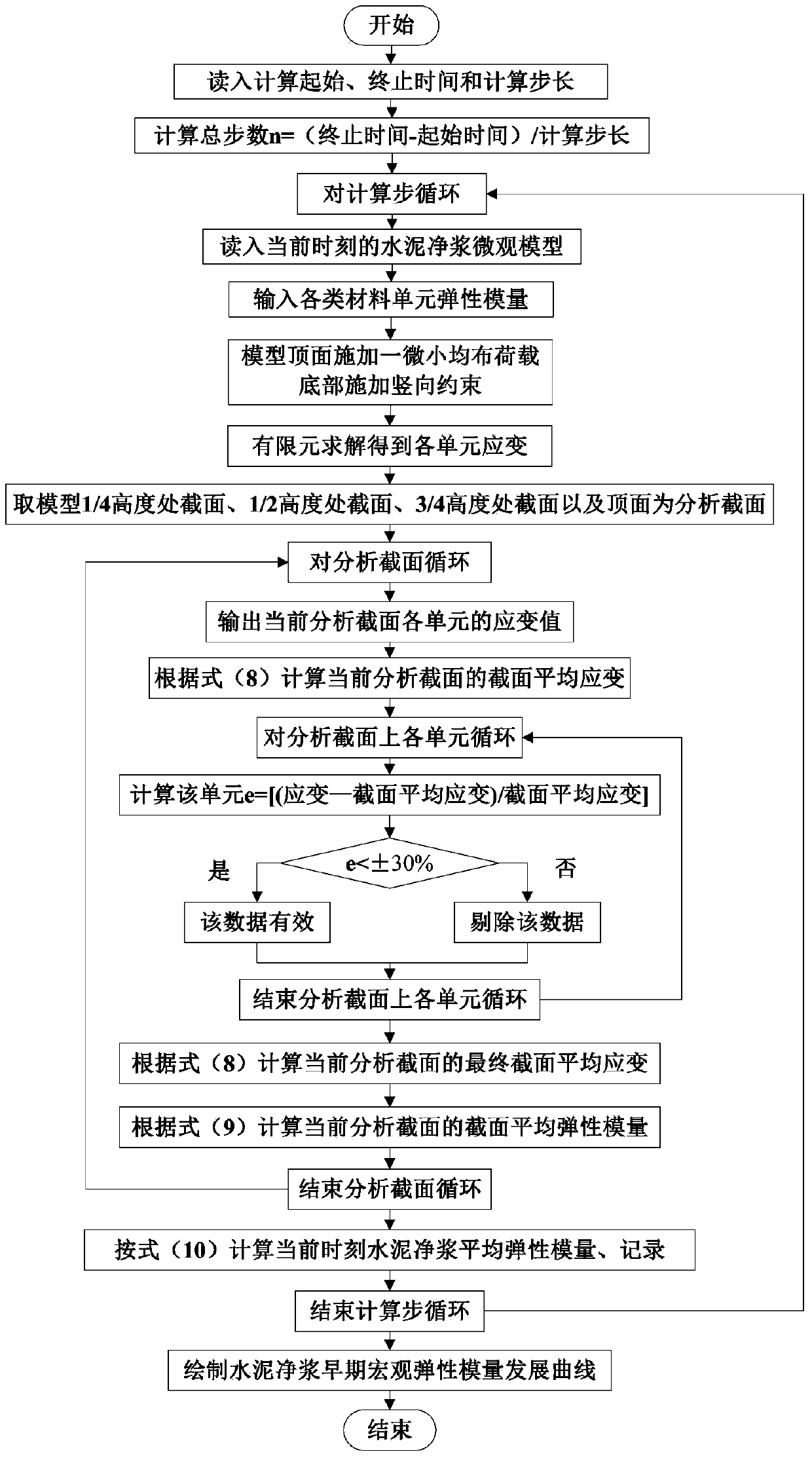

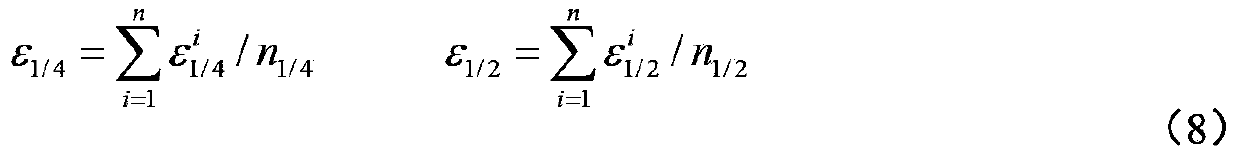

[0054] The present invention proposes a method for calculating the early macroscopic elastic modulus of cement paste under axial stress state by discussing the research of finite element method in the field of early macro performance prediction of cement-based materials. The main step flow chart of the present invention is as figure 2 Shown, the specific implementation method of the present invention is illustrated below in conjunction with the accompanying drawings:

