Axial flux motor applying soft magnetic powder core with high saturation induction density

A technology of magnetic induction and axial flux, applied in the field of motors, to achieve high output power and low eddy current loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Soft magnetic powder cores with high saturation magnetic induction are used in high-power iron cores, which in turn are used in high-power axial flux motors.

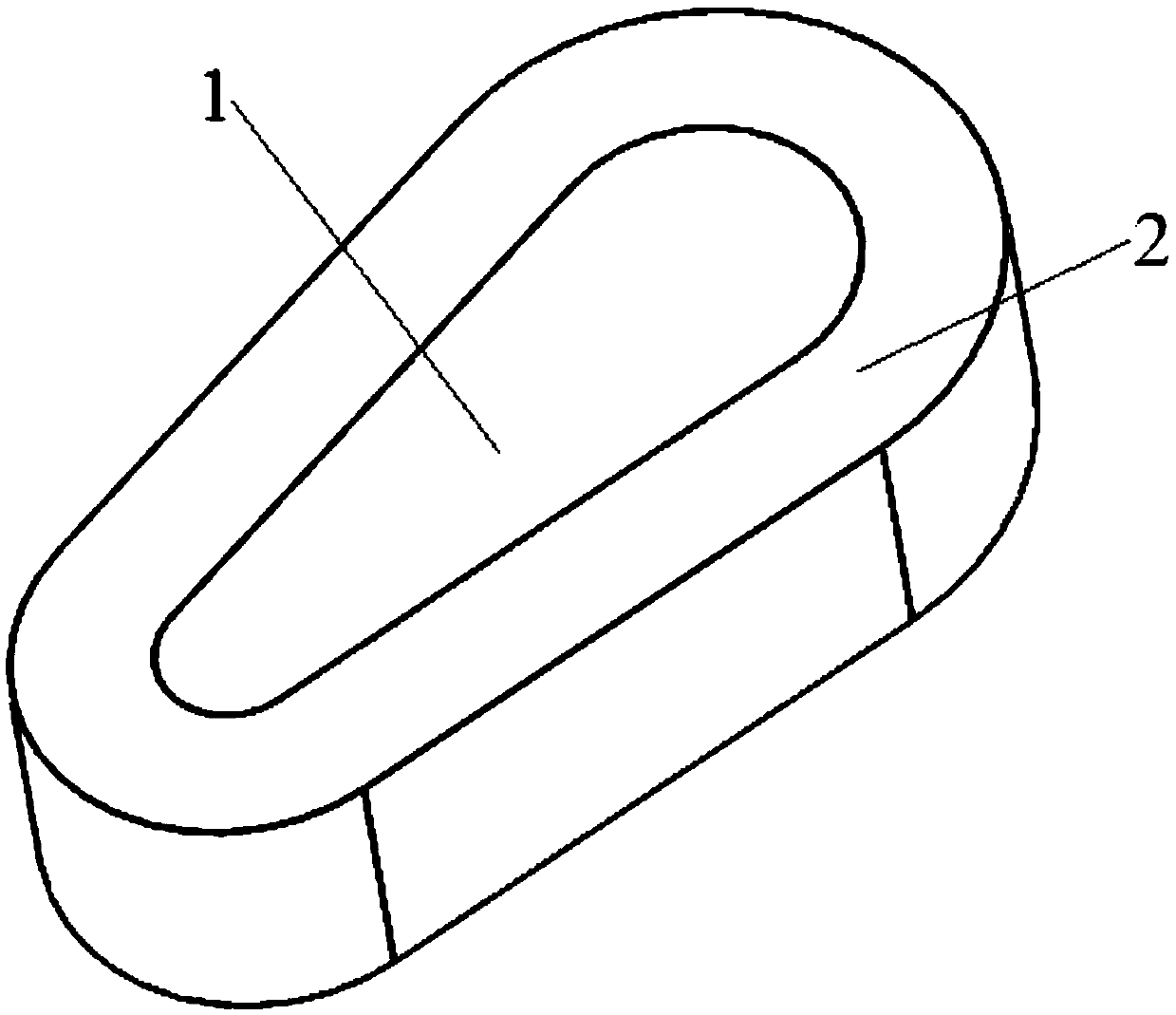

[0043] The iron core is composed of several fan-shaped iron core monomers distributed along the circumference, such as figure 1 As shown, the side of the fan-shaped iron core unit 1 is flat-wound with the coil 2, and the fan-shaped iron core unit 1 is made of a 1k101 high saturation magnetic induction intensity amorphous nanocrystalline soft magnetic powder core.

[0044]In this embodiment, the fan-shaped iron core unit 1 is long and fan-shaped, so that the motor can obtain more pole pairs. In addition, the rounded corners at both ends are tangent to the fan-shaped side, so as to facilitate winding and mold opening Press processing. If necessary, the two fan-shaped straight sides can also present a certain large arc, so as to be more suitable for winding winding. In addition, this embodiment adopts the method of...

