Coated craft paper and production method thereof

A technology for coating kraft cardboard and production methods, which is applied in the field of kraft cardboard, can solve the problem of uneven pigment layer coverage on the paper surface and ink absorption, kraft cardboard is easy to delaminate, break, burst, and is not easy to delaminate, Breakage, peeling and other problems, to achieve the effect of facilitating subsequent coating operations, avoiding the use of chemicals, and having a strong environmental protection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

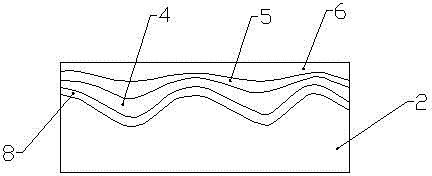

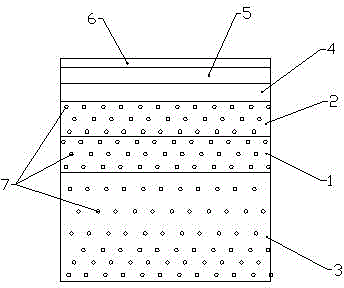

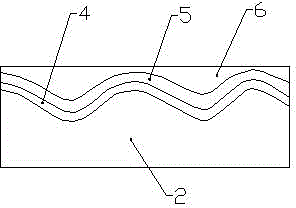

[0067] Example 1, such as figure 2 As shown, a coated kraft cardboard comprises a core paper layer 1, the upper side of the core paper layer is a face paper layer 2, the lower side is a bottom paper layer 3, and the upper surface of the face paper layer 2 is provided with three coating layers , from bottom to top are primer coat 4, middle coat 5 and top coat 6.

[0068] The production method of the above-mentioned coated kraftboard comprises: batching of waste paper, preparation of waste paper slurry, papermaking and forming, compounding of coated base paper, pre-drying, sizing, post-drying, paper surface calendering, paper surface coating , post-processing; among them,

[0069] 1. Waste paper ingredients: In order to solve the problem of multiple sources of waste paper and disordered quality in large-scale production, the mass ratio of American waste: national waste: European waste: Japanese waste is 50%: 20%: 15%: 15%. Fully mixed first, and then pulping, the uniform mixi...

Embodiment 2

[0101] Example 2, except that the following is different from Example 1, other processes are the same as in Example 1: in the step of making the bottom paper layer, 60% of medium fiber waste paper pulp and 40% of short fiber waste paper pulp; in the step of making core paper layer, Medium fiber waste paper pulp is 100%; in the step of making the face paper layer, UKP is used, that is, unbleached wood pulp is 100%; 2%, 8%, 2%; the latex is composed of 80% carboxylated styrene-butadiene latex and 20% biological latex in the primer coating, middle coating and top coating coating steps; the top coating coating step Medium adhesive composition: latex 12%, thickener 1.0%, caustic soda 0.06%, lubricant 0.7%, wet strength agent 0.9% and dispersant 0.02%.

Embodiment 3

[0102] Example 3, except for the following differences from Example 1, other processes are the same as in Example 1: in the step of making the bottom paper layer, 40% of the medium fiber waste paper pulp and 60% of the short fiber waste paper pulp; in the step of making the core paper layer, 70% of medium fiber waste paper pulp, 30% of short fiber waste paper pulp; 30% of long fiber waste paper pulp and 70% of UKP pulp in the process of making face paper layer; 4% of starch paste concentration in the sizing step, penetrant and wet strength , paper strengthening agent and starch content are 5%, 5%, 5% respectively; the latex in the primer coating, middle coating coating and top coating coating steps is composed of 60% carboxylated styrene-butadiene latex and 40% biological latex Composition: Adhesive composition in the top coat coating step: 12% latex, 1.0% thickener, 0.06% caustic soda, 0.8% lubricant, 0.8% wet strength agent and 0.03% dispersant.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com