[0055] Step 1, input the calculation start time, end time and calculation step size, the total number of calculations n=(end time-start time) / calculation step size;

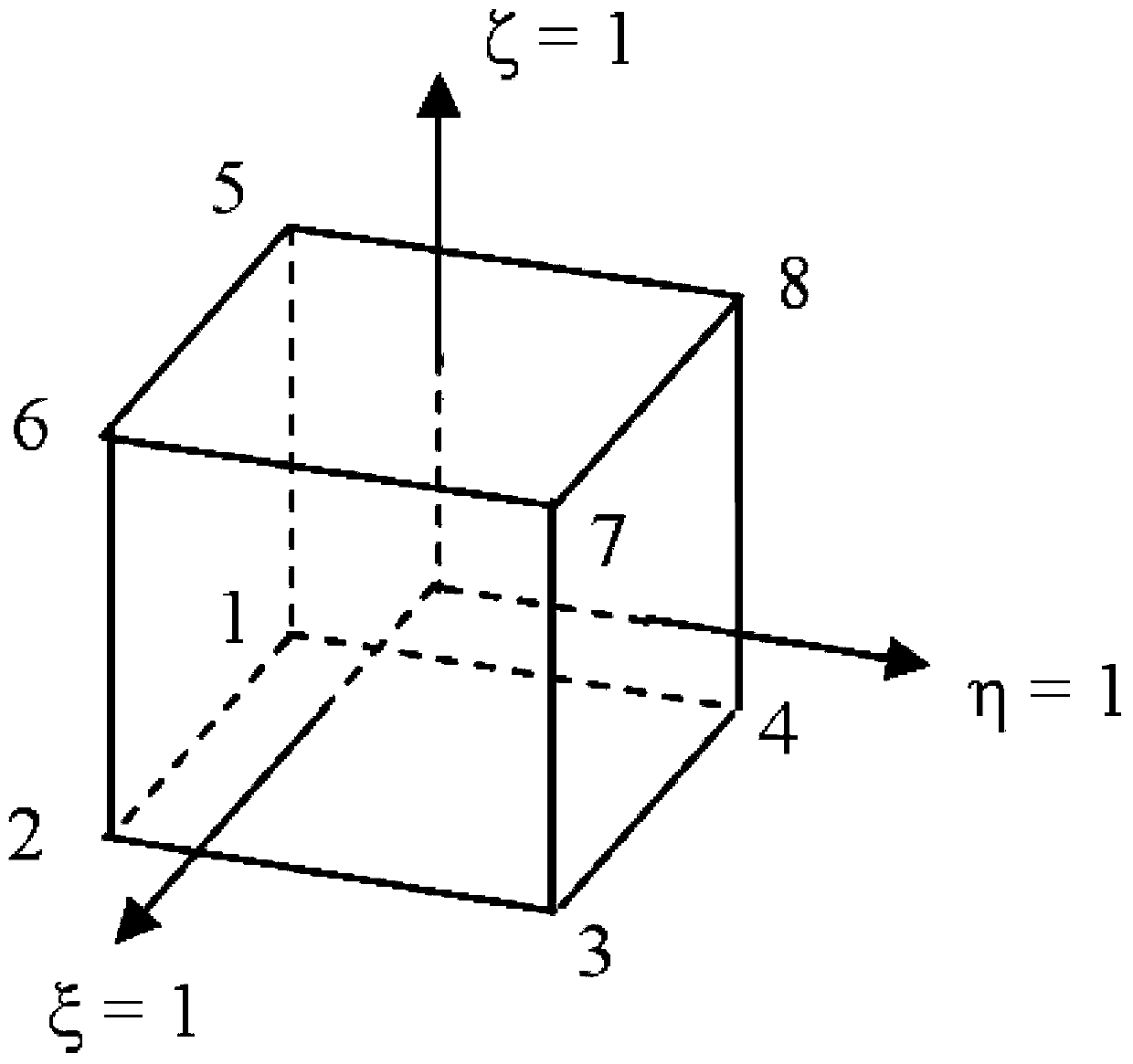

[0056] Step 2: Input the microscopic model of the cement slurry at the current moment in the first calculation step. In the model, each unit has been divided into low-density C-S-H unit, high-density C-S-H unit, CH unit, calcium sulfoaluminate hydrate unit, capillary pore unit, Free water unit and unhydrated cement particle unit;

[0057] Step 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com