Embodiment 2

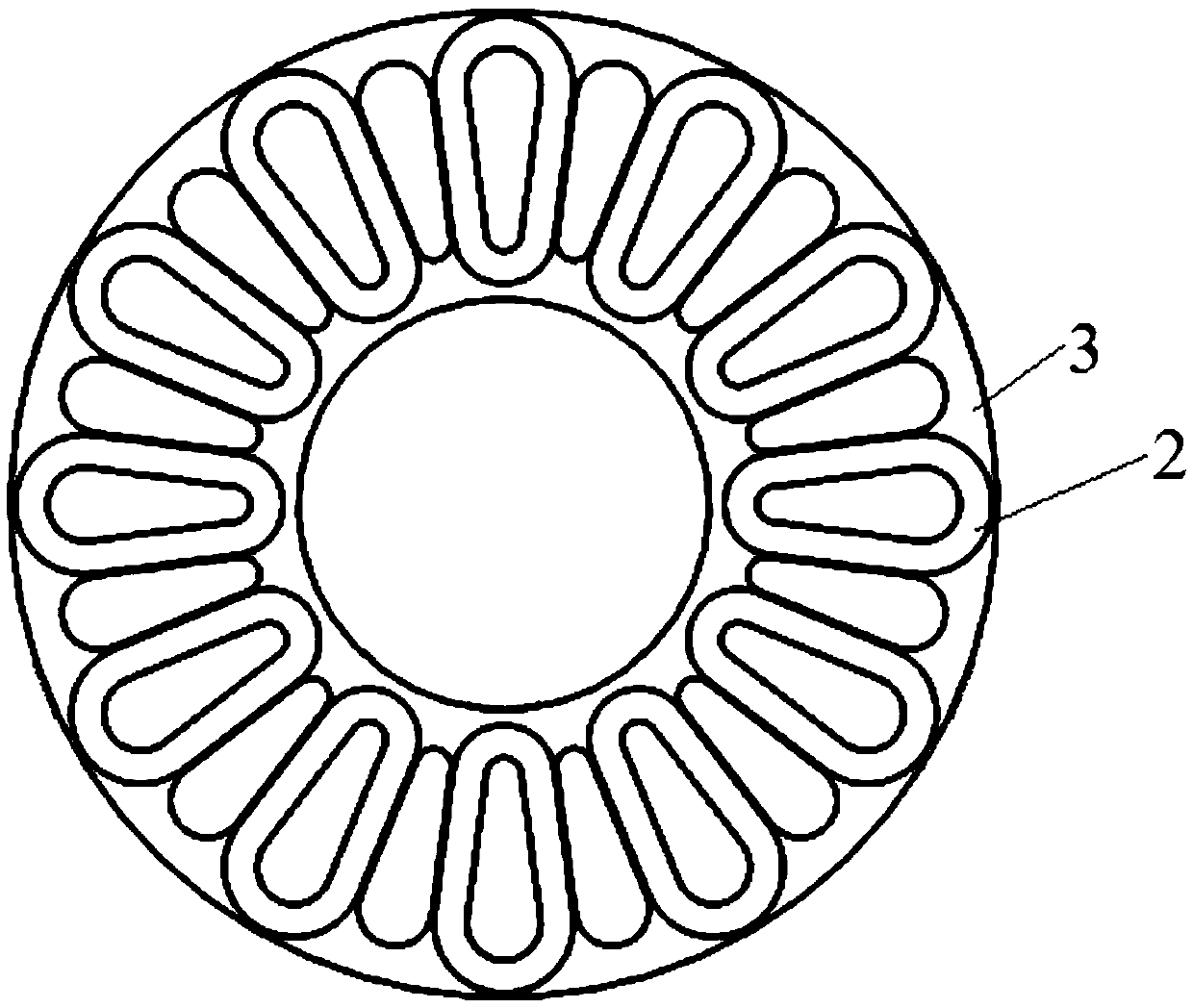

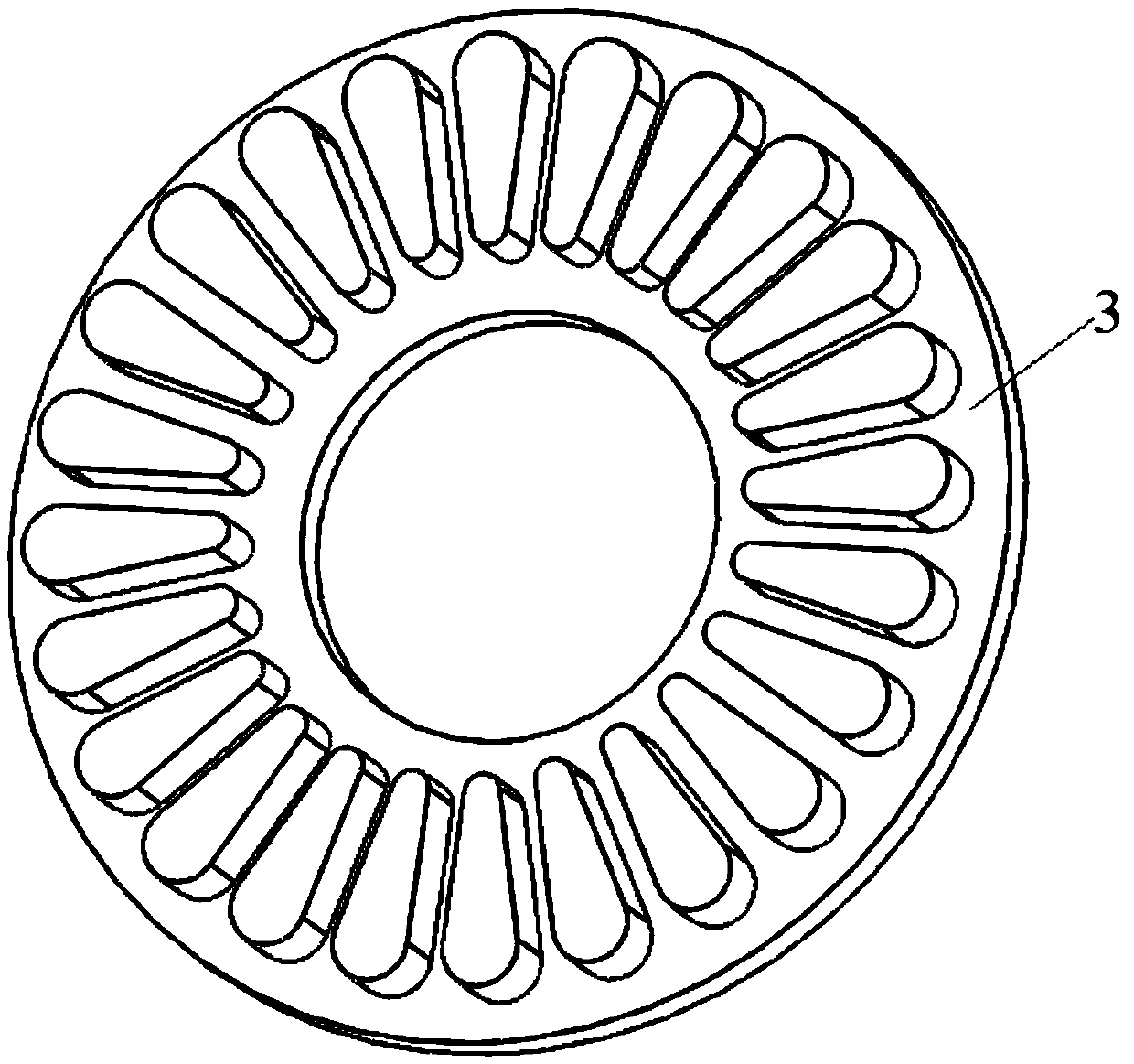

[0046] Use 1k101 amorphous nanocrystalline soft magnetic powder cores with high saturation magnetic induction for high-power iron cores, such as figure 2 As shown, the iron core is composed of a planar ring gear 3 and a coil 2 wound on the planar ring gear. The coil 2 is made according to the shape of the upper teeth of the planar ring gear and then inserted into the planar ring gear. The planar ring gear is 1k101 high It is made of amorphous nanocrystalline soft magnetic powder core with saturation magnetic induction.

[0047] Such as image 3 As shown, the planar ring gear 3 is a single-sided ring gear, such as Figure 4 As shown, the planar ring gear 3 is a double-sided ring gear. For a double-sided ring gear, the teeth on both sides can be aligned or staggered. For small presses that cannot produce larger plane ring gears, the plane gear rings can be divided into smaller parts for forming and processing.

Embodiment 3

[0049] Such as Figure 5 As shown, the composite permanent magnet is composed of a permanent magnet layer 4 and an amorphous nanocrystalline soft magnetic powder core layer 5 with a high saturation magnetic induction of 1k101 in layers overlapping, and there are at least two layers. The attachment method can be through magnetic attraction, and adhesive bonding can be used if necessary. In this embodiment, the permanent magnet has the characteristics of high remanence (minimum about 1.3T), and is preferably a rare earth permanent magnet. And the thickness ratio of the permanent magnet layer to the soft magnetic powder core layer with high saturation magnetic induction is preferably 2:1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic flux density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com