Magnetoresistive sensor arrangement for current measurement

一种磁阻传感器、传感器的技术,应用在测量装置、测量磁变量、测量电变量等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

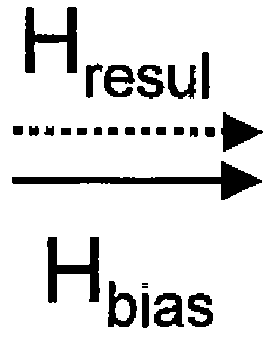

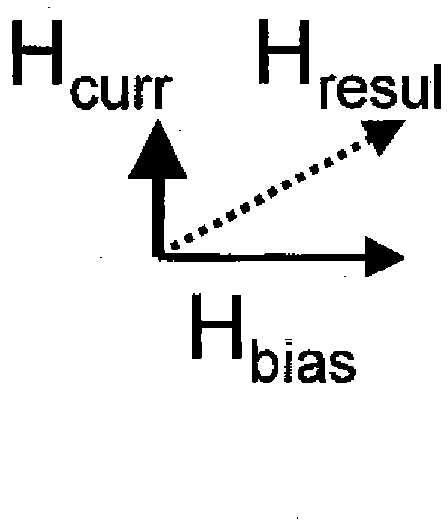

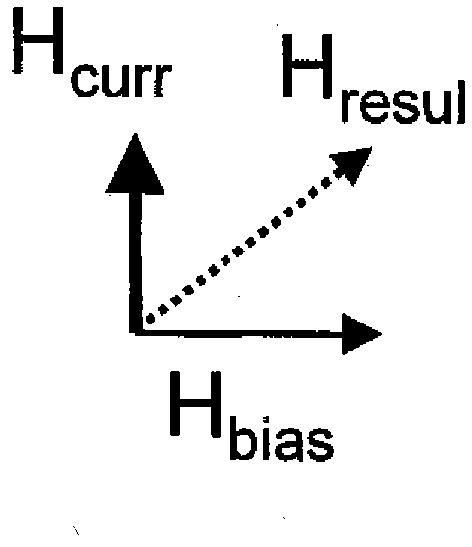

[0043] A magnetoresistive element used in a magnetoresistive sensor is an object that changes its electrical resistance as a function of the magnetization direction of the element for a small probe current passed through the element. The resistance depends approximately on the cosine square of the angle between the probe current and the magnetization of the material. If the current and magnetization point in the same direction, the resistance will be maximum. If the angle between the current flow and the magnetization is 90 degrees, the resistance will be minimal. The device was installed such that the probe current was inclined by 45 degrees relative to the main magnetic field to be measured, and the bias magnetic field was further inclined by another 45 degrees so that it was inclined by 90 degrees relative to the main magnetic field. In this case, the resistance of the magnetoresistive element is sensitive to the main magnetic field up to the point where the magnitude of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com