Catalyst for preparing low-carbon olefins by one-step conversion of synthetic gas and preparation method thereof

A technology of low-carbon olefins and synthesis gas, which is applied in the field of catalysts and preparations for one-step conversion of synthesis gas to low-carbon olefins. It can solve the problems of high methane selectivity, insufficient catalyst stability, and limitations, and achieve low selectivity, Excellent catalytic performance, high selectivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

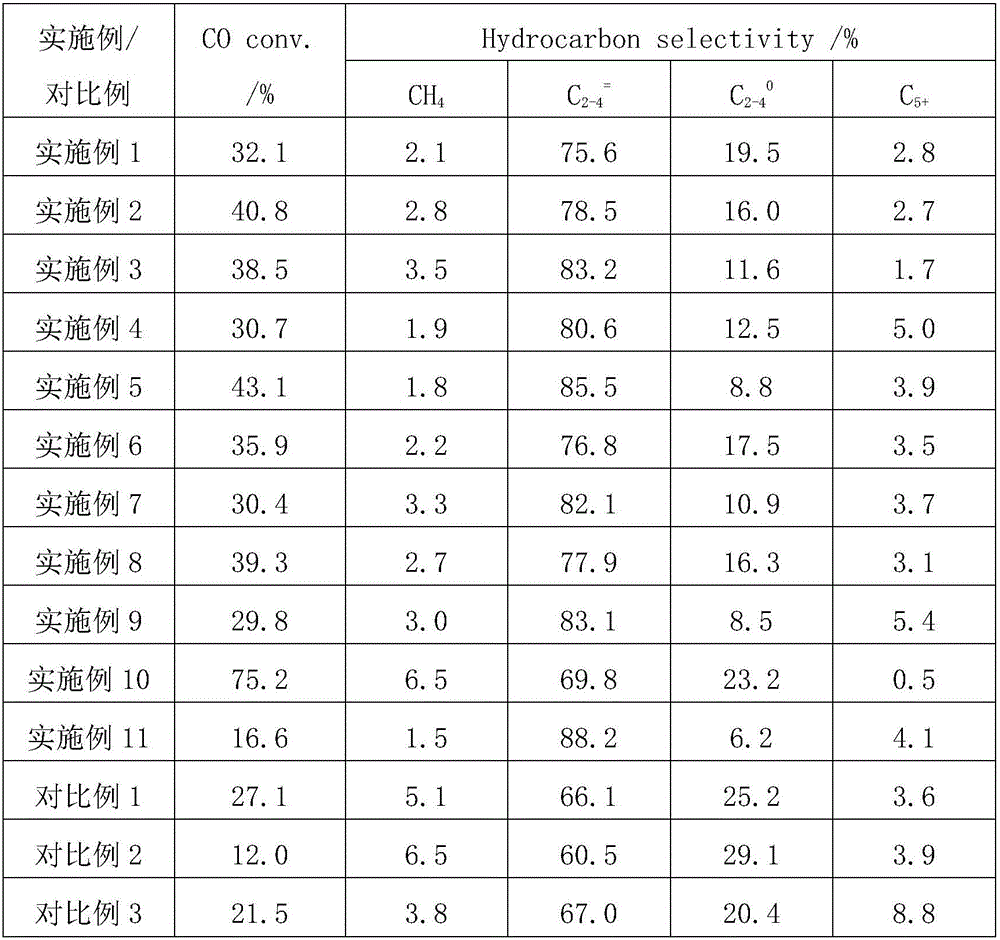

Examples

Embodiment 1

[0027] Weigh 0.78g Ga(NO 3 ) 3 , add 60ml deionized water and stir for 2h. Weigh 2.0 g of cerium-zirconium solid solution and add it to the Ga-containing aqueous solution, stir at 60°C for 7 hours, then heat up to 80°C and evaporate to dryness, transfer the obtained sample to a drying oven and dry at 60°C for 12 hours. Add the above dried solid powder and 3.43g double microporous zeolite molecular sieve H-Y into 100ml ethylene glycol and stir for 5h, then ultrasonically disperse for 3h, move the filtered and washed sample to a vacuum drying oven and dry at 80°C for 8h . The obtained sample was transferred to a muffle furnace and fired at a rate of 2 °C / min to 500 °C for 10 h. The calcined solid sample is pressed into tablets, and the obtained sample is the catalyst.

[0028] The catalytic reaction is carried out in a fixed-bed high-pressure microreactor, and the H in the syngas 2 The volume ratio to CO is 2, the reaction pressure is 2.0MPa, and the space velocity of the s...

Embodiment 2

[0030] Weigh 0.78g Ga(NO 3 ) 3, add 60ml deionized water and stir for 2h. Weigh 2.0 g of lanthanum-zirconium solid solution and add it to the Ga-containing aqueous solution, stir at 60°C for 7 hours, then heat up to 80°C and evaporate to dryness, transfer the obtained sample to a drying oven and dry at 60°C for 12 hours. Add the above-mentioned dried solid powder and 3.43g double microporous zeolite molecular sieve H-ZSM-5 into 100ml ethylene glycol and stir for 5h, then ultrasonically disperse for 3h, and move the filtered and washed sample to a vacuum drying oven at 80 Dry at ℃ for 8h. The obtained sample was transferred to a muffle furnace and fired at a rate of 2 °C / min to 500 °C for 10 h. The calcined solid sample is pressed into tablets, and the obtained sample is the catalyst.

[0031] The catalytic reaction was carried out in a fixed-bed high-pressure microreactor. The reaction conditions and product analysis were the same as in Example 1. The reaction performance ...

Embodiment 3

[0033] Weigh 0.78g Ga(NO 3 ) 3 , add 60ml deionized water and stir for 2h. Weigh 2.0 g of magnesium-zirconium solid solution and add it to the Ga-containing aqueous solution, stir at 60°C for 7 hours, then heat up to 80°C and evaporate to dryness, transfer the obtained sample to a drying oven and dry at 60°C for 12 hours. Add the above-mentioned dried solid powder and 3.43g double microporous zeolite molecular sieve H-ZSM-11 into 100ml ethylene glycol and stir for 5h, then ultrasonically disperse for 3h, and move the filtered and washed sample to a vacuum drying oven at 80 Dry at ℃ for 8h. The obtained sample was transferred to a muffle furnace and fired at a rate of 2 °C / min to 500 °C for 10 h. The calcined solid sample is pressed into tablets, and the obtained sample is the catalyst.

[0034] The catalytic reaction was carried out in a fixed-bed high-pressure microreactor. The reaction conditions and product analysis were the same as in Example 1. The reaction performanc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com